Tubeline Nitro 275RS, Nitro 525RS Operator's Manual & Parts Manual

Operator’s Manual

& Parts Manual

40299 Rev.1-1 (18/04/2018)

Operator’s Manual

Thank you for choosing the Tubeline 275RS Manure Spreader. Our hope is that it will give you many

years of productive service. This machine is designed to spread various types of manure evenly over

a wide area.

Please read and understand this manual and the machine before operation.

Warranty and Limitation of Liability

All equipment is sold subject to mutual agreement that it is warranted by the company to be free from

defects of materials and workmanship. But the company shall not be liable for special, indirect or

consequential, damages of any kind under this contract or otherwise. The company’s liability shall be

limited exclusively to replacing or repairing without charge, at its factory or elsewhere, at its discretion.

Any material, or workmanship defects which become apparent within one year from the date on which

the equipment was purchased, and the company shall have no liability for damages of any kind. The

buyer by the acceptance of the equipment will assume all liability for any damages, which may result

from the use or misuse by his employees or others.

Nitro Apron Chain Warranty

Tubeline Manufacturing Ltd offers a limited lifetime non-transferable warranty to the original purchaser

of a Nitro manure spreader. This warranty applies to chain link breakage and covers parts only.

Should a connecting link fail, only it will be replaced. However, if a standard link breaks the complete

chain will be provided. Freight and labor to install is the responsability of the purchaser and is not

covered under the terms of the limited warranty.

Tubeline Manufacturing Ltd reserves the right to request the return of the failed chain. Warranty

coverage is null and void unless Warranty Registration form has been completely lled in and is on

le at Tubeline Manufacturing Ltd.

Serial Number

The implement serial number is located above the front left apron drive bearing. This number helps

us to track changes and improvements and must be mentioned when ordering parts or requesting

service. For your convenience, a space has been provided inside the front cover of this manual to

record the serial number, model number, purchase date, and dealer name.

Model # : ____________________________

Serial # : ____________________________

Date Purchased : _____________________

Dealer Name : ________________________

I

Operator’s Manual

- Nitro 275RS

Table of Contents

Operator’s Manual I

Warranty and Limitation of Liability ............................................................I

Nitro Apron Chain Warranty ..................................................................I

Serial Number ............................................................................I

Specications ...........................................................................IV

Principals of Operation ....................................................................V

Section 1 - Safety 1-1

Safety Signal Words / Safety Messages ......................................................1-1

Safety Guidelines .......................................................................1-2

Lighting & Marking .......................................................................1-2

General Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

A Word To The Operator ..................................................................1-3

Equipment Safety Guidelines ..............................................................1-4

Safety Training. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Safety Signs ...........................................................................1-5

How to Install Safety Signs ................................................................1-5

Safety Sign Locations ....................................................................1-6

Safety Decals ..........................................................................1-7

Section 2 - Operation 2-1

Preparation Safety .......................................................................2-1

Hydraulic Requirements ..................................................................2-1

PTO / Horsepower Requirements ...........................................................2-1

Hook-up / Unhooking .....................................................................2-1

Tractor Preparation ......................................................................2-2

Spreader Preparation ....................................................................2-2

Before Using ...........................................................................2-2

After operating for 2 hours: ................................................................2-2

After operating for 10 hours: ...............................................................2-2

Operation Safety ........................................................................2-3

Pre-operation Checklist ...................................................................2-3

Loading ...............................................................................2-4

Unloading .............................................................................2-4

Section 3 - Transportation / Storage 3-1

Transport Safety ........................................................................3-1

Storage Safety ..........................................................................3-1

Maintenance Safety ......................................................................3-1

Travel Speed ...........................................................................3-2

Unplugging ............................................................................3-2

Storage and Cleaning ....................................................................3-2

Nitro 275RS -

Table of Contents

II

Section 4 - Troubleshooting / Maintenance 4-1

Tire Safety .............................................................................4-1

Hydraulic Safety ........................................................................4-1

Fluids & Lubricants ......................................................................4-2

Adjusting Apron Chain Tension .............................................................4-2

Every 10 Hours/Daily .....................................................................4-3

Every 10 Hours/Daily .....................................................................4-4

Every 40 hrs / Weekly ....................................................................4-5

Every 400 hrs / Annually ..................................................................4-5

Section 5 - Parts Breakdowns & Lists 5-1

Hitch .................................................................................5-2

Front Shields ...........................................................................5-4

Front Apron Drive .......................................................................5-6

Driveline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Rear Apron Drive .......................................................................5-10

Endgate ..............................................................................5-12

Beaters ..............................................................................5-14

Floor & Side Boards ....................................................................5-16

Single Axle ............................................................................5-18

Tandem Axle (w/o Scales) ................................................................5-20

Tandem Axle (w/ Scales) .................................................................5-22

Apron Runners ........................................................................5-24

Hydraulic Layout .......................................................................5-26

Section 6 - Optional Features 6-1

Light Kit Assembly .......................................................................6-2

Light Kit Wiring Harness ..................................................................6-4

Flow Control Hydraulics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

Electric Flow Control Wiring ...............................................................6-8

N750LC (GT400) / N750LCNT460 Scales ...................................................6-10

N750LCNT8000 Scales ..................................................................6-11

Chain Drive Hydraulics ..................................................................6-12

Reversing the Apron Chain (with Optional Flow Control) ........................................6-12

Section 7 - PTOs 7-1

39850 - PTO. 375,450,525,600,750 (V80-141P028359-028028-CV80-CLS) ..........................7-2

39852 - PTO. 600, 750 (T60-086P265011-306028-CLS(2500NM) ..................................7-4

Torque Value Chart - Imperial VII

Torque Value Chart - Metric VIII

III Table of Contents - Nitro 275RS

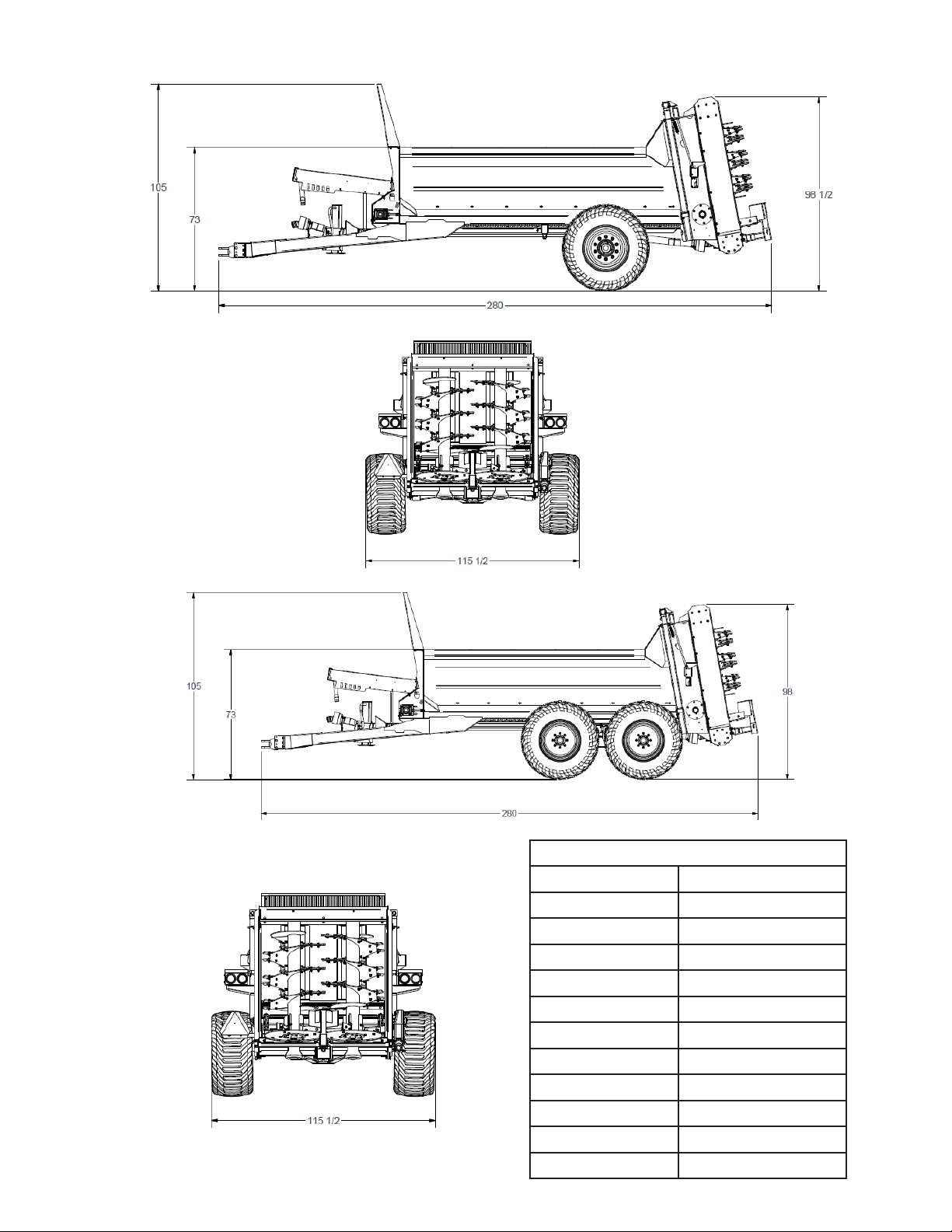

Specications

Nitro 275RS -

Operator’s Manual

Nitro 275

Cu.ft. Struck 220’

Heaped Cu.ft 290’

Inside Width 62”

Inside Depth 32”

Inside Length 160”

Loading Height 69”

Overall Length 23.5’

Beater Diameter 34”

Beater Speed 420 RPM

Axle Type Single/Tandem

Hub Capacity 16,000/12,000 lbs

PTO Speed 1000 RPM

IV

Principals of Operation

The Nitro 275RS Manure Spreader is designed to be hitched behind a tractor. The Manure Spreader

consists of a poly board oor trailer with an apron chain drag system, that pulls material to the rear

of the trailer, through a set of vertical, spinning beaters and is then spread in an even pattern on the

eld. The rear beaters are connected to the tractor’s PTO via gearboxes and PTO drivelines. The

variable speed apron chain is operated from the tractor cab, and controls the speed of materials

being fed through the beaters.

The apron chain and rear lift gate are operated using the tractor’s hydraulic power outputs. The rear

lift gate prevents material from jamming the beaters while loading, as well as preventing material from

falling onto a roadway during transport.

We recommend that you carefully read this entire manual before operating the Manure Spreader.

Please do not assume you know how to operate and maintain your machine before reading this

manual carefully. Keep this manual available for reference.

Call your authorized dealer if you need any assistance or more information.

V

Operator’s Manual

- Nitro 275RS

Section 1 - Safety

Take note! This safety alert symbol is found throughout this manual to call your attention to

instructions involving yourself and others working around the machine.

Failure to follow these instructions can result in injury or death!

This symbol means

- Attention!

Become Alert!

Your Safety is involved!

Safety Signal Words / Safety Messages

CAUTION : Indicates a potentially hazardous situation that may result in injury.

WARNING : Indicates a potentially hazardous situation that could result is serious injury or death.

DANGER : Indicates a hazardous situation that needs to be avoided. It is you the operator that needs

to be aware of these dangers.

If you have any questions not answered in this manual, please contact your dealer or Tubeline

Manufacturing Ltd.

You can also check for a newer manual version at www.tubeline.ca/support

Nitro 275RS -

6455 Reid Woods Drive,

R. R. #4 Elmira

Ontario, Canada

Section 1 - Safety

Email : sales@tubeline.ca

Fax : (519)-669-5808

Tel : (519)-669-9488

N3B 2Z3

1-1

Safety Guidelines

Safety of the operator is one of our main concerns, however we do hear of some accidents that could

have been avoided if some precautions had been taken. To avoid personal injury study the following

precautions and insist those working with you or for you, follow them.

In most cases the pictures will have the shielding in place, in some they may be removed, only to

show a view behind the shield. Keep all the shields, safety doors in place. If they become faulty and

fail to work replace them. They are for your safety, do not operate the equipment with them removed.

Replace any decals that may be missing or that are not readable. Location of the decals is indicated

in this manual.

Do not operate this machine while under the inuence of drugs or alcohol.

Review the safety instructions with all users annually.

This equipment should not be operated by children, or with those unfamiliar with the operation of the

machine. Do not allow persons to operate this machine until they have read this manual and/or were

instructed by a qualied person.

Do not paint over, remove or deface any safety signs or warning decals on your equipment. Observe

all safety signs and practice the instructions on them.

Lighting & Marking

This machine is equipped with lights and reectors as required by the most stringent government and

ASAE specications. They should work with the tractor 7-pin connector.

1-2

Section 1 - Safety

- Nitro 275RS

A Word To The Operator

It is YOUR responsibility to read and understand

the safety section in this book before operating

the Nitro Manure Spreader. You must ensure

that you and anyone else who is going to use,

maintain or work around the Nitro Manure

Spreader be familiar with the use, maintenance

procedures and related safety information

contained in this manual. Remember that YOU

are the key to safety. Good safety practices not

only protect you, but also the people around you.

Most accidents can be prevented. Do not risk

injury or death by ignoring good safety practices.

1. Study the features in this book and make

them a working part of your safety program.

Keep in mind that this safety section is written

only for the Nitro Manure Spreader.

2. Nitro Manure Spreader owners must give

operating instructions to operators or

employees before allowing them to operate

the machine, and at least annually thereafter

per OSHA (Occupational Safety and Health

Administration) regulation 1928.57

3. The most important safety device on

this equipment is a SAFE operator. It is

the operator’s responsibility to read and

understand ALL Safety and Operating

instructions in the manual and to follow these.

4. A person who has not read and understood

all directive and safety instructions is not

qualied to use the Nitro Manure Spreader.

An untrained operator exposes himself and

bystanders to possible serious injury or death.

General Safety

1. Read and understand the Operator’s Manual

and all safety signs before operating,

maintaining, adjusting or cleaning the Nitro

Manure Spreader.

2. All equipment has a limit. Make sure you

understand the speed, brakes (additional

option), stability and load characteristics of

the Nitro Manure Spreader and your tractor

before you start.

3. Make sure the tractor is in proper operating

condition as stated in the tractor Operator’s

Manual. The tractor must have enough

weight and braking capacity, especially when

operating on uneven terrain.

WARNING ! Only use a tractor with a

ROPS cab and seat belt.

4. Have a rst-aid kit available for use should the

need arise and know how to use it.

5. Have a re extinguisher available for use

should the need arise and know how to use it.

6. NEVER allow riders. Keep others away from

your work area.

7. Wear appropriate protective gear. This list

includes but is not limited to:

• Protective shoes with slip-resistant soles

• Protective glasses

• Hearing protection

5. Practice all other usual and customary safe

working precautions and above all ;

REMEMBER ! SAFETY IS YOUR

RESPONSIBILITY. YOU CAN PREVENT

SERIOUS INJURY OR DEATH.

1. This safety section is intended to point out

some of the basic safety situations that can

be encountered during the normal operation

and maintenance of the Nitro Manure

Spreader, and to suggest possible ways of

dealing with these situations. This section is

NOT a replacement for other safety practices

featured in other sections of this book.

Nitro 275RS -

Section 1 - Safety

1-3

• Respirator or lter mask

8. Install and secure all guards before starting.

9. Turn machine off, stop and disable engine,

remove ignition key and place in your pocket

and wait for all moving parts to stop before

servicing, adjusting, repairing, or unplugging.

10. Clear area of people, especially small

children, before using the unit.

11. Review safety related items annually with all

personnel who will operate or maintain the

Nitro Manure Spreader.

12. Where possible avoid operating the Nitro

Manure Spreader near roads, ditches,

embankments or holes. Reduce speed

when operating on rough, slippery, or muddy

surfaces and when turning or crossing slopes,

Stay off slopes too steep for proper operation.

13. Beware of the machine size and have enough

space to allow for operation. Never operate

the Nitro Manure Spreader at high speeds in

crowded places.

14. Do NOT use attachments unless the

attachments are approved optional

equipment.

15. Securely fasten your seat belt before

operating the machine. Always remain seated

when operating the machine.

Equipment Safety Guidelines

1. Safety of the operator and bystanders is

one of the main concerns in designing and

developing equipment. However, every year

many accidents occur which could have been

avoided by a few seconds of thought and a

more careful approach to handling equipment.

You, the operator, can avoid many accidents

by observing the following precautions in this

section. To avoid personal injury or death,

study the following precautions and insist

those working with you, or for you, follow

them.

2. In order to provide a better view, certain

photographs or illustrations in this manual

may show an assembly with a safety shield

removed. However, equipment should never

be used in this condition. Keep all shields in

place. If shield removal becomes necessary

for repairs, replace the shield prior to use.

4. Never use alcoholic beverages or drugs

which can hinder alertness or coordination

while using this equipment. Consult your

doctor about using this machine while taking

prescription medications.

5. Under no circumstances should young

children be allowed to work on this equipment.

Do not allow persons to use or assemble this

unit until they have read this manual and have

developed a thorough understanding of the

safety precautions and of how the machine

works. Review the safety instructions with all

users annually.

6. This equipment is dangerous to children and

persons unfamiliar with its operation. The

operator should be a responsible, properly

trained and physically able person, familiar

with machinery and trained in this equipment’s

operations. If an elderly person is assisting

with work, their physical limitations need to be

recognized and accommodated.

7. Never exceed the limits of a piece of

machinery. If its ability to do a job, or to do it

safely, is in question - DON’T TRY IT.

8. In addition to the design and conguration

of this implement, hazard control and

accident prevention are dependent upon the

awareness, concern, prudence and proper

training of personnel involved in the operation,

transportation, maintenance, and storage of

the machine.

THINK SAFETY! WORK SAFELY!

3. Replace any safety sign or instruction sign

that is not readable or missing. Location of

such safety signs are indicated in this manual.

1-4

Section 1 - Safety

- Nitro 275RS

Safety Training

1. Safety is the primary concern in the

design and manufacture of our products.

Unfortunately, our efforts to provide safe

equipment can be wiped out by a single

careless act of an operator or bystander.

THINK SAFETY! WORK SAFELY!

Safety Signs

2. In addition to the design and conguration

of equipment, hazard control and accident

prevention are dependent upon the

awareness, concern, prudence and proper

training of personnel involved in the operation,

transportation, maintenance and storage of

this equipment.

3. It has been said, “The best safety feature

is an informed, careful operator.” We ask

that you to be that kind of operator. It is

the operator’s responsibility to read and

understand ALL safety instructions in the

manual and follow them. Accidents can be

avoided.

4. Working with unfamiliar equipment can lead

to careless injuries. Read this manual before

assembly or use, to acquaint yourself with

the machine. If this machine is used by any

person other than yourself, or is loaned or

rented, it is the machine owner’s responsibility

to make certain that the operator, prior to

using:

• Reads & understands the operator’s manual.

• Is instructed in safe and proper use.

1. Keep safety signs clean and legible at all times.

2. Replace safety signs that are missing or have

become illegible.

3. Replaced parts that displayed a safety sign

should also display the current sign.

4. Safety signs displayed in Safety Sign Locations

each have a signicant purpose and need to

be cleaned or replaced when necessary.

5. Safety signs are available from your authorized

distributor or dealer parts department or from

the manufacturer.

How to Install Safety Signs

1. Be sure that the installation area is clean and dry.

2. Be sure the temperature is above 10C (50F).

3. Determine the exact position of the new safety

sign before removing the paper backing.

4. Align the sign over the specic area, carefully

press the sign on, slowly peeling away the

backing paper while smoothing the sign in

place.

5. Know your controls and how to stop the

engine and machine quickly in an emergency.

6. Train all new personnel and review

instructions frequently with existing workers.

Be certain only a properly trained and

physically able person will use the machinery.

A person who has not read and understood all

the safety instructions is not qualied to use

the machine. An untrained operator exposes

himself and bystanders to possible serious

injury or death. If the elderly are assisting with

the work, their physical limitations need to be

recognized and accommodated.

Nitro 275RS -

Section 1 - Safety

1-5

5. Small air pockets can be pierced with a pin and

smoothed out using a piece of sign backing

paper.

Safety Sign Locations

The types of safety signs and locations on the equipment are shown in the illustrations that follow.

Good safety requires that you familiarize yourself with the various safety signs, the types of warning,

and the area, or proper function related to that area, that requires your safety awareness.

Examples only - Actual decals may differ in text and graphic representation.

REMEMBER

If safety signs have been damaged, removed, become illegible or parts replaced without safety signs,

new safety signs must be applied. New safety signs are available from your authorized dealer.

H

J

G

E

C

B

I

A

D

F

1-6

Section 1 - Safety

- Nitro 275RS

Item - A

Part # : DE39395

Safety Decals

Item - B

Part # : DE39396

Item - C

Part # : DE42772

Reversing apron chain while spreader is fully loaded will

cause front apron shaft breakage.

Item - D

Part # : DE42782 - Reversing apron chain while spreader is fully

loaded will cause front apron shaft breakage.

Item - E Part # : DE42784

See Operators Manual for

decal explanation.

Nitro 275RS -

Section 1 - Safety

1-7

Safety Decals

Item - F

Part # : DE23845

Item - H

Part # : DE39397

Item - G

Part # : DE23836

Item - I

Part # : DE23838

1-8

Item - J

Part # : DECANADA

Section 1 - Safety

- Nitro 275RS

Section 2 - Operation

Preparation Safety

1. Never use the Nitro Manure Spreader until

you have read and completely understand

this manual and each of the safety messages

found on the safety signs on the Nitro Manure

Spreader.

2. Personal protection equipment including

safety glasses, safety shoes and gloves are

recommended during assembly, installation,

operation, adjustment, maintaining, repairing,

removal, cleaning or moving the unit. Do not

allow long hair, loose tting clothing or jewelry

to be around equipment.

3. Clear working area of obstacles that might

be hooked or snagged, causing injury or

damage.

4. Use only in daylight or good articial light.

and foreign objects. Follow this procedure when

attaching:

1. Clear the area of bystanders and remove

foreign objects from the machine and working

area.

2. Make sure there is enough room to back the

tractor up to the hitch pole.

3. Start the tractor and slowly back it up to the

hitch point.

4. Stop the tractor engine, place all controls in

neutral, set park brake and remove ignition

key before dismounting.

5. Use the hitch pole jack to raise or lower the

pole to align with the drawbar.

6. Install a drawbar pin with provisions for a

mechanical retainer. Install the retainer.

5. Be sure machine is properly maintained,

adjusted and in good operating condition.

6. Ensure that all safety shielding and safety

signs are properly installed and in good

condition.

7. Never ride anywhere on the Nitro Manure

Spreader while setting up, operating or

troubleshooting problems.

8. The upright beaters on the Nitro can maim

or kill. Always check for bystanders before

engaging the PTO.

THINK SAFETY! WORK SAFELY!

Hydraulic Requirements

The Nitro Manure Spreader requires 16 GPM

hydraulic ow for optimal performance.

PTO / Horsepower Requirements

7. Install a safety chain between the tractor

drawbar and the hitch pin.

8. Connect PTO driveline to tractor.

9. Connect the hydraulics. To connect, proceed

as follows:

• Use a clean cloth or paper towel to clean the

couplers on the ends of the hoses. Also clean

the area around the couplers on the tractor.

• Remove the plastic plugs from the couplers

and insert the male ends.

NOTICE: If the direction of motion is wrong,

reverse the couplers.

10. Raise the hitch jack.

11. When unhooking from the tractor, reverse the

above procedure. NOTICE: Occasionally air

may become trapped in the hydraulic circuit,

making it necessary to “bleed” the circuit.

The Nitro 275 Manure Spreader requires a

minimum of 80 horsepower.

Hook-up / Unhooking

The Nitro Manure Spreader should always be

parked on a level, dry area that is free of debris

Nitro 275RS -

Section 2 - Operation

2-1

To perform this operation cycle the hydraulic

several times or especially on older tractors,

temporarily loosen an easily accessible hose

tting enough to allow any trapped air to escape

while cycling the hydraulics. Retighten tting.

Tractor Preparation

Follow this procedure when selecting and

preparing a tractor for use with the machine:

1. Use only a tractor of sufcient power and

weight to adequately handle the machine.

It is recommended that the tractor have

at least 125 PTO horsepower for normal

operating conditions. (See PTO / Horsepower

Requirements on page 2-1.)

2. It is recommended to pin the drawbar in its

centre draft position.

3. Use only a drawbar pin with provisions for

a mechanical retainer. Always install the

retainer.

4. Always attach a safety chain between

the tractor and the machine to prevent

unexpected separation.

Spreader Preparation

2. Check for proper assembly and tighten all

bolts. All bolts were checked at the factory

when assembled but may need to be retorqued as vibrations in shipment may loosen

them slightly.

3. Complete all steps in “Tractor Preparation &

Spreader Preparation” sections.

4. Lubricate the machine. Refer to the Service

section of this manual. Proper maintenance

and lubrication is the user’s responsibility and

must begin before the rst use.

5. Operate the machine slowly for a period of

time to run the chains in and conrm that all

parts work freely.

After operating for 2 hours:

1. Check wheel bolts torque.

2. Check all shields and guards. Tighten as

required.

Your new Nitro spreader has a brief breakingin period that you should follow for optimal

operation, and for maximum lifetime of your

product. When using the machine for the rst

time, it is extremely important to follow all of the

procedures especially those listed in the “Before

using” section to avoid damage:

Before Using

1. Read the Nitro Operator’s Manual. Do not

operate the spreader until the safety

precautions in this manual and the decals on

the spreader have been read and understood

by the operator.

3. Visually inspect all hydraulic hoses and

couplers. See “Hydraulic Safety” in the

Service & Maintenance section of this manual.

4. Check chain tightness. See “Adjust Chain

Tension” in the Maintenance & Safety section

of this manual, page 4-2.

After operating for 10 hours:

1. Repeat the 2 hour service list.

2-2

Section 2 - Operation

- Nitro 275RS

Operation Safety

1. Please remember it is important that you read

and heed the safety signs on the Nitro Manure

Spreader. Clean or replace all safety signs if

they cannot be clearly read and understood.

They are there for your safety, as well as the

safety of others. The safe use of this machine

is strictly up to YOU, the operator.

9. Do not allow riders on the Nitro Manure

Spreader at any time. There is no safe place

for any riders even for troubleshooting issues.

10. Never allow children or unauthorized people

to operate or be around the Nitro Manure

Spreader.

11. Keep the working area clear of people and

other machines to prevent accidents.

2. All things with moving parts are potentially

hazardous. There is no substitute

for a cautious, safe-minded operator

who recognizes potential hazards and

follows reasonable safety practices. The

manufacturer has designed the Nitro Manure

Spreader to be used with all its safety

equipment properly attached, to minimize

the chance of accidents. Study this manual

to make sure you have all safety equipment

attached.

3. Close and secure all guards, deectors and

shields before starting and operating.

4. Read and understand the Owner and

Operator’s Manual before starting. Review

safety instructions annually.

5. Personal protection equipment including

safety glasses, safety shoes and gloves are

recommended during operation, adjustment,

maintaining or repairing. Do not allow long

hair, loose-tting clothing, or jewelry to be

around moving parts.

6. Never place any part of your body where it

could be in danger if movement should occur

during assembly, installation, operation,

maintenance, repairing, unplugging or

moving.

7. Turn tractor off, remove ignition key and place

in your pocket, and wait for moving parts to

stop before servicing, adjusting, repairing or

unplugging.

12. Do not exceed a safe travelling speed when

transporting.

13. Always use extra caution when turning around

corners or in tight areas.

14. The upright beaters on the Nitro can maim or kill.

Always check for bystanders before engaging

the PTO.

Pre-operation Checklist

It is important for both personal safety and

maintaining the good mechanical condition of the

machine that this pre-operational checklist be

followed. Before operating the machine and each

time thereafter, the following areas should be

checked off:

1. Lubricate the machine completely. Refer

to “Service” in the Service & Maintenance

section of this manual.

2. Use only a tractor of adequate power (see

PTO / Horsepower Requirements on pg. 3-1)

and weight to handle the spreader.

3. Ensure that the machine is properly attached

to the tractor using a drawbar pin with

provisions for a mechanical retainer. Make

sure that a retainer is installed.

4. Ensure that the safety chain on the hitch is

installed.

8. Never use alcohol or drugs which can hinder

alertness or coordination while operating

this equipment. Consult your doctor

about operating this machine while taking

prescription medications.

Nitro 275RS -

Section 2 - Operation

2-3

5. Check tires and ensure that they are inated

to the pressure specied for the spreader’s

tires.

6. Check oil level in the tractor hydraulic

reservoir. Top up as required.

WARNING : Use extreme care when working

around a high pressure hydraulic system. Make

sure all connections are tight and all components

are in good repair. Wear hand and eye protection

then searching for suspected leaks.

7. Inspect all hydraulic lines, hoses, ttings

and couplers for tightness. Tighten if there

are leaks. Use a clean cloth to wipe any

accumulated dirt from the couplers before

connecting to the

tractor’s hydraulic system.

See “Hydraulic Safety” in the Troubleshooting

/ Maintenance section of this manual.

8. Inspect all moving and rotating parts. Remove

any debris that has become entangled in the

rear beaters or the PTO drive line.

9. Make sure that all guards and shields are

installed and secured in position.

10. Check the oil level in the gearboxes. Top up

as required.

11. Ensure that the PTO driveline is securely

attached on both ends and can telescope

easily. Check that the PTO driveline shield

rotates freely.

Loading

NOTICE: It is unlawful to allow any manure

spillage to occur on public roadways. Do not

heap load such that manure is allowed to fall off

spreader during transporting on roadways.

Always check the apron chain and slats to make

sure they are not frozen to the bottom of the bed.

Operating the spreader when the slats or chain

are frozen to the bed may cause damage. Also

make sure there are no lumps of manure frozen

to the oor.

It is recommended to make sure the apron chain

is operating properly before loading the spreader.

Unloading

1. Engage the Rear Beaters.

2. Fully Open Rear Gate

Fully extend the cylinders so the gate is fully

open all the way to the top.

NOTICE : Before starting the apron chain, the

operator should get the beaters up to speed and

open the rear gate to desired height.

Turn on the tractor hydraulics used to start the

apron chain. The hydraulics adjust the speed at

which material is being pulled towards the rear

beaters. The slower the speed - the ner the

spread as the rear beaters have more time to

“process” the material.

WARNING : When parking the spreader for

loading, put the tractor in PARK or NEUTRAL and

apply the parking brake.

1. Fully Close Rear Hydraulic Gate

2. Load the Spreader

The manure consistency will determine how full

your spreader can be loaded. Solid manure can

usually be loaded level to slightly heaped. Wet

materials are heavier and may limit loading.

2-4

See Optional Flow Control pages (6-10 to 6-14),

if applicable to your Nitro Manure Spreader.

Section 2 - Operation

- Nitro 275RS

Section 3 - Transportation / Storage

Transport Safety

1. Comply with state and local laws governing

safety and transporting of machinery on public

roads.

2. Do not exceed a safe travel speed. Slow

down on rough terrain and while cornering.

3. Never allow riders on the machine.

4. Keep tractor drawbar and Nitro hitch parallel.

An uneven PTO may shear off a spline shaft.

Below diagram shows standard tractor

dimensions matching the front PTO on the

Nitro spreaders.

Storage Safety

Maintenance Safety

1. Good maintenance is your responsibility. Poor

maintenance is an invitation for trouble.

2. Follow good shop practices.

• • Keep service area clean and dry

• • Be sure electrical outlets and tools are

properly grounded

• Use adequate light for the job at hand

3. Never attempt to service hydraulic

applications while pressurized or with engine

running.

4. Never work under equipment unless it is

blocked securely.

5. Always use personal protection devices such

as hand, eye and hearing protectors, when

performing any service or maintenance work.

1. Store the Nitro Manure Spreader in an area

away from human activity.

2. Do not allow children to play on or around the

Nitro Manure Spreader.

3. Store the Nitro Manure Spreader in a dry,

level area.

6. Where replacement parts are necessary for

periodic maintenance and servicing, genuine

factory replacement parts must be used to

restore your equipment to original

specications. The manufacturer will not be

responsible for injuries or damages caused

by the use of unapproved parts and/or

accessories.

7. A re extinguisher and rst aid kit should be

kept readily accessible while performing

maintenance on this equipment.

8. Periodically tighten all bolts, nuts, and screws

and check that all electrical connections are

properly secured to ensure unit is in a safe

condition.

9. When completing maintenance or service

function, make sure all safety shields and

devices are installed before placing unit into

service.

Nitro 275RS -

Section 3 - Transportation / Storage

3-1

Travel Speed

A suggested starting speed is between 4-5 mph.

This can be adjusted to operator preference.

WARNING: Stop tractor engine, place all controls

in neutral, set park brake, remove ignition key

and wait for all moving parts to stop before

servicing, adjusting, repairing or unplugging.

Storage and Cleaning

WARNING: Normally, the load itself blocks

manure and loose materials from being thrown

towards the front. As the load/pile gets reduced,

the rotation of the rear beaters can throw

some material forward, therefore it is strongly

recommended to lower the rear gate about 1/3

of the way down to prevent debris from being

projected towards the front.

Unplugging

The following is a recommended procedure

that may help if the manure spreader becomes

plugged or the PTO disengages:

1. Disengage the hydraulics that run the apron

chain.

2. Reverse the apron chain by ipping your

tractor hydraulic lever.

3. Engage the hydraulics to reverse the apron chain

in order to back material away from beaters.

Stop apron chain after material is backed

away from beaters or if pile doesn’t move.

Disconnect PTO drive shaft and hydraulic

hoses before cleaning, adjusting, lubricating, or

servicing this machine.

1. The spreader must be thoroughly cleaned

for extended storage. Manure is acidic and

will damage paint and cause rusting of metal

components.

2. Allow the spreader to completely unload.

3. To clean the spreader, raise the rear gate.

WARNING: Turn off all power during cleaning

and inspection. Do not use power to move

any components or to discharge material

while cleaning or inspecting.

4. Hose off manure from the outside and inside

of the spreader. Completely clean manure

from moving mechanisms such as the beaters

and rear gate. Remove accumulation in

conned areas or pockets that trap manure.

5. Avoid directing high pressure spray directly on

bearings, seals and ow control valve.

WARNING: Reversing chain under full load will

cause front aporn shaft to bend and/or break.

4. Engage the beaters. Bring beaters back up to

regular speed.

5. Follow the instructions in the Unloading

section (pg. 2-4) to start the apron chain in the

standard operation direction.

If this above procedure does not solve the

situation, closer inspection and possible manual

unplugging may be required. Make sure to stop

tractor and wait for all moving parts to stop before

servicing or unplugging:

3-2

6. Keep high pressure spray moving on painted

surfaces. Sustained spray on cracks or

scratches in paint can result in paint peeling.

7. Allow machine to dry.

8. Lower rear gate completely down before

storing spreader.

9. Inspect the spreader for loose connections,

damaged hydraulic hoses or connections

and for other damaged components. Repair if

necessary so the spreader is ready for future

operation. See Hydraulic Safety on page 4-1.

Section 3 - Transportation / Storage

- Nitro 275RS

Section 4 - Troubleshooting / Maintenance

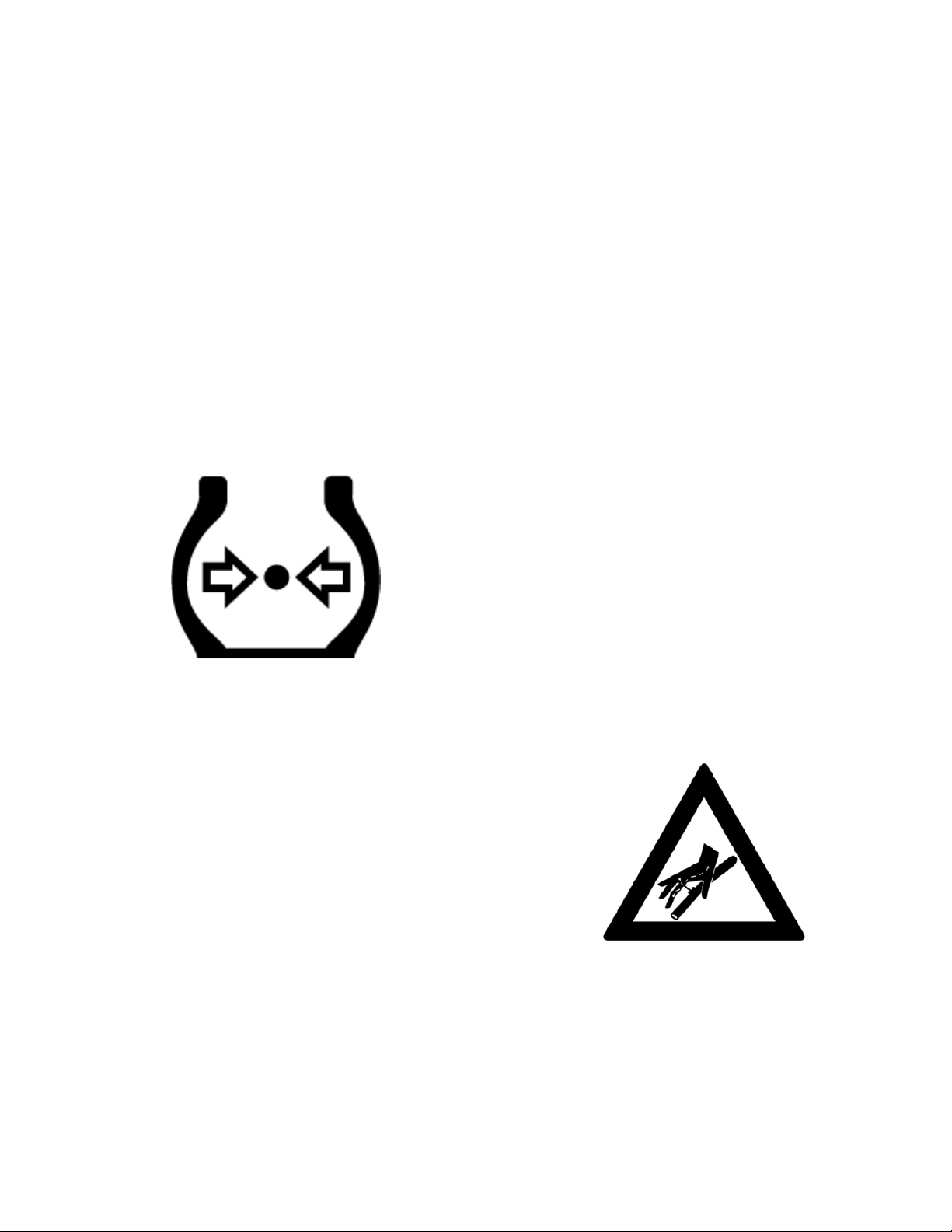

Tire Safety

1. Failure to follow proper mounting procedures

when mounting a tire on a wheel or rim can

produce an explosion which may result in

serious injury or death.

2. Do not attempt to mount a tire unless you

have the proper equipment and experience to

do the job.

3. Have a qualied tire dealer or repair service

perform required tire maintenance.

4. When replacing worn tires, make sure they

meet the original tire specications.

Hydraulic Safety

1. Make sure that all components in the

hydraulic system are kept in good condition

and are clean.

2. Before applying pressure to the system, make

sure that all components are tight, and that

lines, hoses and couplings are not damaged.

3. Do not attempt any makeshift repairs to the

hydraulic lines, ttings, or hoses by using

tapes, clamps or cements. The hydraulic

system operates under extremely high

pressure. Such repairs will fail suddenly and

create a hazardous and unsafe condition.

4. Wear proper hand and eye protection when

rearching for a high pressure hydraulic

leak. Use a piece of wood or cardboard as

a backstop instead of hands to isolate and

identify a leak.

5. If injured by a concentrated high pressure

stream of hydraulic uid, seek medical

attention immediately. Serious infection or

toxic reaction can develop from hydraulic uid

piercing the skin surface.

6. Relieve pressure on the hydraulic system

before maintaining or working on the system.

Nitro 275RS -

Section 4 - Troubleshooting / Maintenance

4-1

Fluids & Lubricants

1. Grease: Use an SAE multi-purpose grease

with extreme pressure (EP) performance. Also

acceptable is an SAE multi-purpose lithium

base grease.

2. Gearbox Oil: Use an SAE 80W90 gear oil for

all operating conditions.

3. Storing Lubricants: Your machine can operate

at top efciency only if clean lubricants are

used. Use clean containers to handle all

lubricants. Store them in an area protected

from dust, moisture and other contaminants.

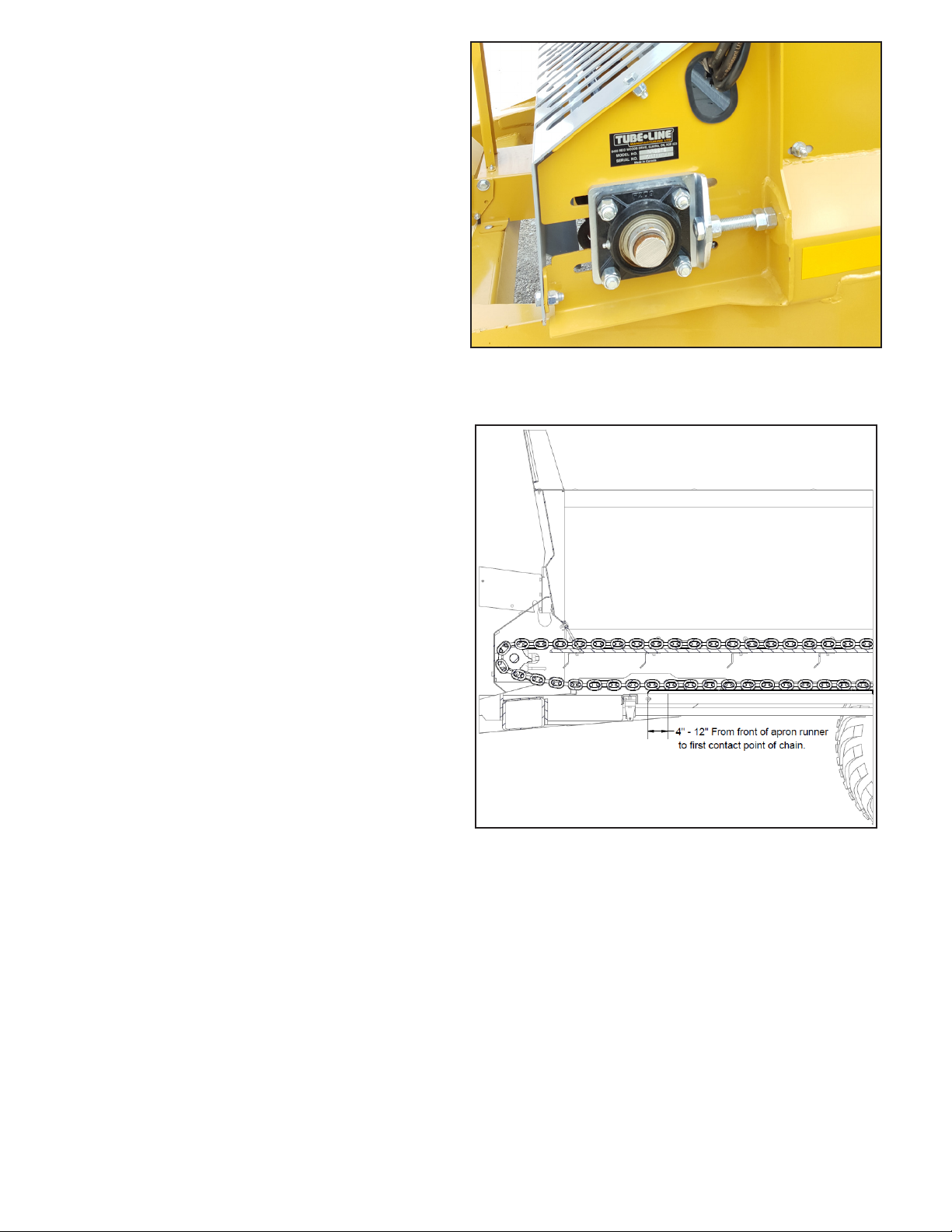

Adjusting Apron Chain Tension

1. Occasionally check the apron chain for any

bent or damaged slats. It is important to

straighten or replace any damaged slats

immediately.

2. The apron chain tension should be checked

and adjusted on occasion. If apron chain has

slack, tightening is required:

• To tighten apron chain, loosen the four bolts

on bearing and turn nut until proper tightness

is achieved (both sides) then tighten 4 bolts

on the bearing.

When adjusting the apron chain tension use the

following procedure.

1. Start on one side and tighten the nut a few

turns.

Apron chain tension adjustment

of spreader.

2. Repeat on opposite side of machine to evenly

tighten chain tension.

3. Repeat this procedure 2-3 times until

moderate chain tension is achieved.

CAUTION: It is important to ensure nuts on 4

bolts on bearing are tightened after adjusting

apron chain. In the event of the nuts not being

tightened, and the apron chain is reversed, equipment damage may occur.

4-2

Correct Apron Chain Adjustment

Section 4 - Troubleshooting / Maintenance

- Nitro 275RS

Greasing your Machine

• Use only a hand-held grease gun for all greasing.

• Wipe grease tting with a clean cloth before greasing, to avoid injecting dirt.

• Replace and repair broken ttings immediately.

• If ttings will not take grease, remove and clean thoroughly. Also clean lubricant passageway.

• Replace tting if necessary.

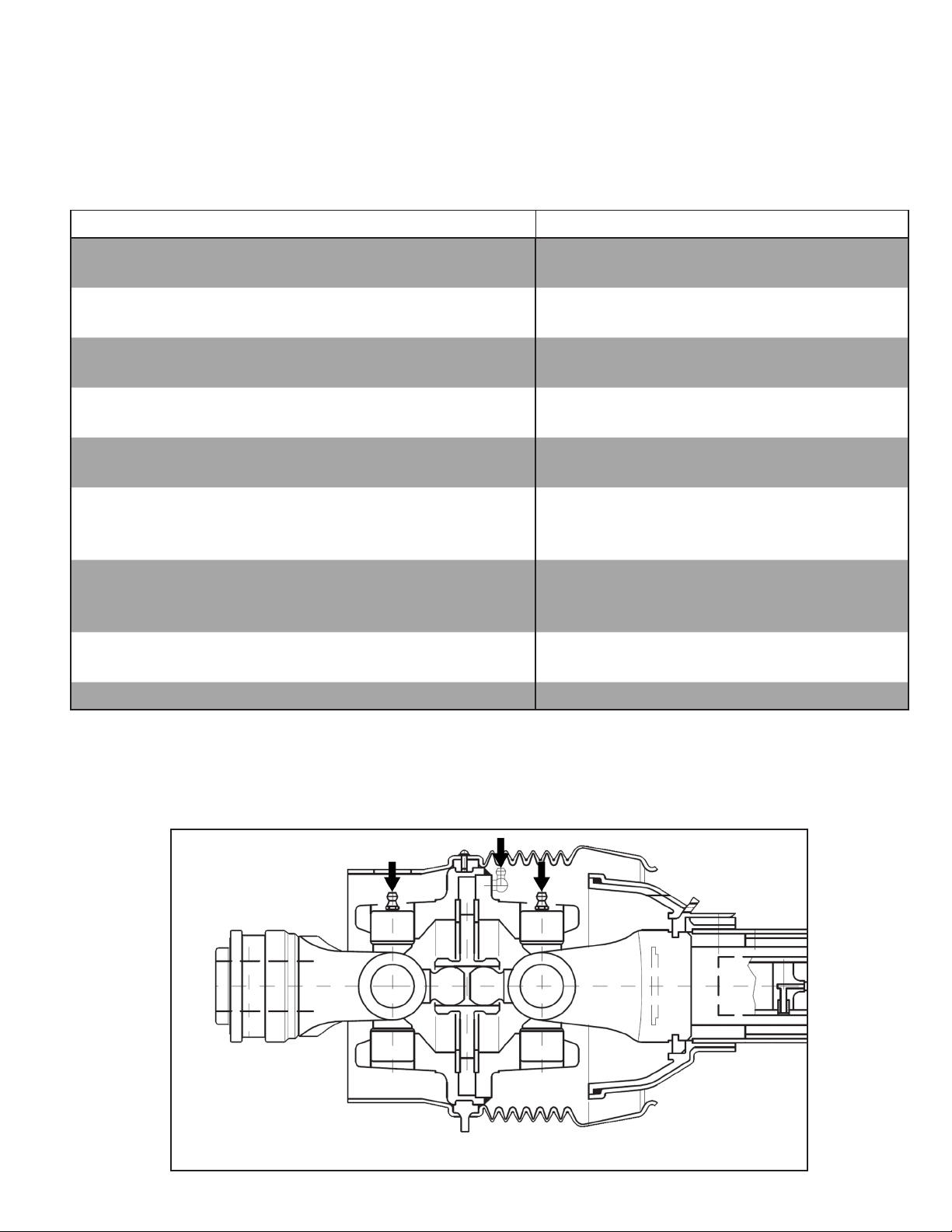

NITRO GREASE POINTS SERVICE RECOMMENDATION

Detail A - Three Driveline Pillow Block Bearings Every 10 hours of operation,

2-3 pumps w/ grease gun

Detail A - One Rear PTO Driveline - 2 crosses w/ zerks,

zerk in inner sleeve

Every 25 hours of operation,

2-3 pumps w/ grease gun

Detail B - Two Top Beater Flange Bearings Every 10 hours of operation,

2-3 pumps w/ grease gun

Detail C - One Front PTO Driveline - 2 crosses w/ zerks,

zerk in inner sleeve

Every 16 hours of operation,

2-3 pumps w/ grease gun

Detail D - Two Front Apron Shaft Flange Bearings Every 10 hours of operation,

2-3 pumps w/ grease gun

Detail E - Beater Gearboxs - Two double shaft (outer),

One triple shaft (center)

Change oil every 200 hours / Semi-

Annually w/ SAE 80W90 gear oil - Remove

a cap to check level, top up as needed

Detail F - One Apron Chain Gearbox Change oil every 200 hours / Semi-

Annually w/ SAE 80W90 gear oil - Check

level with sight glass, top up as needed

Detail G - Two Beater Spinner Chain Couplers Every 10 hours of operation, use aeresol

chain lubricant

Jack Follow manufacturer recommendation

Notice: Nitro spreaders equipped with grease lines still require seperate greasing and/or oil changes

on gearboxes, front driveline bearing, and PTOs.

Nitro 275RS -

Front PTO Driveline CV joint grease points.

Section 4 - Troubleshooting / Maintenance

4-3

Loading...

Loading...