Tubular Vitreous Enamelled

Wirewound Resistors

1600/1900 Series

•

Impervious lead free vitreous enamel coating

• Can be supplied with fixed, adjustable,

tapped or low inductance winding

• Seven termination styles with choice of

mounting arrangements

• Manufactured RoHS compliant

Pb-free terminations*

* Check status of stock when ordering

General Note

Welwyn Components reserves the right to make changes in product specification without notice or liability.

All information is subject to Welwyn’s own data, relates to current manufacture and is considered accurate at time of going to print.

© Welwyn Components Limited · Bedlington, Northumberland NE22 7AA, UK

Telephone: +44 (0) 1670 822181 · Facsimile: +44 (0) 1670 829465 · Email: info@welwyn-tt.com · Website: www.welwyn-tt.com

121

1601 1905 1600 1602 1906 1603 1604

Power rating at 70°C watts 11 16 16.5 17 22 25 35

Resistance range ohms See Table 1

Limiting element voltage volts See Table 1

TCR (-55 to +200°C) ppm/°C Typically: <+75 Maximum + 200

Resistance tolerance % 1, 2, 5, 10 See table 1 for value restrictions

Values E24 preferred

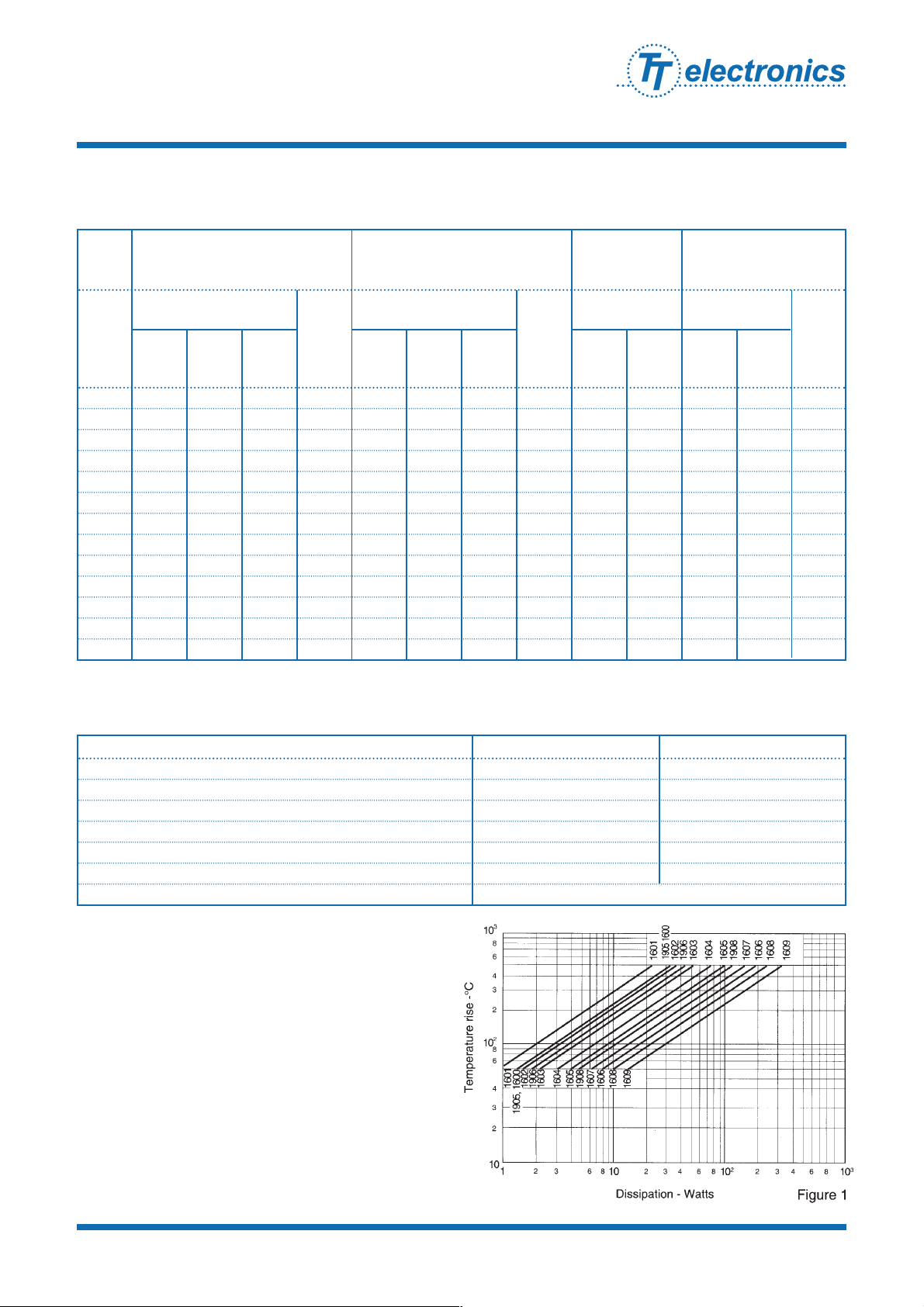

Thermal impedance °C/watt See fig. 1

Operating temperature range °C -55 to +375

1605 1908 1607 1606 1608 1609

Power rating at 70°C watts 47 54 76 91 115 165

Resistance range ohms See Table 1

Limiting element voltage volts See Table 1

TCR (-55 to +200°C) ppm/°C Typically: <+75 Maximum + 150

Resistance tolerance % 1, 2, 5, 10 See table 1 for value restrictions

Values E24 preferred

Thermal impedance °C/watt See fig. 1

Operating temperature range °C-55 to +375

Electrical Data

Issue E · 10.05

A subsidiary of

TT electronics plc

Welwyn Components

Note See Figure 1 for curves of temperature rise / watts dissipation.

General Information

Vitreous enamelled wirewound resistors are capable of

withstanding a higher dissipation size for size, than any other

protected type; this is attributable to the higher operating

temperature which the wire and enamel can withstand.

Vitreous enamel provides exceptionally good protection to the

wire element and is essentially impervious to moisture. The

resistors can safely be used in harsh environmental conditions.

The Welwyn range is based on thirteen sizes of tube, each of

which has a recommended maximum dissipation which limits

operating surface temperature to a maximum of 375°C.

The stability and high reliability of Welwyn tubular vitreous

resistors is a direct result of the best quality materials being

used in their construction.

High purity ceramic tubes have been matched with nickel

chromium resistance wires and specially formulated enamel to

ensure that the resistors can withstand repeated heat cycling

without damage.

Connections between the resistance element and end

terminations are welded; other connections are brazed.

Mounting devices are available which permit resistors to be

mounted by both ends or by one end. Single ended mounting

is recommended for applications which do not subject the

resistor to shock or vibration.

Ferrules and the F type mounting plug are anchored into the

tubes with high temperature adhesive.

Special requirements, for types or styles not described

in this brochure, will be considered for economic

quantities.

*The stated dissipation applies to resistors mounted horizontally with unobstructed bore.

Performance Data

*Dissipation (watts) to Resistance range (ohms) Limiting Low inductance

produce operating element winding resistance

hotspot temperature (°C) of: voltage range (ohms)

Ambient = 20°C Ambient Minimum Termination Min. res. at

= 70°C resistance at style

Type

Max. at Max. at

any either

200 300 375 375 ±5% ±2% ±1% tolerance C

All others

±10% ±5%

tolerance

1601 5 10 14 11 1 15 25 15k 250 150 10 50 1.3k

1905 7 14.5 20 16 1 15 30 30k - 450 10 50 3.5k

1600 7.5 15 21 16.5 1 15 30 56k - 600 10 50 5.0k

1602 8 15.5 22 17 1 20 25 43k 500 350 10 50 4.0k

1906 9.5 19 28 22 1 20 30 50k 700 550 10 50 5.5k

1603 11 22 32 25 1 20 30 83k 850 750 10 50 7.5k

1604 15.5 31 45 35 1 20 60 100k 1300 1000 15 50 11.5k

1605 21 41 59 47 1 30 40 100k 1100 900 15 50 14k

1908 24 47 68 54 1 30 40 100k 1200 1000 10 50 16k

1607 34 66 95 76 1 30 50 100k 1300 900 15 50 22k

1606 41 80 115 91 1 30 40 160k 2100 1900 15 50 32k

1608 52 101 145 115 1 30 50 180k 2100 1800 20 50 38k

1609 74 145 208 165 1 35 50 250k 3000 2500 30 100 58k

Tubular Vitreous Enamelled

Wirewound Resistors

1600/1900 Series

© Welwyn Components Limited Bedlington, Northumberland NE22 7AA, UK

Telephone: +44 (0) 1670 822181 · Facsimile: +44 (0) 1670 829465 · Email: info@welwyn-tt.com · Website: www.welwyn-tt.com

122

Issue E · 10.05

Welwyn Components

Max Typ

Load : 1000 hours at 70°C ∆R% 5.0 3.5

Shelf life : 12 months at room temperature ∆R% 1.0 0.1

Climatic ∆R% 0.5 0.35

Long term damp heat ∆R% 0.2 0.05

Bump and vibration ∆R% 0.1 0.02

Noise (in a decade of frequency) ∆R% zero zero

Pulse Handling Data Available by request

Electrical Data

(continued)

Table 1

Tubular Vitreous Enamelled

Wirewound Resistors

1600/1900 Series

© Welwyn Components Limited Bedlington, Northumberland NE22 7AA, UK

Telephone: +44 (0) 1670 822181 · Facsimile: +44 (0) 1670 829465 · Email: info@welwyn-tt.com · Website: www.welwyn-tt.com

123

Issue E · 10.05

Welwyn Components

ABCDEFGHJK

Type max max max nom max max nom ±.25 max

1601 33.0 17.5 8.2 4.5 5.0 19.5 15 3.0 M3 59

1905 56.1 14.5 6.55 4.5 5.0 17.5 10 3.0 M3 -

1600 61.5 14.5 6.55 4.5 5.0 17.5 10 3.0 M3 -

1602 51.0 17.5 8.2 4.5 5.0 19.5 15 3.0 M3 77

1906 64.3 17.5 8.2 4.5 5.0 19.5 15 3.0 M3 90

1603 74.5 17.5 8.2 4.5 5.0 19.5 15 3.0 M3 101

1604 102 17.5 8.2 4.5 5.0 19.5 15 3.0 M3 128

1605 89.5 24.0 13.2 5.7 6.8 26.5 17 4.0 M4 122

1908 102 24.0 13.2 5.7 6.8 26.5 17 4.0 M4 134

1607 102 32.0 19.2 7.0 9.8 32.0 22 6.4 M6 134

1606 166 24.0 13.2 5.7 6.8 26.5 17 4.0 M4 198

1608 152 32.0 19.2 7.0 9.8 32.0 22 6.4 M6 184

1609 216 32.0 19.2 7.0 9.8 32.0 22 6.4 M6 248

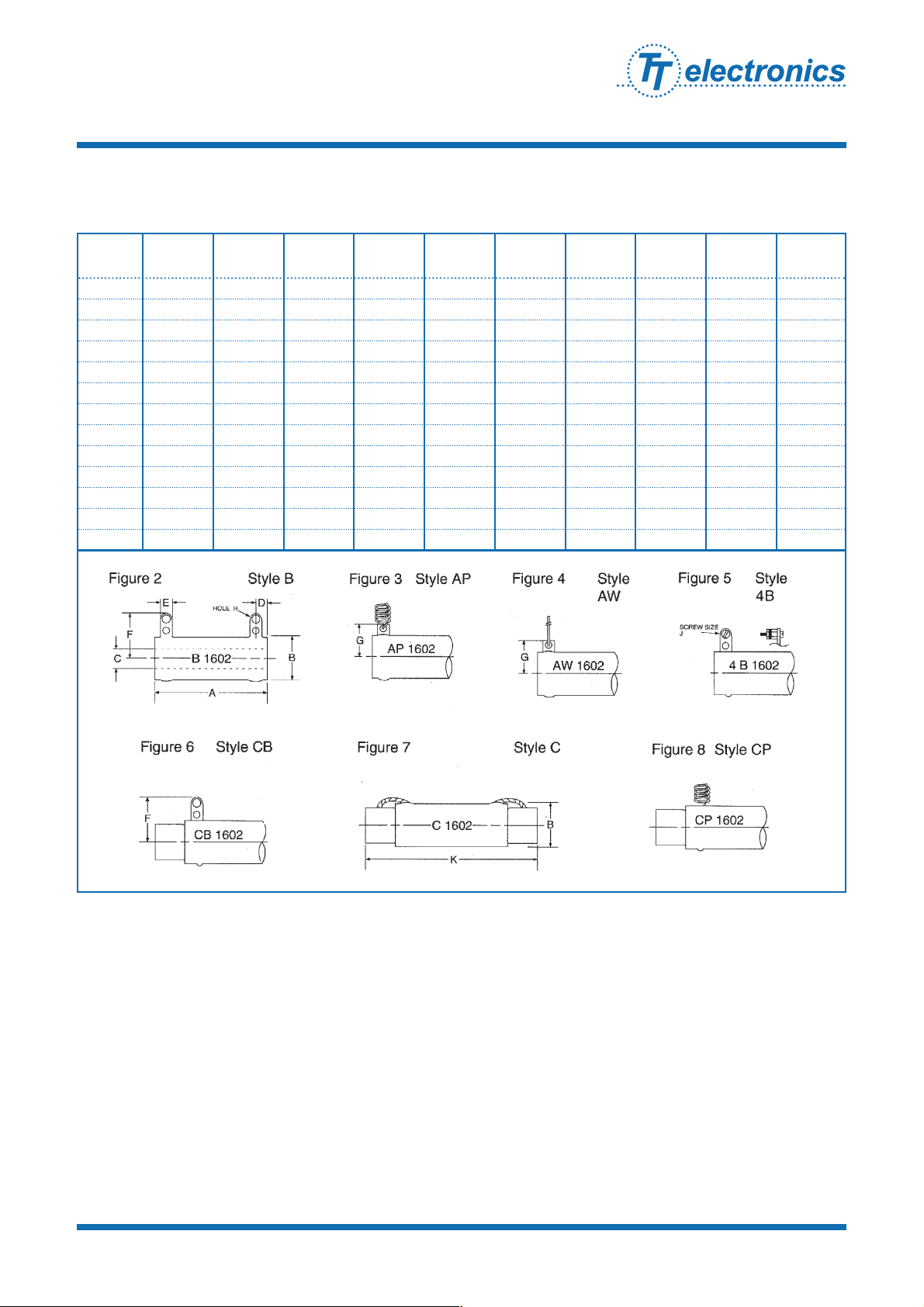

Terminations

Styles B, 4B, AP and AW are available in all 13 tube sizes.

Styles C, CB and CP are available in sizes 1601 to 1609

inclusive, 1906 and 1908

Lugs (Figure 2): Pb free solder coated nickel iron. Denoted

by prefix B to size reference, thus B1602

Pigtails (Figure 3): 14/.193 mm copper, 150 mm minimum

length. Denoted by prefix AP, thus AP1602

Rigid wires (Figure 4): 1.2 mm diameter tinned copper, 32

mm minimum length.

Denoted by prefix AW, thus: AW1602

Lugs with screws, nuts and washers (Figure 5): Nickel

plated brass screws and nuts. Denoted by prefix 4B,

thus: 4B1602.

Ferrule, electrically isolated (Figure 6) Connection to

resistor via Pb free solder coated nickle iron lugs. Denoted

by prefix CB, thus: CB1602.

Ferrule, electrically live (Figure 7) Nickel plated brass.

Denoted by prefix C, thus: C1602.

Ferrule, electrically isolated (Figure 8): Connection to

resistor via pigtails of 14/.193 mm copper, 150mm

minimum length. Denoted by prefix CP thus: CP1602

Marking The resistors are legend marked with type

reference, resistance value, tolerance and manufacturing

date code. Value marking conforms to IEC 62.

Solvent resistance: The vitreous coating and marking are

resistant to all accepted industrial cleaning fluids.

Physical Data

Table 2 Dimensions in millimetres. See fig 2-8 for styles

Tubular Vitreous Enamelled

Wirewound Resistors

1600/1900 Series

© Welwyn Components Limited Bedlington, Northumberland NE22 7AA, UK

Telephone: +44 (0) 1670 822181 · Facsimile: +44 (0) 1670 829465 · Email: info@welwyn-tt.com · Website: www.welwyn-tt.com

124

Issue E · 10.05

Welwyn Components

Table 3

Adjustable Resistors (see Figure 9)

Adjustable resistors use the same basic construction as fixed

resistors already described, and have a window in the vitreous

enamel through which contact is made to the resistive

element by a sliding contact band. The band is fitted with a

clamping screw and nut to retain it firmly in position.

The adjustable winding style has a maximum permissible hot

spot temperature of 300°C and the maximum dissipation, for

an ambient temperature of 20°C, is specified in Table 4. The

partial open winding necessitates a reduced maximum

resistance, when compared with fixed resistors, and the

resistance range is also defined in Table 4.

More than one adjusting band can be fitted, up to the

maximum number specified in Table 3.

Adjustable resistors are available in termination styles B, 4B,

AP, C, CB and CP, in sizes 1602 to 1609 inclusive and 1906

and 1908 denoted by prefix ‘V’.

Manufactured Values

E24 preferred

Standard Selection Tolerance ±10%

All other details of the electrical and environmental

performance of adjustable resistors are the same as for

fixed resistors.

Max. dissipation in Resistance range (ohms)

20°C ambient (watts)

Type

Min. for Min. for Max. for

200°C 300°C styles VC, all other all styles

hot spot hot spot VCP styles

1602 8 15.5 4 3 1.6k

1906 9.5 19 4 3 2.5k

1603 11 22 6 6 3.0k

1604 16 31 8 8 5.3k

1605 21 41 6 6 4.5k

1908 24 47 11 10 7.5k

1607 34 66 11 9 8.1k

1606 41 80 14 13 13.2k

1608 52 101 17 16 15.4k

1609 74 145 25 24 25.5k

Tube A mm B mm Hole C Max. no of

size max. max. dia. mm adjusting

bands

1602

1603 20 27 3.2 1

1906

1604

1605 20 27 3.2 3

1908 25 32 3.7 2

1606 25 32 3.7 4

1607 30 38 3.7 2

1608 30 38 3.7 3

1609 30 38 3.7 5

Table 4

Tubular Vitreous Enamelled

Wirewound Resistors

1600/1900 Series

© Welwyn Components Limited Bedlington, Northumberland NE22 7AA, UK

Telephone: +44 (0) 1670 822181 · Facsimile: +44 (0) 1670 829465 · Email: info@welwyn-tt.com · Website: www.welwyn-tt.com

123

Issue E · 10.05

Welwyn Components

Maximum* Maximum* Maximum*

total resistance number

dissipation with single of taps

in 20°C tap

ambient (ohms)

(watts) with

Type single tap

1905 14.5 9k 1

1600 15.0 12k 1

1602 15.5 9k 1

1906 19.0 13k 1

1603 22 18k 1

1604 31 29k 2

1605 41 34k 2

1908 47 38k 2

1607 66 53k 2

1606 80 78k 4

1608 101 93k 4

1609 145 140k 4

Tapped Resistors See Figure 10

Fixed resistors can be supplied with taps to special order.

Because of the reduced winding length, the total resistance of

a tapped resistor will be less than can be offered on a fixed

resistor of the same size. The reduction is proportional to the

number of taps and Table 5 is intended as a guide.

The minimum resistance per section on all sizes is 1Ω and the

standard selection tolerance for any section is ±10%

Ordering Procedure

Enquiries for tapped resistors must state the following details:

Resistance per section

Maximum dissipation per section

Maximum operating ambient temperature

Maximum permissible dimensions if important

Type of terminations required. (See ‘Terminations’, page 3)

Resistor style or proposed method of mounting.

Table 5

*Maximum total dissipation assumes that this will be

evenly spread over the total element length.

Low Inductance Resistors

Ayrton-Perry wound elements are supplied for low inductance

applications. This winding style has a maximum permissible

hot spot temperature of 300°C. The maximum dissipation is

defined in Table 1 under the heading Operating hot spot

temperature of 300°C, and resistance ranges are defined in

the three right-hand columns of this table.

Application Notes

When cold, vitreous enamel has excellent insulation resistance.

In common with all insulants the specific resistance of the

enamel decreases with increased temperature; therefore, if

operated at any temperature approaching the maximum, the

resistor cannot be classed as an insulated type and should not

be used in contact with any conducting materials.

The recommended dissipations for each of the resistor hot

spot temperatures applies to resistors mounted horizontally. If

the bore is completely blocked a 15% derating is

recommended. However, wherever possible, resistors should

be mounted vertically with unobstructed bore.

This makes best use of the chimney effect of the heated tube

and will encourage a cooling stream of air through the bore.

Allowances must be made, when tubular resistors are mounted

in banks, for the effects produced by radiation between tubes.

Appreciable reduction of hot spot temperature can be

achieved by arranging that resistors are subjected to some

measure of forced draught. In general, it is most efficient to

extract air from the resistor enclosure and arrange that an air

inlet is adjacent to the bottom of the tubes.

If soft soldered connections are used the resistors should be derated

where applicable to limit the hot spot temperature to 300°C.

Tubular Vitreous Enamelled

Wirewound Resistors

1600/1900 Series

© Welwyn Components Limited Bedlington, Northumberland NE22 7AA, UK

Telephone: +44 (0) 1670 822181 · Facsimile: +44 (0) 1670 829465 · Email: info@welwyn-tt.com · Website: www.welwyn-tt.com

126

Issue E · 10.05

Welwyn Components

Bracket Type A B C D E

ref. nom nom nom nom nom

MD40 1600 78 92 10 20 4.2

1905 73 87

1601 50 64

1602 68 82

MD41 1603 91 105 13 20 4.2

1604 119 133

1906 81 95

MD42 1605 106 120

1606 183 197 20 25 5.2

1908 119 133

1607 121 143

MD43 1608 171 193 28 30 5.2

1609 235 257

Ordering Procedure

Mounting brackets should be ordered in

units and the type reference specified.

Ordering Procedure

Mounting clips (and auxiliary locking

springs when required) should be ordered

in units and the type reference specified.

Ordering Procedure

Mounting plugs are denoted by the prefix

‘F’ added to the size reference;

e.g. BF1602 and APF1602.

Clip Type A B C D E F G H J K Auxiliary

ref. type nom. max nom. max max max ±0.2 dia dia nom locking

spring ref

1601 52 68

1602 70 86

MD1

1603 90 106 29 19 17.5 14.5 4.8 4.0 3.9 7.2 MD16

MD4

1604 121 137

1605 108 128

1906 83 99

1607 125 146

MD3

1608 176 197 49 33 32.0 19.0 6.4 4.0 6.3 9.5 MD18

MD6

1609 240 261

Table 6 mounting clip dimension (mm) See Fig. 11

Table 7 Mounting brackets dimensions (mm). See Fig. 12.

Table 8 Mounting plug dimensions (mm) See Fig. 13.

These mounting clips are suitable for termination styles C, CB and CP.

MD4, 5 and 6 have an ear formed in the bottom surface of the bracket to

prevent rotation of the mounting plate. The auxiliary locking springs

ensure positive retention of the tube under severe mechanical shock

conditions. See Figure 11.

These brackets are suitable for termination styles B, 4B, AP & AW

F type bushes are suitable for termination styles B, 4B AP and AW

Type A B C

Min. Max.

1601

1602

1603 1.6 3.7 5.3 M4

1604

1906

1605

1606 1.6 3.7 5.3 M5

1908

1607

1608 3.2 5.2 6.8 M6

1609

Tubular Vitreous Enamelled

Wirewound Resistors

1600/1900 Series

© Welwyn Components Limited Bedlington, Northumberland NE22 7AA, UK

Telephone: +44 (0) 1670 822181 · Facsimile: +44 (0) 1670 829465 · Email: info@welwyn-tt.com · Website: www.welwyn-tt.com

Issue E · 10.05

Welwyn Components

C 1601 - 10R J I

Tube Size

Value (USE IEC62 code)

Ordering Procedure

Specify the full type reference, resistance value and tolerance, using IEC 62 code references.

The addition of L to the prefix describing terminal configuration indicates Ayrton-Perry winding.

Example: Electrically live ferrule terminated 1601 size at 10 ohms and 5% -

Fixed

V Adjustable

F1%

G2%

J5%

K 10%

I Box Standard

Packing

Adjustable Option

Termination Style

B AP AW 4B CB C CP See Figures 2 to 8

Winding & Mounting Options

Tolerance (use IEC62 code)

Standard

L Low Inductabce

F Mounting plug

Note - consult data sheet in detail for valid combinations.

Minimium Ordering Quantity: 10

Order Multiple: 1

Loading...

Loading...