Tucker Auto-Mation SW10, SW19 Installation Manual

!

!

!

920.1020.12 !

1!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

!

!

!

!

!

!

!

!

!

!

TUCKER AUTO-MATION

SW10 (Full Power) & SW19 (Low Energy)

INSTALLATION GUIDE

Surface Mounted Applications

(See APPENDIX for special notes regarding installation on fire rated doors)

!

PLEASE NOTE: NEW 35mm SPINDLE FOR PUSH APPLICATIONS REQUIRES DIFFERENT

HEADER MOUNTING HEIGHT

!

!

!

920.1020.12 !

2!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

IMPORTANT

READ THIS SECTION BEFORE PROCEEDING WITH INSTALLATION

Tucker Auto-Mation, LLC (hereafter referred to as “Tucker”) recommends that all of its

automated pedestrian door products beinstalled by a trained automatic door technician and that the

resulting performance of the product be in full compliance with themost current version of the American

National Standards Institute document A156.10 or A156.19 (whichever is applicable) as well as any

applicable building codes and/or fire codes. Tucker further recommends that a full inspection of the

operating system be performed in accordance with the guidelines of the American Association of Automatic

Door manufacturers (AAADM). This inspection must be performed by a certified AAADM trained inspector.

Tucker recommends this documented inspection be performed upon completion of the installation as well

as, following the completion of every service call thereafter. If service is not performed within one year of

the previous service action, a routine AAADM inspection should be performed and documented. Under no

circumstance should the product operate for more than one year without an AAADM inspection. Tucker

does NOT recommend installation or service, on any of their automated pedestrian door products, by any

individual who is not certified as an AAADM inspector.

Following the installation or service of any Tucker automated pedestrian door product, if it is deemed

unsafe, or is operating in an unsatisfactory manner according to national performance standards or

recommended performance guidelines as defined by Tucker, repairs should be made immediately. If an

immediate repair cannot be made, the product should be disabled, and appropriate measures should be

taken to secure the door in a safe position or to enable the door to safely be used manually. During this

situation, every effort should be made to notify the owner (or person responsible) of the condition and to

advise on corrective actions that must be taken to return the product to safe operation.

LOW ENERGY APPLICATION NOTE

When using the SW10/19 for a low energy application, Tucker Auto-Mation recommends the use of a doormounted presence sensor on the approach side of the door to be used as a secondary activation device. This

type of sensor can be installed at time of installation or can also be retrofitted. This device serves to reactivate the door to the open position should a person enter into the closing path at the approach side of

the door, as it is closing. Once the door is fully closed, a "knowing act" device must then be used for initial

activation. Tucker Auto-Mation considers this device to be essential in reducing the possibility of doors

"timing out" and closing before all pedestrians have passed though the doorway. Check with your Tucker

sales representative to find out about special incentives that may be available for the Torpedo 1 doormounted presence sensor.

!

!

!

920.1020.12 !

3!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

!

TABLE OF CONTENTS:

!

!

Page

Contents

IMPORTANT

READ IMPORTANT NOTICE ABOVE BEFORE BEGINNING TH

E

I

NSTALLATION

OF THIS PRODUCT

2

Important Notices

4

Product

Description & Specifications

5

STEP

1: Header Installation

6-7

STEP

2: Mounting The

Operator & Control Assembly

8-9

STEP

3: Install The Arm Assembly - Standard Applications

10-14

STEP

4: OPTIONAL

- Push

Arm Installation With Increased

Spring Tension

15

STEP

5: OPTIONAL

-

Pull Arm Installation With Increased

Spring Tension

16-17

STEP

6: Adjusting The Mechanical Stops

18-20

STEP

7: Setting The Dip Switches

21

STEP

8:

Wiring Connections

22

STEP

9: Adjusting The Control

23

STEP

10: 120 Volt

AC C

onnection

24-27

STEP

11: Power On & Tune-In

28

T

roubleshooting 28

Job Documentation & Closeout

29

Company Contact

30-31

Appendix - Adjusting The Chain Tensioner

31-38

Appendix –

Wiring Diagrams

39

Appendix - Lock Relay Function

40-41

Appendix -

Fire

rated Door Application

42

Appendix - Tucker Logo Placement

!

!

!

!

!

920.1020.12 !

4!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

PRODUCT DESCRIPTION & SPECIFICATIONS

The Tucker Auto-Mation SW10 & drives. The unique design offers; non-including sensors, push plates, fire

alarm, and electric locks. Troubleshooting when needed. Both units can be configured concealed

application. The Tucker Advanced Programmer (TAP) is provided as an option to access additional

programming features.

!

!

Power Supply

115

VAC (+6%, -10%)

60Hz

Power Consumption

100W

C

urrent Consumption

1A Motor

24

VDC

Permanent Magnet

With Belt Driven Encoder

Header Dimensions

20 3/4” x 4 1/8” x 4 3/4”

(l

x w x d)

Fused Protection

3.5A Fuse (F1 located on I/O Board)

Weight

22

lbs

Per Operator Assembly

Ambient Operating Temperature

-4 to 131º F

Ingress Protection

IP23 (protection

from spray water up to 60º from

the

vertical – ie. Rainstorm)

Maximum

Door Weight

PUSH ARM

PULL ARM

36” Door: 438

lbs

342 lbs

42” Door: 328

lbs

256 lbs

44” Door: 299

lbs

234 lbs

48” Door: 254

lbs

198 lbs

24

VDC Accessories

Power Supply

24

VDC / 500

mA

max.

24

VDC Electric Lock Power Supply

24

VDC / 500

mA

max.

Adjustable Speeds & Timers

Opening Speed

Closing Speed

Hold

Open Time

Standard Selector Switch Functions

Automatic

Hold

Ope

n

Manual

(Off)

Standard Control Outputs

Malfunction Alarm Signal

Electric Lock

Power Supply

24

VDC Accessories

Power Supply

Door

Status

Standard Control Inputs

Interior Activation

Exterior Activation

Emergency

Shutdown Alarm

Output

“Stop” Safety Device (door-m

ounted)

Quick Disc

onnects

TAP-Controller (optional)

!

!

!

!

!

!

!

!

920.1020.12 !

5!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

!

!

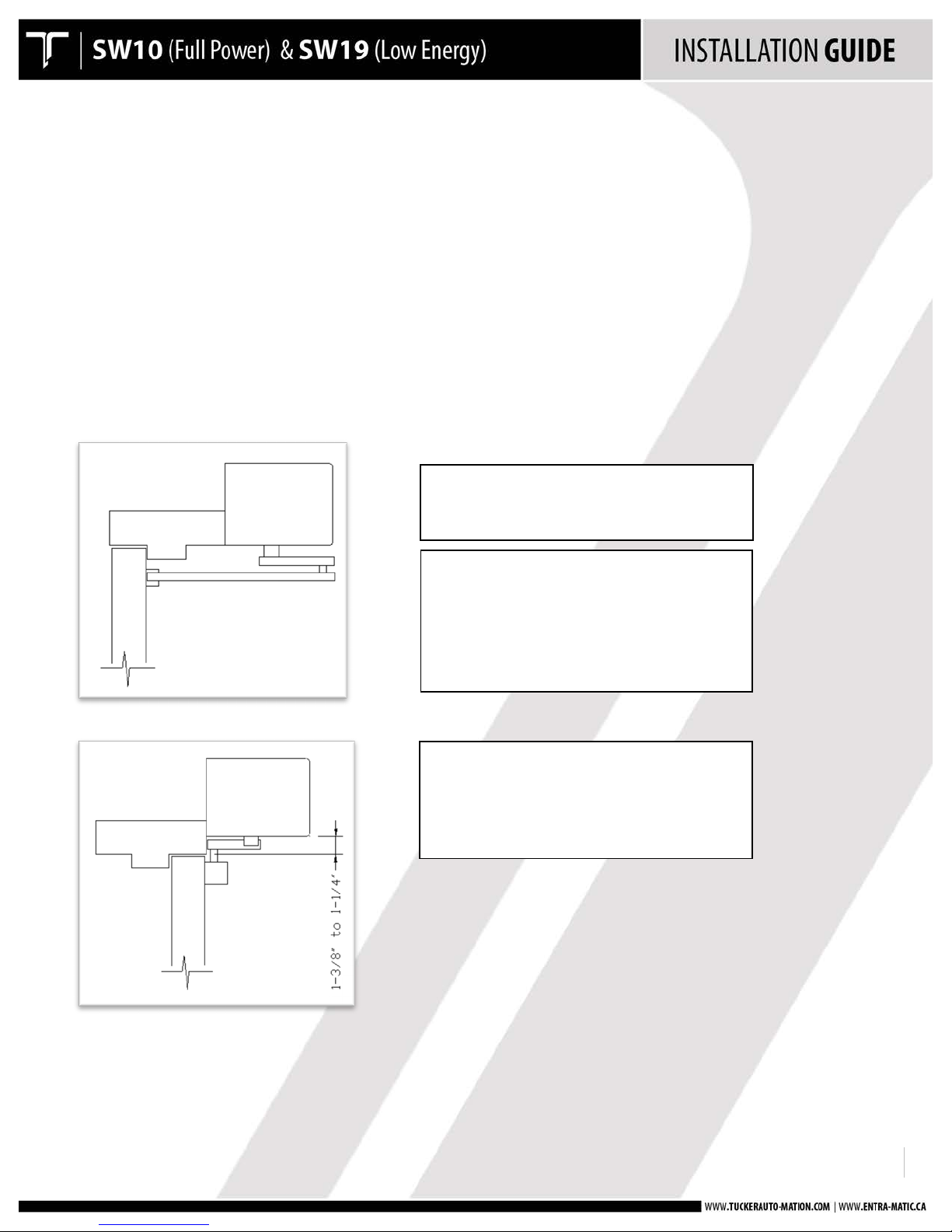

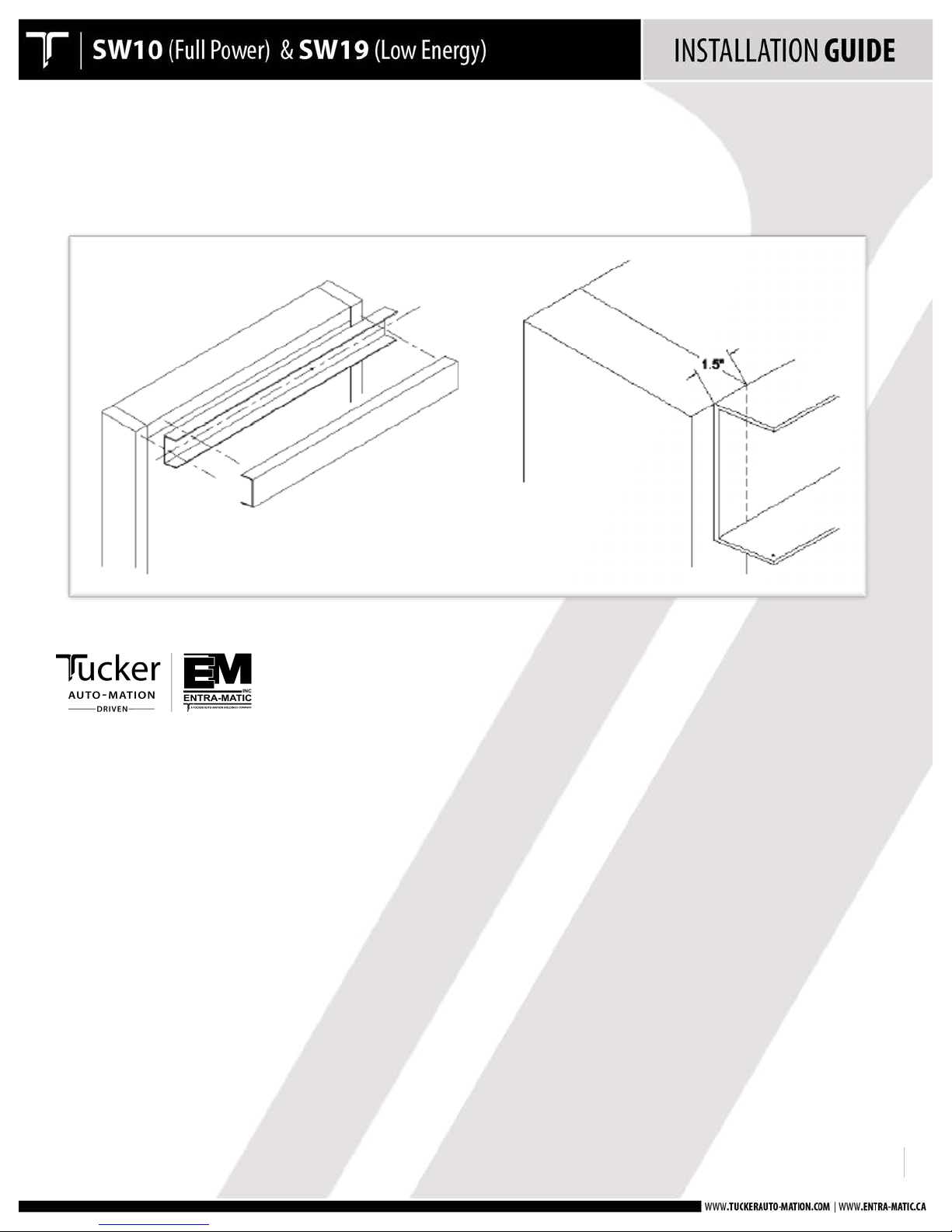

STEP 1: HEADER INSTALLATION

Mount the back-plate to the top door frame using appropriate fasteners for the type of frame.

• Push side mounting: Back-plate is flush with bottom of door frame.

• Pull side mounting: Back-Plate is mounted 1.5” up from bottom door frame.

• Back-plate should overlap each jamb tube by 1.5” – to aide in installation, there is an index line

scribed into the back-plate at 1.5” in from the edge. Align this mark with the inside face of the jamb

tube.

• Refer to the APPENDIX for fire rated door applications.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

PUSH!ARM!APPLICATIONS:!!

Bottom!of!header!is!flush!with!bottom!of!top!

frame.!

PULL!ARM!APPLICATION:!STANDARD!PULL!

ARM!&!DOUBLE!EGRESS!APPLICATIONS!

Double!egress!applications!require!the!use!of!

an!80mm!spindle!adaptor!for!the!side!using!

the!push!arm.!

NOTE:!

Tucker!Auto-Mation!is!now!using!a!35mm!

spindle!adaptor!for!all!standard!push!arm!

applications!–!this!requires!that!the!header!

assembly!be!mounted!as!shown!at!left,!flush!

with!bottom!of!top!frame.!

!

!

!

920.1020.12 !

6!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

STEP 2: MOUNT THE OPERATOR(S)

• One operator works for any hand of door.

• The hand depends on how the operator is mounted to the header.

• Refer to the APPENDIX for fire-rated door applications.

• Determine the hand of the door to be automated and mount the operator & short back-plate

assembly using the 6 screws provided.

!

!

!

!

!

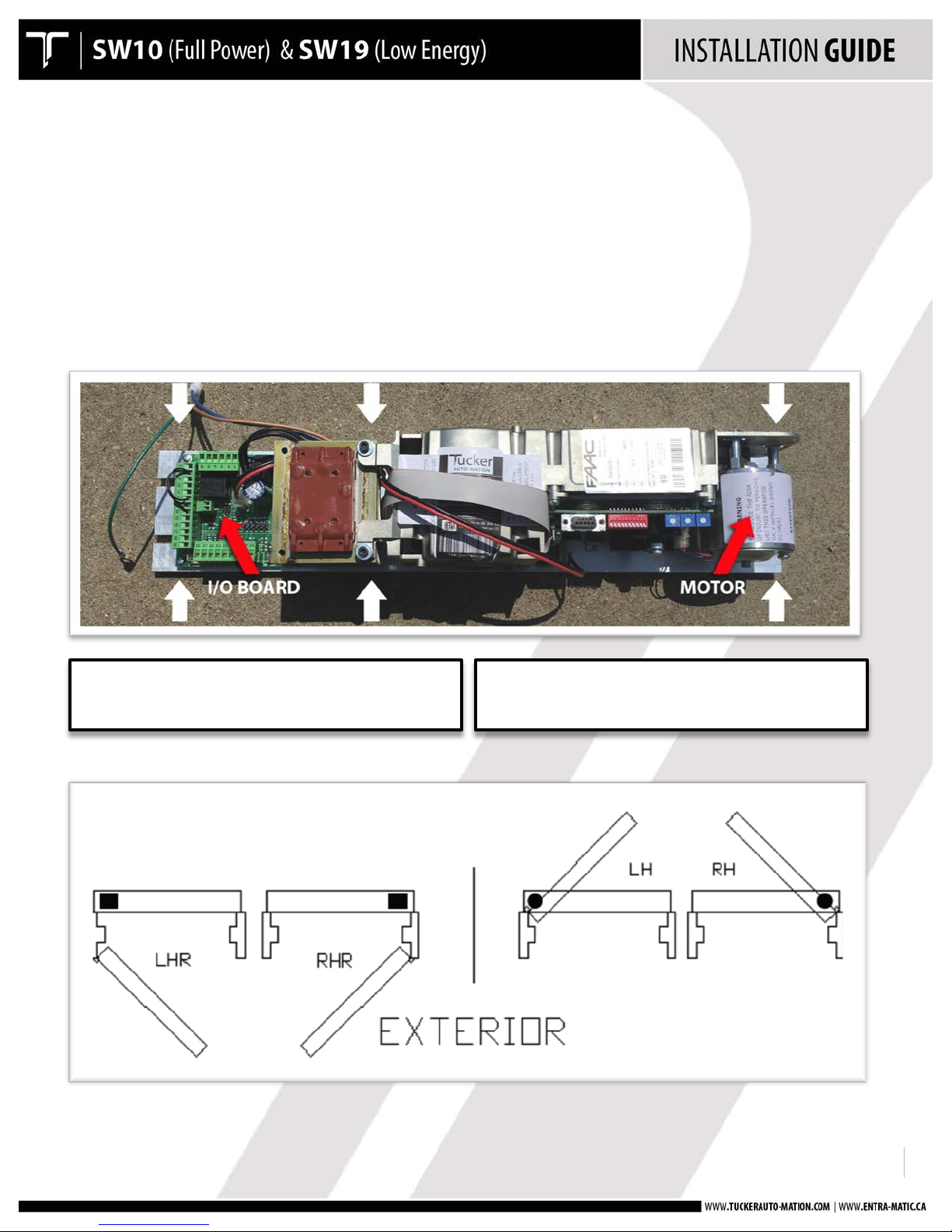

I/O BOARD IS TOWARDS HINGE

JAMB

MOTOR TOWARDS HINGE JAMB

!

!

!

920.1020.12 !

7!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

!

!

!

!

• Mount the header to the doorframe with the screws provided.

• The header will overlap the doorframe by 1-1/2" at each side.!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

920.1020.12 !

8!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

!

!

!

STEP

3:

INSTALL THE ARM ASSEMBLY - STANDARD APPLICATIO

N

!

!

!

!

!

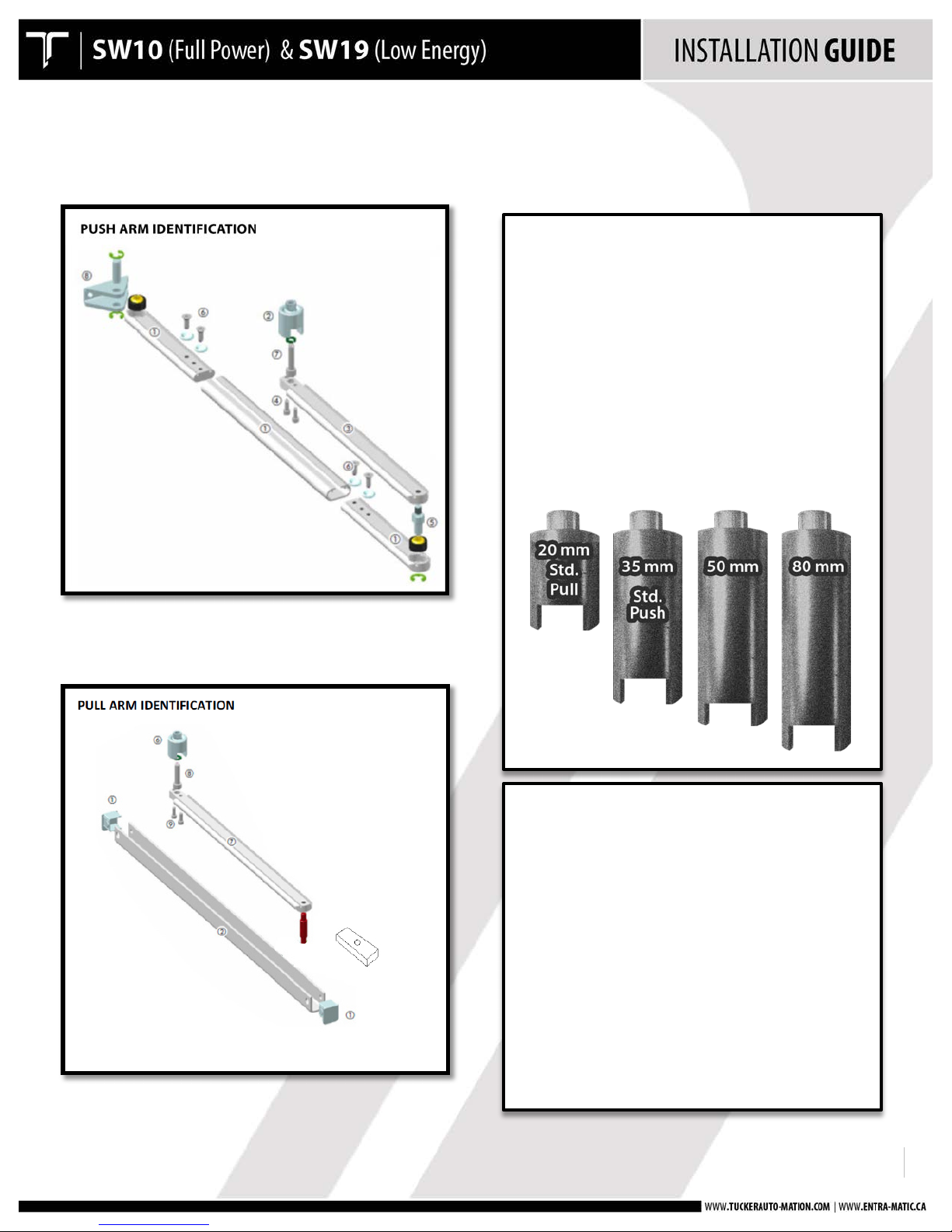

PUSH ARM ASSEMBLY:

1. Secondary Arm With Sleeve

2. Spindle Adaptor

3. Primary Arm

4. Spindle/Arm Attachment Screw

5. Pivot Stud

6. Secondary Arm Attachment

Screws With Dimple Washers

7. Spindle Adaptor Bolt

8. Door Shoe

PULL ARM ASSEMBLY:

1. End caps

2. Slide Track

3. Slide Block Sub-Assembly

4. Slide Blocks

5. Slide Block Separator

6. Slide Block Stud

7. Primary Arm

8. Spindle adaptor Bolt

9. Spindle Adaptor/Arm Attachment

!

!

!

920.1020.12 !

9!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

STEP

3:

INSTALL THE ARM ASSEMBLY - STANDARD APPLICATION

Follow

the instructions listed below

for a standard arm application using

a "push" or a

"pull"

arm assembly.

If using a push arm,

AND

extra door

closing

force

is require,

follow

the instructions

on page 7 for "Optional

-

Push

Arm Installation

With Increased

Spring Tension"

PUSH ARM APPLICATIO

N

Ensure

the main

power

supply is

removed or shut off at the control.

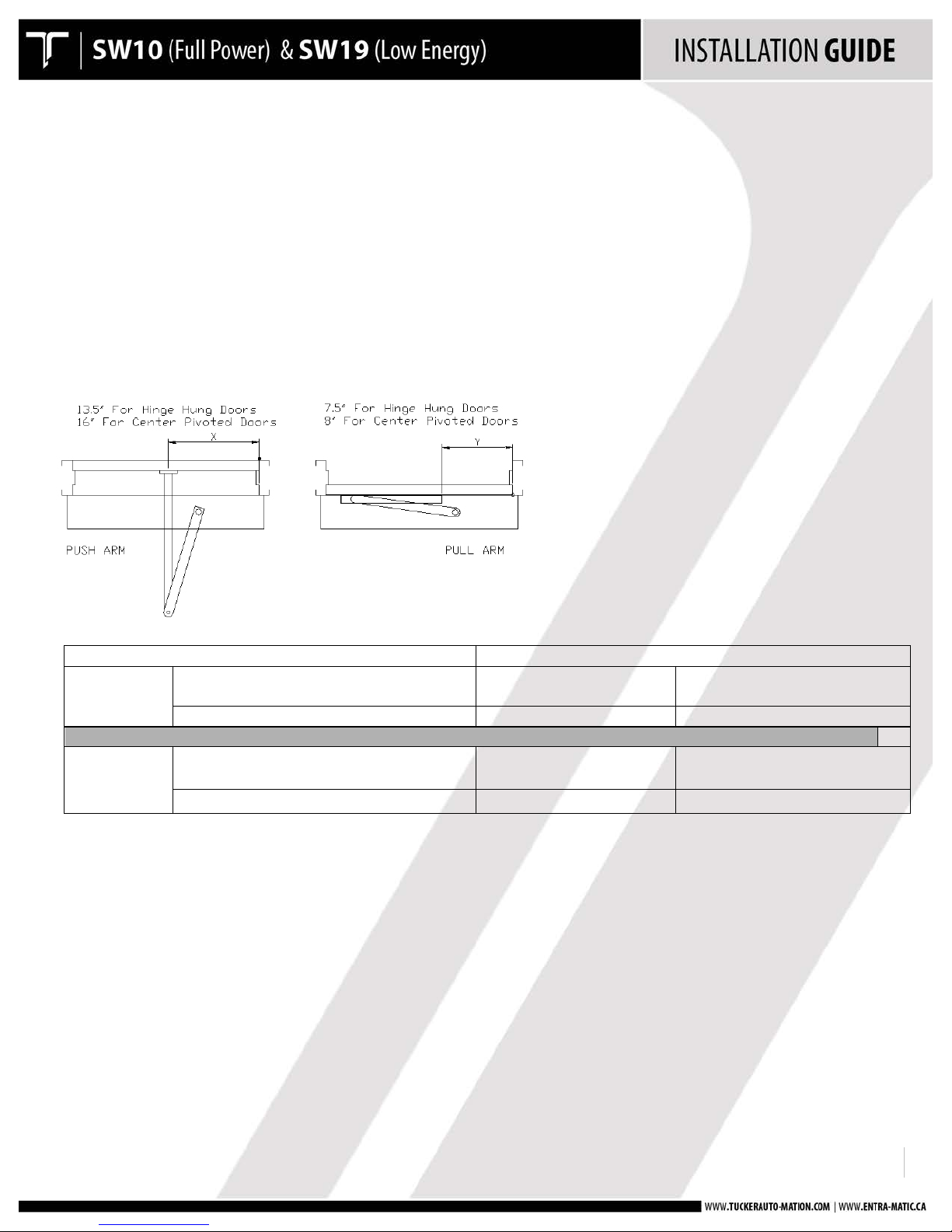

HINGE HUNG

DOORS

CENTER PIVOTED

DOORS

PUSH

APPLICATIO

N

C/L

of

Hinge

to C/L of

Arm Mount

Bracket

Inside face of pivo

t

jamb to Spindle

Inside face of hinge jamb to

C/L

of

Arm

Mount Bracke

t

13.5”

10.5”

16”

PULL

A

PPLI

CATIO

N

Inside face of jamb to

Back Edge

of

Slide Trac

k

Inside face of pivo

t

jamb to Spindle

Inside face of hinge jamb to

Back Edge

of

Slide Trac

k

7 .5 ”

10.5”

8”

!

PULL ARM APPLICATION:

• Includes double egress applications.

• Ensure the main power supply is removed or shut off at the control.

• Install the slide track assembly to the door at the specified location.

• Attach the track with the screws provided.

• Install the primary door arm and spindle onto the operator so that the arm is approximately 30 to 45

degrees past the door closed position.

• Once the arm is installed and tightened, pull the arm towards the opening direction and insert the

drive block into the track assembly.

!

!

!

920.1020.12 !

10!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

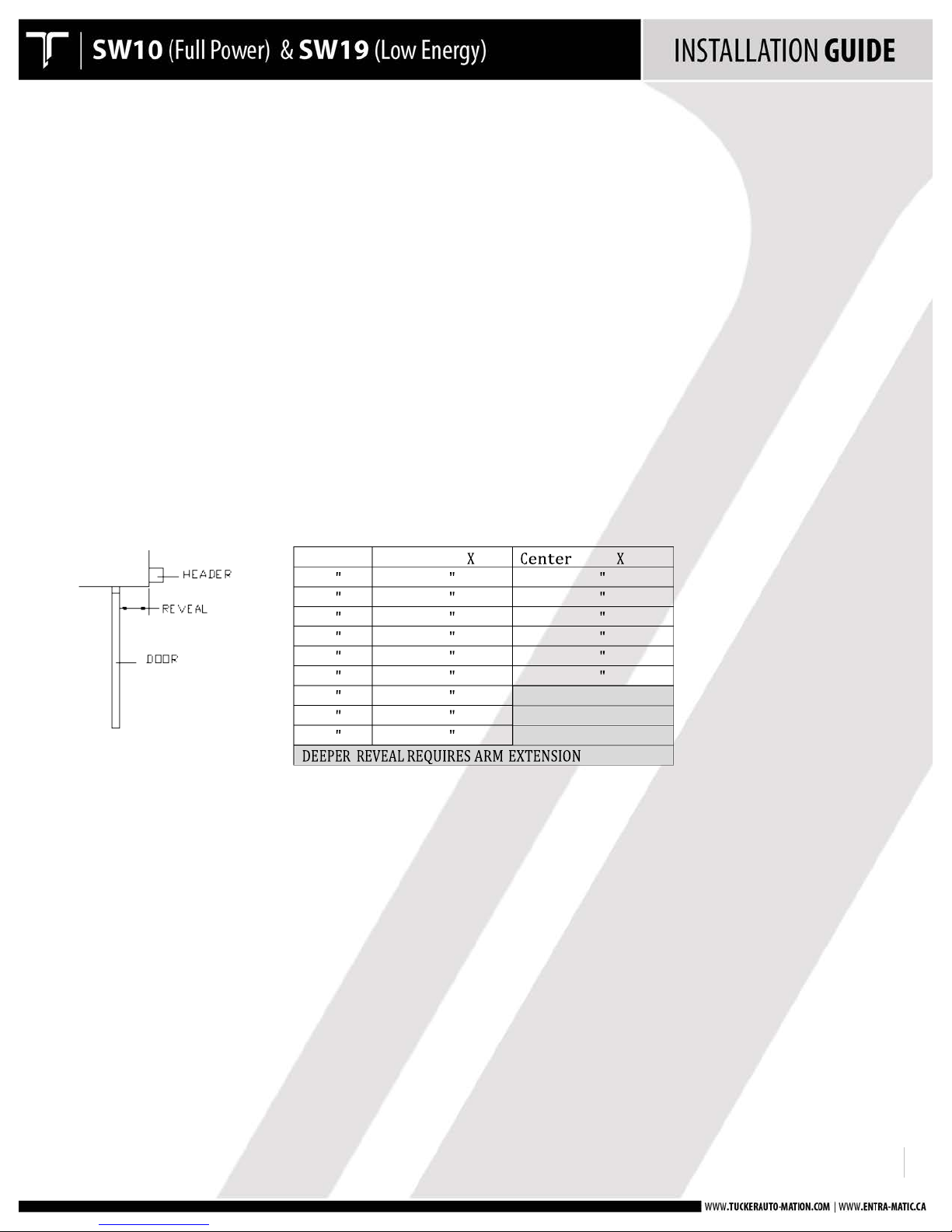

Reveal!

Hinge!Hung! Dim.!

!Pivot! Dim.!

0 !

13 !

16 !

1 !

14 !

17 !

2 !

15 !

18 !

3 !

16 !

19 !

4 !

17 !

20 !

5 !

18 !

21 !

6 !

19 !

!

7 !

20 !

!

8 !

21 !

!

!

!

• Manually move the door from the full closed position to the full open position to make sure there is

enough travel from the operator.

• If more travel is required, adjustment of the mechanical stops on the operator may be required.

• See the next section for adjustment if needed.

STEP

4: OPTIONAL

-

PUSH ARM INSTALLATION WITH INCREASED SPRING

TENSION

!

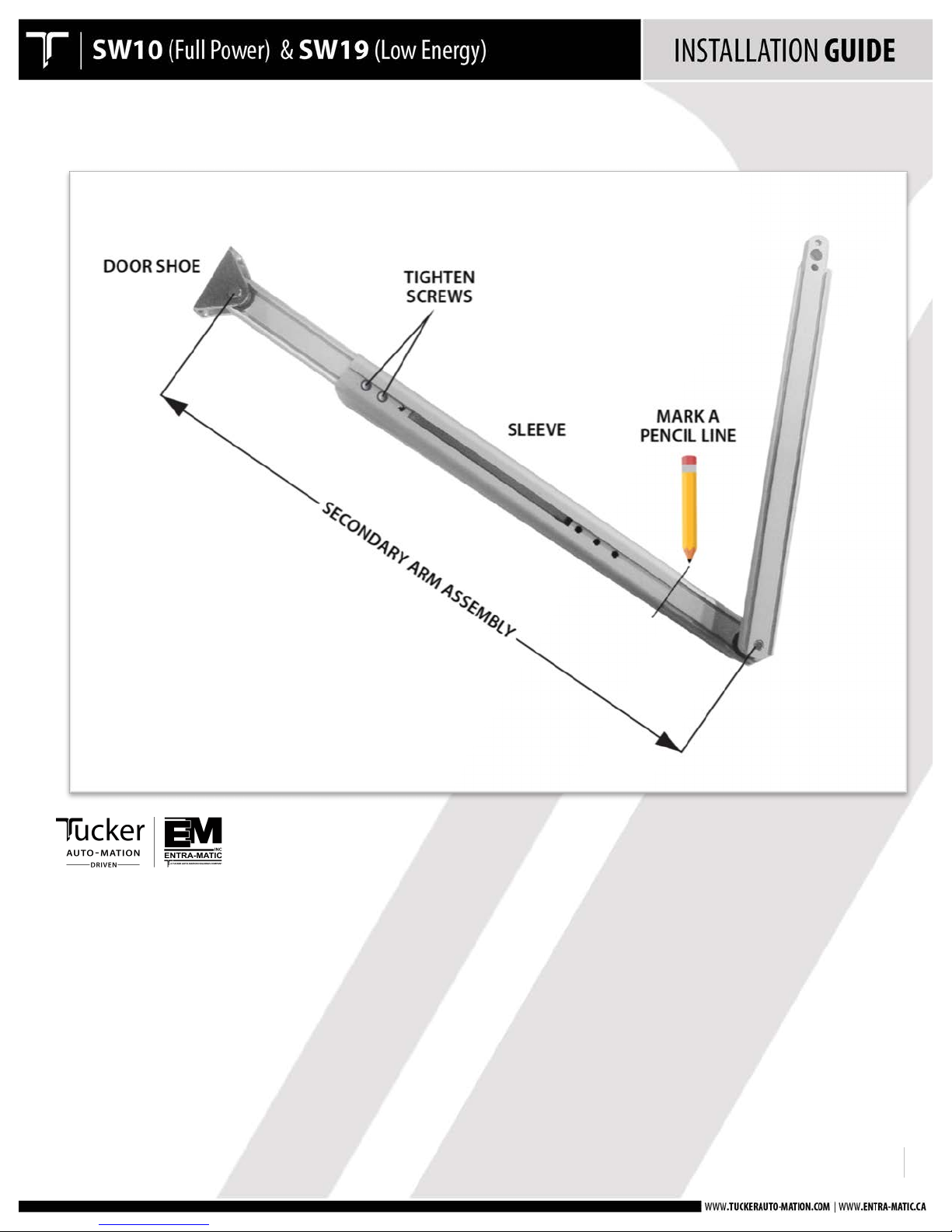

• Prior to beginning the push arm installation, gather the following information about the application:

o Door configuration

o Reveal distance (inches)

• Use the chart below to determine the prescribed length of the secondary arm assembly and note the

dimensions.

• Before

installing

any

portion of the door arm assembly, it

is easiest to

lay

the arm out on a flat

surface and insert

the secondary and primary

arm into

the sleeve as it will

be when installed

on

the

door:

o

Slide

the short arms within

the sleeve to obtain the prescribed

"X" dimension.

o Tighten the screws on the short arm that

is

connected to the door shoe.

o

Double-check

the

"X" dimension

of the arm - this is

the distance

between the center of the

hole

at the

door

shoe and the center of the hole at the pivot point

of the primary

arm (as

shown).

o Mark a

pencil line

at the edge of the sleeve where it overlaps the short arm that

is

connected

to the primary

arm.

This will

make it easier when positioning the primary

arm for

final

installation.

!

!

!

920.1020.12 !

11!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

PUSH ARM

!

!

!

920.1020.12 !

12!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

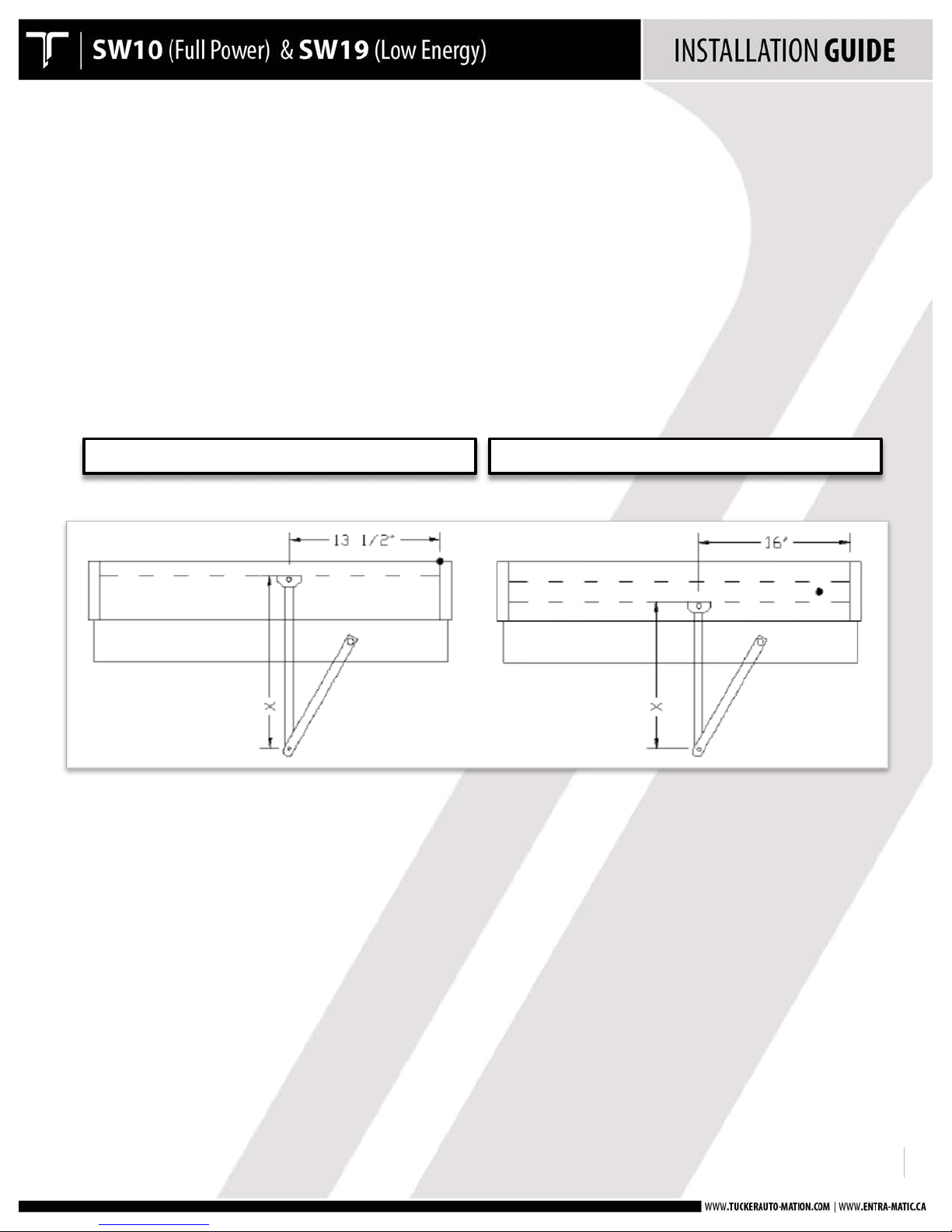

STEP 4 Cont.: OPTIONAL - PUSH ARM INSTALLATION WITH

INCREASED SPRING TENSION

!

• The door shoe and short arm comes pre-assembled - it is

not necessary to take the assembly apart.

• Install

the door shoe per the door hinge / pivot configuration - see below:

o

Hinge Hung Doors: Centerline of door shoe at 13.5"

in

from inside

of hinge jamb

o Center Pivot Doors: Centerline of door shoe at 16"

in

from inside

of pivot jamb

o The

horizontal centerline

of the door shoe

will

be at 2" below the bottom of the back-plate

o

Do NOT

install

the primary

arm until instructed to do so

HINGE HUNG

CENTER PIVOTED

!

!

!

920.1020.12 !

13!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

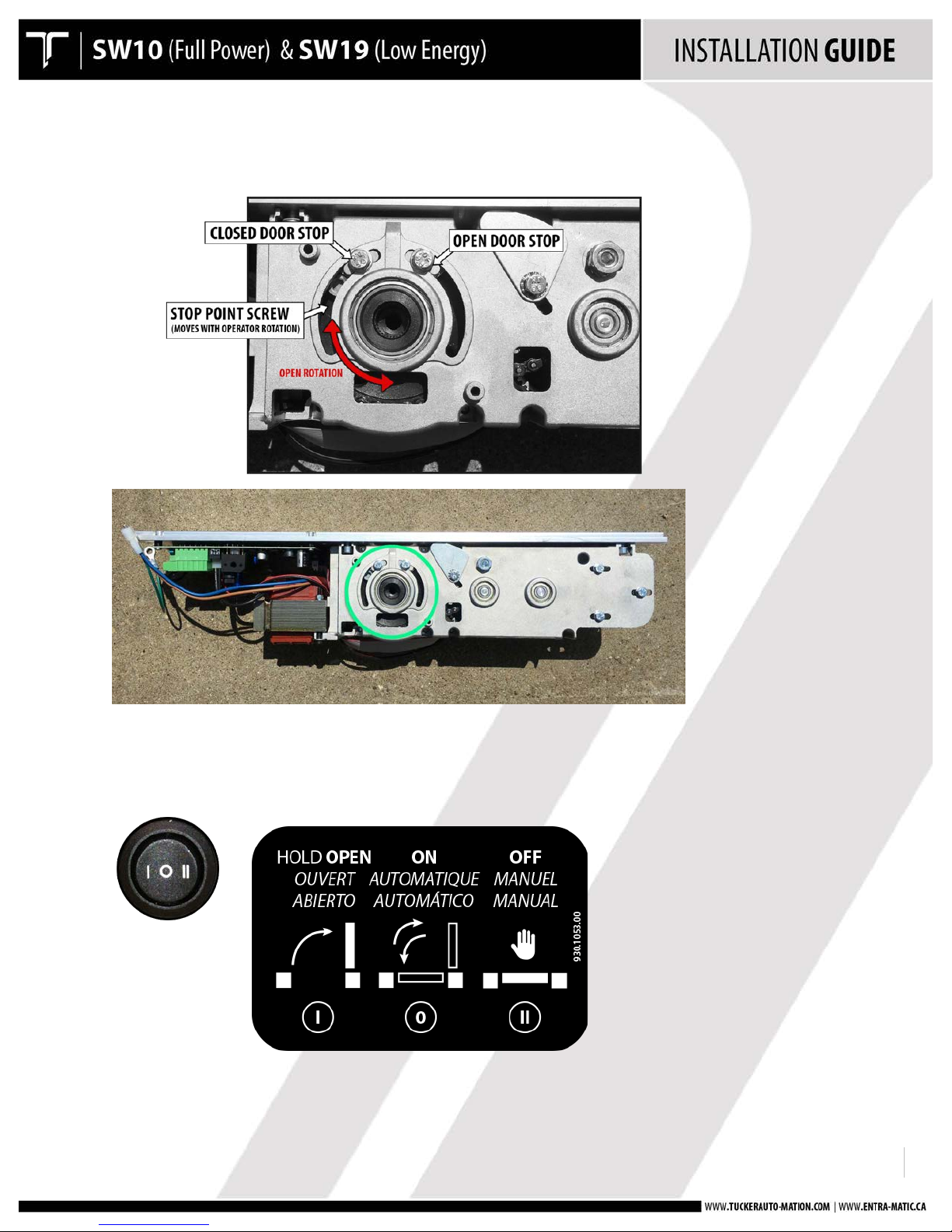

• Ensure the mechanical door stops are at their maximum position as shown.

• Apply 120 VAC Main power to the control

o Place the On-Off-Hold switch to the Hold Open position

Loading...

Loading...