TRANSMISSION

SERVICE

TECHNOLOGY

TT100

USER’S GUIDE

SAFETY SUMMARY

WARNING – MOTION HAZARDS

Engine parts that are in motion can cause serious injury or death. When working near moving engine parts,

wear snug fit clothing and keep hands, fingers and hair away from moving parts. Keep hoses and tools

clear of moving parts. Hoses and tools can be thrown through the air if not kept clear of moving engine

parts. Never wear loose fitting clothing or allow long hair to be exposed to the engine compartment.

The unexpected movement of a vehicle can cause serious injury or death. When working on a vehicle,

always set the parking brake or block the wheels of the vehicle being serviced.

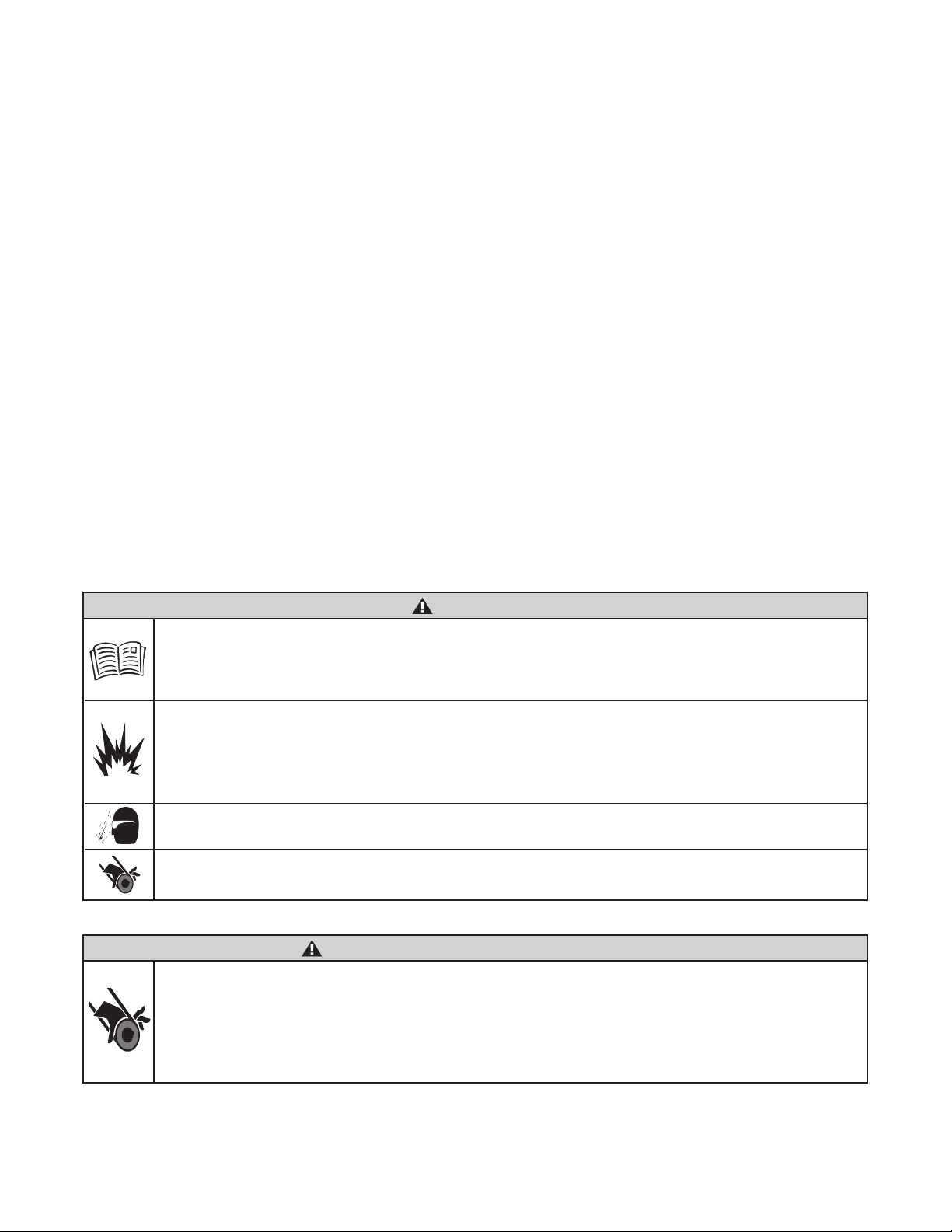

WARNING

Read these instructions completely before using the T- T ECH and save them for future reference.

Before using the T- T ECH, read these instructions and the instruction manual/safety information

provided by the car, truck, boat or equipment manufacturer. Following all manufacturers’

instructions and safety procedures will reduce the risk of accident.

All lead-acid batteries (car, truck and boat) produce hydrogen gas which may violently explode in

the presence of fire or sparks. Do not smoke, use matches or a cigarette lighter while near

batteries. Do not handle the battery while wearing vinyl clothing because static electricity sparks

are generated when vinyl clothing is rubbed. Review all cautionary material on the T- T ECH and in

the engine compartment.

Always wear eye protection, appropriate protective clothing and other safety equipment when

working near lead-acid batteries. Do not touch eyes while working on or around lead-acid batteries.

Use extreme care while working within the engine compartment, because moving parts may cause

severe injury. Read and follow all safety instructions published in the vehicle's Owner's Manual.

Congratulations on the purchase of your new T-TECH Transmission Fluid Exchange System. The following safety

information is provided as a guideline to help you operate your new transmission fluid exchange system under the

safest possible conditions. Any equipment can be potentially dangerous to use when safety or safe handling

instructions are not known or not followed.

A procedure step preceded by

to a person if proper safety precautions are not heeded. A procedure step preceded by CAUTION is an indication

that the step contains a procedure that might damage the equipment being used.

WARNING is an indication that the step contains a procedure that might be injurious

Safety Instructions

Tools are dangerous if misused or abused. To reduce risk of discomfort, illness, injury or even death, read,

understand, and follow these following safety instructions. In addition, make certain that anyone else that uses this

equipment understands and follows these safety instructions as well.

Retain these instructions for future reference. Read all safety instructions carefully before attempting to install,

operate or service this equipment. Failure to comply with these instructions could result in personal injury and/or

property damage. Published standards on safety are also available. For additional information concerning safety,

refer to the following standards and comply with them, as applicable.

ANSI Standard Z87.1 — SAFE PRACTICE FOR OCCUPATION AND EDUCATIONAL EYE AND FACE PROTECTION

— obtainable from the American National Standards Institute, 1430 Broadway, New York, NY 10018

The following safety alert symbols identify important safety messages in this manual. When you see one of the

symbols shown here, be alert to the possibility of personal injury and carefully read the message that follows.

2

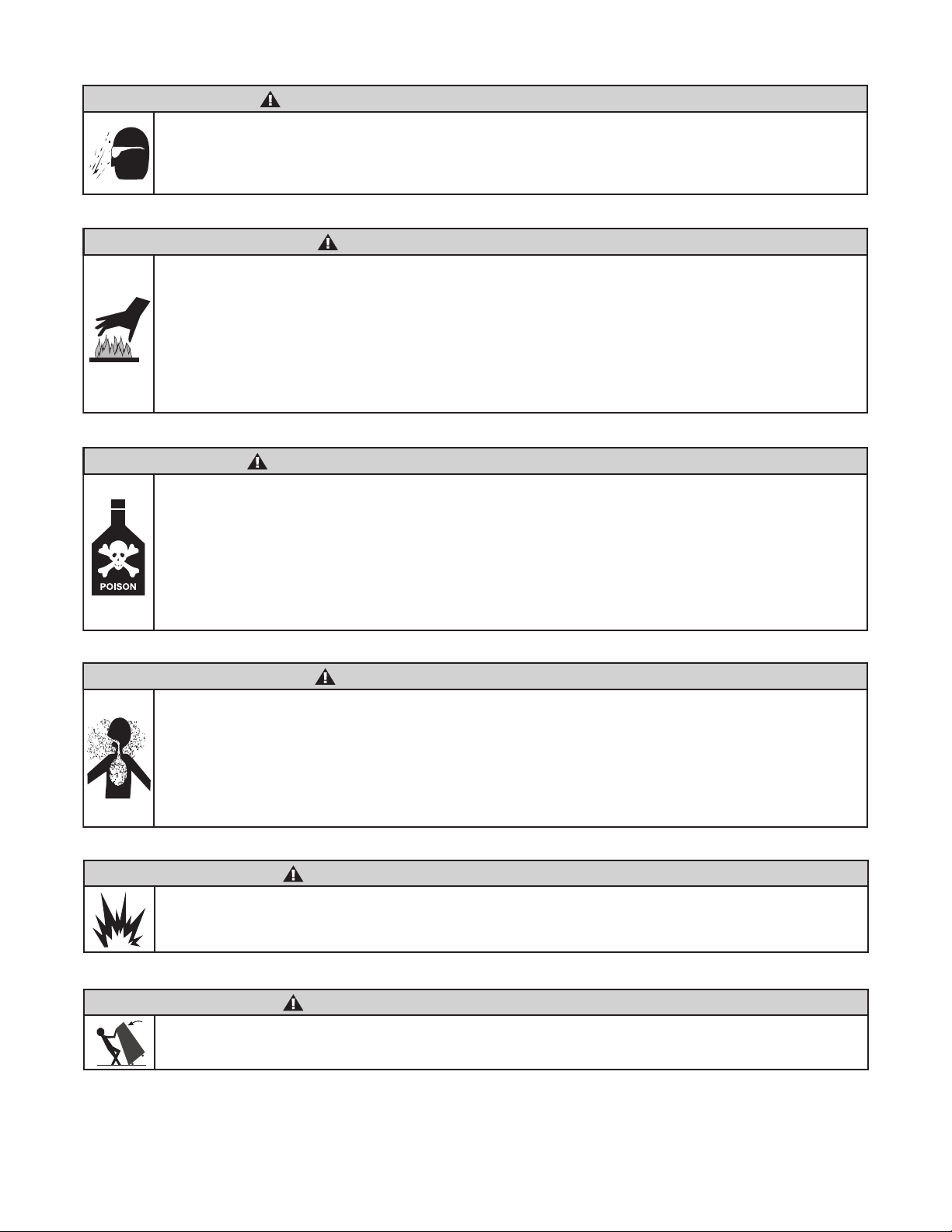

WARNING – HEAT HAZARDS

Vehicle transmissions can be very hot and the fluid is under pressure when the vehicle is running.

Opening a hot, pressurized transmission line can cause hot transmission fluid to be forcibly sprayed

in all directions. Wait until the engine has cooled in the vehicle being serviced before removing a

system line or in any way opening the vehicle transmission system when the system is hot and under

pressure.

Many component parts, in a vehicle that has been running, are hot and can cause serious skin burns.

Take care to not touch hot components. Wait until the vehicle has cooled before attempting to

service.

WARNING – POISONOUS FLUID HAZARDS

This fluid exchanger is intended for transmission fluid only. Transmission fluid is poisonous if

ingested. Ingesting transmission fluid can cause serious illness. Keep transmission fluid where children

and pets cannot get to it. If some transmission fluid should be accidentally swallowed, take the person

or pet in for medical assistance immediately. Be sure to identify to the doctor specifically what it was

that was ingested. If medical assistance is not immediately available, call the local poison center.

Avoid contact with skin and eyes. If skin contact is made, flush affected area with water and wash

immediately. For eye contact, flush with water and apply a suitable eye wash. If irritation persists,

contact a physician.

WARNING – FUME HAZARDS

FUMES, GASSES, AND VAPORS CAN CAUSE DISCOMFORT, ILLNESS, AND DEATH!

Breathing vehicle exhaust emissions can cause sickness, injury, or death. Always work in a properly

ventilated area when servicing a vehicle with the engine running. Never run an engine without proper

ventilation for its exhaust.

Stop the exchange process if you develop momentary eye, nose, or throat irritation. Eye, nose, or

throat irritation indicates inadequate ventilation. Stop work and take necessary steps to improve

ventilation in the work area.

A BATTERY EXPLOSION CAN INJURE, AND CAUSE PROPERTY DAMAGE! A spark near a battery

can cause an explosion. To reduce the risk of a spark near a battery, make the positive connection to

the battery first then the negative connection to the vehicle chassis, at a point away from the battery.

WARNING – EXPLOSION HAZARDS

Do not tip or rock the

T- T ECH

. Such actions could result in serious injury or property damage. Always

lock the wheels when stationary to avoid unintentional movement of the

T- T ECH

.

WARNING – T I P OVER HAZARDS

!

Hot transmission fluid, under pressure, can injure the eyes. Always wear eye protection (safety

glasses) when opening transmission lines to protect the eyes against hot fluids being forcefully

sprayed into them. Ordinary glasses do not have impact resistant lenses, they are NOT safety glasses.

Always clean up transmission fluid spills immediately. Transmission fluid is very slippery when spilled.

WARNING – FLUIDS UNDER PRESSURE

WARNING: This product contains chemicals, including lead, known to the State of California to cause cancer,

birth defects and other reproductive harm. Wash hands after handling.

3

TABLE OF CONTENTS

SAFETY SUMMARY

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Additional Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Fluids Under Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Motion Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Shock Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Heat Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Poisonous Fluid Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Fume Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Explosion Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Tip Over Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

INTRODUCTION

About This MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

The T-TECH Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

T-Tech Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

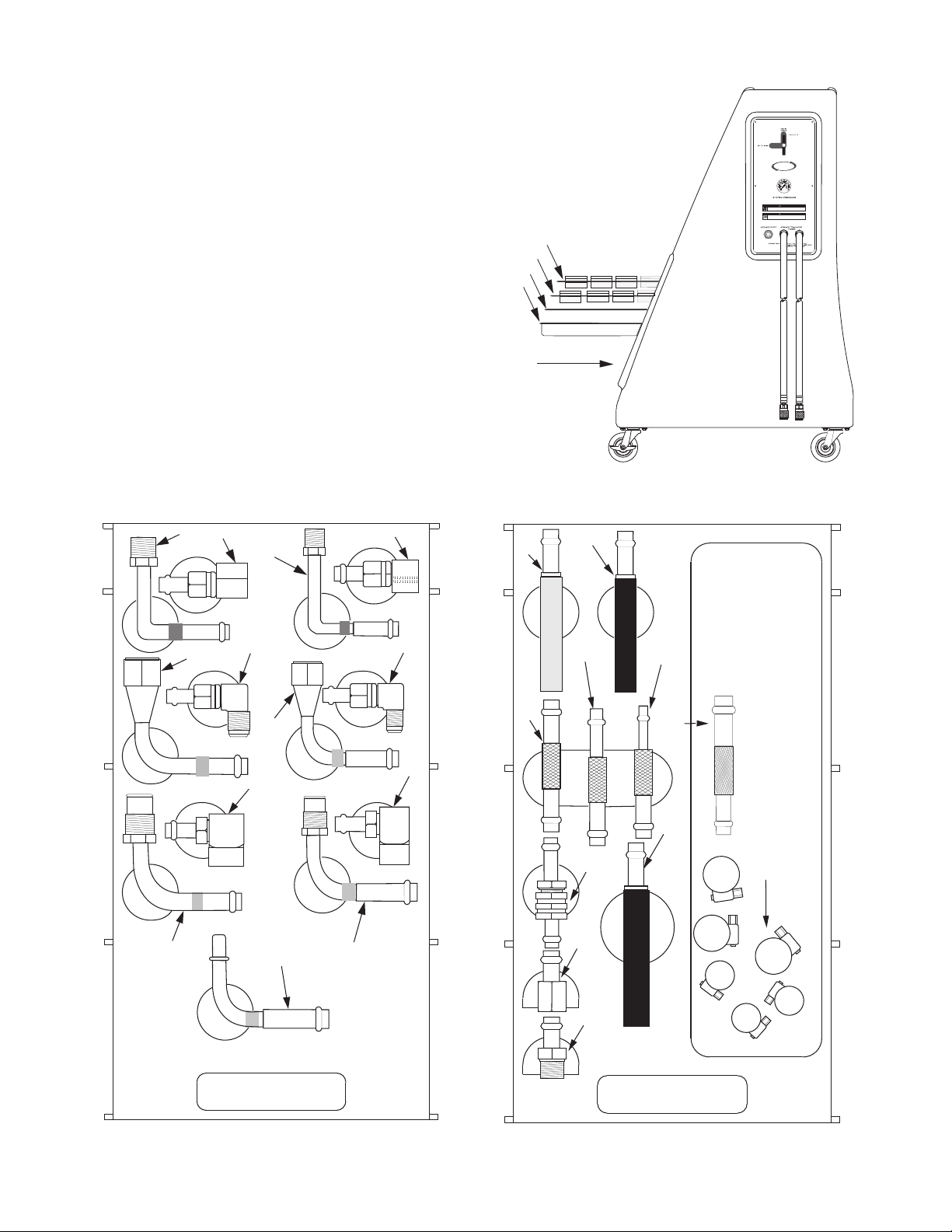

PREPARATION FOR USE

Fitting Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Standard Fittings Assortment Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Cabinet Drawer Storage Layouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Special Fittings Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Removing Air From Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

OPERATION INSTRUCTIONS

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Fill Cylinder Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Using a Bulk Dispenser Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Connecting to the Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Identifying Cooling Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Making Vehicle Service Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Fluid Exchange Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Bypass Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Replace Existing New ATF with Different New ATF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

MAINTENANCE

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

T-TECH APPLICATION NOTES

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

BMW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

BMW General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

BMW 500 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Chrysler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Dodge Dakota (to 1997) and some Ram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Dodge Ram (Pre-2004 Assorted Gasoline engines only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Some Dodge Durango and Dakota 1997-2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Jeep Grand Cherokee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Ford . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Ford Contour . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Ford Escort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Ford Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Ford F-Series Trucks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Ford Taurus & Windstar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Ford Windstar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Mercury Mountaineer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Mercury Mystique . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Mercury Sable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

General Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Quick-Disconnect Equipped Vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Allison Series 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Mazda . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Mercedes-Benz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Nissan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Saab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Toyota . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Volkswagen Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Volvo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

REPLACEMENT PARTS LIST

External Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Internal Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Fittings & Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

PLUMBING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

INTRODUCTION

About This Manual

This manual includes a Safety Summary, Operating Procedures, Machine Preparation, Maintenance Instructions and

Troubleshooting Procedures for transmission fluid exchanging. Anyone intending to use this machine should

become familiar with all the information included in this manual (especially the Safety Summary) before attempting

to use the Transmission Fluid Exchanger. In order to properly perform a complete transmission fluid exchange,

follow all procedures in the order presented. Please take the time to study this manual before operating the

machine. Then keep this manual close at hand for future reference.

The T-TECH Process

Heat is the enemy of transmission fluid. Transmission fluid is a combination of light base oils with an extensive

additive package to control foaming, slip, lubrication, etc. Heat attacks the additive package and oxidizes or burns

it away, leaving you with only the base oils.

In order to slow the oxidation of the additive package, the vehicle manufacturers have designed an oil cooler,

usually in the radiator, that passes all of the transmission fluid through it.

T-TECH uses a patented process of harnessing the pump in the vehicle’s transmission to control the flow of fluid.

This process captures the fluid coming out of the transmission and automatically directs it into the bottom of the

T-TECH cylinder. The used ATF flowing into the bottom of the cylinder pushes against the separating piston and

directs new fluid out the top of the cylinder and back into the vehicle.

The patented T-TECH system makes it IMPOSSIBLE TO HARM A VEHICLE’S TRANSMISSION. The T-TECH

process operates exclusively on the transmission pump pressure, which essentially eliminates the possibility of

over-pressure, under-pressure, overfill or underfill.

T-TECH Fluid Exchange is the preferred method of automatic transmission service because it is designed to offer

the safest and most complete exchange of fluid in the transmission, torque converter, lines and cooler.

The need for a safe and thorough exchange of used ATF has increased as the life expectancy of vehicles increases,

the demands placed on these vehicles grows and the cost of repair rises. Today, nearly every vehicle has an OEMrecommended service for automatic transmissions.

The original pan drop method of service only captured 30% - 40% of the vehicle’s used ATF. Other mechanical

exchange machines force fluid into the vehicle under pressure and can damage the seals inside a transmission.

Discover why vehicle owners throughout North America specify

T-TECH Specifications

Max Pressure: 85 psi, 583 kPa

Weight (approx.): 96 lbs. (43.54 kg)

Depth: 32.5 in. (0.83 m)

Width: 21.5 in. (0.55 m)

Height: 51.5 in. (1.31 m)

Patents: 5,318,080, Re. 38,650; 6,082,416; 6,267,160; 6,330,934

Note: Do not leave your T-TECH in direct sunlight in extremely hot temperatures (>90ºF) for extended periods.

Such exposure can have detrimental effects on the case.

T-TECH when asking for ATF service

6

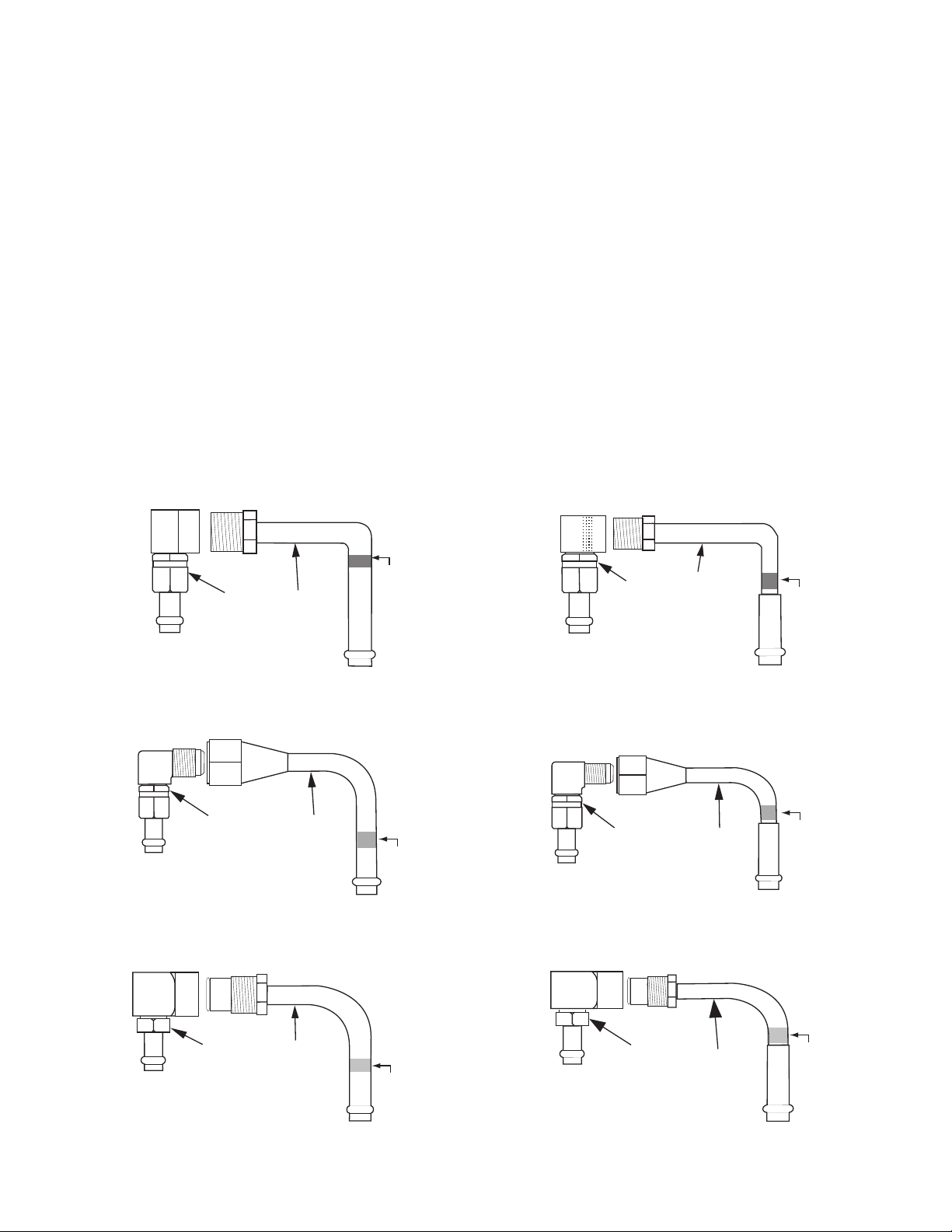

PREPARATION FOR USE

FIT301

FIT302

Red

Band

FIT304

FIT303

Red

Band

FIT306FIT305

Green

Band

FIT310

FIT309

Blue

Band

FIT312

FIT311

Blue

Band

FIT308

FIT307

Green

Band

Although minimal, T-TECH requires some preparation before use. The following instructions describe the necessary

steps to prepare your new transmission fluid exchanger for use.

Fitting Organization

Locate the standard fittings assortment and set each fitting in the T-TECH cabinet storage position identified by the

picture mounted on the backside of the cabinet cover. The standard fittings have a specific storage location inside

the T-TECH cabinet. Most of the fittings are numerically referenced and have a color-coded band for easy

identification.

Throughout each of the operating functions performed using the

T-TECH, various adapters, fittings, or attachments

will require installation in order to service a specific vehicle. This is not considered part of initial preparation for use.

In each case, the setup and connection requirements for a specific task will be added, where necessary, as part of

the procedure for that task.

Standard Fittings Assortment Descriptions

Figure 1 through Figure 14 identify the fittings/components in the standard fittings assortment.

Note: Be aware that any of these fittings along with any of the fittings in the special fittings kits can be used to

service any vehicle as needed.

Figure 1. Fitting 301 and Fitting 302

General Motors – Pre-2000 large and

heavy-duty GM cars, trucks and vans

Figure 2. Fitting 303 and Fitting 304

General Motors – Pre-2000 passenger cars,

light duty trucks and vans

Figure 3. Fitting 305 and Fitting 306

Chrysler/Jeep/Eagle – Pre-2005 Jeep Cherokee

and some passenger vehicles

Figure 5. Fitting 309 and Fitting 310

Ford – Pre-2005 large trucks and vans

Figure 4. Fitting 307 and Fitting 308

Chrysler/Dodge/Eagle – Chrysler Corp. passenger

cars [Fitting 308 also fits Volvo 720/740]

Figure 6. Fitting 311 and Fitting 312

Ford – Small passenger cars and light duty trucks

7

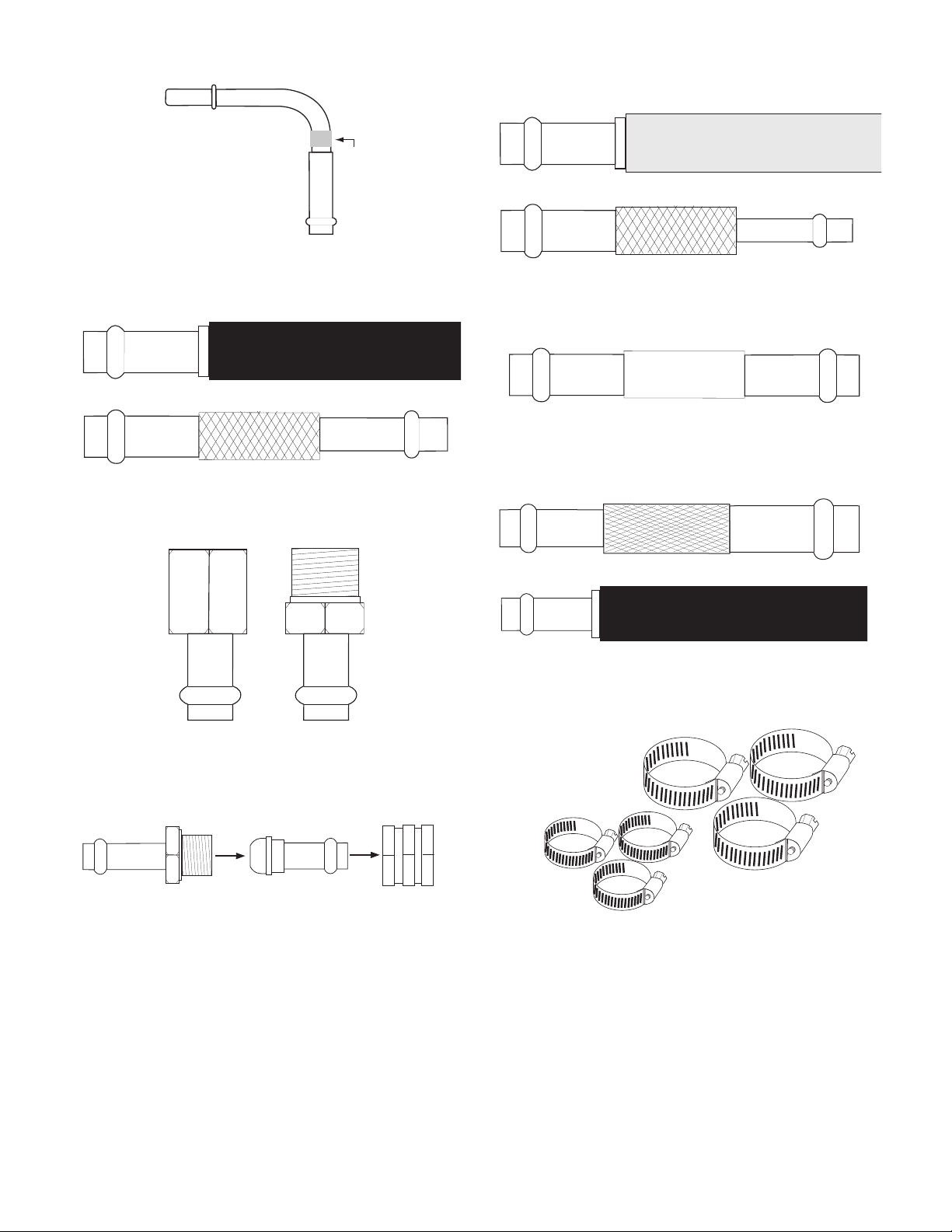

Figure 7. Fitting 314

Blue

Band

FIT315

FIT316

YELLOW

FIT320 FIT323

FIT317

FIT318

BLACK

FIT321

BLACK

FIT324

Ford/Lincoln/Mercury – Fits earlier Ford, Lincoln, and

Mercury small and large passenger vehicles

Figure 9. Fitting 317 and Fitting 318

Any vehicle with 5/16 inch hose connections

Figure 8. Fitting 315 and Fitting 316

Any vehicle with 1/4 inch hose connections

Figure 10. Fitting 319

Any vehicle with 3/8 inch hose connections

Figure 12. Fitting 321 and 324

Any vehicle with 1/2 inch hose connections

Figure 11. Fitting 320 and Fitting 323

Any vehicle with 1/4 inch pipe fittings. Sometimes

used to bypass quick connect receptacles

Mercedes Benz and some BMW

8

Figure 13. Fitting 322

Figure 14. Hose Clamps in two sizes, three each

Cabinet Drawer Storage Layouts

301

302

303

304

305

306

308

307

309

310

311

312

314

RED

RED

GRN

GRN

BLU

BLU

BLU

YELLOW

315

317

316

318

319

321

322

320

323

Hose

Clamps

324

1

2

3

4

5

TECHT

-

®

Failure to follow instructions may cause damage or explosion;

always shield eyes. Read entire instruction manual before use.

WARNING

Do not exceed 75 PSI input pressure when filling the T-TECH.

CAUTION

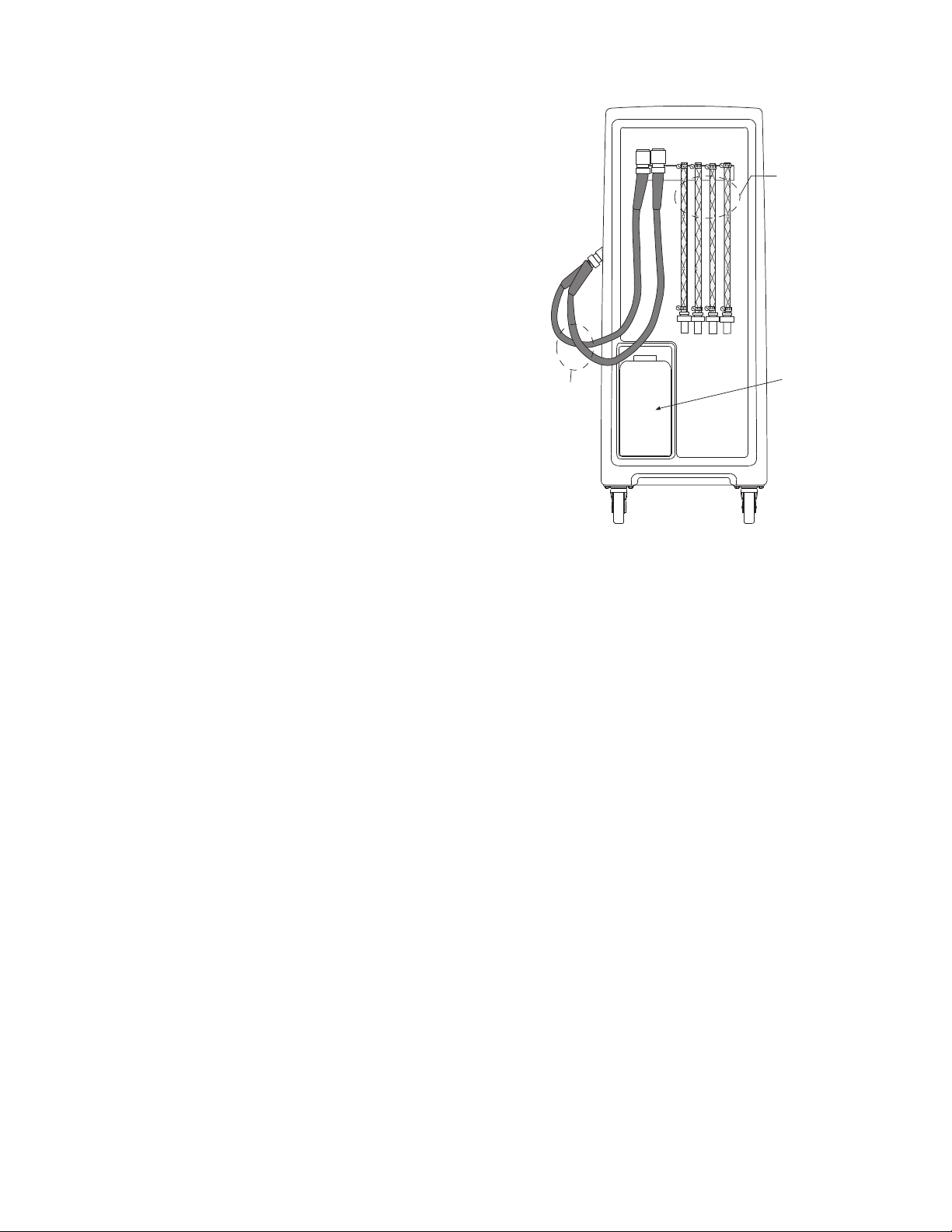

The storage trays in the T-TECH cabinet are defined in

Figure 15. Figure 16 and Figure 17 show the tray layout

for storage of the standard fittings in trays 3 and 4

respectively. The numbers shown in the illustration are

the specific fitting number for the standard fittings and

will be referred to throughout this manual.

Note: The numbers in Figures 16 and 17 correspond

to standard fittings FIT301-FIT324. (There is no fitting

numbered FIT313.)

Figure 15.

1. Special Fittings Tray

2. Special Fittings Tray

3. Standard Fittings Tray

4. Standard Fittings Tray

5. Storage for Manual

Figure 15. T-TECH cabinet organization

Figure 16. Standard Fittings Storage Tray (3) Figure 17. Standard Fittings Storage Tray (4)

9

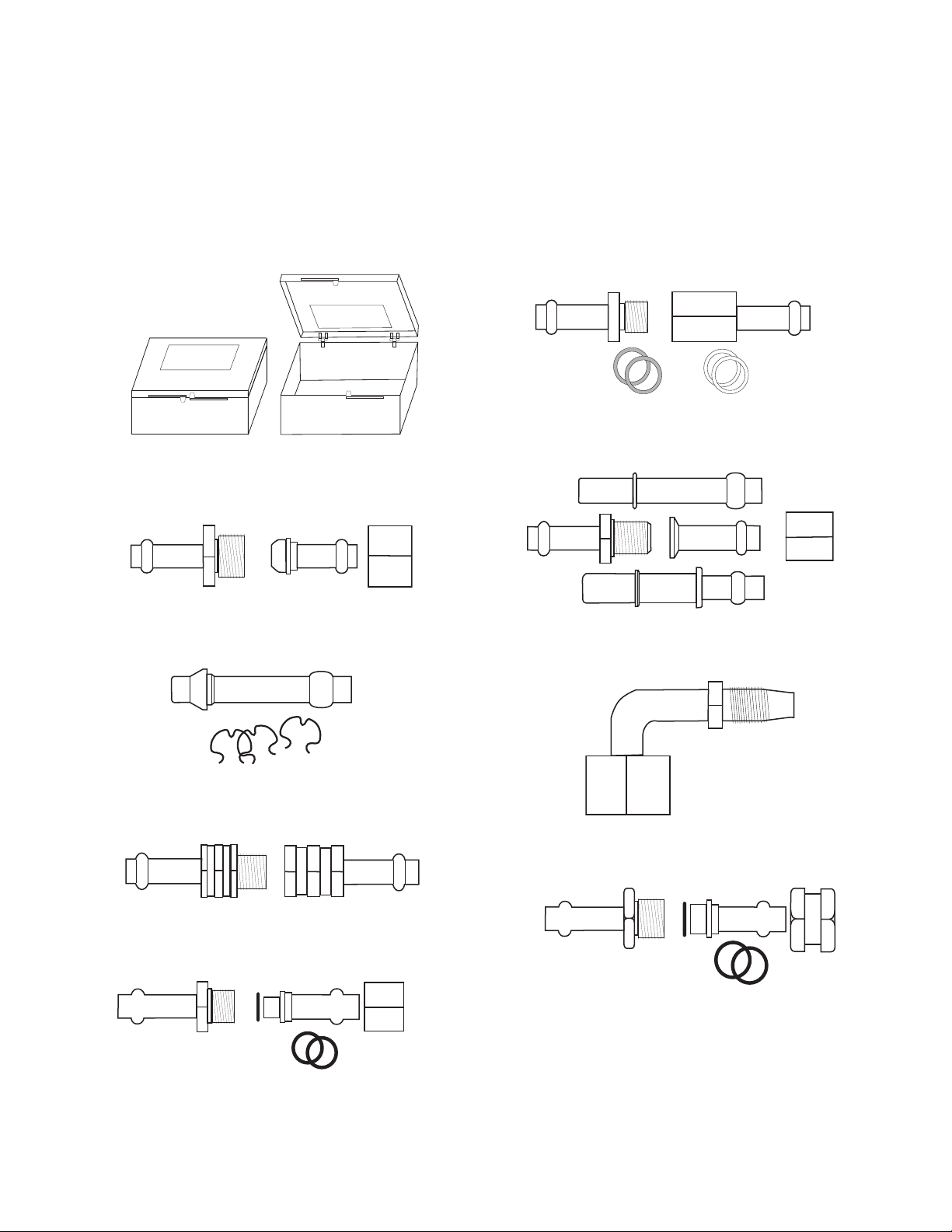

Special Fittings Kits

T- TECH

SPECIAL FITTINGS

T- TECH

SPECIAL FITTINGS

Optional accessories on TT100 must be ordered separately. The special fittings shown in Figure 18 through Figure

34 are stored in small plastic cases (Figure 18) in trays 1 and 2, inside the

CAUTION: Each of the special fittings kits displayed here is a unique matched set of fittings intended for special

use. Always keep the fittings in each kit together. When the fittings in these kits become mismatched, it is possible

to damage the fittings or the vehicle.

Figure 18. FIT165

Replacement plastic storage cases for Special Fittings Kits

T-TECH cabinet (Figure 15).

Figure 19. FIT401

Ford Escort/Nissan/Mazda

Figure 20. FIT402

BMW

Figure 22. FIT404

3/8" Quick Connect, GM/Chrysler

Figure 24. FIT406

Ford/Dodge

Figure 21. FIT403

Ford Taurus/Dodge Full Size Trucks

Figure 23. FIT405

Some Jeep/Chrysler

Figure 25. FIT407

BMW 5 Series and 3 Series

10

Figure 26. FIT408

Ford Contour/Mercury Mystique

Figure 27. FIT409

Volvo

Figure 29. FIT411

Mazda/Ford Banjo Fittings

Figure 28. FIT410

Saab

Figure 30. FIT412

Pre-2005 Dodge Durango/Dakota

Figure 32. FIT414

3/8" Quick Connect, Ford

Figure 31. FIT413

Allison 1000 Series

Figure 33. FIT415

90º 1/2" Quick Connect, Ford

Figure 34. FIT416

90º 3/8" Quick Connect, GM/Chrysler

11

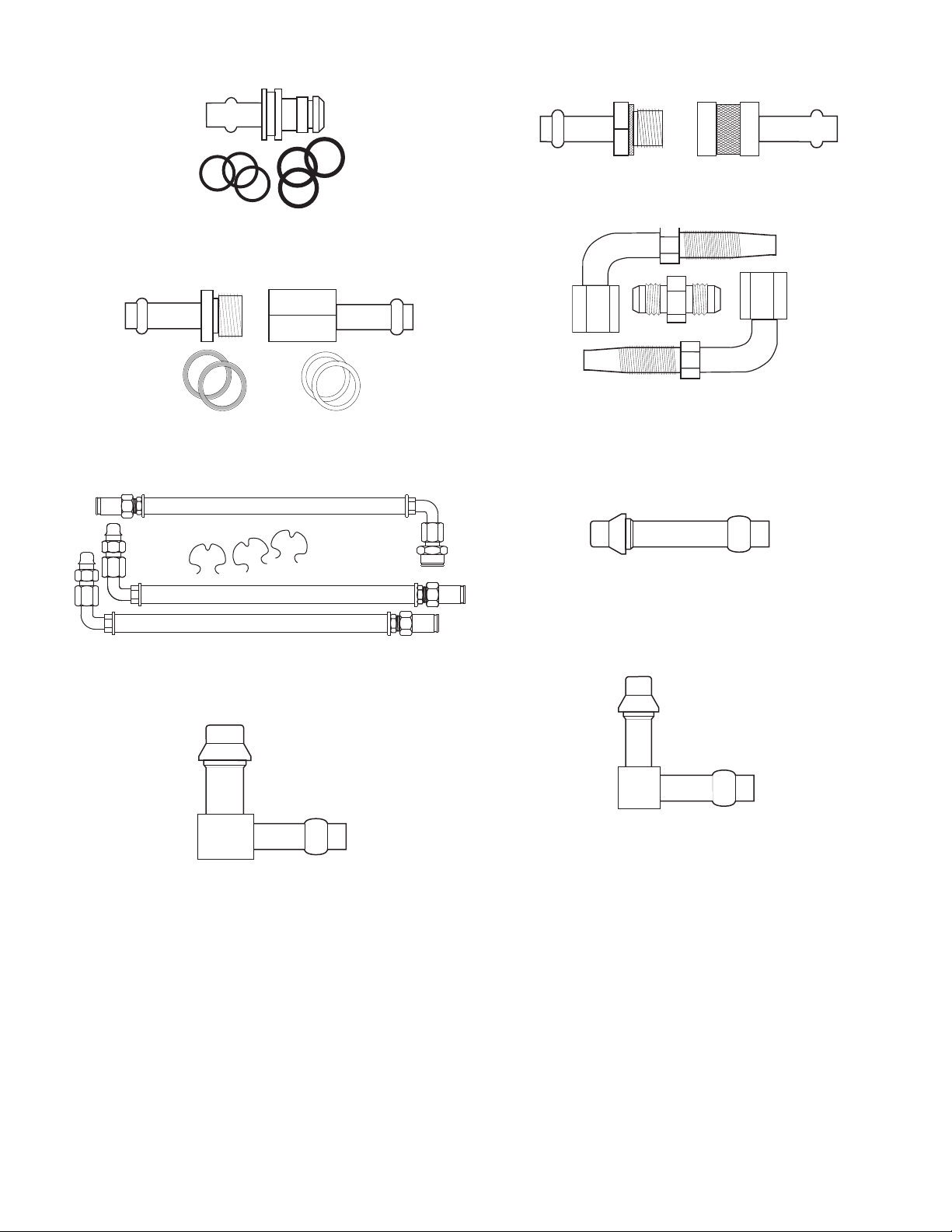

Removing Air From the Cylinder

Service

Transfer

Hoses

Overflow

Ta nk

Service

Hose

Adapters

When using the T-TECH for the first time, there may be

space at the top of the cylinder (air in the cylinder). If not

corrected, this condition may short future exchanges. If for

some reason the piston is at the bottom of the cylinder, or

there is large air pocket above the piston, the piston can be

moved to the top of the cylinder by the following method.

1. Set CONTROL VALVE to SERVICE VEHICLE.

2. Attach a service hose adapter to one of the service

transfer hoses.

3. Insert an air nozzle into the end of the service hose

adapter.

4. Control the air line at 10 psi (138 kPa) or less and

begin filling the bottom of the cylinder with air.

Figure 35. Hoses and Hose Adapters

12

OPERATION INSTRUCTIONS

CONTROL

VALVE

Service Transfer

Hose Connections

(Hard Plumbed)

Control Valve

System

Pressure Gauge

Service Port

TECHT

-

®

Failure to follow instructions may cause damage or explosion;

always shield eyes. Read entire instruction manual before use.

WARNING

Do not exceed 75 PSI input pressure when filling the T-TECH.

CAUTION

For first time use, do not perform any of the following procedures until you have completed the procedures in

Preparation For Use. All procedures must be performed in the order presented.

Figure 36. Control Valve Positions

For each service being performed, always make certain to fill the cylinder with the specific type of ATF required by

the vehicle to be serviced. Once Preparation For Use has been completed, a typical service consists of the

following procedures in the order presented.

1. Fill Cylinder Function

2. Connecting to the Vehicle

3. Fluid Exchange Function

Figure 37. TT100 Side View

13

Overflow

Tank

Bulk Fill

Service

Port

Hoses

To and From

The

Transmission

Automatic

Bypass

Line

Automatic

Alignment

Valve

Check

Valve

Three

Way

Valve

Valve

in

FILL

Position

Check

Valve

Check

Valve

Check

Valve

Old

or

Dirty

Fluid

New

Fluid

Pressure

Relief

Valve

System

Pressure

Bulk

Dispenser Gun

Nipple

Female Coupler

Connects to Male

Coupler on T-Tech

Male

Coupler

on

T-TECH

Control

Panel

Fill Cylinder Function

The Fill Cylinder function is used to fill the T-TECH cylinder with new ATF and empty the cylinder of old ATF.

CAUTION: Fill cylinder completely. Air below the piston will result in an incomplete exchange as this air will

compress and not move the piston at beginning of the exchange process. (This condition usually occurs only during

the initial fill.)

Using a Bulk Dispenser Gun

To use this method, a bulk dispenser gun (see Figure 38) accessory kit must be used. The accessory kit is an

optional kit not supplied with the T-TECH. The bulk dispenser gun accessory kit must be ordered separately (Part

No. FIT200, see Replacement Parts List).

CAUTION: Ensure that your air delivery system does not exceed

75 psi at the point of delivery. Many air systems have a 3:1 or 4:1

pressure ratio – this means you must dial your system down to

compensate for the output delivery ratio. Monitor the gauge on

the T-TECH control panel to ensure that 75 psi is not exceeded.

CAUTION: Fill cylinder completely. Air below the piston will result in

an incomplete exchange as this air will compress and not move the

piston at beginning of the exchange process. If this is the first time

T-TECH machine has been filled, there will be air under the

your

piston instead of old ATF. The air must be allowed to exit just

as if it were old fluid. See Note on Step 3 below.

Figure 38. Bulk Dispenser Gun Connection

T-TECH cylinder).

14

1. Determine ATF type needed for your next service.

2. Set CONTROL VALVE (on control panel on the side of the unit) to FILL CYLINDER.

3. Attach a service hose adapter to the end of each service transfer hose.

Note: Although the used fluid will exit only one service hose when filling the cylinder with new fluid,

it is critical that you connect service hose adapters to both service transfer hoses every time

you fill the T-TECH.

4. Insert both service hoses into a container suitable for collecting and disposing of old ATF. The container

must be capable of holding a minimum of 18 quarts (the full capacity of the

Note: Always follow your local environmental protection agency guidelines for proper disposal

of ATF.

5. Using the proper fittings that correspond to

your dispenser gun, connect the bulk dispenser

gun to the CYLINDER FILLING port on the

control panel on the side of the

T-TECH

(see Figure 38) .

6. Press the trigger on the bulk dispenser gun.

The flow direction for filling new fluid from a

bulk dispenser gun is shown in Figure 39.

7. Verify that the pressure gauge on the

control panel does not exceed a reading of

75 lbs.

8. New fluid should begin flowing into the top of

the cylinder. An equal amount of used ATF is

being displaced and forced out of the

through one of the service hoses and into your

T-TECH

T-TECH

designated used-ATF disposal container.

Figure 39. Flow Direction From A Bulk Dispenser Gun

9. Continue the process until the cylinder is filled

with the required amount of new ATF.

Connecting to the Vehicle

Cooling

Lines

Upper

Radiator

Fitting

Lower

Radiator

Fitting

Upper

Transmission

Fitting

Lower

Transmission

Fitting

Cooling

Lines

Lower

Radiator

Fitting

Upper

Transmission

Fitting

Lower

Transmission

Fitting

Secondary

Transmission

Cooler

Location #1

Transmission

Fittings

Location #2

Upper or Lower

Radiator

Fitting

Location #3

Upper or Lower

Cooling

Line

Cooling

Lines

Upper

Radiator

Fitting

Lower

Radiator

Fitting

Upper

Transmission

Fitting

Lower

Transmission

Fitting

Connecting to the vehicle for service requires identifying the automatic transmission cooling lines and making the

necessary connections to exchange ATF.

Identifying Cooling Lines

Figure 40 is a diagram of a typical automobile transmission cooling system. Transmission cooling systems are

essentially the same from one vehicle to another though they may be routed differently or the fittings might be in

slightly different locations. In some systems, both lines will run to the bottom of the radiator – this is found on

radiators that have top and bottom tanks. Some cooling systems will have a secondary transmission cooler in

addition to the cooler in the radiator (see Figure 41).

Figure 40. Typical Automobile Cooling System Figure 41. Automobile Cooling System

With Secondary Transmission Cooler

Making Vehicle Service Connections

The fittings required to service ATF vary based on vehicle make, and sometimes from model to model. Make sure

the vehicle is shut off and cool. Do not open a transmission system that is hot and under pressure. Figure 42

shows some typical hookup locations. Location #1 is the fittings at the transmission. Location #2 is the fittings at

the radiator. Location #3 shows a location (typical to foreign vehicles) where a rubber hose changes to a steel

tubing line. There must be a removable hose clamp at this location in order to make a connection. Only a few

vehicles will be serviced at this location.

Figure 42. Typical Cooling Hookup Locations Figure 43. Hookup Top Radiator Line

For the hookup procedure, we will use as an example an illustration that represents a 1992 Chevrolet 4-door Blazer,

Figure 43.

1. Always verify that the transmission fluid level is normal before you begin.

2. Look for the easiest spot to break into the transmission system (any existing connection along the entire

system can be used, see Figure 42).

Note: In this vehicle (Chevy Blazer) the top radiator line is determined (for this example) to be the easiest

location to make the T-TECH connection.

3. If available, use a transmission cooling line wrench (an open end wrench, flare nut wrench, or adjustable

wrench) to remove the cooling line from the radiator (see Figure 43).

15

4. Examine the vehicle fittings and compare them to

FIT304

FIT303

Hose

Clamp

Flare

RED

RED

BAND

T-TECH

FITTINGS

Service

Transfer

Hoses

FIT304

Red Band

FIT303

RED

the fitting chart on the back of the

T-TECH

cabinet door. In this case, a Chevrolet fitting is

required and a review of the fitting chart indicates

that FIT303 and FIT304 are the correct choices

(see Figure 44).

5. Connect the male FIT304 fitting into the radiator,

as shown in Figure 45.

6. Connect the female FIT303 fitting onto the vehicle

transmission cooling line as shown in Figure 45.

Note: The connections only need to be snug fit.

Torquing down hard is not required, but they

Figure 44. The Correct Fittings Selection

should still be tight enough to keep the

connections from leaking. If they begin to leak when service starts, see Troubleshooting.

7. Attach service adapter hoses to each fitting as shown in Figure 46.

16

Figure 45. Insert Fittings

Figure 46. Attach Service Adapter Hoses

8. Make certain the hose clamp is tightened on the inside of the hose clamp flare on each fitting

(see Figure 45) to keep the hose from coming off.

CAUTION: Over tightening the adapter hose clamps will destroy the hose ends over a period of time.

Clamp the hoses down with a snug fit only. If they still leak, see Troubleshooting.

9. Connect a service hose adapter to each service transfer

hose (see Figure 47). You are not required to account for

fluid flow when making this connection. The

T-TECH

machine will sense the vehicle’s fluid direction and adjust

so that the used ATF from the vehicle is always coming

into the bottom of the

T-TECH cylinder and the new ATF

is moved out of the top of the T-TECH cylinder and into

the vehicle transmission. When the transfer hoses have

been connected, the system should look like the

illustration in Figure 47.

Figure 47. Connection Complete

Fluid Exchange Function

T-TECH

FITTINGS

Piston Moving

Up From Bottom

Of Cylinder

Old Fluid

New Fluid

T-TECH

FITTINGS

Fluid Between

O-Rings

Overflow

Tank

Bulk Fill

Service

Port

Hoses

To and From

The

Transmission

Automatic

Bypass

Line

Automatic

Alignment

Valve

Check

Valve

Three

Way

Valve

Valve

in

SERVICE

Position

Check

Valve

Check

Valve

Check

Valve

Old

or

Dirty

Fluid

New

Fluid

Pressure

Relief

Valve

System

Pressure

Use this function to exchange old automatic transmission

fluid (ATF) with new ATF.

1. With the T-TECH auto align feature, you need not

be concerned about which service transfer hose

is connected to the transmission cooling line or to

the radiator because flow direction is controlled

through the

2. Set CONTROL VALVE (on the

panel) to SERVICE VEHICLE (pointing straight up).

3. Start the vehicle. The pressure gauge (on the

T-TECH control panel) should read between 10

and 75 lbs., depending on the vehicle being

serviced. If the pressure is below 10 lbs. and the

piston is not moving in an upward direction, see

Troubleshooting.

4. The piston should begin to move upward in the

cylinder (see Figure 49). Notice that the old fluid

enters the cylinder under the piston. The old fluid

pumped in by the vehicle transmission pushes up

on the piston, which in turn pushes an equal

amount of new fluid out the top of the cylinder

and into the vehicle.

5. You may notice some fluid between the O-rings on the piston (see Figure 50). The presence of new ATF is

normal between the O-rings for lubrication of the piston and O-rings. However, if old ATF passes by the

O-rings and into the new ATF, O-ring replacement is needed. (See

6. When the desired amount (vehicle system capacity) of ATF has been exchanged, or the fluid in the service

hose coming from the vehicle runs clear, turn the vehicle OFF, remove all hoses and hose connections and

reconnect the vehicle transmission cooling lines.

7. Restart the vehicle.

8. Check the ATF level in the vehicle. (Check the vehicle dipstick for proper procedure. Some vehicles require

the transmission be in PARK and some in NEUTRAL.)

9. Inspect the vehicle fittings for leaks.

10. Fluid exchange is complete.

T-TECH unit.

T-TECH control

Figure 48. Vehicle Service Flow Direction

Troubleshooting)

Figure 49. Piston Movement Figure 50. Fluid Between O-Rings

17

T-TECH

FITTINGS

Fluid Exchange

Complete – Turn

Vehicle Off

Cylinder Is Now

Filled With Old Fluid

Service

Transfer

Hoses

Waste

Disposal

Container

Service

Hose

Adapter

ATF

Container

Service

Hose

Adapter

Air

Hose

TECHT

-

®

Failure to follow instructions may cause damage or explosion;

always shield eyes. Read entire instruction manual before use.

WARNING

Do not exceed 75 PSI input pressure when filling the T-TECH.

CAUTION

Bypass Feature

The T-TECH bypass feature allows new ATF to loop within the vehicle

when the exchange is complete and the piston is at the top of the

cylinder. This feature allows the operator to walk away (work on

something else, etc.) when the machine is running, without being

concerned about service completion. When the piston reaches the top

of the cylinder (old ATF has displaced all of the new ATF), the bypass

feature is automatically engaged. This causes the new fluid to be forced

into a loop through the vehicle and the

T-TECH unit. The bypass will

continue until stopped when the operator turns the vehicle OFF.

Replace Existing New ATF with Different

New ATF

Use this procedure to replace a new fluid type that is already in the

cylinder with another type of new fluid needed to perform a current

service (e.g. the cylinder is currently filled with DEXRON III but you need

to service a Chrysler that uses MOPAR+ fluid).

To accomplish this task, the piston will be pushed to the top of the

cylinder to force any existing new ATF into a clean storage container so the fluid can be reused. See Figure 61.

1. Set CONTROL VALVE to SERVICE VEHICLE.

2. Attach a service hose adapter to each service transfer hose.

3. Insert one service hose adapter into a clean container to save the fluid that is to be removed from the

cylinder.

4. Insert your air nozzle into the open end of the other service hose adapter.

5. Apply air pressure (air pressure should be above 10 psi but should not exceed 20 psi on the system

pressure gauge).

6. The machine will sense the pressure and the piston should begin to rise. As the piston nears the top of the

cylinder, ease back on the air pressure.

7. When the piston reaches the top of the cylinder,

hold the air nozzle and service hose adapter in a

waste container with the service adapter pointing

away from any personnel. Pressurized air and

possibly some ATF will be expelled out of the end

of the service hose adapter when the air is

released and the line hose is removed.

8. Release the air pressure and remove the nozzle

from the service hose adapter.

9. Refill the cylinder with new ATF fluid of the type

required to perform the service according to FILL

CYLINDER FUNCTION. Make sure to fill the

cylinder until the cylinder is completely full of ATF

to avoid any air pockets under the piston.

Figure 51. Exchange Of Fluids Complete

18

Figure 52. Exchange New Fluids

MAINTENANCE

No

No

Fail

Yes

No

Yes

No

Yes

Yes

No

Yes

No

Is the piston

at the top of the

cylinder?

Yes

The machine is

not filled

with new fluid

Is

CONTROL VALVE

set to

SERVICE

VEHICLE?

Does the

pressure gauge

read zero with engine

running?

Is the

vehicle a

Chrysler or

Mitsubishi?

Is the

overflow tank

filling with new ATF &

is gauge reading below

50 psi (345 kPa)?

Call T- TECH

Te chnical Support.

1-800-328-2921

Orient

CONTROL VALVE to

SERVICE VEHICLE

and retest.

Does

the pressure

gauge read between

10 and 60 psi

(69 & 414 kPa)?

If the vehicle cannot pump at

least 10 psi (69 kPa), a service

may not be completed. Some Toy ota

Camry models may pump at a lower

pressure. Refer to Camry application

notes (pg. 30) for additional

service tips.

Vehicle may have a

clog in the output cooler

line or transmission

pump may need

service.

Some Chrysler and

Mitsubishi products

must be in neutral for

service to begin.

Pressure rellief system

may be malfunctioning.

Call T- TECH Te c hnical

Support.

General

There is no periodic maintenance necessary on the T-TECH unit.

Troubleshooting

The following troubleshooting flow charts are provided for solutions to problems that may occur

during various operating processes.

Vehicle Service

19

Fill Cylinder Using Bulk Dispenser

Yes

No

Is the piston

at the top of the

cylinder?

See REMOVING AIR

FROM THE CYLINDER

for removal

instructions.

Is the

bulk dispenser gun

connected to the

SERVICE

PORT?

Do both

service transfer

hoses have service hose

adapters attached?

Is

adequate

pressure shown on

the pressure gauge?

20-50 psi (138-

345 kPa)

Call T-TECH

Te chnical Support.

1-800-328-2921

Verify CONTROL VALVE

is set to FILL CYLINDER

and retry fill process.

Fail

No

Fail

No

Yes

Yes

Fail

Connect

bulk dispenser gun

to the SERVICE PORT.

Retry fill process.

Attach

service hose

adapters to the service

transfer hoses. Retry

fill process.

Machine

is not receiving

fluid from bulk dispenser

gun. Check gun

orientation.

Is

there a

strong, steady

flow?

Turn bulk dispenser gun off. Disconnect

one hose adapter from transfer hose.

Turn gun on, wait 4-5 sec. Tur n gun

off. Reconnect hose adapter (over

used ATF container). Auto alignment

is corrected. Turn gun on.

No

Is

there a

strong, steady

flow?

No

No

Yes

Yes

20

T-TECH APPLICATION NOTES

Radiator From FIT402

From FIT402

Vehicle In-Line

Transmission

Tubing

General

The information in the following pages provides information for specific T-TECH applications. The information

provided here is listed alphabetically by vehicle manufacturer and vehicle type.

CAUTION: Some automobile manufacturers use snap type connectors on transmission cooling lines. To avoid

damaging the radiator, never remove the fitting from the radiator but rather use the proper disconnect tool to

remove line from fitting.

If a tool is not available, follow the cooler lines to a point where the line and a rubber hose meet and disconnect at

that point. Follow all directions for a proper service.

Typical vehicles utilizing snap type cooler line connections are Ford Taurus, late model Ford pick-ups and SUV’s,

Dodge trucks, most GM products after 2000 and Chrysler vehicles after 2004.

BMW

BMW FIT402

BMW Kit No. FIT402 looks like the Mercedes-Benz Fitting No. FIT322 but is somewhat larger.

CAUTION: These fittings are a matched set and must be kept together in the small plastic box marked FIT402.

Instructions

FIT402 is installed on the BMW as illustrated in Figure 53.

BMW 500 Series FIT407

CAUTION: These fittings are a matched set and must be kept

together in the small plastic box marked FIT407.

Instructions

1. The BMW 500 Series FIT407 utilizes an O-ring to

seal the line instead of the bullet style fitting used on

smaller BMW models.

2. Use the fittings in FIT407 the same way as the

fittings in FIT402 (see Instructions and Figure 53).

Extra O-rings have been included with FIT407.

Figure 53. FIT402 Installation on the BMW

Chrysler

CAUTION: Many Chrysler products use rubber hose to connect to the transmission cooler. The hose usually has

one or more plastic clips along the length to keep the hose away from pulleys, belts, etc. While doing a T-TECH

service, it is possible to dislodge the hose from the clips. Closely monitor the security of the clips and hoses during

T-TECH service to assure that the hose is not cut off by a belt or pulley after the vehicle is returned to customer.

Note: A number of Chrysler vehicles, including some Jeeps, require the vehicle to be in neutral while the

Many late model Chrysler vehicles utilize Internal Quick Connect (IQC) Fittings to join the transmission cooler line to

the radiator. For application instructions related to these vehicles, see GM Instructions, page 27.

engine is running to develop vehicle transmission pressure. The T-TECH exchange process simply will not

work unless vehicle transmission pressure is developed.

21

Dodge Dakota (to 1997) and some Ram

Line

Removal

To ol

From FIT403

Push into the receptacle

until the plastic clip

engages the fitting

Vehicle Transmission

Cooling Line

Attach Service

Adapter Hose

Attach Service

Adapter Hose

Vehicle Transmission

Cooling Line

Radiator

Radiator

Vehicle In-Line

Transmission

Tubing

Radiator

From FIT403

From FIT403

FIT403

Note: Whenever using special fittings from FIT403, start them

by hand and slowly tighten enough to prevent leaks.

Use FIT403 on the 1995 to 1997 Dakota (see FIT412 for post

1997) and some Ram models.

The quick connect fitting in the Dodge Dakota transmission

cooling line (at the radiator) requires a removal tool that is not

supplied. FIT403 is installed on the Dakota as illustrated in

Figure 54.

CAUTION: These fittings are a matched set and must be kept

together in the small plastic box marked FIT403.

Instructions

1. Remove the transmission cooling line with the line

removal tool.

2. Insert the small fitting into the receptacle and continue

pushing until the plastic clip in the receptacle engages

the fitting.

3. Install a service adapter hose on the small fitting and

another on the vehicle transmission cooling line.

Clamp both in place and start service.

Dodge Ram

[Pre-2004 Assorted Gasoline engines only]

Figure 54. FIT403 Installation on Dodge Dakota

CAUTION: It is VERY easy to damage the radiator threads on these vehicles. The radiator fittings on assorted 19952004 DODGE RAM TRUCKS are brass and the threads are 9/16-24 ultra fine cut. The threads can be stripped as

the technician removes the line. We recommend that you access the line either at the transmission or at the hose

clamp connection (if available). If you decide to remove the radiator fitting, use the following steps to help eliminate

damaging the fitting. Careful handling of the vehicle is the responsibility of the technician.

any liability for vehicle damage.

The quick connect fitting in the Dodge Ram transmission

cooling line (at the radiator) requires a removal tool that is not

supplied. The FIT403 male fitting goes on the end of the steel

line and the female fitting goes on the radiator (see Figure 55).

CAUTION: These fittings are a matched set and must be kept

together in the small plastic box marked FIT403.

Instructions

T-TECH will not accept

1. Spray the fitting with penetrating oil.

2. Break the nut loose with a wrench.

3. Finish removing by hand only.

4. Replace the nut by hand only.

Note: Whenever using special fittings from FIT403

start them by hand and only tighten enough to

prevent leaks.

Figure 55. FIT403 Installation on some Dodge Ram

1. Remove the transmission cooling line with the line removal tool.

2. Insert the small FIT403 fitting into the receptacle and continue pushing until the plastic clip in the

3. Insert the large FIT403 fitting onto the transmission cooling line (see Figure 55).

receptacle engages the fitting (see Figure 55).

4. Install a service adapter hose on each fitting. Clamp both in place and start service.

22

Dodge Ram [Pre-2001 Turbo Diesel]

Vehicle In-Line

Transmission

Tubing

Radiator

From FIT412

From FIT412

Connect to

Service Hose

Adapter

Connect to

Service Hose

Adapter

Instructions

1. The Dodge Turbo Diesel uses the large quick connect fitting in FIT403, but it is easier to locate the 1/2 inch

hose connection near the bottom of the radiator and use 1/2 inch fittings FIT321 and FIT324 with hose

clamps.

Some Dodge Durango and Dakota 1997-2004 FIT412

FIT412 is a three part fitting (see Figure 56).

Instructions

1. Remove the transmission cooling line from the

radiator connection.

2. Connect one of the elbow fittings to the fitting

attached to the radiator.

3. Install one the service hose adapters to the other

end of the elbow fitting and secure in place with

one of the hose clamps.

4. Insert the small double ended fitting into the

vehicle in line transmission tubing connector.

5. Connect the second elbow fitting to the other end of the small double ended fitting.

6. Install a second service hose adapter to the other end of the elbow fitting and secure in place with one of

the hose clamps. Start service.

Figure 56. FIT412 Installation On Dodge Durango

Jeep Grand Cherokee FIT405

CAUTION: These fittings are a matched set and must be kept together in

the small plastic box marked FIT405.

FIT405 contains a special close radius fitting to make connection to Grand

Cherokee and some other models of Jeep easier. This fitting will fit behind

the battery box for the radiator connection (see Figure 57).

Figure 57. FIT405 For Installation

On Jeep Grand Cherokee

General Ford Notes

CAUTION: Use caution when servicing Ford products. Some Taurus models use a very large snap-in fitting that

actually holds the transmission cooler in the radiator.

transmission cooling line from the fitting. The following method can be used wherever snap-in style fittings are

encountered.

1. Removing the transmission cooling line from this fitting requires the use of a tool such as the

LISLE #37000 A/C AND FUEL LINE DISCONNECT SET.

CAUTION: The snap-in fittings contain O-rings that seal the transmission cooling line to the receptacle. If the

O-ring is broken, the fitting will leak. The only way to fix this problem is to replace the entire receptacle (Ford

part #F3D3-7D273-A) along with a metal safety clip (Ford part #F3D2-73465-A) that must also be reinstalled.

Note: Whenever using special fittings from FIT403, start them by hand and only tighten enough to

prevent leaks.

2. After the transmission cooling line has been released, insert the fitting from FIT403 into the radiator fitting.

3. Attach one of the standard fittings (such as FIT321) or a service adapter hose to the transmission cooling

line for service.

DO NOT REMOVE this fitting. Remove, instead, the

23

Ford Contour FIT408

To Service

Adapter Hose

To Radiator

O-Ring

To Service

Adapter Hose

Transmission

Cooling Line

O-Ring

FIT401 White

Nylon Gasket

Stock Copper Gasket

Stock Copper Gasket

Vehicle

Radiator

Receptacle

From FIT401

From FIT401

Stock Bolt

FIT408 is a two part fitting that requires an O-ring seal to

the transmission line.

CAUTION: These fittings are a matched set and must be

kept together in the small plastic box marked FIT408.

Instructions

1. Remove the transmission cooling line from the

radiator.

2. Attach the female portion of FIT408 to the

transmission cooling line.

3. Attach the male portion of FIT408 to the radiator

(see Figure 58).

Ford Escort FIT401

CAUTION: These fittings are a matched set and must be kept

together in the small plastic box marked FIT401.

Instructions

1. Remove the vehicle bolt, fitting and crush washers from

the radiator.

2. Install the

washers.

3. Install the

white nylon gasket (supplied) (see Figure 59).

4. After T-TECH service is complete, remove the fittings and

store in FIT401, reinstall factory parts and start the engine.

Check for leaks and fluid quantity.

T-TECH female half to the stock bolt and

T-TECH male half into the radiator using the

Figure 58. FIT408 Installation on Ford Contour

Figure 59. FIT401 Installation on Ford Escort

24

Ford Explorer

Many 2001 to 2006 Ford Explorer and Mercury Mountaineer models have an internal thermostat that controls the

flow of the fluid to the cooler. This thermostat solenoid remains closed until the vehicle reaches proper operating

temperature (140°F). There is no bypass or pressure relief mechanism in this solenoid that can be forced open. This

situation will result in low or no flow of transmission fluid to and though the

times.

The following procedure is recommended to improve service times on the above vehicles:

1. Connect the

T-TECH to the vehicle (varies by model).

2. Start the vehicle, set the parking brake and with foot on brake, place in neutral increasing engine speed to

1600 RPM.

3. When the transmission fluid reaches 140°, the solenoid will open and the fluid will start to flow through the

cooler lines and to the cooler.

4. Continue to keep a foot on the brake, maintain the engine at 1600 RPM and the vehicle in neutral to

maintain optimum transmission fluid temperature and flow.

5. If no fluid flow occurs, use a non-contact thermometer and check the temperature of the transmission pan.

If not at 140° raise the engine speed to 1900 RPM to increase the transmission temperature.

6. If the fluid temperature is at or above 140° and fluid does not flow, stop the process. In some cases, the

thermostat or solenoid valve may be defective (not allowing fluid flow) and need servicing. Inspect the

transmission fluid condition and if the fluid is extremely burnt it may indicate a defective thermostat or

solenoid. This must be remedied before a service can be performed.

7. To ensure correct fluid level, always check the fluid level prior to vehicle leaving the bay. Refer to Sealed

Transmission service guidelines below.

T-TECH, causing delays in service

Many 2002 to 2006 Ford Explorers and Mercury Mountaineer models feature a sealed transmission system with no

automatic transmission dipstick. The instructions below outline the proper service techniques for fluid level check

on such models using the

Suggested Service Tools: Oil suction gun, 3/16" Allen or T-30 Torx wrench and a T-TECH FIT516 Ford Fill Adapter Kit.

1. Ensure the vehicle is sitting level. Start the vehicle and warm the transmission to operating temperature

(120° to 140°F).

2. With foot on the brake, slowly place shift selector in each gear position momentarily returning to park when

complete.

3. With engine still running, access the underside of the vehicle and locate the transmission drain plug. Using

the appropriate tool, remove the center plug from the drain plug, holding the drain plug in place.

4. If fluid runs out of center of the drain plug, allow to drain to a slow drip and replace the center plug. The

vehicle fluid level is correct.

5. If no fluid runs out, thread the FIT516 Ford Fill Adapter into the center plug opening. Using an oil suction

gun, inject 1 pint of correct ATF into vehicle through the Ford Fill Adapter and remove the oil suction gun.

6. If fluid runs out, follow Step #4, first removing the FIT516 Ford Fill Adapter. If no fluid drains out, inject

another .25 pint of fluid following above instructions. Repeat until fluid drains out. Follow Step 4 above,

first removing the FIT516 Adapter.

7. Shut-off the engine. Fluid check is complete.

Note: The transmission pan will hold 3 quarts of ATF when filled to correct level, vehicle is running and

sitting level.

T-TECH FIT516 Ford Fill Adapter Kit.

F-Series Trucks

CAUTION: Late model F-Series trucks feature a Quick Connect fitting at the the radiator. DO NOT REMOVE this

fitting. Remove, instead, the transmission cooling line from the fitting. The following method can used be wherever

this Quick Connect fitting is encountered.

F-150 Instructions

1. Remove the transmission cooling line from this radiator fitting using the 3/8" Ford Quick Disconnect

Removal Tool (Part No. FIT512).

2. After the transmission cooling line has been released, insert the fitting from FIT414 into the radiator fitting.

3. Attach a service adapter hose to the FIT414 fitting and to the transmission cooling line for service.

F-250 Instructions

1. Remove the transmission cooling line from this radiator fitting using the 1/2" Ford Quick Disconnect

Removal Tool (Part No. FIT513).

2. After the transmission cooling line has been released, insert the fitting from FIT415 into the radiator fitting.

3. Attach a service adapter hose to the FIT415 fitting and to the transmission cooling line for service.

25

Ford Taurus and Windstar FIT403

From

Kit #6

To Radiator

Or Transmission

From

Kit #6

From

Kit #6

To Radiator

Or Transmission

To Radiator

Or Transmission

FIT321

Transmission

Cooling line

Larger Fitting

From FIT403

Attach Service

Adapter Hose

Attach Service

Adapter Hose

For some 1993

and newer

For some 1993

and older

Line

Removal

To ol

Transmission

Attach Service

Adapter Hose

Smaller Fitting

From FIT403

Transmission

Transmission

FIT403 must be installed at the transmission in Ford Taurus and Windstar and in the Mercury Sable. For some 1993

and newer vehicles, use the larger diameter fitting in FIT403 (see Figure 60) with FIT321 used as the female side.

For some 1993 and older use the smaller diameter fitting in FIT403.

CAUTION: These fittings are a matched set and must be kept together in the small plastic box marked FIT403.

CAUTION: Do not remove the quick connect receptacle located

on the radiator of the Ford Windstar, Taurus, and Mercury Sable.

On some of those vehicles, the receptacle fitting holds the cooler

inside the radiator tank. Removing the receptacle will allow

radiator coolant to leak out.

The quick connect may be released. The transmission cooler line

can be removed and fitted with the appropriate

However, most of the vehicles leave very little room to work so the

recommended fitting hookup is at the transmission itself. The

cooling at the transmission can be removed and fitted with the

appropriate

T-TECH fitting.

Instructions

1. Remove the transmission cooling line.

2. Insert the appropriate FIT403 fitting (see Figure 60) into

the receptacle and continue pushing until the plastic clip

in the receptacle engages the fitting.

3. Install a service adapter hose on the FIT403 fitting and

another on the vehicle transmission cooling line, using

FIT321. Clamp both in place and start service.

T-TECH fitting.

Figure 60. FIT403 Installation on Ford Taurus,

Ford Windstar & Mercury Sable

Ford Windstar FIT406

FIT406 fittings (Figure 61) have two thin grooves cut into the flats to identify them.

CAUTION: These fittings are a matched set and must be kept together in the small plastic box marked FIT406.

Windstar, Taurus, Dodge Dakota, some Ford 1981 and up and many GM and Chrysler models use various snap-in

connectors for the cooling lines. Field experience has found the most effective way to remove these fittings is by

the procedure identified below.

CAUTION: Do not remove the quick connect receptacle

located on the radiator of the Ford Windstar, Taurus, and

Mercury Sable. On some of those vehicles, the receptacle

fitting holds the cooler inside the radiator tank. Removing the

receptacle will allow radiator coolant to leak out.

The quick connect may be released. The transmission cooler

line can be removed and fitted with the appropriate

fitting. However, most of the vehicles leave very little room to

work so the recommended fitting hookup is at the transmission

itself. The cooling at the transmission can be removed and

fitted with the appropriate

Instructions

T-TECH fitting.

1. Spray WD-40 or similar oil into and around the fitting.

This lubricates the captive o-ring.

2. Remove the transmission cooling line from the

radiator.

26

3. Attach FIT406 Female to the cooling line.

4. Attach FIT406 Male to the radiator or transmission.

5. Install a service adapter hose on each fitting, clamp

both in place and start service.

T-TECH

Figure 61. FIT406 Installation on Ford Windstar

Mercury Mountaineer

See Ford Explorer Instructions.

Mercury Mystique FIT401

CAUTION: These fittings are a matched set and must be kept together in the small plastic box marked FIT401.

Instructions

1. Remove the stock bolt, the fitting and the crush washers from the radiator.

2. Install the

3. Install the T-TECH male half into the radiator using the white nylon gasket (supplied).

4. After T-TECH service is complete, remove the fittings and store in case FIT401, reinstall factory parts and

start the engine. Check for leaks and fluid quantity.

T-TECH female half to the stock bolt and washers.

Mercury Sable FIT403

Note: Whenever using special fittings from FIT403 start them by hand and only tighten enough to prevent leaks.

FIT403 must be installed at the transmission in the Mercury Sable. Use the larger fitting in FIT403 (see Figure 54)

along with FIT321.

Ford Taurus and Windstar FIT403 Instructions.

See

General Motors

Special Fittings Kit FIT404 and FIT416 are to be used on any GM vehicle utilizing 3/8" “E” clip snap fittings.

This includes Blazers and Astro vans from the mid-90’s through all 2006 GM vehicles (except Allison equipped

vehicles, see pg. 28).

1. Locate a transmission cooler line where it attaches to the radiator. Remove the plastic cover, sliding back

onto the cooler line, exposing the “E” clip.

2. Using a small hook, awl or screwdriver, remove the “E” clip from the radiator fitting. (This clip will need to

be reinstalled to hold the FIT404/FIT416 male adapter in place during the ATF exchange.)

Note: An alternative is to use a T-TECH GM 3/8" Quick Disconnect Tool (Part No. FIT514) to disengage the

cooler line without removing the “E” clip, ensuring the clip is not damaged during installation.

3. Remove the cooler line from the radiator fitting and reinsert the “E” clip back onto the radiator fitting.

4. Insert the male fitting (FIT404 or FIT416, depending on your access requirements) until it engages in the

radiator fitting.

5. Connect a service adapter hose onto the T-TECH fitting and onto the transmission cooler line.

6. When service is complete, reverse the installation procedure. Always replace the “E” clip with a new one

(Part No. FIT510) prior to connecting the transmission cooler line back into the radiator fitting.

Note: The “E” clips are easily stretched or bent when removed. The design of the “E” clips utilizes 3

pressure points to hold a line in place. If any of these points are compromised, the line may come out

of the radiator, causing fluid leaks and the transmission to run low on fluid.

prior to final connection of the cooler line back into the radiator fitting.

7. After reassembly is complete, test on the cooler line to ensure connection is secure. Reinstall the plastic

cover back over the fitting to keep out dirt and debris.

8. Check vehicle for leaks and proper fluid levels.

ALWAYS install a new clip

27

Allison Series 1000 Special Fitting Kit FIT413 (Optional)

To Radiator

To Service

Adapter

Hose

(Banjo Fitting)

Transmission

Cooling

Line

Vehicle

Stock

Bolt

Washer

(brass)

FIT411

Female

FIT411

Male

Washer

(nylon)

CAUTION: T-TECH Automatic Transmission Fluid Exchange Machines are designed to bleed Automatic

Transmission Fluid (ATF) into the overflow container if system pressures exceed 85 PSI. Please note that the

FIT413 Kit cannot be used in conjunction with

of that early model.

When servicing an Allison 1000 transmission, it is critical to warm the vehicle up prior to service, as this

transmission system can exhibit pressures up to 125 PSI when cold. After the fluid reaches normal operating

temperature, the system pressure will drop to approximately 70 PSI and service can be performed.

Never exceed idle when servicing the Allison 1000 as doing so will raise the system pressure in excess of 85 PSI,

forcing open the

T-TECH pressure overflow valve and directing ATF into the overflow tank.

Instructions

Note: During the 2003 model year, GM changed the design of the fittings used to connect the Allison 1000 cooler

line to the radiator. As a result, you will encounter different fitting requirements for these vehicles, based on model

year. Your new

T-TECH FIT413 Special Fittings Kit is designed to enable service, regardless of model year.

Your T-TECH FIT413 Kit contains 3 hose assemblies. The female hose assembly utilizes a universal fitting and will

adapt to both the old and new Allison models. There are 2 male hose assemblies: the “short” nose male hose

assembly is designed to fit older Allisons while the “long” nose hose assembly will fit the newer Allisons.

Care must be taken to match the correct male fitting to the application to avoid connection issues and leaking of

fluid. As a double-check, always compare the transmission cooler line fitting to the FIT413 male hose assembly to

ensure proper selection.

1. Locate a transmission cooler line where it attaches to the radiator. Remove the plastic cover, sliding back

onto the cooler line, exposing the “E” clip.

2. Using a small hook, awl or screwdriver, remove the “E” clip from the radiator fitting. (This clip will need to

be reinstalled to hold the FIT413 male adapter in place during the ATF exchange.)

3. Remove the cooler line from the radiator fitting and match to the corresponding male hose assembly from

the FIT413 Kit to ensure that the correct male hose assembly is used for the service.

4. Reinsert the “E” clip back onto the radiator fitting and connect the proper FIT413 male hose assembly.

5. Connect the FIT413 female hose assembly onto the transmission cooler line.

6. When service is complete, reverse the installation procedure. Always replace the “E” clip with a new one

(Part No. FIT511) prior to connecting the transmission cooler line back into the radiator fitting.

Note: The “E” clips are easily stretched or bent when removed. The design of the “E” clips utilizes 3

pressure points to hold a line in place. If any of these points are compromised, the line may come out of

the radiator, causing fluid leaks and the transmission to run low on fluid. It is strongly recommended that

you install a new clip prior to final connection of the cooler line back into the radiator fitting.

7. After reassembly is complete, test on the cooler line to ensure connection is secure. Reinstall the plastic

cover back over the fitting to keep out dirt and debris.

8. Check vehicle for leaks and proper fluid levels.

T-TECH Model No. JB100 because of the pressure limitations

Mazda FIT411

Mazda uses a banjo fitting similar the Ford Escort and Saab

900/9000 except that it is larger, see Figure 62.

CAUTION: These fittings are a matched set and must be

kept together in the small plastic box marked FIT411.

Instructions

1. Remove the vehicle stock bolt, donut fitting, and

washer from the radiator.

2. Install the female half of special fitting kit FIT411

on the vehicle stock bolt (through the donut fitting)

28

with the removed washer added.

Figure 62. FIT411 Installation On Mazda Vehicles

3. Install the male half of the special fitting FIT411 into the radiator with a supplied nylon gasket.

To Service

Adapter

Hose

To Service

Adapter

Hose

(Banjo Fitting)

Transmission

Cooling

Line

Vehicle

Stock

Bolt

FIT410 Female

FIT410

Male

To Radiator

4. When service is completed, return the fittings to special fittings case.

5. Reinstall factory parts.

6. Start the engine.

7. Check for leaks and fluid quantity.

Mercedes-Benz Standard Fitting FIT322

The Mercedes-Benz standard fitting FIT322 looks similar to the BMW special fittings FIT402 but is somewhat

smaller.

Instructions

Use the instructions and picture for BMW FIT402.

Nissan FIT411

Some Nissan models use a banjo fitting similar to the Ford Escort and Saab 900/9000 except that it is larger. See

the figure for Mazda FIT411.

CAUTION: These fittings are a matched set and must be kept together in the small plastic box marked FIT411.

Instructions

1. Remove the vehicle stock bolt, donut fitting, and washer from the radiator.

2. Install the female half of special fitting kit FIT411 on the vehicle stock bolt (through the donut fitting) with

the removed washer added.

3. Install the male half of the special fitting FIT411 into the radiator with a supplied nylon gasket.

4. When service is completed, return the fittings to special fittings case.

5. Reinstall factory parts.

6. Start the engine.

7. Check for leaks and fluid quantity.

SAAB 900 and 9000 FIT410

CAUTION: These fittings are a matched set and must be kept together in the small plastic box marked FIT410.

Instructions

1. Remove the vehicle hollow bolt along with the washers

from the radiator.

2. Install the female half of FIT410 (see Figure 63) onto

the hollow bolt along with the washers.

3. Install the male half of FIT410 into the radiator with a

supplied white nylon gasket.

T-TECH service is complete, remove the fittings

and return them to FIT410.

Figure 63. FIT410 Installation On Saab Vehicles

4. When

5. Reinstall factory parts.

6. Start the engine.

7. Check for leaks and verify fluid quantity.

29

Toyota

O-Ring

Lathe Cut Ring

Transmission Cooling

Line Attached to

Radiator

FIT409 Special

Fitting

Radiator

Clip

Radiator

Radiator

Standard Fitting

FIT321

Sevice Adapter

Hose

Transmission Cooling

Line

Toyota Camry

Note: When servicing Toyota Camry’s with 4 cylinder engine, a low line pressure condition may be encountered.

This is normal and requires the following steps to perform the service.

1. With the T-TECH connected to the vehicle through a cooler line, start the vehicle.

2. Set the parking brake, with one foot on brake, place the transmission in neutral and increase the engine

speed to 1900 RPM. Monitor the exchange process until completed.

3. If the transmission is still not producing the needed pressure for an exchange, increase the engine speed

to 2300 RPM. Monitor the exchange process until completed.

4. If the line pressure is still too low to perform a service, stop the exchange and disconnect the

vehicle may have other problems that need to be corrected before service can be completed.

T-TECH. The

Volkswagen

A fluid exchange service cannot be performed on most Volkswagen automobiles, including Jetta, Golf, Passat and Audi.

CAUTION: These vehicles do not have automatic transmission fluid cooler lines. In some cases, Volkswagen

transmission lines may have radiator coolant in them. This is because the heat exchanger is located inside the

transaxle.

Volvo 850 FIT409

The Volvo 850 uses a fitting that requires special parts to complete a T-TECH service.

CAUTION: Some of these fittings are a matched set and must be kept together in the small plastic box marked

FIT409.

Instructions

1. With an expansion pliers (a common screwdriver, 1/2 inch