Page 1

TUFFSTUFF FITNESS INTERNATIONAL

OWNER’S MANUAL

Maintenance & Assembly Instructions

IMPORTANT: KEEP THIS MANUAL FOR FUTURE REFERENCE

NOTICE

It is the Purchaser’s/Owner’s obligation:

1. To disclose and post all Rules & Regulations, Danger, Warning and Caution

labels a xed on the machine to their customers/users.

2. Equipment to be installed by TFI Authorized Dealer or a service company

approved by TFI.

3. Provide trained personnel, supervision and correct usage of the equipment.

4. Provide scheduled inspection, maintenance & repairs and must be performed

by TFI Authorized Dealer or a service company approved by TFI.

5. Must use only genuine Tu Stu replacement parts.

CHR-500

Half Cage w/Safety Stopper and

Dip Handles

CHR-500_Rev0

Revision Date 5-19-2014

Page 2

Table of Contents

OVERHEAD SPECIFICATIONS .........................................................................Page 2

DANGER, WARNING, & CAUTION LABELS INFORMATION ...............Page 3-5

IMPORTANT SAFETY INSTRUCTIONS ..........................................................Page 6

REGISTRATION, SERVICE & ASSEMBLY ........................................................Page 7

INSPECTION/MAINTENANCE ......................................................................... Page 8

ASSEMBLY STEPS ........................................................................................ Page 9-12

PARTS LIST ......................................................................................................... Page 13

PRE-ASSEMBLED COMPONENTS .........................................................Page 14-15

WARRANTY ....................................................................................................... Page 16

Tu Stu Fitness International Inc. continually engages in research related to product improvements. Please take the time to carefully read through

this owner’s manual thoroughly. Instructions contained in this owner’s manual are not intended to cover all details or variations possible with

equipment, or to cover every contingency that may be met in conjunction with assembly, installation, operation, maintenance or troubleshooting of

the equipment. Eventhough we have prepared this owner’s manual with extreme care, neither the manufacturer nor the author can accept

responsibility for any errors in, or omission from, the information given. Should additional information be required, or should situations arise that are

not covered by this owner’s manual, the matter should be directed to Customer Service at Tu Stu Fitness International Inc. in Chino, California.

2

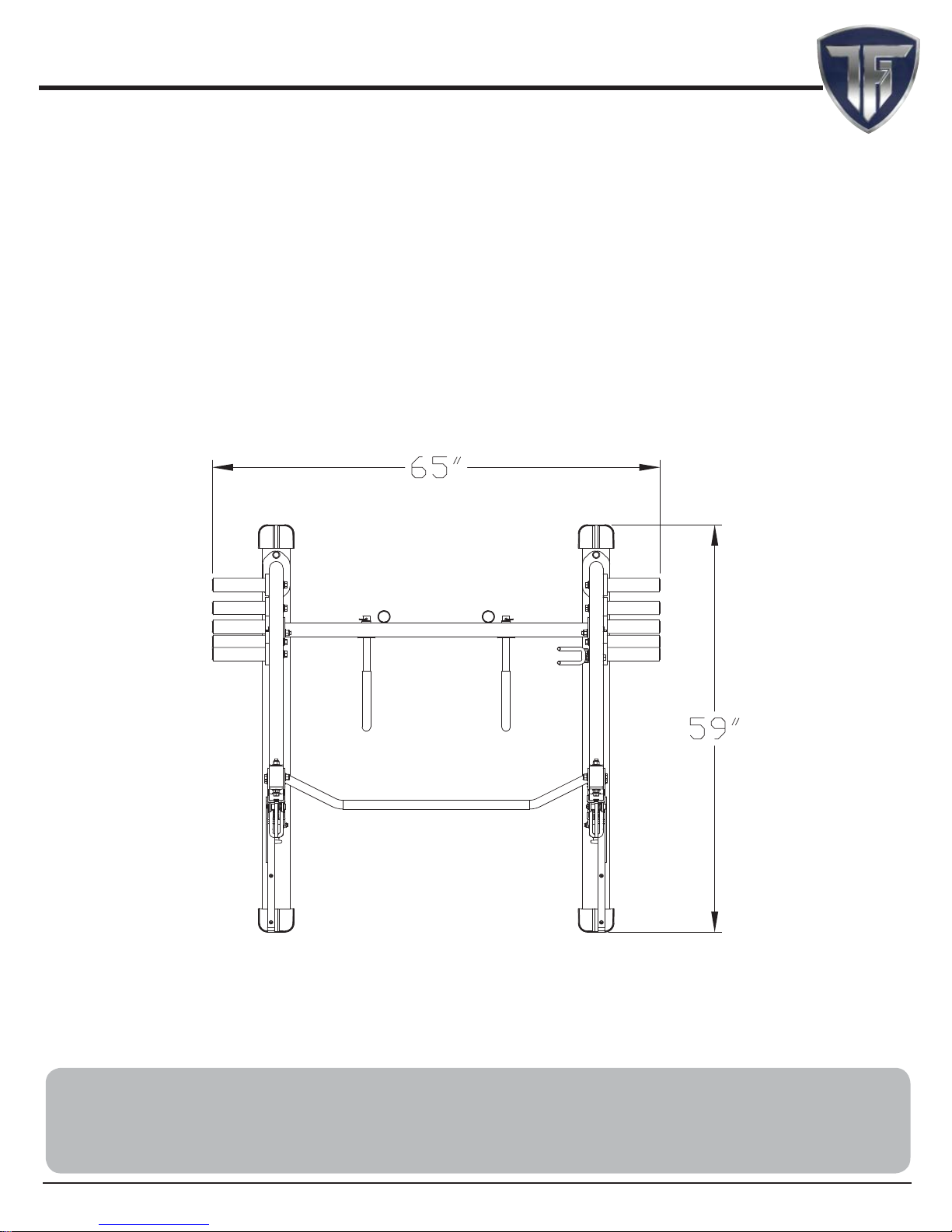

L 59” X W 65” X H 84”

PRODUCT WEIGHT 235 lbs

MAX-LOAD WEIGHT LIMIT - 600 lbs

CHR-500 Half Cage w/Safety Stopper and Dip Handleswww.tu stu tness.com

Page 3

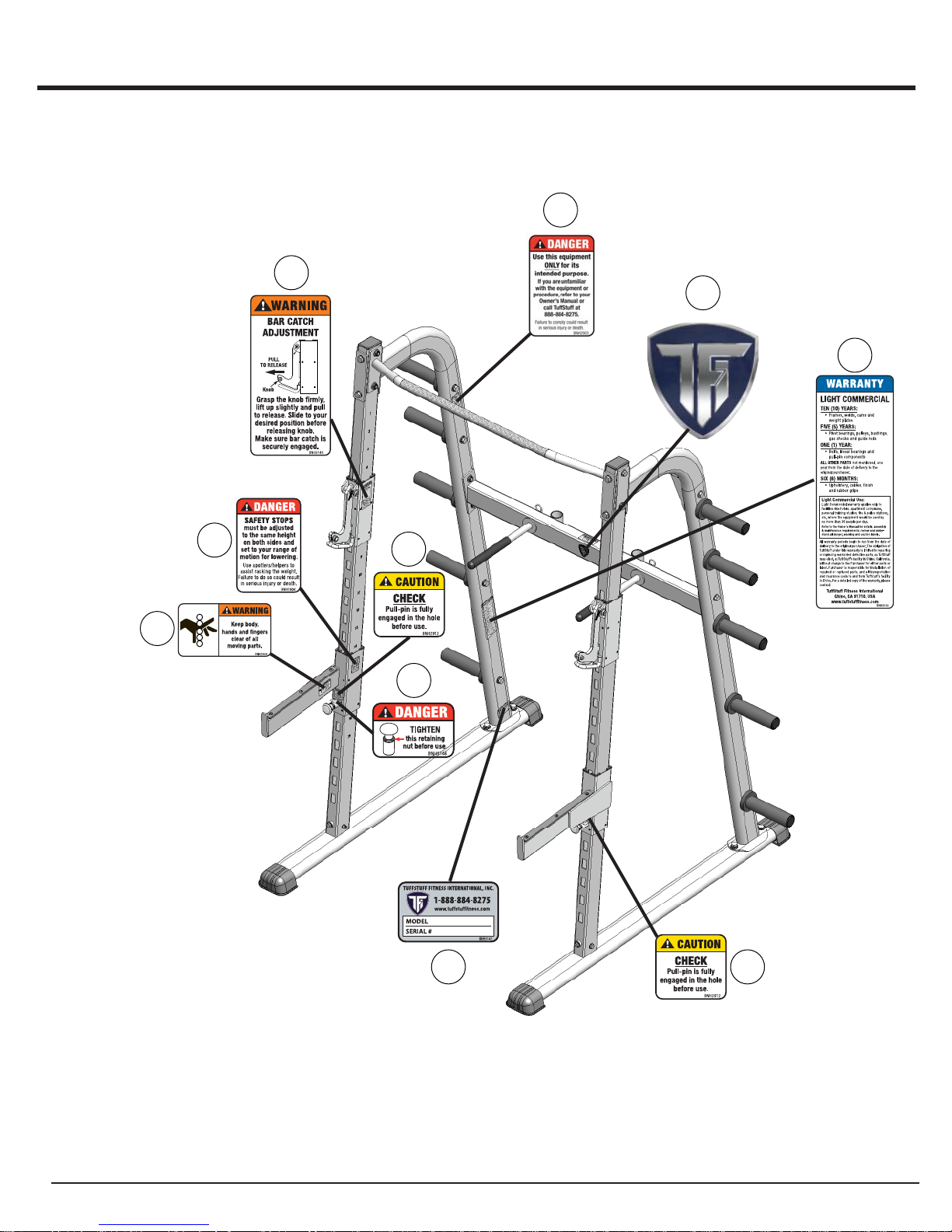

Carefully read ALL Danger, Warning & Caution labels posted on the machine

37

43

47

46

44

36

34

35

33

34

CHR-500 Half Cage w/Safety Stopper and Dip Handles www.tu stu tness.com

3

Page 4

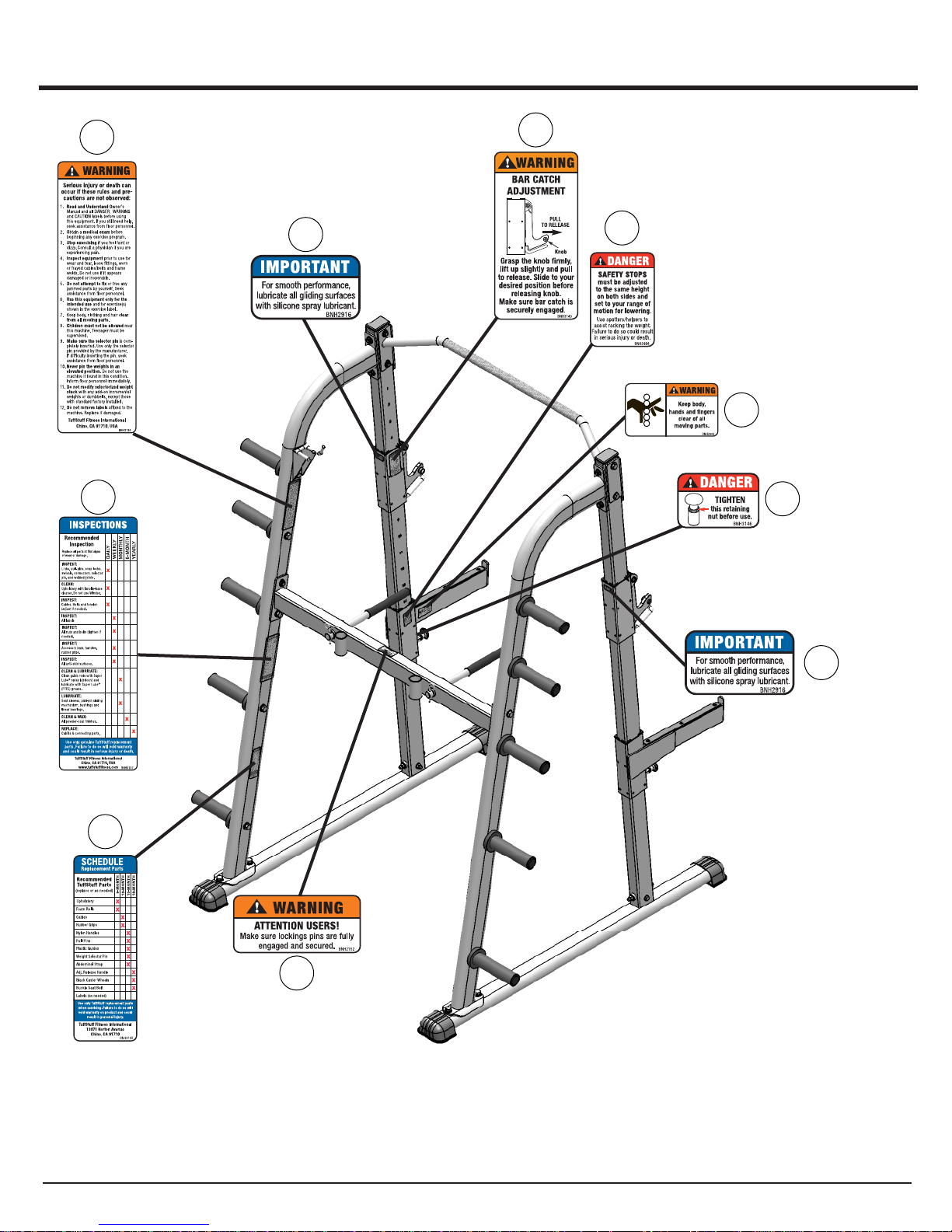

Carefully read ALL Danger, Warning & Caution labels posted on the machine

45

39

38

42

36

44

35

40

38

41

4

CHR-500 Half Cage w/Safety Stopper and Dip Handleswww.tu stu tness.com

Page 5

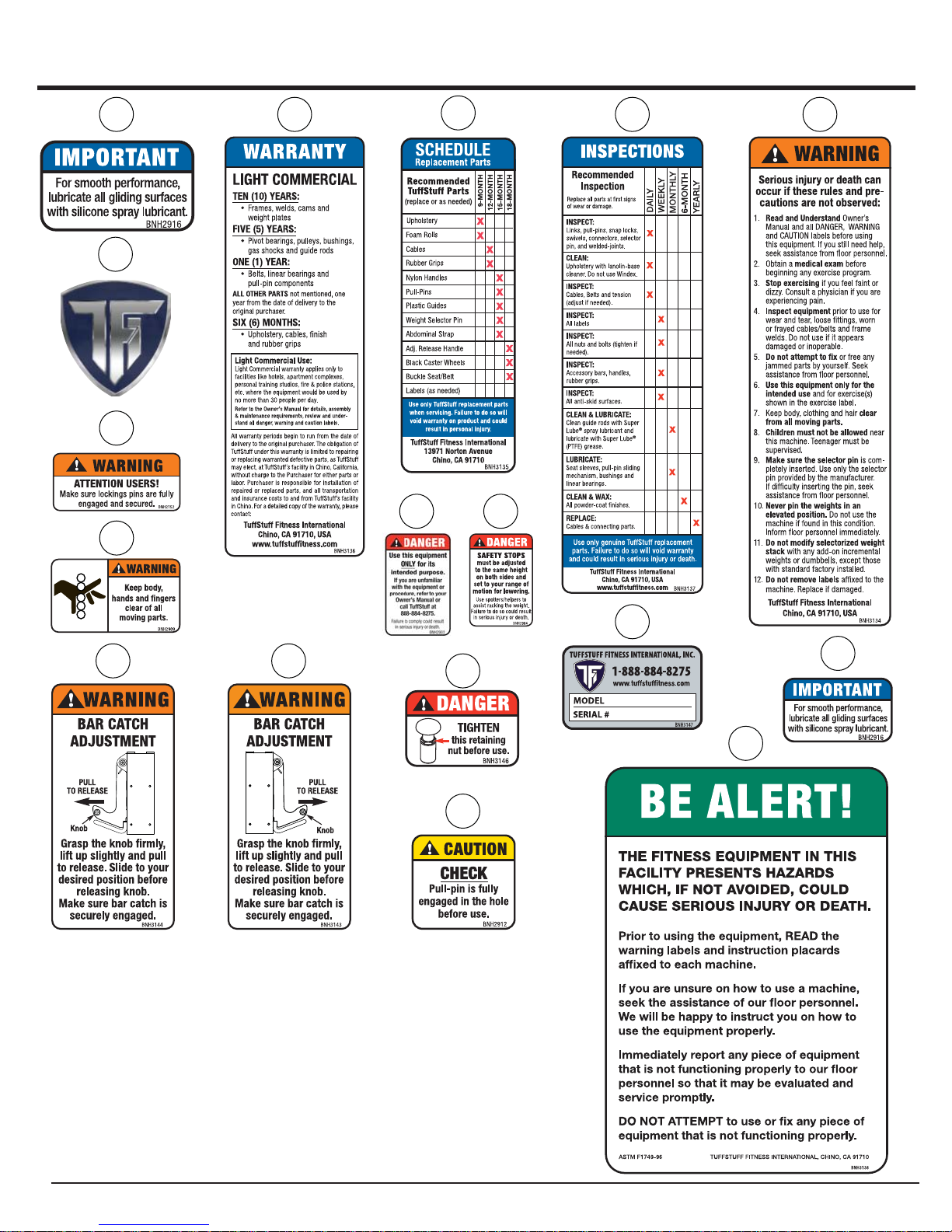

Carefully read ALL Danger, Warning & Caution labels posted on the machine

38

47

41

44

46

37

40

39 45

36

4243

It is extremely important that the Facility Sign shown to the left

be installed in plain view of the unit.

You should have received it along with this Owner’s Manual. If

you did not receive this Facility Sign with your order, you can

obtain one at no cost to you from Tu Stu Fitness by contacting

our service department at:

35

34

36

38

32

1 (888) 884-8275

service@tu stu .net

service1@tu stu .net

CHR-500 Half Cage w/Safety Stopper and Dip Handles www.tu stu tness.com

5

Page 6

Important Safety Instructions

It is the responsibility of the facility owner and/or owner of the equipment to review the Owner’s Manual with their facility

personnel and understand all Danger, Warning and Caution labels a xed on the machine. It is the responsibility of the oor

personnel to instruct users on proper operation of the equipment and review all danger, warning and caution labels.

SERIOUS INJURY OR DEATH CAN OCCUR

IF THESE SAFETY PRECAUTIONS ARE NOT OBSERVED:

1. Obtain a medical exam before beginning any exercise program.

2. Read and understand Owner’s Manual and all Danger, Warning

and Caution labels before using this equipment. If you still need

help, seek assistance from oor personnel.

3. Inspect the equipment before each use for wear and tear, loose

ttings, worn or frayed cables and frame welds. DO NOT USE if it

appears to be inoperable or damaged.

4. Stop exercising if you feel faint or dizzy. Consult a physician if you

are experiencing pain.

5. Use this equipment only for the intended use.

6. Keep body, clothing and hair clear from all moving parts. Do not

attempt to free any jammed parts by yourself.

7. Always warm-up before and cool-down after weight training.

Warm-up for 10-15 minutes with stretching and cardiovascular

exercises. Cool-down should include light stretching exercises for

5-15 minutes.

8. Never hold your breath – will limit the ow of oxygen to your brain

and may cause dizziness. The most often used breathing pattern is

inhaling during least resistance and exhaling during maximum

resistance.

9. Do not use accessories or accessory attachments that are not

recommended by TFI.

8. Children must not be allowed near the equipment. Teenager must

be supervised.

9. Replace immediately all parts at rst sign of wear or damage. If

unable to replace worn or damaged components/parts, remove

machine from service until the repair is made.

10. Use only genuine Tu Stu replacement parts. Failure to do so will

void warranty and could result in serious injury or death to the users.

11. Do not remove any decals a xed to the machine. Replace if

damaged.

12. Do not alter or modify the original manufacturer’s weight stack

with any add-on incremental weights, weight plates or

DUMBELLS except those with standard factory installed option.

13. Maintain a service contract with a TFI Authorized Dealer or a

Professional Service Company approved by TFI. Keep a service

log of all maintenance and repair activities. NOTICE: It is the sole

responsiblity of the owner or facility operator to ensure that regular

maintenance is performed.

Facility Safety Guidelines and Practices

1. Read and understand the Owner’s Manual before assembling,

servicing or using the equipment.

2. Equipment to be installed by TFI Authorized Dealer or

Professional Service Company approved by TFI.

3. Make sure each machine is set up and operated on a solid level

surface. Do not install equipment on an uneven surface.

4. Provide an adequate safety perimeter between the machine,

walls and other equipment to ensure that the facility has proper

clearance for usage and training.

5. Post and disclose all safety, rules and regulations on a bulletin

board easily accessible to users.

6. Perform regular maintenance (see Inspection Label). Pay special

attention to areas most susceptible to wear and tear, including but

not limited to cables, pulleys and rubber grips.

7. Do not lean against or pull on the framework, weight stack or

any component at all times.

6

DANGER: indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING: indicates a potentially hazardous situation which, if not

avoided, will result in death or serious injury.

CAUTION: indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury.

CHR-500 Half Cage w/Safety Stopper and Dip Handleswww.tu stu tness.com

Page 7

Registration, Service & Assembly

Thank you for purchasing the CHR-500 Half Cage w/Safety Stopper and Dip Handles. This machine is part of the Tu Stu line of

quality strength training equipment. To maximize your use of the equipment, please study the Owner’s Manual thoroughly.

Registration

To avoid unnecessary delays on warranty parts and to insure that a

permanent record of your purchase is on le with our company, be

sure to register online at http://www.tu stu tness.com or mail to

address shown below within 10 days of purchase.

Obtaining Service

Please use this Owner’s Manual as your guide to all parts included in

your shipment. When ordering parts, you must specify the part number

and description from this owner’s manual. Use only genuine Tu Stu

replacement parts when servicing the equipment. Failure to do

so will void warranty and could result in serious injury or death.

For information about product operation or service:

Phone: 909-629-1600 Toll Free 888-884-8275

Fax: 909-629-4967

E-mail: service@tu stu .net or service1@tu stu .net

Hours: M–F 8:00 – 4:30 PST

Or write to: Tu Stu Fitness International Inc.

Customer Service

13971 Norton Avenue, Chino, CA 91710

Retain this Owner’s Manual for future reference when ordering

service or parts. To assist you better, please be prepared to

provide the following information:

1. Model Number 2. Place of Purchase

3. Serial Number 4. Part # and Description

Required Tools

The basic tools that you will need to assemble the CHR-500 but are not

limited to:

• 9/16” , 3/4”, 1/2” combination wrenches

• Adjustable wrench

• Ratchet wrench with 9/16” , 3/4”, 1/2” sockets

• External retaining ring pliers

• Rubber mallet, measuring tape & utility knife

• Super Lube® spray lubricant and grease

• Windex or household glass cleaner

Allow ample space around the machine for safe unrestricted use and

easier access.

Insert all bolts in the same direction. For aesthetic appearance, insert all

bolts in the same direction unless speci ed (in text or illustration) to do

otherwise.

Leave room for adjustments. Do not fully tighten fasteners until

instructed in the assembly steps to do so (to prevent any di culty with

alignment of parts during the assembly process). When not instructed,

tighten fasteners such as bolts, nuts and screws so the unit is stable, but

leave room for adjustments.

Assembly Tips

Read all “Notes” on each page before beginning each step.

While you may be able to assemble the CHR-500 using the illustrations

only, IMPORTANT safety notes and other tips are included in the text.

Some pieces may have extra holes that you will not use. Use only those

holes indicated in the instructions and illustration.

NOTE: With so many assembled parts, proper alignment and

adjustment is critical. While tightening the nuts and bolts,

be sure to leave room for nal adjustments.

CAUTION: Obtain assistance from TFI if you have di culty

assemblying the CHR-500. Please do not attempt to

complete the assembly as this could result in equipment

failure and serious injuries to the users.

Symbols & Description

Assembly Requirements

Follow these installation requirements when assemblying the CHR-500.

Use the overhead view on the Content Page to layout your oor plan

before assemblying.

Set up the CHR-500 on a clean, solid, at surface. A smooth, at surface

under the machine helps keep it level.

Loosely Tighten

70%

Fully Tighten

Loosely Tighten

Loosely tighten all hardware in this step. DO NOT Fully

Tighten. Some component(s) may need pre-assembly

and or alignment during the assembly process.

Fully Tighten

Wrench tighten all hardware in this step.

100%

CHR-500 Half Cage w/Safety Stopper and Dip Handles www.tu stu tness.com

7

Page 8

Inspection/Maintenance

Perform regular maintenance (see Inspection Label). Pay special attention to areas most susceptible to wear and tear, including

but not limited to cables, pulleys and rubber grip. TFI recommends you maintain a service contract with a TFI Authorized Dealer or a

Professional Service Company approved by TFI. Keep a service log of all maintenance and repair activities. Extra copies can be downloaded

from our website www.tu stu tness.com

INSPECTION / MAINTENANCE RECORDS

DATE REPLACEMENT REPAIRS INSPECTED BY

8

WARRANTY REPAIRS

DATE REPLACEMENT REPAIRS INSPECTED BY

CHR-500 Half Cage w/Safety Stopper and Dip Handleswww.tu stu tness.com

Page 9

Step 1

Step 1 Assembly List

Item # Description Qty.

1 BASE FRAME 2

*2 REAR SIDE FRAME RT 1

*3 REAR SIDE FRAME LT 1

17 PLASTIC HORIZONTAL ELLIPTICAL SHOE W/LOCK 4

23 HEX HEAD CAP SCREW GR-5 Z/P 1/2-13 X 1 4

26 FLAT WASHER SAE Z/P 1/2” 4

28 SPLIT LOCK WASHER B-Z/P 1/2” 4

ȘŘ

NOTE:

1. IT IS STRONGLY RECOMMENDED THAT

TWO PEOPLE PARTICIPATE IN THE

ASSEMBLY OF THIS UNIT.

ŗŝ

Řř

ŘŞ

ŗ

ŗŝ

ŘŜ

ŗŝ

Řř

ŘŜ

ŗ

Șř

ŘŞ

Loosely Tighten

Loosely Tighten

70%

70%

ŗŝ

CHR-500 Half Cage w/Safety Stopper and Dip Handles www.tu stu tness.com

Loosely tighten all hardware in this step.

DO NOT Fully Tighten. Some component(s)

may need pre-assembly and or alignment

during the assembly process.

9

Page 10

Step 2

ȘŗŘ

ŗŜ

ŘŜ

Step 2 Assembly List

Item # Description Qty.

*5 REAR CROSS BRACE 1

8 ACCESORIE HOLDER BRACKET 1

*12 OLYMPIC ADAPTER 1 X 8 10

16 RUBBER WASHER 1 7/8 ID X 4 1/4 OD X 9/16 10

21 HEX HEAD CAP SCREW GR-5 Z/P 1/2-13 X 2 3/4 3

22 HEX HEAD CAP SCREW GR-5 Z/P 1/2-13 X 1 1/4 2

23

HEX HEAD CAP SCREW GR-5 Z/P 1/2-13 X 1 8

26 FLAT WASHER SAE Z/P 1/2” 16

28 SPLIT LOCK WASHER B-Z/P 1/2” 10

NYLON INSERT THIN PATTERN LOCK NUT Z/P 1/2-13

29

ŘŞ

Řř

3

ȘŗŘ

Řŗ

ŘŜ

Řř

ŘŜ

Ş

ŘŜ

Řş

Řş

Řř

ŘŞ

ŘŜ

Řş

ŘŜ

Řŗ

ȘŗŘ

ŘŜ

Řř

ŘŘ

Șś

ŘŜ

ŘŜŗŜ

ŘŘ

ŘŞ

ŘŜ

Řŗ

ŘŜ

ŘŞ

Řř

Řř

ŘŞ

Loosely Tighten

Loosely Tighten

70%

70%

Loosely tighten all hardware in this step.

DO NOT Fully Tighten. Some component(s)

may need pre-assembly and or alignment

during the assembly process.

10

Řř

ŘŞ

ŘŜ

ŗŜ

ȘŗŘ

CHR-500 Half Cage w/Safety Stopper and Dip Handleswww.tu stu tness.com

Page 11

Step 3

Step 2 Assembly List

Item # Description Qty.

*6 SELECTOR POST RT 1

*7 SELECTOR POST LT 1

*9 BAR HOLDER RT 1

*10 SAFETY STOPPER RT 1

*11 SAFETY STOPPER LT 1

14 REINFORCEMENT PLATE 1/4 X 2 X 7 7/8 2

18 NYLON SPACER 3/8 X 7/8 X 3/8 4

19 HEX HEAD CAP SCREW GR-5 Z/P 1/2-13 X 4 4

24 HEX HEAD CAP SCREW GR-5 Z/P 3/8-16 X 4 1/4 2

25 HEX HEAD CAP SCREW GR-5 Z/P 3/8-16 X 2 1/2 2

26 FLAT WASHER SAE Z/P 1/2” 8

27 FLAT WASHER SAE Z/P 3/8” 8

29 NYLON INSERT THIN PATTERN LOCK NUT Z/P 1/2-13 4

30 NYLON INSERT THIN PATTERN LOCK NUT Z/P 3/8-16 4

*62 BAR HOLDER LT 1

ŗŚ

ŘŜ

ŗş

NOTE:

1. DO NOT REMOVE THE CARBOARD FROM THE

ITEMS LISTED BELOW AS IT IS USED TO ASSIST

IN THIS STEP. SLIDE THE CARRIAGE OVER THE

UPRIGHTS TO PUSH THE CARBOARD OUT AS

SHOWN.

UPRIGHT

Řş

CARDBOARD

ŘŜ

Řş

Loosely Tighten

Loosely Tighten

ȘŗŖ

Řś

Șş

Řŝ

ŘŚ

Řŝ

ŗŞ

ŗŞ

ȘŜ

Řŝ

řŖ

ŗş

ŘŜ

ŗŚ

ŘŜ

ȘŜŘ

Șŝ

ŗŞ

Řŝ

řŖ

70%

70%

Șŗŗ

řŖ Řś

Řŝ

Loosely tighten all hardware in this step.

DO NOT Fully Tighten. Some component(s)

may need pre-assembly and or alignment

during the assembly process.

CHR-500 Half Cage w/Safety Stopper and Dip Handles www.tu stu tness.com

ŗŞ

ŘŚ

11

Page 12

Step 4

ŘŖ

ŗś

ŘŜ

Řş

Step 4 Assembly List

Item # Description Qty.

4 TOP CROSS BRACE 1

*13 DIPPING HANDLE 2

15 REINFORCEMENT PLATE 1/4 X 2 1/2 X 7 2

20 HEX HEAD CAP SCREW GR-5 Z/P 1/2-13 X 3 4

26 FLAT WASHER SAE Z/P 1/2” 8

29 NYLON INSERT THIN PATTERN LOCK NUT Z/P 1/2-13 4

ŘŜ

53 HITCH PIN 210 WW 2

Ś

Řş

ŘŜ

ŗś

ŘŜ

śř

ŘŖ

Fully Tighten

Șŗř

Șŗř

śř

100%

Fully Tighten

Wrench tighten all hardware in this and

previous loosely tighten steps.

12

CHR-500 Half Cage w/Safety Stopper and Dip Handleswww.tu stu tness.com

Page 13

Parts List

COLOR CHART

GRAY= SUB-ASSEMBLY PARTS

BLACK= HARDWARE

CHR-500

CHR-500 REV0

Parts List

Item No. Description Rev. Part No. Qty. Item No. Descri ption Rev. Part No.

1

BASEȱFRAME 0 UP8255 2 32

2 REARȱSIDEȱFRAMEȱRT

3 REARȱSIDEȱFRAMEȱLT

4 TOPȱCROSSȱBRACE

5 REARȱCROSSȱBRACE

6 SELECTORȱPOSTȱRT

7 SELECTORȱPOSTȱLT

8 ACCESORIEȱHOLDERȱBRACKET

9

BARȱHOLDER 0 UP8188 2 40

10 SAFETYȱSTOPPERȱRT

11 SAFETYȱSTOPPERȱLT

12

OLYMPICȱADAPTERȱ1ȱXȱ8 0 UP8196 10 43

13 DIPPINGȱHANDLE

14 REINFORCEMENTȱPLATEȱ1/4ȱXȱ2ȱXȱ7ȱ7/8

15 REINFORCEMENTȱPLATEȱ1/4ȱXȱ2ȱ1/2ȱXȱ7

16

RUBBERȱWASHERȱ1ȱ7/8ȱIDȱXȱ4ȱ1/4ȱODȱXȱ9/16ȱTK

17

PLASTICȱHORIZONTALȱELLIPTICALȱSHOEȱW/LOCK

18 NYLONȱSPACERȱ10.5MMȱIDȱXȱ20MMȱODȱXȱ10MM

19

HEXȱHEADȱCAPȱSCREWȱGRȬ5ȱZ/Pȱ1/2Ȭ13ȱXȱ4

20

HEXȱHEADȱ

21

HEXȱHEADȱCAPȱSCREWȱGRȬ5ȱZ/Pȱ1/2Ȭ13ȱXȱ2ȱ3/4

HEXȱHEADȱCAPȱSCREWȱGRȬ5ȱZ/Pȱ1/2Ȭ13ȱXȱ1ȱ1/4

22 BNH2167 2 53

HEXȱHEADȱCAPȱSCREWȱGRȬ5ȱZ/Pȱ1/2Ȭ13ȱXȱ1

23 BNH0842 12 54

HEXȱHEADȱCAPȱSCREWȱGRȬ5ȱZ/Pȱ3/8Ȭ16ȱXȱ4ȱ1/4

24 BNH2074 2 55

25 HEXȱHEADȱCAPȱSCREWȱGRȬ5ȱZ/Pȱ3/8Ȭ16ȱXȱ2ȱ1/2 BNH2044 2 56

FLATȱWASHERȱSAEȱZ/Pȱ1/2Ȉ

26

FLATȱWASHERȱSAEȱZ/Pȱ3/8Ȉ

27

SPLIT

28

NYLONȱINSERTȱTHINȱPATTERNȱLOCKȱNUTȱZ/Pȱ1/2Ȭ13

29

NYLONȱINSERTȱTHINȱPATTERNȱLOCKȱNUTȱZ/Pȱ3/8Ȭ16

30

31 HEXȱKEYȱALLOYȱ

CAPȱSCREWȱGRȬ5ȱZ/Pȱ1/2Ȭ13ȱXȱ3

ȱLOCKȱWASHERȱBȬZ/Pȱ1/2Ȉ

3/32Ȉȱȱȱȱȱȱȱȱ BNH0373 1

0 UP8256 1 33

0 UP8257 1 34

0 UP8258 1 35

0 UP8259 1 36

0 UP8260 1 37

0 UP8261 1 38

0 UP8262 1 39

0 UP8189 1 41

0 UP8190 1 42

0 UP8094 2 44

0 UP8263 2 45

0 UP8264 2 46

BNH0933 10 47

BNH3236 4 48

BNH4285

BNH2113 4 50

BNH0331 4 51

BNH2065 3 52

BNH2031 38 57

BNH2030 12 58

BNH2519 14 59

BNH2027 11 60

BNH2026 8 61

2

FACILITYȱSIGNȱBEȱALERT!ȱTHEȱFITNESSȱEQUIPMENT...

LABELȬTFIȱSERIALȱNO.ȱ2.5ȱXȱ1.5

LABELȬCAUTIONȱCHECKȱȱPULLȬPINȱISȱFULLY...ȱ1ȱ1/2ȱXȱ1ȱ3/8

LABELȱDANGERȱCHECKȱRETAININGȱNUT...ȱȱ1.5ȱXȱ1

LABELȬDANGERȱSAFETYȱSTOPS...ȱ

LABELȬDANGERȱUSEȱTHISȱEQUIPMENTȱONLY...ȱ

LABELȬIMPORTANTȱFORȱSMOOTHȱPERFORMANCE...

LABELȬINSPECTIONSȱRECOMMENDEDȱINSPECTION…

LABELȬSCHEDULEȱREPLACEMENTȱPARTS...

LABELȬWARNINGȱATTENTIONȱUSERS!ȱ

LABELȬWARNINGȱBARȱCATCHȱLT,ȱ2ȱXȱ4

LABELȬWARNINGȱBARȱCATCHȱRT,ȱ2ȱXȱ4

LABELȬWARNINGȱKEEPȱBODY,ȱHANDS...ȱ1ȱ1/2ȱXȱ2ȱ5/8

LABELȬ

WARNING_SERIOUSȱINJURYȱORȱDEATH

LABELȬWARRANTYȱLIGHTȱCOMMERCIAL

TFIȱEMBLEMȱ1.88ȱHIGHȱXȱ1.98ȱWIDEȱBLUEȱANDȱCHROME

SWINGȱLOCKȱJȬHOOK

ABSȱSLEEVEȱ1ȱ1/2ȱXȱ8ȱ

49

BUTTONȱHEADȱSOCKETȱCAPȱSCREWȱGRȬ8ȱBȬZ/Pȱ3/8Ȭ16ȱXȱ1ȱ1/4

FLATȱHEADȱSOCKETȱCAPȱSCREWȱZ/PȱM6Ȭ1.0ȱXȱ15

HARDȱGRIPȱ.875ȱXȱ8ȱBLACK BNH0523

HITCHȱPINȱ210ȱWW BNH0568 2

PLASTICȱINSERTȱCAPȱ2ȱXȱ3

PLASTICȱCORNERȱTUBEȱGLIDEȱ7/8ȱXȱ10ȱ1/8

PLASTICȱINSERTȱCAPȱ1ȱ7/8ȈȱRDȱ10Ȭ14ȱGA BNH0003

PUSHȱPULLȱPINȱ1/2ȱXȱ2ȱ7/8ȱLIGHTȱSPRING BNH0542

SAFETYȱSTOPPERȱPLASTICȱSTRIPȱ1ȱXȱ15

SHOULDERȱBOLTȱALLOYȱ1/2ȱXȱ55MM

SOCKETȱSETȱSCREWȱZ/Pȱ10Ȭ32ȱXȱ1/8

TORSIONȱSPRINGȱ21MM,ȱ3MMȱWIRE

1/8 BNH1527

MAKE...ȱ(REV0)

0 UP8038 2

BNH3138 1

BNH3147 1

BNH2912 2

BNH3146 2

BNH2904 2

BNH2903 1

BNH2916 2

BNH3137 1

BNH3135 1

BNH2152 1

BNH3143 1

BNH3144 1

BNH2909 2

BNH3134 1

BNH3136 1

BNH4304 1

BNH2521

BNH3280 6

BNH0052 2

BNH2847

BNH4279

BNH4284

BNH2088

BNH4278

Qty.

10

2

2

16

10

2

2

2

2

2

Pre-Assembled Com ponents

Item No. Description Rev. Part No. Qty. Item No. Descri ption Rev. Rev. Qty.

*2 REARȱSIDEȱFRAMEȱRT

*3 REARȱSIDEȱFRAMEȱLT

*5 REARȱCROSSȱBRACE

*6 SELECTORȱPOSTȱRT

*7 SELECTORȱPOSTȱLT

*9

BARȱHOLDERȱRT 0 UP8188X1 1

0 UP8256X1 1

0 UP8257X1 1

0 UP8259X1 1

0 UP8260X1 1

0 UP8261X1 1

CHR-500 Half Cage w/Safety Stopper and Dip Handles www.tu stu tness.com

*10 SAFETYȱSTOPPERȱRT

*11 SAFETYȱSTOPPERȱLT

*12

OLYMPICȱADAPTERȱ1ȱXȱ8 0 UP8196X1 10

*13 DIPPINGȱHANDLE

*62

BARȱHOLDERȱLT 0 UP8188X2 1

0 UP8189X1 1

0 UP8190X1 1

0 UP8094X1 2

13

Page 14

Pre-Assembled Components

*2

UP8256X1

*3 UP8257X1 *5 UP8259X1

Ř

řŝ

řş

ŚŜ

ŚŖ

Śś

ř

ś

Śŗ

Śŝ

*9

UP8188X1

řŖ

řŖ

Řŝ

ŘŜ

ŚŞ

Řŝ

Ŝŗ

ŗŞ

řř

śŖ

*62

śśśś

řŞ

Śř

ŘŜ

śş

ş

UP8188X2

śśřŞ

ŚŘ

ŘŜ

Řŝ

řŖ

ş

śś

ŘŜ

śş

Ŝŗ

ŚŞ

ŗŞśŖ

řŖ

Řŝ

14

CHR-500 Half Cage w/Safety Stopper and Dip Handleswww.tu stu tness.com

Page 15

Pre-Assembled Components

śŞ

śŗ

śś

śś

ŗŖ

śŝ

ŜŖ

řŜ

řŚ

řś

ŚŚ

śś

śŗ

śś

śŞ

śŝŜŖ

ŗŗ

řŜ

řŚ

řś

ŚŚ

śŘ

ŗř

Ŝ

śŚ

ŝ

śŚ

śŜ

Śş

ŗŘ

*10

UP8189X1

*11 UP8189X2

*13

UP8094X1

*6

UP8260X1

*7 UP8261X1 *12 UP8196X1

CHR-500 Half Cage w/Safety Stopper and Dip Handles www.tu stu tness.com

15

Page 16

LIGHT COMMERCIAL WARRANTY

This warranty applies only in the United St

TuffStuff brand name. TFI warrants to the original purchaser that TuffStuff equipment will be free from defects in material and workmanship.

All warranty periods begin to run from the date of purchase to the original purchaser. The warranty and remedies set forth herein are conditioned

upon proper storage

not manufactured by TFI or products which are altered without the express written consent of TFI.

, installation, use and maintenance and conformance with any recommendations of TFI. This warranty does not cover products

LIGHT COMMERCIAL WARRANTY:

TEN (10) Years: Structural main frames, welds, cams and

weight plates.

FIVE (5) Years: Pivot bearings, pulleys, bushings, guide rods

and gas shocks.

ONE (1) Year: Belts, linear bearings and pull-pin components.

All other parts not mentioned elsewhere in the warranty will expire one

(1) year from the date of purchase to the original purchaser.

SIX (6) Months: Upholstery, cables

Light Commercial Use:

Light Commercial Warranty applies to facilities like hotels, apartment complexes,

personal training studios, fire & police stations, etc. where the equipment

would be used by no more than 30 people per day.

ates to the products manufactured or distributed by TuffStuff Fitness International (TFI) under the

HOME LIFETIME WARRANTY:

LIFETIME of the equipment while owned by the original

purchaser (applies only to defects from manufacturer only).

This warranty does not cover:

1. TuffStuff products sold for and used in a commercial or

institutional environment.

2. Any damage, failure or loss caused by accident, misuse, neglect,

, finish and rubber grips.

abuse, improper assembly, improper maintenance, or failure to

follow instructions or w

warning labels posted on the machines.

3. Use of the product in a manner for which it was not designed.

4. Original product that is altered, or the use of replacement parts

and components of another manufacturer other than TuffStuff.

arnings in the owner’s manual and

The obligation of TFI under this warranty is limited to repairing or replacing warranted defective parts as TFI may elect, at TFI’s facilit

California, without charge to the purchaser. Purchaser is responsible for installation of repaired or replaced parts, and all transportation and

insurance costs on returned or replaced equipment to and from TFI’s facility in Chino.

THE FOREGOING SHALL CONSTITUTE THE SOLE REMEDY OF THE PURCHASER AND THE SOLE LIABILITY OF TFI WITH REGARD TO WARRANTY. NO IMPLIED STATUTORY

WARRANTY OR IMPLIED STATUTORY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE SHALL APPLY. IN NO EVENT, WHETHER AS A

RESULT OF BREACH OF CONTRACT, WARRANTY, NEGLIGENCE OR OTHERWISE, SHALL TFI BE LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES

INCLUDING, BUT NOT LIMITED TO, LOSS OF PROFITS OR REVENUE, LOSS OF USE OF EQUIPMENT, COST OF CAPITAL, COST OF SUBSTITUTION EQUIPMENT, DOWNTIME

COST, OR CLAIMS OF CUSTOMERS OR PURCHASER FROM SUCH DAMAGE.

This written warranty is the final, complete and exclusive agreement of the parties with respect to the quality or performance of the equipment

and no action for breach of this written warranty or any implied warranty shall be commenced more than one (1) year after the accrual of the cause

of action. No modification of this warranty or waiver of

sentative of the party. Contact TuffStuff Fitness International at 13971 Norton Avenue, Chino, CA 91710, before returning any defective equipment.

This warranty gives you specific legal rights and you may also have other rights, which may vary from state to state.

its terms shall be binding on either party unless approved in writing by an authorized repre-

y in Chino,

SERIAL #

Write your Serial number here for future reference

TuStu Fitness International, Inc.

13971 Norton Avenue, Chino, CA 91710, USA Phone: 909-629-1600 Fax: 909-629-4967

www.tustutness.com service@tustu.net or service1@tustu.net

Purchase Date

Loading...

Loading...