查询OP280供应商

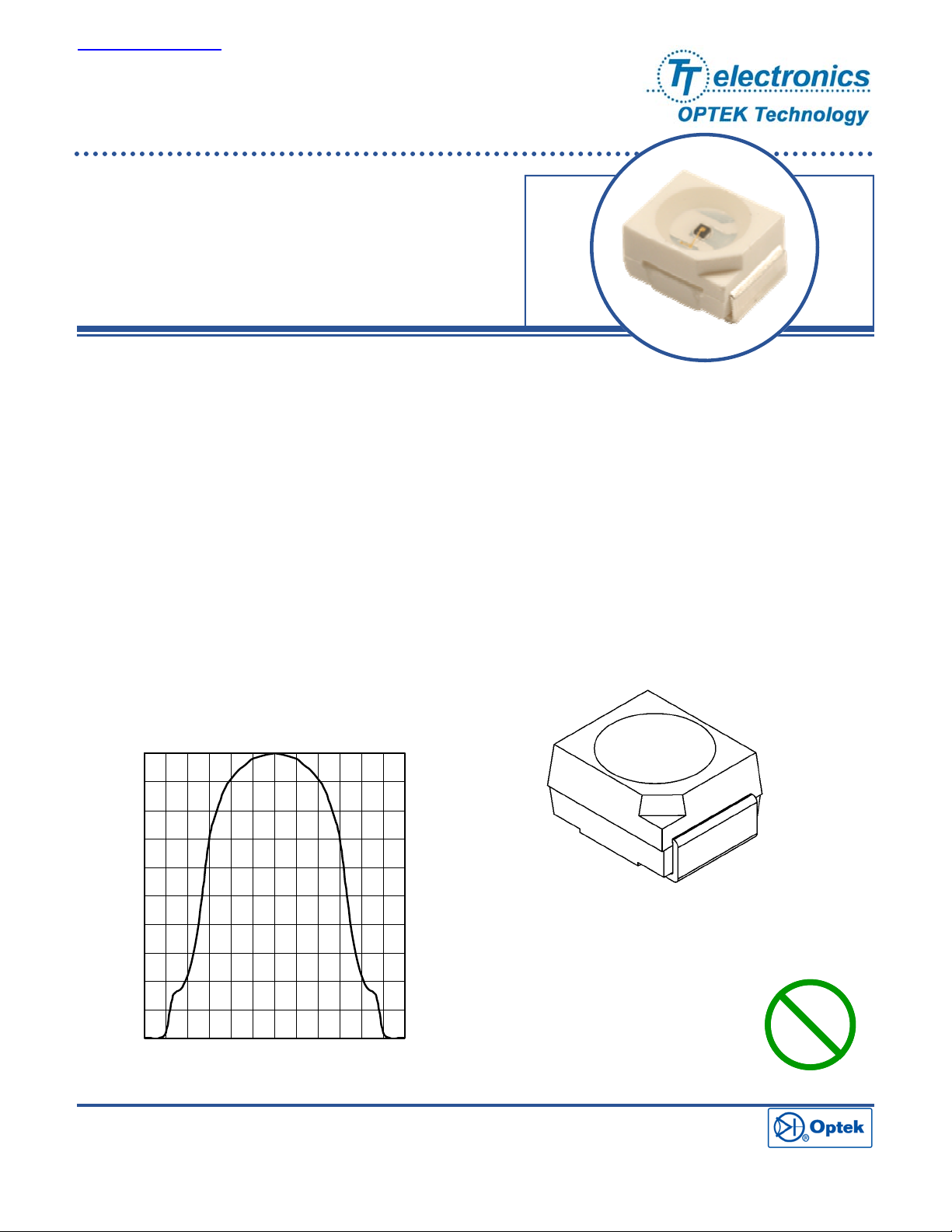

Infrared Light Emitting Diode

in SMT Plastic Package

OP280

• Wide Beam Angle

• High Power

• Plastic Leadless Chip Carrier (PLCC-2)

• 880nm Wavelength

The OP280 is a GaAlAs infrared LEDs mounted in a plastic SMT package. The device flat lens window which allows a wide beam angle. This device is packaged in a plastic leadless chip carrier (PLCC-2) that is suitable for

single device or array applications. The OP280 is mechanically and spectrally matched to the OP580 phototransistor.

Applications

• Non-Contact Position Sensing

• Datum detection

Relative Radiant Intensity vs.

Angular Displacement

100%

80%

60%

40%

• Machine automation

• Optical encoders

OP280

Relative Radiant Intensity

20%

0%

-90 -60 -30 0 30 60 90

Angular Displacement (Degrees)

Optek reserves the right to make changes at any time in order to improve design and to supply the best product possible.

OPTEK Technology Inc.— 1645 Wallace Drive, Carrollton, Texas 75006

Phone: (800) 341-4747 FAX: (972) 323– 2396 sensors@optekinc.com www.optekinc.com

Pb

RoHS

A subsidiary of

TT electronics plc

SMT Infrared LED

OP280

Absolute Maximum Ratings

TA = 25o C unless otherwise noted

Storage Temperature Range -40° C to +85° C

Operating Temperature Range -25° C to +85° C

Lead Soldering Temperature 260° C

Reverse Voltage 30 V

Continuous Forward Current 50 mA

Power Dissipation 130 mW

Notes:

1. Solder time less than 5 seconds at temperature extreme.

2. De-rate linearly at 2.17 mW/° C above 25° C.

(1)

(2)

Electrical Characteristics (T

SYMBOL PARAMETER MIN MAX UNITS CONDITIONS

E

Apertured Radiant Incidence 0.5 mW/cm2 IF = 20mA

e(APT)

VF Forward Voltage 1.5 V I

IR Reverse Current 100 µA VR = 2.0V

λP Peak Emission Wavelength nm IF = 10mA

ΘHP Emission Angle at Half Power Points 100 Deg. IF = 20mA

tr, tf Rise and Fall Time 500 ns I

3. E

is a measurement of the apertured radiant incidence upon a sensing area 0.081” (2.06mm) in diameter, perpendicular to and cen-

e(APT)

tered on the mechanical axis of the lens, and 0.590” (14.99mm) from the measurement surface. E

the measured area.

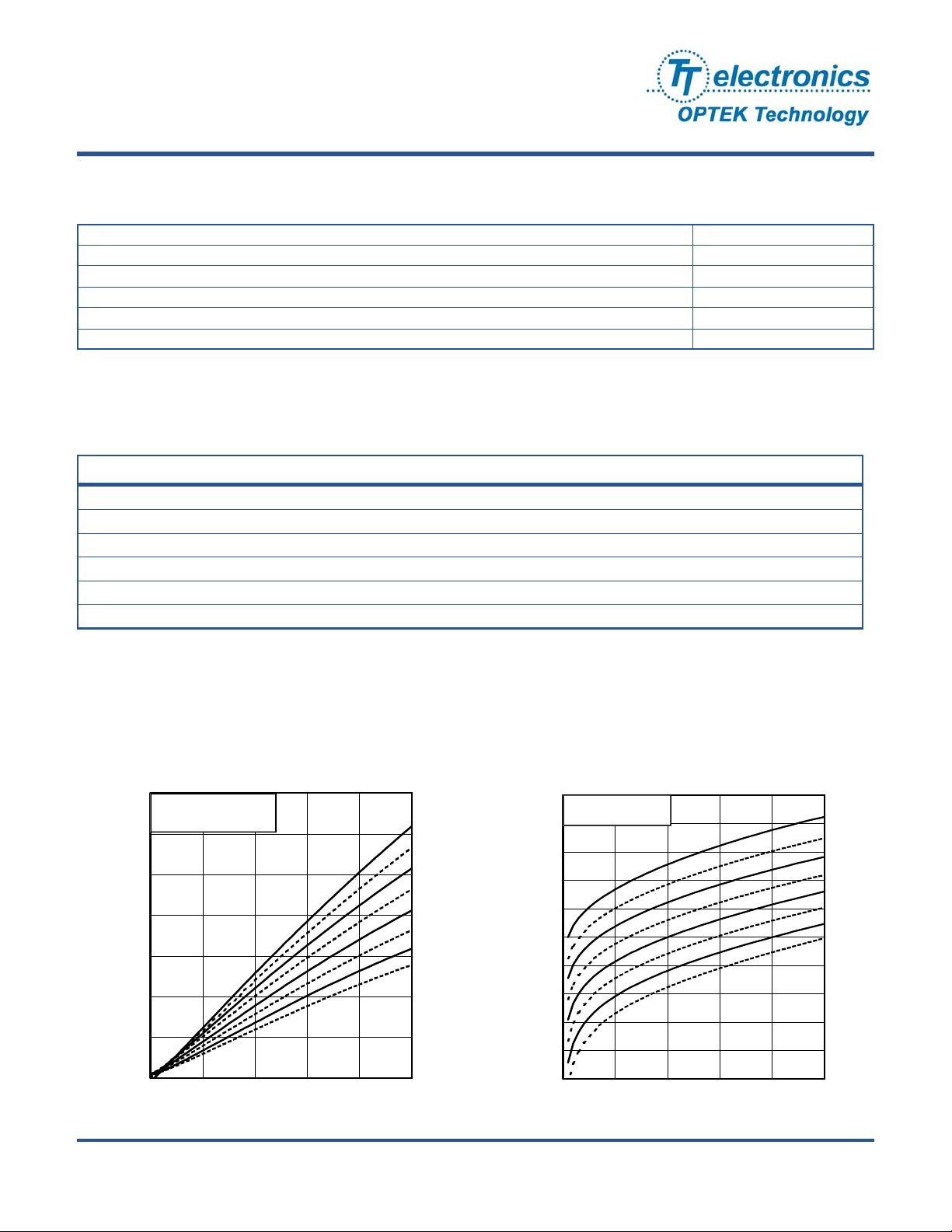

Relative Radiant Intensity vs.

Forward Current vs. Temperature

350%

Normalized at IF = 20mA,

TA = 20°C. Temperatures

stepped in 20°C Increments

300%

250%

= 25°C unless otherwise noted)

A

TYP

890

1.5

-40°C

1.4

(3)

= 20mA

F

= 100mA, PW = 10µs, 10% D.C.

F(PEAK)

is not necessarily uniform within

e(APT)

Forward Voltage vs. Forward

Current vs. Temperature

Temperatures stepped

in 20 °C Increments

-40°C

200%

150%

100%

Relative Radiant Intensity

50%

0 10 20 30 40 50

100°C

Forward Current (mA)

OPTEK Technology Inc.— 1645 Wallace Drive, Carrollton, Texas 75006

Phone: (800) 341-4747 FAX: (972) 323– 2396 sensors@optekinc.com www.optekinc.com

1.3

1.2

Forward Voltage (V)

1.1

1.0

0 10 20 30 40 50

Forward Current (mA)

100°C

Issue 1.1 07.05

Page 2 of 3

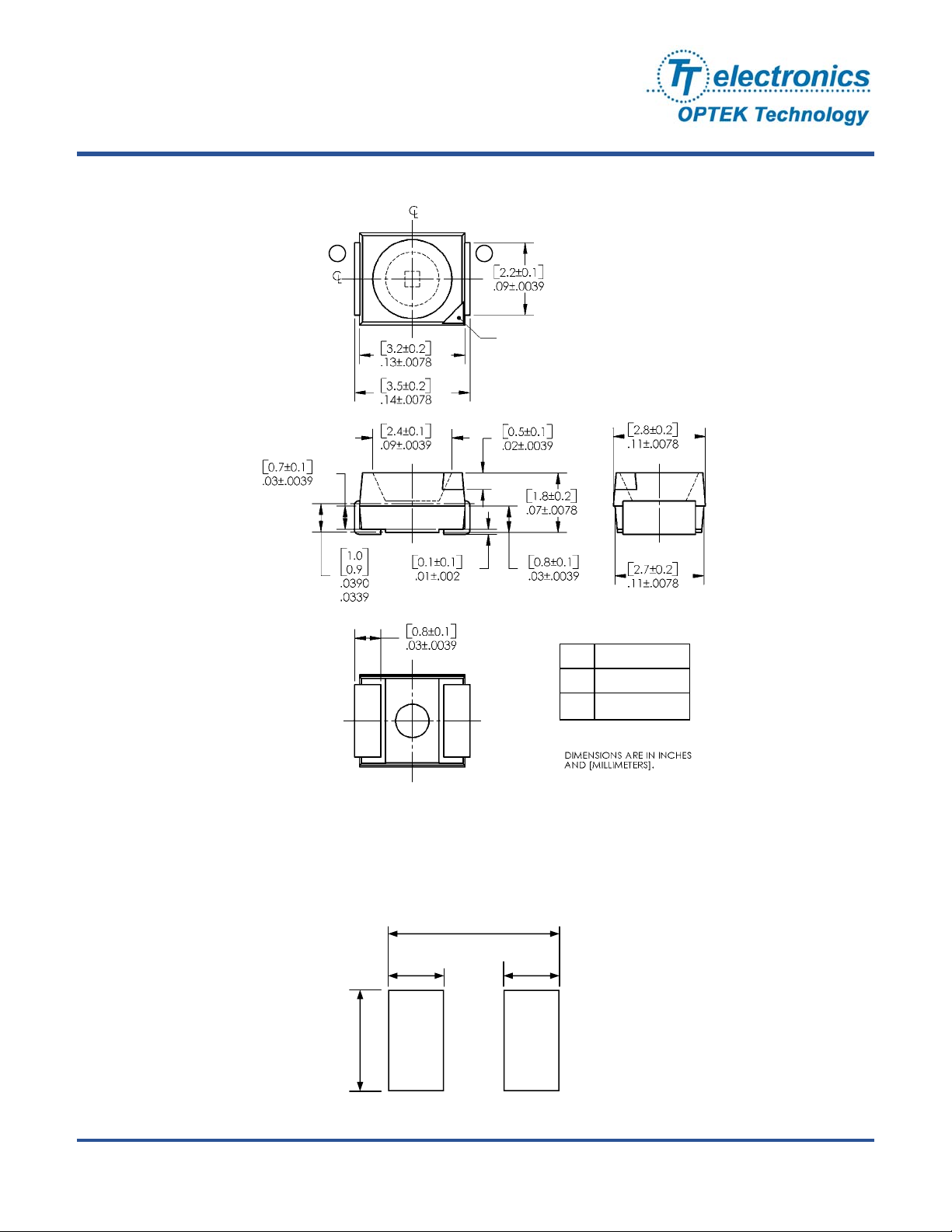

SMT Infrared LED

OP280

1

2

ANODE MARK

PIN FUNCTION

1 Cathode

2 Anode

RECOMMENDED SOLDER PADS

[4.50±0.10]

.177±.0039

[1.50±0.10]

.059±.0039

[2.60±0.10]

.102±.0039

OPTEK Technology Inc.— 1645 Wallace Drive, Carrollton, Texas 75006

Phone: (800) 341-4747 FAX: (972) 323– 2396 sensors@optekinc.com www.optekinc.com

[1.50±0.10]

.059±.0039

Issue 1.1 07.05

Page 3 of 3

Loading...

Loading...