Page 1

THURLBY THANDAR INSTRUMENTS

Model 1705

PROGRAMMABLE TRUE RMS MULTIMETER

INSTRUCTION MANUAL

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 1

Page 2

Table of Contents

Introduction 2

Specifications 3

Safety 8

EMC 9

Installation 10

General Operation 12

Making Basic Measurements 16

Dual Measurement Mode 19

Advanced Features 21

Data Logging and Printing 25

Calibration 27

Maintenance 28

Remote Operation 29

Remote Commands 34

General Commands 34

Main Display Commands 35

Dual Measurement Mode Commands 37

First Level Modifier Commands 37

Second Level Modifier Commands 38

Data Logging Commands 39

Calibration Commands 40

Default Settings 41

1

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 2

Page 3

Introduction

This programmable true RMS multimeter has dual measurement capability and a dual display †

which can show either two independent measurements, a measurement together with its range or

a measurement with one of the many calculated functions available.

The key features are:

• Large, high contrast, liquid crystal dual display.

• 0.04% basic accuracy, 12000 counts.

• Manual or autoranging.

• DC and AC Volts, DC and AC current, Resistance, Capacitance, and Frequency measurement;

Continuity and Diode checks.

• True RMS AC and AC+DC measurement.

• Display nulling and Ohms null.

• Touch hold mode - holds onto a stable reading until updated.

• 100 point data logger.

• Measurement post-processing to give:

dB and power measurement with settable reference impedance

percentage deviation from a user-entered reference

linear scaling with offset

limits comparison for go/no go testing

automatic storage of minimum and maximum readings.

• Remote control via addressable RS232 (standard) or GPIB (factory-fit option) interfaces.

• Closed case software calibration.

• Fully compliant with EN61010-1 Safety and EN61326 EMC standards.

† Licensed under U.S. Pat. 4,825,392

2

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 3

Page 4

g

ACCURACY

Accuracies apply for 1 year 19°C to 25°C. Temperature coefficient outside these limits is <0.1 x

quoted range accuracy per °C.

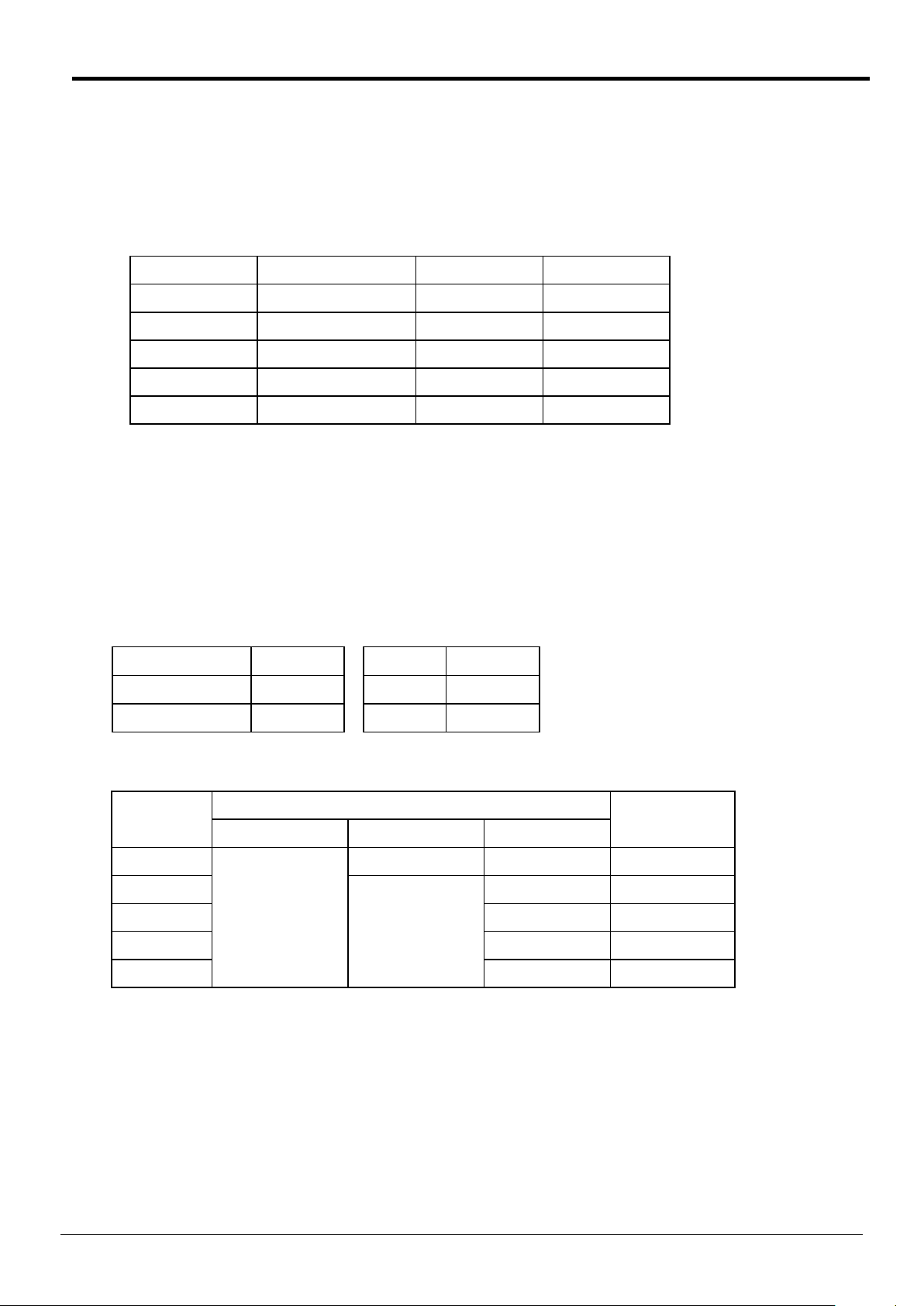

DC Volts

Range Accuracy Resolution

Specifications

100mV

1000mV 0.04% ± 2 dig. 100uV

10V 0.06% ± 2dig. 1mV

100V 0.06% ± 2 dig. 10mV

1000V 0.06% ± 2 dig. 100mV

0.06% ± 3 di

.*

10uV

* after null

Input Impedance:

10MΩ//<100pF, except for Vdc plus Vac measurement when the

1MΩ ac attenuator is in parallel with the 10MΩ dc attenuator.

Maximum Input: 1kV DC or AC peak, any range.

NMR: >60dB at 50/60Hz.

1kΩ Unbalanced CMR:

>90dB at DC/50Hz/60Hz.

Maximum Allowable AC Voltage While Measuring DC Voltage

Range Max AC Range Max AC

100mV, 1000mV 6V 10V 80V (45Hz-50kHz) that can be applied without

100V 200V 1000V 1000V affecting the accuracy of the DC measurement.

The table shows the maximum AC voltage

AC Volts (True RMS)

Range Accuracy Resolution

45Hz - 10kHz 10kHz - 20kHz 20kHz - 50kHz

100mV 1% ± 20 dig. - 10µV

1000mV 1% ± 50 dig 100µV

10V 0.2% ± 20 dig 0.2% ± 20 dig 1% ± 80 dig 1mV

100V 1% ± 80 dig 10mV

750V - 100mV

Accuracy specifications apply for readings between 1,000 and 12,000 counts. Additional error at

crest factor = 3 typically 0.2%.

Extended frequency performance

(typical):

Input Impedance:

Maximum Input: 750V rms, 1000V peak; any range.

1kΩ Unbalanced CMR:

100mV range <-1dB at 50kHz; 1000mV, 10V and

100V ranges <-1dB at 100kHz.

1MΩ//<100pF

>60dB at DC/50Hz/60Hz

3

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 4

Page 5

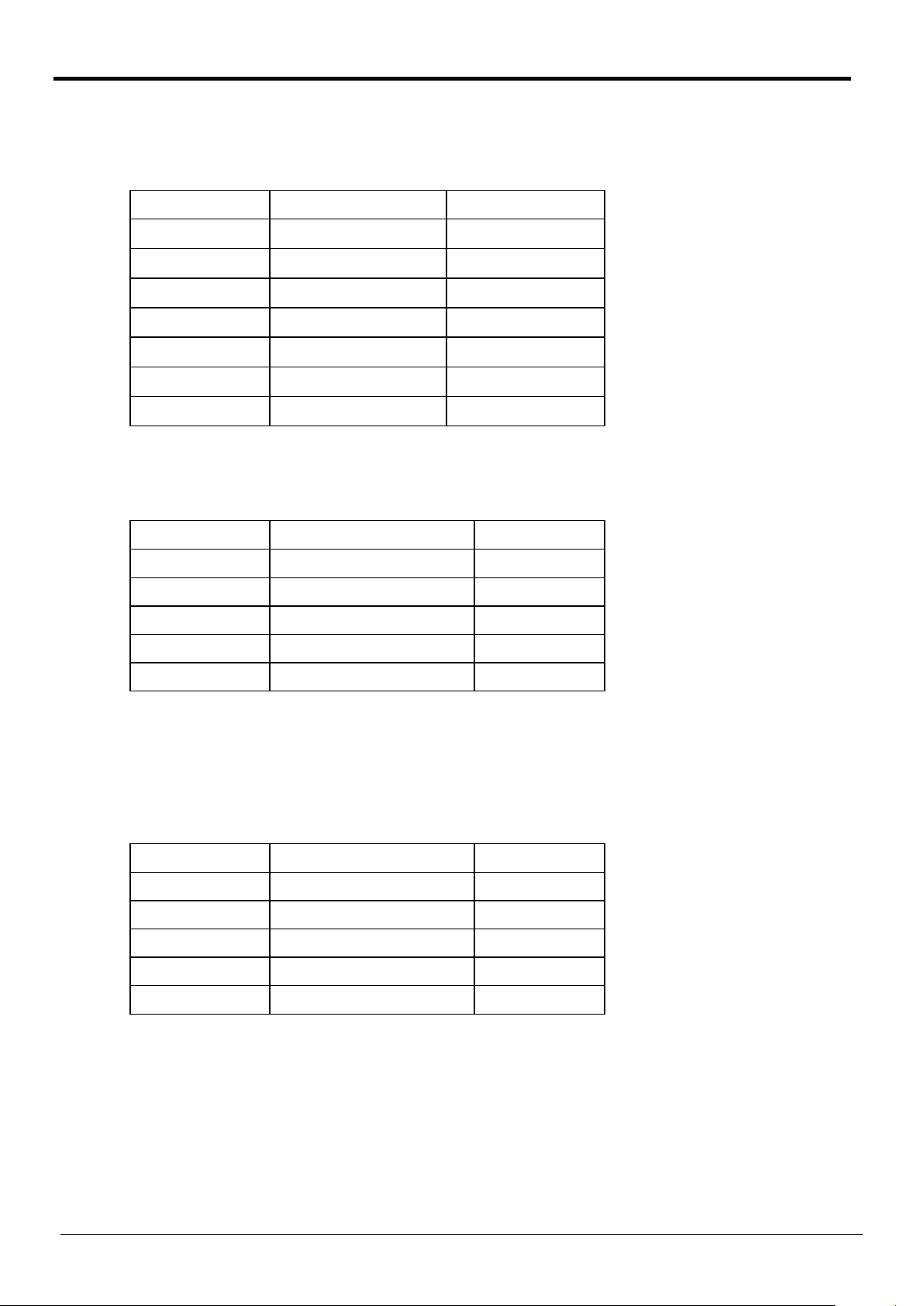

(AC + DC) Voltage Accuracy

Total measurement error will not exceed the sum of the separate ac and dc accuracy

specifications plus 1 display count.

Resistance

Range Accuracy Resolution

Maximum Input: 300V DC or AC rms, any range.

Maximum Open Circuit Voltage: 4V

DC Current

100Ω

1000Ω

10kΩ

100kΩ

1000kΩ

10MΩ

20MΩ

Range Accuracy Resolution

1mA 0.1% ± 3 dig. 100nA

100mA 0.1% ± 3 dig. 10uA

10A 0.3% ± 3 dig. to 1A 1mA

10A 1.0% ±3 dig. to 5A 1mA

10A 3% ± 10 dig to 10A 1mA

0.1% ± 3 dig.

0.08% ± 2 dig.

0.09% ± 2 dig.

0.09% ± 2 dig.

0.12% ± 2 dig.

0.5% ± 2 dig.

0.5% ± 2 dig.

10mΩ

100mΩ

1Ω

10Ω

100Ω

1kΩ

10kΩ

Maximum Input: mA ranges - 500mA DC or AC rms, 250V, fuse protected.

10A range - 10A DC or AC rms, 250V, fuse protected.

Typical Voltage Burden: mA ranges - <250mV

10A range - <500mV

AC Current (True RMS)

Range Accuracy (45Hz - 10kHz) Resolution

1mA 0.35% ± 20dig. 100nA

100mA 0.35% ± 20 dig. 10uA

10A 0.5% ± 20 dig. to 1A 1mA

10A 1.2% ± 20 dig to 5A 1mA

10A 3% ± 20 dig. to 10A 1mA

Accuracy specifications apply for readings between 1,000 and 12,000 counts. Additional error at

crest factory = 3 typically 0.2%.

Maximum Input: mA ranges - 500mA DC or AC rms, 250V, fuse protected.

10A range - 10A DC or AC rms, 250V, fuse protected.

Typical Voltage Burden: mA ranges - <250mV

10A range - <500mV

4

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 5

Page 6

Frequency

Range: 10Hz to 100kHz

Input sensitivity: Better than 30m Vrms (100mV range); better than 10% of range

Capacitance

Range Accuracy Resolution

100Hz 0.01Hz

1000Hz 0.01% ± 1 dig. 0.1Hz

10kHz 1Hz

100kHz 10Hz

for all other Vac and Iac ranges.

Range Accuracy Resolution

10nF

100nF 100pF

1uF 2% ± 5 dig. 1nF

10uF 10nF

100uF 5% ± 5 dig. 100nF

Continuity and Diode Test

Continuity:

Diode Test: Test current approximately 0.5mA; displays voltages up to 1.2V.

Maximum Open Circuit

Voltage:

Maximum Input: 300V DC or AC rms, any range.

DISPLAY

Display Type: High contrast LCD. Main display 4½ digits 17mm high, secondary

Scale Length: 4¼ digits (12000 counts) in most modes.

Annunciators: LCD annunciators for all ranges, functions and program modes.

10pF

1000Ω range selected; audible tone sounds for impedance <10Ω.

4V

display 5 digits 10mm high.

Reading Rate: Varies with function, maximum 4/sec.

Overrange: Display flashes 12000 if input too great for range.

Overflow: Displays -Or- if calculated result overflows display.

COMPUTING FUNCTIONS

Null (Relative) Stores current reading and subtracts it from future readings.

Ω Null:

Hold: Reading is frozen

T-Hold (Touch & Hold): Reading is frozen when stable.

dB:

5

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 6

Additional non-volatile function for nulling test lead resistance.

Displays measurement in dBm relative to 600Ω or other user-entered

impedance.

Page 7

AC plus DC: The RMS value of the ac plus dc parts of the signal is calculated and

% Deviation: Displays % deviation from entered reference value.

Ax+B: Linear scaling of results, with offset.

Limits: Reading displayed with HI, LO, or PASS with respect to user-defined

Min/Max: Minimum and maximum reading stored.

Power: Calculates V

VA: Calculates and displays Volts x Amps.

Data Logger: Manual or automatic storage of 100 measurements. Storage interval

INTERFACES

Full remote control facilities are available through the RS232 (all models) or GPIB (alternative

mains-only version) interfaces.

RS232: Baud rates 2400, 9600 or 19200. Complies fully with the ARC

displayed.

high and low limits.

2

/R and displays in Watts with respect to a user-defined

impedance.

1s to 9999s, manually from keyboard, or by remote contact closure.

(Addressable RS232 Chain) interface standard. Address selectable

from the front panel. Operational only when the meter is powered from

the AC input.

GPIB (IEEE-488): The meter can be specified with an IEEE-488 interface. This is an

alternative version which operates only from AC mains; IEEE-488 is

not a retrofittable option. Address selectable from the front panel.

POWER REQUIREMENTS

AC Input: 220V-240V or 110-120V AC ±10%, 50/60Hz, by internal adjustment;

5VA max. Installation Category II.

Batteries: 6 x C cells, disposable or rechargeable.

Battery Life: >150 hours from alkaline cells; typically 70 hours from rechargeable

cells.

GENERAL

Operating Range: +5°C to + 40°C, 20% to 80% RH

Storage Range:

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 1.

Safety: Complies with EN61010-1.

EMC: Complies with EN61326.

Size: 260(W) x 88(H) x 235(D)mm, excl. handle and feet.

−20°C to + 60°C

Weight: 2.0kg.

6

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 7

Page 8

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

Model 1705 True RMS Programmable Multimeter and

Model 1705GP True RMS Programmable Multimeter with GPIB

meet the intent of the EMC Directive 89/336/EEC and the Low Voltage Directive 73/23/EEC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Communities.

EMC

Emissions: a) EN61326 (1998) Radiated, Class B

b) EN61326 (1998) Conducted, Class B

c) EN61326 (1998) Harmonics, referring to EN61000-3-2 (2000)

Immunity: EN61326 (1998) Immunity Table 1, Performance B, referring to:

a) EN61000-4-2 (1995) Electrostatic Discharge

b) EN61000-4-3 (1997) Electromagnetic Field

c) EN61000-4-11 (1994) Voltage Interrupt

d) EN61000-4-4 (1995) Fast Transient

e) EN61000-4-5 (1995) Surge

f) EN61000-4-6 (1996) Conducted RF

Safety

Multimeter: EN61010-1

Installation Category I measurements to 1000V,

Installation Category II measurements to 600V,

Pollution Degree 1.

Probes: IEC1010-2-031

Rated to 1000V, Installation Category III.

CHRIS WILDING

TECHNICAL DIRECTOR

2 July 2004

7

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 8

Page 9

Safety

This multimeter is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical Equipment for

Measurement, Control and Laboratory Use). It is an Installation Category II instrument intended for

operation from a normal single phase supply.

WARNING! THIS INSTRUMENT MUST BE EARTHED WHEN OPERATED FROM A MAINS SUPPLY

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When operated from the internal batteries the multimeter meets the safety requirements for a Safety

Class II (reinforced insulation) product and does not require grounding for safety.

The test leads supplied with this instrument meet the requirements of IEC1010-2-031 and are rated

to 1000V Cat III; use only these test leads with the meter or a set of equivalent performance.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 1 environment (no pollution,

or only dry non-conductive pollution) in the temperature range 5°C to 40°C, 20% - 80% RH (non-

condensing). It may occasionally be subjected to temperatures between +5° and −10°C without

degradation of its safety. It has been designed for Installation Category II measurement use to

600VDC/ACrms. and Installation Category I measurement use to 1000VDC/750VACrms. The full

definitions of Categories I and II can be found in IEC664, but the following can be taken as a guide:

Installation Category I is signal level e.g. telecommunication, electronic equipment, with smaller

transient overvoltages than Installation Category II.

Installation Category II is local domestic supply level, e.g. portable equipment and appliances. In

particular, Category II does not include distribution level supplies, e.g. three phase installations

which are classified as Installation Category III.

For this equipment 2500V is the maximum peak transient overvoltage that can be tolerated by any

terminal with respect to earth ground without impairing safety.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range. In particular excessive moisture may impair safety.

When the instrument is connected to its supply or its inputs are connected to live voltages, terminals

may be live and opening the covers or removal of parts (except those to which access can be

gained by hand) is likely to expose live parts. The apparatus shall be disconnected from all voltage

sources before it is opened for any adjustment, replacement, maintenance or repair. Any

adjustment, maintenance and repair of the opened instrument under voltage shall be avoided as far

as possible and, if inevitable, shall be carried out only by a skilled person who is aware of the

hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be withdrawn

from use and returned for checking and repair. Make sure that only fuses with the required rated

current and of the specified type are used for replacement. The use of makeshift fuses and the

short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it and in particular use only a soft dry cloth to clean the

display window. The following symbols are used on the instrument and in this manual:

WARNING - risk of electric shock.

CAUTION - refer to accompanying documentation;

incorrect operation may damage the meter.

8

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 9

mains earth (ground)

direct current

alternating current

Page 10

This instrument has been designed to meet the requirements of the EMC Directive 89/336/EEC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2000) Class A; the instrument is Class A by product category.

Immunity

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved were:

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air, 4kV contact, Performance B.

b) EN61000-4-3 (1997) Electromagnetic Field, 3V/m, 80% AM at 1kHz, Performance B.

EMC

c) EN61000-4-11 (1994) Voltage Interrupt, 1 cycle, 100%, Performance A.

d) EN61000-4-4 (1995) Fast Transient, 1kV peak (AC line), 0.5kV peak (DC Outputs),

e) EN61000-4-5 (1995) Surge, 0.5kV (line to line), 1kV (line to ground), Performance A.

f) EN61000-4-6 (1996) Conducted RF, 3V, 80% AM at 1kHz (AC line only; DC Output

According to EN61326 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

Where Performance B is stated the multimeter will continue to function but accuracy may deviate

from Specification under the test conditions. However, the possible deviations are small and

infrequent and are unlikely to be a problem in practice.

Cautions

To ensure continued compliance with the EMC directive the following precautions should be

observed:

Performance B.

connections <3m not tested), Performance A.

a) only use screened cables and connectors to connect between the multimeter’s RS232

interface and other equipment.

b) after opening the case for any reason ensure that all signal and ground connections are

remade correctly before replacing the cover. Always ensure all case screws are correctly

refitted and tightened.

c) In the event of part replacement becoming necessary, only use components of an identical

type, see the Service Manual.

9

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 10

Page 11

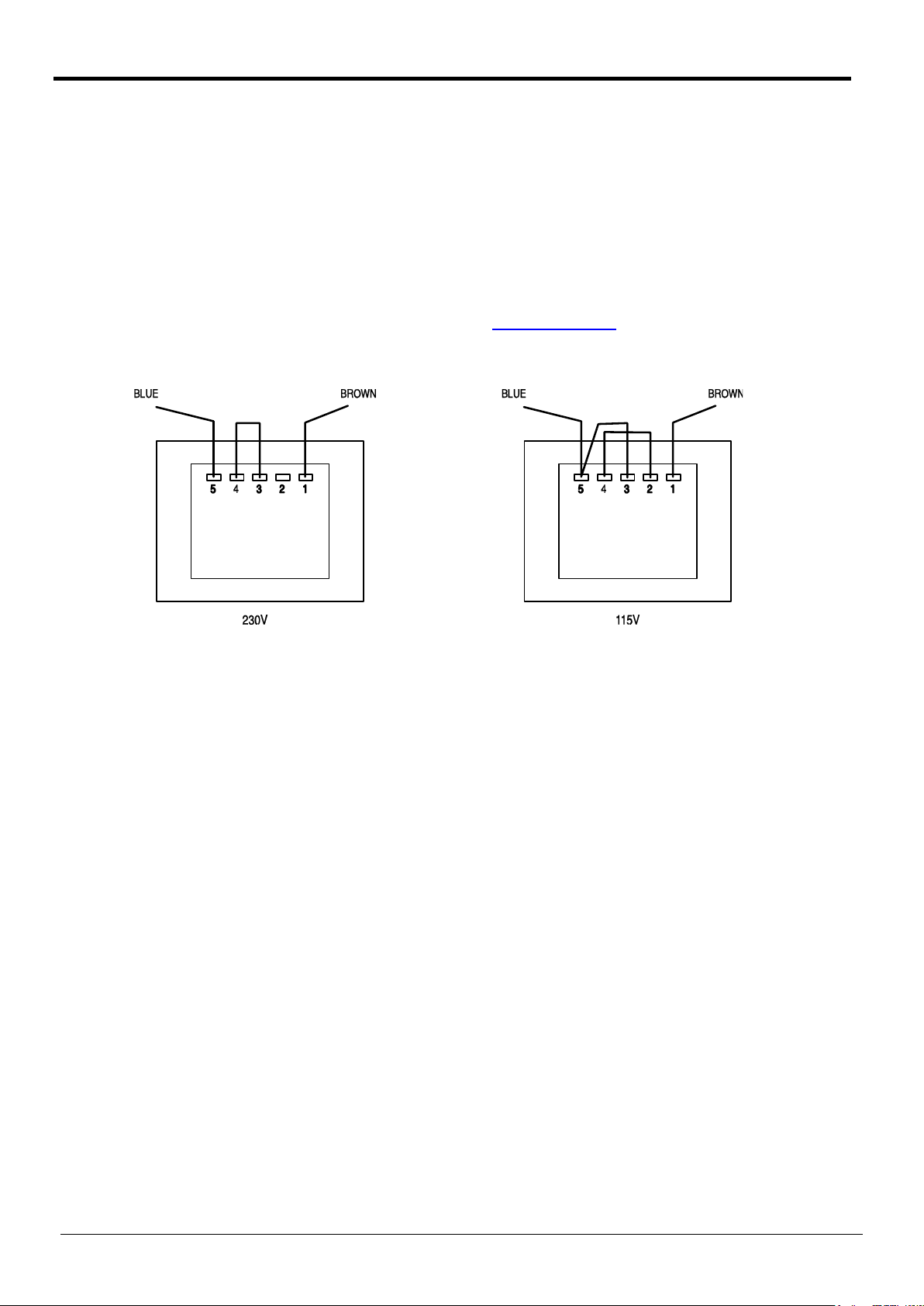

Mains Operating Voltage

Check that the instrument operating voltage marked on the rear panel is suitable for the local

supply. Should it be necessary to change the operating voltage, proceed as follows:

1) Disconnect the instrument from all voltage sources.

2) Unclip the front bezel by gently pulling the centre of each long edge up and forward.

The case halves are held together by 4 plastic push-rivets. Use the blade of a small

screwdriver in the slot beside each rivet to first ease out the rivet head and then fully remove

the rivet body. Separate the case halves. Visit www.tti-test.com

3) Change the transformer connections following the diagrams below:

Installation

for further details.

4) Reassemble in the reverse order.

5) To comply with safety standard requirements the operating voltage marked on the rear panel

must be changed to clearly show the new voltage setting.

Mains Lead

When a three core mains lead with bare ends is provided it should be connected as follows:-

WARNING! THIS INSTRUMENT MUST BE EARTHED WHEN OPERATED FROM AN AC LINE SUPPLY

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

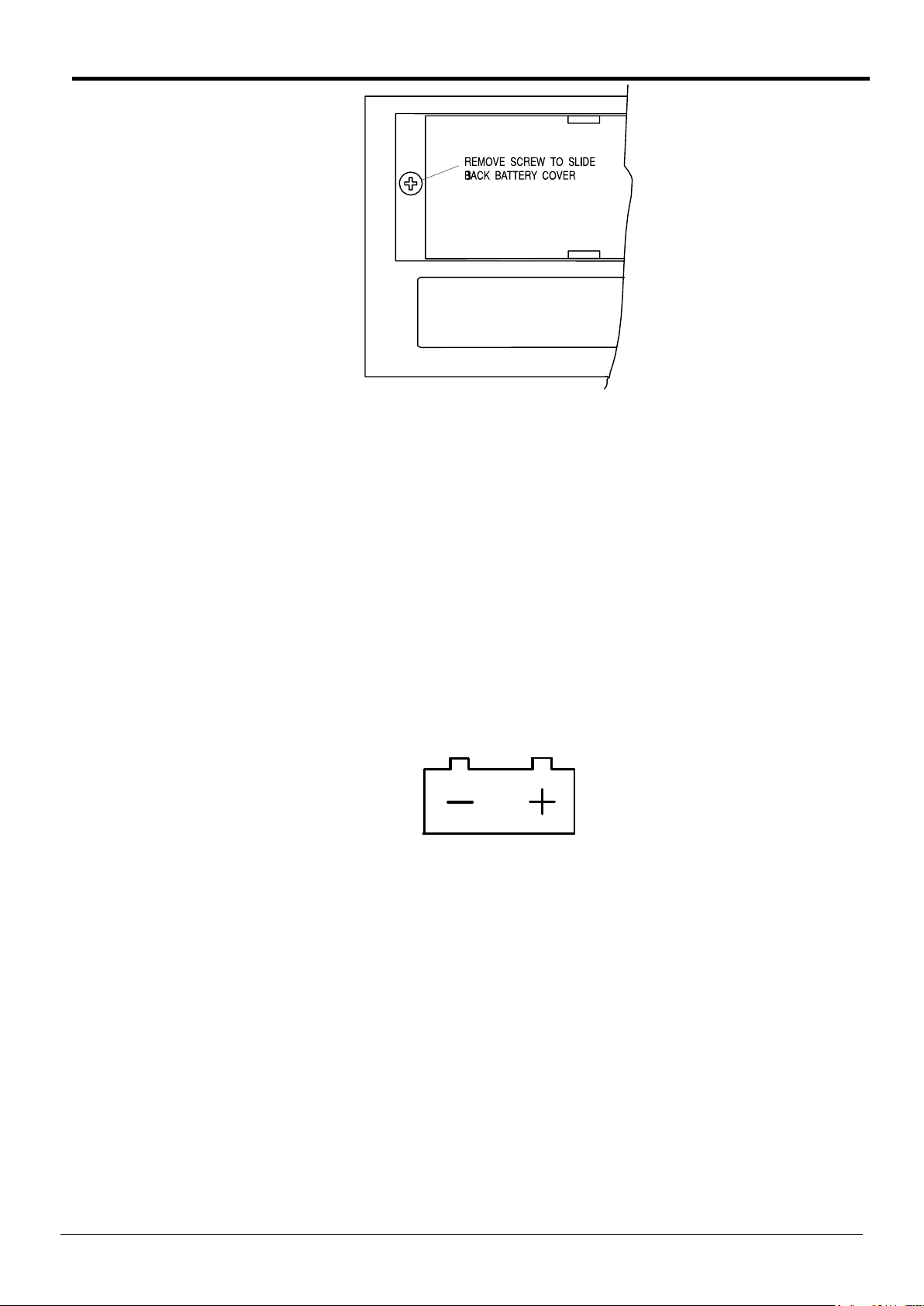

Battery Operation

To fit or replace the six ‘C’ cells, slide off the battery cover at the rear of the instrument and

remove the battery tray. For safety reasons the battery cover can only be slid off after first

removing the security screw with a screwdriver. Always refit the security screw after changing the

batteries.

Brown - Mains Live

Blue - Mains Neutral

Green / Yellow - Mains Earth

10

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 11

Page 12

Either rechargeable or disposable cells may be used; fit into the battery tray observing the polarity

marked in the tray. Suitable cells are as follows:

Rechargeable: 2 Amp hour, e.g. NCC200, AN220, VR2C, RSH1.8, P-180C.

Disposable: Alkaline, e.g. MN1400.

Zinc Carbon, e.g. R14B, R14S.

If batteries are fitted it is essential that the disposable/rechargeable selector switch on the rear

panel is positioned correctly before applying external power via the AC socket.

WARNING! If disposable batteries are fitted and the selector is set in the rechargeable

position, there is a risk of explosion if the meter is connected to an AC supply.

The Rechargeable batteries are charged at a ‘trickle’ rate of C/20; the time to fully charge from

completely discharged is approximately 28 hours.

Low battery condition is indicated by showing the battery symbol in the top left-hand corner of the

display; when this symbol shows, approximately 5% of battery life remains.

Handle

Adjust the handle position by pulling out the ends and rotating the handle to the desired position.

There are sixteen possible positions including five facing forward which provide upward tilts for

the most convenient bench operation. The handle may be swung out of the way to the back or

front of the instrument if no tilt is required. The natural spring in the handle will lock it into position

when the handle is released.

11

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 12

Page 13

This section is a general introduction to the features and organisation of the multimeter intended

to be read before using the instrument for the first time. Detailed operation is covered in later

sections, starting with Making Basic Measurements.

Connections

Input Sockets

The input sockets are 4mm safety sockets on a 19mm pitch designed to accept 4mm safety plugs

with fixed or retractable shrouds. The sockets are all rated to 1000V (Cat I)/600V (Cat II) with

respect to earth ground.

The input impedance between V/Ω and COM is nominally 10MΩ on dc ranges and 1MΩ on ac

ranges. The black COM socket is considered less positive than the red socket.

The mA/10A current sockets are low impedance; the voltage burden between mA/10A and COM

at full scale is <250mV for the mA ranges and <500mV for the 10A range. The black COM socket

is considered less positive than the white mA/10A sockets.

Multimeter Test Leads

General Operation

RS232

The test leads supplied meet the requirements of IEC1010-2-031 and are rated to 1000V Cat III.

Use only the test leads provided, or a set of similar performance, to ensure safe operation.

Alternative test leads should be rated to at least 1000V (Cat I), 600V (Cat II) and 10A current

capability.

The RS232 interface only operates when the instrument is run from an ac supply; RS232 signal

ground is then connected to the safety ground. The interface is fully isolated from the

measurement system.

9-pin D-connector compatible with the Thurlby Thandar ARC (Addressable RS232 Chain) system.

The pin connections are shows below:

Pin Name Description

1 - Power to optional PC-02

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4 - No internal connection

5 GND Signal ground

6 - No internal connection

7 RXD2 Secondary received data

8 TXD2 Secondary transmitted data

9 GND Signal ground

Pin 2, 3 and 5 may be used as a conventional RS232 interface with XON/XOFF handshaking.

Pins 7,8 and 9 are additionally used when the instrument is connected to the ARC interface.

Signal grounds are connected to safety ground.

To ensure compliance with EMC legislation use only screened cable assemblies with screened

connectors when connecting to other equipment.

GPIB (IEEE-488)

An IEEE-488 interface is available on the alternative mains-only version; IEEE-488 is not a

retrofittable option. The GPIB connector is located on the rear panel together with the switch

which selects between RS232 and GPIB.

12

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 13

Page 14

The interface is fully isolated from the measurement system and the GPIB signal grounds are

connected to the safety ground. The pin connections are as specified in IEEE std. 488.1-1987.

The implemented subsets are:

The address is selectable from the front panel.

Switching On

Power Switch

The multimeter is switched on and off with alternate presses of the Operate key; this key only

switches the DC power to the measurement circuits. It does not switch the AC power, when this is

connected, which means that the isolated RS232 and GPIB circuits continue to be powered and

rechargeable cells (if fitted) continue to be charged. When the instrument is not in use, and if

battery recharging is not required, disconnect from the AC supply.

If the AC supply is removed whilst the meter is switched on one of two things will happen. If the

meter had been switched on (with the Operate key) after connection to AC power the meter will

automatically power off; if continued operation (from batteries) is required it will be necessary to

switch the instrument back on again. In this way the accidental exhaustion of batteries is avoided

when AC power is switched off, e.g. when a whole bench of equipment is switched off from a

master switch.

SH1, AH1, T8, L4, SR0, RL2, PP0, DC1, DT0 C0, E2

However, if the meter had been switched on and run from batteries before the AC power was

connected it will continue to run when the AC power is later removed. In this mode the batteries

provide back-up in the event of an AC power failure, useful if the meter is “baby-sitting” making,

for example, Min-Max measurements over a long time period.

When the instrument is switched on with the Operate key the display first shows all the display

segments whilst running an auto-zero routine before setting the operating conditions as described

below.

Power-up Settings

At power-up the default action is to restore power-down settings, including any modifiers selected

at the time that the meter was turned off.

To restore factory default settings (see Default Settings section), hold the Cancel key depressed

whilst the meter is turned on with the Operate key; the buzzer will sound to signify that the

defaults have been restored.

To review the revision of the installed software hold the Shift key depressed whilst the meter is

turned on with the Operate key; the revision will be shown as r x.x until the Shift key is released.

To show all the display segments together (i.e. perform a display test) hold any other key

depressed whilst the meter is turned on with the Operate key; the display will continue to show all

segments until another key is pressed.

Buzzer

A short beep is sounded whenever a valid key is pressed. Longer beeps are reserved to indicate

illegal key presses, e.g. selecting Hz in the secondary display when the primary display has been

set to Vdc; such keystrokes are not accepted.

13

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 14

Page 15

Keyboard Organisation

The keys can be considered in two groups:

The two rows of keys in the lower half of the keyboard directly select the functions and ranges of

both the primary and secondary displays. When pressed alone the function keys select the

function of the primary display, cancel any secondary function, and set autorange; the operating

range is shown in the secondary display. Pressing Select 2nd followed by a function key selects

the function of the secondary display; this is explained fully in the Dual Measurement Mode

section, which also details which combinations of functions can be used.

Auto/Man and Range Up/Range Down keys are additionally used when editing numbers for some

of the modifier functions, see the Number Editing section.

The two rows of keys in the upper part of the keyboard give access to all the modifiers, i.e.

mathematical functions which act upon the primary measurement function. At the simplest level

these are, for example, the display of ac voltages in dBs; more complex functions include Ax + b

scaling, delta % and data logging. The access to and operation of all modifiers is fully explained

in the Advanced Features section later in this manual. It is sufficient to note here that some keys

have different functions during modifier editing, indicated by the blue legend beside the keys, and

some keys have shifted functions (following the pressing of the Shift key), marked beneath the

keys in yellow.

Number Editing

Delta %, Limits and Ax + b modifiers operate with numbers which are set by entering edit mode

after the modifier has been selected. Number editing operates in the same way for all these

modifiers and is described here to avoid repetition in each of the modifier sections.

The appropriate modifier is first selected by successive presses of the FUNCTION key as

described fully in the Second Level Modifiers section. Edit mode is entered by pressing the EDIT

key whilst the selected modifier is flashing in the modifier menu. The primary display changes to

show the parameter being edited and the number itself, together with the appropriate units, is

shown in the secondary display; the selected modifier symbol continues to flash with all the other

annunciators off. For example, selecting Edit mode for the Limits modifier will show:

14

Keyboard

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 15

Page 16

The position of the decimal point and the units of the parameter being edited are determined by

the range in use at the time the modifier is selected. The exception is A of Ax+b which has its

decimal point position fixed after the first digit, i.e. the range for A is ±0.0001 to ±9.9999. If the

meter is in autorange mode and the range in use is inappropriate (e.g. Ohms function is selected

with no input present, causing it to autorange to 20MΩ) first select the required range with the

Range Up/Range Down keys.

Once edit mode is selected, editing is controlled by the Range Up, Range Down and Auto/Man

keys which have the edit mode functions of Change Digit, Step Digit and +/- (change sign)

respectively, as indicated by the blue legend beside the keys.

The flashing digit is the one currently editable; its value can be incremented through the values 0

to 9 and back to 0 using the Change Digit key. The selection of the editable digit is made with the

Step Digit key which moves the flashing digit from left to right, with wrap-around from the

rightmost digit to the leftmost. The sign of the number can be changed with the digit cursor in any

position by alternate presses of the +/- key.

During number editing the default value can always be entered by pressing Clr, the edit function

of Cancel. The current meter reading can be entered as the new number by pressing Copy Rdg,

the edit function of the Null key; this is not allowed for A of Ax + b. If the modifier has more than

one parameter, pressing Edit will save the number just edited and display the new parameter.

Number editing can always be exited without changing the parameter being edited (i.e. the

previous value is restored) by pressing Esc, the edit function of Local.

To exit edit mode with the new number stored press Run to operate the modifier or Edit if there is

another parameter to be edited. To exit edit mode with the new number stored but the modifier

not running press FUNCTION to return to the modifier list and then Cancel.

If the range is subsequently changed the number is retained and will be correctly displayed if edit

mode is reselected in the new range. Note, however, that if a lower range is selected and the

number is too large to be shown on that range, the display will read 99999.

The Change Digit key is also used to increment through the available choices during the editing

of those parameters which have a limited selection of numbers; these include the reference

impedance for dB measurement, interface address and Baud rate.

The Range Up and Range Down keys autorepeat if held; autorepeat also operates when these

keys are used in edit mode.

15

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 16

Page 17

This section describes how basic measurements are made, i.e. single measurement mode only

and no post-processing of the results.

Scale Length

The scale length is ±12000 for all measurements except capacitance (full scale 1200) and the

20MΩ resistance range (full scale 2400).

Function Selection

All functions are directly selected by pressing the appropriate function key (Vdc, Ω, Hz, etc.).

Changing function always cancels any modifiers already running and sets autorange; providing

the appropriate function has been selected (e.g. Ω for resistance measurement) and the

parameter to be measured is within the range of the meter, a valid reading should always be

shown. The exception is 10A current measurement which requires manual range selection, see

next section.

The units and function are shown in the display (e.g. mV dc) together with AUTO to indicate

autorange.

When a function is selected in this way the smaller secondary display will show the operating

range with units, except for capacitance. If this is not required the secondary display can be

turned off by pressing Select 2nd followed by Cancel; the range will be displayed again when the

function is next changed, or by pressing Select 2nd twice.

Making Basic Measurements

The Continuity/Diode check test key selects continuity test with the first press and then alternates

between the modes with further presses. The appropriate annunciator indicates the current

selection. Continuity sets the meter to the 1000.0Ω range and buzzes for values below

approximately 10Ω.

Vdc+Vac or Idc+Iac measurements are made by pressing both Voltage range or both current

range keys together. The reading displayed is the RMS sum √(dc2 + ac2) and ac+dc is shown

beside it. Both ac and dc measurements are made on the same range: the instrument will

autorange to a range which gives an in-range reading for both the ac and dc component of the

parameter. However, if the result exceeds the range maximum the meter will autorange up to

permit the result to be shown as an in-range reading.

Range Selection

Selecting a new function always sets autorange to ensure an in-range reading is made with

maximum resolution whenever possible; the meter ranges up at 12000 counts and ranges down

at 1000 counts.

There are, however, situations when it is desirable to lock the range; for example, to stop the

meter autoranging to the 20MΩ range and back between successive resistance measurements of

lower resistance values, or to set a lower resolution range when an unstable parameter is being

monitored. To lock the range, change from auto to manual ranging, see below.

Manual range changing is selected either by alternate presses of the Auto/Man key, which locks

the meter in its present range, or by using the Range Up/Range Down keys which both change

the range and lock the meter in that new range. The MAN annunciator is displayed to indicate

manual ranging. Overrange is indicated by flashing the display at 12000 counts. Autoranging can

be restored by pressing the Auto/Man key again.

As explained later in the appropriate sections, secondary functions in dual measurement mode

are autoranging only; the exception is 10A range selection which is manual only, for both main

and secondary displays, at all times.

16

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 17

Page 18

Making Voltage Measurements

Voltage measurements are made using the red V/Ω socket and the black COM socket having

selected the appropriate function and range as described above.

The meter will show a minus sign (on dc measurements) when the voltage applied to the red

socket is more negative than that applied to the black socket.

The maximum voltage that can be applied between V/Ω and COM is 1000V DC or 750V AC (Cat

I); damage to the instrument may result if this limit is exceeded.

WARNING! The maximum input voltage to ground must not exceed 1000V (Cat I) or 600V (Cat

II) dc or ac rms. Safety will be impaired if these ratings are exceeded, see Safety section at the

beginning of the manual.

Making Current Measurements

Having selected the appropriate current function, current measurements up to 120mA are made

using the white mA socket and the black COM socket; current measurements up to 10A are made

using the 10A and COM socket. The meter will show a minus sign (on dc measurements) when

the polarity of the current is out of the mA or 10A sockets.

Current measurements using the mA socket can be autoranged between 1.0000 mA and

100.00mA ranges; measurements up to 10A can be made using the 10A socket having manually

ranged to 10A with the Range Up key.

The 1mA and 100mA ranges, using the mA socket, are protected by a 500mA (F) HBC fuse and

the 10A range, using the 10A socket, is protected by a 10A (F) HBC fuse. Both fuses are fitted

inside the instrument and replacement is described in the Maintenance section later in the

manual.

Note: After measuring high current using the 10A input, thermal voltages are generated that may

create errors when making measurements on the most sensitive dc voltage, current or Ohms

ranges immediately afterwards. To ensure that the specified accuracy is maintained, allow 10

minutes for the thermal effects to fade before making sensitive measurements.

Making Resistance Measurements

Resistance measurements are made using the V/Ω and COM sockets. Residual test lead

resistance can be nulled out using the Ohms null facility as follows:

Connect the test leads together and press Shift, Null (Ω Null is the shifted function of Null). The

100Ω range is set automatically and the NULL annunciator flashes; the meter stores the reading

that it detects after 5 seconds provided that it is less than 1.00Ω (100 counts). A beep sounds

when the null is completed and the display should show zero Ohms and no NULL annunciator;

the meter returns to its previous range, or AUTO if autorange had been operational before Ohms

null was selected.

If the reading cannot be nulled, because the offset is too large, the reading will not change and

the buzzer will not sound.

The Ohms null is stored as a floating point value which is used on all ranges; it is not lost when

the function is changed or when the instrument is turned off. Ohms null can be cancelled by either

pressing the Ω and Cancel keys together, by selecting Ohms Null and not generating a sub 1.00Ω

reading within the next 5 seconds, or by holding the Cancel key down at power-up to restore the

system defaults.

Normal Null can be used together with Ohms Null.

17

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 18

Page 19

Making Continuity and Diode Checks

Continuity and diode checks are made using the V/Ω and COM sockets.

Pressing the Continuity/Diode check key selects Continuity mode with the first press; the

continuity indicator is shown in the display. The 1000Ω range is selected and readings below

approximately 10Ω sound the continuity buzzer.

A further press selects diode check; the diode annunciator is shown in the display. The 1000mV

range is selected and the approximate diode voltage at 0.5mA is shown (1.2V maximum).

Reverse diode connection will show overload.

Further presses of the key will alternate between Continuity and Diode check.

Making Capacitance Measurements

Capacitance measurements are made using the V/Ω and COM sockets. Capacitance

measurement is selected by pressing the µF key. Five ranges (10nF to 100µF) are available with

1200 count full scale giving resolutions of 10pF to 100nF respectively.

Zero calibration at the factory is carried out with no test leads connected; ideally, capacitors to be

measured should be connected directly to the sockets. Test leads, if used, should be kept as

short as possible to minimise stray capacitance but nevertheless a non-zero reading will generally

be present when the lowest ranges are selected. To eliminate this offset it is recommended that

the meter reading is nulled, once the require range has been selected, with the test leads in their

measurement positions but no capacitor connected. It is also recommended that battery

operation is used when making capacitance measurements, to minimise reading jitter. Note that

because the capacitor is discharged between each measurement, the reading rate on the 100µF

range is slower.

Making Frequency Measurements

Frequency measurements are made using the V/Ω and COM sockets.

Press the Hz key to select frequency mode. Four ranges (100Hz to 100kHz) are available giving

resolutions of 10mHz to 10Hz respectively over an operating frequency range of 10Hz to 120kHz.

Reciprocal counting techniques ensure fast reading updates (4 readings/second) even on the

lowest range.

Measurements are made using the ac Volts input circuitry which is autoranged to provide suitable

sensitivity. At low signal levels use a screened lead and an adaptor (BNC to 4mm plugs, 19mm

pitch) to preserve signal quality and avoid spurious readings from stray pick-up. The minimum

measurable signal is typically <30mV rms across the frequency range.

Frequency can also be measured in dual measurement mode, see next section. When measuring

the frequency of an ac current the minimum measurable signal is typically <10% of range

maximum, e.g. <0.1mA on the 1mA range.

Zero Calibration

An automatic zero calibration of the basic DC measurement circuitry is performed every time that

the instrument is switched on. However, if the meter has been stored at a temperature outside

the specified operating range, and is switched on before it has fully acclimatised to the working

environment, accuracy may be affected as the meter’s temperature changes. To ensure optimum

accuracy, particularly on the 100mV and mA current ranges, zero calibration can be repeated

when the meter has acclimatised by using the Null key as follows:

Press the Null key and continue to hold it down until nULL shows in the main display (about 3

seconds later). nULL continues to show whilst the auto-zero is being performed (typically 5

seconds); on completion the display returns to it previous mode.

Auto-zeroing in this way cancels Null if this was already selected; press Null again to re-select if

required.

18

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 19

Page 20

In Dual Measurement Mode a completely independent but complementary measurement can be

made and displayed on the secondary display. The two independent measurements are actually

made alternately, not simultaneously, and the display update rate for each measurement is

consequently reduced. Note that this is not the same as when, in dual display mode, both a

measurement and a modified version of that measurement are displayed, e.g. ac Volts and the

dB equivalent; in this case only a single measurement is being made and the measurement rate

is unchanged; further information is given later in this section.

Dual Measurement Combinations

All practical combinations of functions are allowed in Dual Measurement Mode; those of no

practical use (e.g. dc Volts and Frequency) are not selectable. The full list is as follows:

Main Display Secondary Display

Vdc Vac, Idc, Iac

Vac Vdc, Idc, Iac, Hz

Idc Vdc, Vac, Iac

Iac Vdc, Vac, Idc, Hz

Dual Measurement Mode

Hz Vac, Iac

Capacitance, Ω, and Continuity/Diode check cannot meaningfully be combined with other

measurements and are therefore always excluded from the secondary display. Vac+Vdc and

Iac+Idc are also excluded because they already involve dual measurements; when they are being

used no secondary display can be set.

The same measurement can be displayed in both displays, if required, at the single measurement

update rate; in this mode the displays both use the range set for the main display.

The secondary display is selected by pressing Select 2nd followed by the function; pressing an

illegal function will cause a warning beep and the key entry will be ignored. Pressing Select 2nd

twice will return the meter to single measurement mode with the range shown in the secondary

display; pressing Select 2nd followed by Cancel turns the secondary display off. Selecting any

main display function will also return the meter to single measurement mode.

The secondary measurement, with the exception of the 10A current ranges, always autoranges.

The 10A current ranges are set by first selecting the function (Select 2nd followed by Iac or Idc)

then pressing Select 2nd followed by Range Up; return to the mA autoranges is by pressing

Select 2nd followed by Range Down. However, if both main and secondary displays are making

current measurements, the range of the secondary measurement is always that of the main

display.

If Vdc and Vac are the two measurement functions, autoranging of the secondary display is

restricted such that the dc measurement range is not lower than the ac range; this ensures that

the dc measurement is not affected by a high ac signal, see the table in the Specification (page

3). For example, if the main display is set to 10Vdc the secondary display can autorange between

the 100mV, 1000mV and 10Vac ranges. In this example, low levels of ripple could be measured

(on the 100mV range) on a 10Vdc supply rail, but an ac input >12V will cause the secondary

display to flash 12000 (overload) warning the user to select a higher main display dc range such

that the secondary ac measurement is in range. Similarly, if the main display is set to 100Vac

then the secondary display will not autorange below 100Vdc, even for small dc inputs.

When frequency is selected for the secondary display the measurement is made using the ac

range set in the main display. This presents no problems if the main display is in autorange but if

a higher range has been set manually, such that the reading is less than 10% of the range

maximum, the signal level may not be adequate for frequency measurement.

19

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 20

Page 21

Making Voltage and Current Dual Measurements

Measuring ac and dc Volts, or ac Volts and frequency, etc. still only require two measurement

probes because both parameters of the dual measurement are made at the same physical point.

Simultaneous measurement of voltage and current on the same circuit will however require a

third connection, see the diagram:

Note that the voltage measured at the multimeter terminals is that across the load plus the

voltage drop in the common lead which is now carrying the whole circuit current. Even if the

resistance of the lead is very low, errors may arise at high currents and low voltages (i.e. low load

resistance) because the lead resistance becomes significant compared with the load.

Measurement Update Times

As discussed at the beginning of this section, the reading update rate is reduced in Dual

Measurement Mode because the two readings are made alternately. However, the reading rate is

not simply halved because enough time must be allowed for each measurement to fully settle to

the different conditions before the display is updated; unless this is done neither display will

reliably show the true measurement value. The settling time depends on the differences between

the main and secondary measurement range, function, and signal level; the delay is longest when

both displays show an ac measurement. Note that the settling times allowed assume a steady

state signal; varying signals will give unpredictable readings.

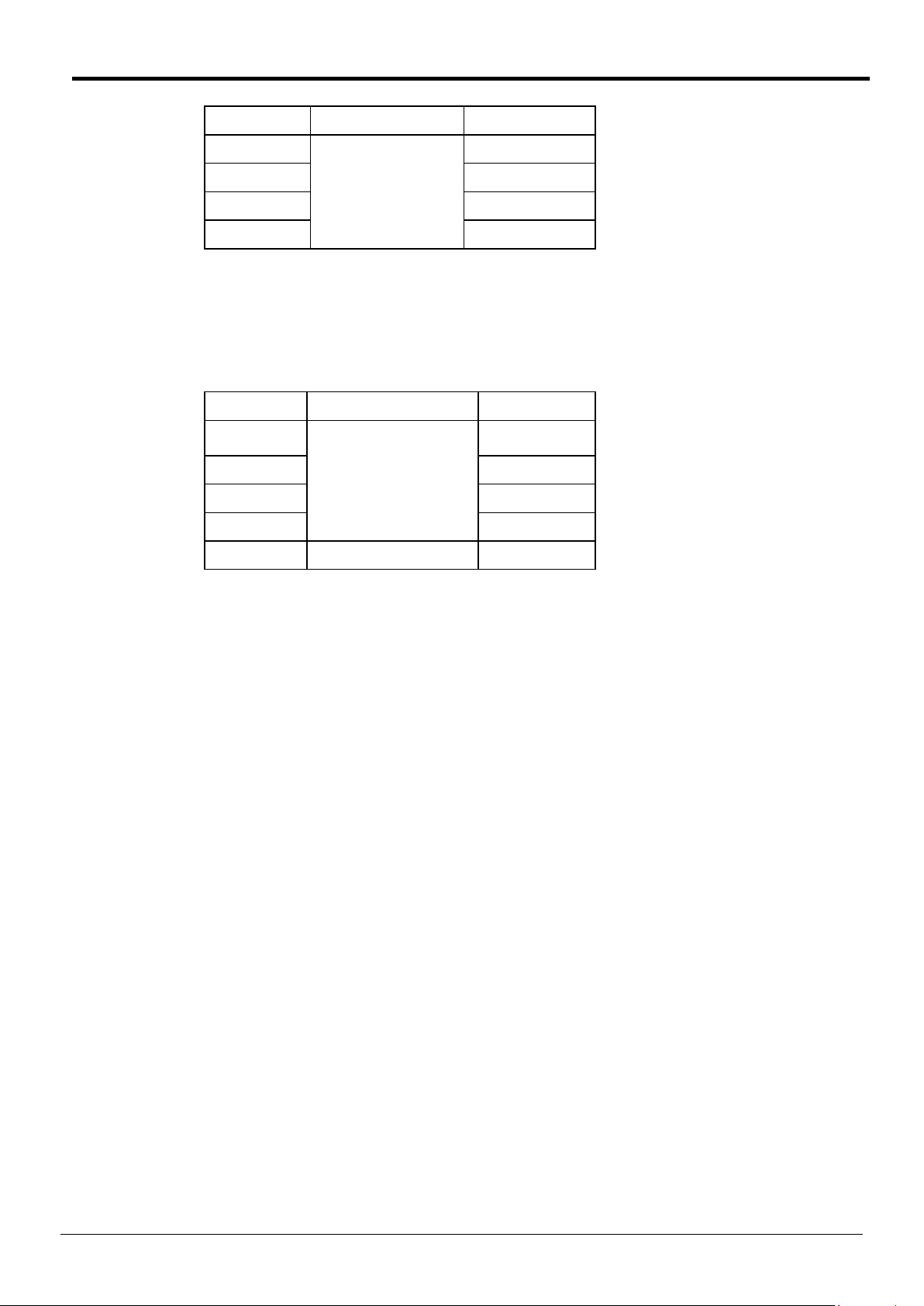

The table below summarises the measurement time (i.e. the time for the measurement to settle

and the display to be updated) for each parameter in all the permitted display combinations.

Main Secondary Measurement Time

Any Function None

Vdc, Vac, Idc, Iac, Hz Same as Main

.25s

.25s

Vac, Iac Hz

Hz Vac, Iac

Vac, Iac, Vdc, Idc, Hz

Vdc, Idc, Hz Vac, Iac

Vac Iac 4s †

Iac Vac 4s †

† This time is extended to 8s if the measurement value is <1000 counts to allow for the increased settling

time required by the True RMS converter at low input levels.

20

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 21

.25s

.25s

.5s

.5s

Page 22

The advanced features of this multimeter are all accessed using the keys in the top two rows of

the keyboard. Broadly, they divide into First Level Modifiers which are accessed via dedicated

keys (dB, Hold and Null) and Second Level Modifiers which are all accessed from a menu using

the FUNCTION modifier key.

All modifiers are post-processors of some sort which act on the basic measurement to produce a

modified result. Most modifiers make use of the secondary display to show either the modified

results with the actual reading in the main display, or vice-versa; consequently Dual Measurement

Mode is not allowed when running any of the modifiers. Selecting any modifier cancels Dual

Measurement Mode.

First Level Modifiers

The following modifiers are selected directly using a dedicated key.

Hold

Pressing Hold freezes the main display and shows the HOLD annunciator. The normal, updated,

reading will be shown in the secondary display if the meter is not in dual measurement mode,

except for capacitance. Hold does not operate on the secondary display.

Advanced Features

T Hold

Null

Hold can be used with dB and Null. Hold is cancelled by pressing Hold again or by changing

range or function.

T Hold is selected by pressing Shift then T-Hold (the shifted function of Hold); T-HOLD shows in

the display. In this mode the meter will hold a reading until a new non-zero measurement has

been detected; this allows the user to touch-probe the measurement point, remove the probes

and read the meter afterwards. Note, however, that care should be taken when using T-Hold with

the most sensitive voltage ranges; when the probes are lifted from the circuit being measured,

their high impedance means that stray pick-up might generate another ‘valid’ reading and the true

T-Hold reading may be lost.

T-Hold operates in both manual and autorange modes; it is cancelled by pressing Hold again or

by changing function.

Null is selected by pressing the Null key. Pressing Null locks the meter in the selected range,

shows NULL and MAN in the display, stores the current reading and subtracts it from all following

readings. The normal, un-nulled, reading will be shown in the secondary display if the meter is not

in dual measurement mode, except for capacitance.

Null can be used with Hold. Null is cancelled by pressing Null again or by changing range or

function.

dB

dB (deciBel) can be selected only when Vac is already in the main display. Pressing dB shows

the dB value of the Vac measurement (referred to the current impedance setting) and displays the

dB annunciator. dBs are shown in a fixed format with 0.1dB resolution, whatever range the Vac

measurement is being made on. If no secondary function is selected the normal reading will be

shown in the secondary display.

The value displayed is in dBm and is calculated from the formula:

dB = 10 log

Where R is the selected reference impedance.

21

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 22

(1000 x V2/R)

10

Page 23

The default reference impedance is 600Ω but a different value can be selected by entering the

edit mode. With dB already selected press EDIT; the main display will now show rEF and the

current impedances will be shown in the secondary display. Use the Range Up/Range Down keys

to scroll through the list of impedances which can be set:

50, 75, 93, 110, 124, 125, 135, 150, 250, 300, 500, 600, 900, 1000, 1200, and 8000Ω. Pressing

Clr, the edit function of Cancel, enters the default value of 600Ω. To exit edit mode saving the new

reference impedance press Run or dB; to exit edit mode without changing the value (i.e. the

previous value is restored) press Esc.

Hold can be used with dB mode, but selecting any other function will cancel dB; pressing dB

again will also cancel it.

Second Level Modifiers

Second level modifiers are mutually exclusive; selecting a second level modifier cancels any

previous one. Selecting a second level modifier cancels Dual Measurement Mode. Pressing

Cancel, or changing the function or range, will cancel the modifier but the parameter values are

saved.

Selection and Editing

All modifiers are selected by pressing the FUNCTION key. The first press shows all the available

modifiers as a ‘menu’ with the last-selected one flashing. Subsequent presses of FUNCTION

make each modifier flash in turn; the current selection is the flashing one.

To run the selected modifier press Run at this point; the flashing modifier symbol is now static and

all the other modifiers annunciators are off. When running, the modified value appears on the

secondary display; the main display continues to show the un-modified value. Pressing Cancel

during modifier selection, or while a modifier is running, cancels the modifier and returns the

meter to single measurement mode.

To edit the parameters of a secondary modifier press Edit when the required modifier is either

selected (i.e. flashing) in the menu or is already running; the annunciator flashes with all other

modifier symbols off. During editing the name of the modifier parameter is shown in the main

display (e.g. A for Ax + b, HI for High Limit, etc.) and the parameter value is shown in the

secondary display. The digits of this number are incremented and selected using the Change

Digit, Step Digit and +/- keys as described earlier in the Number Editing section. Pressing Clr, the

edit function of Cancel enters the default value of the parameter; pressing Copy rdg, the edit

function of Null, enters the current meter reading as the parameter value when this is permitted.

When editing is complete, pressing Edit again will save the parameter and display the next one to

be edited, if there is more than one. Pressing Run exits edit mode, saving the parameters, and

runs the modifier. Pressing Esc exits edit mode without saving any new parameters (the previous

ones are restored) and exits the modifier. Pressing FUNCTION exits edit mode, saving the

parameters, and returns to the modifier ‘menu’.

Delta %

The Delta % function displays, in the secondary display, the percentage deviation of the current

measurement from a reference value; the main display shows the normal reading.

Delta % = Reading - Reference

Reference

The Delta % maximum display is ±999.99% and the resolution is fixed at 0.01%. The display

shows - Or - if the maximum is exceeded.

To select Delta % press the FUNCTION key until the Delta % symbol flashes in the menu of

modifiers. Pressing Edit will then permit the reference to be set as described earlier in the

Number Editing section; during edit the main display shows rEF. The reference value is a number

variable over the range ±00000 to ±99999; the decimal point position is set by the range in use

22

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 23

%

Page 24

during edit. The reference default value of 10000 (decimal point determined by range) can be

entered by pressing Clr and the latest meter reading can be entered by pressing Copy rdg.

Limits

High and low limits can be set, against which the current reading is compared. When running, the

main display shows the actual reading and the secondary display shows PASS (reading between

or equal to set points), HI (reading >HI) or LO (reading <LO).

Having selected Limits from the modifier menu with the FUNCTION key (LIMITS symbol flashing),

pressing Edit will permit the HI and LO limits to be set in turn using the Change Digit, Step Digit

and +/- keys as previously described in the Number Editing section. HI or LO will show in the

main display during edit, as appropriate. The units and decimal point position are set by the

current meter range which must be selected before the modifier is selected and editing begins. If

the value and resolution of the set points requires two different ranges to be used to set the

values it will be necessary to exit the edit mode and modifier after setting the first limit so that the

range can be changed for the second limit.

The limits can be set anywhere in the range ±00000 to ±99999 with the decimal point set by the

range selected during editing. Pressing Clr enters the default value of +00000; pressing Copy rdg

enters the current reading.

Min-Max

Ax + b

This modifier stores the maximum (most positive) and minimum (most negative) values that occur

when the modifier is run and displays one or other in the secondary display simultaneously with

the current measurement in the main display.

To select Min-Max, press the FUNCTION key until the Min Max symbols flash in the menu of

modifiers. Pressing Run will initiate the function and display the minimum value in the secondary

display, indicated by the Min symbol only now showing. Further presses of Run will alternate the

secondary display between Min and Max.

Min and Max are stored as floating point numbers and the modifier can be operated with the

meter changing ranges either manually or by autorange.

To reset the current min or max without exiting the function, select Min or Max with alternate

presses of the Run key and press Edit.

Changing function cancels Min-Max.

When running, the scaled value (Ax + b) is shown in the secondary display and the normal value

(x) is shown in the main display. If the scaled reading exceeds ±99999, -Or- is shown in the

secondary display to indicate over-range.

To select Ax + b press the FUNCTION key until the Ax + b symbol flashes in the menu of

modifiers; pressing Edit will then permit the two parameters, A and b, to be set as described

earlier in the Number Editing section; A or b will show in the main display during edit, as

appropriate. A is variable from ±0.0001 to ±9.9999, with the decimal point in a fixed positon after

the first digit; the default value is 1.0000, entered by pressing Clr. b is a floating point number

variable over the range ±00000 to ±99999 with the decimal point and units set by the range

selected during editing; the default value is zero, entered by pressing Clr, and the current

measurement value can be entered as b by pressing Copy rdg.

23

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 24

Page 25

Watts

VA

The Watts function calculates power using the formula

2

Watts = V

/R

It can only be run when Vdc or Vac are selected in the main display. The reference impedance

can be set anywhere between 1 and 99999 Ohms.

To select Watts press the FUNCTION key until the W symbol flashes in the menu of modifiers.

Pressing Edit will then permit the reference impedance to be set as described earlier in the

Number Editing section; rEF shows in the main display while the reference impedance (in the

secondary display) is being edited.

The VA function calculates power by multiplying voltage and current readings. The meter must be

connected for both voltage and current measurement, see Making Voltage and Current Dual

Measurements section, with Vdc or Vac selected for the main display.

To select VA press the FUNCTION key until the VA symbol flashes in the menu of modifiers.

Pressing Run will run the modifier; the meter automatically switches to dual measurement mode

and selects Iac or Idc as the secondary measurement for Vac or Vdc main display settings

respectively. The VA symbol will show in the display and the secondary display will show the

power in VA units.

24

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 25

Page 26

Data Logger

The logger function can store up to 100 readings from the main display in non-volatile memory.

The store is linear, without wrap-around. Readings are triggered by either the internal timer,

manual key press, remote contact closure or RS232 remote command. Readings are stored as

floating-point numbers with their units and reading number but without any form of time stamping.

Data Logging and Printing

Setting and Running the Logger

To use the logger first set up the measurement function and range required on the Main display.

To select Logger press the FUNCTION key until the LOGGER symbol flashes in the menu of

modifiers; then press Edit to set the logger triggering interval. During edit mode the main display

shows PEr (period) and the secondary display shows the logger internal timer period (in seconds)

which can be edited using the Change Digit/Step Digit keys as described earlier in the Number

Editing section. The period can be set from 1 second to 9999 seconds; setting the period to 0000

turns the internal timer off.

The Manual Log key, remote contact closure (at the RS232 input) and RS232 remote commands

are all logically OR’ed with the internal timer. Thus to use any of these means of triggering the

logger the internal timer should be set to 0000; this is the default value and can most easily be

set by pressing Clr during edit.

To set the logger to be triggered by remote contact closure the internal timer period must be set to

0000 (see above) and the RS232 interface must be configured for remote triggering. To do this

press Shift then Baud (the shifted function of Run); the main display changes to show bAUd and

the secondary display shows the current setting. Use the Range Up/Range Down keys to step

through the choices until triG shows in the display; exit the selection at this point by pressing

Baud again or Esc. The RS232 interface is now configured to act as a remote trigger for the data

logger by contact closure between pins 2 and 3; do not apply an external voltage to these pins or

damage to the instrument may result. Reselect the logger using the FUNCTION key.

The logger is run by pressing the Run key and stopped by the Cancel key; a short beep is

sounded every time a measurement is stored.

The logger starts from location 1 if the store is empty and from the next empty store location on

subsequent occasions; when the logger reaches 100 measurements it ignores further triggers.

Pressing Cancel while the logger is running will stop the logger and exit the function without

losing the data.

Reviewing Results and Clearing the Logger

The logger results can be reviewed at any time by pressing Shift, Logger Rcl (the shifted function

of EDIT); if the Logger is running, this action will stop it.

The logged result is shown in the main display with the reading number in the secondary display;

the LOGGER annunciator is shown. All valid store locations can be inspected by scrolling through

them with the Range Up and Range Down keys. Empty store locations cannot be selected and

the scrolling ‘wraps-around’ from highest valid location to location 1 when ranging up and viceversa when ranging down. Press Esc to exit logger recall mode.

To clear the logger press Shift, Clr Logger (the shifted function of Cancel); if the loggers is

running, this action will stop it. The secondary display will briefly show the LOGGER symbol and

‘none’ in the secondary display to show that it has been cleared; if the logger is reviewed when all

locations are empty it will similarly show ‘none’ briefly in the secondary display.

To print the logger results, see next section.

25

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 26

Page 27

Printing

The current display reading or the logger results can be output via the RS232 port. Connect the

device to the RS232 port. Press Shift then Baud (the shifted function of Run) and use the Range

Up/Range Down keys to select an appropriate Baud rate; exit Baud rate selection by pressing

Baud again or Esc. The other parameters are fixed and are as follows:

Start bits 1

Data bits 8

Parity None

Stop bits 1

With the interface set up a reading will be sent to the device each time the Print key is pressed.

Printing Data Logger Readings

Set the interface up as described in the appropriate section above. Press Shift, Logger Rcl (the

shifted function of EDIT) to recall the logger results to the display. Pressing Print whilst in this

logger display mode will cause the complete contents of the logger to be printed. Each result is

printed on a separate line and consists of the store location, value and measurement units.

26

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 27

Page 28

General

Calibration is guaranteed as in the specification. The Manufacturers provide a re-calibration

service, as do most of their agents overseas. Where owners wish to carry out re-calibration

themselves, this should only be done by skilled personnel with access to precision equipment

working in conjunction with the service manual which may be purchased directly from the

Manufacturers or their agents overseas.

Zero Calibration

An automatic zero calibration of the basic DC measurement circuitry is performed every time that

the instrument is switched on. If the meter has been stored at a temperature outside the specified

operating range, and is switched on before it has fully acclimatised to the working environment,

meter accuracy may be affected as the meter’s temperature changes. To ensure optimum

accuracy the zero calibration can be repeated when the meter has acclimatised by using the Null

key as follows:

Press the Null key and continue to hold it down until nULL shows in the main display (about 3

seconds later). nULL continues to show whilst the auto-zero is being performed (typically 5

seconds); on completion the display returns to its previous mode.

Calibration

DC zero calibration affects all measurement ranges, but ac measurements, resistance and

capacitance have additional zero adjustments which are only made during the full calibration

routine. However, if there is a small residual offset on the most sensitive ranges, it can always be

nulled out using the Null or Ohms Null facilities, see appropriate sections.

50Hz/60Hz Rejection

The analogue-to-digital converter operation can, by software adjustment, be optimised for either

50Hz or 60Hz ac line rejection; the NMR and CMR figures given in the Specification assume that

the appropriate frequency rejection has been set, as described below.

To check or change the ac line rejection setting press Shift followed by Address (the shifted

function of FUNCTION) and then depress the Cal switch (accessible through the front panel Cal

hole) with a small tool until it clicks on. The main display will show REJ and the secondary display

will show either 50 or 60. Press the Range Up/Range Down keys to toggle between 50 and 60Hz

rejection. When the correct frequency has been selected (to suit the local ac supply) release the

Cal switch by depressing it again with a small tool and then press Run; the display should return

to normal measurement mode.

27

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 28

Page 29

Routine maintenance is limited to re-calibration (described above), battery replacement

(described in the Installation section) and cleaning. The only repair maintenance that can be

carried out by the user is current range fuse replacement.

Cleaning

If the meter requires cleaning use a cloth that is only lightly dampened with water or a mild

detergent. Polish the display window with a soft dry cloth.

WARNING! TO AVOID ELECTRIC SHOCK, OR DAMAGE TO THE METER, NEVER ALLOW

WATER TO GET INSIDE THE CASE. TO AVOID DAMAGE TO THE CASE OR DISPLAY

WINDOW NEVER CLEAN WITH SOLVENTS.

Current Range Fuses

The mA socket is protected by a 500mA (F) HBC fuse and the 10A socket by a 10A (F) HBC fuse,

both mounted internally. To replace a fuse, proceed as follows:

1. Disconnect the instrument from all voltage sources.

2. Remove the 4 screws from the underside and lift off the case upper.

3. Replace the fuse with one of an identical rating using the diagram below as a guide.

Maintenance

4. Reassemble in the reverse order.

28

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 29

Page 30

Introduction

RS232 remote control is standard and can be used either in a conventional one-to-one mode or

in addressable mode as part of an ARC (Addressable RS232 Chain) system; RS232 can only be

used when the meter is powered from an AC supply.

GPIB (IEEE-488) remote control is available in addition to RS232 on a mains-only version; it is

not a retrofittable option.

The ARC (Addressable RS232 Chain) interface allows a collection of instruments, up to a

maximum of 32, to be connected to a single serial interface on a PC or other computer system.

Each instrument may then be uniquely addressed so that commands for that instrument may be

sent and ignored by all other instruments connected to the interface. Additionally, ARC

instruments may be used on a simple RS232 interface in non-addressable mode without

modification.

Available as an option is the ARCTALK software package for IBM compatible PCs. At the simplest

level, ARCTALK provides realtime direct control of instruments on the ARC bus from the PC’s

keyboard. However, it can be used more effectively to create complete ‘programs’ within which

several instruments can be set-up and/or measurements read back; responses can be captured

in a ‘response’ file for later use, e.g. by another application which could, for example, generate a

graph of the data.

Remote Operation

The following sections detail the operation of the instrument via both GPIB and ARC (RS232).

Where operation is common no distinction is made between the two; where differences occur

these are details in separate sections for GPIB and ARC.

RS232/GPIB Selection

The required interface must be selected using the rear panel slide switch before the meter is

switched on. Set the switch and switch on; if GPIB is selected the main display will show IEEE for

1 second as verification.

Address and Baud Rate Selection

Each instrument connected to the ARC or GPIB bus must be assigned a unique address and, in

the case of ARC, all must be set to the same baud rate.

To set the address press Shift then Addr (the shifted function of FUNCTION); the main display

shows Add and the secondary display shows the current address setting. Increment/decrement

the address with the Range Up/Range Down beep or enter the default address (1) by pressing

Clr (the edit function of Cancel). Exit address selection mode by pressing Esc.

To set the Baud rate press Shift then Baud (the shifted function of Run); the main display shows

bAUd and the secondary display shows the current Baud setting. Step through all possible

settings using the Range Up/Range Down keys or enter the default rate (9600) by pressing Clr

(the edit function of Cancel). Exit Baud selection mode by pressing Esc.

Two further settings, PC-02 and Trig, are listed with the Baud rate. These are for when the RS232

interface is used with a parallel printer or remote data-logger trigger, respectively; refer to the

Printing and Data Logger sections for details.

Remote/Local Operation

At power-on the instrument will be in the local state; in this state all keyboard operations are

possible. When the instrument is addressed to listen and a command is received the remote state

will be entered and the REM symbol will show in the display. In this state the keyboard is locked

out and only remote commands will be processed. The instrument may be returned to the local

29

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 30

Page 31

All instruments on the interface must be set to the same baud rate and all must be powered on,

otherwise instruments further down the daisy chain will not receive any data or commands.

30

state by pressing the Local key; however, the effect of this action will remain only until the

instrument is addressed again or receives another character from the ARC interface, when the

remote state will once again be entered.

ARC Interface

ARC Interface Connections

The 9-way D-type serial interface connector is located on the instrument rear panel. The pin

connections are as shown below:

Pin Name Description

1 - Power to optional PC-02

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4 - No internal connection

5 GND Signal ground

6 - No internal connection

7 RXD2 Secondary received data (see diagram)

8 TXD2 Secondary transmitted data (see diagram)

9 GND Signal ground

Pins 2, 3 and 5 may be used as a conventional RS232 interface with XON/XOFF handshaking.

Pins 7, 8 and 9 are additionally used when the instrument is connected to the ARC interface.

Using a simple cable assembly, a ‘daisy chain' connection system between any number of

instruments, up to the maximum of 32 can be made, as shown below:

The daisy chain consists of the transmit data (TXD), receive date (RXD) and signal ground lines

only. There are no control/handshake lines. This makes XON/XOFF protocol essential and allows

the inter-connection between instruments to contain just 3 wires. The wiring of the adaptor cable

is shown below:

Telemeter Electronic GmbH | Joseph-Gaensler-Str. 10 | Phone +49 906 70693-0 | Fax +49 906 70693-50 | www.telemeter.info 31

Page 32

The ARC standard for the other interface parameters is as follows:

Start bits 1

Data bits 8

Parity None

Stop bits 1

In this instrument, as with most other ARC instruments, these parameters are fixed.

ARC Character Set

Because of the need for XON/XOFF handshake it is possible to send ASCII coded data only;