TUFFCAT 2X1000, 2X1500, 3X1000, 3X1250, 2X1000P Owner's Manual

...

®

High Pressure Cleaning System

Standard and Pulsating

Owner’s Manual

Standard Models

2X1000, 2X1500, 3X1000, 3X1250

Pulsating Models

2X1000P, 3X1000P

SAVE THESE INSTRUCTIONS

High Pressure Cleaning System

ONE YEAR LIMITED WARRANTY

For one year from date of purchase, when the

High Pressure Cleaning System is maintained

and operated according to the instructions in the

SEND PREP AID to Cat Pumps, 1681 - 94th Lane

N.E., Minneapolis, MN 55449 or call 763-780-5440

for assistance.

owner’s manual, we will repair, free of charge,

any defects in material or workmanship.

Replacement of parts or accessories with non-

original items or servicing of unit other than that

This warranty does not cover repairs necessary

as a result of operator neglect or abuse or normal

specifically outlined in owner’s manual will VOID

THE WARRANTY.

wear. This cleaning system may be returned to

any Cat Pump distributor or directly to the factory .

TABLE OF CONTENTS

Features............................................................................................................................................................................3

Specifications..............................................................................................................................................................3

Important Safeguards

Rules for Safe Operation

Grounding Instructions

Ground-Fault Circuit-Interrupter

Extension Cords

Motor Reset

Accidental Submersion

...............................................................................................................................................................5

.......................................................................................................................................................................5

Assembly and Start-up.......................................................................................................................................6-7

Operation

Pressure Adjustment and Gauge Reading

Vari-Nozzle Adjustmen

Chemical Injection

Unit Shut-Down and Storage Instructions

Freeze Protection

Lubrication

Draining and Adding Oil ..................................................................................................................................................

........................................................................................................................................................................10

Maintenance of the Pump

Disassembly of the Discharge Valve Assembly

Disassembly of the Seal Assembly

Reassembly of the Seal Assembly

Reassembly of the Discharge Valve Assembly

Maintenance of the Crankcase, Unloader, Chemical Injector, Pulsator..................15

Cleaning System Parts List.............................................................................................................................16

Cleaning System Exploded View...............................................................................................................17

SF Pump Exploded View and Parts List..............................................................................................18

Unloader Exploded View and Parts List..............................................................................................19

Chemical Injector Exploded View and Parts List........................................................................19

Troubleshooting........................................................................................................................................................20-21

Standard and Optional Accessories.......................................................................................................22-23

.................................................................................................................................................4

...................................................................................................................................................4

.....................................................................................................................................5

...................................................................................................................................................5

....................................................................................................................8

t ...................................................................................................................................................8

............................................................................................................................................................9

.....................................................................................................................9

.............................................................................................................................................................10

............................................................................................................11

................................................................................................................................12

.................................................................................................................................13

.............................................................................................................14

10

!!

▲ CAUTION ▲

READ AND FOLLOW ALL SAFETY RULES AND

INSTRUCTIONS BEFORE OPERATING THIS UNIT.

INSTRUCTIONS GIVEN THIS SYMBOL

!

▲

ARE FOR PERSONAL SAFETY.

BE SURE TO FOLLOW THEM.

2

FEATURES

®

SPECIFICATIONS

1. The proven dependability of the SF

ceramic plunger pump offering unequaled

performance life in its horsepower range.

2. A custom designed, industrial electric

motor featuring Thermal Overload

Protection with reset button and low amp

draw performance.

3. 35 foot electrical cord with Ground-Fault

Circuit-Interrupter (GFCI) protection for

maximum safety during operation.

4. A convenient pop-up cord wrap making

carrying and storing easy and neat.

5. Impact resistant, lightweight molded plastic case free of excess weight and bulk.

6. Easy to read, flat-mount, glycerine-filled

pressure gauge to monitor system operation and meet exact cleaning needs.

7. Adjustable pressure regulating unloader

to set and maintain system pressure for

various cleaning applications.

8. Adjustable downstream chemical injector

with inlet hose and chemical strainer.

MODEL 2X1000 and 2X1000P

Listed LR 91309

80U8

Flow......................................2.0 GPM (7.6 LM)

Pressure ..............................1000 PSI (70 Bar)

Horsepower...................................1.5 (1.5)

Voltage................110 to 115V, 60 HZ (110 to 115V, 60 HZ)

Maximum Amperage ......................15 (15)

Weight......................................60 lbs. (27.1 kg)

PUMP MODEL...................2LIDX20E

MODEL 2X1500

Flow......................................2.0 GPM (7.6 LM)

Pressure ..............................1500 PSI (105 Bar)

Horsepower...................................2.0 (2.0)

Voltage................110 to 115V, 60 HZ (110 to 115V, 60 HZ)

Maximum Amperage ......................20 (20)

Weight......................................73 lbs. (33.2 kg)

PUMP MODEL...................2LIDX20E

MODEL 3X1000 and 3X1000P

Flow......................................3.0 GPM (11.4 LM)

Pressure ..............................1000 PSI (70 Bar)

Horsepower...................................2.0 (2.0)

Voltage................110 to 115V, 60 HZ (110 to 115V, 60 HZ)

Maximum Amperage ......................20 (20)

Weight......................................73 lbs. (33.2 kg)

PUMP MODEL...................2LIDX30E

9. Shut-off spray gun with molded extension

and quick coupling allows easy assembly

and quick changes to many optional

accessories.

10.Vari-Nozzle with extension, featuring

adjustable spray angle and high/low pressure settings for chemical application and

pressure cleaning flexibility.

11.30 foot, 3/8 inch, wire braid, nonmarking

high pressure hose with swivel and quick

disconnect for convenience in assembly

and operation.

12.Safety By-Pass hose with Thermo Valve

to minimize excessive liquid heat build-up.

Note: 100V, 50HZ, 60HZ available upon request.

Flow......................................2.4 GPM (9.0 LM)

Pressure ..............................1000 PSI (70 Bar)

Horsepower...................................2.0 (2.0)

Voltage...........................220V, 50 HZ (220 V, 50 HZ)

Maximum Amperage ...................10.2 (10.2)

Weight......................................73 lbs. (33.2 kg)

PUMP MODEL...................2LIDX30E

COMMON SPECIFICATIONS

Inlet *Pressure.......Flooded to 40 PSI (Fld to 3 BAR)

Max. **Liquid Temperature.......140°F (60°C)

Pump Oil Capacity....................11 oz. (0.35 L)

Hose Length...............................30 ft. (9.1M)

Cord Length (w/GFCI)............... 35 ft. (10.7M)

Wand Length .............................36 in. (91 cm)

Dimensions...........21.75x17.0x9.62" (553x432x244mm)

*Contact factory for information on optional inlet suction kit

**or high temperature version.

MODEL 3X1250

3

IMPORTANT SAFEGUARDS

WARNING - When using this product basic

precautions should always be followed,

including the following:

IMPORTANT: This manual should be read

and understood thoroughly before assembly

and operation of this High Pressure Cleaning

System. Keep this manual available for

future reference in servicing or ordering parts

or accessories.

Failure to follow basic safety rules and precautions could result in serious injury, shock

or fire.

RULES FOR SAFE OPERATION

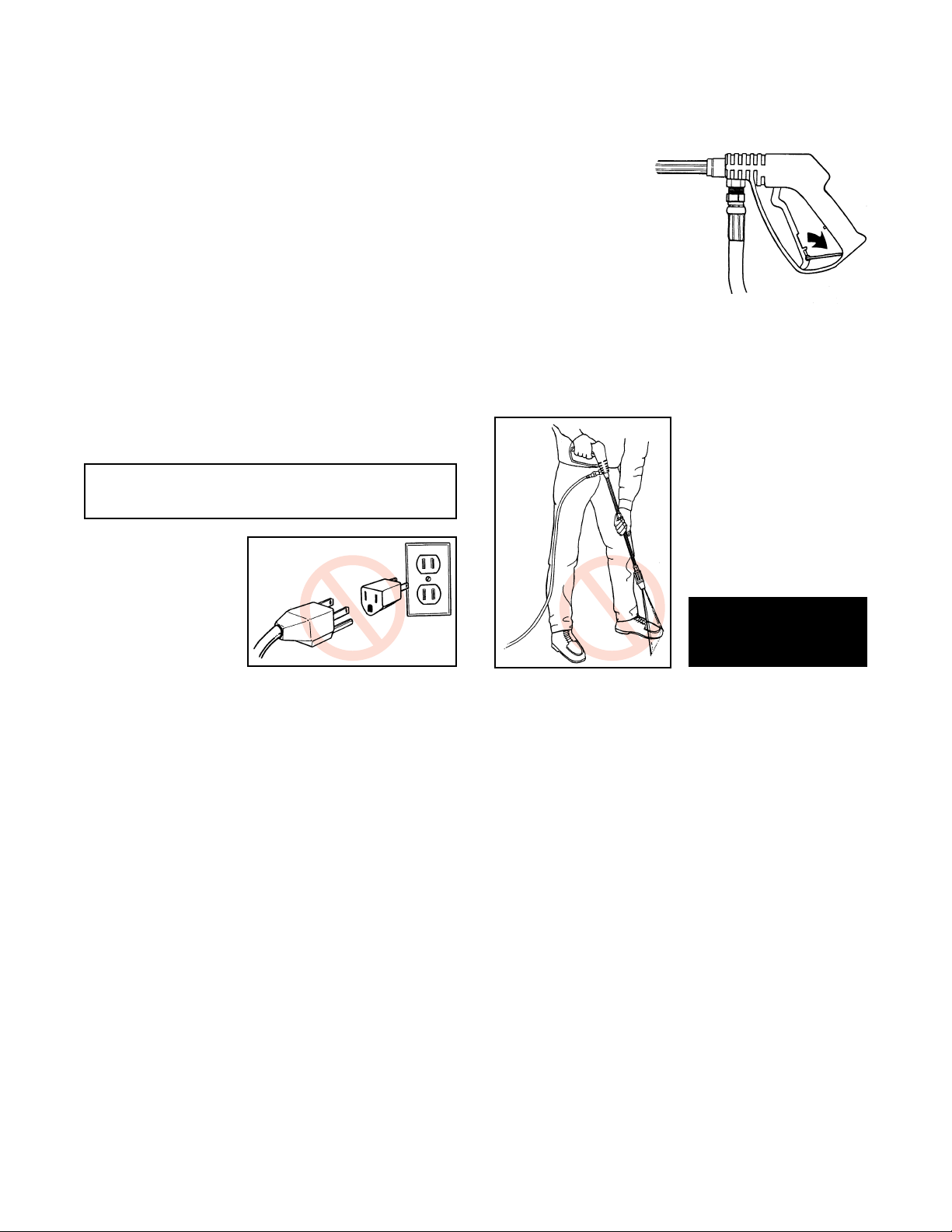

!

▲ WARNING ▲

Risk of shock or electrocution.

●

Connect only to

properly grounded

outlet.

●

Do not remove

ground pin or use

cheater.

●

Know how to stop the product and bleed pressures

quickly. Be thoroughly familiar with the controls.

●

Do not overreach or stand on unstable support.

●

Keep good footing and balance at all times.

●

Do not use extension cords unless plugged into a

GFCI protected outlet and cord meets specifications

shown under “Extension Cords” in this manual.

●

Keep all connections dry and off ground.

●

Inspect electric cord before using and do not use if

damaged.

●

Do not spray at electrical areas.

●

Do not touch plug with wet hands.

●

This product is provided with a Ground-Fault

Circuit-Interrupter built into the power cord plug. If

replacement of the plug or cord is needed, use only

identical replacement parts.

●

Do not modify electric outlet. Have a qualified

electrician install the properly grounded outlet.

●

Unplug cord from receptacle before disconnecting

cleaning system from extension cord.

●

Keep operating area clear of all persons.

●

Never leave unit unattended while running.

!

●

To reduce the risk of injury, close supervision is

necessary when a product is used near children.

●

Stay alert - watch

what you are doing.

●

Engage safety lock on gun

trigger when not spraying.

●

Do not place hand over end of

nozzle, injury will result.

●

Do not remove nozzle guard.

●

Do not lift or pull unit by

pop-up cord wrap.

●

Do not operate the product when fatigued or

LOCK

under the influence of alcohol or drugs.

●

Do not spray at people or animals.

●

WARNING

Risk of injection or

injury - Do not direct

discharge stream at

persons.

●

Follow the maintenance

instructions specified in

the manual.

SAVE THESE

INSTRUCTIONS

In case of accidental injection with water,

contact physician.

GROUNDING INSTRUCTIONS

This product must be grounded. If it should

malfunction or break down, grounding provides a path of least resistance for electrical

current to reduce the risk of electric shock.

This product is equipped with a cord having

an equipment-grounding conductor and a

grounding plug. The plug must be plugged

into an appropriate outlet that is properly

installed and grounded in accordance with all

local codes and ordinances.

DANGER: Improper connection of the equipment-grounding conductor can result in a

risk of electrocution. Check with a qualified

4

electrician or service person if you are in

doubt as to whether the outlet is properly

grounded. Do not modify the plug provided

with the product—if it will not fit the outlet,

have a proper outlet installed by a qualified

electrician. Do not use any type of adapter

with this product.

GROUND-FAULT

CIRCUIT-INTERRUPTER

PROTECTION

This pressure washer is provided with a

GROUND-FAULT CIRCUIT-INTERRUPTER

(GFCI) built into the plug of the power supply

cord. This device provides additional protection from the risk of electric shock. Should

replacement of the plug or cord become necessary, use only identical replacement parts

that include GFCI protection.

If the GFCI is not the AUTOMATIC RESET

TYPE, it must be manually TESTED and

RESET each time the cleaning system is

plugged in. Press firmly to assure internal

spring activates switch. Push “test” then push

“reset”. Motor will not start if GFCI does not

reset. Check circuit

breakers or outlet.

If circuit breaker is

not tripped and

unit will not reset,

contact local

service center.

RESET

not in use". Use only extension cords having

an electrical rating not less than the rating of

the product. Do not use damaged extension

cords. Examine extension cord before using

and replace if damaged. Do not abuse extension cord and do not yank on any cord to disconnect. Keep cord away from heat and sharp

edges. Always disconnect the extension cord

from the receptacle before disconnecting the

product from the extension cord.

Extension Cord Length

Model up to 50 feet 50 to 100 feet

2X1000 14 AWG 12 AWG

2X1500 12 AWG 10 AWG

3X1000 12 AWG 10 AWG

3X1250 14 AWG 12 AWG

Extension cords are not recommended unless

they are plugged into a ground-fault circuitinterrupter found in circuit boxes or protected

outlet receptacles.

MOTOR RESET

This cleaning system has a motor reset button

in the event the motor overheats or overloads.

If the motor stalls turn the power switch to

OFF and unplug. Follow the guidelines under

“TROUBLESHOOTING” to determine the

cause of the motor shutdown. A plastic extension inserted into the reset hole on the side of

the case will initiate motor operation. TEST

AND RESET THE GFCI BEFORE TURNING

THE UNIT “ON”.

EXTENSION CORDS

!!

▲ WARNING ▲

To reduce the risk of electrocution, keep all

connections dry and off the ground. Do not

touch plug with wet hands.

Use only 3-wire extension cords that have

3-prong grounding-type plugs and 3-pole cord

connectors that accept the plug from the product. Use only extension cords that are intended for outdoor use. The extension cords are

identified by a marking “Acceptable for use

with outdoor appliances; store indoors while

RESET

ACCIDENTAL SUBMERSION

The molded case of this cleaning system is not

watertight. In case of accidental submersion,

case must be opened and all internal components thoroughly dried. Pump crankcase

should be drained and fresh oil added. See

“LUBRICA TION” for additional information.

5

ASSEMBLY AND START-UP

Remove the cleaning system from the carton

and inspect for damage or missing components. Keep box for storage or shipping unit

if service is required.

Place unit on a hard level surface and

visually verify that the oil level is at the dot in

center of gauge. The unit is shipped slightly

overfilled. Tip case to see air bubble before

operation.

Set unit on a hard level surface. Do not operate unit in tall grass or on other soft surface

that would restrict air flow to and from the

bottom of the case.

AIR FLOW

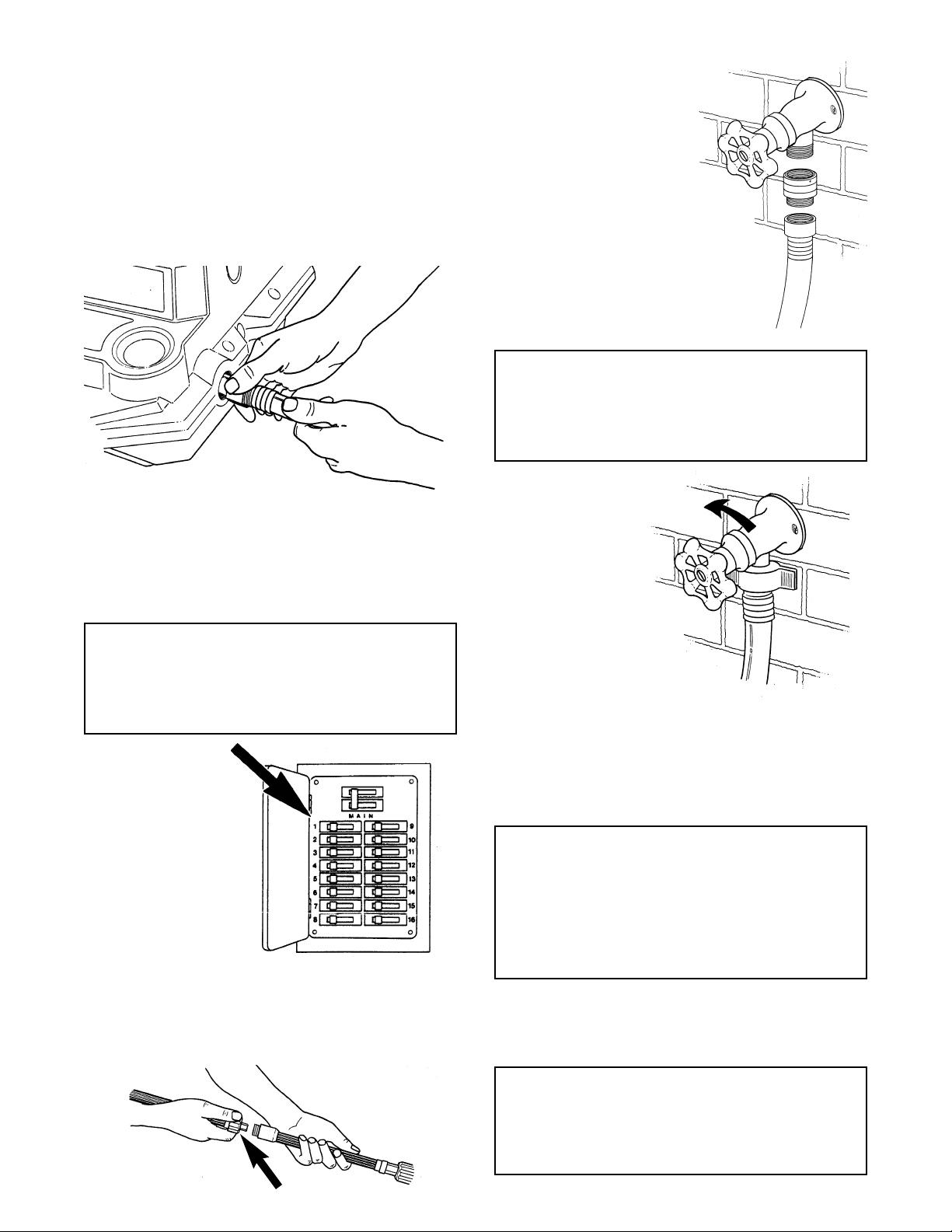

Attach the high pressure hose quick-disconnect to the discharge nipple on the top of the

case by pulling back the collar and pressing

over the nipple. Push down until it snaps into

position.

CAUTION

Lack of proper lubrication will result in

severe damage to pump. Visually check oil

before each use.

Be sure the power switch is in the “OFF”

position.

NOTE

When attaching accessories to the inlet

connection or chemical injector, some

movement may be noticeable. Each connection is o-ring sealed and the movement

is normal.

6

Attach a garden hose to the inlet fitting on the

side of the case. Check for the gasket and

screen in the fitting. The gasket assures a

good seal and the screen keeps debris from

entering the pump. CLEAN THIS SCREEN

periodically to avoid restricting liquid to the

pump. Inlet line must be a minimum of 1/2".

Be certain the inlet water supply is sufficient

before operating unit.

Uncoil the power cord and connect to a properly grounded receptacle. Voltage should be

between 110 and 115 to avoid stalling or

overloading motor. (15 amp for 1.5 H.P.,

20 amp for 2.0 H.P.)

CAUTION

2 H.P. Model must be plugged into an

outlet that is rated for 20 amps or greater

or the circuit breaker will trip.

15 amp

2X1000

20 amp

2X1500

3X1000

3X1250

Attach Vari-Nozzle with extension to gun with

extension. Snap Vari-Nozzle fitting into

extended hex collar on gun extension and

thread on hand tight.

Remove the

BACK FLOW

FAUCET

PREVENTER

from the owner’s

manual plastic

bag. Thread

female end of

preventer onto

BACK FLOW

PREVENTER

water supply

faucet. Then

thread garden

hose onto

GARDEN

HOSE

preventer.

CAUTION

Be certain to install the BACK FLOW

PREVENTER to prevent chemicals or soap

from flowing back into the supply line.

Turn inlet

water supply to

OPEN

the unit to full

open. Inlet water

temperature

should not

exceed the

maximum listed

in specifications.

Bleed air from system by triggering gun. With

adequate water pressure, unit should prime

within one minute. Trigger the gun with the

Vari-Nozzle in the (forward) low pressure

position to speed the priming.

CAUTION

If the unit is run with an inadequate inlet

water supply the unit will cavitate.

Cavitation causes the pump to operate

loudly, vibrate and cause damage to

the pump.

Flip power switch from “OFF” to “ON”.

Then trigger gun to assure all air is bled from

system.

CAUTION

NEVER leave unit unattended in by-pass

(with trigger gun shut off) for prolonged

periods.

7

OPERATION

PRESSURE ADJUSTMENT AND

GAUGE READING

Before using the cleaning system, the operating pressure must be set. The cleaning

system is equipped with a pressure gauge

for setting and monitoring system pressure.

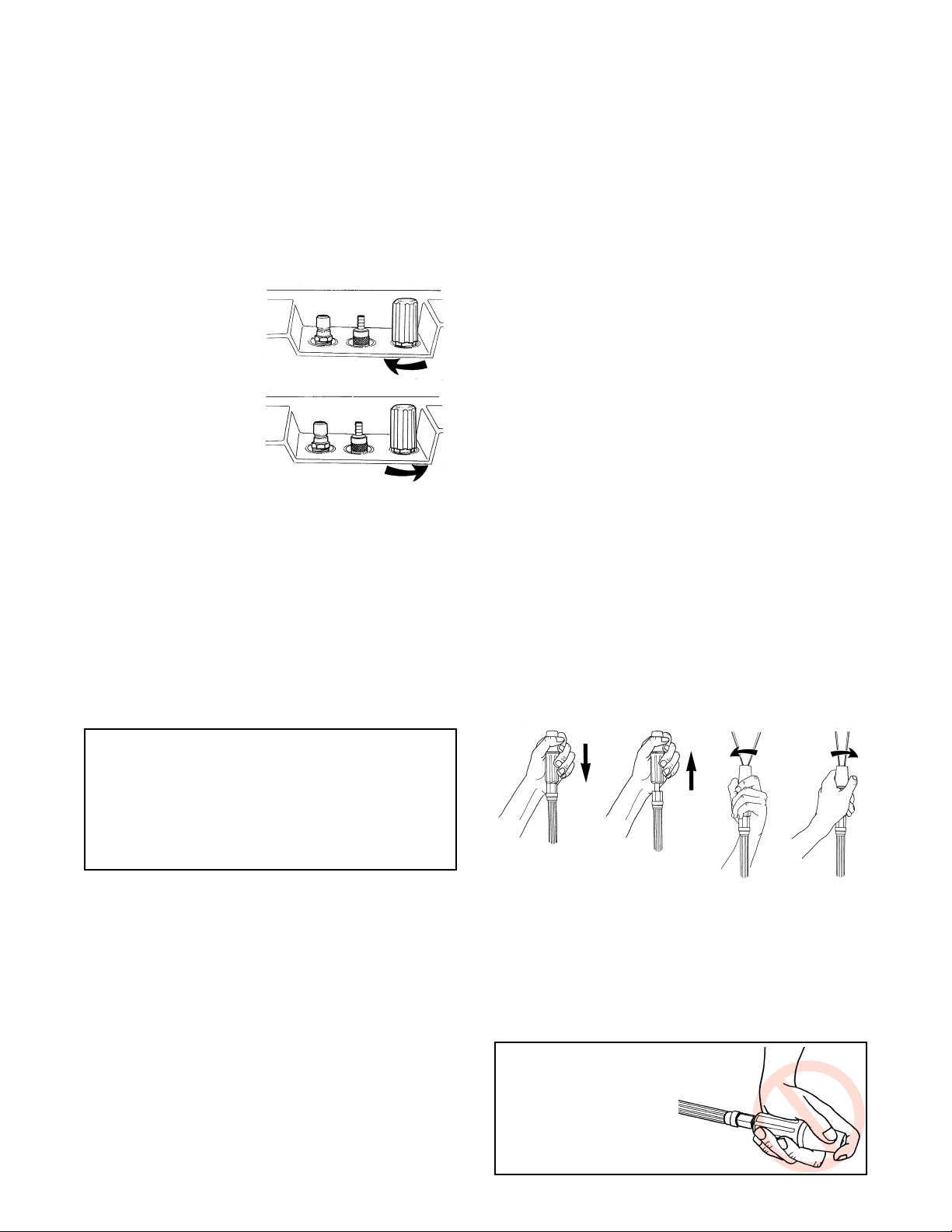

To set or adjust

pressure, rotate the

unloader adjustment

knob, marked “PSI”

on the top of the

case clockwise to

increase pressure

and counterclockwise to decrease

pressure. Make all

adjustments with the gun off (trigger

released). Adjust unloader 1/2 turn, squeeze

trigger and read pressure. If operating pressure has not been reached, repeat until

desired pressure is reached. Do not exceed

the maximum operating pressure listed in

specifications. Be certain to use only the

Vari-Nozzle provided with cleaning system or

replacement nozzle sized for the flow and

pressure of unit.

several times and check reading. If pressure

still has not dropped shut the unit off and consult “TROUBLESHOOTING”. For safety and

optimum life, operation in by-pass should not

exceed 6 minutes.The cleaning system is

equipped with an internal by-pass hose and

Thermo Valve. The Thermo Valve will sense

the rise in liquid temperature as a result of

running the unit in by-pass and bleed a small

amount of heated water from the bottom of

the case. Cool inlet water will fill the line and

protect the pump from overheating.

Prolonged operation in by-pass at high

pressure may result in damage to the pump

or the unloader. Turn system “OFF” during

prolonged periods of nonuse.

VARI-NOZZLE ADJUSTMENT

This unit is equipped with a multi-function

nozzle. The Vari-Nozzle changes from high

pressure (back position) to low pressure

(forward position) with an easy push-pull

motion. Changing from high to low pressure

permits the the low pressure adjustable chemical injector to begin drawing chemical into the

system. When chemical is no longer needed,

CAUTION

The maximum operating pressure of your

cleaning system has been secured at the

factory with a Locking Collar . Tampering or

removal of the Locking Collar on the

unloader valve will VOID THE WARRANTY.

Check your gauge while setting pressure

and periodically during operation. Changes

in pressure will warn you of wear or improper

operating conditions. If maximum pressure

cannot be reached or pressure drops after

prolonged use, it is most likely due to a worn

nozzle or lack of sufficient inlet water to the

unit. Consult “TROUBLESHOOTING” or call

your local service center.

When unit is running but in by-pass (gun off,

trigger released) pressure should drop to

approximately 100 PSI. If the pressure reading on the gauge does not drop, trigger gun

HIGH

PRESSURE

LOW

PRESSURE

WIDE

SPRAY

NARROW

SPRAY

return to high pressure (back position). The

Vari-Nozzle will also rotate right to left to adjust

from a 0° to 60° spray angle for desired cleaning needs. Make high to low pressure adjust-

ments with gun off or trigger released.

!!

▲ WARNING ▲

Do not place hand

over end of nozzle

while spraying or

adjusting nozzle.

8

Loading...

Loading...