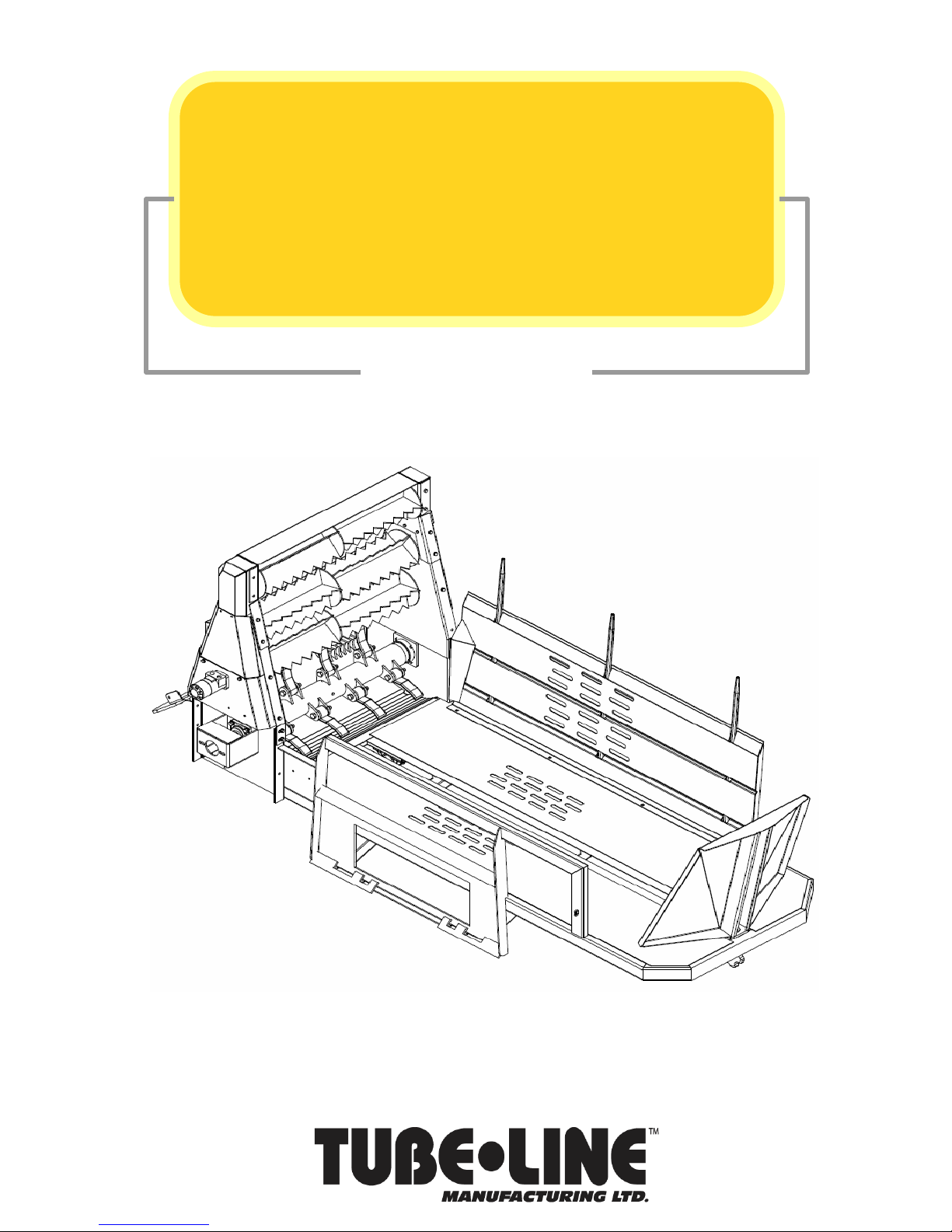

Tubeline Boss I Operator's Manual

Operator's Manual

Tube-Line Bale Processor

Boss I

3

TABLE OF CONTENTS

TUBE LINE Manufacturing

3928 Steffler Road

RR# 4

Elmira, ON N3B 2Z3

Canada

1-888-856-6613

Fax 519-664-0492

sales@tubeline.com

www.tubeline.com

Owner and Operator and Safety Information ……………………....3-6

Definitions of Safety Terms and Symbols, Accident Prevention ...3

Safety Instructions ……………………………………………..4-5

Safety Signs ...........................................................................6

Power Unit Specifications ………………………………….……….…..7

Installation Instructions ……………………………………...…………7

Hydraulic Instructions …………………………………………………..7

Operation …………………………………………………………..…….8

Maintenance ……………………………………………………………..9

Service ……………………………………………………………..……..9

Grease Points …………………………………………………………..10

Deck Assembly …...………………………………….………...………11

Top Beater Assembly …………………………………………...…….12

Bottom Beater Assembly………………………………………………13

Ram Assembly ………………………………….…………………...…14

Hydraulic Schematic …………………………………………………..15

Warranty Policy………………………………………….………...……16

4

INTRODUCTION

Thank you for purchasing your new Boss I square bale processor. Your Boss I was designed to

load and shred all types of forage in large square bales up to 1500 pounds (680 kg). Maximum

length of bales is 84” (213 cm) X 36” (91 cm) X 36” (91 cm)

The Boss I square bale processor has multiple uses:

Laying windrows in open fields.

Filling feed bunks – fence line, circular, etc.

Spreading forage for livestock bedding.

Spreading mulch over perennial plants such as strawberries and mushrooms.

The Boss I was carefully designed and manufactured to give you many years of dependable

service. You or any other person, who will be assembling, operating, maintaining or working with

this product, are required to read and completely understand the information and instructions

contained in this manual. If anyone does not fully understand every part of this manual, please

obtain further assistance by contacting the dealer from which this product was purchased or by

contacting Tube·Line at the telephone number or address listed on the previous page of this

manual. Keep this manual available for reference whenever this product is being handled or

used. Provide this manual to any new owners and/or operators.

GENERAL INFORMATION

The purpose of this manual is to assist you in safely assembling, mounting, operating and

maintaining your Boss I. Read this manual carefully to obtain valuable information and

instructions that will help you achieve safe and dependable service. The illustrations and data

used in this manual were current at the time of printing, but due to possible engineering and/or

production changes, this product may vary slightly in detail. Tube·Line reserves the right to

redesign and/or change components as necessary without notification.

Throughout this manual, references may be made to:

Power Unit The engine-driven machine to which this product must be attached.

Right, Left,

Front, Rear

Directions which are determined in relation to the operator of the equipment

when seated in the normal operating position.

IMPORTANT Precautions that must be followed to prevent damage to equipment.

NOTICE Precautions that must be followed to prevent substandard performance.

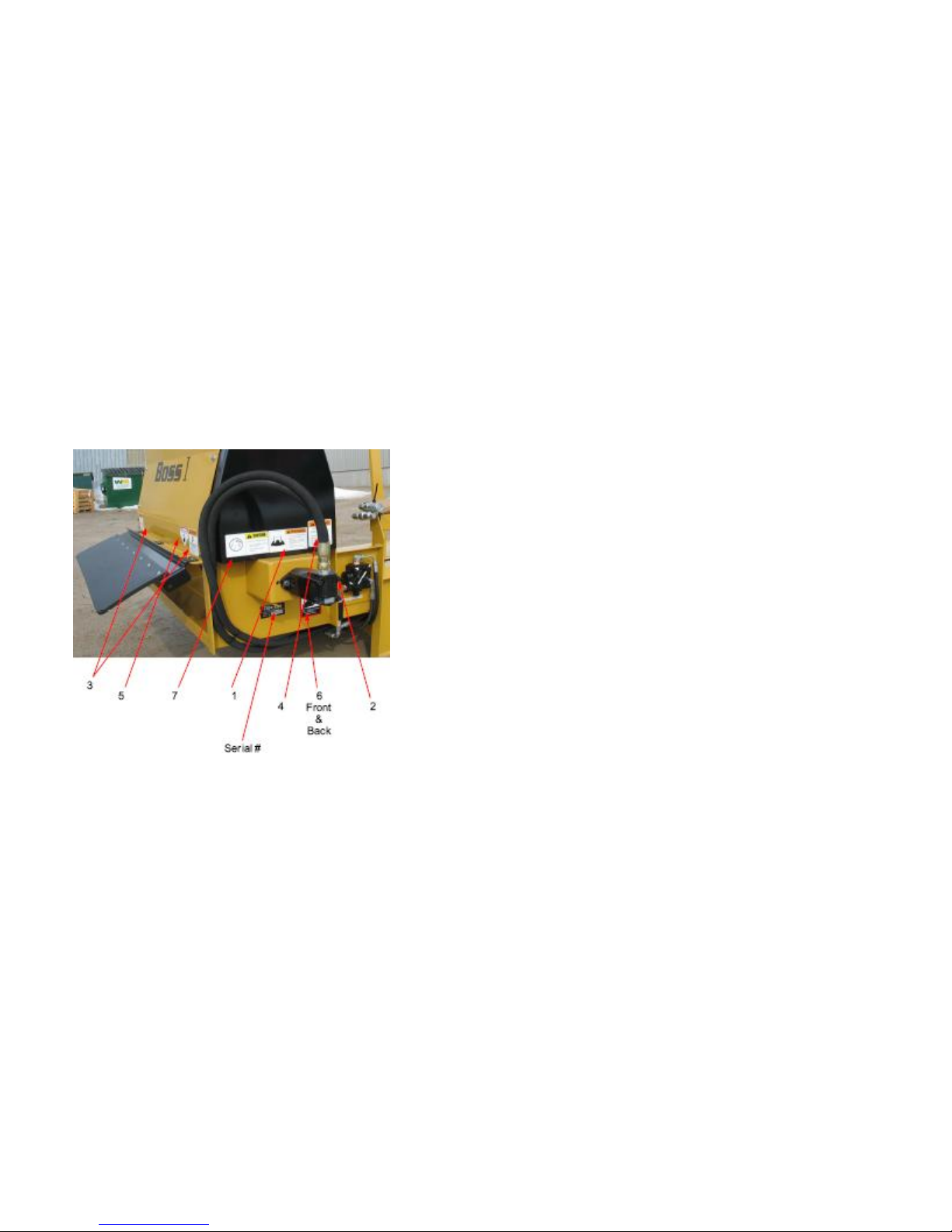

SERIAL NUMBER LOCATION

Always refer to the model and serial number when ordering parts or requesting

information from your dealer. The serial number plate is located on upper left

front corner of the tub of your Boss I. Refer to diagram on page 6.

5

DEFINITION OF SAFETY TERMS AND SYMBOLS

Throughout this manual, the terms DANGER, WARNING and CAUTION are used to

indicate the degree of hazard to personnel if proper safety procedures are not followed.

These words will be used in conjunction with the Safety Alert Symbol: a dark triangle

containing a white exclamation mark.

The Safety Alert Symbol means:

- ATTENTION! - BECOME ALERT! - YOUR SAFETY IS INVOLVED!

DANGER Indicates an imminently hazardous situation, which, if not avoided,

WILL result in death or serious injury.

WARNING Indicates a potentially hazardous situation, which, if not avoided,

Could result in death or serious injury.

CAUTION Indicates a potentially hazardous situation, which, if not avoided,

May result in minor or moderate injury;

OR

May also be used to alert against unsafe practices, which may result in damage to property.

The safety information given in this manual does not replace any safety

codes, insurance needs, federal, state and local laws.

ACCIDENTS CAN BE PREVENTED WITH YOUR HELP!

The best safety device is a careful operator.

Tube·Line and your dealer ask that YOU be

that careful, responsible equipment operator.

Pay attention to the job at hand. Do not let

your mind lose concentration on what you are

doing. No accident prevention program can

be successful without the wholehearted

cooperation of the person who is directly

responsible for the operation of the

equipment.

If accidents are to be prevented (and

accidents can be prevented), that prevention

will come from equipment operators who

accept their complete responsibility and

anticipate the results of their actions.

The designer, the manufacturer, and the

safety engineer all help create a safe product,

but their combined efforts can be wiped out

with a single careless act by the operator of

that product.

Do not attempt to operate this equipment

under the influence of drugs or alcohol.

YOU ARE THE KEY TO SAFETY BECAUSE:

YOU are responsible for the SAFE operation and

maintenance of YOUR Side Discharge Bucket.

YOU are responsible to familiarize yourself, and

anyone else who will assemble, operate, maintain, or

work around this product, with the safety information

contained in this manual.

YOU are responsible to read ALL information

contained in this manual to any operators or

maintenance personnel who are not fully able to read

the written English language. Whether YOU read the

manual as written or translate it into another

language, YOU must make certain that all operators

and maintenance personnel have complete

understanding of the full and exact contents of this

manual.

YOU can reduce the risk of injury or death by

following all safety precautions and by using good

safety practices.

6

Safety Instructions

WORK SAFELY – A CAREFUL OPERATOR IS THE BEST INSURANCE AGAINST

ACCIDENTS!!

SECTION 1

WARNING SECTION

WARNING

Obey all safety instructions listed in this section and throughout this manual. Failure to obey instructions

in this section could result in death or serious injury.

BEFORE ATTEMPTING ANY TYPE OF ASSEMBLY, OPERATION, MAINTENANCE OR OTHER WORK

ON OR NEAR THIS PRODUCT:

READ AND COMPLETELY UNDERSTAND THIS MANUAL.

READ AND COMPLETELY UNDERSTAND THE MANUALS PROVIDED WITH YOUR POWER UNIT,

LOADER AND QUICK-ATTACH. Read and understand all safety signs on this product and on your power

unit, loader and quick-attach. Know all your controls and know how to quickly stop all power unit

movements, the processor movement, and the engine in case of emergency. Know and obey all

applicable government rules, O.S.H.A regulations, local laws and other professional guidelines for your

operation. Make sure that anyone who will be assembling, mounting, maintaining, repairing, removing

and/or storing this product: Has been instructed in the safe operation of this product and of the power unit

and the quick-attach to which this product is attached. Is physically and mentally capable of the safe

operation of this type of equipment. Is not under the influence of drugs or alcohol. Is carefully supervised

from a safe distance, especially if such person is inexperienced.

Wears personal protective equipment (i.e. hardhat, safety glasses, work gloves, protective shoes,

respirator, ear protection, etc.) Does not wear loose fitting clothes, loose or uncovered hair or any

accessories (jewelry, necktie, scarf, wrist watch, etc.) that can catch and entangle on moving parts.

Has annually reviewed all safety instructions. Know and follow good work practices when assembling,

mounting, maintaining, repairing, removing and storing this product: Work on a level surface in a well lit

area. Keep the area clean and dry. Use properly grounded electrical outlets and tools. Use the right tool

for the job at hand. Make sure that your tools are in good condition for performing the desired function.

When using tools, wear the protective equipment specified by the tool manufacturer (i.e. hardhat, safety

glasses, work gloves, protective shoes, etc.).

WHEN YOUR POWER UNIT IS USED DURING ANY TYPE OF ASSEMBLY, OPERATION,

MAINTENANCE OR OTHER WORK ON OR NEAR THIS PRODUCT:

Before leaving the operator’s station or before beginning any type of work on this product, lower this

product to the ground, apply your power unit’s parking brake, stop the engine, remove the starter key, wait

for all moving parts to stop and then relieve all pressure in the hydraulic lines. Refer to your power unit’s

operator’s manual for instructions on how to relieve hydraulic pressure in lines.

Know your loader’s safe lifting and operating capacity and the weight of this product. See the

specifications in this manual for the weight of this product and refer to your power unit’s and loader’s

operator’s manuals for safe operating limits. Lift capacity may be reduced if using a quick-attach.

Never allow anyone, except the operator, to be around the power unit or this product when either is in

motion. Do not start up unless others are clear of the work area. Do not allow riders on this product or the

power unit. Do not stand or climb on this product when raised. Do not place any part of your body under

any part of this product unless this product is securely resting on adequate blocking or on the ground. Do

not use blocking made of concrete blocks, logs, buckets, barrels or any other material that could suddenly

collapse or shift positions. Do not use wood or steel blocking that shows any signs of material decay. Do

not use wood blocking that is warped, twisted or tapered. Never operate controls from the ground.

Operate the controls only from the operator’s station. Never leave the equipment unattended with the

engine running or with this product raised on the loader. Be aware of the added weight and width of this

product. Reduce travel speeds accordingly, especially when traveling over rough ground. Keep this

product close to the ground and under control when transporting. When transporting, be sure processor

does not block view of vehicle lights or road.

7

WARNING SECTION [Continued]

WARNING

Obey all safety instructions listed in this section and throughout this manual. Failure to obey instructions in

this section could result in death or serious injury.

WHEN DEALING WITH HYDRAULICS DURING ANY TYPE OF ASSEMBLY, OPERATION,

MAINTENANCE OR OTHER WORK ON OR NEAR THIS PRODUCT:

Hydraulic fluid under pressure can penetrate the skin and cause serious injury or death. Hydraulic leaks

under pressure may not be visible! If any fluid penetrates the skin, GET IMMEDIATE MEDICAL

ATTENTION!! Wear safety glasses, protective clothing and use a sound piece of cardboard or wood when

searching for hydraulic leaks. DO NOT USE YOUR HANDS!

Before connecting or disconnecting hydraulic hoses, read your tractor or power unit’s operator’s manual

for detailed instructions on connecting and disconnecting hydraulic attachments. Make certain that all parts

meet the specifications for this product when installing or replacing hydraulic hoses or fittings. After

connecting hydraulic lines: Slowly and carefully raise the loader and cycle the rollback / dump cylinders to

check hose clearances and to check for any interference. Operate the hydraulics on this product to check

hose clearances and to check for any interference. Make certain that the hoses cannot interfere with or

actuate the quick-attach mechanism. Make certain that hoses will not be pinched, or get tangled, in any

equipment. Do not lock the auxiliary hydraulics of your power unit in the “ON” position.

Refer to your power unit’s operator’s manual and this manual for procedures and intervals, then inspect

and maintain the entire hydraulic system to insure that the fluid remains cleans, that all devices function

properly and that there are no fluid leaks.

WHEN MOUNTING THIS PRODUCT TO YOUR POWER UNIT:

Refer to the operator’s manuals of your power unit, your loader and your quick-attach for special or

detailed mounting instructions. This product should fit onto the quick-attach or loader arms of your power

unit the same as the original products that were designed by your loader / quick-attach manufacturer. If

this product does not fit properly, contact Tube·Line before operating. Never place your finger into the

mounting plate or 3-point hitch or loader holes. A slight movement of the power unit or this product could

cause serious injury.

Make certain that all safety signs are in place and legible. Refer to the safety sign page in this manual for

the placement of safety signs for this product. Inspect driveline shield for free rotation. Replace all

damaged or excessively worn parts and hardware only with genuine Tube·Line parts or with properly rated

fasteners, hydraulic hoses or fittings. Make certain that all locking pins, latches and connection devices are

properly installed and secured. Make certain that all shields are in place and secure. Remove all foreign

objects from processor.

Never use processor on a power unit that is not equipped with a cab or ROPS, and operator restraints

(seat belts or equivalent devices).

Make sure bales are free from foreign objects.

Drive slowly through gates and doors.

Know your loader’s safe operating weight limit and the weight of your loader attachment.

WHEN ADJUSTING, SERVICING OR REPAIRING THIS PRODUCT:

Make no modifications to your processor.

When making repairs, use only genuine Tube·Line parts or, for fasteners, hydraulic hoses or hydraulic

fittings, use only properly rated parts.

Replacement parts, for parts with safety signs attached, must also have safety sign attached.

Think SAFETY!

Work SAFELY!

8

SAFETY SIGN LOCATIONS

PLACEMENT OR REPLACEMENT OF SAFETY SIGNS

Clean the area of application with non-flammable solvent, then, wash the same area with

soap and water. Allow the surface to fully dry. Remove the backing from the safety sign,

exposing the adhesive surface. Apply the safety sign to the position shown in the diagram

above and smooth out any bubbles.

INSTRUCTIONS

Keep all safety signs clean and legible.

Replace all missing, illegible or damaged safety signs.

Replacement parts for parts with safety signs attached must also have safety signs attached.

Safety signs are available free of charge from your dealer or from Tube-Line.

9

Loading...

Loading...