Tuff Birds

Super Tough Wings & Planes

Micro BEE

Specifications:

Ÿ WingSpan: 600MM

Ÿ All-Up-Weight: ~ 200gms

Ÿ CG Location: 130MM back from Nose Tip.

What's Included:

Ÿ 2 EPP Wing Panels in Wing Beds

( Left + Right )

Ÿ Laser Cut Aircraft grade Plywood sheet

(Motor Mount, Control Horns & Battery Tray )

Ÿ Corrugated Plastic 3MM Winglets ( 2Nos )

Ÿ 1ft x 6ft 1.7Mil Lamination Film.

~120mm Pushrods

Linkage Connectors

Ÿ 5x250 mm Carbon Fiber Strip

Ÿ Velcro

Ÿ Paper Knife

Ÿ Elevon Throw Gauge

Ÿ Instructional Manual

Ÿ 2 Nos

Ÿ 2 Nos

Requires:

Ÿ 4-6 Channel Programmable Radio (Tx-Rx)

Ÿ 1000-1400mah 2S Lipo

Ÿ 6Amp-12Amp Brushless ESC

Ÿ 2 Nos 5gms-9gms Servo

Ÿ Micro Brushless Motor (12-20gms)

Ÿ 5-6inch Propellor

Building Tools:

Ÿ Hot Glue Gun and Glue Sticks

Ÿ Cyanoacrylate Glue ( FeviKwik etc )

Ÿ Screwdrivers & Allen Key

Ÿ Paper Tape & Clear Packing Tape

Ÿ An Iron ( If Laminating )

Ÿ Soldering Iron and Solder Wire

Ÿ Ruler , Pen and a Flat Working Table

Congratulations on your purchase of the

TuffBirds MicroBee EPP 600MM Flying Wing.

We hope these build instructions will help you

complete the build easily. Though the build

itself doesn't take much time, just be sure to

double check everything before cutting and

glueing.

Before flying, do the preflight checks

thoroughly, and we hope you will have a great

time flying the Micro Bee.

1

Ver 1.0 12 May 2018

600MM Flying Wing

goo.gl/Vrqb9b

Build

Video

:

BUILD INSTRUCTIONS

Tuff Birds

Super Tough Wings & Planes

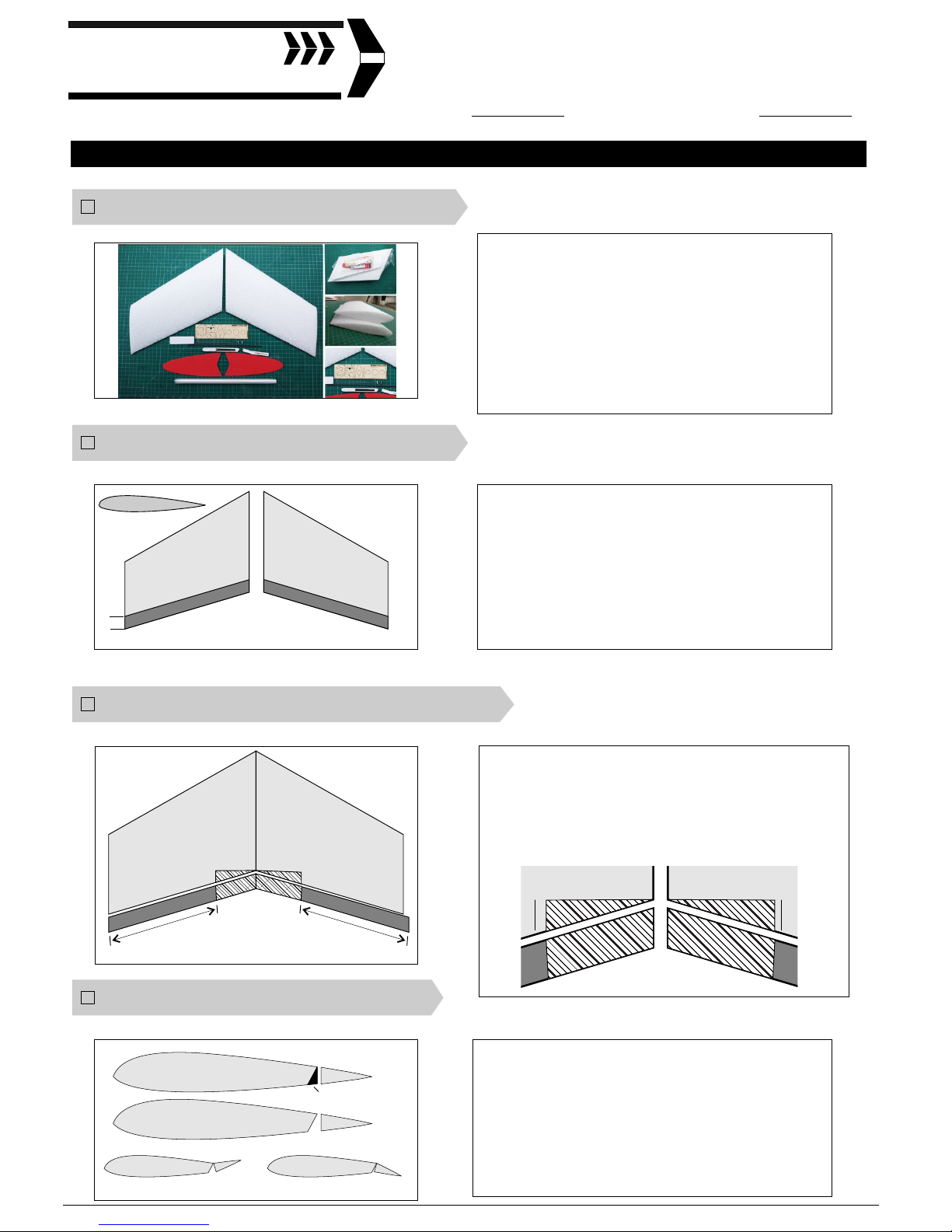

From the Wing Panels, cut the Elevons as

shown. Both elevons need to be same size. It

helps if you cut one Elevon, and use that as a

template to cut the second. The width of the

Elevons is 30MM.

Unpack and lay out everything from the kit.

Identify all the parts . Note and mark the Left and

Right Wing panels. In case you find anything

missing, stop and contact us before proceeding

with the build. The Left and Right Wing Panels

can be identified by the Airfoils. The slightly

flatter side is towards the bottom.

1. Layout and Identify the parts.

2. Cut the Elevons.

30MM

ELEVON

ELEVON

Next, we need to cut out some space for the

prop. Trim the inboard part of the Elevons so that

240MM of elevons is left. Make sure that both

sides are symmetrical. Next on both panels cut

and remove the area as shown.

3. Trim Elevons & cut space for prop

240MM

240MM

The wing panels need to be beveled to allow for

the Down movement of Elevons. Cut the bevel as

illustrated across the length of the panel with a

sharp knife. Try to cut the entire bevel with a

single pass of the knife.

4. Bevel the Wing

Area to be cut-off

Elevon Movement UP Elevon Movement DOWN

2

Micro BEE

600MM Flying Wing

20MM

20MM

Top

Bottom

Ver 1.0 12 May 2018

BUILD INSTRUCTIONS

Tuff Birds

Super Tough Wings & Planes

Test fit the panels, and use a bead of CA to glue

the panels together. Make sure they are aligned.

Leave aside to dry. When completely set, add a

bead hot glue and wipe it off to secure the entire

joint.

Use the Battery tray as a guide to make space for

the cut out of the battery area.

Cut only as deep as required for the battery. Leave

at least 10MM of foam at the bottom of the wing.

The Battery bay is usually required to be cut as far

forward as possible. The battery location may

need to be adjusted later to get the plane

balanced properly.

5. Cut Battery Location

6. Join Wing Panels

7. Install Spars

If Laminating , then laminate the elevons in at

least 2-3 layers to add rigidity. Laminate the

bottom wing first and then the top side. Hinge

using Laminate or Clear packing tape.

If not laminating, then use our EPP Hot Glue

Hinge method to install the elevons.

8. Laminate Panels OR Hot Glue Hinge

The 5MM Spar has to be installed on the panels

Use the knife to make a shallow cut, and use the

end of the spar to make enough space for a tight

fit Use CA to glue the spar. The Main Spar can be

glued 130Mm from the tip of the nose. This is

the CG location.

5MM Spar

130MM

3

Micro BEE

600MM Flying Wing

Ver 1.0 12 May 2018

BUILD INSTRUCTIONS

Tuff Birds

Super Tough Wings & Planes

Use CA or Hot Glue to install the Winglets at the

Wing Tips. Align the Winglets so they are flush

from the leading edge and as centered on the

tips as possible.

Servos need to be installed as far forward as

possible. Ensure that the linkage is perpendicular

to the elevon hinge line. Install the control horn so

that the hole is on top of the hinge line.

9. Install Servos & Linkages

11. Install Winglets

10. Assemble Motor Mount

This is the most cruicial step . CG of this wing

should be 130MM from the nose tip. Adjust the

placement of battery to get the CG to this

position. Flying wings are very sensitive to CG,

and if the CG is off by more than 5MM the plane

will not fly properly.

12. Check CG

Assemble the Motor mount using the 4 parts as

shown. The small arrows marked need to be

facing towards the top. Use CA to Glue the parts

together. Install the motor mount on the wing,

keeping it as centered as possible.

130 MM

4

Micro BEE

600MM Flying Wing

90°

90°

Ver 1.0 12 May 2018

BUILD INSTRUCTIONS

Tuff Birds

Super Tough Wings & Planes

13 Wiring Diagram

Motor

ESC

BATTERY

RX

Servo 2

Servo 1

PROP

LEFT

RIGHT

Left Elevon Moves Up | Right Elevon Moves Down

Plane will Roll/Turn Right

LEFT

RIGHT

Left Elevon Moves Down | Right Elevon Moves Up

LEFT AILERON

RIGHT AILERON

Down Elevator

LEFT

RIGHT

Both Elevons Move down

Plane will Nose Down / Dive

Plane will Nose UP / Climb

UP Elevator

LEFT

RIGHT

Both Elevons Move UP

CH 1

CH 2

CH 3

FPV Gear

14 Elevon Mixing

Use the supplied throw gauge to set the throws

of Elevons. Start with the recommendation and

then you may adjust later to suit your flying

style.

Check all linkages to be tight, and slop-free.

Double check the CG balance point.

15 Final Checks

Elevon Throws

Throw Gaug

e

Elevon at Neutral

5

Micro BEE

600MM Flying Wing

Plane will Roll/Turn Left

Ver 1.0 12 May 2018

Common Problems:

1. CG too far back. Flying wings will not fly tail heavy. A good sign you are tail heavy is you can’t control the

plane or the plane won’t stay trimmed. When you try to loop the plane will roll over. Add weight to the nose

to see if the problems resolve. It is not uncommon to need an extra oz or two of lead depending on how light

you build.

2. Too much movement in the elevons so the plane stalls on launch as you pull up on the elevator. This is a

very common problem!!!! May be combined or confused with tail heavy airplane symptoms.

3.Loose servos in the foam, linkages and push rods that flex, and poor leverage with push rods not installed

per plans, elevons are too soft and twisting.

BUILD INSTRUCTIONS

Tuff Birds

Super Tough Wings & Planes

6

Micro BEE

600MM Flying Wing

Essential Preflight Checks:

1. Check CG. #1 Check. DO NOT FLY If you don't get this

right.

2. Check Elevon Mixing

3. Check Neutral Trim

4. Check throws.

5. Check Prop direction and thrust

6. Check for any slop in Elevon/linkage Connectors

First Flight Checks:

1. Fly in a open ground with no obstacles.

2. For the first flights have someone experienced do the

checks and trim out the model

3. Launch the model with about 50% power and INTO the

wind.

4. Remember - Safety first. Fly Safely and responsibly.

Have fun and Enjoy. But fly responsibly. Find out a large open field, free from trees, buildings, obstructions

and people. Ensure you comply with local regulation laws.

Before flying your model, it is recommended you have an experienced flier from your region test fly the

model and trim it out for you . In case you have no such help, do not despair.

We suggest you go and do some computer simulation practice ( Realflight G4.5 , Phoenix etc ) afterwards this

airplane should be easy enough for you to fly.

Follow all of the Preflight checks mentioned below. Double check the control surfaces. They should all be

neutral and check again for control reversing. Check for wind direction. The airplane is always launched and

landed against the wind. So move to a location in your field from where you have a clear area ahead against

the wind to launch.

Always keep the model within sight and within the confines of your flying field.

The TuffBirds MicroBee has been Designed, prototyped, tested and manufactured in India by Vortex-RC. All

Contents are copyright , and no part may be copied, or duplicated in any form without the written permission

from Team Vortex-RC.

Visit us at and www.Vortex-RC.com www.TuffBirds.in

Ver 1.0 12 May 2018

Loading...

Loading...