Page 1

ASSEMBLY INSTRUCTIONS

Apollo Modular Gym System

Leg Press Station

Standard

Deluxe

America’s Premier Exercise Equipment

Revision Date 08-23-05

Leg Press Station Rev0

Page 2

Introduction

A

bout the Leg Press Station

Congratulations on your new purchase of the Leg Press Station.

We hope you are completely satisfied with this product and wish

you many years of enjoyment.

T

uff Stuff Equipment

Every Tuffstuff product has been built to precise quality

standards and has been carefully packaged to ensure that damage

will not occur during shipment. The TuffStuff Warranty and signature

indicating final inspection has been conducted by our line foreman,

is an expression of our confidence in the completeness, the

materials, and workmanship of this product.

W

arranty

SEE A COPY OF WARRANTY ON BACK PAGE

R

egistration Card

To avoid unnecessary delays in warranty service and to insure

that a permanent record of your purchase is on file with our factory,

be sure to complete the warranty registration card and send it to

TuffStuff Fitness Equipment today.

Prior to the Assembly of the Leg Press Station

1. We advise you to consult your local Tuff Stuff retailer if you

should have a question or problem regarding the proper

assembly of this unit.

2. Neatly organize and identify all parts according to the Exploded

View Diagram on Fold-out Pg. 7 and the Parts List on Pg. 8.

Tool Requirements

1. One 9/16” combination wrench

2. One ratchet

3. One 9/16” socket

4. One rubber mallet

5. Multi-purpose grease

6. Measuring tape

7. Utility knife

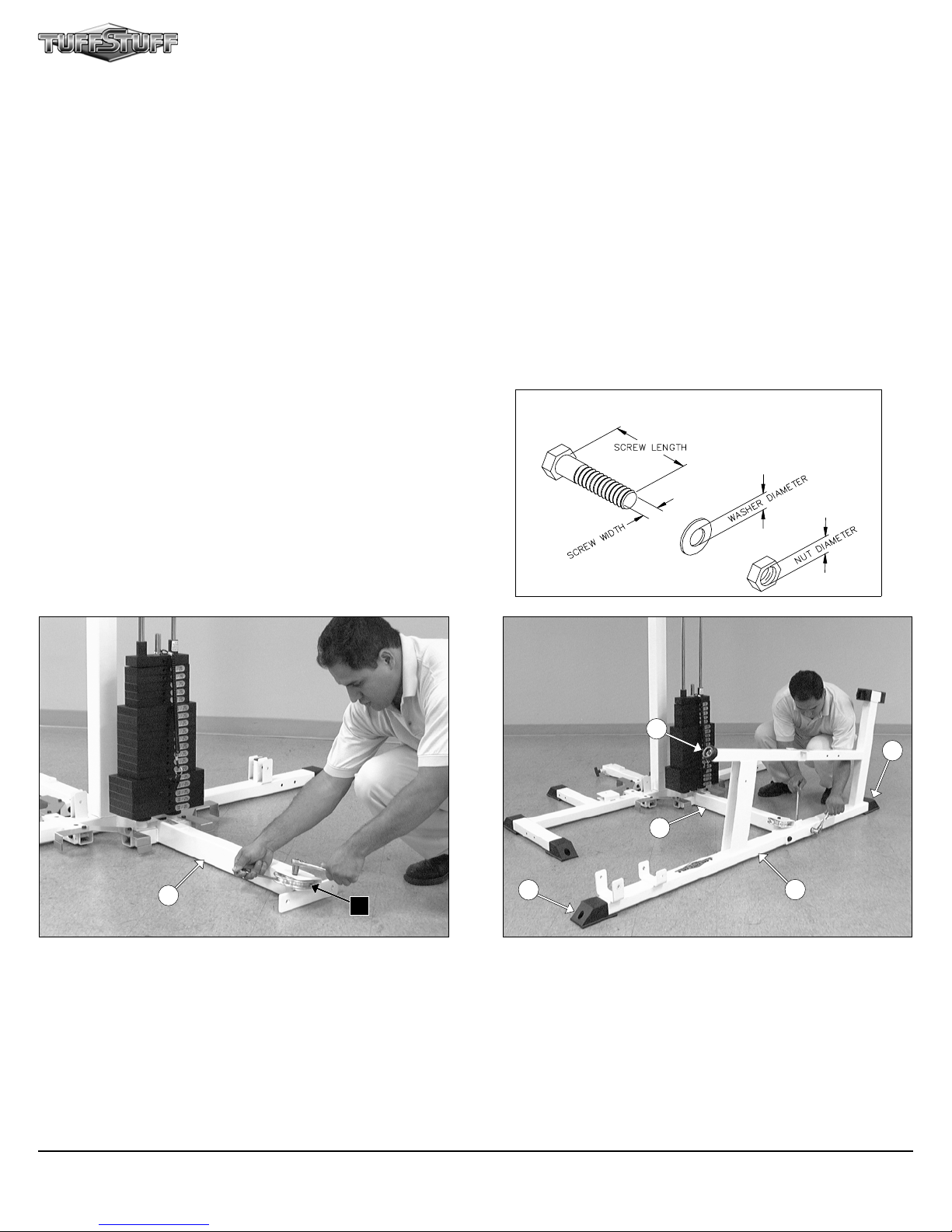

Hardware Measurement Diagram

Specifications

1. Maximum Wt. Capacity - 200 Lbs.

2. Total Machine Weight - 150 Lbs.

Note: Due to continuing product improvements, specifications and designs are subject to change

withou t notice.

46

D5

132

153

132

46

47

FIG. 1 Attach a Pulley 4 1/2” Rd. (#78-Labeled D5) to the Leg

Press Bottom Connector (#46) pulley bracket using one Hex Head

Cap Screw 3/8-16 X 1 3/4 (#101), two Flat Washers SAE 3/8” (#94),

and one Nylon Insert Jam Lock Nut 3/8-16 (#123).

1

FIG. 2 Using a rubber mallet, insert two Plastic End Caps 2 X 3

(#132) onto the tube-ends of the Leg Press Main Frame (#47). Next,

attach the Rubber Bumper 3/8 X 2 1/2 (#153) to the tube-end of the

Leg Press Main Frame (#47) using one Hex Head Cap Screw 3/8-16

X 1 1/2 (#100), and the Steel Bumper Washer 3/8” (#177).

Next, affix the Leg Press Main Frame (#47) to the Leg Press Bottom

Connector (#46) using two Hex Head Cap Screws 1/2-13 X 4 3/4

(#112), four Flat Washers SAE 1/2” (#93), and two Nylon Insert Lock

Nuts 1/2-13 (#124).

Leg Press Station

Page 3

Assembly Instructions

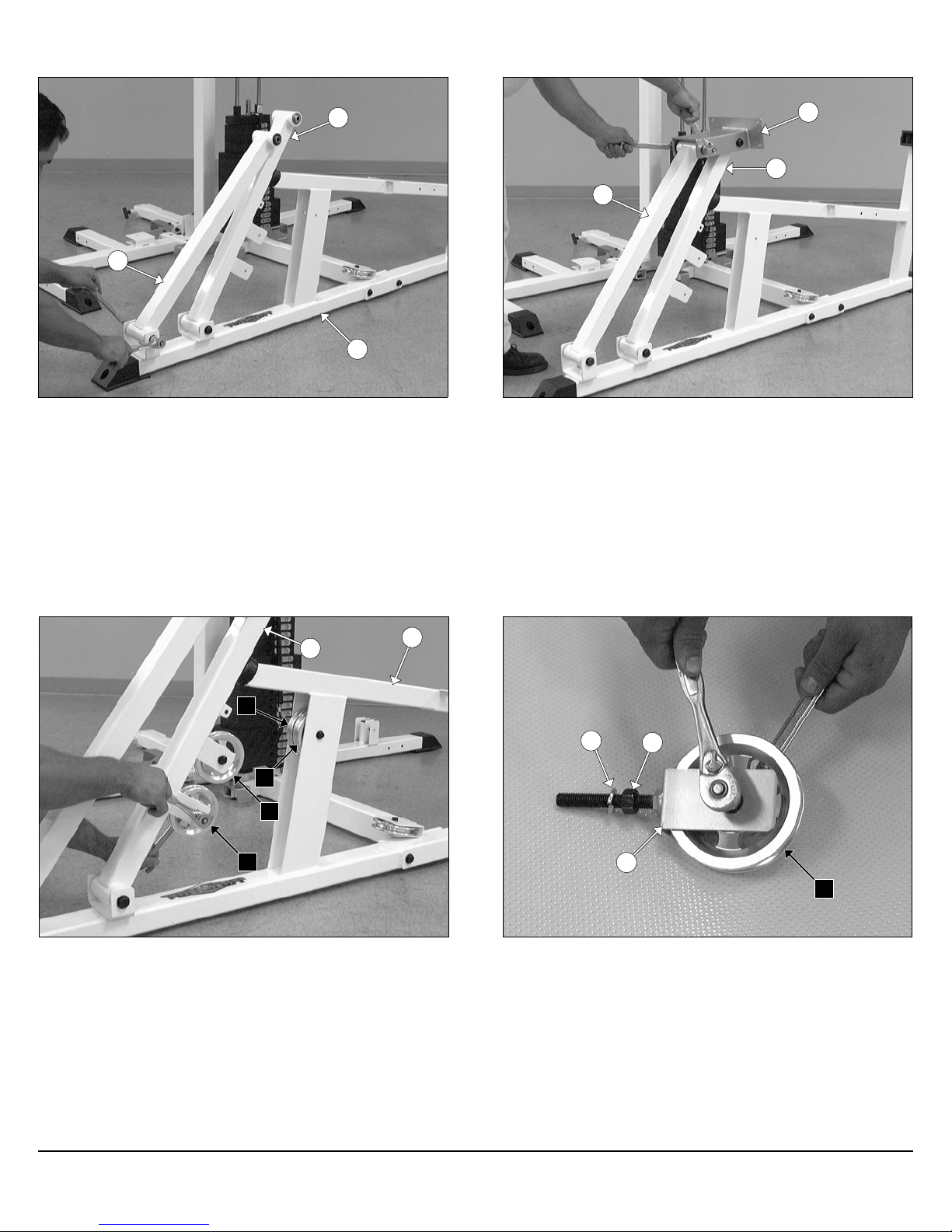

52

51

47

FIG. 3 Attach the Fulcrum with Brackets (#52) and the Fulcrum

(#51) to the Leg Press Main Frame (#47) using two Hex Head Cap

Screws 1/2-13 X 5 1/2 (#111), four Flat Washers SAE 1/2” (#93), and

two Nylon Insert Jam Lock Nuts 1/2-13 (#127).

50

52

51

FIG. 4 Next, attach the Foot Plate Bracket (#50) to the Fulcrum

with Brackets (#52) and the Fulcrum (#51) using two Hex Head Cap

Screws 1/2-13 X 5 1/2 (#111), four Flat Washers SAE 1/2” (#93), and

two Nylon Insert Jam Lock Nuts 1/2-13 (#127).

52

47

D1

D3

D2

D4

FIG. 5 Attach two Pulleys 4 1/2 Rd. (#78-Labeled D1, D3) to the

Leg Press Main Frame (#47) using one Hex Head Cap Screw 3/8-16

X 2 3/4 (#104), two Flat Washers SAE 3/8” (#94), and one Nylon Insert

Jam Lock Nut 3/8-16 (#123).

Next, attach two Pulleys 4 1/2 Rd. (#78-Labeled D2, D4) to the Ful-

crum with Brackets (#52) using two Hex Head Cap Screws 3/8-16 X 1

3/4 (#101), four Flat Washers SAE 3/8” (#94), and two Nylon Insert Jam

Lock Nuts 3/8-16 (#123).

176

89

45

D7

FIG. 6 Locate one of the Adjustable Pulley Brackets (#45) and attach one Pulley 4 1/2 Rd. (#78-Labeled D7) using one Hex Head Cap

Screw 3/8-16 X 1 3/4 (#101), two Flat Washers SAE 3/8” (#94), and

one Nylon Insert Jam Lock Nut 3/8-16 (#123). Next, thread one Finished Hex Nut 1/2-13 (#89) and insert one Split Lock Washer

1/2” (#176) onto the Screw of the Adjustable Pulley Bracket (#45).

Leg Press Station

2

Page 4

89

176

90

56

45

1

176

55

FIG. 7 Next, attach the assembled Adjustable Pulley Bracket

(#45) to the receptacle of the Weight Stack Frame (#1) using one Split

Lock Washer 1/2” (#176) and one Finished Hex Nut 1/2-13 (#89).

52

56

FIG. 8 Thread one Finished Hex Jam Nut 1/2-13 (#90) and insert

one Split Lock Washer 1/2” (#176) onto the Screw of the Leg Press

Cable (#55). Next, Locate the Swivel Cable End (#56) and thread it to

the bolt of the Leg Press Cable (#55).

D1

55

55

FIG. 9 Next, attach the Swivel Cable End (#56) to the Fulcrum

with Brackets (#52) using one Hex Head Cap Screw 3/8-16 X 1 3/4

(#101), two Flat Washers SAE 3/8” (#94), one Nylon Insert Jam Lock

Nut 3/8-16 (#123).

3

D2

FIG. 10 Route the Leg Press Cable (#55) around the Pulley 4 1/2

Rd. (#78-Labeled D1). Next, route under then up the Pulley 4 1/2 Rd.

(#78-Labeled D2).

Note: Refer to the Cable Mapping Diagram on fold-out page 6for

further detailed illustration of the Leg Press Cable (#55) routing.

Leg Press Station

Page 5

Assembly Instructions

D3

55

D4

FIG. 11 Next, route the Leg Press Cable (#55) around the Pulley 4

1/2 Rd. (#78-Labeled D3). Next, route around the Pulley 4 1/2 Rd.

(#78-Labeled D4). Continue to route through the opening of the Leg

Press Main Frame (#47).

Note: Refer to the Cable Mapping Diagram on fold-out page 6

for further detailed illustration of the Leg Press Cable (#55)

routing.

47

1

55

D6

46

D5

FIG. 12 Route the Leg Press Cable (#55) around the Pulley 4 1/2

Rd. (#78-Labeled D5), and then through the tube of the Leg Press Bot-

tom Connector (#46). Next, route under the Pulley 4 1/2 Rd. (#78Labeled D6).

Note: Refer to the Cable Mapping Diagram on fold-out page 6

for further detailed illustration of the Leg Press Cable (#55)

routing.

D7

55

72

FIG. 13 Continue to route up and over the Pulley 4 1/2 Rd. (#78Labeled D7).

Next, attach the Leg Press Cable (#55) to the Top Plate/Selector Bar

(#72) using one Split Bolt 1/2-13 X 1 (#171), and one Split Lock Washer

(#176).

Note: Refer to Fig. B on fold-out page 6 for further clarification

of this hardware assembly.

Fully Fasten: Proceed fully fasten this hardware assembly.

31

32

FIG. 14 Attach the Right Handle (#31) and the Left Handle (#32) to

the Leg Press Main Frame (#47), in the position as shown above,

using two Hex Head Cap Screws 3/8-16 X 3 1/4 (#105), four Flat

Washers SAE 3/8” (#94), and two Nylon Insert Lock Nuts 3/8-16

(#125).

47

Leg Press Station

4

Page 6

53

140

47

FIG. 15 Affix the Seat Pad (#53) to the Leg Press Main Frame

(#47) using two Hex Head Cap Screws 3/8-16 X 1 1/4 (#99), one Hex

Head Cap Screw 3/8-16 X 3 (#113-Labeled with a black arrow), and

three Flat Washers SAE 3/8” (#94).

54

49

FIG. 16 Using a rubber mallet, insert one Plastic Insert Cap 1 3/4”

Sq. (#140) into the tube-end of the Adjustable Back Pad Tube (#49).

Next, attach the Adjustable Back Pad Tube (#49) to the Back Pad

(#54) using two Hex Head Cap Screws 3/8-16 X 1 1/4 (#99), and two

Flat Washers SAE 3/8” (#94).

54

49

179

47

FIG. 17 Insert the assembled Adjustable Back Pad Tube (#49) to

the Leg Press Main Frame (#47).

48

50

FIG. 18 Caution: It is strongly recommended to use another

person in assisting with this assembly.

Attach the Foot Plate (#48) to the Foot Plate Bracket (#50) using four

Flat Head Socket Cap Screws 3/8-16 X 1 1/4 (#91), four Flat Washers

SAE 3/8” (#94), and four Nylon Insert Lock Nuts 3/8-16 (#125).

5

Leg Press Station

Page 7

CHART

BOLD FONT = SUB-ASSEMBLY PARTS

REGULAR FONT = HARDWARE

Leg Press Station (Deluxe)

Parts List

ITEM NO. DESCRIPTION PART NO. QTY. ITEM NO. DESCRIPTION PART NO. QTY.

31 RIGHT HANDLE UP0270 1

32 LEFT HANDLE UP0271 1

45 ADJUSTABLE PULLEY BRACKET UP0127 1

46 LEG PRESS BOTTOM CONNECTOR UP2011 1

47 LEG PRESS MAIN FRAME UP2012 1

48 FOOT PLATE UP2014 1

49 ADJUSTABLE BACK PAD TUBE UP2015 1

50 FOOT PLATE BRACKET UP2018 1

51 FULCRUM UP2019 1

52 FULCRUM WITH BRACKETS UP2020 1

53 SEAT PAD UP0146 1

54 BACK PAD UP0145 1

55 LEG PRESS CABLE UP2024 1

56 SWIVEL CABLE END UP2032 1

76 ALUMINUM CAP 1" RD. (CAP-100) BNH0537 2 144 PLASTIC TUBE GUIDE W/LIP-TEETH 2 1/4" SQ. BNH0059 2

78 ALUMINUM PULLEY 3/8" X 4 1/2" BNH0069 7 153 RUBBER BUMPER 3/8 X 2 1/2 BNH05111

80 BEARING 6203 W/TWO 1/2 BUSHINGS BNH0835 8 156 RUBBER GRIP 1 ID X .125 X 8 BNH0966 2

82 BRONZE BUSHING 3/8 X 1/2 X 5/16 BNH0737 2 169 SOCKET SET SCREW ALLOY 10-32 X 1/8 BNH0473 4

89 FINISHED HEX NUT B/O 1/2-13 BNH0201 2 171 SPLIT BOLT Z/P 1/2-13 X 1 BNH04791

90 FINISHED HEX JAM NUT B/O 1/2-13 BNH0655 1 174 SPLIT LOCK WASHER 3/8" BNH0658 1

91 FLAT HEAD SOCKET CAP SCREW B/O 3/8-16 X 1 1/4 BNH0667 4 176 SPLIT LOCK WASHER Z/P 1/2" BNH0572 4

92 FLAT PHILLIPS MACHINE SCREW 8-32 X 1/4 BNH0408 1 177 STEEL BUMPER WASHER Z/P 3/8" BNH04981

93 FLAT WASHER SAE 1/2" BNH0238 12 179 TURN/PULL PIN W/KNOB AND LOCK BNH0989 1

94 FLAT WASHER SAE 3/8" BNH0239 29 180 URETHANE BUMPER 1 3/4 BNH0229 1

96 CABLE HEX TAP BOLT 1/2-13 X 3 1/2 BNH1131 1 186 DECAL-ADJUST CABLE HERE BNH0789 1

99 HEX HEAD CAP SCREW 3/8-16 X 1 1/4 BNH0273 4 187 DECAL-EXERCISE LEG PRESS STATION BNH1675 1

100 HEX HEAD CAP SCREW 3/8-16 X 1 1/2 BNH0303 1

101 HEX HEAD CAP SCREW 3/8-16 X 1 3/4 BNH0274 4

102 HEX HEAD CAP SCREW 3/8-16 X 2 BNH0279 2

104 HEX HEAD CAP SCREW 3/8-16 X 2 3/4 BNH0278 1

105 HEX HEAD CAP SCREW 3/8-16 X 3 1/4 BNH0312 4

111 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 5 1/2 BNH0267 4

112 HEX HEAD CAP SCREW GR-5 B/O 1/2-13 X 4 3/4 BNH0895 2

113 HEX HEAD CAP SCREW GR-5 B/O 3/8-16 X 3 BNH0282 1

123 NYLON INSERT JAM LOCK NUT 3/8-16 BNH0365 6

124 NYLON INSERT LOCK NUT 1/2-13 BNH0212 2

125 NYLON INSERT LOCK NUT 3/8-16 BNH0214 8

127 NYLON INSERT JAM LOCK NUT 1/2-13 BNH0366 4

132 PLASTIC END CAP 2 X 3 BNH0606 2

140 PLASTIC INSERT CAP 13/4" SQ BNH0053 1

Leg Press Station (Standard)

Parts List

All parts same as Leg Press Station (Deluxe), except for the part listed below

ITEM NO. DESCRIPTION PART NO. QTY. ITEM NO. DESCRIPTION PART NO. QTY.

78 NYLON PULLEY 3/8 X 4 1/2 BNH0506 7

Leg Press Station 8

Page 8

DO NOT DISCARD THIS MANUAL

TUFFSTUFF WARRANTY

TuffStuff warrants to the original purchaser that TuffStuff equipment will be free from defects in material and

workmanship. All warranty periods begin to run from the date of delivery to the original purchaser. The warranty

and remedies set forth herein are conditioned upon proper storage, installation, use and maintenance and conformance with any recommendations of TuffStuff. This warranty does not cover products not manufactured by

TuffStuff or products which are altered without the express written consent of TuffStuff. This warranty as specified:

FULL COMMERCIAL WARRANTY (more than 5 hours of use per day): a) Frames, welds, cams and

weight plates -- Lifetime, b) Pivot bearings, pulleys, bushings, gas shocks and guide rods -- Five (5) years, c)

Belts, linear bearings and pull-pin components -- One (1) year, and d) Upholstery, cables, finish and rubber grips

-- Six (6) months.

LIGHT COMMERCIAL WARRANTY (less than 5 hours of use per day): a) Frames, welds, cams and weight

plates -- Lifetime, b) Pivot bearings, pulleys, bushings, gas shocks and guide rods -- Five (5) years, c) Linear

bearings, finish and pull-pin components -- One (1) year, and d) Upholstery, cables and rubber grips -- Three

(3) months, and all other parts not mentioned elsewhere in this warranty will expire one (1) year from the date of

delivery to the original purchaser. The obligation of TuffStuff under this warranty is limited to repairing or replacing warranted defective parts, as TuffStuff may elect, at TuffStuff’s facility in Pomona, California, without

charge to purchaser for either parts or labor. Purchaser is responsible for installation of repaired or replaced parts,

and all transportation and insurance costs on returned or replaced equipment to and from TuffStuff’s facility in

Pomona.

THE FOREGOING SHALL CONSTITUTE THE SOLE REMEDY OF THE PURCHASER AND THE

SOLE LIABILITY OF TUFFSTUFF WITH REGARD TO WARRANTY. NO IMPLIED STATUTORY

WARRANTY OR IMPLIED STATUTORY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE SHALL APPLY. IN NO EVENT, WHETHER AS A RESULT OF

BREACH OF CONTRACT, WARRANTY, NEGLIGENCE OR OTHERWISE, SHALL TUFFSTUFF BE

LIABLE FOR SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT

LIMITED TO, LOSS OF PROFITS OR REVENUE, LOSS OF USE OF EQUIPMENT, COST OF CAPITAL, COST OF SUBSTITUTION EQUIPMENT, DOWNTIME COST, OR CLAIMS OF CUSTOMERS

OR PURCHASER FROM SUCH DAMAGE.

This written warranty is the final, complete and exclusive agreement of the parties with respect to the quality or

performance of the equipment and no action for breach of this written warranty or any implied warranty shall be

commenced more than one (1) year after the accrual of the cause o f action. No modification of this warranty or

waiver of its terms shall be binding on either party unless approved in writing by an authorized representative of

the party. Contact TuffStuff Fitness Equipment, Inc. at 1325 E. Franklin Avenue, Pomona, California 91766,

before returning any defective equipment.

TuffStuff Fitness Equipment, Inc.

1325 E. Franklin Avenue

Pomona, CA 91766, USA

Ph: 909-629-1600 Fax: 909-629-4967

E-mail: service@tuffstuff.net Net: www.tuffstuff.net

Loading...

Loading...