Page 1

THURLBY THANDAR INSTRUMENTS

PRECISION LINEAR POWER SUPPLIES

PL SERIES

INSTRUCTION MANUAL

Page 2

Table of Contents

Specification 2

Safety 4

EMC 6

Installation 7

Connections 8

Operation 9

Maintenance 12

Instructions en Francais

Sécurité 13

Installation 14

Fonctionnement 16

Entretien 19

Bedienungsanleitung auf Deutsch

Sicherheit 20

Installation 21

Betrieb 23

Wartung 27

1

Page 3

Specification

MAIN OUTPUT(S)

Output Range: Nominally 0-32V, (PL320/330); 0-15.5V (PL154).

Nominally 0-2·1A (PL320); 0-3·1A (PL330); 0-4A (PL154).

Output Voltage Setting: By coarse and fine controls; resolution <5mV across the range.

Output Current Setting: By single logarithmic control.

Output Mode: Constant voltage or constant current modes with automatic cross-over.

Decimal points flash to indicate constant current mode.

Configuration Selection:

(QMD and QMT only)

Isolated, True parallel, Series, or Series Tracking via front panel switches.

Output Switch: Isolates the output and permits voltage and current limits to be set up before

connecting the load.

Output Terminals: 4mm terminals on 19mm (0·75") spacing.

Sensing: Remote via 4mm terminals or direct via shorting links (provided).

Output Impedance:

Constant Voltage:

Constant Current:

<5 mΩ at 1kHz.

Typically 50 kΩ with voltage limit at maximum.

Output Protection: Up to maximum output voltage +20 Volts forward; diode clamped for reverse

voltages and up to 3A reverse current.

Load & Line Regulation: < 0·01% of maximum output for 90% load change or 10% line change.

Ripple and Noise: Typically <1 mV rms.

Transient Response: < 20 µsec to within 50 mV of setting for 90% load change.

Temperature Coefficient: Typically < 100 ppm/

O

C.

Meter Type: Dual 3·75 digit (4095 count) with 12·5mm (0·5") LEDs. Reading rate 4Hz.

Meter Resolution: 10 mV and 1mA over the entire range.

Meter Accuracy: Voltage 0·1% of reading + 1 digit, current 0·3% of reading + 1 digit.

Current Meter Damping: ~20 ms, switchable to 2 sec for averaging of rapidly varying loads.

LOGIC OUTPUT (PL320QMT & PL330QMT)

Output Voltage Range: 4 to 6 Volts.

Output Current: 0·1 to 4 Amps (PL320QMT); 0·1 to 7 Amps (PL330QMT).

Output Switch: Electronic.

Output Terminals: 4mm terminals on 19mm (0·75") spacing.

Over-Voltage Protection: Above 7 Volts.

Output Protection: Clamped by the over-voltage protection circuit for forward voltages over

7 Volts and up to 1 Amp forward current. Diode clamped for reverse voltages

and up to 3 Amps reverse current.

Load & Line Regulation: < 0·01% of maximum output for 90% load change or 10% line change.

Ripple and Noise: Typically <1 mV rms.

2

Page 4

Transient Response: < 20 µsec to within 50 mV of setting for 90% load change.

Temperature Coefficient: Typically < 100 ppm/

o

C.

Metering

(PL330QMT

only):

Meter Type:

3·75 digit (4095 count) with 12·5mm (0·5") LEDs. Reading rate 4Hz.

Meter Resolution:

Meter Accuracy:

10 mV and 10 mA

0·5% of reading + 1 digit.

GENERAL

AC Input Voltage: Internally set for 110, 120, 220, 230 or 240VAC 50/60 Hz; operating range

±10% of setting. Installation Category II.

Power Consumption: Single Dual Triple

15V / 4A or 30V / 2A: 160VA 320VA 400VA

30V / 3A: 250VA 500VA 600VA

Operating Range: 5

O

C to 40 OC, 20% to 80% RH.

Storage Range: -20

O

C to +60 OC.

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

Weight: Single Dual Triple

15V / 4A or 30V / 2A: 5.0kg 9.5kg 12.5kg

30V / 3A: 6.0kg 12.0kg 15.0kg

Size: Single Dual Triple.

155 mm wide 350 mm wide 425 mm wide

All units 170mm high and 265mm deep, except PL330 versions 300mm

deep.

Safety: Complies with EN61010-1.

EMC: Complies with EN61326.

3

Page 5

Safety

This instrument is Safety Class I according to IEC classification and has been designed to meet

the requirements of EN61010-1 (Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use). It is an Installation Category II instrument intended for operation

from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5°C and –10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair. Capacitors inside the power supply may still be

charged even if the power supply has been disconnected from all voltage sources but will be

safely discharged about 1 minute after switching off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:-

Earth (ground) terminal.

alternating current (ac)

direct current (dc)

4

Page 6

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the following power supplies:

PL154, PL320, PL320QMD, PL320QMT, PL330, PL330QMD, PL330QMT

meet the intent of the EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Communities.

EMC

Emissions: a) EN61326-1 (2006) Radiated, Class B

b) EN61326-1 (2006) Conducted, Class B

c) EN61326-1 (2006) Harmonics, referring to EN61000-3-2 (2006)

Immunity: EN61326-1 (2006) Immunity Table 1, referring to:

a) EN61000-4-2 (1995) Electrostatic Discharge

b) EN61000-4-3 (2006) Electromagnetic Field

c) EN61000-4-11 (2004) Voltage Interrupt

d) EN61000-4-4 (2004) Fast Transient

e) EN61000-4-5 (2006) Surge

f) EN61000-4-6 (2007) Conducted RF

Performance levels achieved are detailed in the user manual.

Safety

EN61010-1 Installation Category II, Pollution Degree 2.

CHRIS WILDING

TECHNICAL DIRECTOR

1 May 2009

5

Page 7

EMC

This instrument has been designed to meet the requirements of the EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2006) Class A; the instrument is Class A by product category.

Immunity

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved are shown below (requirement shown in

brackets):

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air, 4kV contact, Performance A (B).

b) EN61000-4-3 (2006) Electromagnetic Field:

3V/m, 80% AM at 1kHz, 80MHz – 1GHz: Performance A (A) and 1.4GHz to 2GHz:

Performance A (A); 1V/m, 2.0GHz to 2.7GHz: Performance A (A).

c) EN61000-4-11 (2004) Voltage Interrupt: ½ cycle, 0%: Performance A (B);

1 cycle, 0%: Performance B (B); 25 cycles, 70% and 250 cycles, 0%: Performance B (C).

d) EN61000-4-4 (2004) Fast Transient, 1kV peak (AC line), 0·5kV peak (signal connections),

Performance B (B).

e) EN61000-4-5 (2006) Surge, 0·5kV (line to line), 1kV (line to ground), Performance A (B).

f) EN61000-4-6 (2007) Conducted RF, 3V, 80% AM at 1kHz (AC line only; signal

connections <3m, therefore not tested), Performance A (A).

According to EN61326-1 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

Cautions

To ensure continued compliance with the EMC directive observe the following precautions:

a) Connect the generator to other equipment using only high quality, double−screened cables.

b) After opening the case for any reason ensure that all signal and ground connections are

remade correctly and that case screws are correctly refitted and tightened.

c) In the event of part replacement becoming necessary, only use components of an identical

type, see the Service Manual.

6

Page 8

Installation

Mains Operating Voltage

Check that the operating voltage of the instrument shown on the rear panel is suitable for the

local supply. Should it be necessary to change the operating voltage range proceed as follows:

1. Ensure that the instrument is disconnected from the AC supply.

2. Remove the screws holding the case upper and handle.

3. Lift off the case upper.

4. If the transformer primary taps are marked: A 0-110-120 B 0-110-120, rewire as follows:

240V operation: Neutral (blue) wire to A0; Link (red) wire from A120 to B0;

Live (brown) wire to B120.

230V operation: Neutral (blue) wire to A0; Link (red) wire from A110 to B0;

Live (brown) wire to B120.

220V operation: Neutral (blue) wire to A0; Link (red) wire from A110 to B0;

Live (brown) wire to B110.

120V operation: Neutral (blue) wire to A0; Link (blue) wire from A0 to B0;

Link (brown) wire from A120 to B120; Live (brown) wire to B120.

110V operation: Neutral (blue) wire to A0; Link (blue) wire from A0 to B0;

Link (brown) wire from A110 to B110; Live (brown) wire to B110.

Alternatively, if the transformer primary taps are numbered 1 to 6, rewire as follows:

230V operation: Neutral (blue) wire to 6; Link (red) wire from 3 to 4;

Live (brown) wire to 1.

115V operation: Neutral (blue) wire to 6; Link (blue) wire from 3 to 5;

Link (red) wire from 2 to 4; Live (brown) wire to 1.

Note: Units factory set to 220, 230 or 240V will have no blue link wire - this must be provided

when converting to 110/115/120V operation. When converting a 110/115/120V unit to

220/230V/240V the blue link wire should be discarded.

5. Reassemble in the reverse order.

6. Change the fuse type if necessary.

Important Note: Safety regulations state that the AC line voltage to which the apparatus is set

must be clearly marked on the outside. If the line voltage setting is changed, it is imperative that

the voltage marked on the label close to the power lead entry point is also changed.

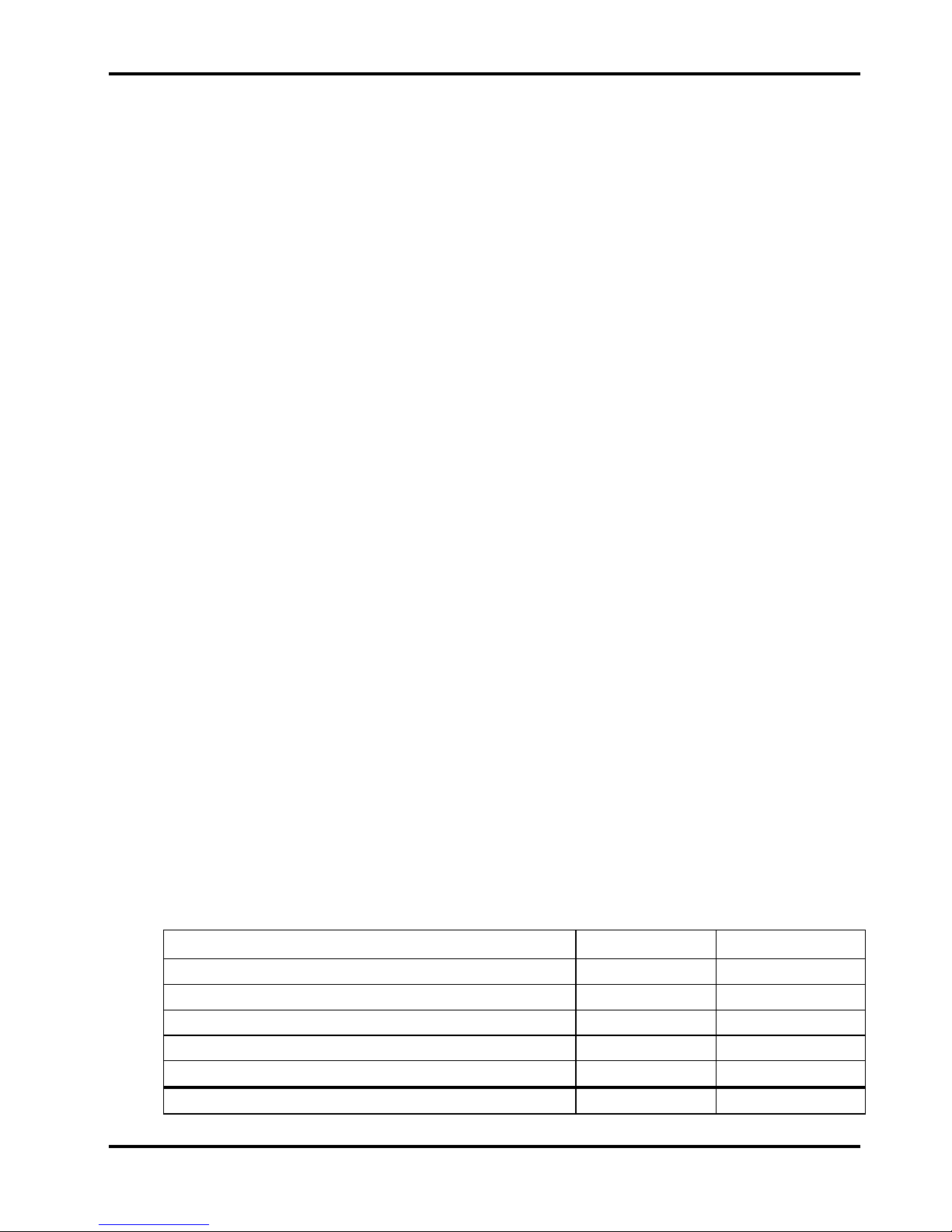

Fuse

The AC fuse is located on the back panel; note that the PL320QMT and PL330QMT have an

additional AC fuse for their logic output sections. The correct fuse type is 20mm x 5mm 250V

HBC time-lag with the following rating:

Model 220/230/240V 110/115/120V

PL320 / PL154 (single) 1·6A (T) 3.15A (T)

PL330 (single) 2A (T) 4A (T)

PL320QMD / PL320QMT 3.15A (T) 6.3A (T)

PL330QMD 4A (T) 8A (T)

PL330QMT 5A (T) 10A (T)

PL320QMT & PL330QMT Logic 0utput: 1.6A (T) 3.15A (T)

7

Page 9

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Mains Lead

When a three core mains lead with bare ends is provided this should be connected as follows:

BROWN - MAINS LIVE

BLUE - MAINS NEUTRAL

GREEN/YELLOW - EARTH

Safety Earth Symbol

As the colours of the wires in the mains lead of this apparatus may not correspond with the

coloured markings identifying the terminals in your plug proceed as follows:

The wire which is coloured green-and-yellow must be connected to the terminal in the plug which

is marked by the letter E or by the safety earth symbol or coloured green or green-and-yellow.

The wire which is coloured blue must be connected to the terminal which is marked with the letter

N or coloured blue or black.

The wire which is coloured brown must be connected to the terminal which is marked with the

letter L or coloured brown or red.

If the unit is to be connected to the main supply by fixed wiring, rather than via an AC line plug,

then the protective earth (ground) wire in the 3 core mains lead shall be connected to a protective

conductor before any other connection is made.

WARNING! THIS APPARATUS MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

Mounting

This instrument is suitable both for bench use and rack mounting. It is delivered with feet for

bench mounting.

Rack kits for mounting supplies in a 19” rack are available from the Manufacturers or their

overseas agents.

Connections

All connections are made from the front panel.

The load(s) should be connected to the positive (red) and negative (black) terminals marked

OUTPUT.

Remote sense connections to the load, if required, are made from the positive (red) and negative

(black) SENSE terminals. The shorting links between OUPTUT and SENSE terminals should be

removed when remote sensing is required. Replace the shorting links (red SENSE to red

OUTPUT, black SENSE to black OUTPUT) when remote sensing is not in use.

The green terminal marked

is connected to the chassis and safety earth ground.

8

Page 10

Operation

Main Outputs

Setting Up the Output

With the power switch ON and the output switch OFF the output voltage and current limit may be

accurately set using the three output controls prior to connection to the load. The left hand meter

indicates voltage and the right hand meter indicates current.

With the output switch in the OFF (set) position, the current meter shows the value of the current

limit setting (indicated by all the decimal points coming on); with the output switch ON, it shows

the value of load current flowing.

Unless remote sensing is required the shorting bars should be placed from + sense to + output

and from - sense to - output. Ensure that the terminals are properly tightened before use.

Constant Voltage

The voltage output is set using the coarse and fine voltage controls; the current control sets the

maximum current that can be supplied.

Constant Current

If the load resistance is low enough such that, at the set level of output voltage, a current greater

than the current limit setting would flow, the supply will automatically move into constant current

operation.

The current output is set using the current limit control; the voltage controls set the maximum

voltage that can be generated.

Constant Current Indication

When the unit is operating in constant current mode, either by intention or because the current

limit point has been reached, the decimal points on the current meter will flash to indicate

constant current rather than constant voltage operation.

Instantaneous Current Output

The current limit control can be set to limit the continuous output current to levels down to 1 mA.

However, in common with all precision bench power supplies, a capacitor is connected across the

output (isolated by the output switch) to maintain stability and good transient response. This

capacitor charges to the output voltage, and short circuiting of the output will produce a short

current pulse as the capacitor discharges which is independent of the current limit setting.

Current Meter Damping

The digital meters have a reading rate of about four readings per second and a damping time

constant of 20 ms, thus providing virtually instantaneous response to reading changes.

If the unit is used to supply a load varying at a rate faster than about 0·5Hz, difficulty may be

experienced in interpreting the current meter readings. This problem can be alleviated by

pressing the button marked DAMPING. This increases the current meter damping time constant

to 2 seconds with the result that the meter will tend to read the average current flowing rather

than following the variations. This facility should only be used when necessary since it greatly

increases settling time and reduces absolute accuracy.

Series or Parallel connection with other units

The output of the power supply unit is fully floating and may be used in series with other power

supply units to generate high DC voltages up to 300V DC.

9

Page 11

WARNING! Such voltages are exceedingly hazardous and great care should be taken to shield

the output terminals for such use. On no account should the output terminals be touched when

the unit is switched on under such use. All connections to the terminals must be made with the

power switched off on all units.

It should be noted that the unit can only source current and cannot sink it, thus units cannot be

series connected in anti-phase.

The unit can be connected in parallel with others to produce higher currents.Where several units

are connected in parallel, the output voltage will be equal to that of the unit with the highest output

voltage setting until the current drawn exceeds its current limit setting, upon which the output will

fall to that of the next highest setting, and so on. In constant current mode, units can be

connected in parallel to provide a current equal to the sum of the current limit settings.

Application of an external voltage source to the output

In common with all series regulated single-ended power supplies, the unit is not capable of

sinking current provided from an external source.

If a voltage greater than the set output voltage of the unit is applied from an external source, the

internal regulator will turn off, no current will flow, and the voltage meter will read the applied

voltage. No damage will result providing the applied voltage does not exceed the maximum

output voltage of the power supply by more than 20 Volts. Application of a voltage greater than

this is prohibited.

If a reverse voltage is applied, this will be clamped by an internal reverse protection diode. The

reverse current should not exceed 3 Amp.

Additional Instructions for Quad Mode Dual Versions

Quad-Mode Dual versions of the power supplies incorporate a bank of four interlocked pushbutton switches which enable any one of four different modes of operation to be selected. These

are as follows:

1. Isolated

Each power supply operates as a completely separate and independent unit, electrically isolated

from the other.

2. Parallel

The output from both units is channelled into the Master unit (right hand side), increasing its

current output capability accordingly. The Master unit then behaves exactly as a single power

supply of increased current capability. The Slave unit (left hand side) becomes inoperative. The

resolution of the current meter is 2mA on the PL330QMD in parallel mode.

3. Series

Operation is as in Isolated mode, except that the Slave positive output terminal is internally

connected to the Master negative output terminal.

4. Tracking

Operation is as for Series mode, except that the Master voltage controls operate on the Master

and Slave units simultaneously. The current limit controls on each unit continue to operate

individually. Tracking accuracy is better than ±0·3% of setting ± 0·1% of full range.

The Slave output switch should always be on. Both outputs are then switched from the Master

output switch.

Remote sensing cannot be used in either Series or Tracking modes, therefore the shorting bars

should be left in place.

10

Page 12

Additional Instructions for Quad Mode Triple Versions

The Quad-Mode Triple consists of a Quad-Mode Dual as described in the previous section, plus a

logic supply.

P310QMT Logic Supply

This has a fixed 5V 1·5A output which is isolated from the other supplies.

The logic supply is protected against short circuits. It is protected against external forward

voltages up to 16 Volts and reverse voltages by a diode: the reverse current must not exceed 3

Amps.

PL320QMT & PL330QMT Logic Supply

Setting the Output

Set the output with the calibrated control. With the output switch OFF the meter (PL330 only)

displays voltage; with the switch ON it displays load current. Unless remote sensing is required

the shorting bars should be placed from + sense to + output and from - sense to - output.

Current Limit (PL320QMT)

Current limit is indicated by lighting the CURRENT LIMIT LED and is set by a calibrated control

with a range of 0·1A to 4A. The power supply is not designed to operate in constant current mode

as a current source.

Current Limit (PL330QMT)

Current limit is indicated by all the decimal points flashing and is set by a calibrated control with a

range of 0·1A to 7A. The power supply is not designed to operate in constant current mode as a

current source.

Protection

Over-voltage protection is fitted to this supply and will be triggered if the voltage across the output

terminals exceeds 7 Volts. If this occurs the power supply output is crowbared by a thyristor; the

power supply will then shut down and TRIP will be shown in the display. The power supply can be

reset by turning off the DC output switch or by turning the supply off.

The power supply is protected from reverse voltages by a diode; the reverse current must not

exceed 3 Amps.

General

Connection to the Load

The load should be connected to the positive (red) and negative (black) terminals marked

OUTPUT. Both are fully floating and either can be connected to ground. The negative terminals

are permanently connected to the power supply output, whilst the positive ones are switched

electromechanically (main outputs) or electronically (logic outputs). The green terminal is

connected to chassis and to the earth (ground) of the AC input cable.

If the unit is to be used with live measuring or load circuits which have protective earth terminals,

ensure that all protective earth terminals are connected to a protective conductor prior to

switching on (the green front panel terminal may be used for this purpose).

If the unit is to be used with live measuring or load circuits which do not have protective earth

terminals, ensure that the unit AC line plug is inserted before making connections between the

unit output terminals and such circuits.

11

Page 13

Remote Sensing

The unit has a very low output impedance, but this is inevitably increased by the resistance of the

connecting leads. At high currents, this can result in significant differences between the indicated

source voltage and the actual load voltage, (two 50mΩ connecting leads will drop 0·2V at 2 Amps,

for instance). This problem can be minimised by using short, thick, connecting leads, but where

necessary it can be completely overcome by using the remote sense facility.

This requires the sense terminals to be connected to the output at the load instead of at the

source; remove the two shorting bars and connect the sense terminals directly to the load. To

avoid instability and transient response problems, care must be taken to ensure good coupling

between each output and sense lead. This can be done either by twisting the leads together or by

using coaxially screened cable (sense through the inner). An electrolytic capacitor directly across

the load connection point may also be beneficial.

The voltage drop in each output lead must not exceed 0·5 Volts.

The shorting bars must be re-fitted if the remote sensing facility is not being used. Remote

sensing cannot be used in the tracking or series modes on either output.

Other Considerations

The power supplies generate considerable heat and require a full air cooling flow for correct

operation. Do not obstruct any of the cooling slots in the cover, or block the inflow of air at the

bottom.

Avoid allowing the supply to get damp, and keep away from corrosive fluids.

Maintenance

The Manufacturers or their agents overseas will provide repair for any unit developing a fault.

Where owners wish to undertake their own maintenance work, this should only be done by skilled

personnel in conjunction with the service manual which may be purchased directly from the

Manufacturers or their agents overseas.

Cleaning

If the PSU requires cleaning use a cloth that is only lightly dampened with water or a mild

detergent. Polish the display window with a soft dry cloth.

WARNING! TO AVOID ELECTRIC SHOCK, OR DAMAGE TO THE PSU, NEVER ALLOW

WATER TO GET INSIDE THE CASE. TO AVOID DAMAGE TO THE CASE OR DISPLAY

WINDOW NEVER CLEAN WITH SOLVENTS.

12

Page 14

Sécurité

Cet instrument est de Classe de sécurité 1 suivant la classification IEC et il a été construit pour

satisfaire aux impératifs EN61010-1 (Impératifs de sécurité pour le matériel électrique en vue de

mesure, commande et utilisation en laboratoire). Il s'agit d'un instrument d'installation Catégorie II

devant être exploité depuis une alimentation monophasée habituelle.

Cet instrument a été soumis à des essais conformément à EN61010-1 et il a été fourni en tout

état de sécurité. Ce manuel d'instructions contient des informations et avertissements qui doivent

être suivis par l'utilisateur afin d'assurer un fonctionnement de toute sécurité et de conserver

l'instrument dans un état de bonne sécurité.

Cet instrument a été conçu pour être utilisé en interne dans un environnement de pollution

Degré 2, plage de températures 5°C à 40°C, 20% - 80% HR (sans condensation). Il peut être

soumis de temps à autre à des températures comprises entre +5°C et –10°C sans dégradation

de sa sécurité. Ne pas l'utiliser lorsqu'il y a de la condensation.

Toute utilisation de cet instrument de manière non spécifiée par ces instructions risque d'affecter

la protection de sécurité conférée. Ne pas utiliser l'instrument à l'extérieur des tensions

d'alimentation nominales ou de la gamme des conditions ambiantes spécifiées.

AVERTISSEMENT! CET INSTRUMENT DOIT ETRE RELIE A LA TERRE

Toute interruption du conducteur de terre secteur à l'intérieur ou à l'extérieur de l'instrument

rendra l'instrument dangereux. Il est absolument interdit d'effectuer une interruption à dessein. Ne

pas utiliser de cordon de prolongation sans conducteur de protection, car ceci annulerait sa

capacité de protection.

Lorsque l'instrument est relié à son alimentation, il est possible que les bornes soient sous

tension et par suite, l'ouverture des couvercles ou la dépose de pièces (à l'exception de celles

auxquelles on peut accéder manuellement) risque de mettre à découvert des pièces sous

tension. Il faut débrancher toute source de tension éventuelle de l'appareil avant de l'ouvrir pour

effectuer des réglages, remplacements, travaux d'entretien ou de réparations. Les condensateurs

qui se trouvent dans le bloc d'alimentation risquent de rester chargés, même si le bloc

d'alimentation a été déconnecté de toutes les sources de tension, mais ils se déchargeront en

toute sécurité environ 1 minute après extinction de l'alimentation.

Eviter dans la mesure du possible d'effectuer des réglages, travaux de réparations ou d'entretien

lorsque l'instrument ouvert est branché à une source d'alimentation, mais si c'est absolument

nécessaire, seul un technicien compétent au courant des risques encourus doit effectuer ce

genre de travaux.

S'il est évident que l'instrument est défectueux, qu'il a été soumis à des dégâts mécaniques, à

une humidité excessive ou à une corrosion chimique, la protection de sécurité sera amoindrie et il

faut retirer l'appareil, afin qu'il ne soit pas utilisé, et le renvoyer en vue de vérifications et de

réparations.

Uniquement remplacer les fusibles par des fusibles d'intensité nominale requise et de type

spécifié. Il est interdit d'utiliser des fusibles bricolés et de court-circuiter des porte-fusibles.

Eviter de mouiller l'instrument lors de son nettoyage.

Les symboles suivants se trouvent sur l'instrument, ainsi que dans ce manuel.

Borne de terre (masse)

courant alternatif (c.a.)

courant continu (c.c.)

13

Page 15

Installation

Tension d'utilisation secteur

Vérifier que la tension opérationnelle de l'instrument indiquée sur le panneau arrière est

appropriée pour l'alimentation locale. Procéder de la manière ci-dessous pour changer la gamme

de tensions opérationnelles:

1. S'assurer que l'instrument est débranché de l'alimentation c.a.

2. Enlever les vis de retenue de la manette et de la partie supérieure du boîtier.

3. Retirer la partie supérieure du boîtier.

4. Si les prises du primaire du transformateur sont marquées de manière A 0-110-120

B 0-110-120, recâbler de la manière suivante:

Utilisation 240V: Fil neutre (bleu) à A0

relier le fil (rouge) de A120 à B0

fil sous tension (marron) à B120

Utilisation 230V: Fil neutre (bleu) à A0

relier le fil (rouge) de A110 à B0

fil sous tension (marron) à B120

Utilisation 220V: Fil neutre (bleu) à A0

relier le fil (rouge) de A110 à B0

fil sous tension (marron) à B110

Utilisation 120V: Fil neutre (bleu) à A0

relier le fil (bleu) de A0 à B0

relier le fil (marron) de A120 à B120

fil sous tension (marron) à B120

Utilisation 110V: Fil neutre (bleu) à A0

relier le fil (bleu) de A0 à B0

relier le fil (marron) de A110 à B110

fil sous tension (marron) à B110

Autrement, si les prises du primaire du transformateur sont numérotées 1 à 6, recâbler de la

manière suivante:

Utilisation 230V: Fil neutre (bleu) à 6

relier le fil (rouge) de 3 à 4

fil sous tension (marron) à 1

Utilisation 115V: Fil neutre (bleu) à 6

relier le fil (bleu) de 3 à 5

relier le fil (rouge) de 2 à 4

fil sous tension (marron) à 1.

Nota: Les appareils réglés en usine sur 220V/230V ou 240V ne disposent pas de fil de

liaison bleu - ce fil doit être fourni lors de la conversion pour l'exploitation 110/115/220V.

Lors de la conversion d'un appareil 110/115/120V en 220V/230V/240V retirer le fil de

liaison bleu.

5. Effectuer le remontage dans l'ordre inverse.

6. Le cas échéant, changer le type de fusible.

Remarque importante: Les réglementations de sécurité exigent une désignation distincte de la

tension de ligne c.a. à laquelle l'appareil est réglé, ce à la partie externe. En cas de changement

du réglage de la tension de ligne, il est extrêmement important de changer également la tension

marquée sur l'étiquette à proximité du point d'entrée du câble d'alimentation.

14

Page 16

Fusible

Le fusible c.a. se trouve sur le panneau arrière; il faut noter que le PL320QMT et PL330QMT ont

un fusible c.a. supplémentaire pour leurs sections de sortie logiques. Le type de fusible correct

est 20 mm x 5 mm 250V, action différée HBC avec valeurs nominales suivantes:

Modèle 220/230/240V 110/115/120V

PL320 / PL154 (simple) 1·6A (T) 3·15A (T)

PL330 (simple) 2A (T) 4A (T)

PL320QMD / PL320QMT 3·15A (T) 6·3A (T)

PL330QMD 4A(T) 8A (T)

PL330QMT 5A (T) 10A (T)

PL320QMT & PL330QMT Sortie logique: 1.6A (T) 3.15A (T)

Uniquement remplacer les fusibles par des fusibles d'intensité nominale requise et de type

spécifié. Il est interdit d'utiliser des fusibles bricolés et de court-circuiter des porte-fusibles.

Câble secteur

Relier de la manière suivante tout câble secteur à trois conducteurs à fils nus:

MARRON - SECTEUR SOUS TENSION

BLEU - SECTEUR NEUTRE

VERT/JAUNE - TERRE

Symbole Terre de protection

Il est possible que les couleurs des fils du câble secteur de cet appareil ne correspondent pas

aux marques de couleur d'identification des bornes de la fiche, et par suite, il est recommandé de

procéder de la manière suivante:

Relier le fil vert et jaune à la borne de la fiche désignée par la lettre E ou par le symbole Terre de

protection, ou en vert, ou en vert et jaune.

Relier le fil bleu à la borne désignée par la lettre N, ou en bleu ou noir.

Relier le fil marron à la borne désignée par la lettre L, ou en marron ou rouge.

S'il faut relier l'appareil à l'alimentation principale par un câblage fixe, plutôt que par une fiche de

ligne c.a., relier le fil de terre (masse) de protection du câble secteur à 3 conducteurs à un

conducteur de protection avant d'effectuer des connexions.

AVERTISSEMENT! CET APPAREIL DOIT ETRE RELIE A LA TERRE

Toute interruption du conducteur de terre secteur à l'intérieur ou à l'extérieur de l'instrument

rendra l'instrument dangereux. Il est absolument interdit d'effectuer une interruption à dessein. Ne

pas utiliser de cordon de prolongation sans conducteur de protection, car ceci annulerait sa

capacité de protection.

Montage

Cet instrument est approprié pour être monté sur établi ou sur baie. Il est fourni avec des pieds

en vue de montage sur établi.

On peut se procurer des kits de baie pour monter des alimentations dans une baie de 19" auprès

du Constructeur ou de ses agents à l'étranger.

15

Page 17

Fonctionnement

Sorties Principales

Réglage de la sortie

L'interrupteur d'alimentation allumé et le commutateur de sortie éteint, l'utilisation des trois

commandes de sortie permet de régler avec précision la limite de tension et de courant de sortie

avant d'effectuer une connexion à la charge. L'appareil de mesure gauche indique la tension et

l'appareil droit le courant. Le commutateur de sortie éteint (réglé), l'appareil de mesure courant

indique la valeur du réglage de limite du courant (indiquée par toutes les virgules décimales

affichées); le commutateur de sortie allumé, la valeur du courant de charge qui passe est

affichée.

A moins d'avoir besoin de télédétection, mettre les barres de court-circuitage de détection + à

sortie + et de détection - à sortie -. S'assurer que les bornes sont bien serrées avant toute

utilisation.

Tension constante

Les commandes de tension approximatives et de précision permettent de régler la tension de

sortie; la commande de courant règle le courant maximum qui peut être fourni.

Courant constant

Si la résistance de charge est suffisamment basse pour permettre à un courant supérieur à celui

du réglage de limite de courant de passer au niveau de tension de sortie réglé, l'alimentation

passera automatiquement en mode courant constant. La commande de limite de courant permet

de régler le courant de sortie; les commandes de tension règlent la tension maximale qui peut

être générée.

I

ndication de courant constant

Lorsque l'appareil fonctionne en mode courant constant, soit à dessein, soit parce que la limite de

courant a été atteinte, les virgules décimales de l'appareil de mesure de courant clignotent pour

indiquer que l'exploitation s'effectue avec un courant constant plutôt qu'avec une tension

constante.

Sortie de courant instantanée

On peut régler la commande de limite de courant pour limiter le courant de sortie continu à des

niveaux aussi bas que 1 mA. Toutefois, ainsi que c'est le cas de toutes les alimentations de

précision sur établi, un condensateur est relié entre les bornes de sortie (isolé par le

commutateur de sortie) afin de maintenir une stabilité ainsi qu'une bonne réponse transitoire. Ce

condensateur se charge jusqu'à la tension de sortie, et le court-circuitage de la sortie produit une

brève impulsion de courant lors du déchargement du condensateur indépendamment du réglage

de limite de courant.

Amortissement de l'ampèremètre

Les appareils de mesure numériques ont une cadence de lecture d'environ quatre lectures par

seconde et une constante de temps d'amortissement de 20 ms, ce qui donne une réponse

pratiquement instantanée aux changements de lecture. Si on utilise l’appareil pour fournir une

charge qui varie à une cadence supérieure à 0·5Hz, il risque d’être difficile d'interpréter les

valeurs de l'ampèremètre. On peut résoudre ce problème en appuyant sur le bouton marqué

DAMPING. Ceci augmente la constante de temps d'amortissement de l'ampèremètre à 2

secondes et par suite l'appareil tend à lire la moyenne du courant qui passe, plutôt que de suivre

les variations. Uniquement utiliser cette option lorsqu'on en a besoin, car elle augmente

nettement le temps de stabilisation et réduit la précision absolue.

16

Page 18

Connexion en série ou en parallèle avec d'autres appareils

La sortie du bloc d'alimentation a une charge entièrement constante et elle peut être utilisée en

série avec d'autres blocs d'alimentation pour générer des hautes tensions c.a. pouvant atteindre

300V c.c. AVERTISSEMENT! Des tensions de ce genre sont extrêmement dangereuses et il

faut prendre soin de protéger les bornes de sortie pour une utilisation de ce genre. Il ne faut sous

aucun prétexte toucher les bornes de sortie lorsque le bloc est allumé ou utilisé de cette manière.

Effectuer toutes les connexions aux bornes lorsque l'alimentation est coupée à tous les blocs

d'alimentation.

Il faut noter que l'appareil peut uniquement recevoir du courant mais sans le dissiper, de sorte

que les appareils ne peuvent pas être reliés en série en phase opposée.

Il est possible de relier l'appareil en parallèle avec d'autres appareils, afin de produire des

courants de sortie supérieurs. Lorsque plusieurs appareils sont reliés en parallèle, la tension de

sortie est égale à celle de l'appareil dont le réglage de tension de sortie est le plus haut possible,

jusqu'à ce que le courant dissipé dépasse le réglage de limite de courant; la sortie descend alors

à la valeur du réglage suivant le plus élevé et ainsi de suite. En mode courant constant, il est

possible de relier des appareils en parallèle afin de donner un courant égal à la somme des

réglages de limite de courant.

Application d'une source de tension externe à la sortie

Ainsi que c'est le cas de toutes les alimentations régulées en série à une seule extrémité,

l'appareil n'est pas en mesure de dissiper de courant provenant d'une source externe. En cas

d'application d'une tension supérieure à la tension de sortie de l'appareil réglée depuis une

source externe, le régulateur interne est mis hors service, aucun courant ne passe et le voltmètre

lit la tension appliquée. Il n’y aura pas de dégâts, à condition que la tension appliquée ne

dépasse pas la tension de sortie maximale de l'alimentation de plus de 20V. Il est interdit

d'appliquer une tension supérieure à cette valeur. En cas d'application de tension inverse, elle

sera fixée par une diode de protection inverse interne. Le courant inverse ne doit pas dépasser

3A.

Instructions supplémentaires pour les versions doubles mode quadruple

Les versions doubles mode quadruple des alimentations comprennent un groupe de quatre

commutateurs à boutons-poussoirs verrouillés qui permettent de sélectionner un mode parmi

quatre modes différents. Il s'agit des modes suivants:

1. Isolement

Chaque bloc d’alimentation fonctionne en tant que bloc entièrement séparé et indépendant isolé

électriquement des autres.

2. En parallèle

La sortie des deux blocs est transmise dans l'appareil principal (droit), avec augmentation de la

capacité de courant de sortie en conséquence. L'appareil principal se comporte exactement

comme un seul bloc d'alimentation de capacité de courant accrue. L'appareil asservi (gauche)

devient inopérationnel. La résolution de l'ampèremètre est de 2 mA sur le PL330QMD en mode

en parallèle.

3. En série

Même fonctionnement qu'en mode d'isolement, si ce n'est que la borne de sortie positive de

l'appareil asservi est reliée de manière interne à la borne de sortie négative de l'appareil principal.

4. Alignement

Même fonctionnement qu'en mode en série, si ce n'est que les commandes de tension principale

fonctionnent simultanément sur les appareils principal et asservis. Les commandes de limite de

courant de chaque appareil continuent à fonctionner individuellement. La précision d'alignement

est supérieure à ±0·3% du réglage ±0·1/ de la gamme totale.

17

Page 19

Le commutateur de sortie de l'appareil asservi doit toujours être allumé. Le commutateur de

sortie de l'appareil principal assure alors la commutation des deux sorties. Il n'est pas possible

d'utiliser la télédétection en mode en série ou alignement et il faut donc laisser en place les

barres de court-circuitage.

Instructions supplémentaires pour les versions triples mode quadruple

La version triple mode quadruple est composée de la version double mode quadruple décrite à la

section précédente, plus alimentation logique.

Alimentation logique P310QMT

Elle a une sortie fixe de 5V, 1·5A isolée des autres alimentations. L'alimentation logique est

protégée contre les courts-circuits. Elle est protégée contre des tensions directes externes

pouvant atteindre 16V et contre des tensions inverses par une diode: le courant inverse ne doit

pas dépasser 3A.

Alimentation logique PL320QMT & PL330QMT

Réglage de la sortie

Régler la sortie au moyen de la commande calibrée. Le commutateur de sortie éteint, l'appareil

(PL330 uniquement) affiche la tension; le commutateur allumé, il affiche le courant de charge. A

moins qu'on ait besoin de télédétection, mettre les barres de court-circuitage de détection + à

sortie + et détection - à sortie -.

Limite de courant (PL320QMT)

Allumer la diode électroluminescente (DEL) de LIMITE DE COURANT pour indiquer la limite de

courant et utiliser une commande calibrée pour la régler à une intensité comprise entre 0·1A et

4A. L'alimentation n'est pas prévue pour être utilisée en mode courant constant en tant que

source de courant.

Limite de courant (PL330QMT)

La limite de courant est indiquée par le clignotement des virgules décimales; utiliser une

commande calibrée pour la régler à une intensité comprise entre 0·1A et 7A. L'alimentation n'est

pas prévue pour être utilisée en mode courant constant en tant que source de courant.

Protection

Cette alimentation dispose d’une protection contre tension excessive qui se déclenchera si la

tension entre les bornes de sortie dépasse 7V. Si ceci se produit, la sortie d'alimentation est

limitée sous l'effet d'un thyristor; l'alimentation est alors mise à l'arrêt et TRIP (déclenchement)

sera indiqué sur l'affichage. Eteindre le commutateur de sortie c.c. ou couper l'alimentation pour

réenclencher l'alimentation. L'alimentation est protégée contre toute tension inverse par une

diode; le courant inverse ne doit pas dépasser 3A.

Généralités

Connexion à la charge

Relier la charge aux bornes positive (rouge) et négative (noire) marquées OUTPUT. Les deux ont

une charge entièrement constante et il est possible de relier l'une ou l'autre à la terre. Les bornes

négatives sont reliées en permanence à la sortie de l'alimentation et les bornes positives sont

connectées de manière électromécanique (sorties secteur) ou électroniquement (sorties

logiques). La borne verte est reliée au châssis et à la terre (masse) du câble d'entrée c.a.

S'il faut utiliser le bloc avec des circuits de mesure ou en charge sous tension disposant de

bornes de mise à la terre de protection, s'assurer que toutes les bornes de mise à la terre de

protection sont reliées à un conducteur de protection avant de l'allumer (il est possible d'utiliser la

borne verte du panneau avant à cet effet). S'il faut utiliser le bloc avec des circuits de mesure ou

en charge sous tension sans bornes de mise à la terre de protection, s'assurer que la fiche de

ligne c.a. du bloc est branchée avant d'effectuer de connexions entre les bornes de sortie du bloc

et des circuits de ce genre.

18

Page 20

Télédétection

Le bloc a une impédance de sortie très réduite, mais la résistance des câbles de raccordement

l'augmente automatiquement. En cas de courants élevés, ceci peut entraîner des différences

importantes entre la tension de source indiquée et la tension de charge véritable (par exemple,

deux câbles de raccordement de 50 mΩ entraîneront une chute de 0·2V à une intensité de 2A). Il

est possible de réduire ce problème au minimum au moyen de câbles de raccordement courts et

épais et, le cas échéant, le résoudre entièrement au moyen de l'option de télédétection). Ceci

nécessite la connexion des bornes de détection à la sortie de la charge plutôt qu'à la source;

enlever les deux barres de court-circuitage et relier les bornes de détection directement à la

charge. S'assurer qu'il y a un bon couplage entre chaque sortie et fil de détection pour éviter tout

problème d'instabilité et de réponse transitoire. On peut y parvenir soit par torsion des fils soit par

utilisation de câble blindé coaxialement (détection par le conducteur interne). Il peut s'avérer utile

de relier directement un condensateur électrolytique au point de connexion de charge. La chute

de tension de chaque fil de tension ne doit pas dépasser 0·5V. Il faut remettre les barres de courtcircuitage si on n'utilise pas l'option de télédétection. Il n'est pas possible d'utiliser la télédétection

en modes en série ou alignement d'une des deux sorties.

Autres considérations

Les blocs d'alimentation produisent une chaleur considérable et nécessitent un écoulement d’air

de refroidissement complet pour assurer un fonctionnement correct. Eviter de boucher les

rainures de refroidissement du couvercle ou de bloquer l'arrivée d'air à la partie inférieure. Eviter

toute humidité de l'alimentation et maintenir le bloc à distance des fluides de corrosion.

Entretien

Le Constructeur ou ses agents à l'étranger répareront tout bloc qui tombe en panne. Si le

propriétaire de l'appareil décide d'effectuer ses propres réparations, ceci doit uniquement être

effectué par un personnel spécialisé qui doit se référer au manuel de révisions que l'on peut se

procurer directement auprès du Constructeur ou de ses agents à l'étranger.

Nettoyage

S'il faut nettoyer le bloc d'alimentation, utiliser un chiffon légèrement imbibé d'eau ou d'un

détergent doux. Nettoyer le cadran d'affichage au moyen d'un chiffon sec et doux.

AVERTISSEMENT! EMPECHER TOUTE INTRODUCTION D'EAU DANS LE BOITIER AFIN

D'EVITER TOUT CHOC ELECTRIQUE ET DEGATS AU BLOC D'ALIMENTATION. NE JAMAIS

UTILISER DE DISSOLVANTS POUR NETTOYER LE BLOC, AFIN D'EVITER

D'ENDOMMAGER LE BOITIER OU LE CADRAN D'AFFICHAGE.

19

Page 21

Sicherheit

Dieses Gerät wurde nach der Sicherheitsklasse (Schutzart) I der IEC-Klassifikation und gemäß

den europäischen Vorschriften EN61010-1 (Sicherheitsvorschriften für elektrische Meß-, Steuer,

Regel- und Laboranlagen) entwickelt. Es handelt sich um ein Gerät der Installationskategorie II,

das für den Betrieb von einer normalen einphasigen Versorgung vorgesehen ist.

Das Gerät wurde gemäß den Vorschriften EN61010-1 geprüft und wurde in sicherem Zustand

geliefert. Die vorliegende Anleitung enthält vom Benutzer zu beachtende Informationen und

Warnungen, die den sicheren Betrieb und den sicheren Zustand des Gerätes gewährleisten.

Dieses Gerät ist für den Betrieb in Innenräumen der Umgebungsklass 2 , für einen

Temperaturbereich von 5° C bis 40° C und 20 - 80 % relative Feuchtigkeit (nicht kondensierend)

vorgesehen. Gelegentlich kann es Temperaturen zwischen +5° und –10°C ausgesetzt sein, ohne

daß seine Sicherheit dadurch beeinträchtigt wird. Betreiben Sie das Gerät jedoch auf keinen Fall,

solange Kondensation vorhanden ist.

Ein Einsatz dieses Geräts in einer Weise, die für diese Anlage nicht vorgesehen ist, kann die

vorgesehene Sicherheit beeinträchtigen. Auf keinen Fall das Gerät außerhalb der angegebenen

Nennversorgungsspannungen oder Umgebungsbedingungen betreiben.

WARNUNG! - DIESES GERÄT MUSS GEERDET WERDEN!

Jede Unterbrechung des Netzschutzleiters innerhalb oder außerhalb des Geräts macht das Gerät

gefährlich. Eine absichtliche Unterbrechung ist verboten. Die Schutzwirkung darf durch

Verwendung eines Verlängerungskabels ohne Schutzleiter nicht aufgehoben werden.

Ist das Gerät an die elektrische Versorgung angeschlossen, so können die Klemmen unter

Spannung stehen, was bedeutet, daß beim Entfernen von Verkleidungs- oder sonstigen Teilen

(mit Ausnahme der Teile, zu denen Zugang mit der Hand möglich ist) höchstwahrscheinlich

spannungsführende Teile bloßgelegt weden. Vor jeglichem Öffnen des Geräts zu Nachstell-,

Auswechsel-, Wartungs- oder Reparaturzwecken, Gerät stets von sämtlichen Spannungsquellen

abklemmen. Kondensatoren in der Stromversorgung können auch noch nach Abschalten

sämtlicher Stromversorgung Spannung führen, sie entladen sich jedoch innerhalb von etwa einer

Minute nach Spannungsabschaltung.

Jegliche Nachstellung, Wartung und Reparatur am geöffneten, unter Spannung stehenden Gerät,

ist nach Möglichkeit zu vermeiden. Falls unvermeidlich, sollten solche Arbeiten nur von

qualifiziertem Personal ausgeführt werden, das sich der Gefahren bewußt ist.

Ist das Gerät eindeutig fehlerbehaftet, bzw. wurde es mechanisch beschädigt, übermäßiger

Feuchtigkeit oder chemischer Korrosion ausgesetzt, so können die Schutzeinrichtungen

beeinträchtigt sein, weshalb das Gerät aus dem Verkehr zurückgezogen und zur Überprüfung

und Reparatur eingesandt werden sollte.

Sicherstellen, daß nur Sicherungen der vorgeschriebenen Stromstärke und des vorgesehenen

Typs als Ersatz verwendet werden. Provisorische “Sicherungen” und der Kurzschluß von

Sicherungshaltern ist verboten.

Beim Reinigen darauf achten, daß das Gerät nicht naß wird.

Am Gerät werden folgende Symbole verwendet:

Erdungsklemme

Wechselstrom

Gleichstrom

20

Page 22

Installation

Zunächst ist zu prüfen, ob die am Gerät eingestellte Betriebspannung, die aus den Angaben auf

der Geräterückseite ersichtlich ist, für den Betrieb am örtlichen Speisenetz korrekt ist. Sollte es

erforderlich sein, die Einstellung für den Betriebsspannungsbereich zu ändern, ist wie folgt

vorzugehen:

1. Sicherstellen, daß das Gerät vom Wechselstromnetz getrennt ist.

2. Die Schrauben entfernen, mit denen Gehäuseoberteil und Griff befestigt sind. .

3. Das Gehäuseoberteil abnehmen.

4. Wenn die Transformator-Primäranschlüsse mit A0-110-120 und B0-110-120 gekennzeichnet

sind, die Verdrahtung wie folgt ändern:

240V-Betrieb: Nulleiter (blau) auf A0

Verbindungsleitung (rot) von A120 nach B0

Stromführender Leiter (braun) auf B120

230V-Betrieb: Nulleiter (blau) auf A0

Verbindungsleitung (rot) von A110 nach B0

Stromführender Leiter (braun) auf B120

220V-Betrieb: Nulleiter (blau) auf A0

Verbindungsleitung (rot) von A110 nach B0

Stromführender Leiter (braun) auf B110

120V-Betrieb: Nulleiter (blau) auf A0

Verbindungsleitung (blau) von A0 nach B0

Verbindungsleitung (braun) yon A120 nach B120

Stromführender Leiter (braun) auf B120

110V-Betrieb: Nulleiter (blau) auf A0

Verbindungsleitung (blau) von A0 nach B0

Verbindungsleitung (braun) von A110 nach B110

Stromführender Leiter (braun) auf B110

Alternativ, wenn die Transformator-Primäranschlüsse mit 1 bis 6 gekennzeichnet sind, die

Verdrahtung wie folgt ändern:

230V-Betrieb: Nulleiter (blau) auf 6

Verbindungsleitung (rot) von 3 nach 4

Stromführender Leiter (braun) auf 1

115V-Betrieb: Nulleiter (blau) auf 6

Verbindungsleitung (blau) von 3 nach 5

Verbindungsleitung (rot) von 2 nach 4

Stromführender Leiter (braun) auf 1

Hinweis: Geräte, die werkseitig auf 220V, 230V oder 240V eingestellt sind, besitzen keine blau

Verbindungsleitung. Diese muß für die Umstellung auf den 110/115/120-Volt-Betrieb zusätzlich

bereitgestellt werden. Zur Umstellung eines für den 110/115/120-Volt-Betrieb vorgesehenen

Geräts auf den 220/230/240-Volt-Betrieb muß die blau Verbindungsleitung entfernt werden.

5. Das Gerät wieder zusammenbauen. Dabei in umgekehrter Reihenfolge vorgehen.

6. Die Sicherung falls erforderlich durch anderen Sicherungstyp ersetzen.

Wichtiger Hinweis: Die Sicherheitsvorschriften schreiben vor, daß die Netz-Wechselspannung,

auf die das Gerät eingestellt ist, außen am Gerät eindeutig angegeben sein muß. Wenn die

Einstellung für die Netzspannung geändert wird, muß die Spanriungsangabe auf dem

Bezeichnungsschild in der Nähe des Eingangs der Stromzuführung entsprechend geändert

werden.

21

Page 23

Sicherung

Die Sicherung (Wechselspannung) befindet sich in der Geräterückwand. Zu beachten ist, daß

die Geräte PL320QMT und PL330QMT einze zusätzliche Wechselspannungssicherung für ihren

Logic-Ausgangteil besitzen. Als korrekter Sicherungstyp ist eine 20 mm x 5 mm 250V HBV träge

Sicherung mit folgenden Kenndaten zuverwenden:

Modell 220/230/240V 110/115/120V

PL320 / PL154 (einfach) 1·6A (T) 3·15A (T)

PL330 (einfach) 2A (T) 4A (T)

PL320QMD / PL320QMT 3·15A (T) 6·3A (T)

PL330QMD 4A (T) 8A (T)

PL330QMT 5A (T) 10A (T)

PL320QMT & PL330QMT Logic-Ausg. 1.6A (T) 3.15A (T)

Beim Austausch einer Sicherung ist darauf zu achten, daß nur Sicherungen für die geforderte

Nennstromstärke und des hier angegebenen Typs verwendet werden. Die Verwendung

behelfsmäßiger Sicherungen und das Kurzschließen des Sicherungshalters sind nicht zulässig.

Netzanschlußkabel

Wenn ein dreiadriges Netzkabel mit blanken Enden im Lieferumfang enthalten ist, muß dieses

wie folgt angeschlossen werden:

BRAUN - STROMFÜHRENDER LEITER

BLAU - NULLEITER

GRÜN/GELB - SCHUTZLEITER

Schutzleitersymbol

Für den Fall, daß die Farben der Adern des Netzkabels von diesem Gerät nicht mit den

Farbmarkierungen übereinstimmen, die beim Stecker zur Kennzeichnung der Klemmen

verwendet wurden, ist wie folgt vorzugehen:

Der grün/gelbe Leiter muß an diejenige Klemme im Stecker angeschlossen werden, die mit dem

Buchstaben E oder dem Schutzleitersymbol gekennzeichnet ist oder die Farbe Grün oder

Grün/Gelb aufweist.

Der blaue Leiter muß an die Klemme angeschlossen werden, die mit dem Buchstaben N

gekennzeichnet ist oder die Farbe Schwarz aufweist.

Der braune Leiter muß an die Klemme angeschlossen werden, die mit dem Buchstaben L

gekennzeichnet ist oder die Farbe Rot aufweist.

Wenn das Ger'at nicht über einen Netzstecker an das Wechselstromnetz angeschlossen werden

soll, sondern vielmehr über eine feste Verdrahtung, dann muß zunächst der Schutzleiter (Erdung)

des dreiadrigen Netzkabels mit einem Schutzleiter verbunden werden, bevor irgendein anderer

Anschluß hergestellt wird.

WARNUNG! DIESES GERÄT MUSS GEERDET SEIN!

Jede Unterbrechung des Netzschutzleiters innerhalb oder außerhalb des Geräts macht das Gerät

gefährlich. Eine absichtliche Unterbrechung ist verboten. Die Schutzwirkung darf durch

Verwendung eines Verlängerungskabels ohne Schutzleiter nicht aufgehoben werden.

22

Page 24

Betrieb

Hauptausgänge

Einstellen des Ausgangs

Wenn sich der Netzschalter in der Stellung ON (EIN) und der Ausgangsschalter in der Stellung

OFF (AUS) befindet, können die Ausgangsspannung und die Strombegrenzung mit Hilfe der drei

Ausgangsregler vor der Lastzuschaltung akkurat eingestellt werden. Der linke Zähler gibt die

Spannung an und der rechte Zähler die Stromstärke.

Wenn sich der Ausgangsschalter in der Einstellposition OFF befindet, zeigt der Stromzähler den

eingestellten Wert für die Strombegrenzung an (angezeigt durch das Aufleuchten sämtlicher

Dezimalpunkte). Befindet sich der Ausgangsschalter dagegen in der Stellung ON, so gibt der

Wert den Laststrom an, der fließt.

Wenn die Istwert-Fernerfassung nicht benötigt wird, müssen die Kurzschlußbrücken wie folgt

angebracht sein: von der positiven Klemme für die Abtastung (SENSE +) zur positiven

Ausgangsklemme (OUTPUT +) und von der negativen Klemme für die Abtastung (SENSE -) zur

negativen Ausgangsklemme (OUTPUT -) Dabei ist sicherzustellen, daß die Klemmen vor dem

Gebrauch ordungsgemäß angezogen werden.

Konstantspannung

Der Spannungsausgang wird mit Hilfe der Regler COARSE und FINE VOLTAGE zur Grob- und

Feineinstellung der Spannung eingestellt. Über den CURRENT-Regier wird der maximal

lieferbare Strom eingestellt.

Konstantstrom

Wenn der Lastwiderstand ausreichend niedrig ist, so daß beim eingestellten

Ausgangsspannungspegel ein Strom fließen würde, der den eingestellten Grenzwert für die

Stromstärke übersteigt, vollzieht das Gerät automatisch den Übergang in den

Konstantstrombetrieb.

Der Stromausgang wird mit Hilfe des Strombegrenzungsreglers CURRENT LIMIT eingestellt.

Über die VOLTAGE-Regier wird die maximal erzeugbare Spannung eingestellt.

Konstantstrornanzeige

Wenn das Gerät im Konstantstrommodus arbeitet, sei es, daß dies beabsichtigt ist, oder weil der

Punkt für die Strombegrenzung erreicht ist, blinken die Dezimalpunkte im Stromzähler. Hierdurch

wird angezeigt, daß das Gerät im Konstantstrommodus und nicht im Konstantspannungsmodus

arbeitet.

Augenblickswer't der Stromabgabe

Der Ausgangsdauerstrom kann mit Hilfe des Strombegrenzungsreglers (CURRENT LIMIT) auf

einen Pegel bis minimal 1 mA begrenzt werden. Wie bei allen anderen Präzisions-Tischgeräten

für die Stromversorgung ist jedoch auch bei diesem Gerät ein Kondensator parallel zum Ausgang

geschaltet (getrennt durch den Ausgangsschalter), damit für Stabilität und ein gutes transientes

Lastverhallen gesorgt ist. Dieser Kondensator lädt sich bis zur Ausgangsspannung. Bei

Kurzschließung des Ausgangs wird ein kurzer Stromimpuls erzeugt, wenn sich der Kondensator

entlädt, welcher unabhängig vom eingestellten Stromgrenzwert ist.

Stromzählerdärnpfung

Die Meßfolge der Digitalzähler beträgt ca. vier Messungen pro Sekunde, die

Beruhigungszeitkonstante 20 ms. Hierdurch ist quasi ein sofortiges Ansprechen auf

Meßwertänderungen gegeben.

23

Page 25

Wenn das Gerät zur Speisung eines Verbrauchers eingesetzt wird, und die dabei auftretenden

Belastungsschwankungen eine Rate von ca. 0·5 Hz überschreiten, kann sich die Auswertung der

vom Stromzähler abgelesenen Werte als problematisch erweisen. Dieses Problem kann

abgeschwächt werden, indem die mit DAMPING (ämpfung) gekennzeichnete Taste gedrückt

wird. Hierdurch wird die Beruhigungszeitkonstante des Stromzählers auf 2 Sekunden erhöht, mit

dem Ergebnis, daß die Abiesewerte des Stromzählers von der Tendenz her eher den mittleren

Stromfluß widerspiegeln, als daß sie allen Schwankungen folgen. Diese Einrichtung sollte nur

dann verwendet werden, wenn dies tatsächlich erforderlich ist, denn bei ihrem Einsatz verlängert

sich die Beruhigungszeit erheblich, und die absolute Genauigkeit wird herabgesetzt.

Reihen- und Paralleischaltung mit anderen Geräten

Da der Ausgang des Netzteils vollständig polentialfrei ist, kann er mit anderen Netzgeräten zur

Erzeugung hoher Gleichspannungen bis maximal 300V in Reihe geschaltet werden.

WARNUNG! Spannungen in dieser Größenordnung sind überaus gefährlich. Bei einer solchen

Einsatzweise sollten die Ausgangsklemmen mit größter Sorgfalt abgeschirmt werden. Unter

diesen Bedingungen dürfen die Ausgangsklemmen keinesfalls berührt werden, wenn das Gerät

eingeschaltet ist. Wann immer Verbindungen mit den Klemmen hergestellt werden, müssen

sämtliche Geräte ausgeschaltet sein.

Zu beachten ist dabei, daß das Gerät ausschließlich stromliefernd, nicht aber stromziehend

arbeiten kann, und daß die Geräte daher nicht gegenphasig in Reihe geschaltet werden können.

Das Gerät kann zur Erzeugung einer höheren Stromabgabe mit anderen Geräten parallel zu

diesen geschaltet werden. Wenn mehrere Geräte parallel geschaltet werden, entspricht die

Ausgangsspannung der Ausgangsspannung des Geräts, bei dem der Einstellwert für die

Ausgangsspannung am höchsten ist, bis die Stromaufnahme den bei diesem Gerät eingestellten

Grenzwert überschreitet, woraufhin der Ausgang auf die zweilhöchste Einstellung abfällt, und so

weiter. Im Konstantstrombetrieb können Geräte parallel geschaltet werden, wodurch sich eine

Stromabgabe erreichen läßt, die der Summe der Einstellwerte für die Strombegrenzung

entspricht.

Anlegen von Spannung aus einer externenQuelle an den Ausgang

Wie alle anderen seriengeregelten Eintakt-Netzgeräte ist das Gerät nicht in der Lage, Strom aus

einer externen Quelle zu ziehen. Wenn von einer externen Quelle eine Spannung angelegt wird,

die größer als die eingestellte Ausgangsspannung des Geräts ist, schaltet der interne Regler ab,

es fließt kein Strom, und der Spannungsmesser zeigt die angelegte Spannung an. Solange die

angelegte Spannung die maximale Ausgangsspannung des Netzteils nicht um mehr als 20Volt

übersteigt, führt dies nicht zu einem Schaden beim Gerät. Das Anlegen einer höheren Spannung

als dieser ist untersagt.

Wenn eine Rückspannung angelegt wird, so wird diese über eine interne Rückstromschutzdiode

abgefangen. Der Rückstrom darf 3 Ampäre nicht übersteigen.

Zusätzliche Anweisungen Für Quad-Mode-Dualversionen

Die Quad-Mode-Dual-Versionen der Stromversorgung weisen eine Reihe mitvier abhängigen

Druckknopfschaltern auf, über die jede der vier verschiedenen Betriebsarten angewählt werden

kann. Diese vier Betriebsarten sind folgende:

1. Isolated

Jedes Netzteil arbeitet als vollständig getrennte, unabhängige Einheit und ist von den anderen

potentialgetrennt.

2. Parallel

Die Ausgänge beider Geräte werden in der Master-Einheit (rechte Seite) zusammengeführt und

erhöhen damit deren Stromabgabekapazität entsprechend. Die Master-Einheit verhält sich dann

genauso wie ein einzelnes Netzteil mit erhöhtem Stromabgabevermögen. Die SlaveEinheit (linke

Seite) wird außer Betrieb gesetzt. Beim Modell PL330QMD beträgt die Auflösung des

Stromzählers im Parallelbetrieb 2 mA.

24

Page 26

3. Series

Betrieb wie im Isolated-Modus, jedoch mit dem Unterschied, daß die positive Ausgangsklemme

der Slave-Einheit intern mit der negativen Ausgangsklemme der Master-Einheit verbunden ist.

4. Tracking

Betrieb wie im Series-Modus jedoch mit dem Unterschied, daß die Master-Spannungsregier an

der Master-Einheit und der Slave-Einheit gleichzeitig arbeiten. Die Strombegrenzungsregler der

einzelnen Einheiten arbeiten nach wie vor getrennt. Die Genauigkeit der Nachsteuerung ist

besser als ±0·3% der Einstellung ±0·1 % des Gesamtbereichs.

Der Slave-Ausgangsschalter muß stets eingeschaltet sein. Beide Ausgänge werden dann über

den Master-Ausgangsschalter geschaltet.

Da eine Istwert-Fernerfassung in den Betriebsarten Series und Tracking nicht möglich ist, sollten

die Kurzschlußbrücken an Ort und Stelle verbleiben.

Zusätzliche Anweisungen Für Die Quad-Mode-Tripleversionen

Die Quad-Mode-Tripte-Version umfaßt zusätzlich zu den im vorhergehenden Abschnitt

beschriebenen Merkmale der Quad-Mode-Dual-Version eine Logikversorgung.

PL310QMT Logic-Versorgung

Diese besitzt eine festen 5-V-, 1·5-A-Ausgang, der von den anderen Zuleitungen getrennt ist.

Die Logic-Versorgung ist vor Kurzschlüssen und vor externen Vorwärtsspannungen bis maximal

16 Volt geschätzt. Ferner ist sie durch eine Diode vor Rückspannungen geschätzt: der

Rückstrom darf eine Stärke von 3A nicht übersteigen.

PL320QMT und PL330QMT Logic-Versorgung

Einstellen des Ausgangs

Die Einstellung des Ausgangs erfolgt über den geeichten Regler. Wenn sich der

Ausgangsschalter in der Stellung OFF befindet, zeigt der Zähler (nur bei PL330) die Spannung

an. Wenn sich der Schalter in ON-Stellung befindet, wird der Laststrom angezeigt. Wenn die

Istwert-Fernerfassung nicht benötigt wird, müssen die Kurzschlußbrücken wie folgt angebracht

sein: von der positiven Klemme für die Abtastung (SENSE +) zur positiven Ausgangsklemme

(OUTPUT +) und von der negativen Klemme füi die Abtastung (SENSE -) zur negativen

Ausgangsklemme (OUTPUT -)

Strombegrenzung (PL320QMT)

Die Strombegrenzung wird durch das Aufleuchlen der CURRENT LIMIT-LED angezeigt. Die

Einstellung erfolgt über einen geeichten. Regler mit einen Einstellbereich von 0·1A bis 4A. Das

Netzteil ist nicht dafür ausgelegt, im Konstantstrombetrieb als Stromquelle zu arbeiten.

Strombegrenzung (PL330QMT)

Die Strombegrenzung wird durch das Blinken sämtlicher Dezimalpunkte angezeigt. Die

Einstellung erfolgt über einen geeichteri Regler mit einen Einstellbereich von 0·1A bis 7A. Das

Netzteil ist nicht dafür ausgelegt, im Konstantstrombetrieb als Stromquelle zu arbeiten.

Schutz

Diese Stromversorgung verfügt über einen Überspannungsschutz, der ausgelöst wird, wenn die

Spannung an den Ausgangsklemmen über 7 Volt ansteigt. Wenn dieser Fall eintritt, erfolgt die

Schnellabschaltung des Stromversorgungsausgangs durch einen Thyristor. Das Netzteil wird

ausgeschaltet, und in der Anzeige erscheint die Meldung 'TRIP'. Das Netzteil kann zurückgesetzt

werden, indem der Gleichstrom-Ausgangsschalter oder die Versorgung ausgeschaltet wird. Das

Netzteil ist durch eine Diode vor Rückspannungen geschützt. Der Rückstrom darf einen Wert

von 3A nicht überschreiten.

25

Page 27

Allgemeines

Anschluß des Verbrauchers

Der Anschluß des Verbrauchers sollte über die positiven (roten) und die negativen (schwarzen)

Klemmen erfolgen, die mit 'OUTPUT" beschriftet sind. Beide sind vollständig potentialfrei. Jede

der beiden Klemmen kann mit Erde verbunden werden. Die negativen Klemmen sind permanent

mit dem Ausgang des Netzteils verbunden, wohingegen die positiven Klemmen

elektromechanisch (Hauptausgänge) oder elektronisch (Logikausgänge) geschaltet werden. Die

grüne Klemme wird mit dem Chassis und mit der Erdung des Zuleitungskabels (Wechselstrom)

verbunden.

Wenn das Gerät in Verbindung mit stromführenden Meß- oder Verbraucherkreisen eingesetzt

werden soll, die Schutzerdungsklemmen aufweisen, ist sicherzustellen, daß vor dem Einschalten

zunächst sämtliche Schutzerdungsklemmen mit einem Schutzleiter verbunden werden. (Zu

diesem Zweck kann die grüne Anschlußklemme in der Frontplatte verwendet werden). Wenn das

Gerät in Verbindung mit stromführenden Meß- oder Verbraucherkreisen eingesetzt werden soll,

die keine Schutzerdungsklemmen aufweisen, ist sicherzustellen, daß der Netzstecker

(Wechselstrom) des Geräts eingesteckt wird, bevor irgendeine Verbindung zwischen den

Ausgangsklemmen des Geräts und solchen Stromkreisen hergestellt wird.

Istwert-Fernerfassung

Die Ausgangsimpedanz ist bei dieser Einheit sehr niedrig, wird aber unvermeidbar durch den

Widerstand der Verbindungsleitungen erhöht. Bei hohen Stromstärken können sich hieraus

erhebliche Unterschiede zwischen der angezeigten Quellenspannurig und der tatsächlichen

Lastspannung ergeben (bei zwei 50-mΩ-Anschlußleitungen ergibt sich beispielsweise ein

Spannungsabfall von 0·2V bei 2A). Dieses Problem kann durch die Verwendung kurzer

Verbindungsleitung mit großer Drahtstärke minimiert und, falls erforderlich, durch die Verwendung

der Einrichtung zur Istwert-Fernerfassung sogar ganz ausgeschaltet werden.

Zu diesem Zweck müssen die SENSE-Klemmen mit dem Ausgang des Verbrauchers statt mit

dem Ausgang der Quelle verbunden werden. Hierzu die beiden Kurzschlußbrücken entfernen

und die SENSE-Klemmen direkt mit dem Verbraucher verbinden. Um Probleme bezüglich der

Stabilität und des Einschwingverhaltens zu vermeiden, ist sorgfältig darauf zu achten, daß eine

gute Kopplung zwischen dem jeweiligen Ausgang und der Abtastleitung gegeben ist. Dies läßt

sich auf zweierlei Arten erreichen: entweder indem die Leitungen miteinander verdrillt werden

oder indem ein koaxial geschirmtes Kabel (Abtastung über den Innerleiter) verwendet wird. Auch

ein Elektrolytkondensator direkt am Lastanschlußpunkt kann hiervon Nutzen sein. Der

Spannungsabfall darf bei keiner Ausgangsleitung mehr als 0·5 Volt betragen. Die

Kurzschlußbrücken müssen wiedereingesetzt werden, wenn die Einrichtung zur IstwertFernerfassung nicht genutzt wird. In den Betriebsarten "Tracking" und "Series" kann für keinen

der Ausgänge eine lstwert-Fernerfassung erfolgen.

Weitere Hinweise

Die Wärmeabgabe ist bei diesem Gerät beträchtlich. Damit ein fehlerfreier Betrieb gewährleistet

ist, muß daher eine ungehinderte Kühlluftzirkulation sichergestellt sein. Die Lüttungsschlitze in

der Verkleidung dürfen keinesfalls versperrt werden. Auch an der Unterseite muß die Luft

ungehindert zuströmen können. Das Gerät darf nicht feucht werden und ist von aggresiven

flüssigen und gasförmigen Medien fernzuhalten.

26

Page 28

Wartung

Die Hersteller bzw. deren Vertretungen im Ausland bieten die Instandsetzung von Geräten an, bei

denen eine Störung aufgetreten ist. Wenn der Eigentümer die Wartungsarbeiten selbst

durchfuhren möchte, hat er dafür Sorge zu tragen, daß diese Arbeiten ausschließlich von

entsprechend qualifiziertem Personal und gemäß den Vorgaben im Wartungshandbuch

ausgeführt werden, das direkt bei den Herstellern oder deren Vertretungen im Ausland bezogen

werden kann.

Reinigung

Falls die Stromversorgung der Reinigung bedarf, eine mit Wasser oder einem milden Detergens

angefeuchteten Lappen benutzen. Anzeigefenster mit einem weichen, trockenen Lappen

polieren.

WARNUNG! ZUR VERMEIDUNG EINES ELEKTRISCHEN SCHLAGS BZW. BESCHÄDIGUNG

DER STROMVERSORGUNGSEINHEIT, DAFÜR SORGEN, DASS KEIN WASSER INS

GEHÄUSE EINDRINGT. UM SCHADEN AM GEHÄUSE BZW. AM ANZEIGEFENSTER ZU

VERMEIDEN, KEINE LÖSUNGSMITTEL ZUR REINIGUNG VERWENDEN!

27

Page 29

Thurlby Thandar Instruments Ltd

Glebe Road, Huntingdon, Cambridgeshire PE29 7DR, England

Telephone: +44 (0)1480 412451 Fax: +44 (0)1480 450409

International website: www.tti-test.com UK website: www.tti.co.uk

e mail: sales@tti-test.com

Book Part No. 48511-0170 Issue 12

Loading...

Loading...