TTHERM GEO TVA series, TVT series Installation & Operating Instructions Manual

Single and Two-Stage

Packaged Geothermal Heat Pump

Installation & Operating Instructions

Models: TVA/TVT-***

Application

Forced air Geo source installation

Equipped for optional AUX EL strip heat (controller included)

Dual Heat, LMC (load management control), etc. – add option TT-INT

3-Phase Models

Domestic Water Heater, Desuperheater

Note

Tested to UL Standards 1995 and CSA Standards C22.2

Also see and use GI102

Energy Star promotes the desuperheater and it is offered as an optional item for

all TTHERM GEO™ heat pumps. Our exclusive GEO Logic™ control system

optimizes the operation of a desuperheater, operating the systems only when

there is adequate energy available to provide heat to the domestic hot water.

However, to maximize the times the desuperheater aides in providing domestic

hot water, a hot water preheat tank is suggested.

The GEO Logic control board has various required setup adjustments, see Field Setup section.

TTHERM GEO heat pumps leave the factory setup to operate on an open loop. See Open Loop

Solenoid section.

DO NOT DESTROY THIS MANUAL. PLEASE READ CAREFULLY AND KEEP IN A

SAFE PLACE FOR FUTURE REFERENCE BY A SERVICE TECHNICIAN.

Model Number:____________________________

Serial Number:_____________________________

Installing Contractor:________________________

Important information

12/06/2012 GI202

Table of Contents

Introduction 1

Safety Considerations 2

TTHERM GEO Heat Pump Configurator (GC002) 3

Mechanical Specifications 4

Electrical Data 6

Duct System and Blower 7

Duct Sizing Chart 8

Product Dimensions 9

Installation Requirements 10

Mechanical Installation Overview 11

Mechanical Installation Source Water 12

Antifreeze 15

Open Loop Solenoid 16

Converting to Right Hand Return 18

Optional Electric Strip Heat (AUX EL) 19

Desuperheater, Domestic Hot Water (SWH) 20

Condensate Drain 22

Electrical Installation 23

GEO Logic Controller 24

Add-On Option and Accessories 25

Field Setup Overview 27

Dual Fuel/Utility Control 29

Operation Indicators 30

Power On, Start Up 35

Operational Tips 37

Preventative Maintenance 40

TVT & TVA Operating Conditions Tables 41

Troubleshooting 45

Drawing GR201 p1 – Water to Air Heating Mode – refrigerant circuit 48

Drawing GR201 p2 – Water to Air Cooling Mode – refrigerant circuit 49

Drawing UAW553 – Electrical Diagram 50

Warranty Information – GX002 51

12/06/2012 GI202

Introduction

Geothermal heat pumps are able to heat and cool spaces with efficiencies exceeding 350% by taking advantage

of solar heat stored in the earth’s crust and the earth’s relatively stable temperatures. In the winter time, heat is

moved from the earth into the home and concentrated using a refrigeration system. Since the heat already exists

in the soil, the cost of operation of the geothermal heat pump is, in effect transportation cost for the free heat. In

the summer, heat is removed from the home by reversing the refrigeration process and sending heat back out

into the earth. A geothermal system consists of an earth source (either open loop or earth loop heat exchanger),

a geothermal heat pump containing the refrigeration system and a ductwork system for delivering the

conditioned air to the individual rooms. To learn more about geothermal heating, please visit our web site at

www.tthermgeo.com

This is a prewired package system with the necessary controls for various forced air heating applications. The

GEO Logic control uses a standard, multi-wire heat pump room thermostat to initiate and terminate all heat/cool

functions. There are various temperature sensors, pressure sensors, water flow switch, etc. which continuously

monitor the heat pump system. The interaction of these sensing components, room thermostat requests, and the

various heat pump refrigeration components plus optional AUX electric element heater are all controlled by an

integrated microprocessor system (GEO Logic). The various setup conditions for this microprocessor based

controller determine the application and geo product series. These setups are initially programmed by the

factory, but special PC software and cable are available for reprogramming as required for controller

replacement and/or other options which may apply to the specific installation. See Additional Equipment

Concerns, Field Setup or Programming, Operation Indicators, User Instructions, Control Sequence, and

Troubleshooting sections within this manual for further details on the GEO Logic control.

An optional T2-TT-INT-1 plug-in module is available to properly handle other applications with utility load

control, backup furnace, backup boiler, dual fuel, etc. In addition to the compressor and AUX heater, proper

operation of the forced blower and control of the external pumps are also operated with this optional module.

Moving and Storage

Units should be stored in original packaging in a clean dry area. Store and move units in normal upright

position. Do not stack units. Transport in vertical position only.

Initial Inspection

Be certain to inspect all cartons and crates as units are received before signing the freight bill. Verify that all

items received have no physical damage. Report any damages or shortages on the freight bill. The purchaser is

responsible for filing the necessary claims with the carrier. Concealed or hidden damages not discovered until

removing packaging must be reported to the carrier within 15 days of receipt.

Unit Location and Mounting

Locate the unit in an indoor area where the ambient temperature will remain above 45°F [8°C]. TTHERM GEO

provides 3 removable panels for ease of servicing; front (2), right and left bottom. This unit is zero clearance

rated; however, allow enough room to remove panels for service and maintenance. We suggest setting the unit

on a sound vibration pad, see accessories price sheet, part # E2-0122. Water supply should not be hard plumbed

directly with copper or PVC pipe as this could transfer any vibration to living space. Consider using Hose Kit

part # L3-0015B to minimize transferred vibration.

Please read and understand conditions associated with proper installation, unauthorized changes, and POWER ON

procedures.

Warranty Statement

See the last page of this manual for detailed limited warranty coverage explanation.

12/06/2012 1 GI202

Safety Considerations

WARNING

BEFORE PERFORMING SERVICE OR MAINTENANCE OPERATIONS ON A SYSTEM, TURN OFF

MAIN POWER SWITCHES TO THE INDOOR UNIT. IF APPLICABLE, TURN OFF THE ACCESSORY

HEATER POWER SWITCH. ELECTRICAL SHOCK COULD CAUSE PERSONAL INJURY.

Installing and servicing heating and air conditioning equipment can be hazardous due to system pressure and

electrical components. Only trained and qualified service personnel should install, repair or service heating and

air conditioning equipment. Untrained personnel can perform the basic maintenance functions of cleaning coils

and cleaning and replacing filters. All other operations should be performed by trained service personnel.

When working on heating and air conditioning equipment, observe precautions in the literature, tags and labels

attached to the unit and other safety precautions that may apply, such as the following safety measures:

Follow all safety codes.

Wear safety glasses and work gloves.

Use a quenching cloth for brazing operations.

Have a fire extinguisher available for all brazing operations.

Warnings, Cautions, and Notes

Throughout this manual there are warnings, cautions and notes containing various levels of important

information. Read all of these items carefully before performing any installation, servicing or troubleshooting

of the system.

Warnings are for any item which MUST be followed and failure to do so could result in serious injury or even

death and/or serious damage to the equipment.

Cautions relate to potentially hazardous situations or important practices which if ignored could cause minor to

moderate injury or cause equipment damage or performance problems.

Notes are used to indicate items of high importance but are not related to a hazardous situation.

12/06/2012 2 GI202

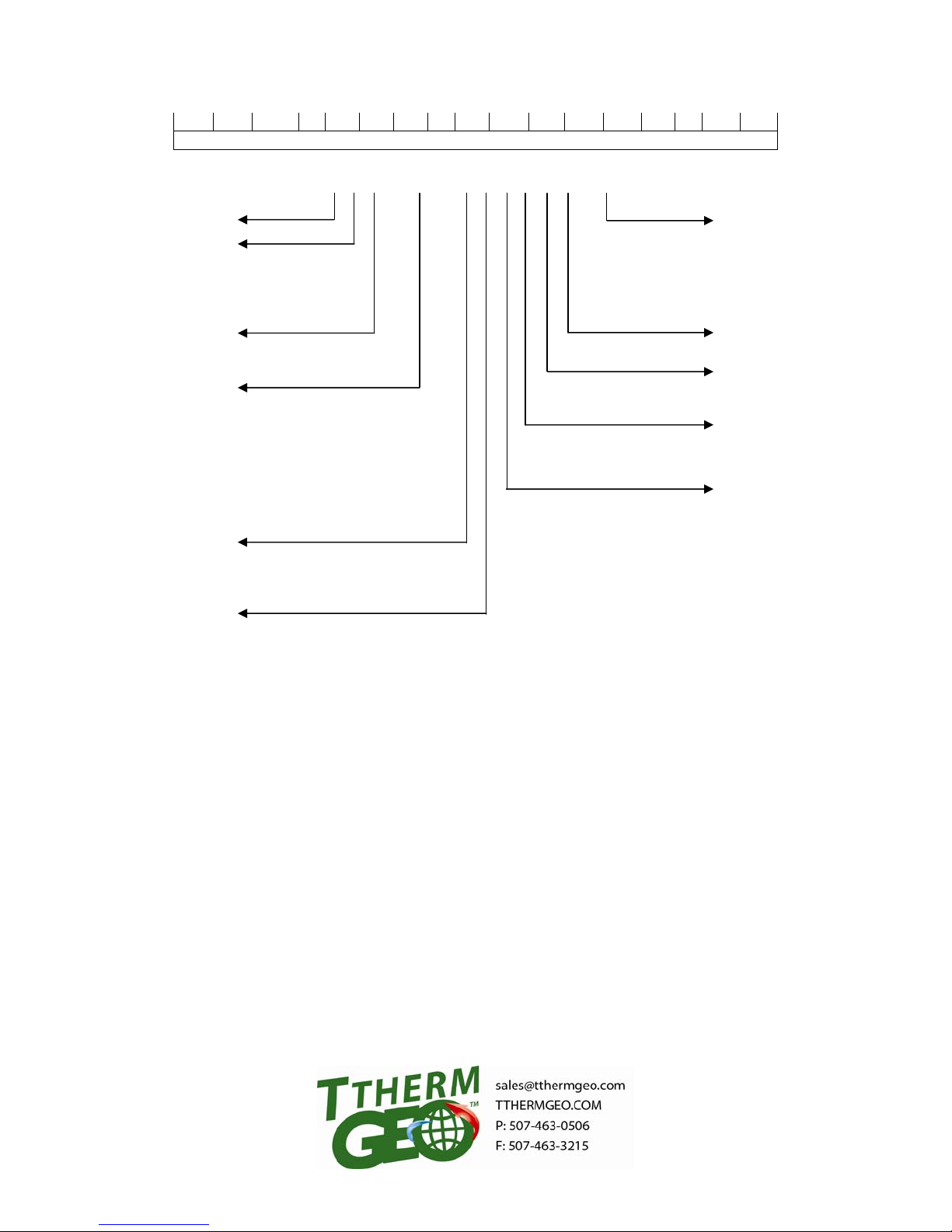

T V T - 0 4 8 - 1 C L D X 1 - X X

1 2 3 4 5 6 7 8 9 10 11 12 13 14

TTHERM GEO (1)

Unit Style (2)

C = Combo

H = Hydronic

S = Split

V = Vertical

Unit Type (3)

A = Single Stage

T = Two Stage

Nominal Tonnage (4, 5, 6)

Voltage Option (7)

Heat Exchanger Option (8)

M = Copper (Load) & Cupronickel

S = Stainless (THT only)

024 = 2-ton

036 = 3-ton

042 = 3.5-ton

048 = 4-ton

060 = 5-ton

072 = 6-ton

096 = 8-ton

120 = 10-ton

144 = 12-ton

1 = 208/230V, 1 Ph

2 = 208/230V, 3 Ph

3 = 460/480V, 3 Ph

C = Copper

N = Cupronickel

(Source)

TTHERM GEO Heat Pump Configurator

Model Number Digits

TVT-048-1CLDX1-XX

Auxiliary kW Option* (13, 14)

05 = 4.8 kW

10 = 9.6 kW

15 = 14.4 kW

20 = 19.2 kW

XX = None

*Can be factory or field installed

Vintage (12)

1

Miscellaneous Kits (11)

A = Soft Start Kit (Installed)

X = None

Desuperheater Option (10)

D = Desuperheater w/Factory

Installed Pump

X = None

Configuration Option (9)

L = Left Return (Standard)*

R = Right Return

C = Split Air Coil

X = N/A or No Split Air Coil

*Left return can be field converted to right return

10/12/2012 GC002

n

e

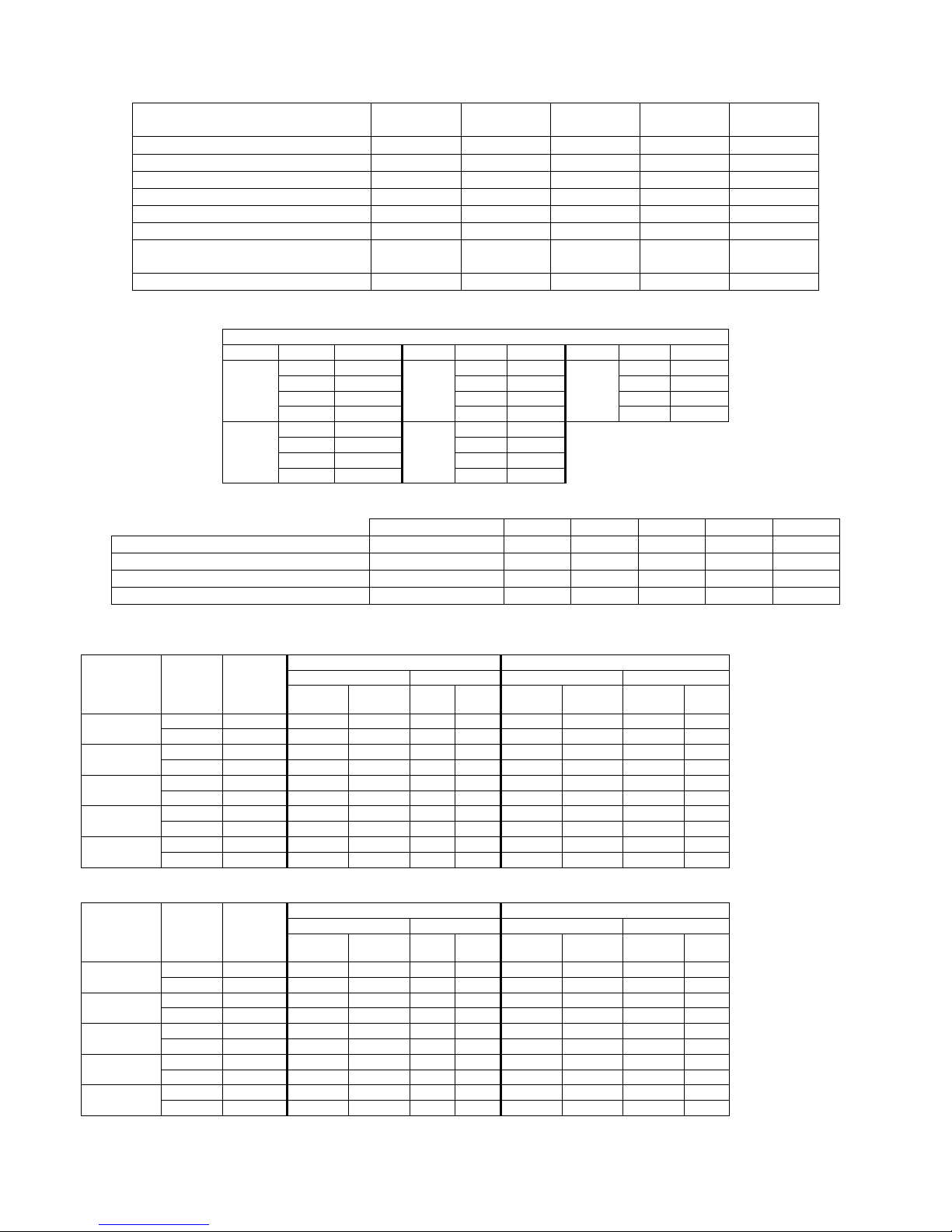

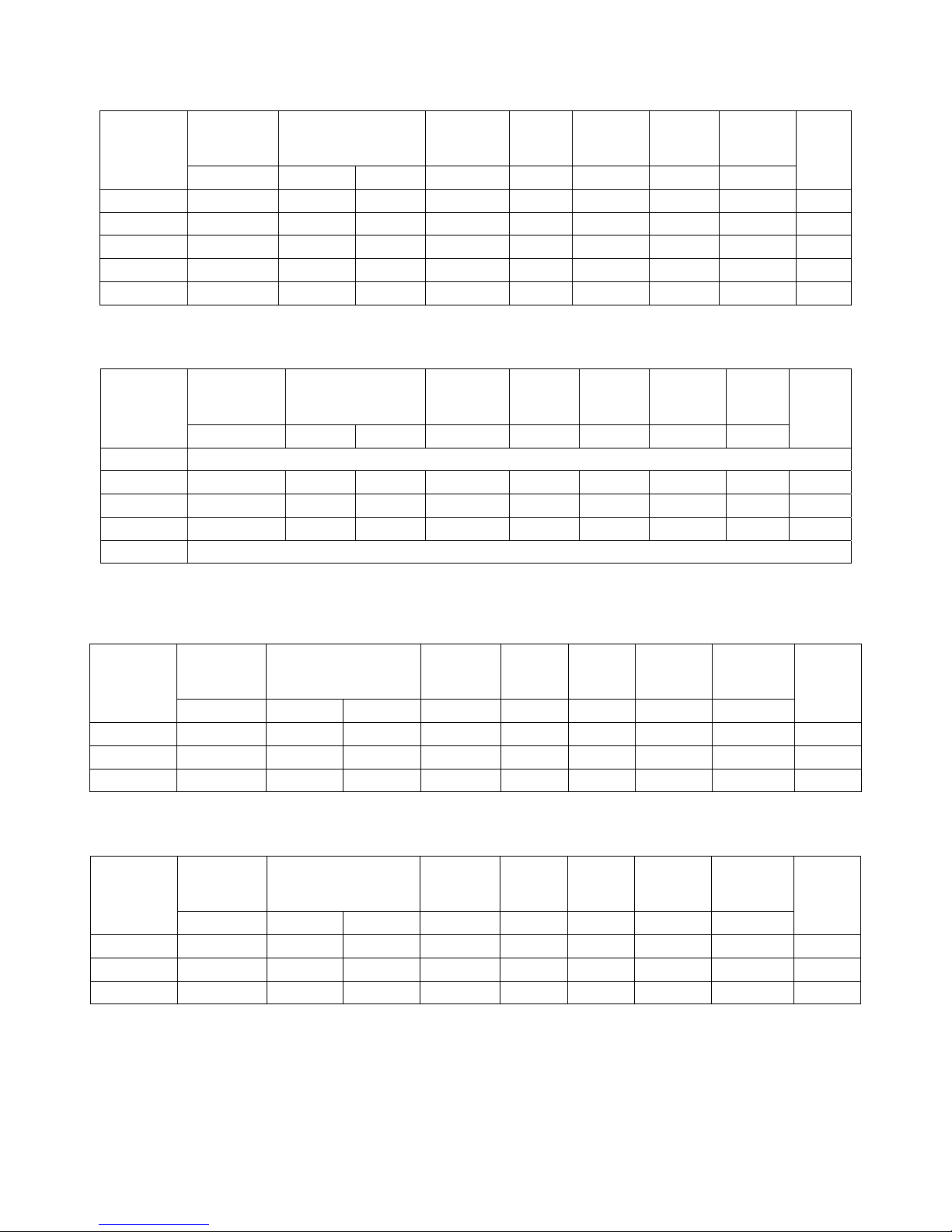

TVT - Mechanical Specifications – R410A Two-Stage Compressor

MODEL

TVT-024

(2 ton)

TVT-036

(3 ton)

TVT-042

(3.5 ton)

TVT-048

(4 ton)

TVT-060

(5 ton)

Coax & Piping Water Volume – gal .43 .65 .77 1.1 1.1

Source Temperature °F (min/max) 20°/120° 20°/120° 20°/120° 20°/120° 20°/120°

Nominal source differential* ° F (H/C) 3/12° 9/11° 10/11° 6/11° 6/10°

Factory Charge R410A 2 lbs. 14 oz. 4 lbs. 8 oz. 4 lbs. 8 oz. 6 lbs. 4 oz. 6 lbs. 4 oz.

Static Pressure – Nominal 0.3 0.3 0.3 0.3 0.3

Static Pressure – Design 0.5 0.5 0.5 0.5 0.5

Air Filter

Weight– Packaged (lbs) 440 480 490 503 530

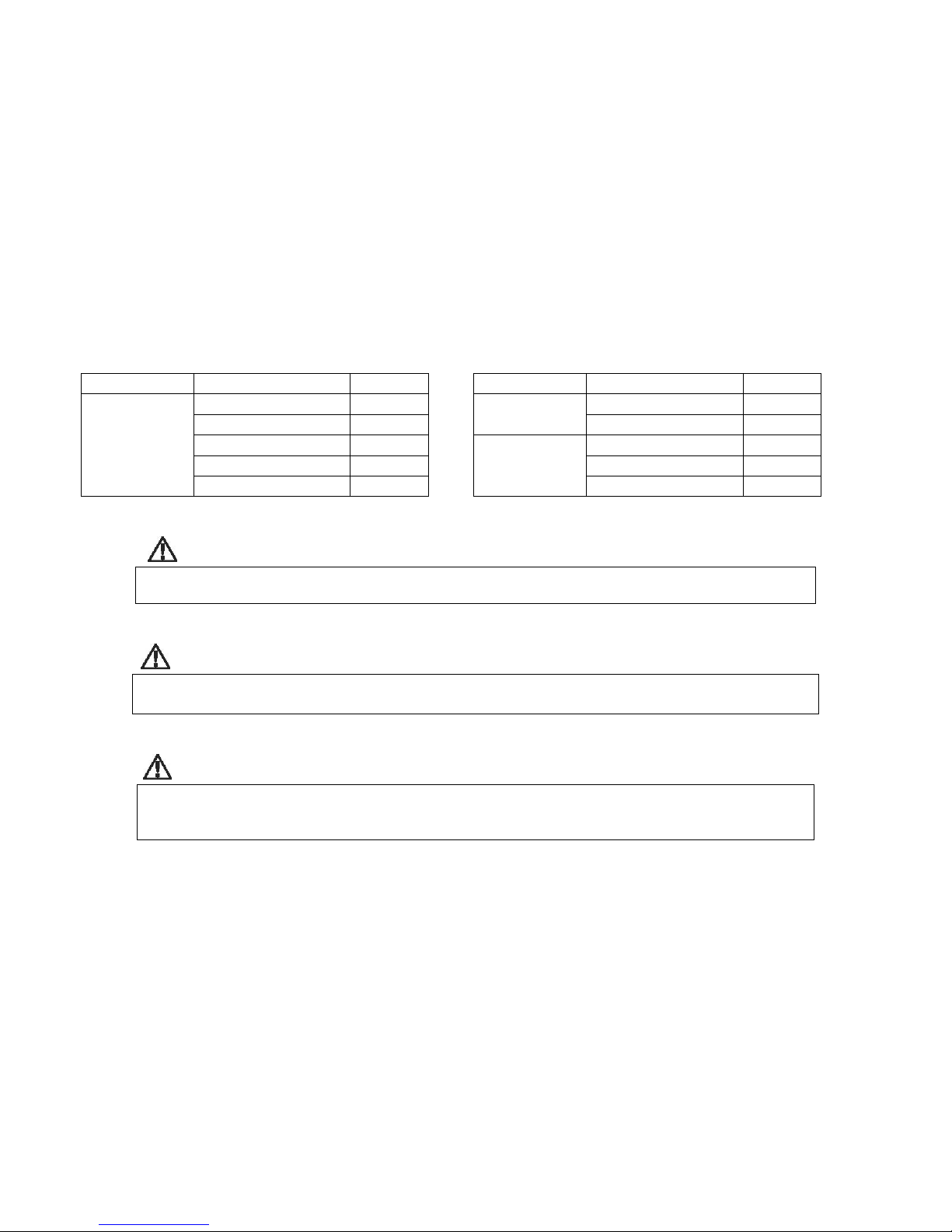

HEAT EXCHANGER PRESSURE DROP TABLE

7/8 X 21 7/8

X 27 1/2

Water-to-Air (Source Side, Pure Water @ 68° F)

Model GPM PSID Model GPM PSID Model GPM PSID

4 1.2 (ref) 7 2.5 10 1.9

2-ton

6 2.7 (ref) 10.5 4.5 15 3.6

8 3.6 (ref) 14 7.0 20 5.8

3.5-ton

10 5.6 (ref)

6 1.8 (ref) 8 1.3

3-ton

9 2.4 (ref) 12 2.5

12 4.3 (ref) 16 4.0

4-ton

15 6.7 (ref)

PRESSURE DROP MULTIPLIERS

7/8 X 28 7/8

X 27 1/2

17 9.5

20 5.8

7/8 X 28 7/8

X 27 1/2

5-ton

7/8 X 27 1/2

X 37 7/8

25 8.5

7/8 X 27 1/2

X 37 7/8

Freeze Point (° F) 20° F 25° F 30° F 35° F 40° F

Pure Water Multiplier 32 1.00 1.00 1.00 1.00 1.00

Methanol 12.5%* Multiplier 16.2 − 1.25 1.21 1.18 1.15

Propylene Glycol 20%* Multiplier 18.4 1.39 1.35 1.31 1.28 1.24

Ethanol 20%* Multiplier 18.1 1.56 1.47 1.42 1.36 1.31

TVT - HEATING – ISO 13256-1 SPECIFICATION – ENERGY STAR

Model Stage

TVT-024

TVT-036

TVT-042

TVT-048

TVT-060

TVT - COOLING – ISO 13256-1 SPECIFICATION – ENERGY STAR

Model Stage

TVT-024

TVT-036

TVT-042

TVT-048

TVT-060

*By volume Feet of Head = PSI x 2.31

GWHP – Ground Water GLHP – Ground Loop

Source

GPM

50° F 68° F 32° F/41° F 68° F

Capacity

Btu/h

Blower

CFM

Temp

Rise

COP

Capacity

Btu/h

Blower

CFM

Temp

Rise

COP

FL 10 30.3 850 32 4.01 24.1 850 26 3.66

PL 10 23.0 725 29 4.20 19.9 725 26 3.98

FL 9 42.2 1200 34 4.05 32.8 1200 27 3.88

PL 9 30.5 1000 30 4.19 27.0 1000 26 4.04

FL 10.5 44.6 1312 33 4.07 35.6 1312 26 3.59

PL 10.5 31.5 1100 29 4.39 28.4 1100 25 4.07

FL 12 55.7 1500 36 4.01 44.4 1500 29 3.55

PL 12 37.3 1200 30 4.14 33.4 1200 27 3.67

FL 15 70.8 1875 35 4.08 55.5 1875 28 3.83

PL 15 53.1 1480 32 4.20 46.3 1480 29 4.07

1. Capacities are based on

GWHP – Ground Water GLHP – Ground Loop

Source

GPM

59° F 80.6° F 77° F/68° F 80.6° F

Capacity

Btu/h

Blower

CFM

Temp

Drop

EER

Capacity

Btu/h

Blower

CFM

Temp

Drop

EER

2. Stated Btu/h is the ISO

FL 10 36.5 950 22 24.1 32.7 950 20 16.1

PL 10 28.4 825 21 21.9 26.4 825 22 22.1

FL 9 47.0 1250 23 20.1 44.2 1250 22 15.9

3. Temp rise is based on sensibl

PL 9 35.1 1050 22 23.4 34.5 1050 21 21.3

FL 10.5 49.3 1400 22 19.3 47.6 1400 21 14.9

4. All ratings based upon

PL 10.5 36.4 1150 21 24.1 37.6 1150 20 21.1

FL 12 64.2 1600 23 20.1 58.3 1600 22 15.9

PL 12 47.7 1275 22 23.7 46.1 1275 22 21.5

5. Ground Loop Heat Pump

FL 15 75.8 2000 23 19.7 70.9 2000 23 15.2

PL 15 56.9 1650 21 23.3 55.7 1650 22 20.5

temperatures shown in headi

source is left group, return air

right group.

13256-1 formula adjusted,

actual HP supply energy

delivered is 2% greater.

only.

operation at lower voltage of

dual voltage rated models.

ratings based on 15%

antifreeze solution.

12/06/2012 4 GI202

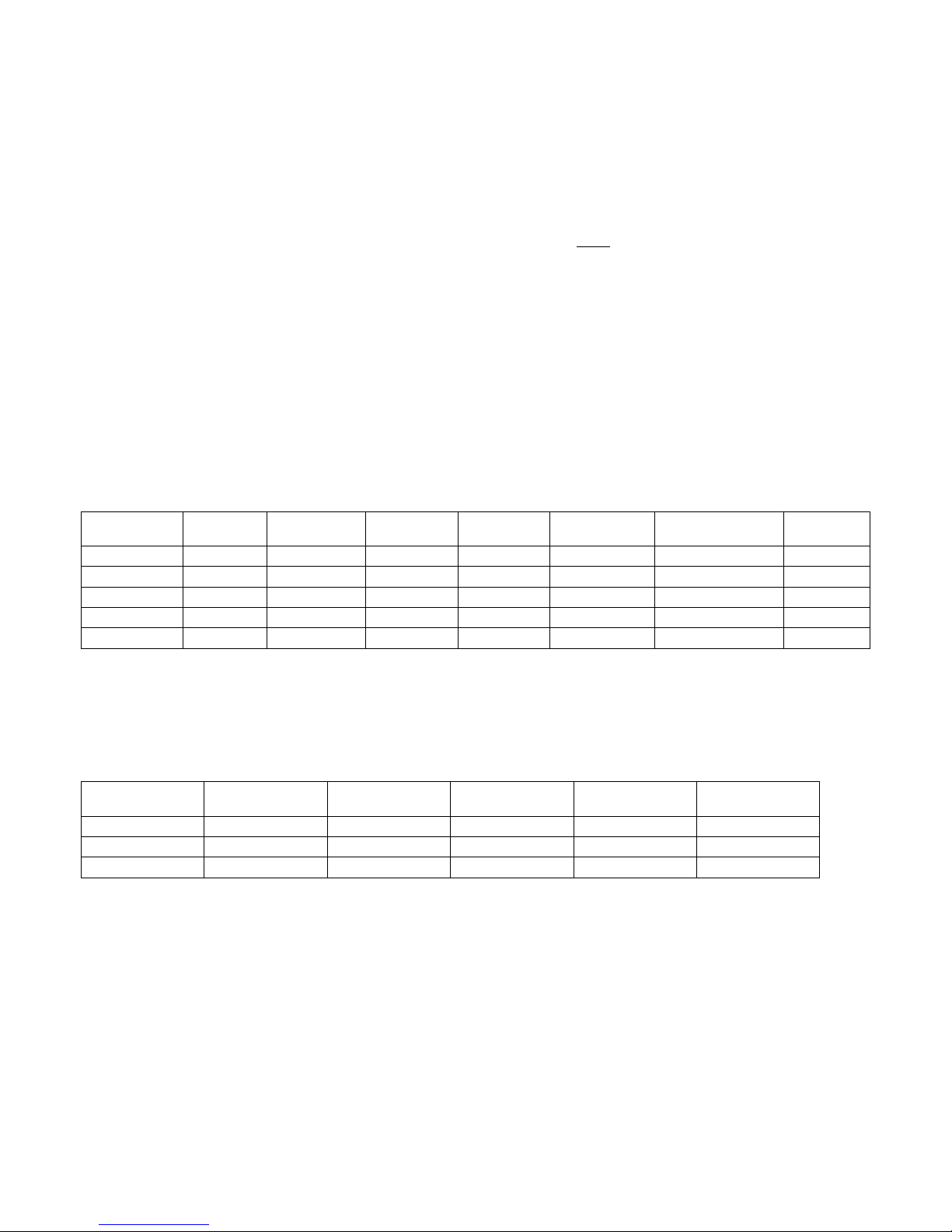

MODEL

TVA-036

(3 ton)

TVA-048

(4 ton)

TVA-060

(5 ton)

Coax & Piping Water Volume – gal .65 1.1 1.1

Source Temperature °F (min/max) 20°/120° 20°/120° 20°/120°

Nominal source differential* °F (H/C) 9/11° 6/11° 6/10°

Factory Charge R410A 4 lbs. 8 oz. 6 lbs. 4 oz. 6 lbs. 4 oz.

Static Pressure – Nominal 0.3 0.3 0.3

Static Pressure – Design 0.5 0.5 0.5

Air Filter

Weight– Packaged (lbs) 460 480 503

HEAT EXCHANGER PRESSURE DROP TABLE

7/8 X 28 7/8

X 27 1/2

Water-to-Air (Source Side, Pure Water @ 68° F)

Model GPM PSID Model GPM PSID Model GPM PSID

6 1.8 (ref) 8 1.3 10 1.9

3-ton

9 2.4 (ref) 12 2.5 15 3.6

12 4.3 (ref) 16 4.0 20 5.8

15 6.7 (ref)

4-ton

20 5.8

PRESSURE DROP MULTIPLIERS

7/8 X 27 1/2

X 37 7/8

5-ton

7/8 X 27 1/2

X 37 7/8

25 8.5

Freeze Point (° F) 20° F 25° F 30° F 35° F 40° F

Pure Water Multiplier 32 1.00 1.00 1.00 1.00 1.00

Methanol 12.5%* Multiplier 16.2 − 1.25 1.21 1.18 1.15

Propylene Glycol 20%* Multiplier 18.4 1.39 1.35 1.31 1.28 1.24

Ethanol 20%* Multiplier 18.1 1.56 1.47 1.42 1.36 1.31

1. Capacities are based on temperatures shown in heading, source is left group, return air is right group.

2. Stated Btu/h is the ISO 13256-1 formula adjusted, actual HP supply energy delivered is 2% greater.

3. Temp rise is based on sensible only.

4. All ratings based upon operation at lower voltage of dual voltage rated models.

5. Ground Loop Heat Pump ratings based on 15% antifreeze solution.

*By volume Feet of Head = PSI x 2.31

TVA – HEATING – ISO 13256-1 SPECIFICATION – ENERGY STAR

Model

Source

GPM

TVA-036 10 42.6 1200 34 4.28 32.7 1200 27 3.66

TVA-048 13 57.3 1500 35 4.10 45.2 1500 27 3.60

TVA-060 15 63.5 1875 35 4.10 50.7 1875 28 3.60

GWHP – Ground Water GLHP – Ground Loop

50° F 68° F 32° F 68° F

Capacity

Btu/h

Blower

CFM

Temp

Rise

COP

Capacity

Btu/h

Blower

CFM

Temp

Rise

COP

TVA – COOLING – ISO 13256-1 SPECIFICATION – ENERGY STAR

Model

Source

GPM

TVA-036 10 42.0 1250 23 22.9 38.1 1250 21 17.5

TVA-048 12 55.4 1600 24 22.2 52.6 1600 23 17.1

TVA-060 15 65.0 2000 23 21.4 63.8 2000 23 17.1

GWHP – Ground Water GLHP – Ground Loop

59° F 80.6° F 77° F 80.6° F

Capacity

Btu/h

Blower

CFM

Temp

Drop

EER

Capacity

Btu/h

Blower

CFM

Temp

Drop

EER

TVA – Mechanical Specifications – R410A Single Stage Compressor

12/06/2012 5 GI202

TVT - Electrical Data – Single Phase

Model

Loop

Pump

(Ext)

Total Min.

Voltage Compressor Blower

(60 Hz) RLA LRA FLA FLA FLA FLA Ampac.

Desup.

Pump

Max.

Fuse/

HAC

R

TVT-024 208/230-1 13.1 73 4.5 .15 4.4 23.1 25.4 30

TVT-036 208/230-1 17.9 96 6.1 .15 4.4 28.6 33.0 50

TVT-042 208/230-1 21.2 104.0 6.1 .15 4.4 31.9 37.2 50

TVT-048 208/230-1 27.1 152.9 6.1 .15 4.4 37.8 44.4 70

TVT-060 208/230-1 29.7 179.2 7.3 .15 4.4 41.6 49.0 70

TVT - Electrical Data – Three-Phase

Model

Loop

Pump

(Ext)

Total Min.

Voltage Compressor Blower

(60 Hz) RLA LRA FLA FLA FLA FLA

Desup.

Pump

Ampac.

Max.

Fuse/

HAC

R

TVT-024 NOT AVAILABLE

TVT-036 200/230-3 14.2 88 6.1 .15 4.4 24.9 28.3 40

TVT-042 200/230-3 14.0 83.1 6.1 .15 4.4 24.7 25.8 40

TVT-048 200/230-3 16.5 110.0 6.1 .15 4.4 28.3 32.5 50

TVT-060 NOT AVAILABLE

TVA – Electrical Data – Single Phase

Model

Voltage Compressor Blower

(60 Hz) RLA LRA FLA FLA FLA FLA Ampac.

Desup.

Pump

Loop

Pump

(Ext)

Total Min.

Max.

Fuse/

HACR

TVA-036 208/230-1 17.9 112.0 6.1 .15 4.4 28.6 33.0 50

TVA-048 208/230-1 26.4 134 6.1 .15 4.4 37.5 43.5 70

TVA-060 208/230-1 28.3 178.0 7.3 .15 4.4 40.2 47.2 70

TVA – Electrical Data – Three-Phase

Loop

Pump

(Ext)

Total Min.

Max.

Fuse/

HACR

Desup.

Pump

Model

Voltage Compressor Blower

(60 Hz) RLA LRA FLA FLA FLA FLA Ampac.

TVA-036 200/230-3 13.5 88 6.1 .15 4.4 24.2 27.5 40

TVA-048 200/230-3 17.6 123 6.1 .15 4.4 31.1 36.2 50

TVA-060 200/230-3 20.5 155 7.3 .15 4.4 32.4 37.5 50

12/06/2012 6 GI202

Duct System and Blower

Metal ductwork should be used, and flexible connectors are required for supply and return air duct connections.

All TVA & TVT THERM GEO units have flanges for connecting your supply plenum and return ductwork.

If the duct system is installed in an uninsulated space, the metal ductwork should be insulated on the outside to

prevent heat loss, absorb noise, and prevent condensation during cooling.

If the TTHERM GEO is connected to existing ductwork, the ductwork must

have the capacity to handle the air

volume required to unload the heat pump. Undersized ductwork will cause noisy operation due to high air

velocity, and poor operating efficiencies. Check the Duct Sizing Chart provided.

The TTHERM GEO heat pumps use a variable speed ECM blower motor. The GEO Logic controller determines

the speed of the motor based on mode and operation sequence. The blower speed can be fine-tuned to each

installation with the tweak switches described below.

The blower will not operate properly if ductwork is not attached. The ductwork provides static pressure to give

the blower motor a load to work against. All blower compartment covers must be in place for the heat pump to

operate correctly.

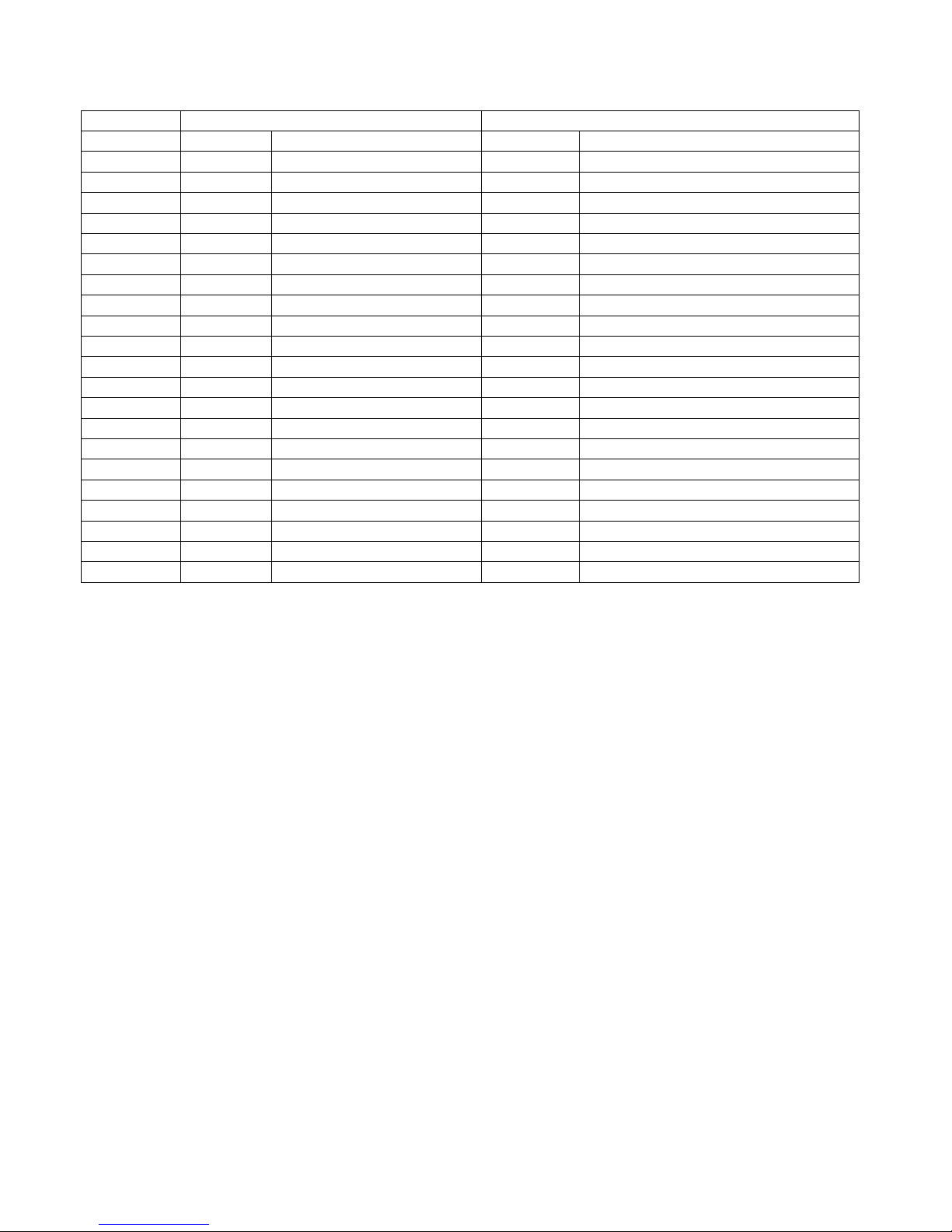

TVT - Blower CFM – Two Stage Compressor

Model G Cool Y Heat Y Cool Y2 Heat Y2 Cool Y 2 Heat + W2 E

TVT – 024 390 640 735 850 980 980 680

TVT – 036 515 900 965 1200 1290 1380 960

TVT – 042 575 985 1080 1310 1440 1500 1050

TVT – 048 660 1125 1235 1500 1650 1725 1200

TVT – 060 825 1400 1545 1875 2060 2160 1500

CFM Rounded

Y2 can be field fine-tuned or tweaked with a 4 position switch. The 4 positions are 0%, -6%, +6%, +12%

G can be field fine-tuned or tweaked with a 4position switch. The 4 positions are 0%, -6%, +6%, +12%

See figure 8 for location of 4 position switch

TVA - Blower CFM – Single Stage Compressor

Model G Cool Y Heat Y Cool Y Heat + W2 E

TVA - 036 515 1200 1290 1380 960

TVA - 048 660 1500 1650 1725 1200

TVA - 060 825 1875 2060 2160 1500

CFM Rounded

Y can be field fine-tuned or tweaked with a 4 position switch. The 4 positions are 0%, -6%, +6%, +12%

G can be field fine-tuned or tweaked with a 4position switch. The 4 positions are 0%, -6%, +6%, +12%

See figure 8 for location of 4 position switch

The “Y” tweak switch is the 2

The “G” tweak switch is the 3

Be very sure the tweak switches are set in their position indents.

nd

switch below the 10 pin thermostat socket.

rd

switch below the 10 pin thermostat socket.

12/06/2012 7 GI202

Duct Sizing Chart

Acceptable Branch Duct Sizes Acceptable Main or Trunk Duct Sizes

CFM ROUND Rectangular Round Rectangular

100 6” 4x8, 4x6

150 7” 4x10, 5x8, 6x6

200 8” 5x10, 6/8,4x14,7x7

250 9” 6x10, 8x8, 4x16

300 10” 6x14, 8x10, 7x12

350 10” 6x20, 6x16. 9x10

400 12” 6x18, 10x10, 9x12 10” 4x20, 7x10, 6x12, 8x9

450 12” 6x20, 8x14, 9x12, 10x11 10” 5x20, 6x16, 9x10, 8x12

500 10” 10x10,6x8, 8x12, 7x14

600 12” 6x10, 7x18, 8x16, 10x12

800 12” 8x18, 9x15, 10x14, 12x12

1000 14” 10x18, 12x14, 8x24

1200 16” 10x20, 12x18, 14x15

1400 16” 10x25, 12x20, 14x18, 15x16

1600 18” 10x30, 15x18, 14x20

1800 20” 10x35, 15,20, 16x19, 12x30, 14x25

2000 20” 10x40, 12x30, 15x25, 18x20

2200 22” 10x40, 15x25, 20x20

2400 22” 12x40, 16x25, 20x20

Table calculated for 0.05 to 0.10 inches of water friction per 100’ of duct. At these duct design conditions, along

with the pressure drop through the filter, the total design external static is 0.20 inches of water.

12/06/2012 8 GI202

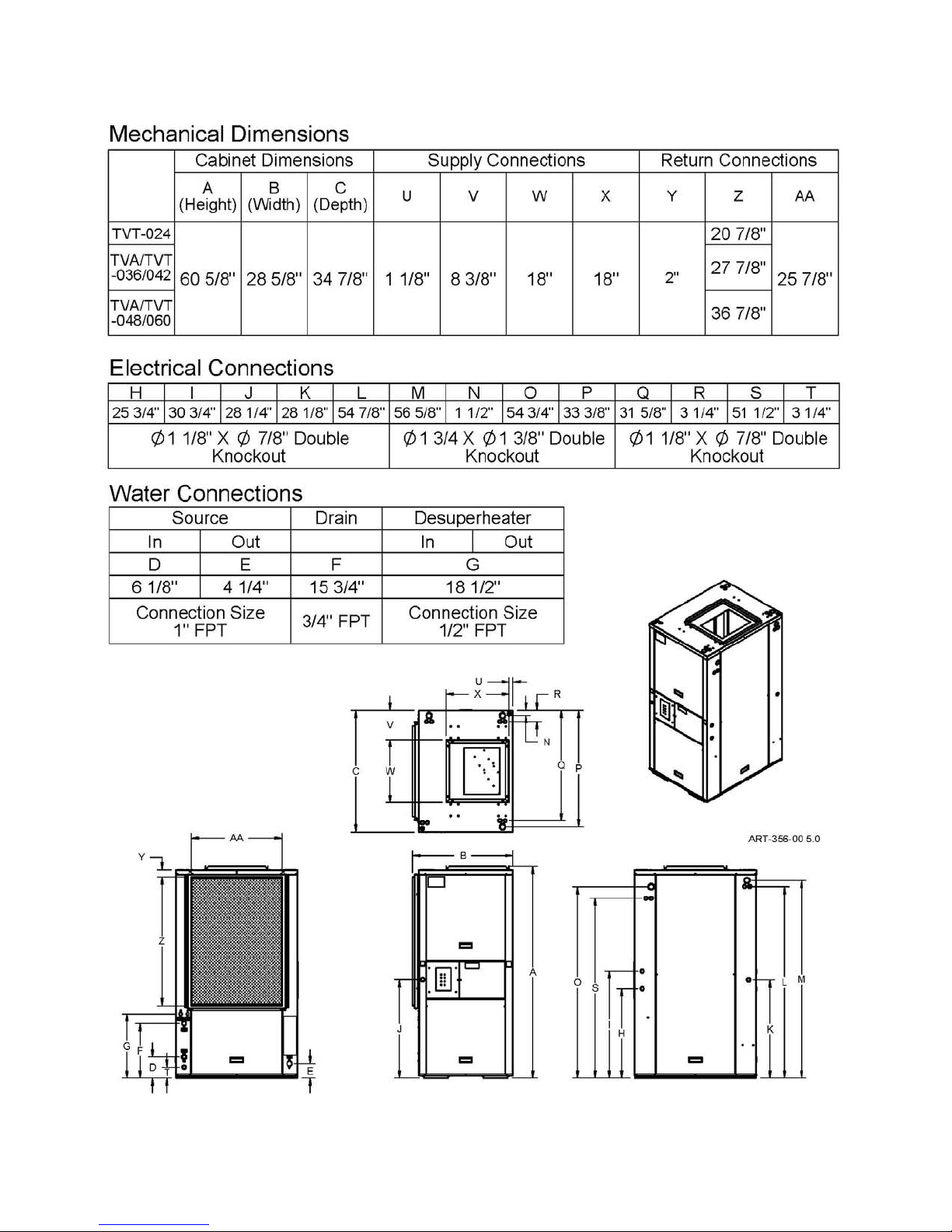

Product Dimensions

12/06/2012 9 GI202

Installation Requirements

1. All installation work must be performed by trained, qualified contractors or technicians. TTHERM GEO

sponsors installation and service schools to assist the installer. Contact TTHERM GEO at

sales@tthermgeo.com

WARNING

ALL ELECTRICAL WIRING MUST BE IN ACCORDANCE WITH NATIONAL ELECTRIC CODE

AND LOCAL ELECTRIC CODES, ORDINANCES, AND REGULATIONS.

WARNING

OBSERVE ELECTRIC POLARITY AND WIRING COLORS. FAILURE TO OBSERVE COULD

CAUSE ELECTRIC SHOCK AND/OR DAMAGE TO THE EQUIPMENT.

CAUTION

This unit can only be used for its intended purpose as described in this manual. Any internal

wiring changes, modifications to the circuit board, modifications or bypass of any controls, or

installation practices not according to the details of this manual will void the product warranty,

the safety certification label, and manufacturer product liability. TTHERM GEO cannot be

held responsible for field modifications, incorrect installations, and conditions which may

bypass or compromise the built-in safety features and controls.

2. If this is a Dual Fuel system, this product relates only to the addition to the furnace ducting system external

to the gas or oil force air furnace. The owner/installer assumes all responsibility and/or liability associated

with any needed installation of the gas/oil furnace, fuel system, flue, chimney, etc. Any instructions or

comments made within this manual (or factory phone assistance) relating to the gas/oil furnace are provided

as comments of assistance and “helps” only.

for upcoming dealer training events.

CAUTION

This unit shall not be operated (either heating section or blower) until the interior of the

structure is completed and cleaned. This also means all duct work must be complete with filter,

etc. Manufacturer’s warranty is void if this unit is operated during structure construction.

CAUTION

Hazards or unsafe practices could result in property damage, product damage, severe personal

injury and/or death.

3. All removed or discharged refrigerant must be recovered In accordance with local and federal statutes.

Should a compressor need replacing, the compressor oil is to remain with the compressor. Refrigerant lines

on the compressor must be capped during service.

4. Remember, safety is the installer’s responsibility and the installer must know this product well enough to

instruct the end user on its safe use.

At TTHERM GEO the safety of the installer and the end user is of highest priority. Remember, safety

is the installer’s responsibility and the installer must know this product well enough to instruct the end

user on its safe use. Professional installers should be trained and experienced in the areas of handling

electrical components, sheet metal products, and material handling processes.

12/06/2012 10 GI202

p

Mechanical Installation Overview

This TTHERM GEO series unit cannot correct airflow problems inherent within the duct work system. The

following items should be carefully considered and properly followed for all installations:

Examination of the existing forced air furnace – Prior to starting this installation, examine the total furnace

system and make necessary comments or recommendations to the homeowner. Remember, if a marginal

condition exists within the existing duct work system, the installation of a geothermal heat pump will not cure

PRE-EXISTING conditions. Consider such items as adequate cold air return and supply duct. Inspect and count

supply and return registers for size and number.

Heating capacity – Size the geothermal heat pump according to the normal heating requirements as the building

exists today

. Do not necessarily match to the existing furnace nameplate because it may be oversized. The

geothermal heat pump should be properly sized for the heat loss of the house. Heat loss and heat gain audits

should be done to determine proper equipment sizing.

Flexible duct connections – Flex duct connections are required for both the supply and return duct connections

and metal duct systems.

Other plenum equipment – Auxiliary equipment such as humidifiers, zone plenum dampers, etc., located

within the plenum which may cause a non-uniform airflow issues may have to be removed if they cause to great

reduction to system airflow.

Comment – zone dampers cause back pressure on the blower and overall reduced airflow. Reduced airflow

can cause the geothermal unit to perform poorly or in some cases cause icing or freeze ups in the air coil. If

the smallest zone cannot handle the minimum CFM requirements of the heat pump a dump zone and/or allow

air flow to bypass to other zones.

Insufficient cold air return capacity – Installation experience indicates this is a major concern. In fact, it

could represent a problem in as many as 60% of the installations, especially if there is a requirement to increase

airflow when the existing cold air return capacity is already undersized or restricted. Check the static pressure

within the return cabinet or the suction at the filter cabinet door. Do not assume because there is a register on

the wall, the hole behind the register or the passageways are equal to this register. Sharp offsets and transitions

in the cold air return system often cause severe restrictions. Expect to add additional registers or a relief register

in the main cold air return duct. Best practice would include both high and low return registers.

Closed Loop Applications – Closed loop system re-circulates the same water/antifreeze solution through a

closed system of underground high-density polyethylene pipe. As the solution passes

through the pipe it collects heat (in the heating mode) that is being transferred

Horizontal Closed Loop

from the relatively warm surrounding soil through the pipe and into the relatively

cold solution. The solution is circulated back to the heat pump that extracts its

heat and then returns to the ground to absorb more heat from the earth. Earth

loops must be sized properly for each particular geographic area and individual

capacity requirements.

The TTHERM GEO series heat pumps are designed to operate on either vertical

or horizontal closed loop applications. (Figures 1 & 2) Vertical loops are

Figure 1

typically installed with a well drilling rig up to 200 feet (61 meters) deep or more. Horizontal systems are

typically installed with excavating or trenching equipment approximately six to eight feet (1.8 – 2.4 meters)

deep, depending on geographic location and length of pipe used. Horizontal bored loops are typically installed

15 feet deep.

Lake or Pond Loops – Closed loop systems may also be used in lakes or rivers to

Vertical Closed Loo

supply a heat source to the heat pump. Typically a loop consisting of geothermal

pipe can be designed and placed in an area at least 12ft (3.7 meters) with some water

currents present. In any lake or pond, municipal and local codes must be observed

in regards to a lake or pond loop. The use of an environmentally friendly loop fluid

like Propylene Glycol should be considered in the event damage should ever occur

to the loop.

Consult sales at TTHERM GEO or an IGSHPA or CGC certified installer for proper

Figure 2

loop design and installation. State and local codes apply.

12/06/2012 11 GI202

Mechanical Installation Source Water

WARNING

LOOP DESIGN IS EXTREMELY IMPORTANT FOR PROPER HEAT PUMP OPERATION.

INCORRECT LOOP DESIGN WILL REDUCE HEAT PUMP EFFICIENCY, CAUSE POOR

PERFORMANCE OR MAY RENDER THE SYSTEM UNUSABLE. IF YOU LACK EXPERIENCE

DESIGNING LOOP FIELDS, CONTACT AN IGSHPA OR CGC CERTIFIED GEOTHERMAL

LOOP CONTRACTOR FOR PROPER INSTALLATIONS.

Water Connections General

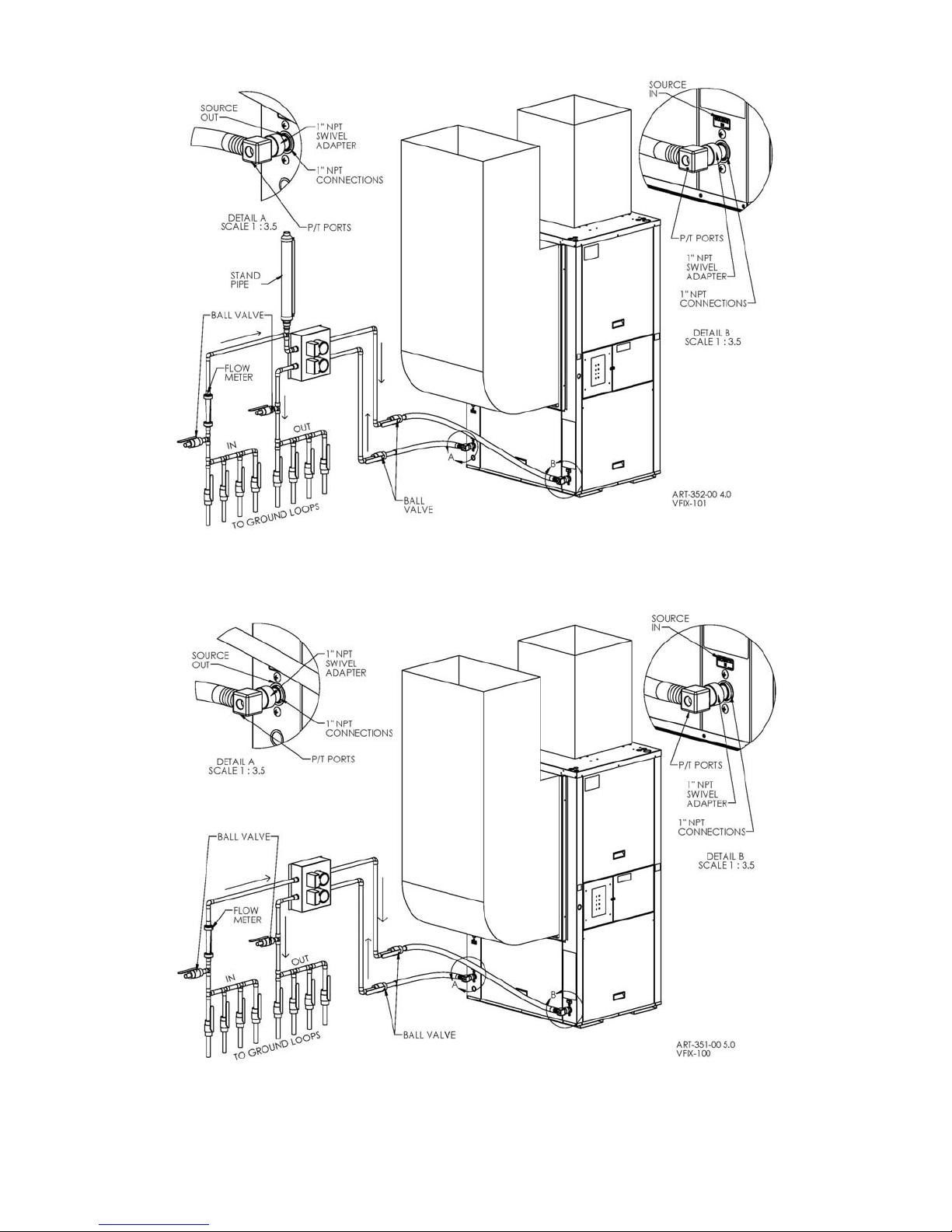

The following pages outline typical piping arrangements for the most common source water connection options,

as well as flushing and filling procedures and antifreeze requirements for closed loop systems. TTHERM GEO

recommends hose kits for the source water connection points at the heat pump. This will provide a flexible

connection to reduce and isolate vibrations transmitting from the compressor into other parts of the system.

Hose kits also provide P/T ports for monitoring pressure and temperature (see below).

Note

TTHERM GEO heat pumps are factory set for open loop. J11 must be removed for proper

operation on an antifreeze protected closed loop. See figure on page 26 for the location of J11.

Once closed loops are completed, they must be pressure tested to at least 60 PSI to ensure integrity. Once

pressure is tested, loop must be purged of all foreign debris and filled with fluid. All air must be removed at this

time by flushing the system. (Page 11, Table 2) shows approximate fluid volumes.

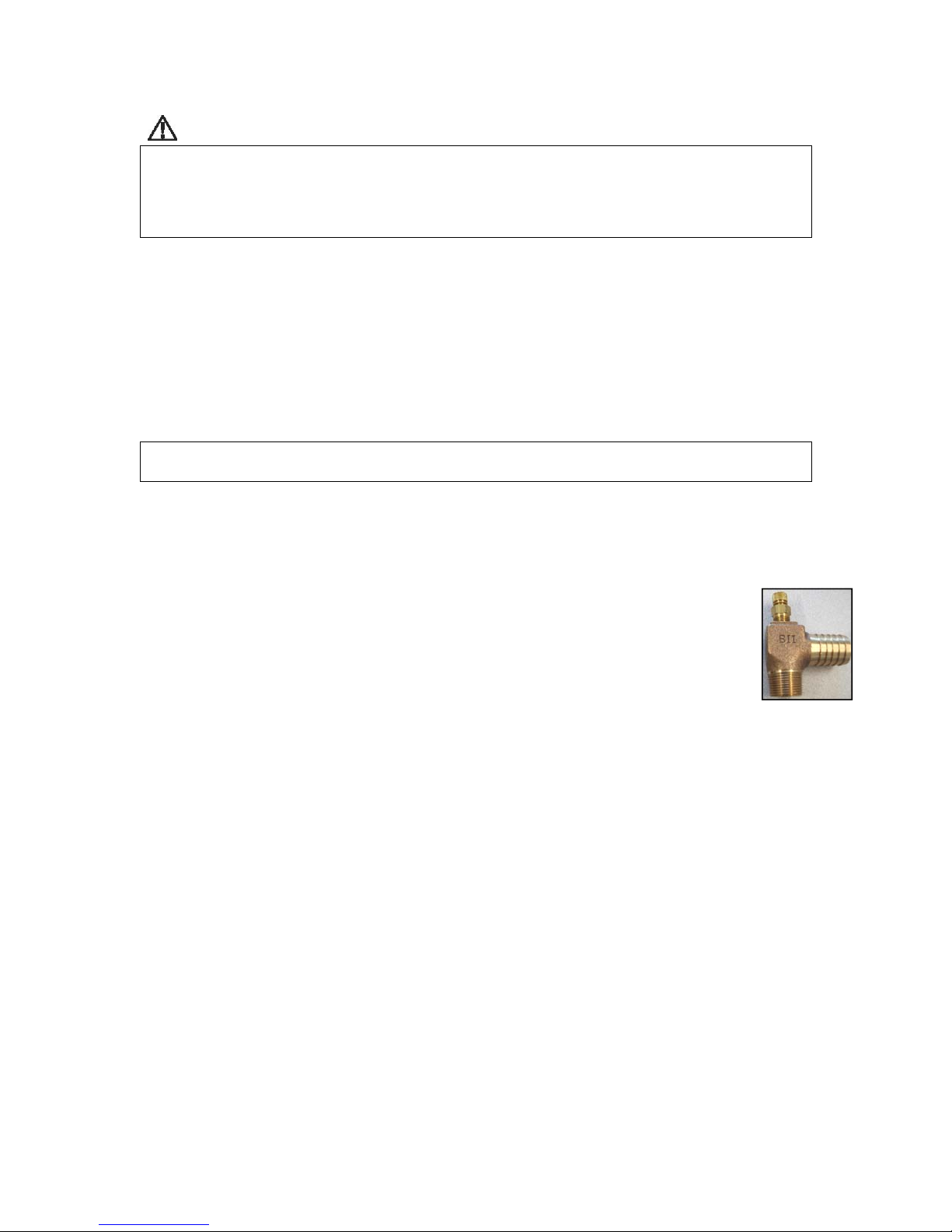

Pressure/Temperature (P/T) plugs – Should be installed in the adaptor elbow on the entering

and leaving water line of the heat pump on a closed system. (Figure 3) A thermometer can be

inserted into the P/T ports to check entering and leaving water temperatures. A pressure gauge

can also be inserted into these P/T ports to determine the pressure differential between the

entering and leaving water. This pressure differential can then be compared to the engineering

specifications data to determine the flow rate of the system. Non Pressurized Loops require an

air separator/stand pipe to eliminate air and to hold enough fluid to compensate for the expansion and

contraction of the loop pipe and fluid. Purge and fill valves should be placed between the loop manifold valves

and the insulated pump pack.

A Flow Meter is an important part of the system. It provides a visual indicator of loop flow in GPM.

A flow meter can be installed on either side of the pump pack, but must be installed per manufacture

recommendations so it reads accurately.

Non Pressurized Loops require an air separator/stand pipe to eliminate air and to hold enough fluid to

compensate for the expansion and contraction of the loop pipe and fluid. Purge and fill valves should be placed

between the loop manifold valves and the insulated pump pack. See figure 4.

P/T Adapter

Figure 3

12/06/2012 12 GI202

Pressurized Loops do not require an air separator. They require purge and fill ports between the loop manifold

valves and the insulated pump pack. After purging a pressurized loop, it should maintain 45 to 60 psi static

pressure. The Geothermal Loop Pipe stretches under pressure so may need to be pressurized above the desired

pressure several times to achieve the recommended static pressure. Pressurized loops must maintain enough

static pressure to compensate for the expansion and contraction of the loop pipe and fluid.

Loop Pump Selection – Select a loop circulation pump based upon the GPM required and total system pressure

drop. See specification, page 4. Geothermal heat pump Btu/h capacity and efficiency are directly related to the

GPM flow through the unit.

Vibration pad – We recommend setting the unit on a sound vibration pad, available from most distributors or

accessories price sheet – E2-0122.

Water quality – Models with standard copper heat exchanger coils require the installer to evaluate water quality

and meet minimum water properties.

pH < 7.5

Calcium hardness < 100 PPM

Iron fouling < 0.2 PPM (Ferrous)

< 0.5 PPM of oxygen

Hydrogen sulfide (H

S) < 0.5 PPM

2

Chloride levels < 20 PPM

Erosion/clogging < 10 PPM, particles

Filter, if required < 800 micron size

Softened water is recommended along with 2 oz of common house chlorine bleach for every 10 gallons of

water.

12/06/2012 13 GI202

Figure 4 – Non-Pressurized Closed Loop with Flow Center – Typical piping diagram.

Figure 5 – Pressurized Closed Loop with Flow Center – Typical piping arrangement.

12/06/2012 14 GI202

Antifreeze

When considering the earth loop solution, water quality is very important. TTHERM GEO recommends a

minimum of soft water (not well water) treated with 2 oz. of household chlorine bleach for each 10 gallons of

total volume. TTHERM GEO’s recommended antifreeze concentration is 22% which will yield a freeze

protection of 18° F. This concentration of glycol requires additional additives to protect the system. TTHERM

GEO recommends Enviro-Guard HD propylene glycol for this reason.

Over antifreeze protecting a loop field decreases pumping capacity when the loop gets cold and reduces thermal

transfer. Under protecting a loop field will cause the THERM GEO heat pump to take action protecting itself

from damage. This action will result in a loss of geothermal capacity, and AUX heat may be required to

maintain the temperature in the home.

Table 2 – Approximate Fluid Volume (gal) per 100ft

Pipe Size Volume Pipe Size Volume

Polyethylene

¾” IPS SDR 11 3.02 1” 4.1

1” IPS SDR 11 4.73

1-1/4” IPS SDR 11 7.55 1” 4.5

1-1/2” IPS SDR 11 9.93 1.25” 6.8

2” IPS SDR 11 15.36

Rubber Hose

Copper

Type M

1.25” 6.4

1.5” 9.5

WARNING

PREVENTING FREEZE-UP IS INSTALLER/USER RESPONSIBILITY. DAMAGE CAUSED BY

FREEZE-UP IS NOT COVERED BY WARRANTY.

CAUTION

Softened water is recommended along with 2 oz of common household chlorine bleach for every

10 gallons of water.

WARNING

NOT ALL GLYCOLS PROVIDE THE SAME LEVEL OF CONCENTRATION. MOST GLYCOLS

DO NOT CONTAIN ENOUGH INHIBITORS FOR THE RECOMMENDED CONCENTRATION

LEVELS.FOR GEOTHERMAL SYSTEMS..

Open Loop– An open system gets its name from the open discharge of water after it has been used by the heat

pump. A well pump and well must be available that can supply all of the water requirements of the heat pump

along with any other water requirements drawing off that same well. The well must be capable of supplying the

heat pumps required flow rated for up to 24 hours per day for the coldest winter day.

Figure 6 shows the necessary components for water piping of an open system. First a bladder type pressure tank

with a “draw down” of at least 1-1/2 to 2 times the well pump capacity must be installed on the supply side of

the heat pump to prevent short cycling the well pump. Constant pressure well pumps need to deliver the GPM

flow rate of the TTHERM GEO heat pump and other possible consecutive demands. Shut off valves and boiler

drains on the entering and leaving water lines are necessary for future maintenance. A screen strainer is placed

on the supply line with a mesh size of 40 to 60 and enough surface area to allow for particle buildup between

cleanings. Hose kits are installed between the heat pump and ridged plumbing to reduce vibration transfer. Hose

kits have pressure temperature (P/T) plugs placed in the supply and discharge hydrant elbows so that

12/06/2012 15 GI202

Loading...

Loading...