Page 1

!

920.1020.15

1

!

!

!

!

!

!

!

!

!

!

!

TUCKER AUTO-MATION

SW10 (Full Power) & SW19 (Low Energy)

INSTALLATION GUIDE

Surface Mounted Applications

!

!

Page 2

!

920.1020.15

2

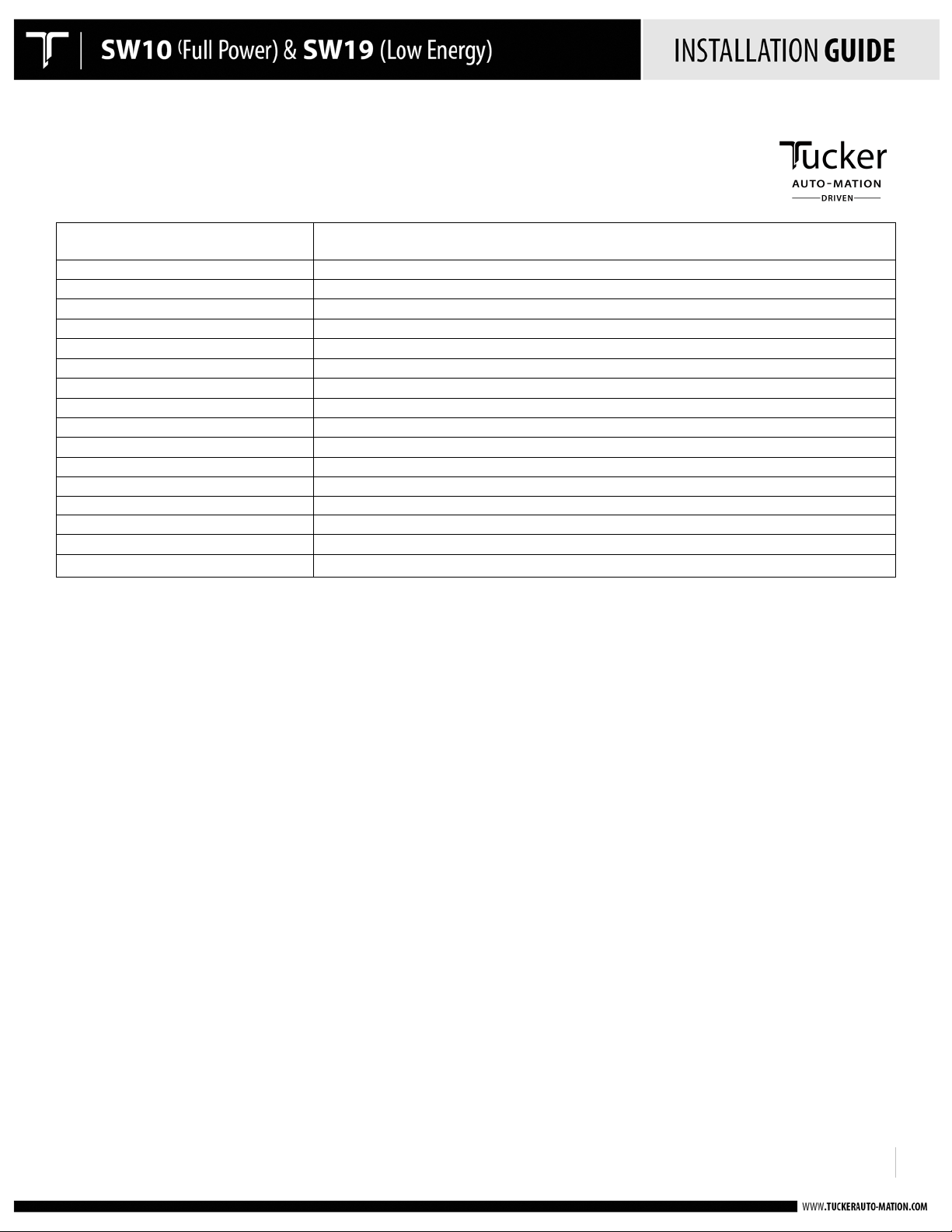

PAGE

CONTENTS

3

Important Notices

4

Product Description & Specifications

5-10

Header Installation

11-14

Mounting The Operator & Control Assembly

15-17

Push Arm Installation

17-18

Pull Arm Installation 19

120 Volt AC Connection

20

Power On & Indications

21-24

Set-Up Procedures

25

Wiring Connections

26

Adjusting The Mechanical Door Stop

27

Troubleshooting

28

Job Documentation & Closeout / Accessories / Company Contact

29-31

Appendix - Wiring Diagrams

32-33

Appendix - Fire Rated Door Application

25 (KP EVO 1-25)

Appendix - Tap Programming Device - KP evo

!

TABLE OF CONTENT

S:

!

!

Page 3

!

920.1020.15

3

!

IMPORTANT

READ THIS SECTION BEFORE PROCEEDING WITH INSTALLATION

Tucker Auto-Mation, LLC (hereafter referred to as “Tucker”) recommends that all of its automated

pedestrian door products be installed by a trained automatic door technician and that the resulting

performance of the product be in full compliance with the most current version of the American National

Standards Institute document A156.10 or A156.19 (whichever is applicable) as well as any applicable building

codes and/or fire codes. Tucker further recommends that a full inspection of the operating system be

performed in accordance with the guidelines of the American Association of Automatic Door manufacturers

(AAADM). This inspection must be performed by a certified AAADM trained inspector. Tucker recommends

this documented inspection be performed upon completion of the installation as well as, following the

completion of every service call thereafter. If service is not performed within one year of the previous service

action, a routine AAADM inspection should be performed and documented. Under no circumstance should

the product operate for more than one year without an AAADM inspection. Tucker does NOT recommend

installation or service, on any of their automated pedestrian door products, by any individual who is not

certified as an AAADM inspector.

Following the installation or service of any Tucker automated pedestrian door product, if it is deemed unsafe,

or is operating in an unsatisfactory manner according to national performance standards or recommended

performance guidelines as defined by Tucker, repairs should be made immediately. If an immediate repair

cannot be made, the product should be disabled, and appropriate measures should be taken to secure the

door in a safe position or to enable the door to safely be used manually. During this situation, every effort

should be made to notify the owner (or person responsible) of the condition and to advise on corrective

actions that must be taken to return the product to safe operation.

LOW ENERGY APPLICATION NOTE

When using the SW10/19 for a low energy application, Tucker Auto-Mation recommends the use of a doormounted presence sensor on the approach side of the door to be used as a secondary activation device. This

type of sensor can be installed at time of installation or can also be retrofitted. This device serves to re-activate

the door to the open position should a person enter into the closing path at the approach side of the door, as

it is closing. Once the door is fully closed, a "knowing act" device must then be used for initial activation.

Tucker Auto-Mation considers this device to be essential in reducing the possibility of doors "timing out" and

closing before all pedestrians have passed though the doorway. Check with your Tucker sales representative

to find out about special incentives that may be available for the Torpedo 1 door-mounted presence sensor.

!

!

!

Page 4

!

920.1020.15

4

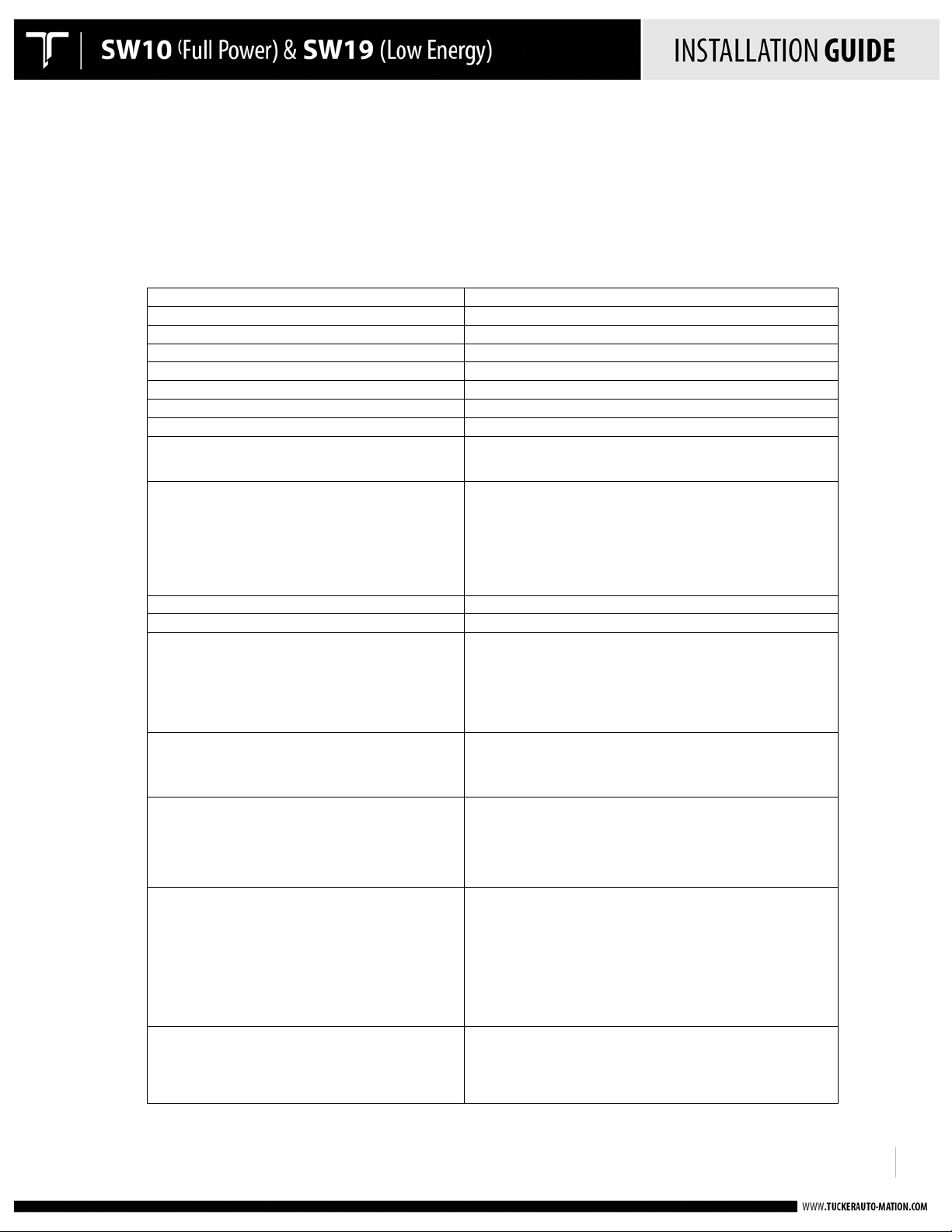

Power Supply

115

VAC (+6%, -10%)

60Hz

Power Consumpti

on

100W

C

urrent Consumpti

on

1A

Mot

or

24

VDC

Permanent Magnet

With Belt Driven Encoder

Header Dimensions

20 3/4” x 4 1/8” x 4 3/4”

(l

x w x d)

Fused Protection

3.5A Fuse (F1 locate

d on I/O Board)

Weight

22

lbs

Per Operator Assembly

Ambient Operating Temperature

-4 to 131º F

Ingress Protection

IP23 (protection from spray water up to 60º from th

e

vertical – ie. Rainst

orm)

Maximum

Door Weight

PUSH ARM

PULL ARM

36” Door: 438

lbs

342 lbs

42” Door: 328

lbs

256 lbs

44” Door: 299

lbs

234 lbs

48” Door: 254

lbs

198 lbs

24

VDC Accessories Power Supply

24

VDC

/

I A. Max

24

VDC Electric Lock

Power Supply

24

VDC

/

I A. Max

Adjustable Speeds & Timers

Opening Speed

Closing Speed

Hold

Open Tim

e

Closing Speed

with power off

Standa

rd Select

or Switch Functions

Automati

c

Hold O

pen

Manual

(Off)

Standa

rd Control Outputs

Malfunction

Alarm Signal

Electric Lock

Relay

24

VDC Accessories Power Supply

Door

Status

Standa

rd Control Inputs

Interior Activati

on

Exterior Activati

on

Emergency Shutdow

n

Alarm Output

“Stop” Safety Device (door-mounted)

Safety Device Inpu

t

Secondary Activation

Quick Disconnects

TAP-Controller (optional)

!

PRODUCT DESCRIPTION & SPECIFICATIONS

The Tucker Auto-Mation SW10 & drives. The unique design offers; non-including sensors, push plates, fire

alarm, and electric locks. Troubleshooting when needed. Both units can be configured concealed application.

The Tucker Advanced Programmer (TAP) is provided as an option to access additional programming features.

!

!

!

!

!

!

Page 5

!

920.1020.15

5

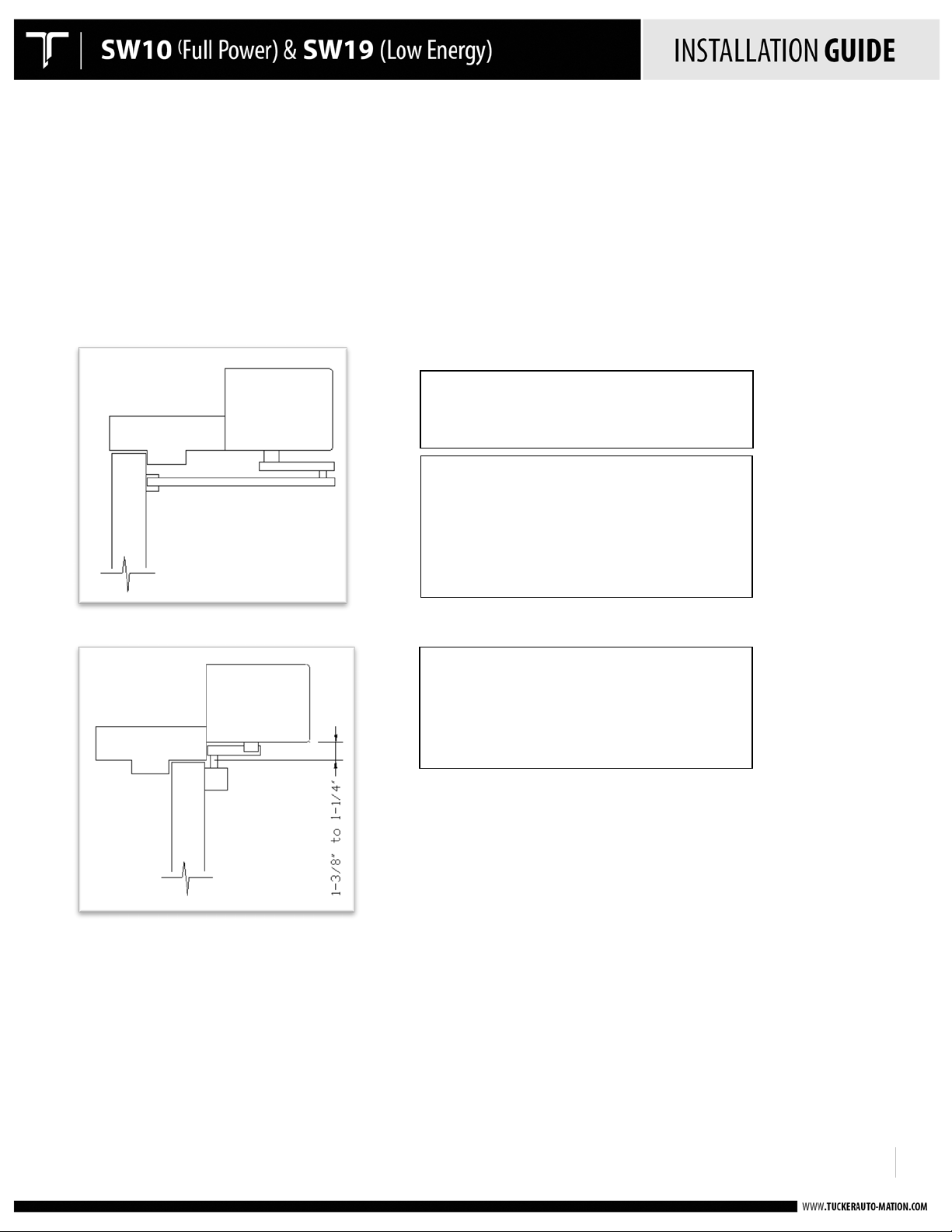

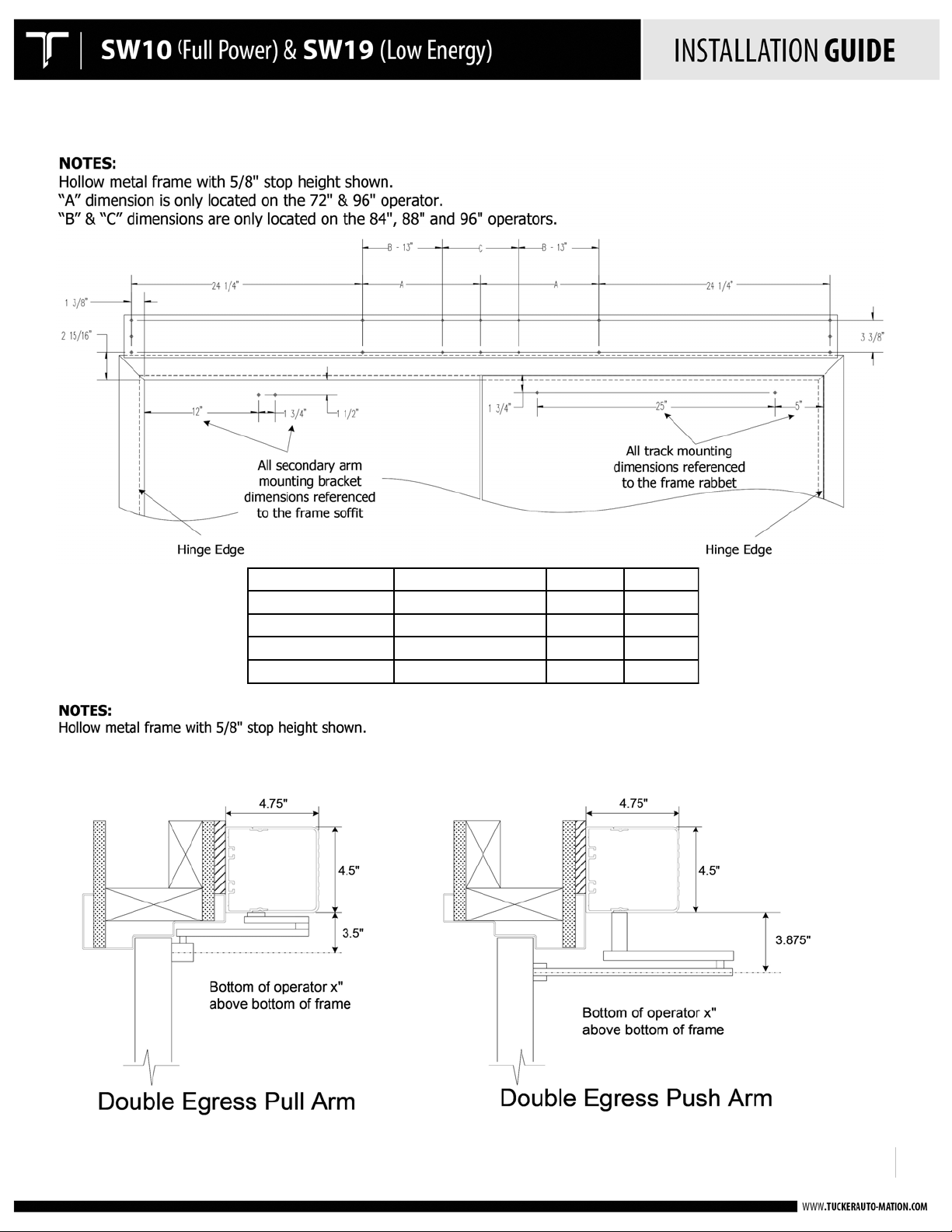

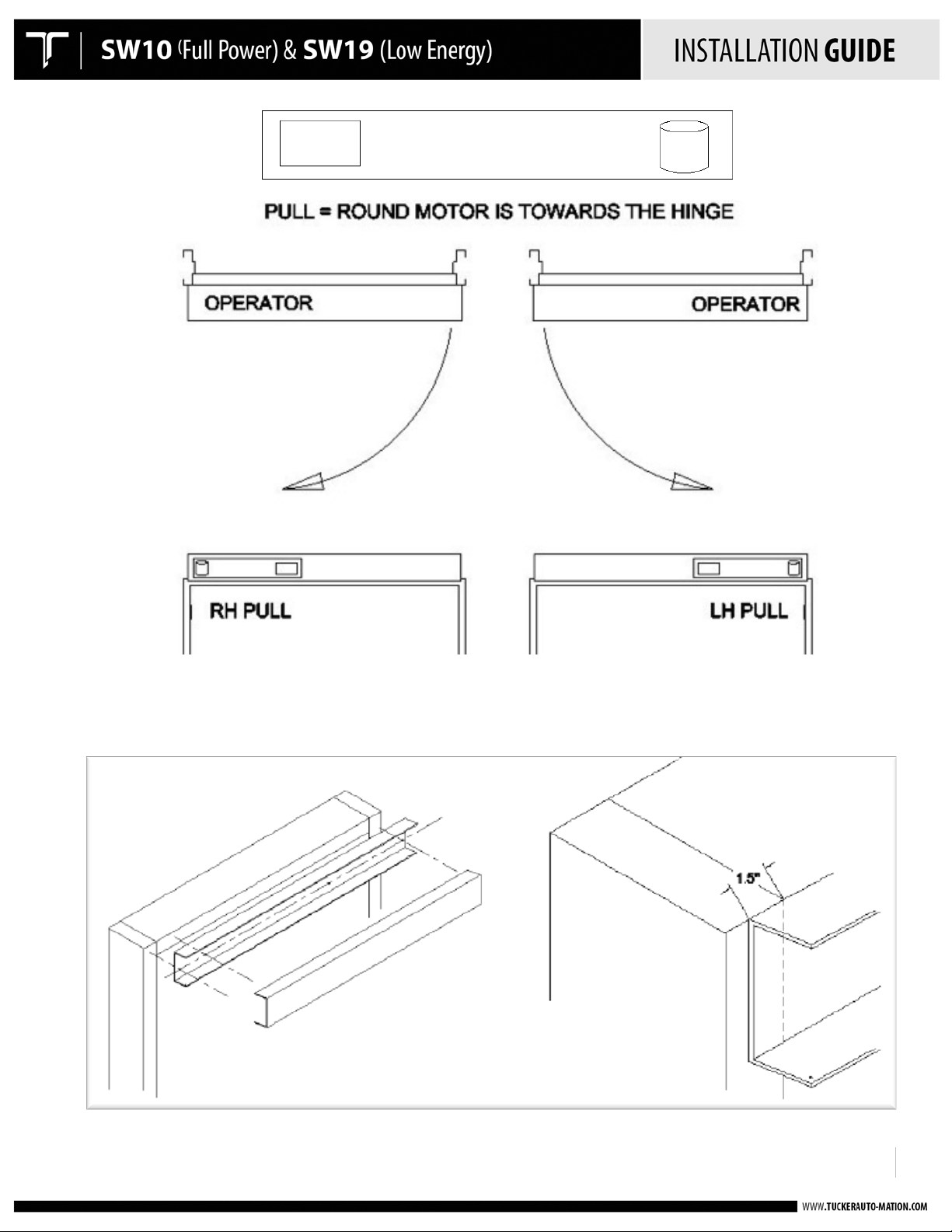

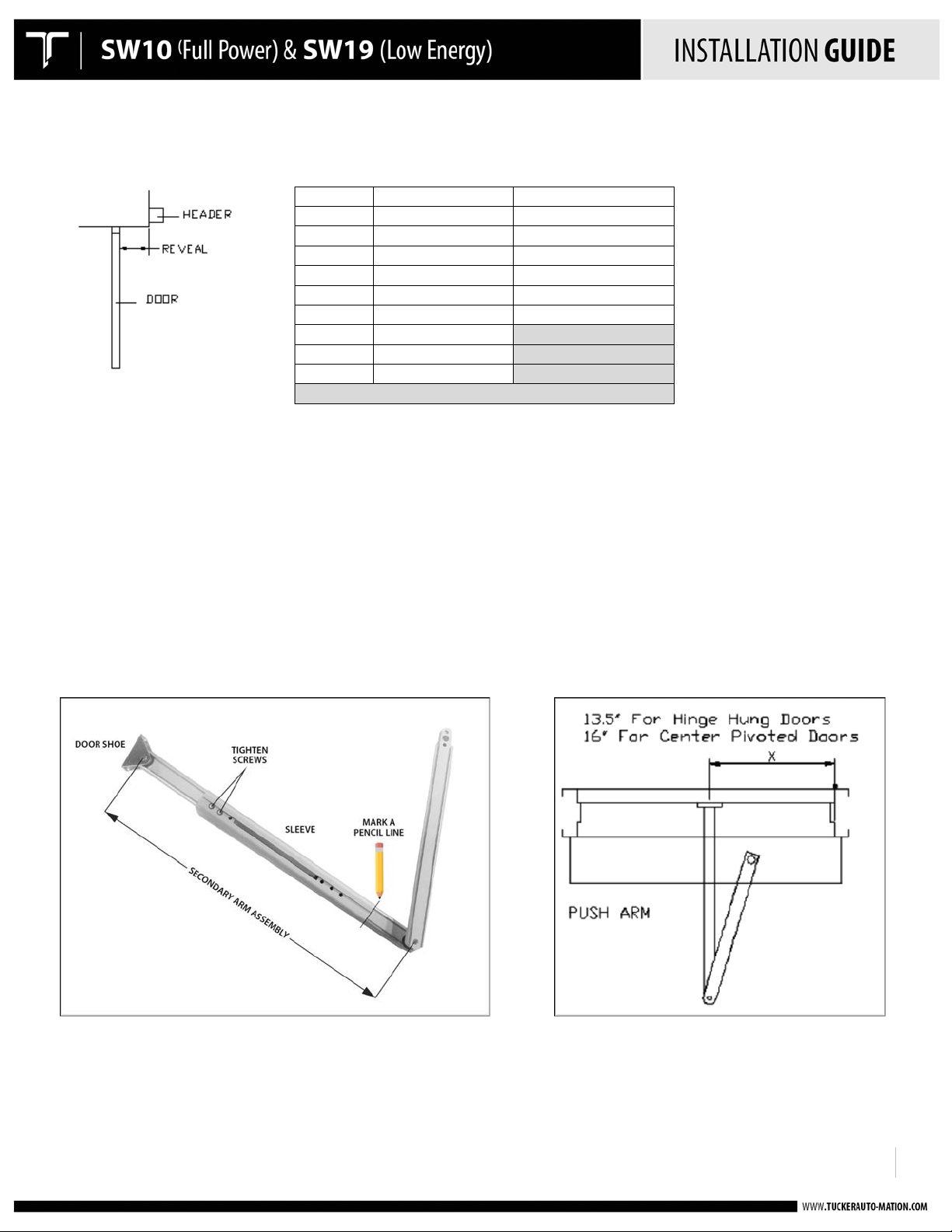

PUSH ARM APPLICATIONS:

Bottom of header is flush with bottom of top

frame.

PULL ARM APPLICATION: STANDARD PULL ARM

& DOUBLE EGRESS APPLICATIONS

Double egress applications require the use of an

80mm spindle adaptor for the side using the

push arm.

NOTE:

Tucker Auto-Mation is now using a 35mm

spindle adaptor for all standard push arm

applications – this requires that the header

assembly be mounted as shown at left, flush

with bottom of top frame.

!

!

!

HEADER INSTALLATION

Mount the pre-drilled back-plate to the top door frame using appropriate fasteners for the type of

frame. (Refer to Door Prep drawings on pgs. 6-10.)

• Push side mounting: Pre-drilled back-plate is flush with bottom of door frame.

• Pull side mounting: Pre-drilled back-plate is mounted 1.5” up from bottom door frame.

• Back-plate should overlap each jamb tube by 1.5”.

• Refer to the APPENDIX for fire rated door applications.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Page 6

!

920.1020.15

6

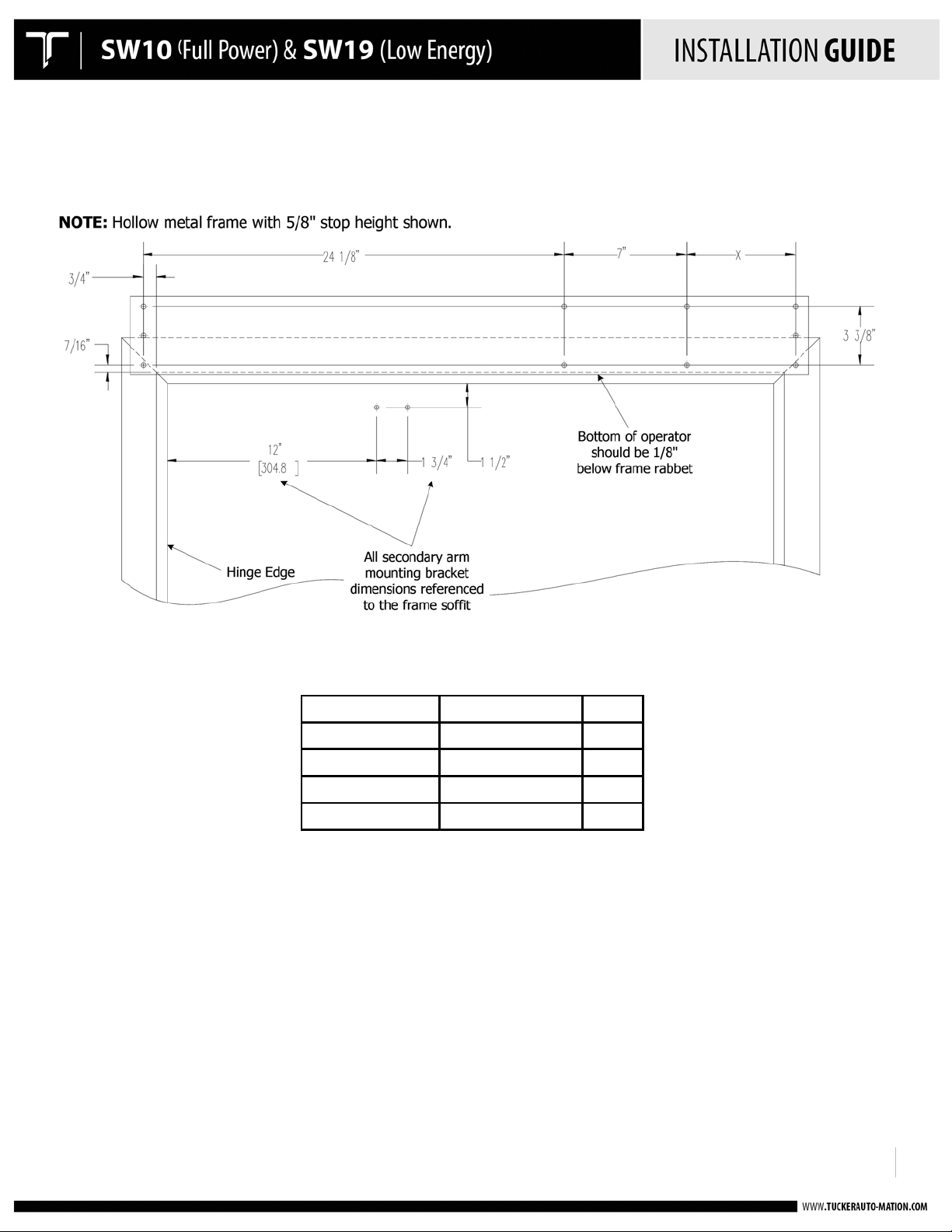

Opening Width

Operator Width

X Dim

36"

39"

6.25"

42"

45"

12.25" 44"

47"

14.25"

48"

51"

18.25"

!

Door Prep drawings:

PUSH SIDE INSTALLATION SINGLE

!

!

Page 7

!

920.1020.15

7

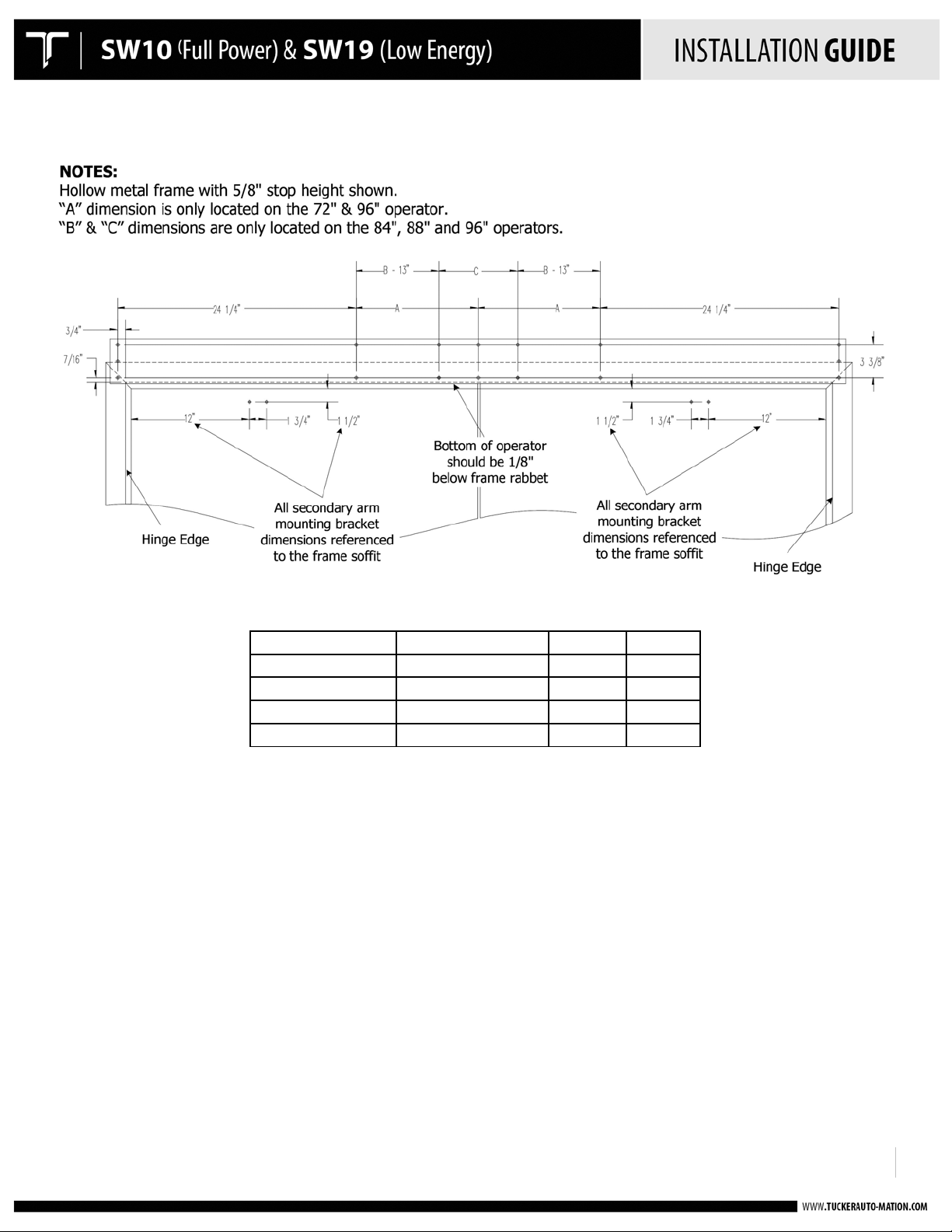

Opening Width

Operator Width

A Dim

C Dim

72" 75"

12-7/16"

N/A

84" 87"

N/A

10-7/8"

88" 91"

N/A

14-7/8"

96" 99"

24-7/16"

22-7/8"

!

PUSH SIDE INSTALLATION DOUBLE

!

!

Page 8

!

920.1020.15

8

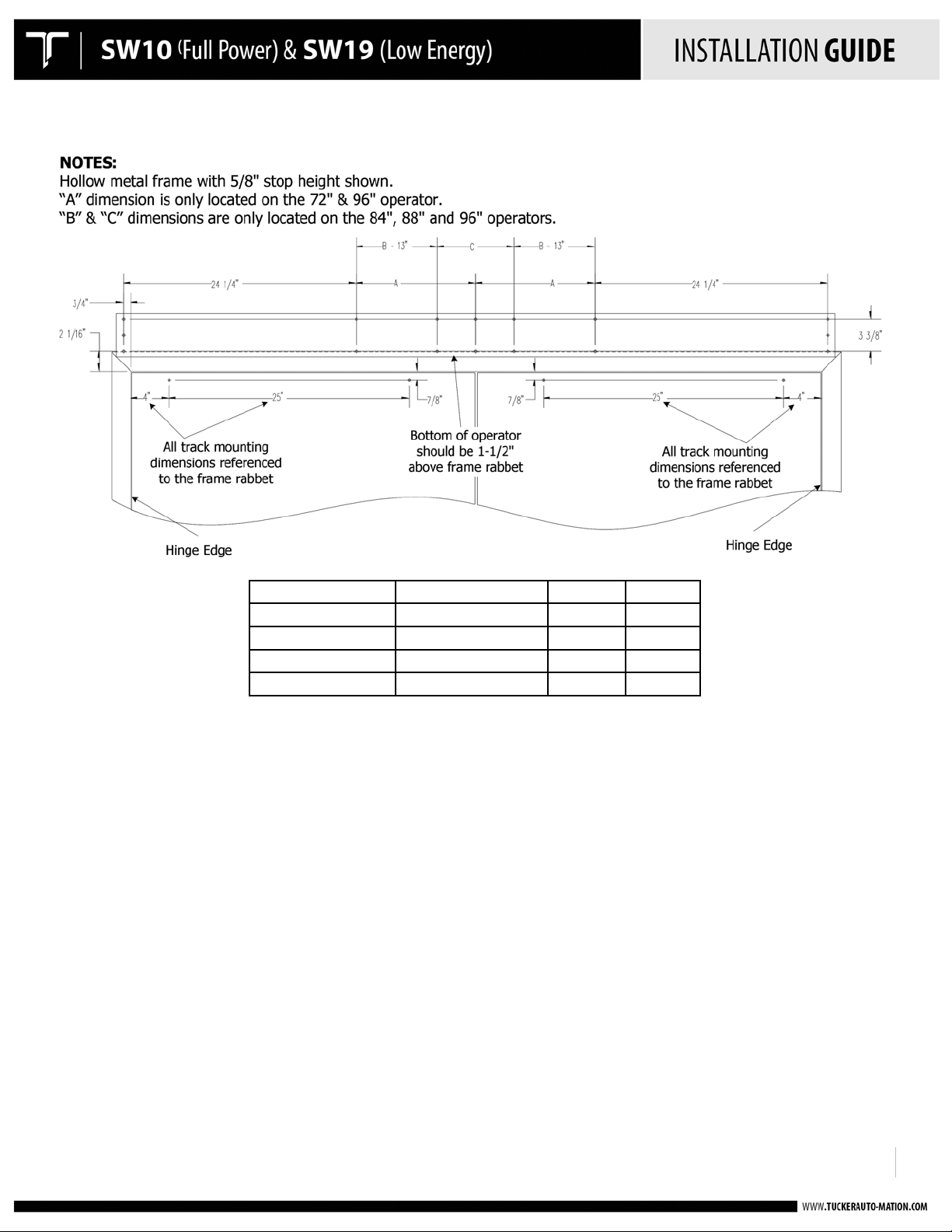

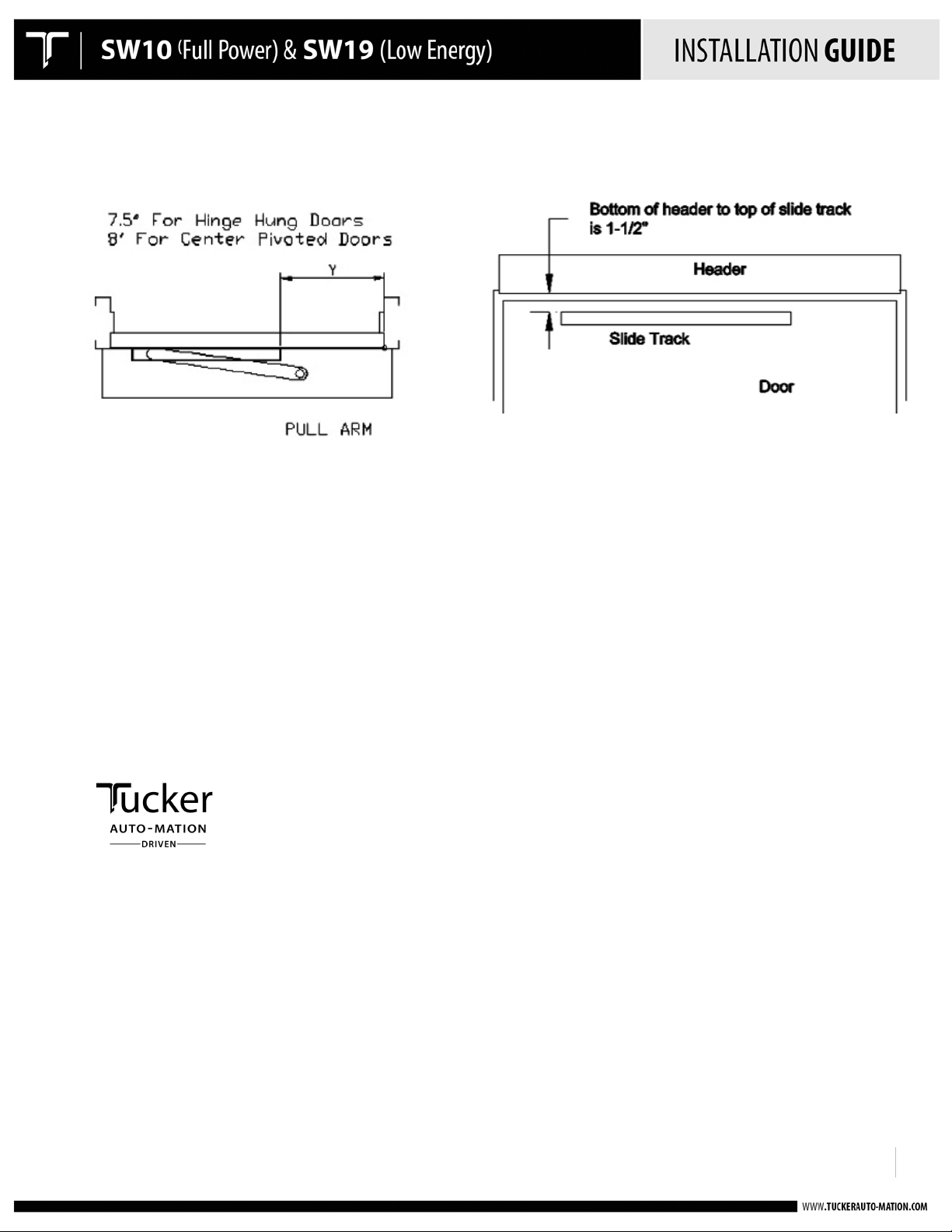

Opening Width

Operator Width

Y Dim 36"

39"

6.25"

42"

45"

12.25" 44"

47"

14.25" 48"

51"

18.25"

!

PULL SIDE INSTALLATION SINGLE

!

!

Page 9

!

920.1020.15

9

Opening Width

Operator Width

A Dim

C Dim 72" 75"

12-7/16"

N/A

84" 87"

N/A

10-7/8"

88" 91"

N/A

14-7/8"

96" 99"

24-7/16"

22-7/8"

!

PULL SIDE INSTALLATION DOUBLE

!

!

Page 10

!

920.1020.15

10

Opening Width

Operator Width

A Dim

C Dim 72" 75"

12-7/16"

N/A

84" 87"

N/A

10-7/8" 88" 91"

N/A

14-7/8"

96" 99"

24-7/16"

22-7/8"

!

DOUBLE EGRESS INSTALLATION

!

!

Page 11

!

920.1020.15

11

!

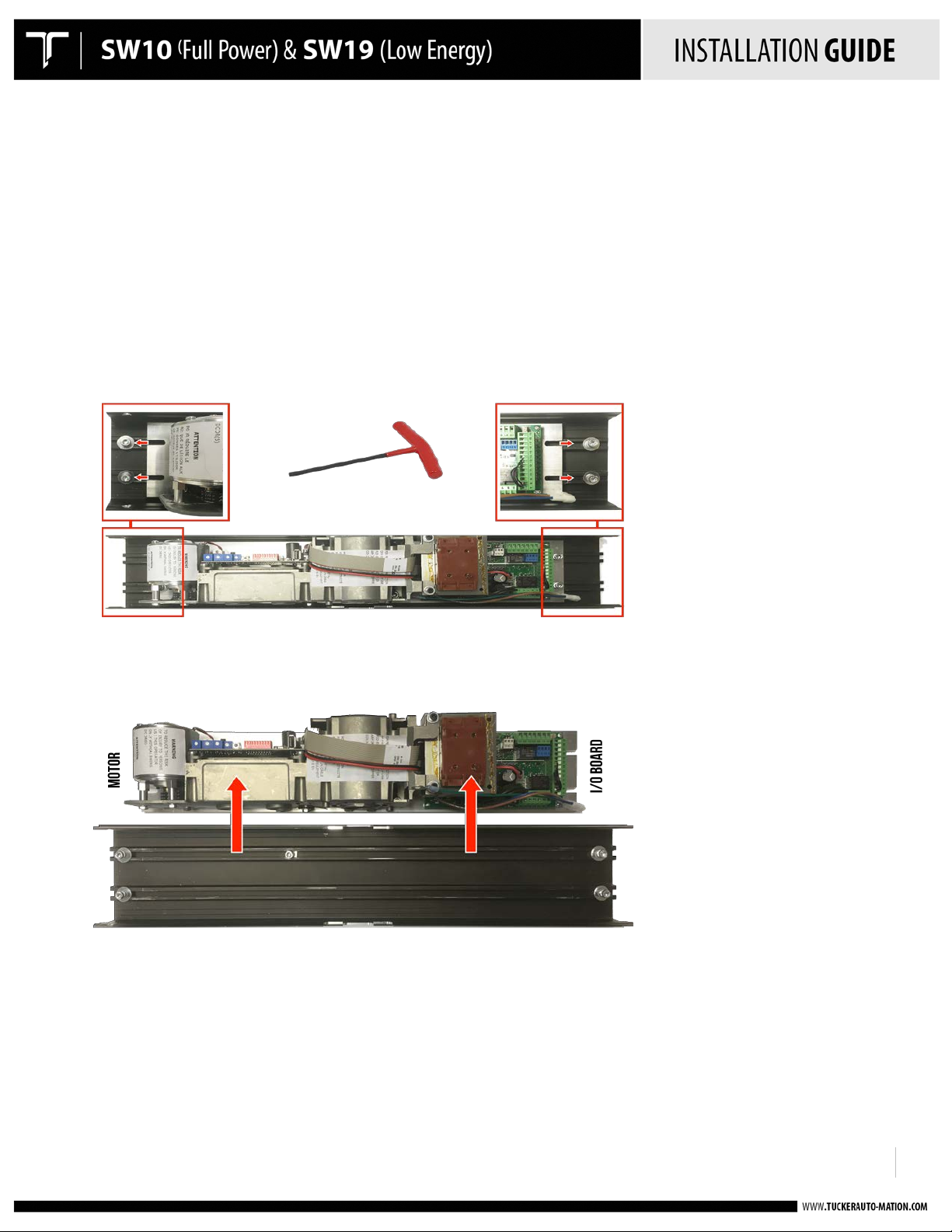

MOUNT THE OPERATOR(S)!!

!

• Operator is non-handed – same operator for all hands of doors

• Handing is determined by how the operator is mounted inside the header

• The operator is mounted to a short aluminum “drive” plate that is held into the header by 5 mounting screws.

Four (4) of the screws secure the drive plate. One (1) screw is used to locate the drive plate using a ‘keyhole’

configuration. The keyhole allows for easy removal of the drive plate without the need to loosen to screw.

Removing the four (4) screws allows the drive plate & operator to be removed from the header and rotated 180

degrees to change from a push to a pull or vice versa.

!

Drive Plate mounted in standard position using four (4) screws to secure. Loosen the screws using an 5 mm allen

wrench and slide each one off of the drive plate.

!

Drive plate removed by shifting to the left and lifting the drive plate off of the locating screw.

!

!

!

!

!

!

!

!

!

Page 12

!

920.1020.15

12

!

!

!

!

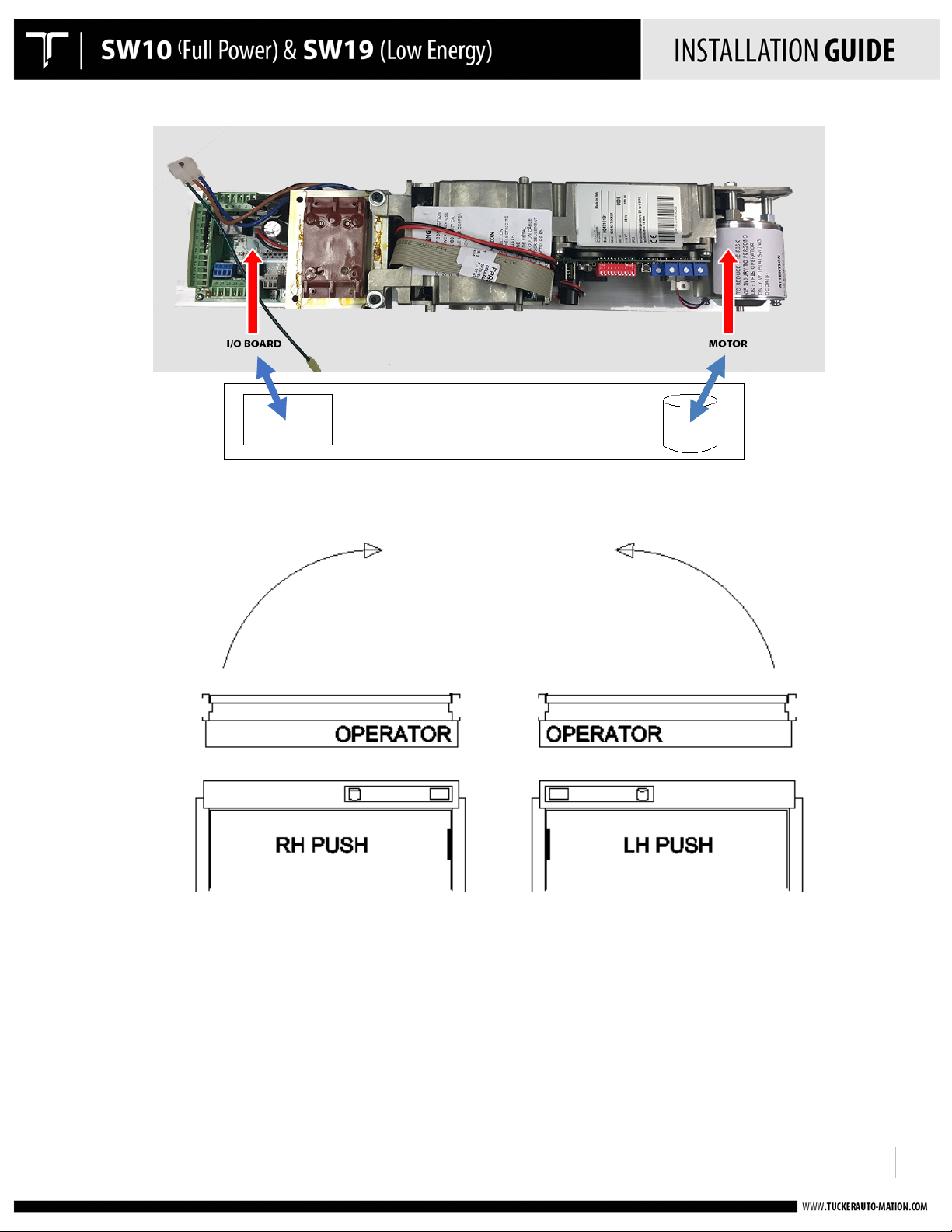

Drive plate rotated 180 degrees to reverse the operator handing. Re-align locating screw to key slot, insert drive plate

and shift to the right into position. Re-position the four (4) screws to secure the drive plate.

!

Key slot configuration & location screw mounted in backplate

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Page 13

!

920.1020.15

13

PUSH = I/O BOARD IS TOWARDS THE HINGE JAMB

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Page 14

!

920.1020.15

14

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

• Mount the header to the doorframe with the screws provided.

• The header will overlap the doorframe by 1-1/2" at each side.!

!

!

!

!

Page 15

!

920.1020.15

15

!

!

!

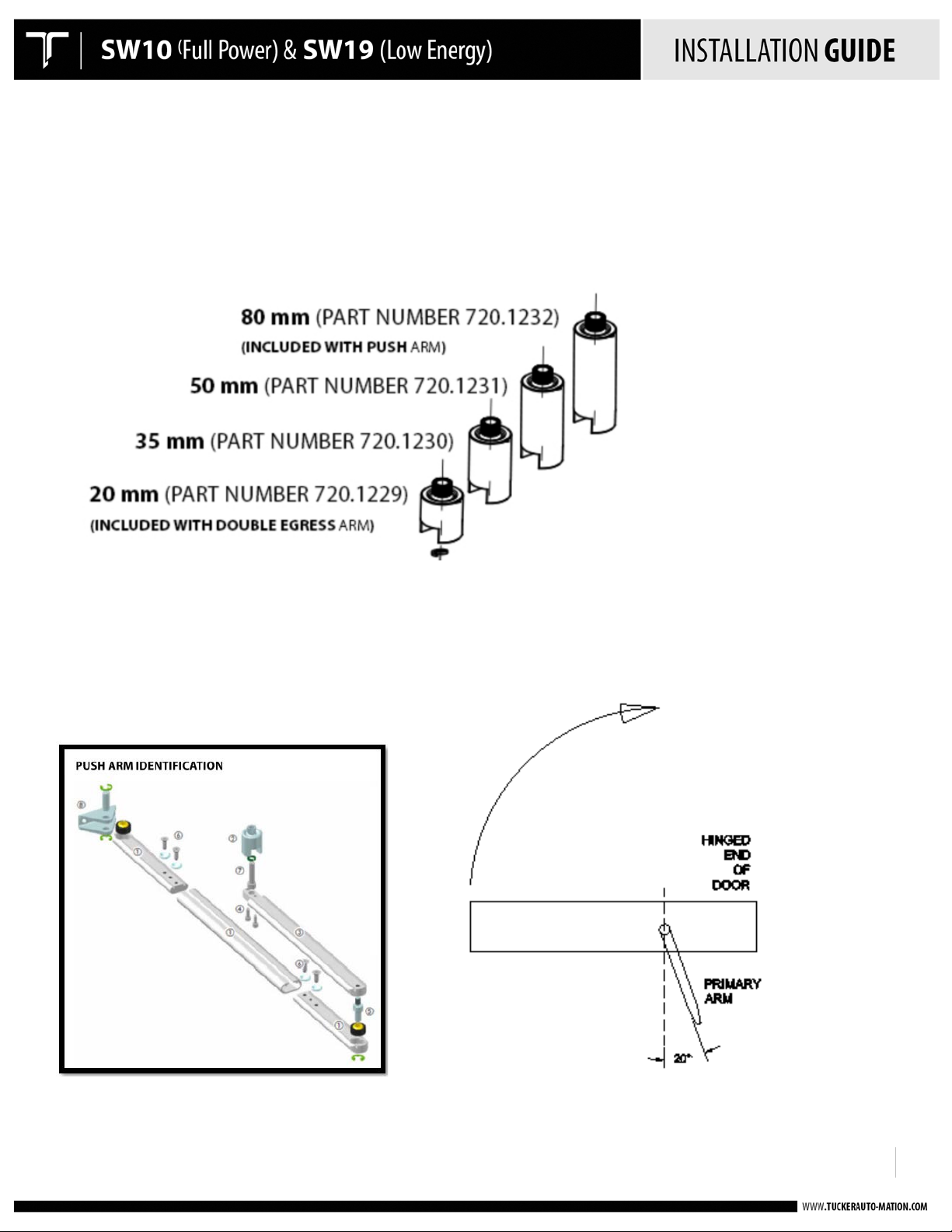

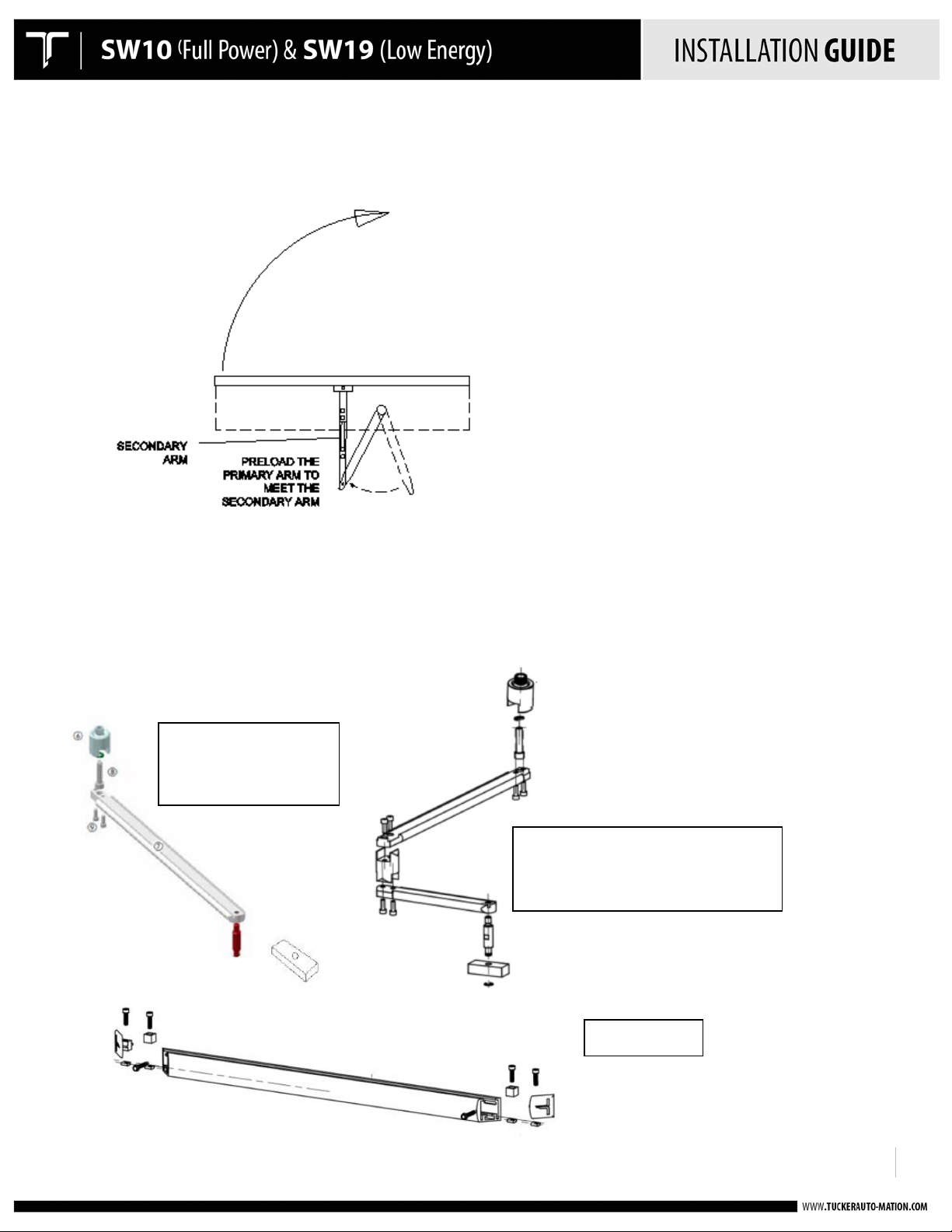

PUSH ARM INSTALLATION

• All push arms come standard with 35mm spindle. 50mm and 80mm available as an accessory.

• Attach the primary door arm approx. 20 degrees past perpendicular and towards the closing direction as shown.

If more spring tension is desired, simply increase the mounting angle to greater than 20 degrees so it results in

increased preload.

!

!

Page 16

!

920.1020.15

16

Reveal

Hinge Hung X Dim.

Center Pivot X Dim.

0

" 13

" 16

"

1

" 14

" 17

"

2

" 15

" 18

"

3

" 16

" 19

"

4

" 17

" 20

"

5

" 18

" 21

"

6

" 19

"

7

" 20

"

8

" 21

"

DEEPER REVEAL

REQUIRES ARM EXTENSION

!

• Adjust the secondary telescopic arm to the prescribed length according to chart:

Before installing

•

insert the secondary and primary arm into the sleeve as it will

Slide

o

o

o

o Mark a

• Attach the secondary arm mounting bracket to the door. The centerline of the bracket should be at 13-1/2” in

from the inside face of the hinge jamb when using butt hinges on the door, and 16” when using a center pivoted

door.

the short arms within the sleeve to obtain the prescribed

Tighten the screws on the short arm that

Double-check

r shoe and the center of the hole

doo

imary

pr

any porti

the

pencil line

arm.

This will

on of the door arm assembly, it is easiest to

be when installed on the door:

is

connected to the door shoe.

"X" dimension of the arm - this is

at the pivot

at the edge of the sleeve where it overlaps

make it easie

r when positioning

the distance between the center of the hole

point of the primary arm (as shown).

the primary arm for

lay

the arm out on a flat

"X" dimension.

the short arm that

final installation.

is

connected to the

surface and

at the

!

!

Page 17

!

920.1020.15

17

Standard Pull Arm

For 0-degree reveal

Use 20mm spindle

Offset (double egress) Pull Arm

For reveal greater than 0 degrees

Use 20mm Spindle

Slide Track

!

• Rotate the primary arm in the opening direction as to reach the pivot point of the secondary. Attach the arms

together with the hardware provided.

PULL ARM INSTALLATION

!

!

Page 18

!

920.1020.15

18

!

• Install the slide track assembly at the pull side of the door at the proper location from the hinge end of the door

as shown below:

• To install the pull arm, the operator must be powered to the full open position, as it is not possible to install the

arm in the closed position as to allow proper preload.

• Power the door to the open position through the use of the hold-open switch on the side of the header. It may

be necessary to first execute a “setup” on the operator prior to doing this. Refer to the applicable section within

this User’s Guide for proper instruction.

• Once the operator is rotated to the full open position, manually move the door to the desired full open position

and insert the slide track guide block into the track. When completed, the end caps to the track can be installed.

!

!

Page 19

!

920.1020.15

19

BLACK: 115 VAC Power

WHITE: Neutral

GREEN: Ground

WARNING:

Ensure all incoming electrical power is shut off before proceeding with any wiring to

SW10/19. Use only with wire harness provided; failure to do so may result in damage to

equipment or personal harm as well as voiding the warranty.

!

120 VOLT AC ELECTRICAL CONNECTION

!

• Connect the main power to the Black / White / Green connector on the back-plate.

o Main power supply: 120 VAC, 15A, Single Phase, 60 Hz. circuit

o Attach the incoming 120 volt AC line wires to the wiring provided in the header – as

shown below.

• DO NOT TURN POWER ON until all remaining wiring has been completed.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Page 20

!

920.1020.15

20

DL1 : GREEN USB CONNECTION

DL2: FLASHING RED LED

DL3: BLUE 5V POWER SUPPLY

DL4: BOARD VALUES DIFFER FROM DIP SWITCHES

(PRESS SW1 MOMENTARILY TO EXTINGUISH YELLOW LED)

!

!

!

POWER ON & INDICATIONS

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Upon applying power, observe the above LED’s.

NORMAL OPERATION: DL3 will come on steady and then begin flashing after a few seconds.

FAULTY OPERATION; DL2 will be flashing red. This indicates…

• An error condition exists – correct as necessary

• Operator requires setup – launch a setup and proceed accordingly

NOTE: DL4 will illuminate yellow anytime a change has been made to the control, such as a speed or time adjustment.

Momentarily press on SW1 to acknowledge the change and extinguish the yellow LED.

HELPFUL NOTES:

• Speed and time adjustment changes will not take effect until the door closes fully after the adjustment has

been made.

• Hold Open time affects the delay following activation from input 10, 11, and 13.

• When Dip Switch 5 is ON, the blue speed and time potentiometers are disabled and will have no effect.

!

!

!

Page 21

!

920.1020.15

21

!

SET-UP PROCEDURES

• Perform a setup at the control as follows:

o Ensure main power is on

o At the I/O control board, depress the SW1 button for approximately 5 seconds.

When the red LED (LD2) at the Adjustment Board begins flashing rapidly, release

the button. The blue LED will continue flashing.

o Door will slowly go open, recycle partially, close and then re-open.

o Do not interrupt the process and do not move the door manually during this

time.

o If the door does not open and the red LED (DL2) is flashing slowly, check to make

sure the motor is plugged in properly at the control board. Correct as necessary.

o Once the setup process is complete, the door will close and the LED will go out.

o Setup is complete.

IMPORTANT NOTE: If the operator stroke is altered in any way, a re-learn must be

accomplished.

• Upon completion of the Setup, activate the door to open and ensure all performance is

acceptable.

• Adjust opening and closing speed as necessary. If speeds are changed, a re-learn is not

required.

• A re-learn is not required following a main power recovery.

• Adjust hold-open time as required.

• Additional adjustments are available through the TAP.

!

!

Page 22

!

920.1020.15

22

SETUP BUTTON

!

B1 – Battery – use CR1216 battery – required to maintain timer settings and date programmed by the TAP

TR1 – Opening speed adjustment

TR2 – Closing speed adjustment

TR3 – Hold-open time adjustment

TR4 – Closing speed adjustment when power is OFF TR4 will only be enabled when jumper J6 is moved to the correct

pins. (it is enabled by default).

J2 – USB port

J4 – Ribbon cable connector between boards

J5 – Motor Connector

J7 – Power supply connector between boards

SW1 – “Parameter Changed” button

SW2 – 10 Position “Functions” Dip Switch

For adjustments beyond those mentioned herein, use the TAP. See TAP Users Guide for additional information.

!

!

Page 23

!

920.1020.15

23

DS1 NOT USED

DS2

SW2

!

SET THE DIP SWITCHES ON THE I/O BOARD

!

• Set the dip switches according to the application.

• Dip switches are used to apply specific functions to the control.

• There are 3 sets of dip switches. TWO 2 - POSITION on the I/O board (DS1 & DS2), and a 10-

position at the adjustment board (SW2).

!

!

!

!

!

!!!!

!

!

!

!

SET THE DIP SWITCHES ON THE ADJUSTMENT BOARD

!

!

!

• Set the dip switches according to the application.

!

Page 24

!

920.1020.15

24

Description

ON

OFF

1

Closed Door Force

Additional force applied while door is

in closed position. Be sure to maintain

ANSI compliance if using on low

energy application. Cannot exceed 30

lbf to get door moving from jamb.

Disabled (Default)

2

Push / Pull Arm

Slide Arm Application. Operator

stroke at 90° degrees or less. Visible

change in performance may not

always be noticeable.

Push Arm Application.

Operator stroke 90° or

greater. (Default)

3

Night Function (Exit

Only)

Allows activation at input 10 when

On-Off switch is in OFF (night

function) position.

Disabled. The On/Off

switch, when OFF, requires

manual operation of the

door. (Default)

4

Push and Go

Enabled

Disabled (Default)

5

Full Power / Low

Energy

Low Energy performance enabled. 5

seconds to open, 7 seconds hold

open, 5 seconds to close. Speed &

time potentiometers are disabled.

Settings are fixed.

Disabled. Control can be

adjusted for full power or

low energy operation via

potentiometers. (Default)

6

Lockout Function

Overhead presence sensor input (17)

is inhibited during closing cycle unless

input 14 is triggered. Connect COM

and Input 14 to NC output of lockout

safety beam.

Disabled. Overhead

presence sensor input (17)

is inhibited during closing

cycle. Otherwise, if

commanded, it keeps an

open door open and a

closed door closed. A

command at Input 14 will

stall the door. (Default).

7

Inhibit at 30

Degrees Before

Door Fully Open

Input is disabled at 30 degrees prior to

full open door position. Eliminates

need for external inhibiting switch.

Stall function remains uninhibited for full door

stroke. (Default)

8

Power Close

Additional closing force applied for

final 10 degrees of closing.

Disabled (Default)

9

Assisted Manual

Closing***

Enabled assisted closing following a

manual opening

Disabled assisted closing

following a manual opening

10

FACTORY USE ONLY

!

!

!

!

!

*** Tucker Auto-Mation recommends the use of a door-mounted secondary activation device

when dip switch 9 is ON - Enabled.

!

!

Page 25

!

920.1020.15

25

Position

Function

Description

TERMINAL STRIP J5

1

Electric Lock

Relay

Common

2

Electric Lock

Relay

N.O. Dry contact – Contact closes upon activation. May be used for fail-secure locks by

routing 1 leg of power though the relay. Relay is triggered by activation inputs 10, 11, or

16. Relay remains energized until door is fully closed again.

3

Electric Lock

Relay

N.C. Dry Contact - Contact opens upon activation. May be used for fail-safe locks by

routing 1 leg of power though the relay. Relay is triggered by activation inputs 10, 11, or

16. Relay remains energized until door is fully closed again.

4

Door Status Closed

N.O. Contact is closed when door is closed. The contact opens as soon as the door

opens.

5

Door Status –

Common

Common contact for door status

6

Door Status Open

N.C. – Contact is closed when door is open. The contact opens as soon as the door starts

to close. This input can be used for motor connection at lockout relay when power is

looped through, thus switching power on when door is open.

TERMINAL

STRIP J4

7

GND

Common GND

8

GND

Common GND

9

+ 24 VDC

I A. Max Current

10

Internal

Activation

Requires N.O. Contact between input 10 & COM. Remains capable to activate when dip

switch 3 is ON AND On-Off switch is OFF.

11

External

Activation

Requires N.O. Contact between input 11 & COM.

12

Emergency

Closing

Requires N.C. contact between 12 & COM. Upon open contact, door closes and overrides

all other inputs. Remains jumpered if input is not used.

13

Secondary

Activation

Requires N.C. contact between 13 & COM. Disabled in full closed position.

14

“Stall” Safety

Requires N.C. contact between 14 & COM. Upon open contact, (Dip 6 OFF) during

opening, door stops, then resumes at reduced speed when input is released.

15

KEY

KEY IMPUT

16

Alarm Input

N.O. contact, when closed causes door closing. All inputs inhibited during closed contact

(not available on all software versions)

17

Overhead

Presence

Sensor Input

Requires N.O. contact between 14 & +24 VDC (input 9). When input is closed it causes an

open door to stay open and a closed door to stay closed. Works in conjunction with dip

switch #6.

18

GND

Common GND

19

GND

Common GND

20

Aux Relay

Auxiliary Relay NOTE: Relay is triggered by input 14

21

Aux Relay

Auxiliary Relay N.O.

22

Aux Relay

Auxiliary Relay N.C.

23

Alarm Output Common

Common

24

Alarm Output

N.O. output is closed upon closed contact from fire alarm. LED 2 also illuminates.

25

+ 24 VDC

I A. Max Current

26

GND

Common GND

Inputs 27 & 28 not used

!

WIRING CONNECTIONS

!

I/O BOARD CONNECTIONS

(wiring diagrams are located in the Appendix)

!

!

Page 26

!

920.1020.15

26

!

ADJUSTING THE MECHANICAL DOOR STOP

• CAUTION – DO NOT REMOVE THE STOPS

• IMPORTANT - This step may be optional depending on your application

• The mechanical stops are located on the top or bottom of the operator, depending on the

hand of the door.

• Apply 120 VAC Main power to the control

o Place the On-Off-Hold switch to the Hold Open position

!

!

Page 27

!

920.1020.15

27

Door will not open

• Check On-Off switch for proper position

• Check LED status for LD 5, 6, and 7. If any of these LED’s are OFF, the

door will not open. They require a normally closed circuit.

• Launch a new setup – see page 26

• Check status of emergency input 12

• Door has traveled close past the 0 degree position

Door will not close

• Check status of LEDs” LD2, 3, 4, 8 on the I/O board.

• If any of the LED’s are ON, check the associated input

Door will not reach its full open or

closed position

• Check the mechanical stops on the operator for proper adjustment

Slow flashing red LED (LD2) at the

Adjustment Control Board

• Indicates a possible fault in the control.

o Check LED status for the other inputs. This will identify if any

inputs are currently active.

• Indicates a potential faulty setup.

o Loose or incorrect motor connection

o Possible loose chain tensioner - refer to Appendix for chain

tensioner adjustment procedures.

o Launch a new setup. If problem repeats and there are no

other discrepancies noted, replace the operator/control subassembly.

Door closes too fast at last 5 to 10

degrees of closing

• Ensure dip switch 8 is OFF.

• Ensure there is no binding of the door as it is closing through the last

few degrees of closing. If binding exists (from a tight bottom sweep,

for example), correct the condition and then re-launch a new setup.

!

TROUBLESHOOTING

!

!

Page 28

!

920.1020.15

28

!

JOB DOCUMENTATION & CLOSEOUT

• Upon completion of the installation, provide the following to the Owner or their assigned

agent:

o Completed & signed work ticket. Be certain to record any serial numbers for items

that were replaced.

o Completed and signed copy of the AAADM inspection form

o AAADM Owner’s Manual

• Additionally, advise the Owner of the work that was performed and ask if there are any

other doors that may require service.

ACCESSORIES

• Tucker BAT Microwave Motion Sensor - PN: 200.1068

• Tucker TORPEDO ONE door-mounted presence sensor - PN: 200.1087

• Spindle Adaptors 20, 50, 80 mm

• TAP Controller – KP EVO

COMPANY CONTACT

• Tucker Auto-Mation Supply, LLC

Toll Free: 1-855-8 TUCKER (1-855-888-2537) – Service: Tel. 412-823-2537

Email: sales@tuckerauto-mation.com

• WWW.TUCKERAUTO-MATION.COM

!

!

Page 29

!

920.1020.15

29

!

APPENDIX - WIRING DIAGRAMS

LOW ENERGY APPLICATION: PUSH PLATES WITH APPROACH SIDE DOOR-MOUNTED SENSOR

!

!

!

!

!

!

• Non-Swing Side (approach) door-mounted sensor is wired into the secondary activation input (13)

at the SW19 I/O board. It is a normally closed circuit.

• Door-mounted sensor will cause re-activation when in detection during the closing cycle.

• Secondary activation input is disabled at the full closed door position.

• Jumpers must be installed between terminal 8 and 12 & 14 if those inputs are not required for the

application. If they are used for the application, they must be connected to a N.C. circuit.

!

!

Page 30

!

920.1020.15

30

!

SIMULTANEOUS PAIRS

!

!

!

!

!

Page 31

!

920.1020.15

31

!

• When wiring controls for use as a simultaneous pair, all required inputs need to be

sync’d (connected) between Door #1 and Door #2 (shown as dotted lines in above

diagram).

• Example shown above: Push plates are connected to inputs 8, 10 and 11 at door #1

and are connected via sync line to Door #2.

• When using pairs of controls, N.C. inputs 12, 13 and 14 may be sync’d to each other,

OR each control may have it’s own jumpers installed. If any of these inputs are

required for the application, the jumper will be removed for the respective input – in

place of the jumper, a N.C. switching circuit will connected to Door #1, and a sync

line will be connected to Door #2.

• For simultaneous pairs, Tucker Auto-Mation provides a dual harness for the On-Off-

Hold switch. Each plug-in connector for the control is wired in parallel to the On-OffHold switch located in the header end-cap. One switch will control both doors.

• All control adjustments (speed & time delay) must be made independantly at each

control.

• All dipswitches at each control must be set independantly and must match between

controls.

• When using the TAP programmer, settings must be made independantly at each

control and must match between controls.

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

!

Page 32

!

920.1020.15

32

!

!!!!!!!!!!!!!

APPENDIX - FIRE RATED DOOR APPLICATION

• Perform the installation according to the instructions outlined in this manual.

Additionally, ensure the following conditions have been met:

o When attaching the door arm to the door,

use steel binding posts (Sex Bolts) to attach.

Do NOT use sheet metal screws into the face

of the door. The door arm bracket must be

through-bolted.

o When attaching the header to

the hollow metal door frame,

ensure there are 5 attaching

screws spaced equally apart.

They should be #12 sheet

metal type screws.

!

!

Page 33

!

920.1020.15

33

!

o Fire rated power operated doors must close and latch during a fire alarm condition.

Ensure proper procedures have been followed to allow a main power disconnect

during a fire alarm condition. Always check to ensure compliance to local building

codes.

§ Upon job completion, always perform a functional test to ensure that the

door(s) close and latch following a power loss.

o Other hardware may be required to complete the installation. For example, for pairs

of doors, if an Astragal is installed, a mechanical door coordinator may be required

to ensure a proper coordinated closing during a power loss.

o Only fire rated hardware shall be used on a fire rated door & frame assembly.

o Ensure the Tucker SW10/19 that is being installed has the proper fire rated label

applied to the header.

!

!

Page 34

!

920.1020.15

34

!

!

APPENDIX - TAP PROGRAMMING DEVICE

Please note, some functions of the SW10/19 controller require the use of a hand-held “TAP” programming device.

The following functions require use of this device for programming:

ü Logic Assignment For Inputs

ü Logic Assignment For Outputs

ü Opening & Closing Acceleration

ü Opening & Closing Deceleration

ü Opening & Closing Strength (obstruction force)

ü Opening & Closing Strength Duration (time duration for obstruction force)

ü Night-Time Hold Open Time

ü Delay On Activation (up to 4 seconds)

ü Electric Lock Interfacing

ü Master/Slave Configuration

ü Cycle Count – Maintenance Reset

ü 7-Day Programmable Timer (With Daylight Savings Time)

ü Troubleshooting & Data

!

!

Page 35

KP evo - TAP CONTROLLER

INSTALLATION GUIDE

TUCKER AUTOMATION

KP evo - TAP CONTROLLER

WWW.TUCKERAUTO-MATION.COM

Page 36

KP evo - TAP CONTROLLER

INSTALLATION GUIDE

IMPORTANT

READ THIS SECTION BEFORE PROCEEDING WITH INSTALLATION

Tucker Auto-Mation, LLC (hereafter referred to as “Tucker”) recommends that all of its automated

pedestrian door products beinstalled by a trained automatic door technician and that the resulting

performance of the product be in full compliance with themost current version of the American National

Standards Institute document A156.10 or A156.19 (whichever is applicable) as well as any applicable

building codes and/or re codes. Tucker further recommends that a full inspection of the operating system

be performed in accordance with the guidelines of the American Association of Automatic Door

manufacturers (AAADM). This inspection must be performed by a certied AAADM trained inspector. Tucker

recommends this documented inspection be performed upon completion of the installation as well as,

following the completion of every service call thereafter. If service is not performed within one year of the

previous service action, a routine AAADM inspection should be performed and documented. Under no

circumstance should the product operate for more than one year without an AAADM inspection. Tucker

does NOT recommend installation or service, on any of their automated pedestrian door products, by any

individual who is not certied as an AAADM inspector. Following the installation or service of any Tucker

automated pedestrian door product, if it is deemed unsafe, or is operating in an unsatisfactory manner

according to national performance standards or recommended performance guidelines as dened by

Tucker, repairs should be made immediately. If an immediate repair cannot be made, the product should be

disabled, and appropriate measures should be taken to secure the door in a safe position or to enable the

door to safely be used manually. During this situation, every eort should be made to notify the owner (or

person responsible) of the condition and to advise on corrective actions that must be taken to return the

product to safe operation.

TUCKER AUTOMATION

KP evo - TAP CONTROLLER

920.1003.02 | 01

WWW.TUCKERAUTO-MATION.COM

Page 37

KP evo - TAP CONTROLLER

INSTALLATION GUIDE

TABLE OF CONTENTS

1. KP EVO ........................................ 3

1.1 Installation and connections .................. 3

1.2 Switching on and the home screen ............ 4

1.3 SELECTION menu ............................. 5

1.4 FUNCTIONS menu ............................ 6

2. DIAGNOSTICS ................................. 44

2.1 LEDs check ................................... 44

I/O board LEDs ................................. 44

Logic board LEDs .................................................................................................14

2.2 Inputs and outputs status check .................................................................................14

2.3 Automation status check ........................................................................................ 14

2.4 Warnings ......................................................................................................15

2.5 Errors ..........................................................................................................16

2.6 Other board data ...............................................................................................17

2.7 Firmware versions ..............................................................................................17

2.8 Log Data ....................................................................................................... 17

KP evo TABLES

A P EVO menu ................................................................. 07

B Access permissions and passwords ............................... 13

C I/O board LEDs .............................................................. 14

D Logic board LEDs .......................................................... 14

E Status ........................................................................... 14

F Warnings ...................................................................... 15

G Errors ............................................................................ 16

H Selecting theupload/download function ...................... 18

I Scheduled maintenance ............................................... 21

3. UPLOAD / DOWNLOAD ........................................................................................ 18

4. PUT TING INTO SERVICE ....................................................................................... 19

4.1 Final checks ...................................................................................................19

4.2 Final operations ............................................................................................... 19

Installing a plastic cover ..........................................................................................19

Installing an aluminium cover ................................................................................... 20

5. MAINTENANCE ................................................................................................ 20

5.1 Inserting / replacing the battery ............................................................................... 20

5.2 Replacing the fuse ........................................................................................... 20

5.3 Routine maintenance ......................................................................................... 21

6. INTERCOM .................................................................................................... 22

6.1 Intermode ................................................................................................... 23

6.2 Interlock ..................................................................................................... 23

Interlock with no memory ....................................................................................... 24

Interlock with memory .......................................................................................... 24

6.3 2 Leaves ..................................................................................................... 24

6.4 2 Leav

es + Interlock .......................................................................................... 24

COMPANY ADDRESS............................................................................................

7.

WWW.TUCKERAUTO-MATION.COM

25

920.1003.02 | 02

Page 38

KP evo - TAP CONTROLLER

1. KP evo

1.1 INSTALLATION AND CONNECTIONS

CARRY OUT THE FOLLOWING OPERATIONS WITH THE

ELECTRICITY SUPPLY DISCONNECTED

1. Disassemble the parts (01 ).

2. Break the cable passage insert.

With reference to 02, the KP EVO is designed

for the cables to enter from the back (1) or from

underneath (2).

3. Decide where to position the support and x it

using suitable screws (01 -1).

4. Connect the KP EVO to the 950N2 using a 4 pair

twisted U/UTP AWG24 cable with a maximum

length of 50m (03).

INSTALLATION GUIDE

1

2

02

An optional key device can be connected between ter-

minals G and K in order to enable/disable the KP EVO.

5. Reassemble the parts indicated in (01 ).

1

1

1

max 50 m

U/UTP CAT.5

4x2xAWG24

J3 950N2

03

01

920.1003.02 | 03

WWW.TUCKERAUTO-MATION.COM

Page 39

KP evo - TAP CONTROLLER

1.2 SWITCHING ON AND THE HOME SCREEN

1. Turn power on to the 950N2

2. The display will show the following in sequence:

KP EVO

BOOTLOADER X.X

in which the Bootloader version appears, then

KP EVO

VERSION X.X

in which the rmware version appears, and lastly

A951

xxx dd/mm/yy

xxxxxx

hh:mm

INSTALLATION GUIDE

3. The 4 buttons are used to select controls that,

depending on the screen, appear on the display

above them.

4. By pressing the relative button on the home screen

(04) you can:

- = set the NIGHT mode

- = set the MANUAL mode

- = switch to the FUNCTIONS menu that includes

all the 950N2 conguration parameters.

- = switch to the SELECTION menu that includes

additional operating modes.

By pressing the button to set the NIGHT or MANUAL

mode, the relative icon is highlighted and the description of the operating mode is updated on the display.

Once MANUAL mode has been set by pressing the

relative button, press it again to return to the previous mode.

The content of this home screen, including the xed

icons and those that may appear under certain circumstances, is explained in 04.

current warnings

A951

xxx dd/mm/yy

xxxxxx

timer active

set / deselect NIGHT mode

hh:mm

KP EVO locked

- product name

- day and date or error

- operating mode

- time

switch to the SELECTION menu

switch to the FUNCTIONS menuset / deselect MANUAL mode

04

920.1003.02 | 04

WWW.TUCKERAUTO-MATION.COM

Page 40

KP evo - TAP CONTROLLER

1.3 SELECTION MENU

To access the SELECTION menu from the home screen,

press the button (05).

4 New icons appear on the display that dene the

operating modes that can be set.

The possible combinations can be obtained by pressing the corresponding buttons (05).

After having set the operating mode, press the OK

button to conrm and return to the home screen.

The description of the operating mode on the display

is updated with the description of the one that has

been set.

description of the current operating

mode

INSTALLATION GUIDE

AUTOMATIC

ALWAYS

OPEN

INTERLOCK

(press for 5 s)

%

xxxxxx

BI-DIRECTIONAL

EXIT ONLY

ENTRY ONLY

OK

conrm and return to

the home screen

TOTALLY

100%

OPEN

PARTIAL

%

OPEN

05

920.1003.02 | 05

WWW.TUCKERAUTO-MATION.COM

Page 41

KP evo - TAP CONTROLLER

1.4 FUNCTIONS MENU

To access the FUNCTIONS menu from the home screen,

press the button (06).

The display prompts for a 4-digit password to be

entered.

INSTALLATION GUIDE

1 LANGUAGE

2 PROGRAMMING

The factory-set password is: 0000

- Set the rst digit using the and buttons.

- Conrm using the OK button to move to the next

digit.

- When all 4 digits have been entered, if the pass-

word is correct, access the FUNCTIONS menu as a

USER or a TECHNICIAN.

- Select the item from the menu using the and

buttons.

- Conrm using the OK button to enter.

Press ESC at any time to return to the home screen.

menu items

3 ERRORS

4 WARNINGS

5 CYCLES COUNT

6 DATE/TIME

7 TIMER

8 PASSWORD

8 INFO

menu name

return to the

home screen

ENTER PASSWORD

****

sets the value

conrms the

value

quits without

saving and

returns to the

previous menu

>1 xxxxxxxx

2 xxxxxxxx

3 xxxxxxxx

4 xxxxxxxx

selects an item

from those listed

in the menu

MENU

conrms the

selection

06

920.1003.02 | 06

WWW.TUCKERAUTO-MATION.COM

Page 42

KP evo - TAP CONTROLLER

A KP EVO menu

1 LANGUAGE

1 ITALIANO

2 ENGLISH

3 FRANCAIS

4 DEUTSCH

5 ESPANOL

6 NEDERLANDS

2 PROGRAMMING

1 INPUTS / OUTPUTS

1 INPUTS I1-I8

I1…I8

0 DISABLED

1 EXTERNAL OPEN

4 INTERNAL OPEN

7 AUTOMATIC OPEN

8 SEMIAUTOM. OPEN

10 KEY

11 PARTIAL OPEN

20 CLOSING SAFETY

21 OPENING SAFETY

22 OVERHEAD PRES. SENS

30 EMERGENCY OPEN

31 EMERGENCY OPEN WITH MEM

34 EMERGENCY CLOSE

35 EMERGENCY CLOSE WITH MEM

36 FIRE ALARM

40 ALWAYS OPEN

41 EXIT ONLY

42 ONLY IN

43 NIGHT

44 MANUAL

45 PARTIAL

46 INTERBLOCK ON

2 OUTPUTS O1/O2

60 TIMER

01…O2

0 DISABLED

1 GONG

2 ERROR

4 EMERGENCY ACTIVATE

5 TEST

6 DOOR NOT CLOSED

7 DOOR OPENED

8 DOOR OPENING

9 LIGHT

10 INTRUSION ACTIVE

11 CLOSING SAFETY

12 SAFETIES

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

TIME 1...90 S

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

NORMALLY OPENED / NORMALLY CLOSED

INSTALLATION GUIDE

ENABLED / DISABLED

TEST

ENABLED / DISABLED

TEST

NORMALLY OPENED / NORMALLY

CLOSED

3 OP/CLRELAY

NORMALLY OPENED / NORMALLY CLOSED

4 EXTERNAL SELECTOR

POSITION 1…POSITION 2

0 DISABLED

1 NIGHT

2 OPENED

3 EXIT ONLY

4 MANUAL

920.1003.02 | 07

WWW.TUCKERAUTO-MATION.COM

Page 43

KP evo - TAP CONTROLLER

2 MOTION

1 OPENING...2 CLOSING

1...10

SLOWDOWN SPACE 0°...90°

0...10

0.1...3.0 s

1...10

1...10

0...30 s

0...30 s

0...90 s

0...90 s

WITH MEMORY / WITHOUT MEMORY

WITH MEMORY / WITHOUT MEMORY

3 TIMING

4 MOTOR LOCK KIT

ENGLISH

5 INSTALLATION

6 INTERCOM

1 SPEED

2 SLOWDOWN

3 STRENGTH

4 STRENGTH DURATION

5 ACCELERATION

6 DECELERATION

1 PAUSE TIME

2 PAUSE TIME

3 NIGHT PAUSE TIME

4 NIGHT SENSOR NIGHT

1 FUNCTION

2 LOCK DELAY 0...60 tenths of a second

3 RELEASE TYPE

1 ARM TYPE

2 SENSOR TYPE

3 START SETUP ARE YOU SURE ?

4 PUSH AND GO

5 PARTIAL STOP SEC.

6 LEAF DELAY 0°...90°

7 SCP

8 REVERSE STROKE

10 INOUT STATE IN1...IN8 01...02

11 DOOR STATUS

12 OTHER BOARD DATA V_MAIN V_ACC POS I_MOT

1 FUNCTION

2 MASTER/SLAVE NR.

3 INTERCOM REG.

4 NODE LIST

]

DISABLED

NIGHT

EXIT ONLY

NIGHT + MONODIR

ALWAYS

WHEN OPENING

CLOSED

SKID

ARTICULATE

DOOR MOUNTED SYSTEM

OPS AND BEAM

0 DISABLED

1 ENABLED

2 FAST FOOD

DISABLED

ENABLED

DISABLED

ENABLED

DISABLED

ENABLED

DISABLED

INTERMODE

INTERLOCK

2 LEAVES

2 LEAVES + INTERBLOCK

INSTALLATION GUIDE

SLOWDOWN SPEED 1...3

920.1003.02 | 08

WWW.TUCKERAUTO-MATION.COM

Page 44

KP evo - TAP CONTROLLER

7 MISCELLANEOUS

1 DEFAULT DEFAULT

2 BOARD'S DISPLAY

3 INTRUSION

4 KPEVO KEY

5 CONSECUTIVE OBST.

6 TEST ERROR

3 ERRORS

The display shows any current errors

4 WARNINGS

the display shows any current warnings

5 CYCLES COUNT

1 CYCLES NUMBER

ABSOLUTE

RELATIVE

2 MAINTENANCE

MAINTENANCE DATE MAINTENANCE CYCLES

3 CYCLES RESET ARE YOU SURE ? resets the number of cycles

ACTIVATE

NO

STOPPED

NOT BLOCKED

DISABLED

ENABLED

WITHOUT USER PSW

BLOCK

CLOSING

OPENING

DISABLED

ENABLED

DO YOU WANT TO LOAD

0...10

0...10

INSTALLATION GUIDE

DEFAULT CONFIG ?

ENGLISH

6 DATE/TIME

1 SET DATE

2 SET TIME

3 DAYLIGHT SAV TIME

DISABLED

7 TIMER

ENABLED

1 TIMER STATE

DISABLED

ENABLED

2 MONDAY

3 TUESDAY

4 WEDNESDAY

5 THURSDAY

6 FRIDAY

7 SATURDAY

8 SUNDAY

9 MON - SUN

10 MON - FRI

11 JOLLY

12 JOLLY SLOTS

SLOT 1

SLOT 2

SLOT 3

SLOT 4

SLOT 5

SLOT 6

APPLY (appears only if selected LUN - SUN or LUN - FRI)

920.1003.02 | 09

WWW.TUCKERAUTO-MATION.COM

Page 45

KP evo - TAP CONTROLLER

INSTALLATION GUIDE

FUNCTION: 0

FUNCTION: 1

FUNCTION: 2

FUNCTION: 3

FUNCTION: 4

FUNCTION: 5

FUNCTION: 6

FUNCTION: 7

FUNCTION: 8

FUNCTION: 9

FUNCTION: 10

8 PASSWORD

1 TECHNICIAN PSW

CHANGE TEC PSW REINSERT TEC PSW NEW PSW INSERTED

2 USER PSW

CHANGE USER PSW REINSERT USER PSW NEW PSW INSERTED

9 INFO

E950E

E950E

KP EVO

■ PROGRAMMING INPUTS/OUTPUTS

BOOT

APP

APP

VER *.*

VER *.*

VER *.*

NO FUNCTION

AUTO BIDIR TOTAL

AUTO OUT TOTAL

AUTO BIDIR PARTIAL

AUTO OUT PARTIAL

TOTALLY OPEN

PARTIAL OPEN

AUTO IN TOTAL

AUTO IN PARTIAL

NIGHT

PARTIAL

NIGHT

INPUTS

The inputs on terminal board J5 of the I/O board can be congured

with the following functions

Each input can be set to NC or NO according to the

device connected to it.

Disabled

No associated function.

External open

When activated, the door opens and remains open as long as the

input is active. When released, the door waits for the pause time

to elapse and then closes.

This has no eect in the EXIT ONLY or NIGHT modes.

Internal open

When activated, the door opens and remains open as long as the

input is active. When released, the door waits for the pause time

to elapse and then closes.

This has no eect in the ONLY IN or NIGHT modes.

Automatic open

When activated, the door opens and remains open as long as the

input is active. When released, the door waits for the pause time

to elapse and then closes.

Active in the BI-DIRECTIONAL, EXIT ONLY and ONLY IN modes.

This has no eect in the NIGHT mode.

Semiautom. open

When activated:

- if the door is not already open, it opens and remains open

- if the door is already open, it closes

e in the BI-DIRECTIONAL, EXIT ONLY and ONLY IN

Activ

modes.

This has no eect in the NIGHT mode.

BEGINNING

END

hh:mm

hh:mm

Key

When activated, the door opens and remains open as long as the

input is active. When released, the door waits for the night pause

time to elapse and then closes.

Active in the BI-DIRECTIONAL, EXIT ONLY, IN ONLY and NIGHT modes.

Partial open

Only opens the master door when activated in the “2 leaves” mode.

Closing safety

When activated:

- If the door is closing, it reopens

- If the door is already open, it prevents it from closing

- If the door is opening, it has no eect

Opening safety

When activated:

- If the door is opening, it stops until it is released

- If the door is already closed, it prevents it from opening

- If the door is closing, it has no eect

Emergency open

When activated, the door opens (always total) and remains open

as long as the input is active. When released, the door waits for

the night pause time to elapse and then closes.

Also active in NIGHT mode.

Emergency open with memory

When activated, the door opens (always total) and remains open

as long as the input is active. When released, the

open until it is Reset

Emergency close

ctivated, the door closes and remains closed as long as the in-

When a

put is active. When released, the door returns to normal operation.

door remains

920.1003.02 | 10

WWW.TUCKERAUTO-MATION.COM

Page 46

KP evo - TAP CONTROLLER

INSTALLATION GUIDE

Emergency close with memory

When activated, the door closes and remains closed as long as the

input is active. When released, the door remains closed until it

is Reset

Fire alarm

When activated, the door closes, regardless of the operating mode

that has been set, with the lock kept in the released position. It

has priority over any commands that may be active.

Always open

When activated, the ALWAYS OPEN mode is set.

Exit only

When activated, the EXIT ONLY mode is set.

Entry only

When activated, the ONLY IN operating mode is set.

Night

When activated, the NIGHT mode is set.

Manual

When activated, the MANUAL mode is set.

Partial

When activated, the PARTIAL mode is set.

Interblock ON

When activated, the INTERLOCK mode is set.

Timer

When activated, the TIMER mode is set.

OUTPUTS

The outputs on terminal board J5 of the I/O board can be congured

with the following functions

Closing safety

The output is activated when a closing safety device is active.

Safeties

The output is activated when a closing or opening safety device

is engaged.

OP/CL RELAY

Species the logic of the door status relay (NC/NO).

EXTERNAL SELECTOR

Species the operating mode associated with positions 1 and 2 of

the selector on the side of the unit.

■ PROGRAMMING MOTION

OPENING/CLOSING

Speed

Sets the speed of movement.

Deceleration

Species the space (in degrees of rotation of the 950N2 shaft) and

the deceleration speed (on 3 levels) of the door before reaching the

nal open / closed positions.

Strength

Species the maximum crushing force.

Strength duration

Species the maximum thrust time before an obstacle is recognised.

Acceleration

Species how quickly the door reaches the set opening speed when

starting from stop.

Deceleration

Species how quickly the door stops.

Each input can be set to NC or NO according to the

device connected to it.

Disabled

No associated function

Gong

The output is activated and deactivated at 1-second intervals when

the safety devices are engaged.

Error

The output is activated if there is an error.

Emrg. active

The output is activated when an Emergency is triggered.

Test

The output commands a FAILSAFE test on the inputs that are cong-

ured as safety devices on which the option of running a TEST before

movement has been enabled.

Door not closed

The output remains active until the door is closed.

Door open

The output remains active as long as the door is open.

Door opening

The output remains active as long as the door is moving.

Light

The output is activated, fo

door is open in NIGHT mode.

Intrusion active

The output is activated when an intrusion is in progress (i.e. when an

unexpected movement of the door from its closed position is detected).

.

r a programmable length of

time, when the

■ PROGRAMMING TIMING

PAUSE TIME

Denes the pause time of the door when opened by a command,

before closing automatically.

PAUSE TIME P&G

Sets the door pause time when opened by a Push & Go command,

before closing automatically.

Night PAUSE TIME

Sets the door pause time when opened by a command in NIGHT

mode, before closing automatically.

NIGHT SENSOR DELAY

When NIGHTmode is set, the internal detector remains active for the

amount of time set in this parameter, to allow it to be opened only

once. The internal detector is disabled immediately after opening

and in any case upon expiry of the set delay.

■ PROGRAMMING MOTOR BLOCK KIT

FUNCTION

Species the operating mode in which the lock is activated.

LOCK DELAY

Species the opening delay time of the door to allow the lock to be

released, particularly motorised locks.

RELEASE TYPE

Species when power is disconnected from the lock after it has been

mechanically released:

Opening = during the opening phase

Closed = when the door is closed again

920.1003.02 | 11

WWW.TUCKERAUTO-MATION.COM

Page 47

KP evo - TAP CONTROLLER

INSTALLATION GUIDE

■ PROGRAMMING INSTALLATION

ARM TYPE

Species the type of transmission arm installed (shoe or articulated)

START SETUP

Carries out a Setup cycle after conrmation.

PUSH AND GO

Sets the function that commands the automatic opening of the door

after an initial manual push:

Disabled = Push & Go not enabled

Enabled = Push & Go enabled

Fast food = Push & Go enabled in “FAST FOOD“mode (manual

opening, motorised closing)

PARTIAL STOP SEC.

Species the detection area of the safety in opening:

Disabled= obstacle detection active over the entire opening stroke

Enabled= obstacle detection NOT active in proximity to the

opening stop

LEAF DELAY

Species the opening delay between the doors of 2 leaf models.

SCP

Species the function that pushes the door with a greater force in

the nal section of the closure. It is useful to activate this function

if there is high friction, if the seals are particularly rigid or if locks

have a sti latch.

■ PROGRAMMING MISCELLANEOUS

CONFIG. DEFAULT

Shows whether the parameters have been modied, and if so, resets

the factory defaults after conrmation.

BOARD'S DISPLAY

Not active.

INTRUSION

Sets the function in which the door resists attempts to open it

manually.

KPEVO KEY

You can choose between:

Block = the user must enter the user password in order to access

the menus that he is authorised to use.

Without user psw = the user doesn’t need to enter the user

password in order to access the menus that he is authorised to use.

CONSECUTIVE OBST.

Species the maximum number of consecutive obstacle detections

in the same direction of movement, before stopping in an error

condition.

TEST ERROR

Species the eect that the TEST will have when it

detects a safety device fault:

Disabled = the door will remain stationary in an error condition

Enabled= the door will continue to operate at minimum speed

Because activating the SCP function also reduces the

sensitivity of the electronic anti-crushing system

the nal section of closing, DO NOT activate theSCP

function in "low energy" mode.

REVERSE STROKE

Sets the function that makes the door carry out a short reverse stroke

before opening to make it easier to the release the lock.

2 EASY REG.

Registration of BUS 2easy devices.

INOUT STATE

The display indicates the status (on / o) of inputs I1-I8 and outputs

O1-O2 in real-time.

DOOR STATUS

The display indicates the status of the automation in real-time.

OTHER BOARD DATA

The display indicates useful diagnostics information in real-time.

■ PROGRAMMING INTERCOM

FUNCTION

Sets the operating mode.

MASTER/SLAVE NR.

Sets the network ID of the unit.

INTERCOM REG.

Registers the units of the network (to be performed only on the

950N2 with ID1).

NODE LIST

Shows the ID of the units registered (on the master).

in

■ ERRORS

In this menu, the display indicates any current errors that there

may be in real time.

■ WARNINGS

In this menu, the display indicates any current alerts that there

may be in real time.

■ CYCLE COUNTER

The 950N2 has two counters:

- total, non-resettable

- partial, resettable

This menu allows you to view the cycles performed by the automation and reset the partial counter.

It is also possible to set a deadline for scheduled maintenance

according to:

- date (optional)

- number of cycles (from 1000 to 1000000)

Alert 60 will be displayed as soon as one of the two settings (date

or number of cycles) is reached.

Logging in with the user password only allows data

to be viewed.

■ DATE/TIME

This menu allows you to set or modify the date, time and turn

European summer time on / o.

920.1003.02 | 12

WWW.TUCKERAUTO-MATION.COM

Page 48

KP evo - TAP CONTROLLER

To keep the settings even if there is no mains power,

which is necessary for the TIMER to work correctly, a

battery must be installed on the Logic board.

■ TIMER

This menu includes all the parameters for conguring the TIMER

function.

When the TIMER is enabled, the operating mode of the door during

the programmed time bands is set automatically.

A maximum of 6 daily time bands can be dened, and an operating

mode, selected from those available, assigned to each one. Each

time band has a start time and an end time.

The time bands must not overlap.

When the TIMER is enabled, the T icon appears on

the home screen.

To manually change the operating mode set by the

TIMER, it rst has to be disabled.

In order for the TIMER to work correctly, a battery

must be installed on the Logic board.

INSTALLATION GUIDE

■ PASSWORD

This menu allows passwords to be set or modied.

To access the FUNCTIONS menu you are prompted to enter a 4-digit

password.

The 950N2 has two passwords available, with dierent access rights

( B)

In order to quickly program groups of days

time bands, it is possible to simultaneously select all the days of the

week (MON - SUN) and all weekdays (MON - FRI). Once the time

bands that have been dened here have been conrmed using the

APPLY option, they will overwrite any time bands that have already

been programmed for individual days.

If it is necessary to program specic days or periods (e.g. recurring

holidays), you may use the JOLLY function.

A maximum of 6 JOLLY time bands can be specied and an operating

mode, selected from those available, assigned to each one. Each

time band has a start time and an end time.

The time bands must not overlap.

The JOLLY time bands are then assigned to a maximum of 6 INTER-

VALS. An interval can be a single day or a series of days.

If a single day is dened, the start and end date of

the interval must be the same.

The interval must refer to same calendar year

ple: for the period from 25/12 to 06/01, 2 intervals

must be created, from 25/12 to 31/12 and from

01/01 to 06/01).

of the week with the

same

(exam-

B sdrowssap dna snoissimrep sseccA

LANGUAGE

PROGRAMMING

ERRORS

WARNINGS

CYCLES COUNT

DATE/TIME

TIMER

PASSWORD

INFO

TECHNICIAN

PSW

(*)

(*)

USER

PSW

* with restrictions

The user is only allowed to modify the user password.

920.1003.02 | 13

WWW.TUCKERAUTO-MATION.COM

Page 49

KP evo - TAP CONTROLLER

2. DIAGNOSTICS

2.1 LEDS CHECK

I/O BOARD LEDS

Each input on the I/O board, has a LED that indicates

the physical state of the contact:

C I/O board LEDs

LED

DL 1 accessories power on accessories power o

DL 2 - DL9 open contact closed contact

LOGIC BOARD LEDS

There are 4 LEDs on the Logic board:

D Logic board LEDs

INSTALLATION GUIDE

E sutatS

CLOSED

OPENING

OPEN

PAUSE

NIGHT PAUSE

CLOSING

EMERGENCY ACTIVATE

MANUAL

NIGHT

STOP

SECURITIES TEST

ERROR

SETUP in progress

LED

DL 1

green

DL 2

red

DL 3

blue

DL 4

yellow

o

on

ashing

fast ashing

2.2 INPUTS AND OUTPUTS STATUS

The status of each input and output can be checked

via the KP EVO.

Go to menu 2.5.9. The display indicates the status of

the logic as shown in 07. Example:

IN1

= input active

IN1

= input not active

no USB

normal condition

no power or

board failure

boar d parameters the

same as trimmer and DIP

switch values

USB connected

error

/

boar d par amet ers

dierent to

trimmer and

DIP swit ch

values

S etup r e -

quested

normal con-

dition

Button

pressed

§

Setup in pro-

gress

/

/

CHECK

AMOTUA 3.2 TION STATUS CHECK

The current status of the automation system can be

checked via the KP EVO.

Go to menu 2.5.10. The display shows information

regarding the status of the automation.

IN1 IN4

IN5

O1

IN2

IN6

O2

IN3

IN7

IN8

07

920.1003.02 | 14

WWW.TUCKERAUTO-MATION.COM

Page 50

KP evo - TAP CONTROLLER

2. 4 SGNINRAW

Alerts provide information regarding the status or

current phase of the automation and errors that do

not prevent it from operating. It is possible to check

any current alerts via the KP EVO.

Go to menu 4 to view the list of current alerts.

If there is at least one alert, an icon appears on the

home screen.

INSTALLATION GUIDE

F sgninraW

Date and time missing

41

- Reset date/time via the KP EVO

Clock battery discharged or missing

42

Emergency active (including command memory)

44

Timer active

45

Timer function in progress

46

Night mode operation

48

Manual mode operation

49

Partial mode operation

50

Obstacle detected during closure

51

Obstacle detected during opening

52

Number of maintenance cycles on E

53

- Carry out a Reset.

- If the alarm persists, replace the Logic board

Searching for strike on closing

58

Maintenance requested

60

KP EVO fault

61

- Check that the correct device is connected and check the

connections.

- If the alarm persists, update the rmware

- If the alarm persists, replace the Logic board

Intrusion in progress

63

Set-up in progress

65

TEST alarm (only if the “test error” parameter is enabled)

68

- Check the operation of the connected devices

- If the alarm persists, replace the device

- If the alarm persists, replace the Logic board

In this condition, the door moves at a slower speed.

Door opened by a semi-automatic command

69

Slave Intercom mode

71

Intercom alarm

72

- Check the connections

- Check the ID

- If the alarm persists, replace the Logic board

Slave Error / Alarm

73

Interlock alarm

74

- Check the connections

- Check the ID

- If the alarm persists, replace the Logic boar

Non-standard programming

80

2

prom corrupted

d

920.1003.02 | 15

WWW.TUCKERAUTO-MATION.COM

Page 51

KP evo - TAP CONTROLLER

INSTALLATION GUIDE

2.5 SRORRE

Errors are malfunctions that prevent the automation

system from working. They are indicated by a steady

red LED on the Logic board.

After every 5 minutes in which a fault condition

persists and for a maximum of 20 consecutive times,

the 950N2 will perform a Reset to attempt to restore

normal operation so as not to require any action if the

condition that caused the error was temporary. If

the fault persists, remove the cause in order to restore

G srorrE

When an error occurs:

1. Check all the electrical connections

2. Carry out a reset.

3. If the problem persists, carry out the operations described in the table one at a time until the problem is

resolved.

Board failure - Replace the Logic board

01

E2

02

03

04

05

07

09

11

12

15

16

18

19

22

prom failure - Replace the Logic board

Motor driver failure - Replace the Logic board

- Replace the motor

Accessories power supply fault - Check that the accessories power supply is not short circuited

- Check that maximum load of the accessories has not been exceeded

- Replace the Logic board

- Replace the I/O board

Microcontroller error - Reload/update the Logic board rmware

- Replace the Logic board

Motor failure - Replace the motor

- Replace the Logic board

Board voltage anomaly - Replace the Logic board

- Replace the I/O board

Closing safety TEST failed - Check the connections of the safety device

- Check that the safety device is working

- Replace the Logic board

Opening safety TEST failed - Check the connections of the safety device

- Check that the safety device is working

- Replace the Logic board

Setup inhibited - Make sure that Night or Manual mode has not been set.

- Make sure that an Emergency command has not been activated

Encoder fault - Replace the Logic board

Firmware not compatible - Update with the correct rmware

High mechanical friction - Make sure that the leaf has been mounted correctly

remove any fric

- Replace the Logic board

- Replace the gearmotor

Programming data corrupted - Reprogram the board or upload the program les that were saved to the USB

storage device.

- Replace the Logic board

normal operation.

The type of error can be identied via the KP EVO

The error code appears on the home page. Go to

menu 5; the display provides information regarding

the current error.

deriuqer noitcArorrE

and that it moves smoothly,

tion

920.1003.02 | 16

WWW.TUCKERAUTO-MATION.COM

Page 52

KP evo - TAP CONTROLLER

INSTALLATION GUIDE

24

26

27

31

39

Consecutive obstacles in closing - Remove the obstacle in closing.

- Make sure that the leaf has been mounted correctly and that it moves smoothly,

remove any friction

Lock failure - Check the wiring of the lock

- Check that the maximum load of the lock has not been exceeded

- Replace the lock

- Replace the Logic board

Motor rotation fault - Check the polarity of the motor cable

Consecutive obstacles in opening - Remove the obstacle in opening

- Make sure that the leaf has been mounted correctly and that it moves smoothly,

remove any friction

Setup data missing or corrupted - Perform Setup

- Replace the Logic board

O 6.2 THER BOARD DATA

Go to menu 2.5.11 of the KP EVO. The display provides

information on the following parameters:

- V MAIN : input voltage to the Logic board (Volts)

- V ACC : output voltage for accessories (Volts)

- POS : position of the rotating shaft (degrees)

- I MOT : current drawn by motor (Amperes)

2.7 FIRMWARE VERSIONS

Go to menu 9 of the KP EVO to view the rmware

versions of the bootloader, the Logic board and the

KP EVO.

2.8 LOG DATA

The 950N2 records the last 512 system events. A

battery must be installed on the Logic board in order

to save the list of events in memory even if the system

is switched o.

To download the data as a text le, see § .

920.1003.02 | 17

WWW.TUCKERAUTO-MATION.COM

Page 53

KP evo - TAP CONTROLLER

INSTALLATION GUIDE

3. UPLOAD / DOWNLOAD

There is a USB port on the Logic board via which the following operations can be carried out:

- Load data from a USB pen drive (UPLOAD).

- Save data to a USB pen drive (DOWNLOAD).

For both operations, the USB pen drive must be formatted with the FAT or FAT 32 le system.

The NTFS format is not recognised.

In order to upload, the les required, the names of which are indicated in H must be present in the root directory

of the USB pen drive.

1. Turn power o to the 950N2.

2. Insert the USB pen drive in the USB port (J2) on the Logic board.

3. Turn power on to the 950N2.

4. If the device is detected correctly, the green LED DL1 of the Logic (08) board lights up steadily.

5. The available functions are selected by briey pressing button SW1 on the Logic board (08). The

operation to be carried out is indicated by the number of ashes of the green LED. Each time the button

is pressed, the operations selected ar

6. Press and

quickly while the procedure is being carried out. When nished, the result is signalled by the status of

the following LEDs:

- yllufsseccus detelpmoc = ylidaets no )1LD( DEL neerg

- red LED (DL2) on steadily = error

7. Turn power o to the 950N2 and remove the USB pen drive.

hold the SW1 button for at least 3 seconds to use the function. The green LED ashes more

e indicated in H .

J2

H eht gnitceleS upload/download function

Green LED DL1 Function

1 ash

2 ashes

3 ashes

4 ashes

950N2 rmware update

le required: 950N2.hex

KP EVO rmware update, including menu translations

les required: KP EVO.hex e KP EVO_L.bin

950N2 and timer conguration upload

les required:

950N2, timer and LOG data conguration download

les written: 950N2.prg , 950N2.tmr , 950N2.log

110

SW1

DL2

DL1

08