Page 1

A SSEMBLY INSTRUCTION MANUAL

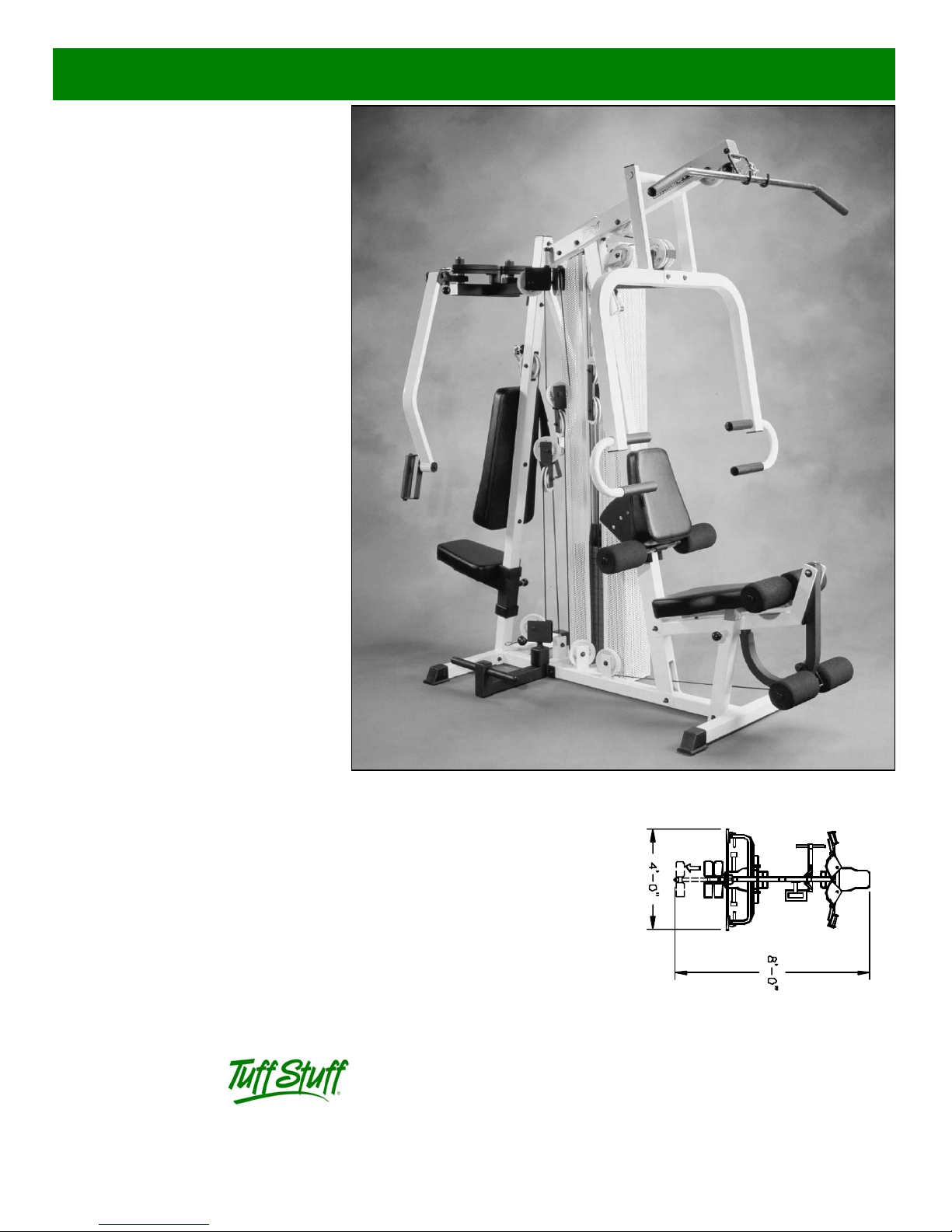

MSL-IV

Muscle IV Home Gym

America’s Premium Exercise Equipment

Revision Date 9 -98

L 8’-0” W 4’-0” H 7’-0”

Page 2

y

Introd

uction

bout the Muscle IV Home Gym (MSL-IV).

Congratulations on your new purchase of the Muscle IV

ome Gym (MSL-IV). This gym is capable of a variet y of

ifferent exercises, as well as, smooth and user-friendly

djustment features. In addition, this gym has been

esigned to meet the needs and performance requirements

r a suitable home exercise machine. We hope you are

ompletely satisfied with this product and wish you many

ears of enjoyment.

uff Stuff Equipment

Every Tuffstuff product has been built to precise quality

tandards and has been carefully packaged to ensure that

amage will not occur during shipment. The limited lifetime

arranty and signature indicating final inspection which was

onducted by our line foreman, is an expression of our

onfidence in the completeness, the materials, and

orkmanship of this product.

arranty

SEE WARRANTY REGISTRATION CARD

egistration Card

To avoid unnecessary delays in warranty parts and to

sure that a permanent record of your purchase is on file

ith our factory, be sure to complete the warranty

gistration card and send it to Task Industries today.

afety Information

) Familiarize yourself and others with the proper operation

nd workout recommendations for each piece of Tuff Stuff

quipment prior to use.

) Consult with your physician before beginning any

xercise program.

) Use proper discretion when children are present.

) Frayed or worn cables can be dangerous and may cause

jury. Periodically check these cables for any indication of

ear.

) Inspect machine for any sign of parts or hardware

ecoming loose.

Maintenance Information

1) Lubrication of all moving parts is essential to the longevit

and optimal performance of your Muscle IV Home Gym.

Initial lubrication of some parts of your gym have been done

at the factory, but the weight stack guide rods must be

lubricated at the time of assembly. We recommend a clear

aerosol, silicone or Teflon spray.

Note: Do not use oil based lubricants as they will attract

dust,dirt, and grime and will eventually gum up and erode

bushings and sealed bearings.

2) All pulleys and bushings should be checked regularly for

signs of wear.

3) Check and adjust tension on cables periodically as it will

maintain proper anatomical function.

4) Periodically check all moving parts, upholstery and grips

for wear. If replacement is necessary, please contact your

local Tuff Stuff retailer or call our Customer Service

Department.

5) As needed, upholstery may be cleaned with a mild

solution of soap and water. Regular use of a vinyl treatment

will add to the life and appearance of your upholstery.

6) All chrome plated surfaces should be cleaned regularly to

prolong the life and luster of the finish. Wipe machine down

with a damp cloth and dry thoroughly each day. At least

once a week your chrome equipment should be polished

with a commercial grade or automotive type chrome polish.

Tool Requirements

1) Two 3/4” Open-end wrenches

2) Two 9/16” Open-end wrenches

3) One rubber mallet

4) Needle nose pliers

5) One can Silicone Spray/ Teflon Spray Lubricant

6) Snap ring pliers

7) Hex Key 3/16” (Supplied)

7) Windex or household glass cleaner

Hardware Measurement Diagram

) Keep hands and limbs clear from weight stack and all

ther moving parts.

1

MSL-IV Muscle IV Home Gym

Page 3

e

y

c

t

Owners’ Manual: Assembly Instruction

s

IMPROVED

See #63 on page 19

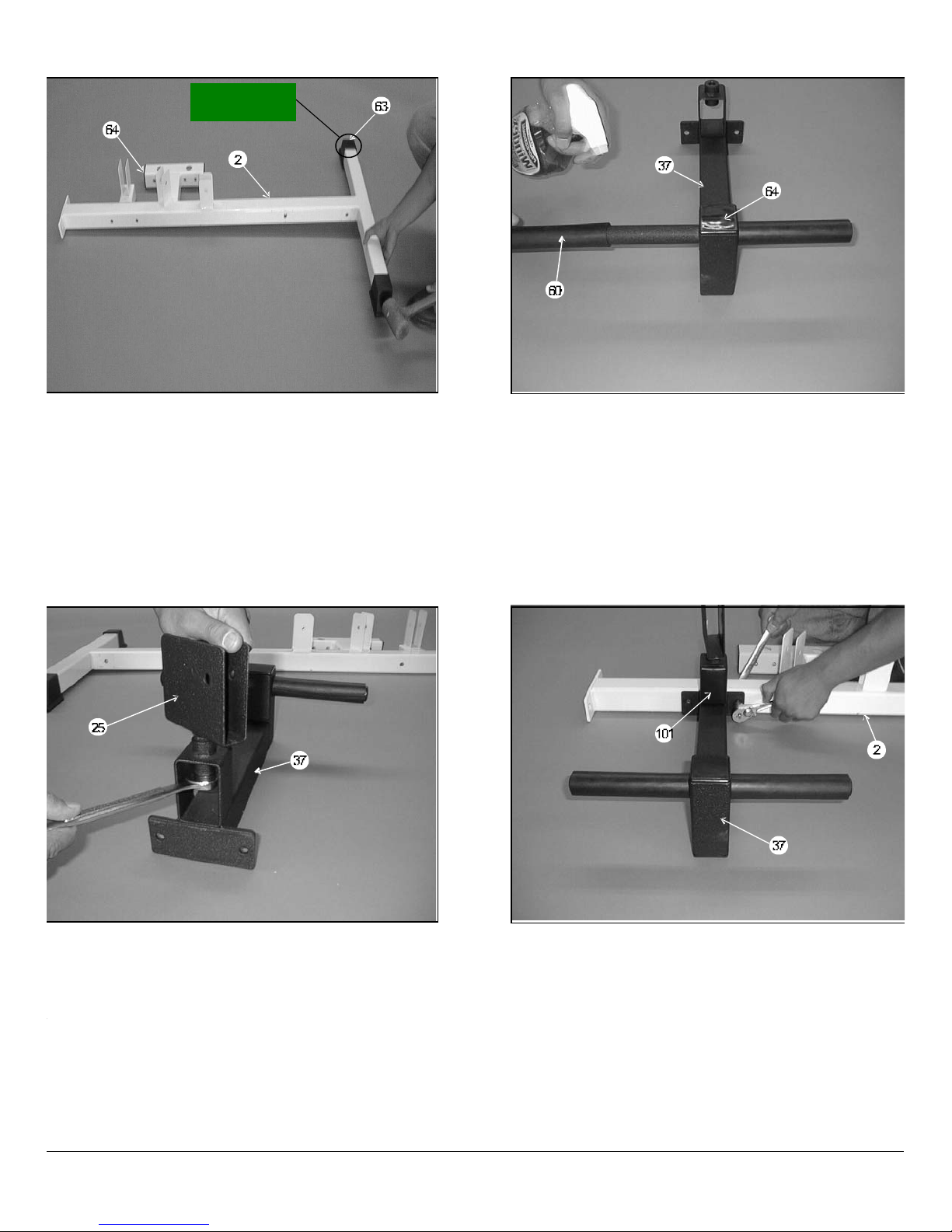

IG. 1 On a flat surface, lay the Base Frame (#2) down

nd insert two Plastic Insert Caps 2” Sq. (#64). Next, insert two

lastic Insert Caps 2” Sq. w/groove (#63) onto the front

tabilizer of the Base Fr ame (#2), as shown above.

FIG. 2 Locate the Low Row Foot Support (#37) and slid

a Hard Grip .875 X 8 (#60) over each end of the tube, as

illustrated above. The hard Grip .875 X 8 (#60) fits very tightl

onto the Low Row Foot Support (#37) and it may be

necessary to use windex or a household glass cleaner (as

shown) to complete this procedure. Next, insert one Plasti

Insert Cap 2” Sq. (#64) into the tube-end of the Low Row Foo

Support (#37).

IG. 3 Install the Low Row Swivel Pulley Bracket (#25)

nto the receptacle on the Low Row Foot Support (#37) and

ecure it using one Nylon Insert Jam Lock Nut 1/2-13 (#88)

nd one Flat Washer SAE 1/2 (#89). Note: It is recommended

hat the axle on the Low Row Swivel Pulley Bracket (#25)be

ubricated with grease prior to this assembly.

SL-IV Muscle IV Home Gym

FIG. 4 Attach the Low Row Foot Support (#37) to the

Base Frame (#2) and secure it using using two Hex Head Cap

Screws 3/8-16 X 2 3/4 (#77), four Flat Washers SAE 3/8 (#90)

and two Nylon Insert Jam Lock Nuts 3/8-16 (#86). Next, insert

two Plastic Insert Caps 2 X 3 (#101) into the pulley bracket

housing on the Low Row Foot Support (#37).

2

Page 4

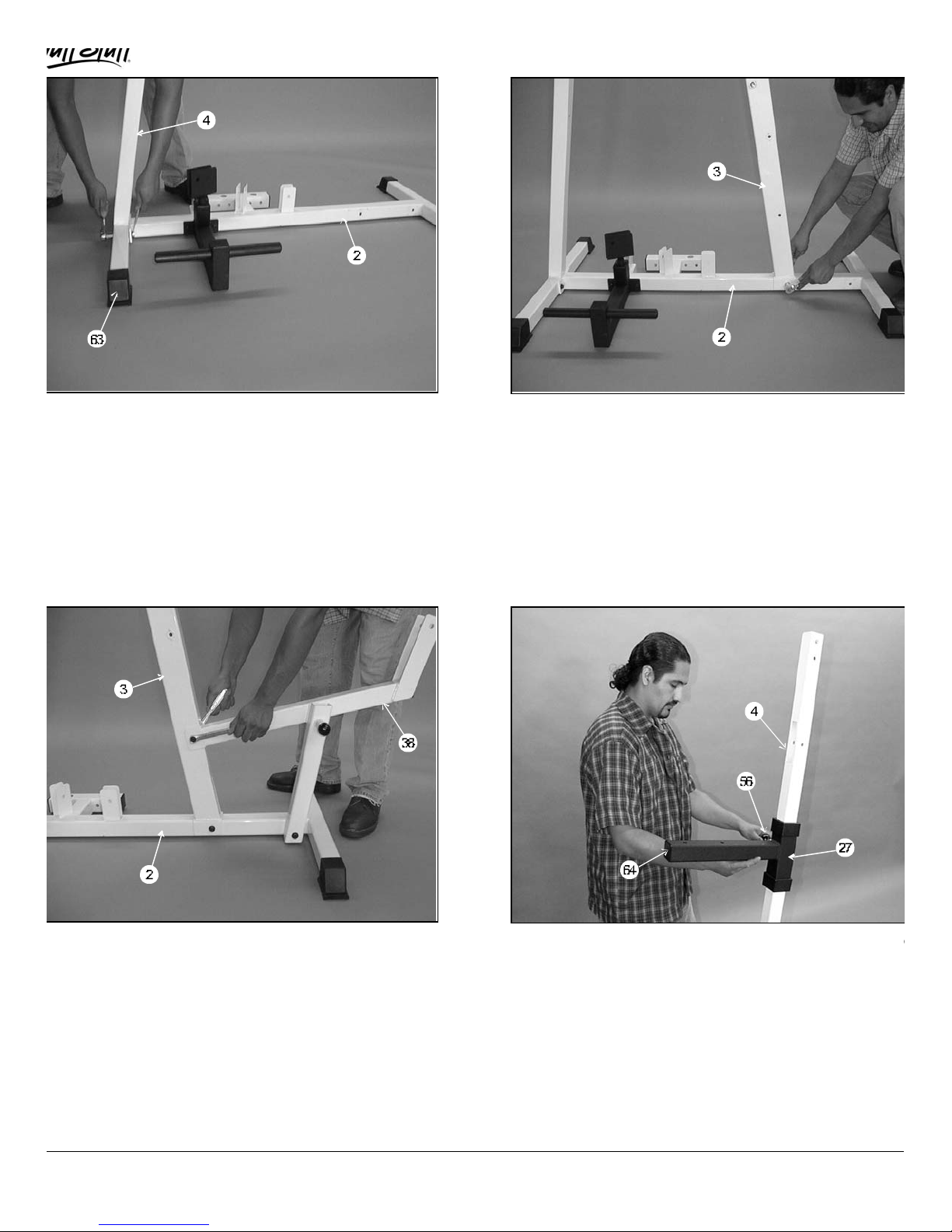

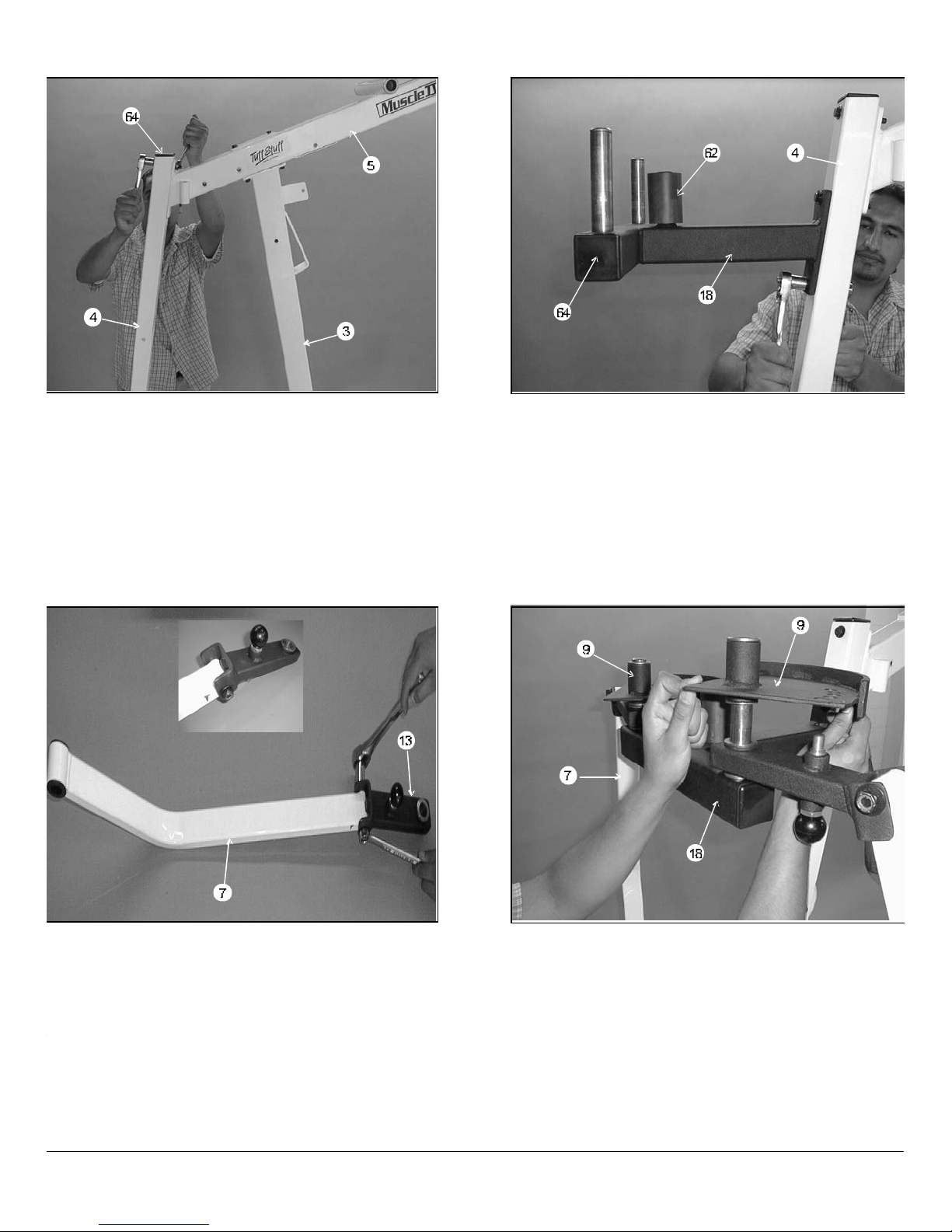

IG. 5 Attach the Rear Upright (#4) to the Base Frame (#2)

e

)

h

nd secure it using two Hex Head Cap Screws 3/8-16 X 2 3/4

#77), four Flat Washers SAE 3/8 (#90) and two Nylon Insert

ock Nuts 3/8-16 (#86). Note: Do not tighten this hardware

ssembly at this time. Next, insert two Plastic End Caps 2” Sq.

/groove (#63) into the Rear Upright (#4), as shown above.

FIG. 6 Attach the Front Upright (#3) to the Base Frame

(#2) and secure it using one Hex Head Cap Screw 3/8-16 X 2

3/4 (#77), two Flat Washers SAE 3/8 (#90) and one Nylon

Insert Jam Lock Nut 3/8-16 (#86). Note: Do not tighten this

hardware assembly at this time.

IG. 7 Attach the Leg Extension Seat Frame (#38) to the

ase Frame (#2). Secure the Leg Extension Seat Frame

#38) to the Base Frame (#2) using one Hex Head Cap Screw

/8-16 X 4 1/2 (#93), two Flat Washers SAE 3/8 (#90) and one

ylon Insert Jam Lock Nut 3/8-16 (#86). Next, secure the Leg

xtension Seat Frame (#38) to the Front Upright (#3) using

ne Hex Head Cap Screw 3/8 -16 X 2 3/4 (#77), two Flat

ashers SAE (#90) and one Nylon Insert Jam Lock Nut 3/8-16

#86). Note: Do not tighten this hardware assembly at this

ime.

3

FIG. 8 Slide the Pec Dec Adj Seat Tube (#27) onto th

Rear Upright (#4),as shown above. Note: Position the Pe

Dec Adj Seat Tube (#27) with the Push-Pull Pin 1/2 (#56

facing the same side as the selector holes on the Rear Uprig

(#4).

MSL-IV Muscle IV Home Gym

Page 5

:

6

e

Owners’ Manual: Assembly Instructions

IG. 9 Secure the Top Pulley Assembly (#5) to the Front

pright (#3) using two Hex Head Cap Screws 3/8-16 X 4 1/4

#99) four Flat Washers SAE 3/8 (#90) and two Nylon Insert

ock Nuts 3/8-16 (#86). Next, secure the Top Pulley

ssembly (#5) onto the Rear Upright (#4) using one Hex

ead Cap Screw 3/8-16 X 3 (#94), two Flat Washers SAE 3/8

#90) and one Nylon Insert Jam Lock Nut 3/8-16 (#86). Note:

his bolt should be placed in the top hole of the Rear Upright

#4).

FIG. 10 Next, attach the Pec Dec Housing (#18) to the

Rear Upright (#4). secure this assembly using one Hex Head

Cap Screw 3/8-16 X 3 1/2 (#8), two Flat Washers SAE 3/8

(#90) and one Nylon Insert Jam Lock Nut 3/8-16 (#86). Note

This bolt should be placed in the top hole of the Pec Dec

Housing (#18). Next, install one Hex Head Cap Screw 3/8 -1

X 3 (#94), two Flat Washers SAE 3/8 (#90) and one Nylon

Insert Jam Lock Nut 3/8-16 (#86) through the lower hole of th

Pec Dec Housing (#18). Finally, install the Rubber Stopper

(#62) and two Plastic Insert Caps 2 Sq. (#64), as shown

above.

IG. 11 Attach the Pec Dec Arm (#7) to the Pec Dec Arm/

am Support (#13) and secure it using one Hex Head Cap

crew 1/2-13 X 3 (#98), two Flat Washers SAE 1/2 (#89) and

ne Nylon Insert Jam Lock Nut 1/2-13 (#88). Repeat this

rocedure for the opposite Pec Dec Arm Assembly. Note: It is

ecommended that the axle on the Pec Dec Arm (#7) be

ubricated with grease prior to assembly.

SL-IV Muscle IV Home Gym

FIG. 12 Mount the assembled Pec Dec Arms (#7) in

Fig.11 to the Pec Dec Housing (#18) axles, as illustrated.

Note: It is recommended that the Pec Dec Housing (#18)

axles be lubricated with grease prior to assembly. Next, mount

the two Pec Dec Cams (#9) onto the the axles of the Pec Dec

Housing (#18), as shown above.

4

Page 6

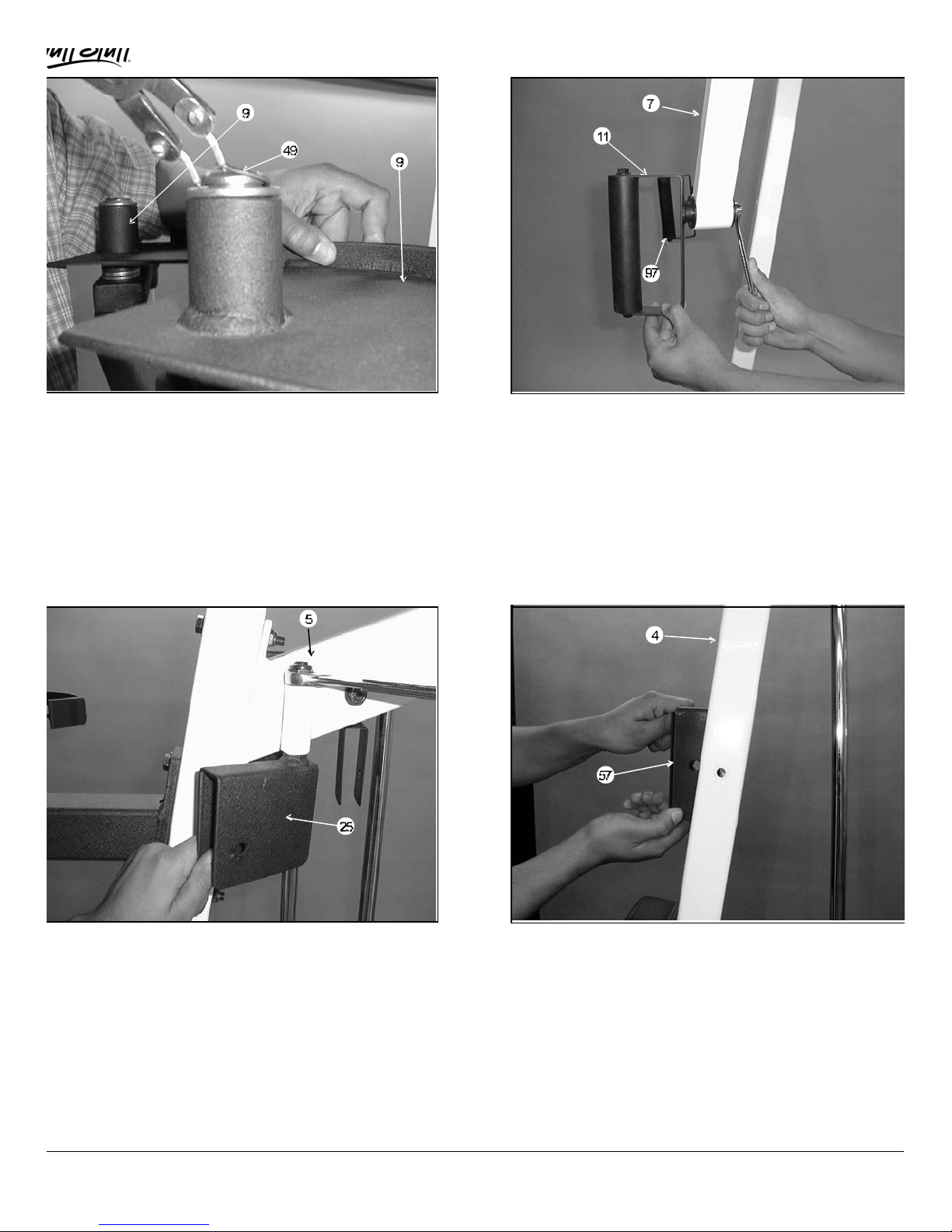

IG. 13 Secure the two Pec Dec Cams (#9) to the Pec

p

ec Housing (#18) using two Retaining Snap Rings (#49).If

ossible, use special snap ring pliers for this job, as shown

bove. If not available, carefully work each Retaining Snap

ing (#49) into the groove, then push down alternately with a

crew driver working the Retaining Snap Ring (#49) into the

roove. Note: Be careful not to distort the Retaining Snap

ing (#49) or bend it.

FIG. 14 Insert a Handle Bracket Left (#11) and Right

(#97) into the two Pec Dec Arms (#7) and secure them using

two Hex Head Cap Screws 3/8 -16 X 1 (#81) and two Fender

Washers 3/8- 1 1/2 (#106).

IG. 15 Insert the two Pec Dec Swivel Pulley Brackets

#25) into the receptacles on the Top Pulley Assembly (#5)

nd secure using four Flat Washers SAE 1/2 (#89) and two

ylon Insert Lock Nuts 1/2-13 (#88). Do not over-tighten these

uts, as the Pec Dec Swivel Pulley Brackets (#25) must

ove freely during use of the machine. Note: It is

ecommended that the Pec Dec Swivel Pulley Brackets (#25)

e greased prior to assembly.

5

FIG. 16 Install the Ab Crunch Insert Bracket (#57) and

one Nylon Pulley 4 1/2 Rd. (#35-Not shown See Fig 56) into

the Rear Upright (#4) and secure it using one Hex Head Ca

Screw 3/8-16 X 2 1/2 (#78), two Flat Washers SAE 3/8 (#90)

and one Nylon Insert Jam Lock Nut 3/8-16 (#86).

MSL-IV Muscle IV Home Gym

Page 7

o

Owners’ Manual: Assembly Instruction

s

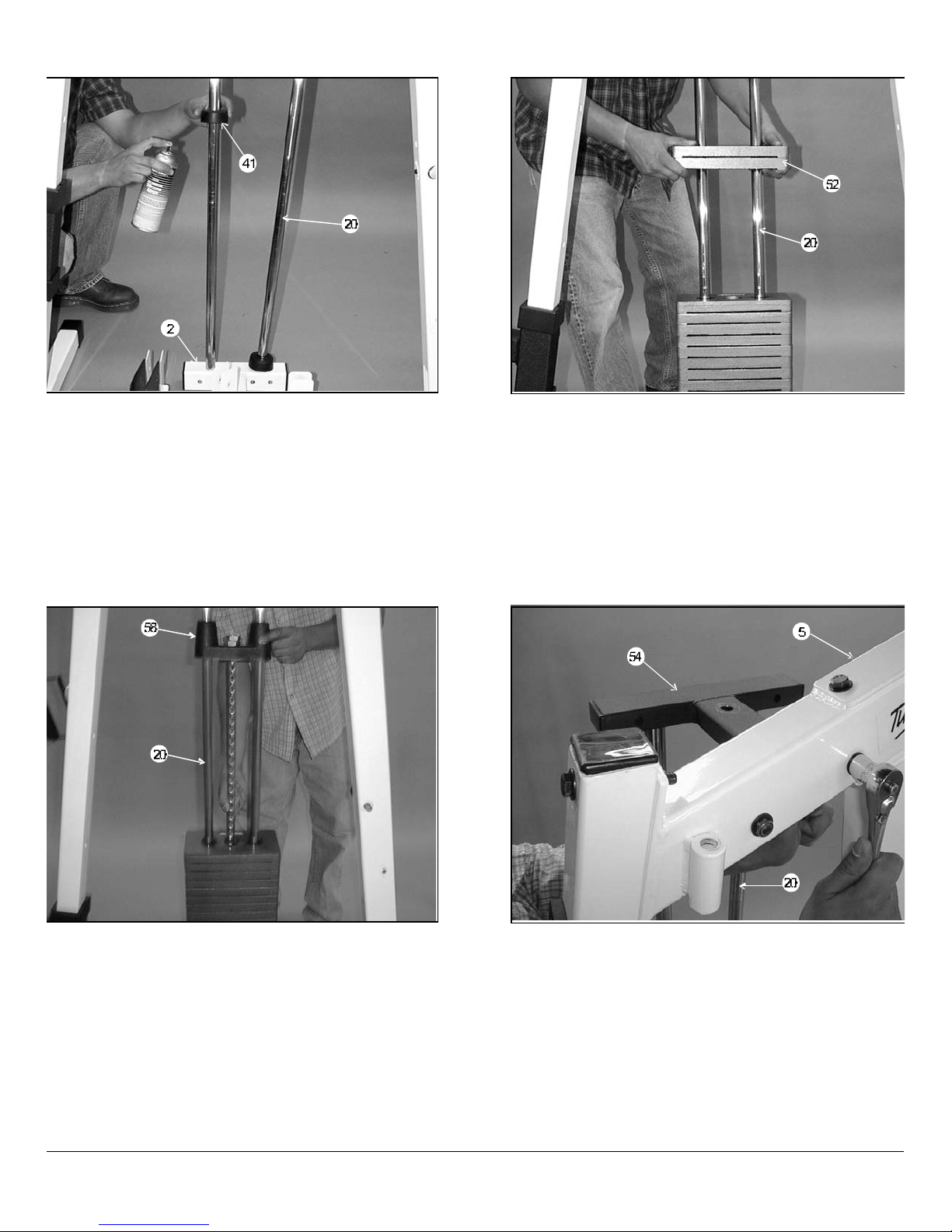

IG. 17 Insert the two Guide Rods (#20) into the

eceptacle of the Base Frame (#2), as shown above. Next,

nsert two Rubber Donuts 1 X 2 1/2 (#41) onto each each

uide Rod (#20). Note: Lubricate the Guide Rods (#20) with

ilicone or teflon lubricant at this time.

FIG. 18 Carefully begin sliding the 10 Lb. Weight Plates

(#52) over the Guide Rods (#20),one or two at a time as our

skill permits. Make sure that the 10 Lb. Weight Plates (#52)

are installed onto the Guide Rods (#20) in numerical order,

beginning with the number 200 at the bottom,190 next, and s

on.

IG. 19 Now slide the Top Plate/Selector Bar (#58) over

he Guide Rods (#20) allowing it to come to rest on the

ompleted weight stack.

SL-IV Muscle IV Home Gym

FIG. 20 Maneuver each of the Guide Rods (#20) into the

holes on the bottom side of the Guide Rod Retainer (#54).

Next, mount the Guide Rod Retainer (#54) along with the two

captive Guide Rods (#20) to the side of the Top Pulley

Assembly (#5). Secure this assembly using two Hex Head

Cap Screws 3/8 -16 X 3 (#94), four Flat Washers SAE 3/8

(#90) and two Nylon Insert Jam Lock Nuts 3/8-16 (#86).

6

Page 8

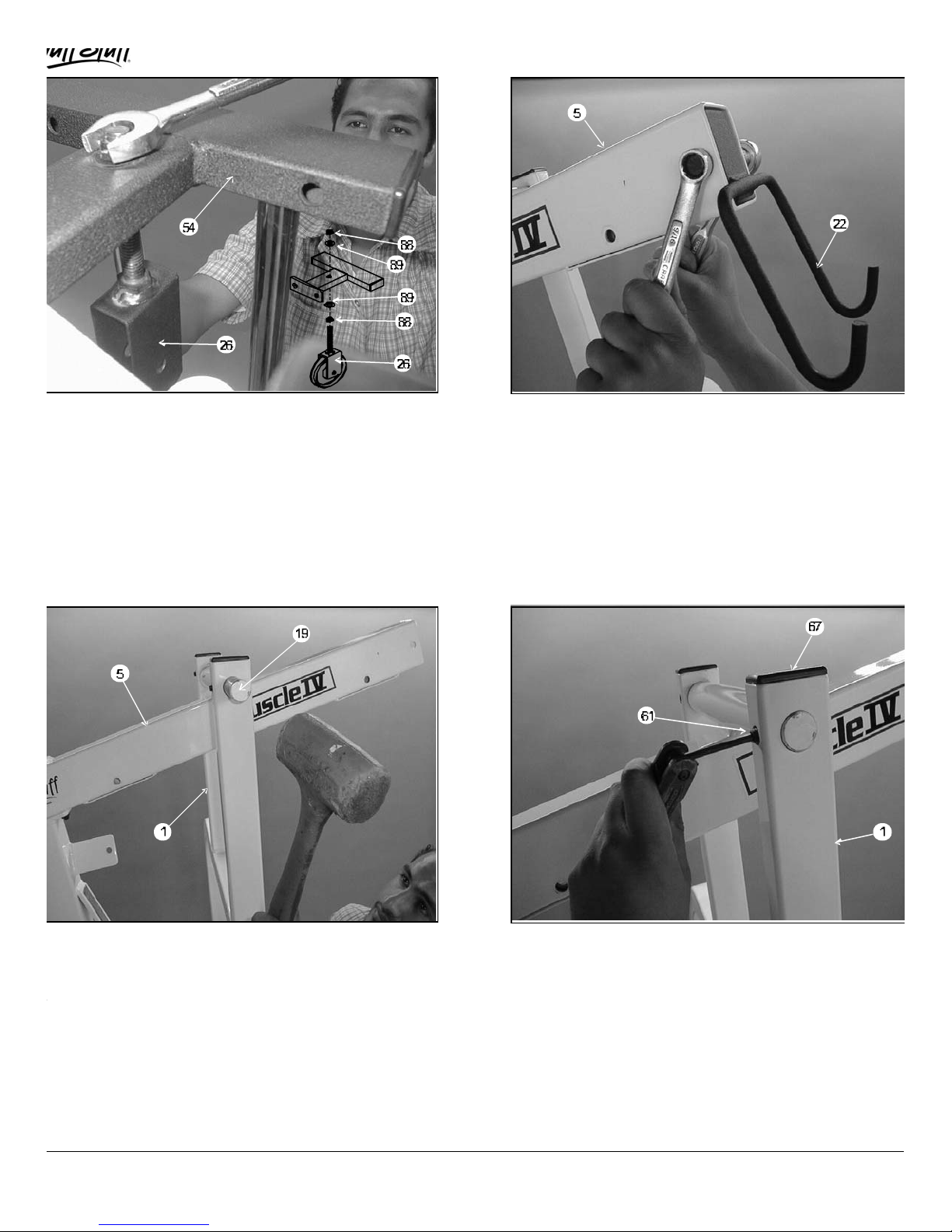

IG. 21 Locate the Adjustable Pulley Bracket (#26) and

r

hread a Hex Nut 1/2 -13 (#88) and a Flat Washer SAE 1/2

#89) onto it. Use the illustration above for further clarification

f this bolt and nut assembly. Next, insert the Adjustable

ulley Bracket (#26) into the Guide Rod Retainer (#54) and

ecure it using one Nylon Insert Jam Lock Nut 1/2-13 (#88)

nd one Flat Washer SAE 1/2 (#89). Note: Loosely secure the

ut to allow adjustment for cable tension later in the assembly

rocess.

FIG. 22 Insert the Lat Bar Holder (#22) into the tube-end of

the Top Pulley Assembly (#5), as shown above. Secure this

assembly using one Hex Head Cap Screw 3/8-16 X 2 1/2

(#78), two Flat Washers SAE 3/8 (#90) and one Nylon Insert

Jam Lock Nut 3/8-16 (#86).

IG. 23 Now position the Press Arm (#1) to the Top Pulley

ssembly (#5), as shown above. Next, press the Pivot Axle 1

11 3/4 (#19) through the holes in the Press Arm (#1) using

rubber mallet hammer until it is flush with both sides. Note:It

s recommened that the Pivot Axle 1 X 11 3/4 (#19) be

reased prior to this assembly.

7

FIG. 24 At the top of each end of the Press Arm (#1) is a

set screw fixture. Secure the Press Arm (#1) using two Set

Screws 3/8-16 X 1/2 (#61). Use the Hex Key 3/16 (#50) tool fo

securing the Set Screws 3/8-16 X 1/2 (#61). Next, insert two

Plastic Insert Caps 1 X 2 (#67) into the tube-ends of the Press

Arm (#1).

MSL-IV Muscle IV Home Gym

Page 9

Next, locate the Black Caster 2 X 1 (#34) and two

4

t

r

e

o

Owners’ Manual: Assembly Instruction

s

IG. 25 Locate the Range Of Motion Device (#48), the

arge Cable Retainer (#107) and two Nylon Pulleys 4 1/2 Rd.

#35). Assemble as shown using one Hex Head Cap Screw

/8-16 X 3 (#94), three Nylon Spacers 3/8 X 3/8 (#72), two Flat

ashers SAE 3/8 (#90) and one Nylon Insert Jam Lock Nut

/81-6 (#86). Refer to Fig. C on page 18 for further clarification

f this assembly.

FIG. 26

Nylon Spacers (#72). Assemble to the Range Of Motion

Device (#48) using one Hex Head Cap Screw 3/8-16 X 2 3/

(#77), two Flat Washers SAE 3/8 (#90) and one Nylon Inser

Jam Lock Nut 3/8-16 (#86). Refer to Fig. Con page 18 fo

further clarification of this assembly.

IG. 27 Locate the Range Of Motion Tube (#47) and one

houlder Bolt 3/8 X 3/8 (#95). Insert the Range Of Motion

ube (#47) into the Range Of Motion Device (#48), as shown

bove. Secure this assembly using the Hex Key 3/16 (#50).

SL-IV Muscle IV Home Gym

FIG. 28 Attach the Range Of Motion Tube (#47) onto th

Press Bar (#1) and secure it using two Hex Head Cap Screws

3/8-16 X 3 1/4 (#76), four Flat Washers SAE 3/8 (#90) and tw

Nylon Insert Jam Lock Nuts 3/8-16 (#87).

8

Page 10

IG. 29 Attach the Foot Roll Bracket (#46) to the Leg

t

d

g

e

xtension Arm (#42) and secure it using one Hex Head Cap

crew 1/2-13 X 2 3/4 (#92), two Flat Washers SAE 1/2 (#89)

nd one Nylon Insert Jam Lock Nut 1/2-13 (#88). Next, install a

ubber Bumper 3/8 X 1 1/2 (#33) to the Leg Extension Arm

#42), as shown above, and secure it using one Hex Head Cap

crew 3/8-16 X 1 (#81) and one Flat Washer SAE 3/8 (#90).

FIG. 30 Attach the Leg Extension Arm (#42) to the Leg

Extension Seat Frame (#38), as shown above, and secure it

using one Hex Head Cap Screw 1/2-13 X 3 1/4 (#96), two Fla

Washers SAE 1/2 (#89) and one Nylon Insert Jam Lock Nut

1/2-13 (#88). Note: Be sure not to over-tighten this hardware

assembly as the Leg Extension Arm (#42) should be allowe

to swivel freely. Also, it is recommended that the Le

Extension Arm (#42) be greased at the pivot point prior to

assembly.

IG. 31 Insert the Foot Roll Tube 1 X 16 (#100) through

he Foot Roll Bracket (#46). Then slide a Foam Foot Roll 7

4 X 1 (#32) onto each end of the Foot Roll Tube 1 X 16

#100). Next, insert a Plastic Insert Cap 1” Rd. (#65) into each

nd of the Foot Roll Tube 1 X 16 (#100).

9

FIG. 32 Attach the Seat Pad (Bench Press) (#45) to th

Bench Press Adj Seat Tube (#39) and secure it using two

Hex Head Cap Screws 3/8-16 X 1 3/4 (#79) and two Flat

Washers SAE 3/8 (#90), as shown above.

MSL-IV Muscle IV Home Gym

Page 11

IG. 33 Insert the Bench Press Adj Seat Tube (#39) into

s

4

6

he receptacle on the Leg Extension Bench Frame (#38),as

hown above. Next, insert two Foam Foot Rolls 7 X 4 X 1

#32) and two Plastic Insert Caps 1” Rd. (#65) onto the tube-

nds of the Foot Roll Tube 1 X 16 (#100). Note: Pull the

ush-pull pin 1/2 (#56) to allow the Bench Press Adj Seat

ube (#39) to adjust up and down.

FIG. 34 On the Bench Press Adj Seat Tube (#39) there i

a threaded socket. Secure the Foot Roll Tube 1 X 16 (#100)

using one Set Screw 1/4-20 X 1/4 (#105). Use the supplied

Hex Key 1/8 (#69) tool for securing this Set Screw (#114).

IG. 35 Mount the Back Pad Adj Bracket (#10) to the

ench Press Back Pad (#44) and secure using two Hex Head

ap Screws 3/8-16 X 1 (#81), two Bumper Washers 3/8 (#108)

nd two Bumper Caps Black (#91). Refer to the Exploded View

n page 19 for further clarification of this assembly.

SL-IV Muscle IV Home Gym

FIG. 36 Secure the Back Pad Bracket (#10) to the Front

Upright (#3) using one Hex Head Cap Screw 3/8-16 X 3 1/

(#76), four Flat Washers Nylon 3/8 (#6), two Flat Washers

SAE 3/8 (#90) and one Nylon Insert Jam Lock Nut 3/8-1

(#86). Refer to the Exploded View on page 19 for further

clarification of this assembly.

10

Page 12

IG. 37 Next, slide the Foot Roll Tube 1 X 23 3/4 (#55)

c

hrough the receptacles on the Back Pad Adj Bracket (#10),

s shown above. Next, install the Foam Foot Rolls 7 X 4 X 1

#32) as described in Fig. 31 on page 9.

FIG. 38 Attach the Pec Dec Seat Pad (#24) to the Pec De

Seat Adj Tube (#27) and secure it using two Hex Head Cap

Screws 3/8-16 X 2 3/4 (#77) and two Flat Washers SAE 3/8

(#90).

FIG. 39 Attach the Pec Dec Back Pad (#43)to

the Rear Upright (#4) and secure it using two Hex

Head Cap Screws 3/8-16 X 2 3/4 (#77) and two

Flat Washers SAE 3/8 (#90).

11

FIG. 40 Route the Lat Cable (#14) through the Top Pulley

Assembly (#5). Then insert one Nylon Pulley 4 1/2 Rd. (#35)

and secure it using one Hex Head Screw 3/8-16 X 2 1/2 (#78),

two Flat Washers SAE 3/8 (#90) and one Nylon Insert Jam

Lock Nut 3/8-16 (#86). Refer to Fig. 1 on page 17 for further

detailed illustration of this cable routing.

MSL-IV Muscle IV Home Gym

Page 13

Owners’ Manual: Assembly Instruction

s

IG. 41 Insert the Lat Cable (#14) and one Nylon Pulley 4

/2 Rd (#35) into the Top Pulley Assembly (#5) and secure it

sing one Hex Head Cap Screw 3/8-16 X 2 1/2 (#78), two Flat

ashers SAE 3/8 (#90) and one Nylon Insert Jam Lock Nut

/8-16 (#86). Refer to Fig. 1 on page 17 and Fig. B on page

8 for further detailed illustration of this cable routing.

FIG. 42 Route the Lat Cable (#14) over, then under the

Nylon Pulley 4 1/2 Rd. (#35), as illustrated above. Refer to Fig.

1 on page 17 and Fig. B on page 18 for further detailed

illustration of this cable routing.

IG. 43 Next, attach a Nylon Pulley 4 1/2 Rd. (#35) to the

ulley bracket on the Front Upright (#3) and secure it using

ne Hex Head Cap Screw 3/8 -16 X 1 3/4 (#79), two Flat

ashers SAE 3/8 (#90), one Nylon Insert Jam Lock Nut 3/8-16

#86) and one Cable Retainer Bracket (#111). Next, route the

at Cable (#14) under, then over the Nylon Pulley 4 1/2 Rd.

#35), as shown above. Refer to Fig. 1 on page 17 and Fig. B

n page 18 for further detailed illustration of this cable routing.

SL-IV Muscle IV Home Gym

FIG. 44 Continue to route the Lat Cable (#14) over the

Nylon Pulley 4 1/2 Rd. (#35), then under, as shown above.

Refer to Fig. 1 on page 17 and Fig. B on page 18 for further

detailed illustration of this cable routing.

12

Page 14

IG. 45 Attach a Nylon Pulley 4 1/2 Rd. (#35) to the

9

9

n

ront Upright (#3) and secure it using one Hex Head Cap

crew 3/8-16 X 3 3/4 (#75), two Flat Washers SAE 3/8 (#90),

ne Nylon Insert Jam Lock Nut 3/8-16 (#86) and one Cable

etainer Bracket (#111). Then continue to route the Lat

able (#14) over the pulley as shown. Refer to Fig. 1 on page

7 and Fig. B on page 18 for further detailed illustration of this

able routing.

FIG. 46 Assemble the Double PulleyPlates 1/8 X 2 X

(#21) using two Nylon Pulleys 4 1/2 Rd. (#35), two Hex Head

Cap Screw 3/8-16 X 1 3/4 (#79), four Flat Washers SAE 3/8

(#90) and two Nylon Insert Jam Lock Nuts 3/8-16 (#86). Refer

to Fig. 1 on page 17 for further detailed illustration of this

cable routing. Next, route the Lat Cable (#14) through the

Double Pulley Plates 1/8 X 2 X 9 (#21), as shown above.

Note: The four holes on the Double Pulley Plates 1/8 X 2 X

(#21) are used to adjust the cable tension once the cable

routing has been completed.

IG. 47 Insert a Nylon Pulley 4 1/2 Rd. (#35) into the

djustable Pulley Bracket (#26) and secure it using one Hex

ead Cap Screw 3/8-16 X 1 3/4 (#79), two Flat Washers SAE

/8 (#90) and one Nylon Insert Jam Lock Nut 3/8-16 (#86).

oute the Lat Cable (#14) through the Adjustable Pulley

racket (#26), as shown above.

13

FIG. 48 Attach the Lat Cable (#14) to the Top Plate /Selecto

Bar (#58) and secure it using one Split Bolt 1/2-13 X 1 (#51) a

one Split Washer 1/2 (#82). Refer to Fig. E on page 18 for

further detailed illustration of this assembly. Note: Be sure this

hardware assembly is securely fastened.

MSL-IV Muscle IV Home Gym

Page 15

f

o

s

6

y

8

Owners’ Manual: Assembly Instruction

s

IG. 49 Begin routing the Pec Dec Cable (#16).Attach one

nd of the Pec Dec Cable (#16) to the Pec Dec Cam (#9) and

ecure it using one Socket Head Cap Screw 1/4 X 3/4 (#102)

nd one Nylon Insert Jam Lock Nut 1/4-20 (#103). Refer to

ig. A on page 18 for further detailed illustration of this

ssembly.

FIG. 50 Attach one Nylon Pulley 4 1/2 Rd. (#35) to each o

the Swivel Pulley Brackets (#25) and secure them using tw

Hex Head Cap Screws 3/8-16 X 1 3/4 (#79), four Flat Washer

SAE 3/8 (#90) and two Nylon Insert Jam Lock Nuts 3/8-1

(#86). Route the Pec Dec Cable (#16) over the Nylon Pulle

4 1/2 Rd. (#35), as shown above. Refer to Fig. Aon page 1

for further detailed illustration of this cable routing.

IG. 51 Insert two Nylon Pulleys 4 1/2 Rd. (#35) into the

ffset Pulley Bracket (#23) and secure them using two Hex

ead Cap Screws 3/8-16 X 1 3/4 (#79), four Flat Washers SAE

/8 (#90) and two Nylon Insert Jam Lock Nuts 3/8-16 (#86).

ext, route the Pec Dec Cable (#16) through this bracket, as

hown above. Repeat the same procedure in Fig. 49 and Fig.

0 to complete the routing of the Pec Dec Cable (#16). Refer to

ig. A on page 18 for further detailed illustration of this cable

outing.

SL-IV Muscle IV Home Gym

FIG. 52 Attach the Leg Extension Cable (#15) to the Leg

Extension Arm (#42) and secure it using one Hex Head Cap

Screw 3/8-16 X 1 (#81) and one Nylon Insert Jam Lock Nut

3/8-16 (#86). Refer to Fig. F on page 18 for further detailed

illustration of this cable routing.

14

Page 16

IG. 53 Insert a Nylon Pulley 4 1/2 Rd. (#35) into the pulley

e

e

s

racket on the Base Frame (#2) and secure it using one Hex

ead Cap Screw 3/8-16 X 1 3/4 (#79), two Flat Washers SAE

/8 (#90) and one Nylon Insert Jam Lock Nut 3/8-16 (#86).

ext, insert the Leg Extension Cable (#15) through the Front

pright (#3) then through the Nylon Pulley 4 1/2 Rd. (#35), as

hown above. Refer to Fig. I on page 17 for further detailed

llustration of this cable routing.

FIG. 54 Next, lift the loose end of the Leg Extension Cabl

(#15) up into the Double Pulley Plates 1/8 X 2 X 9 (#21),as

shown above. Refer to Fig. I on page 17 for further detailed

illustration of this cable routing.

IG. 55 Insert a Nylon Pulley 4 1/2 Rd. (#35) into the

ulley bracket on the Base Frame (#2) and secure it using one

ex Head Cap Screw 3/8 -16 X 1 3/4 (#79), two Flat Washers

AE 3/8 (#90) and one Nylon Insert Jam Lock Nut 3/8-16

#86). Next, route the Leg Extension Cable (#15) through the

ylon Pulley 4 1/2 Rd. (#35), as shown above.

15

FIG. 56 Now, lift the loose end of the Leg Extension Cabl

(#15) and route it through the Offset Pulley Bracket (#23),a

shown above.

MSL-IV Muscle IV Home Gym

Page 17

e

w

Owners’ Manual: Assembly Instructions

IG. 57 Next, route the Leg Extension Cable (#15) through

he Offset Pulley Bracket (#23), as shown above. Refer to

ig. I on page 17 for further detailed illustration of this cable

outing.

FIG. 58 Finally, route the remainder of the Leg Extension

Cable (#15) through the Nylon Pulley 4 1/2 Rd. (#35) located

on the Rear Upright (#4). Then, assemble the Strap Bracket

(#83) and the Abdominal Strap (#53) onto the cable-end of th

Leg Extension Cable (#15). Secure this assembly using one

Shoulder Bolt 3/8 X 3/4 (#80), one Nylon Ball 1 3/4 X 5/16

(#85) and one Nylon Insert Lock Nut 5/16-18 (#84). Refer to

Fig. D on page 18 for further detailed illustration of this

assembly.

IG. 59 Insert the end of the Low Row Cable (#17) into the

ow Row Swivel Pulley Bracket (#40) and secure it into

lace using one Nylon Pulley 4 1/2 Rd. (#35). Use the pulley

ounting hardware described in Fig. 55 on page 15 to fasten

he pulley and cable into place.

SL-IV Muscle IV Home Gym

FIG. 60 Insert a Nylon Pulley 4 1/2 Rd. (#35) and the Lo

Row Cable (#17), as shown above. Use the pulley mounting

hardware described in Fig. 55 on page 15 to fasten the pulley

into place.

16

Page 18

IG. 61 Finally, coonect the end of the Low Row Cable

#17) to the empty pulley bracket located on the Base Frame

#2) and secure it using one Hex Head Cap Screw 3/8 -16 X 1

/4 (#79), two Flat Washers SAE 3/8 (#90), two Nylon

pacers 3/8 X 3/8 (#72) and one Nylon Insert Jam Lock Nut

/8-16 (#86). Refer to Fig. Gon page 18 for further detailed

llustration of this assembly.

See Figure B

See Fig. B

Fig. I

FIG. 62 This completes the assembly of the MSL-IV. It is

recommended that you check and secure all the hardware

assemblies and inspect all cable routing for proper tension and

assembly.

See Figure A

See Figure D

See Figure C

See Figure G, H

See Figure D

Note:Some Parts

Not Shown or cut

away for clarity

See Figure E

See Figure F

17

See Figure G, H

MSL-IV Muscle IV Home Gym

Page 19

Owners’ Manual: Assembly Instructions

FIG. BFIG. A

Note: Some Parts Have Been Cut

Away For Clarity.

FIG. C FIG. D FIG. E

FIG. HFIG. GFIG. F

SL-IV Muscle IV Home Gym

Leg Press Configuration

18

Page 20

19

MSL-IV Muscle IV Home Gym

Page 21

o

o

y

2

0

6

8

4

COLOR CHART

GRAY= SUB-ASSEMBLY PARTS

BLACK= HARDWARE

m N

1 PRESS BAR MSL4-01-00 1 59 COIL CHAIN 3/16 X 21 BNH0017 1

2 BASE FRAME MSL4-02-00 1 60 HARD GRIP .875 X 8 BNH0523 6

3 FRONT UPRIGHT MSL4-03-00 1 61 SET SCREW 3/8-16 X 1/2 BNH0474 2

4 REAR UPRIGHT MSL4-04-00 1 62 RUBBER STOPPER 1 X 2 X 2 3/4 BNH0611 1

5 TOP PULLEY ASSEMBLY MSL4-05-00 1 63 PLASTIC END CAP 2" SQ W/GROOVE BNH0050 4

6 NYLON WASHER 3/8 USS BNH0248 4 64 PLASTIC INSERT CAP 2" SQ BNH0012 1

7 PEC DEC ARM MSL4-07-00 2 65 PLASTIC INSERT CAP 1" RD BNH0002 6

8 HEX HEAD CAP SCREW 3/8-16 X 3 1/2 BNH0280

9 PEC DEC CAM MSL4-08-00 2 67 PLASTIC INSERT CAP 1 X 2 BNH0005 7

10 BACK PAD ADJUSTMENT BRACKET UP179 1 68 PLASTIC INSERT CAP 1 1/4 RD BNH0573 4

11 PEC DEC HANDLE BRACKET (LEFT) MSL4-11-00 1 69 HEX KEY LONG 1/8" BNH0767 1

12 PEC DEC HOUSING MSL4-12-00 1 70 RUBBER HOSE 1 1/4 X 5 1/2 BNH0807 2

13 PEC DEC ARM/ CAM SUPPORT MSL4-13-00 2 71 RUBBER HOSE 1 1/4 X 7 BNH0807 4

14 LAT CABLE MSL4-14-00 1 72 NYLON SPACER 3/8 X 3/8 BNH0392 5

15 LEG EXTENSION CABLE MSL4-15-00 1 73 NYLON BUSHING 1 X 1 1/2 BNH0531 4

16 PEC DEC CABLE MSL4-16-00 1 74 BRONZE BUSHING 1 X 1 1/4 BNH0527 1

17 LOW ROW CABLE MSL4-17-00 1 75 HEX HEAD CAP SCREW 3/8-16 X 3 3/4 BNH0281 1

18 NYLON STEM BUTTON 5/16 BNH0533 2 76 HEX HEAD CAP SCREW 3/8-16 X 3 1/4 BNH0312 3

19 PIVOT AXLE 1 X 11 3/4 UP067 1 77 HEX HEAD CAP SCREW 3/8-16 X 2 3/4 BNH0278 11

20 GUIDE ROD 1 X 72 UP124 2 78 HEX HEAD CAP SCREW 3/8-016 X 2 1/2 BNH0276 4

21 DOUBLE PULLEY PLATE 1/8 X 2 X 9 UP092 2 79 HEX HEAD CAP SCREW 3/8-16 X 1 3/4 BNH0274 1

22 LAT BAR HOLDER 2 X 3 UP096 1 80 SHOULDER BOLT 3/8 X 3/4 BNH0718 2

23 OFFSET PULLEY BRACKET UP121 2 81 HEX HEAD CAP SCREW 3/8-16 X 1 BNH0275 6

24 PEC DEC SEAT PAD UP122 1 82 SPLIT WASHER 1/2" BNH0572 1

25 PEC DEC SWIVAL PULLEY BRACKET UP126 3 83 STRAP BRACKET #20 BNH0562 2

26 ADJ PULLEY BRACKET UP127 1 84 NYLON INSERT LOCK NUT 5/16-18 BNH0215 2

27 PEC DEC SEAT ADJ TUBE UP133 1 85 NYLON BALL 1 3/4 X 5/16 BNH0392 3

28 LAT BAR CHROME 48" UP093 1 86 NYLON INSERT JAM LOCK NUT 3/8-16 BNH0365 2

29 LOW ROW BAR 16" UP094 1 87 NYLON INSERT LOCK NUT 3/8-16 BNH0214 9

30 WEIGHT SELECTOR PIN BNH0064 1 88 NYLON INSERT JAM LOCK NUT 1/2-13 BNH0366 9

31 PLASTIC TUBE GUIDE 2 1/2 SQ BNH0060 2 89 FLAT WASHER SAE 1/2" BNH0238 7

32 FOAM FOOT ROLL 7 X 4 X 1 BNH0043 6 90 FLAT WASHER SAE 3/8" BNH0239 8

33 RUBBER BUMPER 3/8 X 1 1/2 BNH0514 1 91 BUMPER CAP BLACK BNH0412 2

34 BLACK CASTER 2 X 1 BNH0633 1 92 HEX HEAD CAP SCREW 1/2-13 X 2 3/4 BNH0261 1

35 NYLON PULLEY 4 1/2 RD BNH0556 1 9 93 HEX HEAD CAP SCREW 3/8-16 X 4 1/2 BNH0284 1

36 SNAP LINK ZINC BNH0065 3 94 HEX HEAD CAP SCREW 3/8-16 X 3 BNH0282 4

37 LOW ROW FOOT SUPPORT UP177 1 95 SHOULDER BOLT 3/8 X 3/8 BNH0422 1

38 LEG EXTENSION BENCH FRAME UP172 1 96 HEX HEAD CAP SCREW 1/2-13 X 3 1/4 BNH0576 1

39 BENCH PRESS ADJ SEAT TUBE UP171 1 97 HANDLE BRACKET (RIGHT) MSL4-97-00 1

40 PUSH-PULL PIN 1/2" (SPECIAL) BNH0516 3 98 HEX HEAD CAP SCREW 1/2-13 X 3 BNH0264 2

41 RUBBER DONUT BNH0062 2 99 HEX HEAD CAP SCREW 3/8-16 X 4 1/4 BNH0317 3

42 LEG EXTENSION ARM UP150 1 100 FOOT ROLL TUBE 1 X 16 UP053 2

43 PEC DEC BACK PAD UP147 1 101 PLASTIC INSERT CAP 2 X 3 BNH0052 1

44 BACK PAD (BENCH PRESS) MSL4-44-00 1 102 SOCKET HEAD CAP SCREW 1/4 X 3/4 BNH0452 2

45 SEAT PAD (BENCH PRESS) UP173 1 103 NYLON INSERT LOCK NUT 1/4-20 BNH0213 2

46 FOOT ROLL BRACKET UP176 1 104 HEX HEAD CAP SCREW 3/8-16 X 1 1/4 BNH0273 4

47 RANGE OF MOTION TUBE MSL4-47-00 1 105 SET SCREW 1/4-20 X 1/4 BNH0790 2

48 RANGE OF MOTION DEVICE MSL4-48-00 1 106 FENDER WASHER 3/8 X 1 1/2 BNH0195 6

49 RETAINING SNAP RING BNH0419 2 107 CABLE RETAINER BRACKET LARGE UP160 1

50 HEX KEY 3/16 BNH0371 1 108 BUMPER WASHER 3/8 BNH0498 2

51 SPLIT BOLT 1/2-13 X 1 BNH0479 1 109 PVC TUBE 1 X 7 BNH0417 2

52 10 LB WEIGHT PLATE GREY BNH0561 1 9 110 NYLON SPACER 3/8 X 7/8 X 3/4 BNH0726 1

53 ABDOMINAL STRAP BNH0821 1 111 CABLE RETAINER BRACKET UP014 2

54 GUIDE ROD RETAINER HOUSING UP169 1 112 VELCRO ANKLE STRAP 20000-VNAS 1

55 FOOT ROLL TUBE 1 X 23 3/4 UP180 1 113 AXLE TUBE 1 X 7 MSL4-113-00 2

56 PUSH-PULL PIN 1/2" BNH0515 3 114 TUBEING CONNECTOR 3/8-16 BNH0551 4

57 AB CRUNCH INSERT BRACKET UP119 1 115 BRONZE BUSHING 1/2 X 5/8 BNH0528 2

58 TOP PLATE/ SELECTOR BAR UP003 1 116 STAINLESS STEEL TAPE 1 X 8 BNH0740 1

MSL-IV PARTS LIST

Description Part No. Qtytem N

1 66 PLASTIC INSERT CAP 1 1/2 SQ BNH0009 1

Description Part No. Qt

SL-IV Muscle IV Home Gym

20

Page 22

Notes_____________________________________________________________

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

21

MSL-IV Muscle IV Home Gym

Page 23

Notes_____________________________________________________________

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

_________________________________________________________________

SL-IV Muscle IV Home Gym

22

Page 24

DO NOT DISCARD THIS MANUAL

1325 E. Franklin Ave., Pomona, CA 91766

Ph: 909-629-1600 Fax: 909-629-4967

E-mail: taskind@aol.com Net: www.tuffstuff.net

Loading...

Loading...