Page 1

920.1037.02

Page 2

CONTENT

IMPORTANT SAFETY INSTRUCTIONS WARNING _________________________________________________________03

ZAP CONTROL SYSTEM _________________________________________________________________________ 04

OPERATOR PACKAGE __________________________________________________________________________05

DIMENSIONS _______________________________________________________________________________06

OPERATOR INSTALLATION _______________________________________________________________________07

STEP 01 - BEFORE INSTALLING THE OPERATOR ___________________________________________________________08

STEP 02 - OPERATOR MOUNTING ___________________________________________________________________09

STEP 03 - GENERAL INSTALLATION __________________________________________________________________10

STEP 04 - FITTING THE MANUAL OVERRIDE LEVER MECHANISM _________________________________________________12

STEP 05 - FITTING THE WALL BUTTON ________________________________________________________________14

STEP 06 - WALL BUTTON - CONNECTION _______________________________________________________________14

STEP 07 - TRANSMITTER KEY ______________________________________________________________________15

STEP 08 - LED LIGHTS __________________________________________________________________________16

STEP 09 - SAFETY SENSORS ______________________________________________________________________16

MAINTENANCE SCHEDULE ______________________________________________________________________17

INSTALLATION GUIDE 920.1037.03 | 02

PATENTED DESIGN

Tucker ZAP PATENT NUMBER / TITLE / REGISTRATION DA TE:

USA 8,182,381 | Drive arrangement | May 22, 2012

USA 8,115,438 | Aperture closure member control arrangements | Feb. 14, 2012

USA 8,033,374 | Drive arrangement | Oct. 11, 2011

USA 7,633,253 | Control and monitoring arrangements for an aperture closure member | Dec. 15, 2009

USA 7,437,971 | Drive arrangement | Oct. 21, 2008

USA 7,333,308 | Control arrangement | Feb. 19, 2008

USA 7,005,884 | Monitoring apparatus for monitoring electrical drive current for an electric motor | Feb. 28, 2006

USA 6,188,198 | Aperture closures | Feb. 13, 2001

Mexico 243645 | Aparato de monitoreo | Feb. 6, 2007

Canada 2445152 | Monitoring apparatus | June 25, 2013

Canada 2440772 | Control arrangement | June 21, 2011

Canada 2560530 | Drive arrangement | May 21, 2013

Canada 2641641 | Aperture closures | April 26, 2011

Canada 2445123 | Drive arrangement | Feb. 16, 2010

Canada 2338191 | Aperture closures | Dec. 30, 2008

Page 3

1. READ AND FOLLOW ALL INSTALLATION GUIDE INSTRUCTIONS.

2. Install only on a properly balanced* garage door. An improperly balanced door has the potential to inflict severe injury.

Have a qualified service person make repairs to cables, spring assemblies and other hardware before installing the opener.

3. Remove all ropes and remove or make inoperative all locks connected to the garage door before installing the opener.

4. Where possible install the door opener 7 feet or more above the floor. Mount the emergency release to 3 feet above

the floor.

5. Do not connect the opener to the source of power until instructed to do so.

6. Locate the control button:

a. Within sight of the door.

b. At a minimum height of 5 feet so small children are not able to reach it.

c. Away from all moving parts of the door.

7. Install the Entrapment Warning Label next to the control button in a prominent location. Install the Emergency Release

Marking. Attach the marking on or next to the emergency release.

8. After installing the opener, the door must reverse when it contacts a 1.5 inch high object (or a 2” by 4” board laid flat) on

the floor.

9. SAVE THESE INSTALLATION GUIDE INSTRUCTIONS

INSTALLATION GUIDE 920.1037.03 | 03

IMPORTANT SAFETY INSTRUCTIONS WARNING TO

REDUCE THE RISK OF SEVERE INJURY OR DEATH:

* WHAT IS A BALANCED DOOR:

1. Start with the door being “DOWN” (Close).

2. Put the door into manual mode.

3. Pull the door manually about 2 to 3 feet off the floor.

4. The door should “STAY” where you leave it at anywhere

from 1 Ft. from the floor or 1 Ft. from top.

Page 4

PRODUCT OVERVIEW

SAFET MEETS SIMPLICITY

A New Residential Jackshaft Operator, The Patented Zap Residential Garage Door Opener Is Your Answer.

§ No limit switches*

§ Quick and simple installation

§ Universal installation positions

§ No adjustments - automatic calibration

§ Quiet plug and play operator - smooth action

§ With a programmable soft start and soft stop

§ SafetySense

TM

- Senses an obstruction on any part of the door - closing or opening

§ Optional LED strip garage illumination - 5 minutes

§ Photo-Eyes included (safety beam sensors)

§ Supplied with two 433 Mhz transmitters,

§ Visor/wall mounted transmitter + hand held

§ Key chain transmitter

§ USA Canada: UL 325. Europe: CE approvals

§ Patents Design granted

* Mechanical stops can be used to define “END OF TRAVEL”

The Zap features SafetySense

TM

technology, which is one of the industry’s most advanced obstruction detection systems available. This technology allows the

Zap to detect an obstruction on any part of the door, whether it’s opening or closing. This means a safe garage door operator not only for you, but for your door

and its surroundings.

§ THE BUTLER is a heavy duty residential model operator with a 3/4HP motor. It is capable of running sectional overhead garage doors up to 280 square feet

in size, 1280 lbs. In balanced weight, with track configurations such as low headroom, standard lift, high lift, and full vertical lift. Like all the Zap model

operators, the motor assembly only contains the motor, two pulleys and one belt, which means no chains or sprockets making all that unnecessary noise in

your garage or shop.

§ The residential model THE BUTLER only requires 4 3/4” of side clearance and 2 3/4” above the center of your spring shaft, so limited space is not an issue.

This model is supplied with two one button transmitters (remotes), safety photo cells/beams, a 6 foot power cord, and preinstalled motor cover. THE

BUTLER also offers a built in auto close timer and an LED strip light to provide light at the door area. An optional wireless keypad is available.

§ Installation of THE BUTLER is as simple as it gets. It only requires one person with

a ladder to install the motor assembly on the spring shaft. Nothing

mounts to the ceiling,door jamb, or header area, so your garage or shop stay sleek looking. All you need is to power it up by plugging it into a nearby outlet

in your garage or shop. Now it’s just a matter of running the door open and close two times with THE BUTLER and it will set it’s fully open and closed

positions for you. You jus tstand back and watch!

INSTALLATION GUIDE 920.1037.03 | 04

ZAP MOTOR-CONTROL SYSTEM

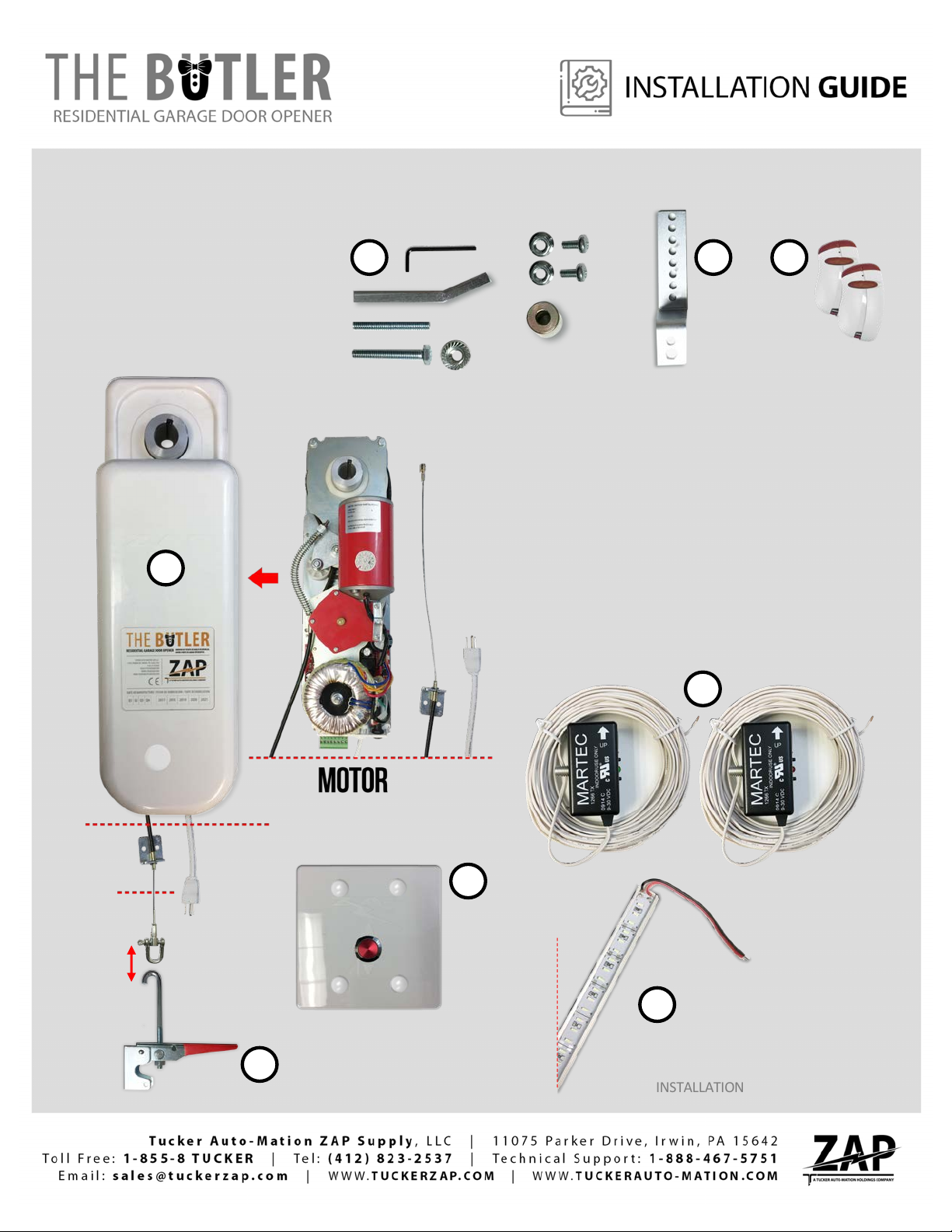

Page 5

INSTALLATION GUIDE 920.1037.03 | 05

OPERATOR PACKAGE

THE BUTLER

115V 50/60 c/s

For Standard Lift Doors Up To 280 Sq. Ft.

YOUR PRIVATE GARAGE DOOR Incorporating

SAFETYSENSE

TM

A. BUTLER OPERATOR

B. TOOL KIT

C. WALL BUTTON

D. HARDWARE

E. OVERRIDE LEVER

(MANUAL RELEASE)

F. 2 TRANSMITTER KEY

(WITH VISOR)

G. PHOTO-EYES

(SAFETY BEAM SENSORS)

H. LED LIGHT STRIP

A

B

G

D F

E

C

H

Page 6

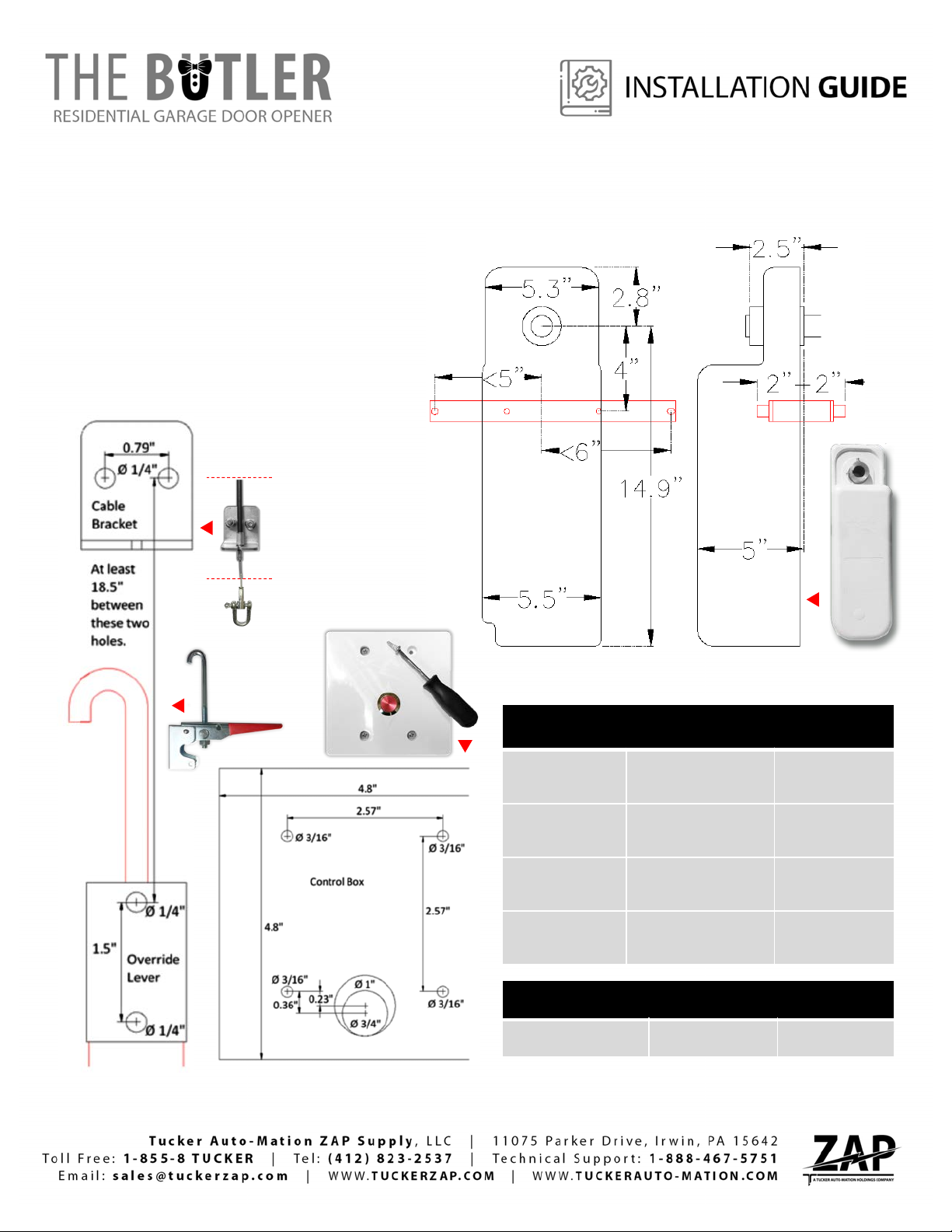

INSTALLATION GUIDE 920.1037.03 | 06

DIMENSIONS

THE BUTLER

115V 50/60 c/s

For Standard Lift Doors Up To 280 Sq. Ft.

YOUR PRIVATE GARAGE DOOR Incorporating

SAFETYSENSE

TM

The Torque Arm fixing range is shown in RED

MAXIMUM DOOR SIZES

Standard lift:

280

sq ft. or 1280 lb.

5.25” drum

diameter

High lift up to 54”:

210

sq ft. or 960 lb.

7.5” drum

diameter

High lift greater

than 54”:

144

sq ft. or 660 lb.

9.38” drum

diameter

Vertical lift:

165

sq ft. or 750 lb.

8.63” drum

diameter

WALL BUTTON

- CONTROL BOX

4.8” H

4.8” W

2.5” D

BUTLER OPERATOR

WALL BUTTON

OVERRIDE

LEVER

Page 7

INSTALLATION GUIDE 920.1037.03 | 07

OPERATOR INSTALLATION

THE BUTLER

115V 50/60 c/s

For Standard Lift Doors Up To 280 Sq. Ft.

YOUR PRIVATE GARAGE DOOR Incorporating

SAFETYSENSE

TM

(Pic 1.1).

PIC 1.1

PIC 1

Installation of THE BUTLER is as simple as it gets. It only requires one person with a ladder to install the motor assembly on the spring shaft.

Nothing mounts to the ceiling, door jamb, or header area, so your garage or shop stay sleek looking. All you need is to power it up by plugging it

into a nearby outlet in your garage or shop. Now it’s just a matter of running the door open and close two times with THE BUTLER and it will set

it’s fully open and closed positions for you. You just stand back and watch!

Page 8

With the door fully open, rotate the door shaft to ensure that the

door will roll forwards under its own weight. (Pic 2). If it won’t then

raise the rear of the track or fit a set of buffer springs. Vertical lift

doors may require a set of buffer springs to provide a physical end

stop.

INSTALLATION GUIDE 920.1037.03 | 08

STEP 01 - BEFORE INSTALLING THE OPERATOR

PIC 2

Next, move the door by hand from

closed to open and back to closed

again. Check that it is either perfectly

balanced or biased slightly open if

perfect balance can’t be achieved. If

the door movement is stiff at any

point, the cause of the problem

should be identified and fixed by a

qualified person. The door must

move smoothly by hand pressure

without significant force or sudden

changes in the effort required to

move the door. (Pic 3).

PIC 3

Page 9

INSTALLATION GUIDE 920.1037.03 | 09

STEP 02 - OPERATOR MOUNTING

/ LEFT MOUNT OR RIGHT MOUMT

- RIGHT OR WRONG LABELS

INTERIOR

GARAGE

DOOR

INTERIOR

GARAGE

DOOR

INTERIOR

GARAGE

DOOR

INTERIOR

GARAGE

DOOR

LEFT MOUNT LEFT MOUNT

RIGHT MOUNT

RIGHT MOUNT

HANDED GARAGE DOOR OPERATOR. IT IS CRITICAL TO RESPECT THE

LABELING. INSTALL TO THE LEFT OR TO THE RIGHT SIDE OF THE DOOR BY

FOLLOWING THE LABEL INDICATION!

Page 10

INSTALLATION GUIDE 920.1037.03 | 10

STEP 03 - GENERAL INSTALLATION

Slide the Control Head onto the jackshaft and select a hole on the

bearing plate or door frame for the torque arm. ((A)-Pic 4.1). If no

hole is available then drill a 1/4” hole in a suitable location. Bolt the

torque arm to the bearing plate or door frame and secure the other

end to the torque arm fixing the hole on the Control Head, use the

supplied spacer if the offset is not enough to clear the drum. (Pic

4.1).

A

PIC 4

THE BUTLER kit includes an anti-rotation torque arm; it is possible to mount the Control Head inboard or outboard

the bearing plates and horizontally or vertically so long as the torque arm is at right angles to the operator. This

stops the operator from moving side to side when the door is moving. ((B)-Pic 5.1).

A

B

ANTI-ROTATION TORQUE ARM

PIC 4.1

90°

B

PIC 5.1

PIC 5

B

+ KIT TO ATTACH TO DOOR TRACK

B

Page 11

INSTALLATION GUIDE 920.1037.03 | 11

C

Align the Control Head driven pulley’s keyway with

the door shaft keyway and fit the supplied key.

Ensure that the Allen screws are firmly tight and

then tighten the lock nuts. ((C)-Pic 6).

PIC 6

If there is no keyway, the hollow door shaft should be drilled. Tighten

one Allen screw to mark the shaft through the screw hole, remove the

Control Head and drill through one wall of the shaft with a 1/4” drill bit.

Replace the keyway Allen screw with the long Allen screw supplied. Refit

the Control Head and re-tighten the torque arm bolts. Align the long

screw with the drilled hole in the shaft and tighten it against the inside

wall of the shaft. Tighten the other Allen screw and both of the lock

nuts. (Pic 7).

C

PIC 7

OPTIONAL – SHAFT EXTENDER IF NEEDED!

SHAFT EXTENDER:

In case the shaft on either side of the garage door does not show at least

3”, you will need a shaft extender to introduce inside hollow metal tube

(Pic 7.1).

TYPES:

a) 1” Hollow shaft extender

b) 1

1/4

” Hollow shaft extender

PIC 7.1

INTERIOR

GARAGE

DOOR

a b

a

Page 12

INSTALLATION GUIDE 920.1037.03 | 12

STEP 04 - FITTING THE MANUAL OVERRIDE LEVER MECHANISM

Drill two 1/4” holes in the door track or frame in a position at least

2” higher than the fully extended position of the Outer Cable

Bracket to allow flexibility of movement for the Bowden cable. Use

the supplied M5 screws and flange nuts to secure the Outer Cable

Bracket to the door track or frame. (Pic 8).

Hang the Manual Override Lever hook on the end of the inner cable

with the lever in the upright position. Mark the mounting hole

positions for the lever on the door track or frame – the supplied

chain may be needed to position the lever withi n 6 feet of the floor.

Drill two 1/4” holes and secure the lever using the M5 screws and

flange nuts supplied. (Pic 9).

PIC 9

PIC 8

M5 screws

M5 screws

MOUNTING HOLE

MOUNTING HOLE

OVERRIDE

LEVER

Page 13

INSTALLATION GUIDE 920.1037.03 | 13

Place the hook in the cable D-shackle or a convenient link of the chain and ensure that the lever

is slightly above horizontal when all of the tension has been taken up. (Pic 10).

It is important that sufficient tension is achieved to compress the override release spring and

ensure that the drive belt does not slip on the motor pulley. Screw the hook in or out so that the

lever requires reasonable hand pressure to lock it into place. (Pic 11). This procedure must be

repeated once the calibration has been completed and on subsequent service visits to allow for

the bedding inof the V-belt.

PIC 11

PIC 10

MOUNTING HOLE

OFF = MANUAL

SIDE VIEW

MOUNTING HOLE

ON = AUTOMATIC

SIDE VIEW

FRONT VIEW

ON = AUTOMATIC

OFF = MANUAL

Page 14

INSTALLATION GUIDE 920.1037.03 | 14

STEP 05 - FITTING THE WALL BUTTON BOX

Mount the box on the wall using suitable fasteners no larger than 3/16” diameter. (Pic 12).

Connect the battery. (Pic 12.1).

AFTER BUTLER OPERATOR AND WALL BUTTON BOX

INSTALLED. HOLD THE WALL BUTTON AND THE RECEIVER

BUTTON TOGETHER FOR 5 SECONDS UNTIL BEEP !

BEEP!

STEP 06 - WALL BUTTON - CONNECTION

HOLD THE WALL BUTTON

HOLD THE RECEIVER BUTTON

PIC 12.1

PIC 12

Page 15

INSTALLATION GUIDE 920.1037.03 | 15

STEP 07 – TRANSMITTER KEY CONNECTION

AFTER BUTLER OPERATOR AND WALL BUTTON BOX

INSTALLED. HOLD THE TRANSMITTER KEY AND THE

RECEIVER BUTTON TOGETHER FOR 5 SECONDS UNTIL

BEEP !

BEEP!

HOLD THE TRANSMITTER

KEY BUTTON

HOLD THE RECEIVER BUTTON

Page 16

INSTALLATION GUIDE 920.1037.03 | 16

STEP 08 – LED LIGHTS INSTALLATION & CONNECTION

INSTALLED TOP RAIL

INSTALLED

FRONT RAIL

OR

36 Inches Long

D

C C

E

LED LIGHTS

CONNECTION:

D. LED LIGHT (+) (RED WIRE)

E. LED LIGHT (-) (BLACK WIRE)

(Stay “ON” for 5 min after activation).

STEP 09 - SAFETY SENSORS INSTALLATION & CONNECTION

THE BUTLER

SAFETY SENSORS

CONNECTION:

A. SAFETY SENSOR 1

A. SAFETY SENSOR 1

B. SAFETY SENSOR 2

B. SAFETY SENSOR 2

A A

B B

D E

WIRE PUSH PLATE IF NEEDED!

A A B B

A A B B

Page 17

INSTALLATION GUIDE 920.1037.03 | 17

Monthly: check that the closing door reverses when the safety sensor

beam is interrupted . Monthly: ensure that the garage door reverses on

contact with a 1.5 inch high object (or a 2” by 4” board laid flat) on the

floor.

During winter: if the door reversesoff a build up of snow or ice then the

doorway should enable the door to close fully.

Every 6 months or 2500 cycles whichever is sooner:

1. Release the Manual Override Lever and move the door manually to

assess the balance of the door and to check if it is binding. (Pic 13).

2. Check the adjustment of the Manual Override Lever tension. The lever

should be horizontal when the release spring is compres s e dand the drive

belt slack is taken up. If the lever tension requires increasing then turn the

lever hook screw clockwise to increase the tension. Do not over-tension

the Manual Override Lever. (Pic 14).

3. Check that the door opens and closes fully.

The motor operator does not require additional lubrication. Do not grease

the door tracks. If there is any doubt about the correct operation of the

door then contact your garage door/opener dealer.

PIC 13

MAINTENANCE SCHEDULE

PIC 14

Loading...

Loading...