2

TO THE OWNER

This manual contains information concerning the adjustment, assembly and maintenance

of your Tube-Line Chainless Bale Feeder. You have purchased a dependable machine,

but only by proper care and operation can you expect to receive the performance and long

life built into the Bale Feeder. Please have all operators read this manual carefully and

keep it available for ready reference.

Your authorized dealer will instruct you in the general operation of your Bale Feeder. Your

dealer’s staff of factory-trained service technicians will be glad to answer any question

that may arise regarding the operation of your Bale Feeder.

This safety alert symbol indicates important safety messages in this manual. When

you see this symbol, carefully read the message that follows and be alert to the

possibility of personal injury or death.

WARNING

Improvements

Tube-Line Manufacturing Inc. is continually striving to improve its products. We reserve the

right to make improvements or changes when it becomes practical and possible to do so,

without incurring any obligation to make changes or additions to the equipment sold

previously.

WARNING

Pictures in this manual may show protective shielding open or removed

to better illustrate a particular feature or adjustment.

Be certain, however, to close or replace all shielding before operating the machine

3

Contents

Safety…………………..…………..5

Parts ………………..…………….15

General information……..………34

Operation………………..……….40

Lubrication ……………………....42

Maintenance…………………..…44

Troubleshooting……………….…45

Optional Equipment………….…..46

4

Precautionary Statements

Personal Safety

Throughout this manual and on machine decals you will find precautionary

statements (“DANGER”, “WARNING”, and “CAUTION”) followed by specific

instructions. These precautions are intended for the personal safety of you

and those working with you. Please take time to read them.

This word “DANGER” indicates an immediate hazardous situation that, if not

avoided, will result in death or serious injury.

________________

DANGER

WARNING

This word “WARNING” indicates a Potentially Hazardous situation that, if not avoided,

could result in death or serious injury.

CAUTION

This word “CAUTION” indicates a potentially hazardous situation that, if not avoided,

may result in minor or moderate injury. It may also be used to alert against unsafe

practices.Failure to follow the danger warning and caution instructions may result in

serious bodily injury or death.

MACHINE SAFETY

The precautionary statement (“important”) is followed by specific

instructions. This statement is intended for machine safety.

IMPORTANT: The word “IMPORTANT” is used to inform the reader of

something he needs to know to prevent minor machine damage if a certain

procedure is not followed.

5

A careful operator is the best operator. Most accidents can be avoided by

observing certain precautions. To help prevent accidents read the following

precautions before operating this equipment. Equipment should be operated

only by those who are responsible and instructed to do so.

Carefully review the procedures given in this manual with all operators. It is

important that all operators be familiar with and follow safety precautions.

1. When transporting the machine on public

roads, make sure the machine is in

compliance with all local road regulation.

2. Before operating the unit be sure that it is

assembled correctly and in good

operating condition.

3. If machine maintenance work, repairs or

adjustments must be done in the field,

they should be done at a spot where the

ground is firm and level. Turn off the

tractor and apply the parking brake. Use

the proper tools and wear suitable

protection (safety goggles, work gloves,

etc.).

4. If any maintenance work, repairs or

adjustments are done which require

disassembly, always make sure that

everything is reassembled or retightened

as it has been prior to making repairs or

adjustments.

5. Follow the schedule provided for

maintenance. By following these

suggestions, it will be possible to keep the

machine operating safely and efficiently,

to the benefit of the user.

6. General checking of bolts, security pins

and split pins must be carried out initially

after the first 8 hours of use.

Subsequently, check every 50 hours and

whenever the machine is laid up for

extended periods.

7. Before applying pressure to the

system, be sure all connections are

tight and that hoses and

connections are not damaged.

8. Fluid under pressure can have

sufficient force to penetrate the

skin, causing serious personal

injury. Always protect the skin and

eyes from escaping fluid under

pressure. If injured by escaping

fluid, obtain medical assistance at

once. Serious infection or reaction

can develop if medical treatment is

not administered immediately.

9. Do not weld on wheels. Welding on

wheels may cause high stress and

a wheel failure.

10. Do not weld on wheels with a

mounted tire. Welding on wheels

with a mounted tire may cause the

tire to burst, causing serious injury

or death.

11. Before leaving the cab, engage

the parking brake, shut down

engine, and wait for all moving

parts to stop.

12. Always keep bystanders away

from machine during operation,

Rotating elements may cause

serious bodily injury.

Safety

Precautionary Statements

6

General Safety

YOU are responsible for the safe operation and maintenance of your Tube-line Chainless Bale

Feeder. You must ensure that you and anyone else who is going to operate, maintain or work around

the Bale Feeder be familiar with the operating and maintenance procedures and related safety

information contained in this manual.

Remember, YOU are the key to safety. Good safety practices not only protect you but also the

people around you. Make these practices a working part of your safety program. Most accidents can

be prevented. Do not risk injury or death by ignoring good safety practices.

Review the operating instructions for this header at least once a year per OSHA regulations 1928.57.

Know the meaning and location of each decal before operating the BF5000.

Watch for this symbol in this manual and on the Bale Feeder:

1. Keep a first aid kit in the cab for emergencies and know how to use it.

2. Do not allow any one to ride on the Bale Feeder while it is in motion.

3. Clear the area of bystanders, especially small children before starting the Bale

Feeder.

4. Do not allow anyone to operate the Bale Feeder who has not been instructed in

how to use the machine.

5. All operators should familiarize themselves with the safety section in the

operator’s manual.

6. Some pictures or illustrations may not show protective shields in place. Make

certain that all protective shields are in place before operating the machines.

Operating and Maintenance safety

1. DANGER, DO NOT stand around or near the Discharge or bed area. Objects

thrown from the beaters may cause death or serious injury

2. Hydraulic leaks can penetrate the skin causing serious injuries. Small leaks can

be invisible and are the most dangerous. Use some object, like cardboard, to

find the leak. Do not use your hand.

7

Ensure that all the pressure is released from the hydraulic lines before repairing.

Replace or repair damaged hoses immediately.

Hydraulic Safety

When checking for oil leaks use a piece of cardboard; DO NOT use your hand:

Escaping fluid under pressure can penetrate the skin causing serious injury.

Avoid the hazard by relieving pressure before disconnecting hydraulic of other lines.

Tighten all line connections before applying pressure.

Protect hands and body from high-pressure fluids.

If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically

removed within a few hours or gangrene may result. Doctors unfamiliar with this type of injury

should reference a knowledgeable medical source. Failure to comply could result in death or

serious injury.

DO NOT weld on or near rotating parts. Welding close to rotating parts will cause warping and

will challenge the structural integrity.

DO NOT weld on or near rotating parts. Welding close to rotating parts may cause warping

thus creating high stress loads for moving or rotating parts.

DO NOT weld on wheels. Welding on wheels may cause high stress and wheel failure.

DO NOT weld on wheels with a mounted tire, Welding on wheels with a mounted tire may

cause tire to burst, causing serious injury or death.

WARNING

8

9

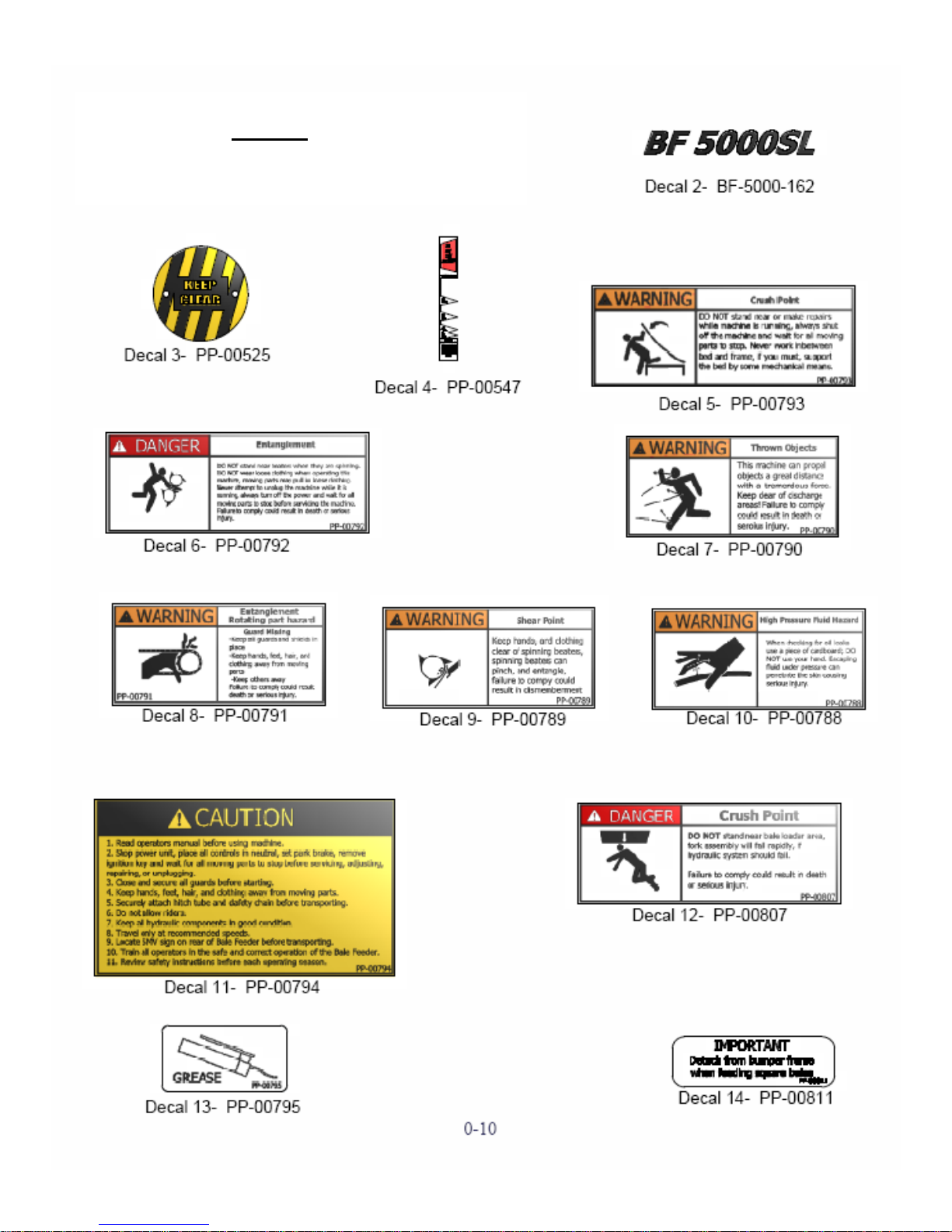

The following safety decals have been placed on your machine in the areas indicated. They

are intended for personal safety and or those working with you. Please take this manual and

walk around your machine to note the content and location of these warning sign. Review

these warning signs and the operating instruction detailed in this manual with your machine

operators. Keep the decals legible, if they are not, obtain replacements from your authorized

dealer. The decal replacement numbers are listed with each decal.

Decals

10

11

12

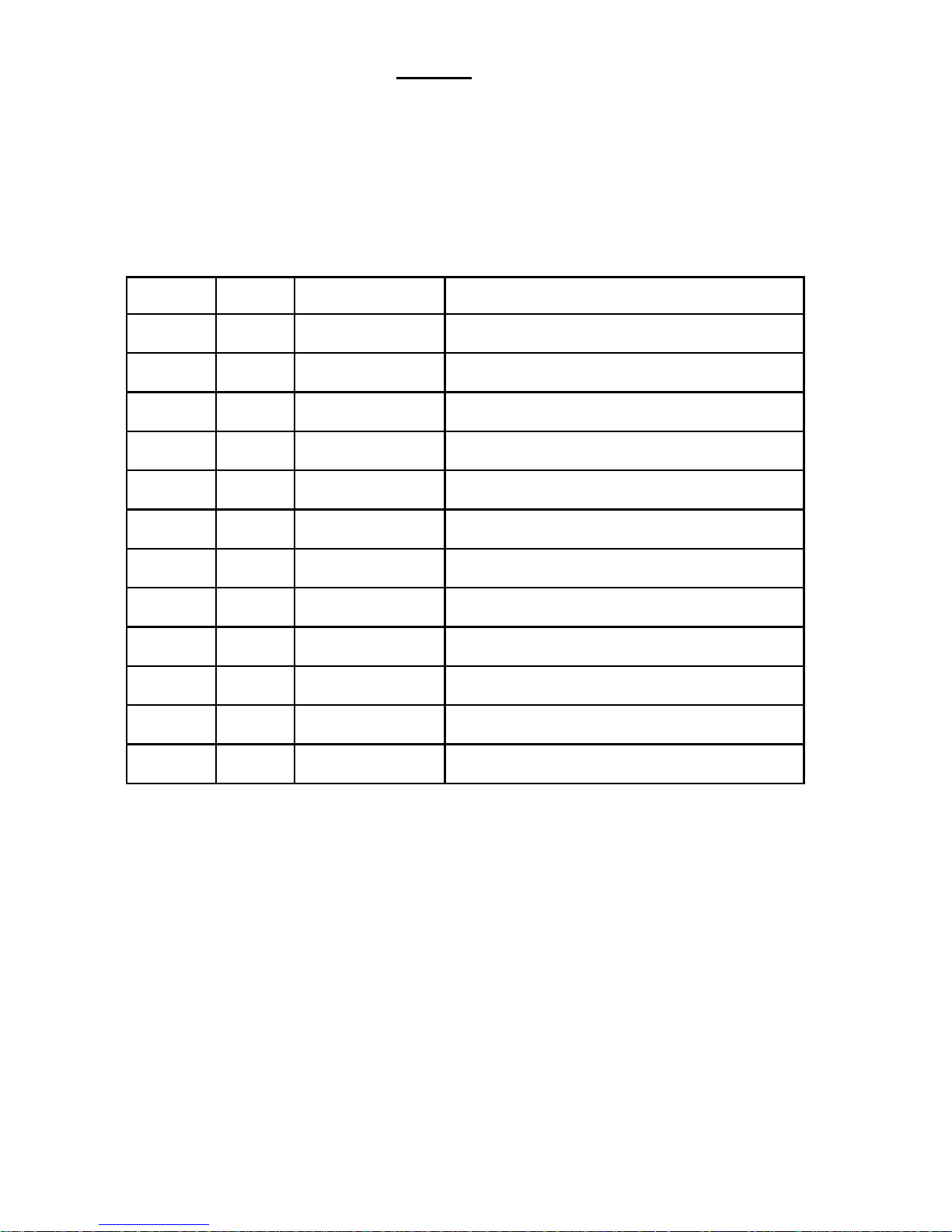

Decals

Item

Qty

Part #

Description

2

1

PP-00525

Keep Clear Decal

3

1

PP-00547

Lift Platform Decal

4

2

PP-00793

Crush Point (Warning) Decal

5

2

PP-00792

Entanglement (Danger) Decal

6

2

PP-00790

Thrown Objects Decal

7

2

PP-00791

Entanglement (Warning) Decal

8

2

PP-00789

Shear Point Decal

9

1

PP-00788

High Pressure Decal

10

1

PP-00794

Read Manual Decal

11

3

PP-00807

Crush Point (Danger) Decal

12

6

PP-00795

Grease Decal

13

2

PP-00811

Detach From Bumper Decal

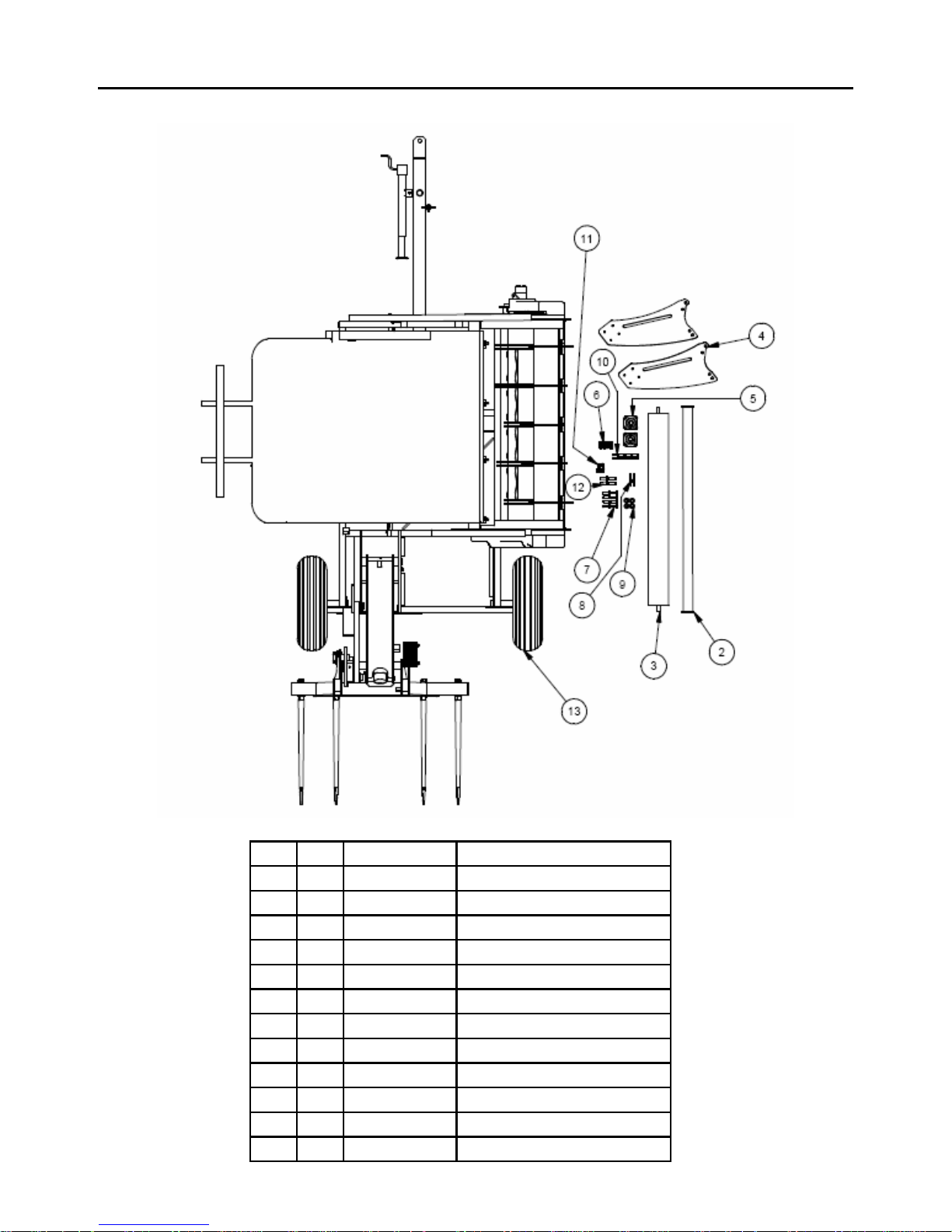

Decals

13

14

Item

Qty

Part #

Description

2

1

BF-5000-a19

Second Roller

3

1

BF-5000-a20

Bumper Roller

4

2

BF-5000-260

Bumper Plate

5

2

PP-00655

F206, 1.125 (ID) Bearing

6

8

PP-00170

5/8-11, UNC Lock Nut

7

8

PP-00323

Gr.3, 5/8-11 x 1.75 Hex Cap Screw

8

8

PP-00332

7/16-14 UNC Lock Nut

9

4

PP-00192

USS Zinc Plated ¾ Flat Washer

10

8

PP-00636

Gr.3, 7/16-14 UNC x 1.5 Hex Cap Screw

11

4

PP-00003

¾-10 UNC Lock Nut

12

4

PP-00047

Gr.3, ¾-10 UNC x 2 Head Cap Screw

13

1

BF-5000-SL-00

Complete Assembly

Items you will find with your Tube-line Self Loading Bale Feeder

15

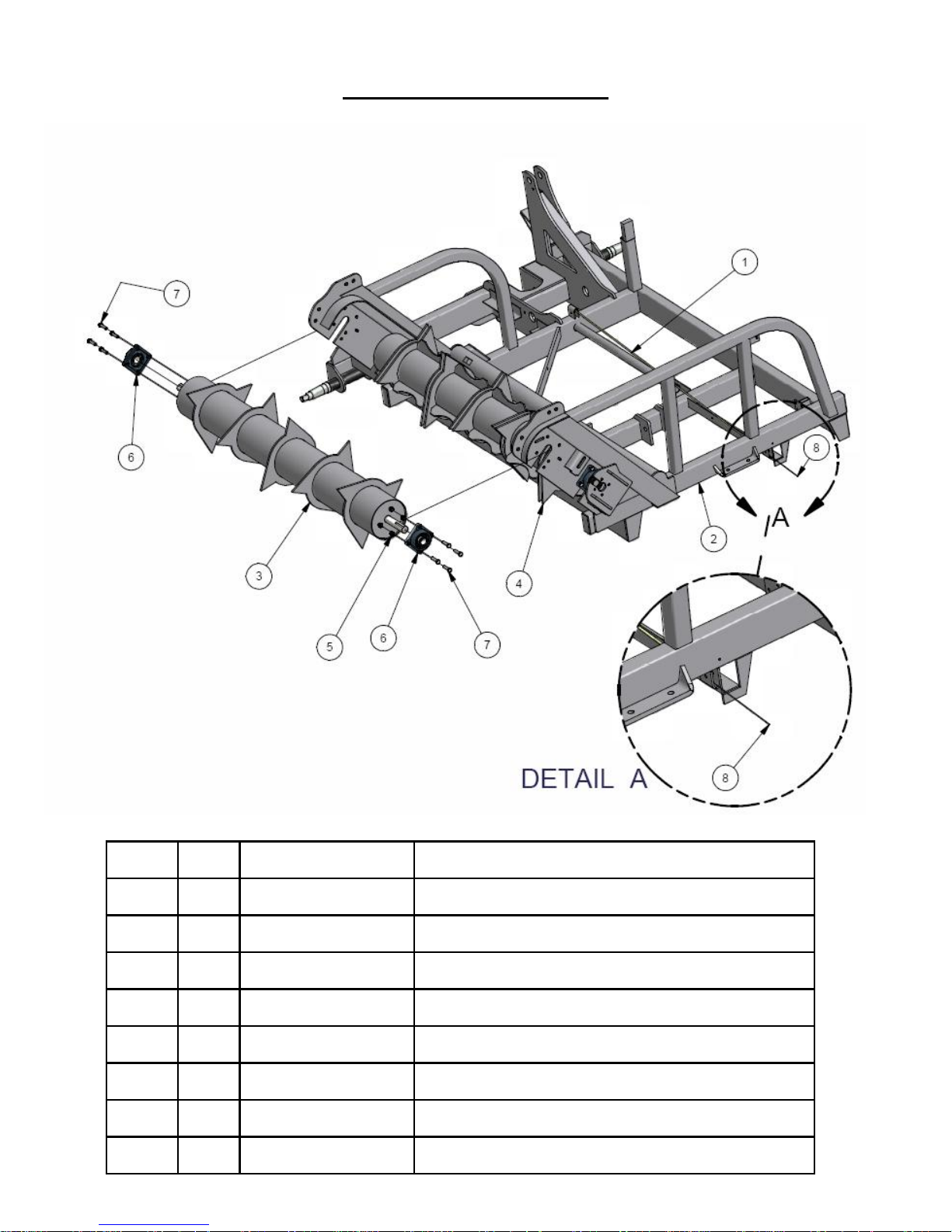

Self Loading Assembly

Item

Qty

Part #

Description

1

1

BF-5000-325

Cord Protector

2

1

BF-5000-SL-00

Frame Assembly

3

1

BF-5000-a01

Top Drum Assembly

4

1

BF-5000-a02

Bottom Drum Assembly

5

16

PP-00014

½-13 UNC Lock Nut

6

4

PP-00309

F207-22 Pillow Block

7

16

PP-00509

Gr.3, 1/2-13 UNC x 1.75 Hex Cap Screw

8

1

PP-00580

1/8” Galv. Braided Wire Cable (96”)

16

Self Loading Assembly

Item

Qty

Part #

Description

1

2

BF-5000-246

Chain Tightener Bracket

2

3

BF-5000-253

Key

3

1

BF-5000-254

60 series-28.5 Links

4

1

BF-5000-255

60 series-32 Links

5

2

BF-5000-a17

Slide Assembly

6

4

PP-00013

1/2-13 UNC Hex Nut

7

8

PP-00035

5/8 Flat Washer

8

2

PP-00060

60-15 Idler Sprocket

9

4

PP-00153

Gr.5 3/8-6 x 1 Hex Head Cap Screw

10

1

PP-00202

HMD Motor MLHPQ400C4B

11

1

PP-00420

60-15 X ID 1” Drive Sprocket

12

8

PP-00504

5/16-18 UNC x .5 Socket Head Set Screw

13

1

PP-00521

60-30 Drive Sprocket

14

1

PP-00522

60-42 Drive Sprocket

15

1

PP-00523

60-15 Drive Sprocket

16

2

PP-00589

Gr.3 5/8-11 UNC x 2 5/8 Hex Head Cap Screw

17

Item

Qty

Part #

Description

1

2

BF-5000-106

Tightener Rod

2

1

BF-5000-108

Bale Feeder Small Guard

3

1

BF-5000-109

Bale Feeder Large Guard

4

1

BF-5000-250

Bottom Tightener Rod

5

6

PP-00008

3/8 Flat Washer

6

6

PP-00026

3/8-16 Hex Nut

7

3

PP-00590

Hand Wheel

Self Loading Assembly

18

Self Loading Assembly

Item

Qty

Part #

Description

1

1

BF-5000-245

Hitch Bracket

2

1

BF-5000-SL-04

Front Hitch Support

3

1

BF-5000-SL-11

Hose Bracket

4

1

PP-00003

¾-10 UNC Lock Nut

5

1

PP-00007

3/8-16 UNC Lock Nut

6

2

PP-00014

½-13 UNC Lock Nut

7

4

PP-00108

¼-20 UNC Lock Nut

8

1

PP-00302

15’ Jack

9

2

PP-00423

Rope Pulley

10

2

PP-00499

Gr.3 ¼-20 UNC x 1.5

11

1

PP-00535

Manual Holder

12

2

PP-00560

Gr.3 ½-13 UNC x 5.5 Hex Head Cap Screw

13

1

PP-00561

Gr.3 ¾-10 UNC x 6 Hex Head Cap Screw

14

1

PP-00643

Gr.3 3/8-16 UNC x 1.25 Hex Head Cap Screw

15

2

PP-00654

Gr.3 ¼-20 UNC x 1.25

19

Self Loading Assembly

Item

Qty

Part #

Description

Item

Qty

Part #

Description

1

10

BF-5000-175

Weight

14

1

BF-5000-a13

Latch Pin Assembly

2

2

BF-5000-257

Spacer

15

1

CY-40019-01-00

4” Bore x 19” Stroke Cylinder

3

1

BF-5000-SL-01

Frame Assembly

16

3

PP-00008

3/8” Flat Washer

4

1

BF-5000-SL-02

Loader Arm Assembly

17

6

PP-00014

½-13 UNC Lock Nut

5

1

BF-5000-SL-03

Fork Frame Assembly

18

2

PP-00016

½ Flat Washer

6

1

BF-5000-SL-08

Arm Assembly

19

3

PP-00153

Gr.5 3/8-16 UNC x 1 Hex Head Cap Screw

7

1

BF-5000-SL-09

Top Loader Arm

20

4

PP-00310

Gr.3 ½-13 UNC x 2.5 Hex Cap Screw

8

1

BF-5000-SL-10

Loader Hook

21

2

PP-00321

Gr.3 ½-13 UNC x 1 Hex Head Cap Screw

9

1

BF-5000-a07

Fork Pin

22

4

PP-00546

Fork Spear (39”)

10

1

BF-5000-a08

Loader Arm Pin

23

2

PP-00557

Gr.3 ½-13 UNC x 5 Hex Head Cap Screw

11

1

BF-5000-a09

Top Loader Arm Pin

24

4

PP-00559

Gr.3 M30 x 3.5 Hex Nut

12

1

BF-5000-a11

Loader Cyl. Bottom Pin

25

1

PP-00648

Roll Pin

13

1

BF-5000-a12

Loader Cyl. Top Pin

1

SK40019

Cylinder Seal Kit

20

Self Loading Assembly

Item

Qty

Part #

Description

1

1

BF-5000-a03

Large Wiper Assembly

2

4

PP-00332

7/16-14 UNC Lock Nut

3

4

PP-00636

Gr.3 7/16-14 UNC x 1.5 Hex Cap Screw

4

2

PP-00637

7/16 Lock Washer

5

2

PP-00638

7/16 Washer

21

Self Loading Assembly

Item

Qty

Part #

Description

1

2

BF-5000-229

Bed Spacer

2

4

BF-5000-238

Bale Extension Pin

3

1

BF-5000-a06

Bed Assembly

4

1

BF-5000-a10

Bale Extension Assembly

5

1

BF-5000-a14

Bed Cyl. Pin Assembly

6

1

BF-5000-a15

Frame Cyl. Pin Assembly

7

1

CY-30014-01-00

3” Bore x 14” Stroke Cylinder

8

2

P-00298

Tire and Rim 11L 15

9

6

PP-00008

3/8 Flat Washer

10

4

PP-00014

½-13 UNC Lock Nut

11

3

PP-00108

¼-20 UNC Lock Nut

12

2

PP-00153

Gr.5 3/8-16 c 1 Hex Head Cap Screw

13

4

PP-00405

Hitch Pin Clip (.15 dia)

14

2

PP-00526

6000lbs Hub Assembly

15

4

PP-00560

Gr.3 ½-13 UNC x 6 Hex Head Cap Screw

16

1

PP-00566

Diverter Valve

17

3

PP-00651

Gr.3 1/4=-20 UNC x 2.25

1

SK30014

Cylinder Seal Kit

22

Self Loading Assembly

Item

Qty

Part #

Description

1

1

BF-5000-a06

Bed

2

1

PP-00516

Plastic Bed

3

1

BF-5000-a16

Stop Pad Assembly

23

Self Loading Assembly

Item

Qty

Part #

Description

1

2

BF-5000-239

Fork Bushing

2

2

BF-5000-240

Arm Pivot Bushing

3

1

BF-5000-269

Cable Spacer

4

1

BF-5000-SL-02

Loader Arm Assembly

5

1

PP-00108

¼-20 UNC Lock Nut

6

3

PP-00227

¼ USS Zinc Plated Flat Washer

7

1

PP-00499

Gr.3 ¼-20 x 1.5

8

2

PP-00565

Knock in Greaser

24

Self Loading Assembly

Item

Qty

Part #

Description

1

1

BF-5000-SL-08

Arm Assembly

2

2

BF-5000-241

Loader Arm Bushing

3

2

PP-00565

Knock in Greaser

4

1

BF-5000-242

Latch Bushing

25

Self Loading Assembly

Item

Qty

Part #

Description

1

1

BF-5000-SL-09

Top Loader arm

2

2

BF-5000-243

Small Loader Arm Bushing

3

2

PP-00565

Knock in Greaser

4

2

BF-5000-244

Large Loader Arm Bushing

26

Indicator Assembly

BF-5000-SL-05

Item

Qty

Part #

Description

1

1

BF-5000-182

Indicator

2

1

BF-5000-183

Indicator Slider

3

1

BF-5000-SL-06

Indicator Assembly aa

4

1

BF-5000-SL-07

Indicator Assembly bb

5

2

PP-00108

¼-20 UNC Lock Nut

6

2

PP-00352

Gr.3 ¼-20 UNC x 1 Hex Cap Screw

7

1

PP-00491

Spring

8

1

PP-00547

Decal - Lift Platform

27

Wiper Assembly

Item

Qty

Part #

Description

1

10

BF-5000-100

Slot Opening Guide

2

5

BF-5000-101

Inside Bracket Guide

3

1

BF-5000-a18

Small Wiper Assembly

4

30

PP-00005

Gr.3 5/16-18 UNC x .75 Hex Head Cap Screw

5

30

PP-00006

5/16 Flat Washer

6

30

PP-00080

5/16-18 Lock Nut

28

Bumper Assembly

Item

Qty

Part #

Description

1

2

BF-5000-260

Bumper Plate

2

1

BF-5000-a19

Second Roller

3

1

BF-5000-a20

Bumper Roller

4

4

PP-00003

¾-10 UNC Lock Nut

5

4

PP-00047

Gr.3 ¾-10 UNC x 2 Hex Head Cap Screw

6

8

PP-00170

5/8-11 UNC Lock Nut

7

4

PP-000192

USS Zinc Plated 3/4 Flat Washer

8

8

PP-00323

Gr.3 5/8-11 UNC x 1.75 Hex Cap Screw

9

8

PP-00332

716-14 UNC Lock Nut

10

8

PP-00636

Gr.3 7/16-14 UNC x 1.5 Hex Cap Screw

11

2

PP-00655

F206 1.125 (ID) Bearing

29

6000lb Hub Assembly

Item

Qty

Part #

Description

1

1

PP-00025

1-UNC Castle Nut

2

1

PP-00028

3/16 x 2 Brass Cotter Pin

3

1

PP-00030

1 Flat Washer

4

6

PP-00031

9/16-18 UNF x 1.75 Wheel Stud

5

1

PP-00527

6000lbs Hub

6

1

PP-00528

D-6000 Dust Cap

7

1

PP-00529

Grease Seal cr20148

8

1

PP-00530

Inner Cone

9

1

PP-00531

Outer Cone

10

1

PP-00532

Outer Cup

11

1

PP-00533

Inner Cup

30

Hydraulic Set-up

31

Item

Qty

Part #

Description

1

1

CY-30014-01-00

Cylinder 3 x 14

2

1

CY-40019-01-00

Cylinder 4 x 19

3

1

PP-00104

Adapter #8 M-ORB/#6 M-JIC

4

1

PP-00166

Adapter #6 M-JIC/#6-NPT

5

1

PP-00202

Hydraulic Motor

6

2

PP-00410

Adapter #* M-JIC/ #10 M-ORB

7

1

PP-00511

Tee #6 F-NPT/#6 F-NPT

8

1

PP-00566

Diverter Valve

9

2

PP-00656

Adapter 90 #8 M-JIC/#8 M-ORB

11

4

PP-00662

Adapter #6 M-JIC/#8 M-NPT

12

4

PP-00661

Pioneer Male Coupler #8 F-NPT

Hydraulic Set-up

32

33

Section 2

General Information

Self Loading Bale Feeder

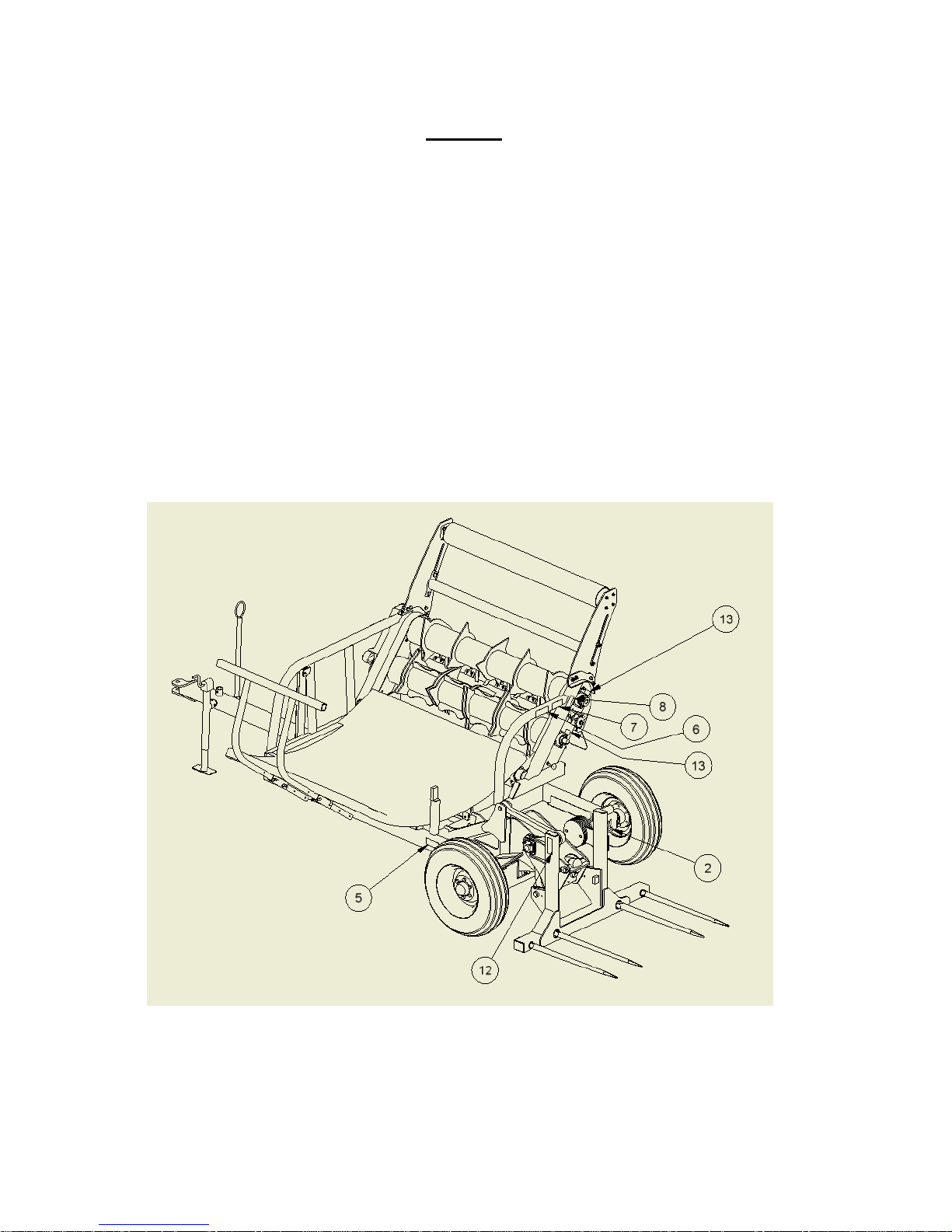

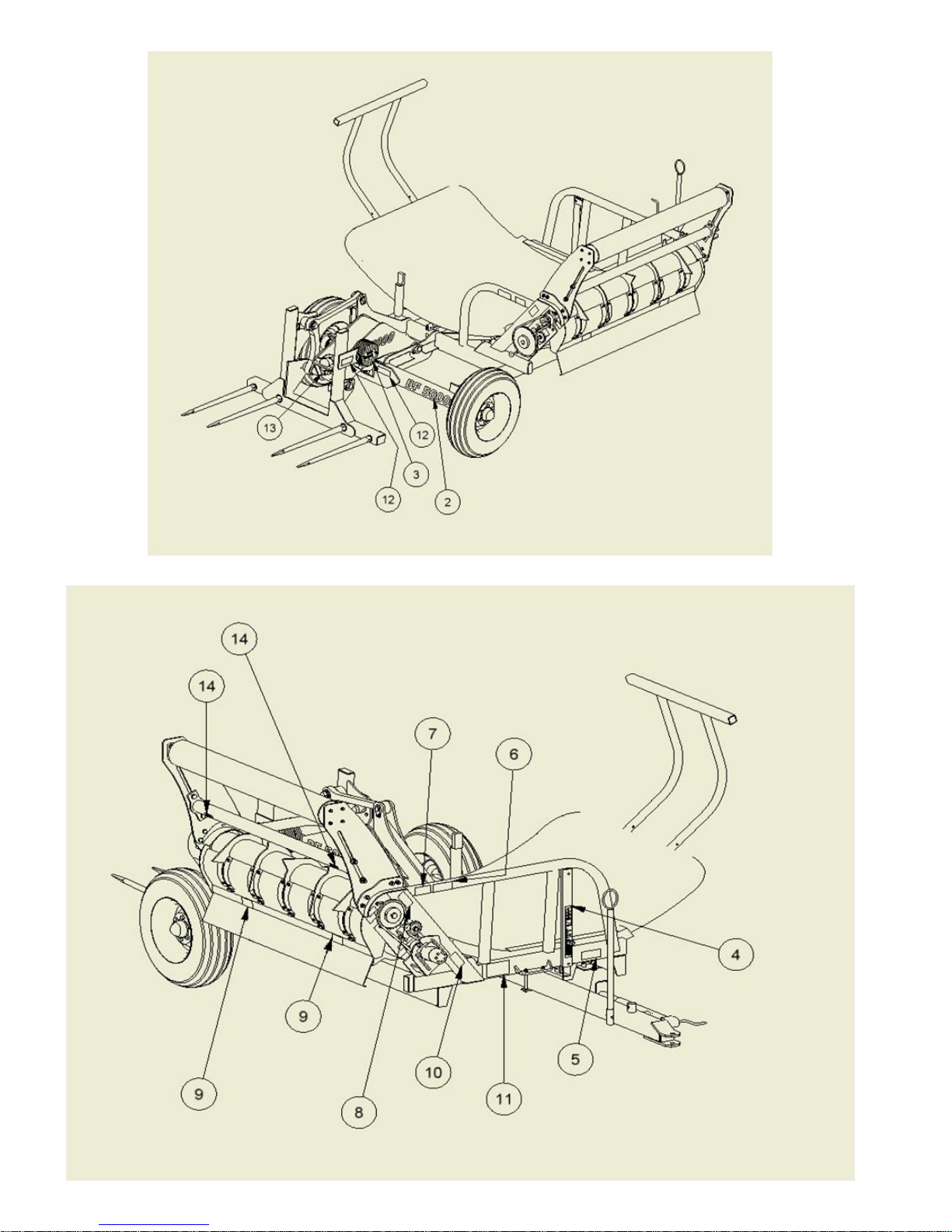

The Self Loading Bale Feeder unit consists of the main components listed below. The

bale Feeder is powered by hydraulic pressure from a tractor. The hydraulic pressure from

a tractor powers the hydraulic motor as well as both lift cylinders.

Principle Components

1. Frame

2. Beaters

3. Bed

4. Beater Motor

5. Bed Cylinder

6. Loader Arm Assembly

7. Fork Frame Assembly

8. Indicator

Section 1

Assembly Information

NOTE: Assembly drawings are intended

for use of replacement parts only, and not

as assembly guide.

NOTE: Assembly drawings are placed in

sequential order, as one would assemble, if

desired part on drawing is shown already

assembled you have gone to far, and must

look at a previous drawing.

34

Self Loading Bale Feeder Terminology

Serial# XX BFSL XXX

XX = year manufactured

BFSL = product identification

XXX = sequential numbering

Model # BF5000SL

BF5000 = BF5000

SL = Self Loading unit

Capacity

2 Bales = this unit can only

contain 2 bales.

Weight

2700 = weight in pounds

Product Identification

The P.S.N stamped on the metal tag(1), is located on the front of the bale feeder.

35

When you first receive the Tube-line Bale

Feeder you will need to install the bumper bale

rollers

1. Secure bumper plate (1), using six 5/8-11

bolts(3), with 5/8-10 nuts(2) to the Tube-line

Bale Feeder.

2. Secure second roller(5), with ¾-10 bolts(2),

¾ flat washer(3) and ¾-10 hex nut(3) to

bumper plate(1).

3. Secure bearing(4), and bumper roller(2),

with 7/16-14 bolts(3), 7/16-14 hex nuts(5) to

bumper plate (1).

Initial Setup

36

Adjusting the BF5000 Beater Guide

1. Loosen 5/16-18 bolt (1), and 5/16-18 nuts.

2. Adjust slot opening guide to 1/16” from

beater and retighten fasteners.

37

1. Reverse tractor and align drawbar hole with

BF5000 and insert pin.

2. Release jack(1), and secure in place(2).

3. Connect hydraulic lines.

4. Do a complete walk-around visual check to

be sure there are no loose parts or

components.

5. Do a visual check of all hoses to make sure

they are securely tied so they will not pinch

or drag during transporting.

WARNING

Make sure to apply the park brake before

leaving the tractor. Death or serious injury

could result if tractor moves.

Tube-line Bale Feeder Hook Up

Check the hitch pins and safety chain periodically to make sure they are secure.

38

1. Transport the Tube-line Bale Feeder with the

SMV(Slow Moving Vehicle) sign, displayed

at the rear of the Tube-line Bale Feeder and

use your hazard lights if the law permits.

Check local road laws before transporting.

2. When transporting the Tube-line Bale

Feeder on the road be aware of the width

length of the Bale Feeder especially while

carrying a square bale.

3. Do not transport the machine at night, at

dawn, or at dusk.

4. Do not exceed 32kph (20mph) during

transport.

Transport Safety

39

Section 3 Operation

Keep bystanders away from the machine.

Failure to comply could result in death or

serious injury.

WARNING

NOTE: Setup instructions assume the operator

already has read and has the Tube-line Bale

Feeder attached to the tractor.

1. Apply hydraulic pressure.

2. Raise and lower bed.

3. Raise and lower bale

loading assembly.

Engage the parking brake on the tractor, shut

the engine down, and wait for all moving parts

to stop before leaving the cab. Failure to

comply could result in death or serious injury

WARNING

4. Check for loose or missing nuts and bolts.

Tighten any that are loose and replace any

missing fasteners.

5. Make sure that all protective shields are in

place and properly secured.

6. Check all hydraulic hoses and fittings to be

sure they are tight and that no hose damage

has occurred during mounting. Repair or

replace any damaged parts before starting

the machine.

Do not run with defective hoses or

fittings. Make sure that there is no

pressure in the hydraulic lines before

checking or repairing. High-pressured

hydraulics can cause death or serious

injury.

7. Restart the Tube-line Bale Feeder.

WARNING

40

Loading Bales (Wrapped Bales)

1. With rear fork assembly down reverse the

unit and pierce bale.

2. Apply hydraulic pressure and lift the bale

until it is approximately 4” above plastic bed.

3. Remove plastic wrap and net wrap.

4. Lower bale onto Tube-line Bale Feeder bed

and release fork rack and lower into loading

position.

5. Once again pierce the bale and lift the bale a

few inches off the ground.

41

Section 4

Lubrication

Introduction

This section gives full details of the

procedures necessary to maintain the Tube-line

Bale Feeder at peak efficiency. Complete all

checks and services in this section at the hour

interval shown.

Important: Failure to complete the required

maintenance at the intervals shown can

cause unnecessary downtime.

The recommended lubrication intervals are

for average conditions. Perform lubrication

more often when operating under

adverse conditions.

Before lubricating the Tube-line

Bale Feeder, always

observe the following precautions:

•Turn off tractor, set parking brake,

remove key and wait for all moving

parts to stop before leaving cab.

Failure to comply could result in

death or serious injury.

WARNING

42

Linkage Assembly (3)

Apply 3 strokes of grease every 25 hours at

point (3) (4 locations).

Loader Arm Assembly (1)

Apply 3 strokes of grease every 25 hours at

point (1) (2 locations).

Beater Bearing (2)

Apply 3 strokes of grease every 50 hours at

point (2) (4 locations).

Cylinder Pivot (4)

Apply 3 strokes of grease every 50 hours at

point (4) (4 locations).

Hub (5)

Apply 3 strokes of grease every 50 hours at

point (5) (2 locations).

Bumper Bearing (6)

Apply 3 strokes of grease every 50 hours at

point (6) (2 locations)

43

Section 5

Maintenance

Complete all checks and services in this section at the hour interval shown.

IMPORTANT: Failure to complete the required maintenance at intervals shown can cause

unnecessary downtime.

The recommended intervals are for average conditions. Perform maintenance more often

when operating the Tube-line BF5000 under adverse conditions.

Before performing any adjustments or maintenance on the Tube-line

BF5000, observe these safety precautions:

•Turn off tractor, set parking brake, remove key and wait for all moving

parts to stop before leaving cab.

Failure to comply could result in death or serious injury.

WARNING

Careful inspection and service of the BF5000 prior to

operation each day will prevent needless breakdowns and

delays in the field. Make the following checks and

adjustments.

Be alert for loose hardware and tighten

or replace as required.

Lubricate the Tube-line BF5000

according to the instructions in the

“Lubrication” section of this manual.

Under adverse conditions, shorten the

lubrication intervals.

Daily Maintenance

Preseason Service

Prior to beginning the harvest after offseason

storage, take the following steps be certain the

Tube-line BF5000 is in good condition.

Check slot opening guide, make sure it is tight

and that the beater blade clears as described in

the “General Information” section.

Lubricate the Tube-line BF5000 according to the

“Lubrication” section of this manual.

Tighten or replace any damaged or missing

fasteners.

End of Season Service

Prior to storing the Tube-line BF5000

during the off season, follow these steps

to ensure easier preparation for the next

season and longer Tube-line BF5000

life

Pack all grease point with grease (see

the “Lubrication” section for grease

points location).

Remove all crop material from the

BF5000.

44

Section 6

Trouble Shooting

Problem: Several biscuits coming out at once.

Suggested remedy: The bed is too high. Lower the bed. The crop material was baled

when wet, reverse beaters 2 turns then forward again.

Round bales

Problem: The rotors turn, but the bale refuses to turn.

Suggested remedy: The platform is not raised high enough. The bale must be pushed

against both beaters.(see pg 3-2)

Problem: Crop material jams between top beater and wiper.

Suggested remedy: The wiper guides may need adjusting. (see pg 2-3)

General

Problem: The bale is dropping too hard onto platform.

Suggested Remedy: Spear bale lower when loading

Problem: Spear frame does not trip before the bale rests on the platform.

Suggested Remedy: Spear bale higher when loading

45

Section 7

Optional Equipment

Bale Extension

The bale extension, available as on option is

used primarily to contain square bales placed

on the bed of the Tube-line BF5000.

The bale extension is designed to contain the

biscuits of crop material placed on the bed of

the Tube-line BF5000, allowing the bale to be

feed and no crop material to spill off the non

feeding side.

Square Bale Extension

Slide bale extension assembly(1) into bed

extension receiver(2).

Secure bale extension with bale extension

pin(3), and hitch pin clip(4).

46

47

48

Loading...

Loading...