Tsurumi Pump KTV series, NK series Operation Manual

17236124/B-10005-6

INTRODUCTION

Thank you for selecting the Tsurumi KTV/NK Series submersible general dewatering pump.

This operation manual explains the product operations and gives important precautions regarding its safe

use. In order to use the product to maximum benefit, be sure to read the instructions thoroughly and follow

them carefully.

To avoid accident, do not use the pump in any way other than as described in this operation manual. Note

that the manufacturer cannot be responsible for accidents arising because the product was not used as

prescribed. After reading this operation manual, keep it nearby as a reference in case questions arise during

use.

When lending this product to another party, always be sure to include this operation manual as well.

If this operation manual should become lost or damaged, ask your nearest dealer or Tsurumi representative

for another copy.

Every effort has been made to ensure the completeness and accuracy of this document. Please contact your

nearest dealer or Tsurumi representative if you notice any possible error or omission.

The contents of this document may not be copied in whole or in part without the express permission of

Tsurumi Manufacturing Co., Ltd.

OPERATION MANUAL

CONTENTS

1. BE SURE TO READ FOR YOUR SAFETY ..................... 1

2. NAME OF PARTS .......................................................... 4

3. PRIOR TO OPERATION ............................................... 5

4. INSTALLATION ............................................................. 6

5. ELECTRICAL WIRING .................................................... 8

6. OPERATION .................................................................... 9

7. MAINTENANCE AND INSPECTION ............................... 12

8. DISASSEMBLY AND REASSEMBLY ............................. 14

9. TROUBLESHOOTING ..................................................17

TSURUMI MANUFACTURING CO., LTD.

KTV/NK

Series

Submersible General Dewatering Pump

-1-

1

BE SURE TO READ FOR YOUR SAFETY

:

The mark indicates an action that must be taken, or instructs how to perform a task. The symbol

inside the mark describes the precaution in more detail ("provide ground work", in the case of the

example on the left).

:

The mark indicates a WARNING or CAUTION item. The symbol inside the mark describes the

precaution in more detail ("electrical shock", in the case of the example on the left).

●

: Operating the equipment improperly by failing to observe this precaution may possibly

cause injury to humans and other physical damage.

: Operating the equipment improperly by failing to observe this precaution may possibly

lead to death or injury to humans.

: Gives information that does not fall in the WARNING or CAUTION categories.

●

:

The mark indicates a prohibited action. The symbol inside the mark, or a notation in the vicinity of

the mark describes the precaution in more detail ("disassembly prohibited", in the case of the

example on the left).

Be sure to thoroughly read and understand the SAFETY PRECAUTIONS given in this section before using

the equipment in order to operate the equipment correctly.

The precautionary measures described in this section are intended to prevent danger or damage to you or

to others. The contents of this manual that could possibly be performed improperly are classified into two

categories:

WARNING

, and

CAUTION

. The categories indicate the extent of possible damage

or the urgency of the precaution. Note however, that what is included under

CAUTION

may at times

lead to a more serious problem. In either case, the categories pertain to safety-related items, and as such,

must be observed carefully.

WARNING

CAUTION

NOTE

Explanation of Symbols:

PRECAUTIONS TO THE PRODUCT SPECIFICATIONS

WARNING

When transporting the product,

pay close attention to its center of

gravity and mass. Use an appropriate lifting equipment to lift the

unit. Improper lifting may result

in the fall of the product which

could cause damage of the

product or human injury.

Electrical wiring should be

performed in accordance with all

applicable regulations in your

country. Absolutely provide a

dedicated earth leakage circuit breaker

and a thermal overload relay suitable for

the product (available on the market).

Imperfect wiring or improper protective

equipment can lead to electrical leakage, fire, or explosion in the worst case.

Install the product properly in

accordance with this instruction

manual. Improper installation

may result in electrical leakage,

electrical shock, fire, water

leakage, or injury.

Provide a secure grounding

dedicated for the product. Never

fail to provide an earth leakage

circuit breaker and a thermal

overload relay in your starter or

control panel (Both available on

the market). If an electrical

leakage occurs by due to a

product failure, it may cause

electrical shock.

PRECAUTIONS DURING TRANSPORT AND INSTALLATION

Do not operate the product under any conditions other than those for which it is specified.Failure to observe the precaution can lead to electrical leakage, electrical

shock, fire, water overflow or other problems.

CAUTION

Frequency

Voltage

-2-

CAUTION

Do not scratch, fold, twist, make

alterations, or bundle the cable, or

use it as a lifting device. The cable

may be damaged, which may

cause electrical leakage, shortcircuit, electrical shock, or fire.

When the product will be carried by

hand, decide the number of persons

considering the mass of the product.

When lifting up the product, do not

attempt to do it by simply bowing

from the waist. Use the knees, too,

to protect your back.

This pump is neither dust-proof nor

explosion-proof. Do not use it at a

dusty place or at a place where

toxic, corrosive or explosive gas is

present. Use in such places could

cause fire or explosion.

If a hose is used for the discharge

line, take a measure to prevent the

hose from shaking. If the hose

shakes, you may be wet or

injured.

Be sure to provide a ground wire

securely. Do not connect the

ground wire to a gas pipe, water

pipe, lightening rod, or telephone

ground wire. Improper grounding

could cause electrical shock.

Use the handle when installing or

carrying the pump. Never use the

cable to carry or to suspend.

Doing so may damage the cable

which could cause electrical

leakage, short circuit, or fire.

Allow the pump to suck as few

foreign object as possible. If there

is a risk that the pump could be

buried under the sediment, place

it on a solid base like concrete

block. Failure to do so may

result in breakdown of the

pump and could cause electrical leakage or short circuit.

Do not use the cabtyre cable if it is

damaged. Connect every conductor of the cabtyre cable securely to

the terminals. Failure to observe

this can lead to electrical shock,

short-circuit, or fire.

Attach a hose securely to the hose

coupling. Imperfect connection of

hose could cause water leakage

which may result in the damage

of nearby walls, floors, and other

equipment.

PRECAUTIONS DURING TEST OPERATION AND OPERATION

CAUTION

WA

RNING

Never try to operate the pump if

somebody is present in the pump

sump. If an electrical leakage

occurs, it can cause electrical

shock.

When changing power connection is

needed to correct the direction of rotation,

be sure to turn off the power supply

(earth leakage circuit breaker,

etc.), and perform the work after

making sure that the impeller has

stopped completely. Failure to do

so may lead to electrical shock,

short-circuit, or injury.

Never start the pump while it is

suspended, as the unit may jerk

and could lead to injury.

Do not operate the product under any

voltage other than described on the

nameplate with the voltage variation limit

within ±10%. If it is operated with a generator, it is strongly suggested not to

operate other equipment with the

same generator. Failure to observe

this caution may cause malfunction and breakdown of the product, which may lead to electrical

leakage or electrical shock.

Do not run the product dry or

operate it with its gate valve closed,

as doing so will damage the

product, which may lead to

electrical leakage or electrical

shock.

Do not use the product in a liquid

other than water. Use in oil, salt

water or organic solvents will

damage it, which may lead to

electrical leakage or electrical

shock.

Do not touch the product with

bare hands during or immediate

after the operation, as the

product may become very hot

during operation. . Failure to

observe this caution may lead

to be burned.

water only

rated

voltage

-3-

PRECAUTIONS DURING MAINTENANCE AND INSPECTION

PRECAUTION TO POWER OUTAGE

In case of power outage, turn off the power supply. The product will resume operation when the power is restored, which presents serious danger to people in the

vicinity.

WARNING

power

outage

CAUTION

WA

RNING

Absolutely turn off the power

supply or disconnect the plug

before starting maintenance or

inspection. Do not work with wet

hands. Failure to observe these

cautions may lead to electrical

shock or injury.

After reassembly, always perform a test operation before resuming use of the product. Improper assembly can result in electrical leakage, electrical shock, fire, or

water leakage.

In case any abnormality (excessive

vibration, unusual noise or odor) is

found in the operation, turn the

power off immediately and consult

with the dealer where it was

purchased or Tsurumi representative. Continuing to operate the

product under abnormal conditions may result in electrical

shock, fire, or water leakage.

Do not disassemble or repair any

parts other than those designated

in the operation manual. If repairs

are necessary in any other than

the designated parts, consult with

the dealer where it was

purchased or Tsurumi representative. Improper repairs can

result in electrical leakage,

electrical shock, fire, or water

leakage.

Test

operation

stop

OTHER PRECAUTION

CAUTION

Never use the product for potable water. It may present a danger to human

health.

Potable

Water

CAUTION

When the product will not be used

for an extended period, be sure to

turn off the power supply (earth

leakage circuit breaker, etc.).

Deterioration of the insulation

may lead to electrical leakage,

electrical shock, or fire.

Do not use the product for hot or

warm liquid over 40℃, as doing so

will damage the product, which

may lead to electrical leakage or

electrical shock.

Do not allow foreign object (pin,

wire, etc.) to enter the suction inlet

of the pump. Failure to observe

this caution could cause it to

malfunction or to operate abnormally, which may lead to electrical leakage or electrical shock.

OFF

-4-

Cabtyre Cable

Hose Coupling

Mechanical Seal

Protective Packing

Handle

Lubricant

Oil Plug

Rear Liner

Oil Casing

Pump Casing

Strainer Stand

Impeller

V-

Ring

Shaft Sleeve

Example ; KTV Series

2

NAME OF PARTS

Example ; NK Series

Note:

The above diagram is typical of the KTV2-22, but some models may vary slightly in

appearance or internal structure.

Note:

The above diagram is typical of the NK2-22, but some models may vary slightly in

appearance or internal structure.

Cabtyre Cable

Hose Coupling

Mechanical Seal

Protective Packing

Handle

Lubricant

Oil Lifter

Oil Plug

Rear Liner

Oil Casing

Pump Casing

Strainer Stand

Impeller

V-

Ring

Shaft Sleeve

-5-

When the pump is delivered, first perform the following checks.

Inspection

While unpacking, inspect the product for damage during shipment, and make sure all bolts

and nuts are tightened properly.

Specification Check

Check the model number to make sure it is the product that was ordered. Be certain it is the

correct voltage and frequency.

Note:

If there is any problem with the product as shipped, contact your nearest dealer or

Tsurumi representative at once.

3

PRIOR TO OPERATION

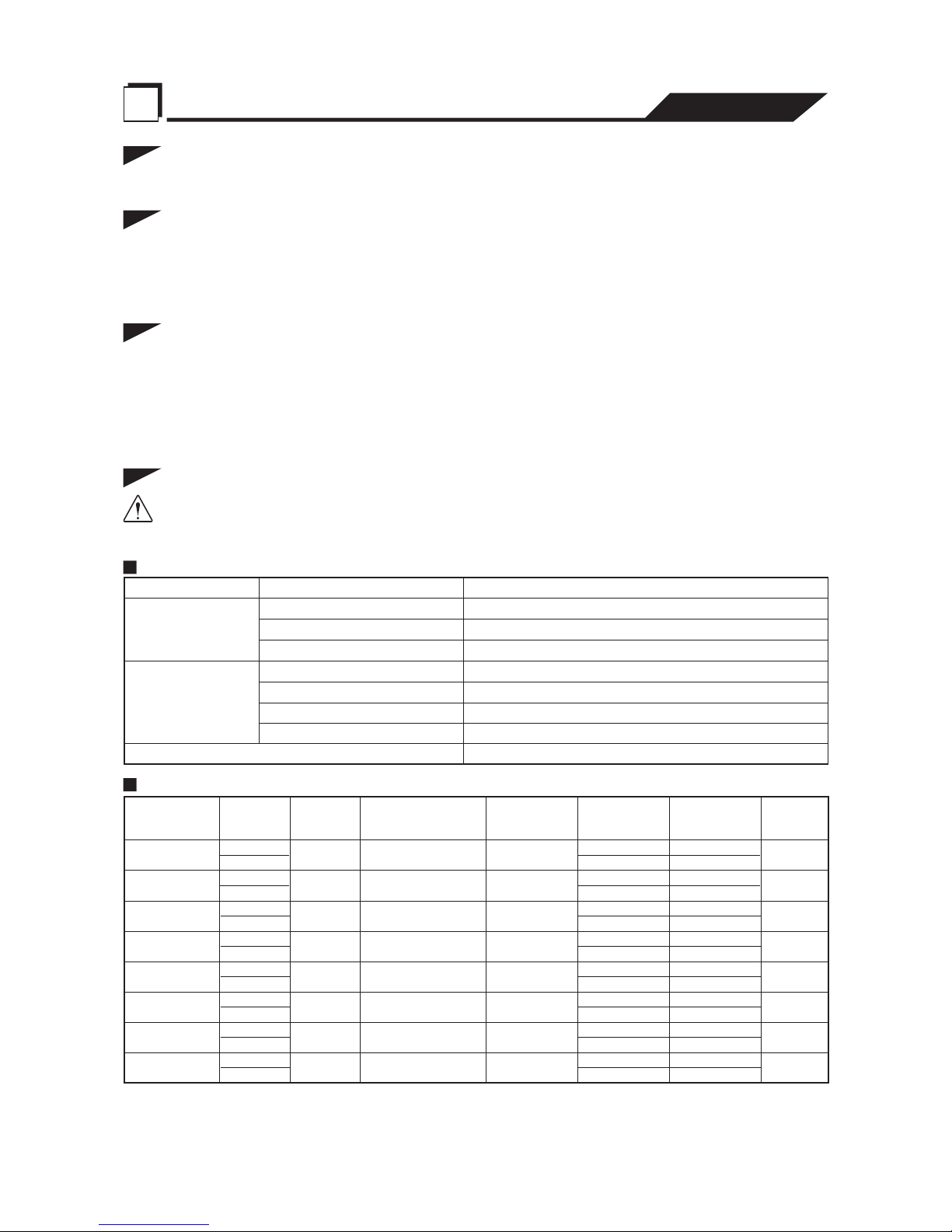

Product Specifications

CAUTION

Do not operate this product under any conditions other than those for which

it is specified. Failure to observe this precaution can lead to electrical shock,

electrical leakage, fire, water leakage or other problems.

Major Standard Specifications

Applicable Liquids Consistency and Temperature

Rain water, Ground water, Sand carrying water ; 0 ~ 40℃

Pump

Impeller

Semi-vortex-Type

Shaft Seal Double Mechanical Seal

Bearing Shielded Ball Bearing

Specification

Dry Submersible Induction Motor 2-Pole

Insulation

Class E (KTV Series), Class B (NK Series)

Protection System (Built-in)

Circle Thermal Protector

Turbine oil VG32 (non-additive) Lubricant

Connection Hose Coupling

Motor

Standard specifications (50/60Hz)

Model

KTV2-8

15.0/16.0 0.32

-/53 85

20.0/21.0 0.42

- /69 110

24.0/26.0 0.53/0.49

- /85 - /130

33.8/35.0 0.50/0.48

- /115 - /127

26.5/28.5 0.83/0.82

- /94 - /217

35.0/37.0 0.98/0.87

- /121 - /230

20.0/21.0 0.42

- /69 111

24.0/26.0 0.53/0.49

- /86 - /130

11

.5

50

3 Direct-on-Line 0.75

KTV2-15 19.5

50

3 Direct-on-Line 1.5

KTV2-22 23.0

50

3 Direct-on-Line 2.2

KTV2-37H 35.0

50

3 Direct-on-Line 3.7

KTV2-37 35.0

80

3 Direct-on-Line 3.7

KTV3-55 * 46.5

80

3 Direct-on-Line 5.5

NK2-15 28.8

50(80)

1 Capacitor-Start 1.5

NK2-22 29.0

50(80)

2

2

2

2

3.2

3.2

2(3.2)

2(3.2)

1

Capacitor-Start

Capacitor-Run

2.2

Bore

(mm)

(inch)

Starting Method Output

(kW)

Max Head

(m)

(feet)

We

ight

(kg)

Max Capacity

(m3/min)

(GPM)

Phase

* USA market: KTV2-55

Note:

The weight (mass) given above is the operating weight of the pump itself, not including the

cabtyre cable.

Note:

If you discover any damage or discrepancy in the product, please contact the dealer where

this equipment was purchased or the Tsurumi sales office in your area.

Accessory Check

Verify that all accessory items are included in the package.

• Hose Band (0.75kW) ..............1 pc

• Operation Manual ................1

Loading...

Loading...