TubeDepot Tweed 5F1 Assembly Manual

Learn Build Play

Assembly Manual

Tweed 5F1

Instructions for Assembling with the:

- Printed Circuit Board (PCB)

with additional modification suggestions and recommended amp settings

version 17.0

May 24, 2017

This manual was developed and published by:

ii TubeDepot.com

TubeDepot.com

Memphis, TN

Written by:

Robert Hull

Edited by:

Mary Klaebel JP Phelps

Design and artwork by:

Robert

Hull

Mary Klaebel

Christian Magee

Acknow

ledgements:

Special thanks to:

Joe Austin Mitchell Bird Rees Shad

Caleb K

im Matt Kirby

Henry Lum Joe Moffett

Brian Overstreet Ben Siler

Doug Sims John Puffer

Rex Cuizon

Copyright © 2009

TubeDepot.com

1958 Vanderhorn Drive

Memphis, TN 38134

(877)289-7994

info@tubedepot.com

REGARDING THESE BOOK MATERIALS

Reproduction, publication, or duplication of this booklet, or any part thereof, in any manner, mechanically,

electronically, or photographically is prohibited without the express written permission of the publisher.

The Author

For permi

, Publisher or Seller assume no liability with respect to the use of the information contained herein.

ssion and other rights under this copyright, contact TubeDepot.com.

page

Table of Contents

TubeDepot.com iii

Preface and Tweed 5 F 1 over view ....................................................................................... iv

Chapter 1

Safety ….........................................................................................................................1

Chapter 2

Tools and Supplies ….....................................................................................................2

Chapter 3

Parts Inventory ...........................…................................................................................3

Chapter 4

Cabinet Preparation …....................................................................................................4

Chapter 5

Circuit Assembly (PCB)…...............................................................................................5

Chapter 6

Chassis Preparation and Assembly …..........................................................................10

Chapter 7

Final Assembly …...........................................................................................................9

Chapter 8

Testing …......................................................................................................................20

Chapter 9

Schematics and Parts Lay out …...................................................................................23

Chapter 10

Cool Modifications …....................................................................................................28

Appendix

A. How to Read Resistor and Capacitor Codes ….......................................................29

B. Soldering Hints ….....................................................................................................32

C. Amplifier Care, Feeding, and Application Hints …...................................................34

D. Drilling Templates …................................................................................................36

Short History of the Tweed Fender Champ

Preface

TM

TM

TM

TM

iv TubeDepot.com

With just 4 watts, the first incarnation of the Fender Champ was introduced in 1948 and

was called the “Champion 800”. It had one 6SJ7 preamp tube, a single 6V6 power tube, and

a 5Y3 rectifier tube. Along with an 8” speaker, it was covered in two toned brown and tan vinyl

and was beautiful to behold. In 1953 the name changed to “Champion 600 ” with a 6”

speaker replacing the original 8”. The two toned vinyl remains, however some of the later

Champion 600's are covered in the new transition tweed covering. By 1953, all Champion

amps were covered in tweed and all still sounded great! These early Champions were the

perfect complement to the new Telecaster family of guitars. But all is not finished yet …

The biggest improvements were brewing. In 1955, the “Champ” is born with the introduction

of the new 12AX7A as the preamplifier tube (replacing the 6SJ7). This brings the output to 5

watts into a 6” speaker. But there is one more big improvement coming. In 1958, along with a

slight component change, the 8” speaker is reintroduced. With this final change, the “mother

of tone” is born. It is as if the planets aligned and whispered to Leo Fender what the near

perfect amp should sound like. He was listening because here it is.

It is this last, near perfect incarnation that we provide for you here.

The tweed champ is one of my favorite amps. Inside its diminutive size rests the heart of an

entire world of music. From blues, to rock-a-billy; from rock-n-roll to soul; from country to jazz,

this amp is capable of holding its own across a wide swath of musical history and genres.

From humble consideration as a “beginner amp”, this amp has become a standard bearer for

what is cool about music.

Therefore imagine my excitement in designing a kit where you can build an incredible amp

on which to put your musical mark on the world. Wow … this is going to be fun!

Thank you for purchasing this great kit. You should be able to easily put this kit together in

an evening or two … whether you have any prior amp building experience or not. I designed

this kit for you to enjoy both building and playing this amp. And once finished, this kit will allow

you to make the best music you can … to make your world mark.

Now, let's have some building and playing fun.

Robert Hull

Director of Technical Services

TubeDepot.com

“Champ” and “Fender” are the property of Fender Musical Instruments Corporation (FMIC). TubeDepot is not

affiliated or associated with FMIC or its subsidiaries and FMIC does not sponsor or endorse any of TubeDepot’s

products.

1

Safety

- DISCLAIMER -

subsidiaries accept no liability for any damage(s), injury(s) or death incurred from

or while building or using this kit.

construction methods are fo

particular procedure in this assembly manual differs from the assembly video, our

recommendation is to follow this manual to insure the best construction possible.

- Used when identifying an action that may cause phys ic al inj ur y or death.

WARNING

- Used when identifying an action that may cause damage to components

and/or equipment.

CAUTION

NOTE

- Used when identifying general points of interest.

TubeDepot.com 1

!!! Read these safety precautions before continuing !!!

ALL tube amplifiers contai n LETHAL VOLTAGES, often several hundred volts which WILL

leave burnt entrance and ex it wounds in skin. These voltages have the potential to cause

permanent physical damage and death. These voltages are present when the amp is

turned on and also for some time after the amp has been turned off. You can still get

shocked with a tube amp turned off and disconnected from AC power.

The above statement is a bit scary, but we want to stress that every piece of electronic

equipment must be treated with respect. When AC power is applied, there is always a chance

for injury or death. With tube amps, even when the AC power is not applied there is still

danger. Being shocked with high voltage is very painful and we do not want anyone finding

out the hard way.

When building this kit, we want your experiences to be both enjoyable and safe. There are

more kits to assemble and we want you to enjoy building and playing them all.

TubeDepot.com, its employees, officers, shareholders, investors and

TubeDepot.com reserves the right to make changes to this manual as new

und to be more efficient and/or safer. When a

Throughout this manual at key points in the construction, we have annotated important

steps with the below alerts. For your safety and to improve construction quality, It is important

that you become familiar with each of these alerts and adhere to their recommendations when

they appear.

Explanation of Alerts

2

Tools and Supplies

2 TubeDepot.com

As with any construction project, there are certain tools and supplies that are recommended

to complete the project. These are tools and supplies not provided with the kit and are instead

provided by the builder.

TubeDepot.com

The following is our recommended list: part number

Phillips screwdriver, #1 and #2 TL-VTSCRSET8

Slip joint pliers

Needle nose pliers TL-VT33

Wire cutters, diagonal TL-VT33

Wire strippers, for 18 and 20 awg wire TL-VT5021

Electric Drill

Drill bit, 3/16” - Chassis mounting in the cabinet

Drill bit, 5/32” - PCB and turret board chassis mounting

Drill bit, 1/8” - Fiberboard mounting

Masking tape, 2”

Ruler or scale, 12” w/ 1/16” markings

Permanent marker, fin e tip

Soldering iron, 25W – 40W (35W recommended) TL-WP35

Solder, electronics safe (60/40 w/ rosin core recommended) TS-24-6040-0027

Flux, electronic – liquid or paste (must be safe for electronic work) TS-83-1000-0186

De-soldering pump extract or TS-384-1000

Solder wick TS-1817-10F

Sponge

The following are really nice to have:

Soldering station w/ temperature control TL-WTCPT

Multimeter w/ DC range of at least 500 V TL-DVM850BL

Variable AC supply (Variac® style)

Current Limiting AC source (build directions in this manual)

Needle nose pliers – small size, for electronics work TL-NN7776

Wire cutters, diagonal – small size, for electronics work TL-170M

Center punch

Nutdrivers - 5/16”, 11/32”, 7/16”, 1/2”

Square, 9”

Scratch Awl

heat shrink, 1/8” x 6” TS-HS-ASST-7

De-burring tool

Fingernail polish (for holding nuts and screws in place)

TubeDepot.com 3

Parts Inventory

3

It is important to review all the parts that came with your kit. The list below is what you

should have received to complete your kit. If you find anything missing, contact us:

Qty Description Application

TubeDepot.com

1958 Vanderhorn Dr.

1 speaker, 8" Jensen MOD, 8 Ω (4 Ω available) speaker

1 chassis, steel chrome plated 5E1/5F1 chassis

1 cabinet, tweed 5E1/5F1 cabinet

1 PCB board, 5E1/5F1 _ printed circuit board

transformers

1 transformer, ClassicTone 40-18027

1 transformer, output tweed 5F1 4 & 8 ohm tap output transformer

tubes

1 5Y3 rectifier tube

1 6V6GT beam power tetrode power tube

1 12AX7 dual triode _ preamp tube

panel hardware

1 knob, vintage pointer

1 fuse holder, conical cap, vintage Fender style fuse holder

1 fuse, 3AG 2A slow-blow fuse

1 lamp holder lamp holder

1 jewel, re d lamp jewel

1 lamp, #47, 6.3 V lamp

2 jack, 12A, shorting, Switchcraft ¼" input jack

1 jack, 11A, open, Switchcraft ¼" speaker jack

3 washer, lock 3/8" jack lock washer

1 plug, Switchcraft ¼" speaker plug

power cord hardware

1 power cord, grounded three prong, 12'

1 strain relief, Heyco power cord strain relief

1 nylon cable clamp power cord clamp

1 screw, zinc plated #8 x 5/8", phillips flat head cord clamp mounting

tube sockets

1 socket, tube, miniature 9pin

2 socket, tube, octal rectifier / power tube

hardware

2 grommets, rubber 3/8" hole

2 bolt, 1 1/2" 10x32 truss screw chassis mounting

2 nuts, KEPS 10x32 chassis mounting

6 screw, zinc plated 6-32 x 1/4", phillips pan head tube socket mounting

9 nuts, KEPS 6x32 tube socket / PCB mounting

1 nuts, 6x32 tube socket w/ solder tab mounting

4 nuts, KEPS 8x32 power / output transformer mounting

2 nuts, 8x32 power transformer w/ solder tab mounting

4 screw, zinc plated 6-32 x 7/8" phillips pan head PCB mounting

4 standoff, nylon; L = .5"; id = .140"; od = .250" PCB mounting

2 screw, zinc plated 8-32 x 1/4", phillips pan head output transformer mounting

2 solder lug, locking, #8 screw grounding at power transformer

1 solder lug, locking, #6 screw grounding at preamp tube socket

1 wire nut power cord to power transformer wiring

electronic, resistors

2 100, 1/2w carbon film

2 68K, 1/2w carbon film input resistors

1 1M, 1/2w carbon film _ input biasing resistor

2 100K, 1/2w carbon film preamp tube plate resistors

rectifier tube

knob

preamp tube

grommets

filament pseudo center tap

power transformer

power cord

Memphis, TN 38134

(877) 289-7994

info@tubedepot.com

2 1.5K,

4 TubeDepot.com

1 22K, 1/2w carbon film feedback resistor

1 220K, 1/2w carbon film biasing resistor

1 470, 3w metal oxide cathode resistor

1 10K, 2w metal oxide B+ resistor

1 22K, 1w metal oxide B+ resistor

electronic, capacitors

2 .022ufd / 630v

2 22ufd / 50V cathode bypass caps

1 22ufd / 500V power supply filter cap

2 10ufd / 450V power supply filter caps

electronic, potentiometers

1 1M pot w/ on-off switch (Alpha )

1 100K trim pot, horizontal mount feedback adjustment

wire

3' wire, 20 awg, stranded, hi-temp PVC – yellow board, general wiring

2' wire, 20 awg, stranded, hi-temp PVC – red board, signal / B+ wiring

2' wire, 20 awg, stranded, hi-temp PVC – black board, ground wiring

3' wire, 18 awg, stranded, hi-temp PVC – green filament wire

2' wire, 18 awg, stranded, hi-temp PVC – black speaker wire, 2' wire, 18 awg, stranded, hi-temp PVC – white speaker wire, +

shielding

3” aluminum tape, 3" width, 10” length, self adhesive electrical and heat shielding

heat shrink

1 heat shrink, 1/4" - black, 6" piece wire dressing / capping

1/2w carbon film

coupling caps

preamp tube cathode resistors

volume / power switch

TubeDepot.com 5

4

Cabinet Preparation

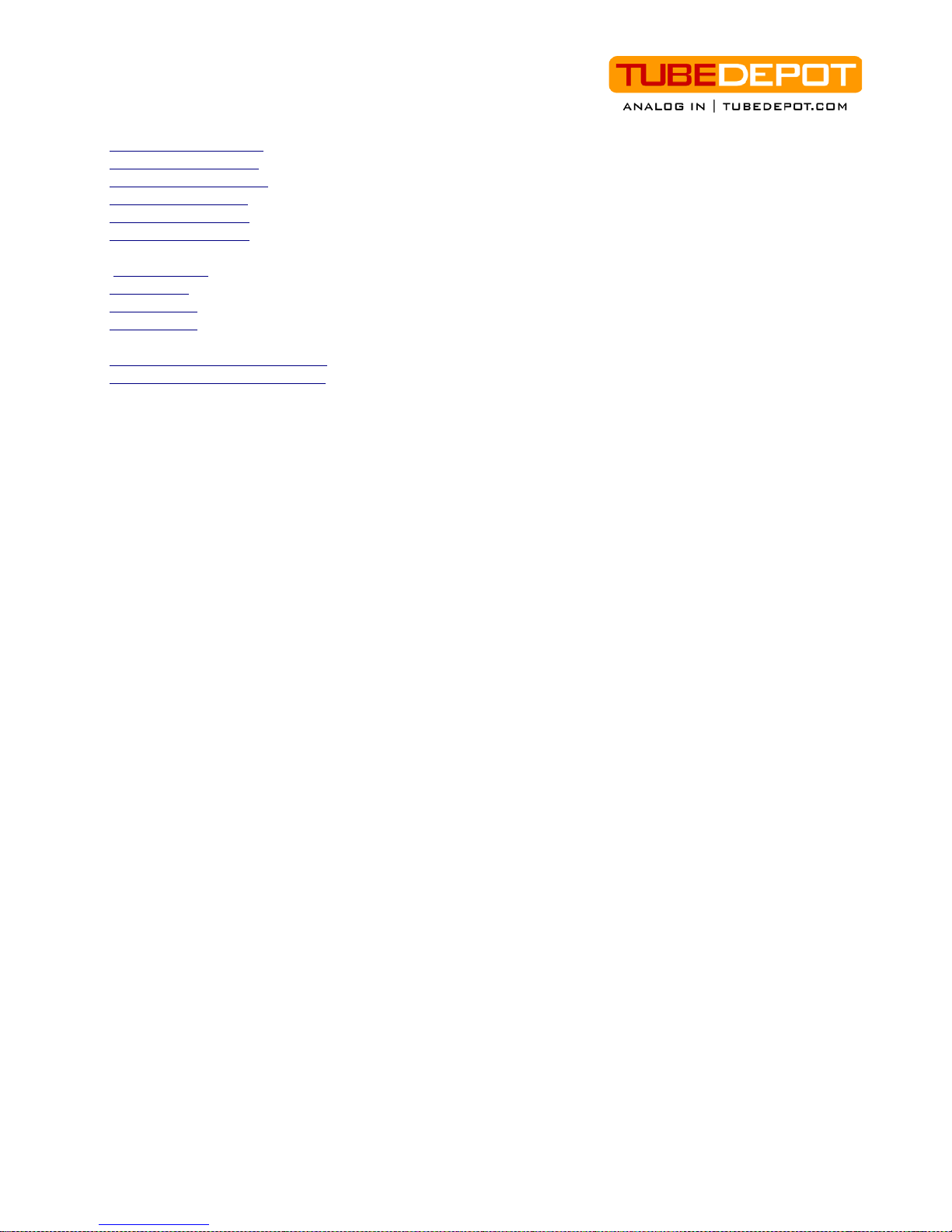

photo 4.1a

4.1

photo 4.1b

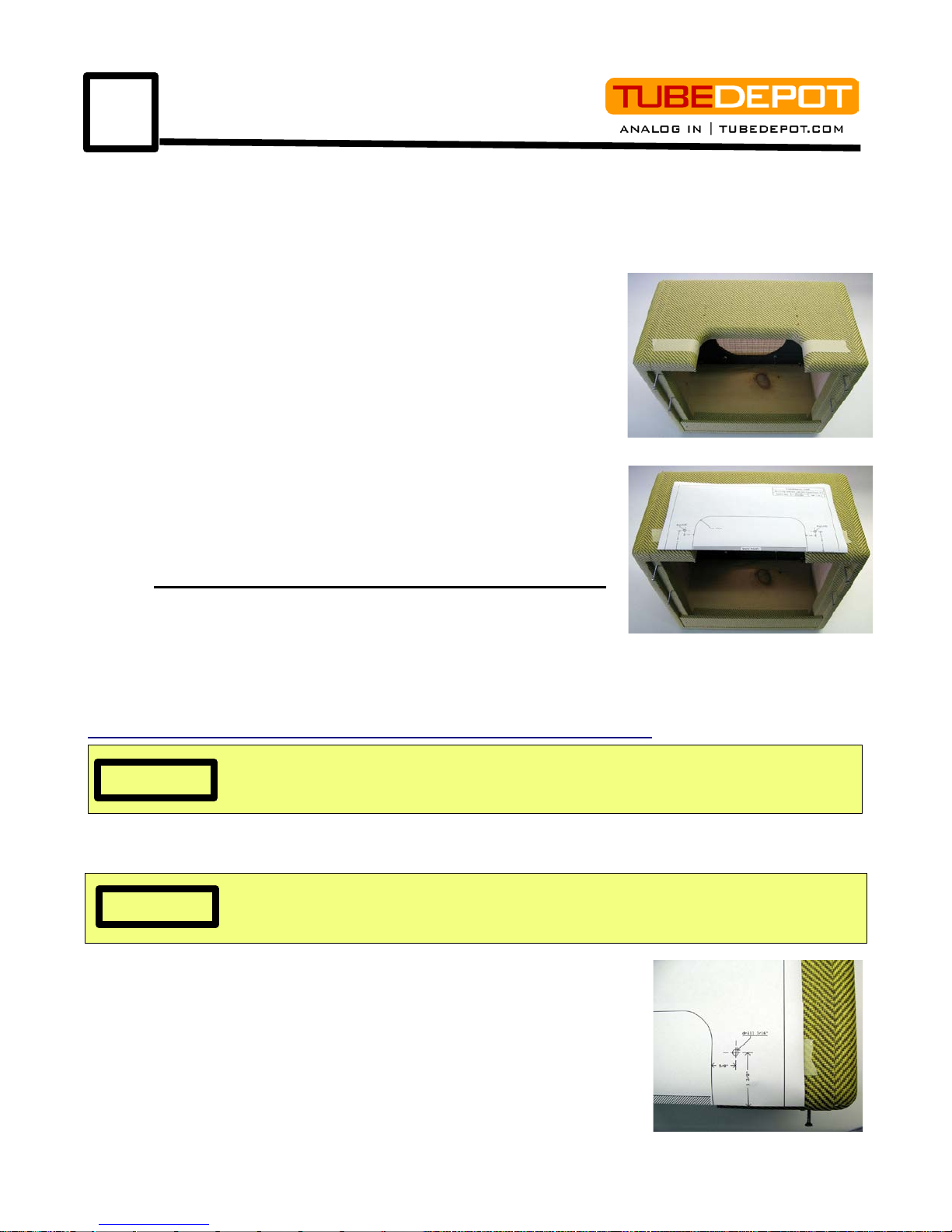

Some printers may automatically reduce the size of the template when printed.

Therefore, prior to use, always physically measure the printed template to insure proper

scale is maintained.

CAUTION

The cabinet drilling template should be aligned to the cabinet's very edge. Verify correct

template placement before drilling. Do NOT bend the template to follow the curved edge.

Always measure several times before drilling.

CAUTION

photo 4.1c

photo 4.1c

This chapter deals with preparing the cabinet for installation of the completed chassis. But

first, we need to take inventory of the parts that came installed on the cabinet.

1. Handle w/ mounting hardware – There should be a single flat brown leather handle

with two metal securing ends all fastened to the cabinet with four screws.

2. Feet, chrome metal glide – There should be four metal feet attached with screws to

the underside of the cabinet.

3. Back panels, upper and lower with screws – There

should be two back panels. The top back panel should be

secured with four panel screws, the bottom panel should

be secured with two panel screws.

4. Baffle bolts with nuts – There should be four bronze

plated bolts attaching the baffle to the cabinet. The baffle

is secured with four KEPS nuts, one on each of these

bolts.

5. Speaker bolts with nuts – There should be four black

bolts exiting from the ba ffle board. There should be four

KEPS nuts (one on each of these black bolts) used for

mounting the speaker.

Drilling for the Two Chassis Mounting Bolts

Step 1 – Remove the amp handle from the top of cabinet

Step 2 – Remove the top back panel (place a small mark on the

inside of the panel to indicate which edge is up)

Step 3 – Apply masking tape on each side of cabinet opening (photo 4.1a).

Step 4 – Download and print the correct sized cabinet drilling template from our website:

http://site.tubedepot.com/pdf/5F1_cabinet_drilling_template.pdf

Step 5 – Fold the correctly sized template at indicated line and place template flat on top of

cabinet, properly centered over the opening (photo 4.1b).

Step 6 – With a pointed tool, make a mark through the template at

the cross hair points marked “drill 3/16” (photo 4.1c). Press lightly

into the tape and cabinet. This doesn't have to be a deep mark, just

enough to see the mark on the masking tape underneath.

Step 7 – Remove the template. With a ruler or scale, check and

verify that the marks are properly aligned on the cabinet top as

referenced to the measur em ents on the template.

Step 8 – If the marks are verified correct, drill the two 3/16” holes,

one at each of these two marks all the way through the top of the

tweed cabinet.

Step 9 – Remove the masking tape and clean up any loose

6 TubeDepot.com

4.2

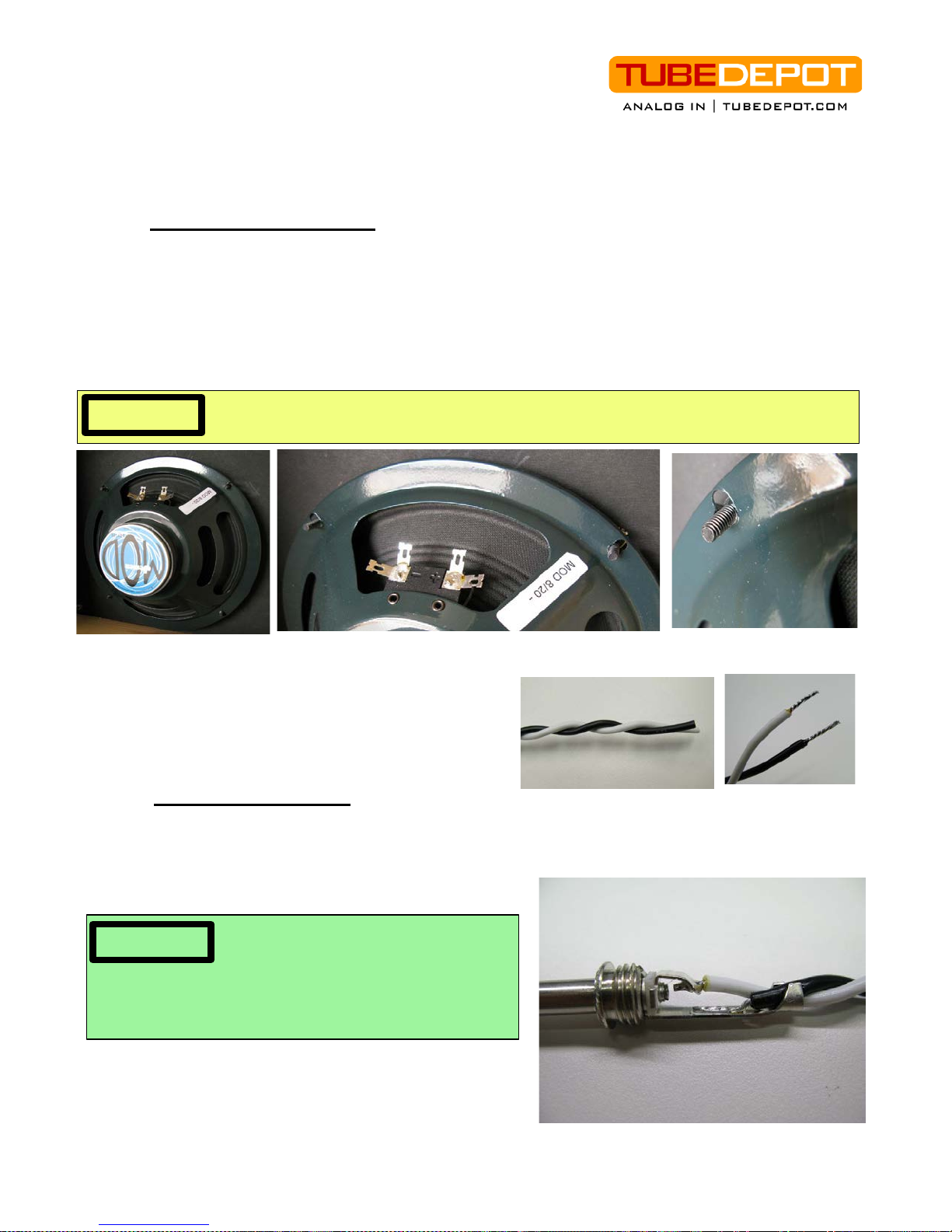

Alignment of all holes during speaker installation is very important. Otherwise, one or more

of the bolts may puncture the speaker cone by accident.

CAUTION

photo 4.2c

photo 4.2b

photo 4.2a

4.3

photo 4.3a

photo 4.3b

NOTE

The ¼” phone plug was invented for use

in telephone switchboards in 1878.

photo 4.3c

Although it is no longer used for telephone switching, this

great plug has become the standard connection type

between musical instrumen ts and outboar d equ ip men t.

material from the holes and test fit the chassis mounting bolts.

Step 10 – With the chassis mounting bolts in the cabinet, test

fit the chassis onto the bolts

Step 11 – Remove chassis and reinstall handle, leaving chassis mounting bolts installed.

Proceed to 4.2

Installing the Speaker

Step 1 – Remove the four nuts from the speaker mounting bolts inside the cabinet.

Step 2 – Remove the speaker from its shipping box. With speaker in hand, carefully align the

speaker mounting holes to the baffle bolts. I recommend installing the speaker with

connecting terminals on top.

Step 3 – Slowly press the speaker onto these bolts, being certain that the bolts are

proceeding through the mounting holes of the speaker equally (photos 4.2a, b, & c).

Step 4 – Once the speaker is installed on the bolts,

install and tighten the KEPS nuts.

Proceed to steps 4.3

Wiring the Speaker

Step 1 – Twist the two lengths of black and white wire together (photo 4.3a).

Step 2 – At one end, strip the insulation back ½ ” from both wires and tin these two wires

(photo 4.3b).

Step 3 – Unscrew the barrel of the ¼ ” phone plug.

Step 4 – Solder the two tinned wires to the plug; white

to center and black to shield (photo 4.3c). Reinstall

plug barrel.

Step 5 – At opposite end of the twisted wire pair, strip the insulation ¼” and tin both wires.

TubeDepot.com 7

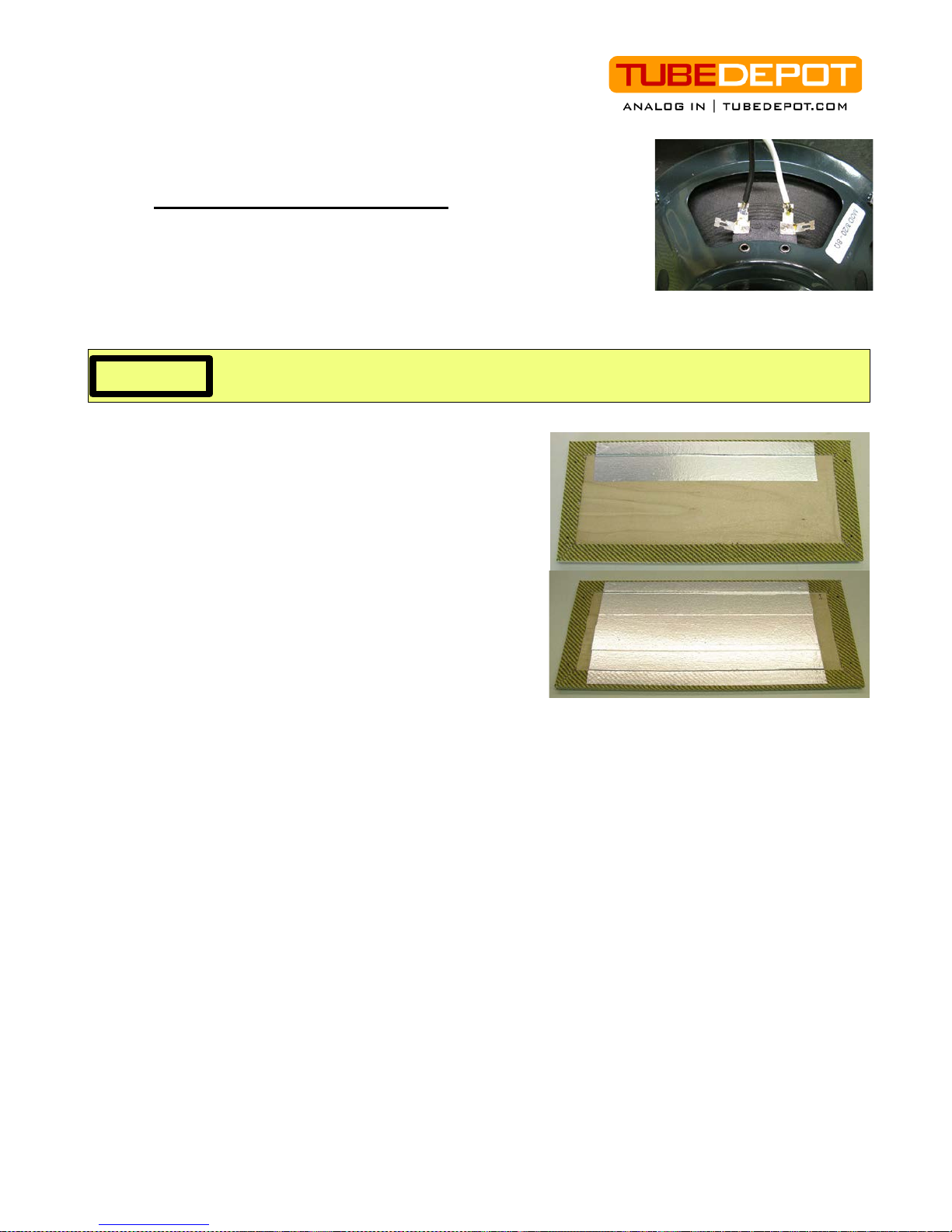

4.4

photo 4.3e

Once the backing is removed from the aluminum tape, the tape will have a tendency to curl.

Be sure to keep the tape straight to avoid having the tape stick permanently to itself.

CAUTION

photo 4.4a

photo 4.4b

Step 6 – Solder these wires to the solder terminals of the

speaker; the white wire to the “+” terminal and the black wire to

the “-” terminal (photo 4.3e).

Proceed to 4.4

Installing the Shielding Tape

Step 1 – Place the removed back panel with the tweed side toward

the desk and the wood side facing up.

Step 2 – Cut the 30” aluminum shielding tape strip into three equal

lengths of 10”

Step 3 – Remove the backing from the first of the three shielding tape strips.

Step 4 – Apply the aluminum tape to the back of the

panel. Leave 1/8th of an inch space at the top of the

panel and centered the strip between the two panel

edges (photo 4.4a).

Step 5 – Remove the backing from the second

shielding tape strip and apply the tape to the back of

the panel similar to the first strip. Place it just below the

first strip, over lapping by 1/8th of an inch and centered

on the panel.

Step 6 – Remove the backing from the final s hi eldi ng

tape strip and apply the tape to the back of the panel

similar to the previous two strips. Align the edge of the

tape along the bottom edge of the panel, offset by 1/8th

of an inch from the bottom edge of the panel and overlapping the second strip (photo 4.4b).

Proceed to chapter 5

8 TubeDepot.com

5

Circuit Assembly

5.1

For great hints on improved soldering skills, review Appendix B at the end of this manual.

Additionally, visit:

NOTE

CAUTION

Electrolytic capacitors DO have a polarity and must be installed into the circuit according to

the markings on the component and the PC board.

NOTE

See “Cool Mods”, chapter 10 for description on how to use this

control

photo 5.1a

Here is where good soldering skills and attention to detail will pay off. By following these

directions, you should be able to complete the circuit assembly quickly and without errors.

I encourage you to first read all the steps to familiarize yourself with not only the installation

flow, but also the components to be used. Appendix A has explanations on how to read the

value codes found on both the resistors and capacitors. Appendix B has helpful hints on

improving soldering skills.

Printed Circuit Board (PCB) Assembly

This PCB was designed to sound great and to maximize your customizing ability in a

compact, easy to assemble package. This PCB layout closely follows the original point-topoint layout in order to duplicate any tone shaping created by component and wiring proximity

interactions. With over-sized traces and through-hole plating, this board will provide years of

trouble free life.

Step 1 – Gather all components necessary to complete the PCB. Separate the components

by type; the resistors in one pile, the capacitors in another, the trim pot a third. The resistors

will be installed first. They have no polarity and can therefore be installed in either direction.

Step 2 – Install a 1.5K / ½ watt resistor (brown, green, red, gold) in R6 position.

Step 3 – Install two 68K / ½ watt resistors (blue, gray, orange, gold) in positions R1 & R2.

Step 4 – Install two 100K / ½ watt resistors (brown, black, yellow, gold) in positions R4 & R5.

Step 5 – Install a 22K / ½ watt resistor (red, red, orange, gold) in position R8.

Step 6 – Install a 220K / ½ watt resistor (red, red, yellow, gold) in position R9.

Step 7 – Install a 1.5K / ½ watt resistor (brown, green, red, gold) in position R7.

Step 8 – Install a 470 / 3 watt resistor (yellow, violet, brown, gold) in position R10. The PC

board says 2 watt but I upgraded to a larger resistor.

Step 9 – Install a 22K / 1 watt resistor (red, red, orange, gold) in position R12.

Step 10 – Install a 10K / 2 watt resistor (brown, black, orange, gold) in position R11. The PC

board says 1 watt but I upgraded to a larger resistor.

Step 11 – Install a 22ufd/50V electrolytic capacitor in position C3. This

component has a polarity, therefore it must be installed according to case

and board markings (photo 5.1a).

Step 12 – Install a 22 u fd/50V elec tr ol y t ic capac i tor in posi ti o n C4. This

component has a polarity, therefore it must be installed according to case

and board markings.

Step 13 – Install the 100K trimmer pot (VR2, negative feedback adj.)

http://www.youtube.com/user/TubeDepotTV and watch “How To Solder”.

to fine tube this amp to your sound.

Loading...

Loading...