Tsurumi Pump EPT3 Series, EPT3-50HA, EPT3-80HA, EPT3-100HA Service & Repair Manual

OPERATION, SERVICE, AND

REPAIR MANUAL

FOR TSURUMI EPT3-SERIES

TRASH PUMPS

MODELS

EPT3-50HA

EPT3-80HA

EPT3-100HA

LIMITED WARRANTY

TSURUMI MANUFACTURING CO., LTD. (“TSURUMI”) warrants to the original end purchaser during

the warranty period, every new TSURUMI pump or product to be free from defects in material and

workmanship under normal use and service, when properly installed, used, and maintained (in accordance with Tsurumi’s Operation, Service, and Repair Manual) for a period of two years from the date

the unit was first installed or twenty six months from the date of shipment by TSURUMI to wholesaler,

whichever comes first.

TSURUMI’S sole obligation under this warranty is to repair or replace at TSURUMI’S option, with new

or remanufactured parts, any part(s) that fail or that are found to be defective during the warranty period. No allowance will be made for shipping charges, damages, labor, or other charges due to failure,

repair or replacement.

This warranty does not apply to any TSURUMI product that has been disassembled without prior

approval of TSURUMI nor does it apply to any product that has been subjected to misuse, neglect,

alteration, misapplication, accident or act of God.

TSURUMI assumes no responsibility for compliance with any regulations, codes, standards, or ordinances applicable to the installation, location, operation or maintenance of its products.

No other warranty, expressed or implied, is authorized by, or applicable to, the seller. No person,

agent or dealer is authorized to enlarge upon this warranty.

TSURUMI expressly disclaims liability for consequential or incidental damages or breach of expressed

or implied warranty; and any implied warrant of fitness for a particular purpose and merchantability

shall be limited to the duration of the expressed warranty.

Some states do not allow limitations on the duration of an implied warranty, so the above limitation or

exclusion may not apply to you. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation of exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other rights, which vary from state

to state.

Tsurumi Manufacturing Co., Ltd.

TABLE OF CONTENTS

Section/Title Page

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1. Using Your Tsurumi Operation, Repair and Service Manual . . . . . . . . . . . . . . . . . . . 1

1-2. Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-3. Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-4. Specifications / Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-5. Performance Curves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1. Operating Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-2. Check the Engine Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-3. Check Engine Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-4. Check Fuel Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-5. Pre-Start Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-6. Starting and Operating the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-7. Using the Trash Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-8. Stopping the Trash Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2-9. Oil Alert . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-1. Troubleshooting Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4-1. Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4-2. Changing Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4-3. Air Cleaner Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4-4. Sediment Cup Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4-5. Cleaning and Adjusting Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4-6. Trash Pump Exploded Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4-7. Description of Mechanical Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4-8. Replacement of Mechanical Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4-9. Replacing of Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5. Storage Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5-1. Procedures for Storing Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6. Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6-1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6-2. Ordering Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Appendix A - Wheel Kit Model PGWK-200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

INTRODUCTION

1-1 Using Your Tsurumi Operation, Repair and Service Manual

We thank you for purchasing a Tsurumi trash pump. We are sure that the trash pump you have selected will meet your portable pumping needs.

This manual applies to the Tsurumi trash pumps listed below. Specifications for the trash pumps are

provided in the SPECIFICATIONS section. Key features of the trash pump are shown in the

DESCRIPTION section.

EPT3-50HA

EPT3-80HA

EPT3-100HA

This manual provides instructions for operation, service, and repair of your trash pump. We strongly

recommend that those who operate the trash pump become familiar with the trash pump’s features

and controls, and read the operating instructions before using the trash pump.

The Operation, Repair, and Service Manual also provides instructions to service, checkout, and repair

the trash pump. This manual also provides replacement parts information.

Repair and service information for the Honda engine is provided in the Owner’s Manual for Models

GX160, GX240, and GX340. A copy of the Owner’s Manual has been provided in the trash pump’s literature package. Parts information for the Honda Engine is available in Honda’s Parts Catalogs.

When there are differences between trash pump models, separate instructions are provided. The separate instructions are provided to make sure the correct procedures are used on the affected trash pumps.

All information in the Tsurumi manuals is based upon the latest production configuration of the trash

pump at the time of approval for printing.

If you have a problem with your trash pump that cannot be resolved using the Operation, Repair, and

Service Manual, or if you have questions about the operation, service, repair, or maintenance of your

trash pump, contact your local Tsurumi trash pump dealer.

1-2 Precautions

Pay special attention to precautionary notes preceded by the words WARNING, CAUTION, and

NOTE

.

W

ARNINGS indicate that there is a strong possibility of personal injury or loss of life if the procedure

is not followed, or if cleaning, lubricating, adhesives, and other materials are not used properly.

CAUTIONS

indicate that there is a possibility of equipment damage

if instructions are not followed.

NOTES

are used in procedures to provide additional or supplemental information to make the proce-

dure easier or more efficient.

W

ARNING:

• The trash pump is designed to give safe and dependable service when operated according

to the instructions in the technical manual provided with the trash pump.

• Do not operate the trash pump before you have read and understand the instructions and

the engine manufacturer’s manual. Failure to do so could result in personal injury or equipment damage.

Introduction Page 1

Tsurumi’s Operation, Service, and Repair Manual

1-3 Safety Precautions

WARNING:

• IN ORDER TO ASSURE SAFE AND EFFICIENT OPERATION OF THE TRASH PUMP, OPERATOR’S SHOULD READ AND COMPLY WITH THE FOLLOWING SAFETY PRECAUTIONS.

• Do not operate the trash pump near gasoline or gaseous fuels because of the potential danger from explosion or fire.

• Do not fill the fuel tank with fuel while the engine is running. Be careful not to spill fuel during

refueling. If fuel is spilled, wipe it off and let it dry before starting the engine.

• Do not smoke or use open flame near the fuel tank.

• Do not place flammable materials near the trash pump. Be careful not to place fuel, matches,

gunpowder, oily cloths, straw, trash, or any other combustibles near the trash pump.

• Do not operate the trash pump inside a room, cave, tunnel, or other insufficiently ventilated

area. Always operate the trash pump in a well-ventilated area. The engine may become overheated, and the poisonous carbon monoxide gas contained in the exhaust gases will endanger human

lives.

• Keep the trash pump at least 1 meter (3 feet) away from any structure or building during use.

When a trash pump is located close to a building or nearby equipment, heat and exhaust from the

engine will cause the surrounding temperature to rise. This will degrade the engines cooling efficiency, causing overheating.

• Do not enclose the trash pump nor cover it with a box. The trash pump has a built-in, forcedair cooling system, and may become overheated if it is enclosed.

• Operate the trash pump on a level surface. It is not necessary to prepare a special foundation

for the trash pump. However, the trash pump will vibrate on an irregular surface. Therefore, choose

a level place without surface irregularities.

• Shutoff the trash pump when moving the trash pump to another work site. It the trash pump

is tilted or moved during operation, fuel may spill and/or the trash pump may tip over, causing a hazardous situation. Proper lubrication cannot be expected if the trash pump is operated on a steep

incline or slope. In such a case, the piston may seize; it may seize even if the oil is above the upper

level.

Page 2 Introduction

Tsurumi’s Operation, Service, and Repair Manual

1-4 Specifications / Key Features

• Heavy-duty Honda Engine— proven reliability—quiet operation—efficient fuel consumption

• Oil Level Sensor—prevents engine operation when oil level is low

• New Design Clean Out Cover— cover removes quickly for clean-out without the need to remove

the suction hose

• New Design—larger pump casing for increased durability

• Mechanical Seal—silicon carbide seal element for long life

• Rubber Vibration Isolation Mounts—isolates pump/engine vibration from the frame for maximum

protection and noise reduction.

• Durable Rolled Steel Frame—for strength and durability

• High Chrome Impeller—increase ability to withstand the impact of debris passing through the pump

• Cast Iron Volute Casing/Stainless Steel Wear Plate/Galvanized Steel Hose Couplings.

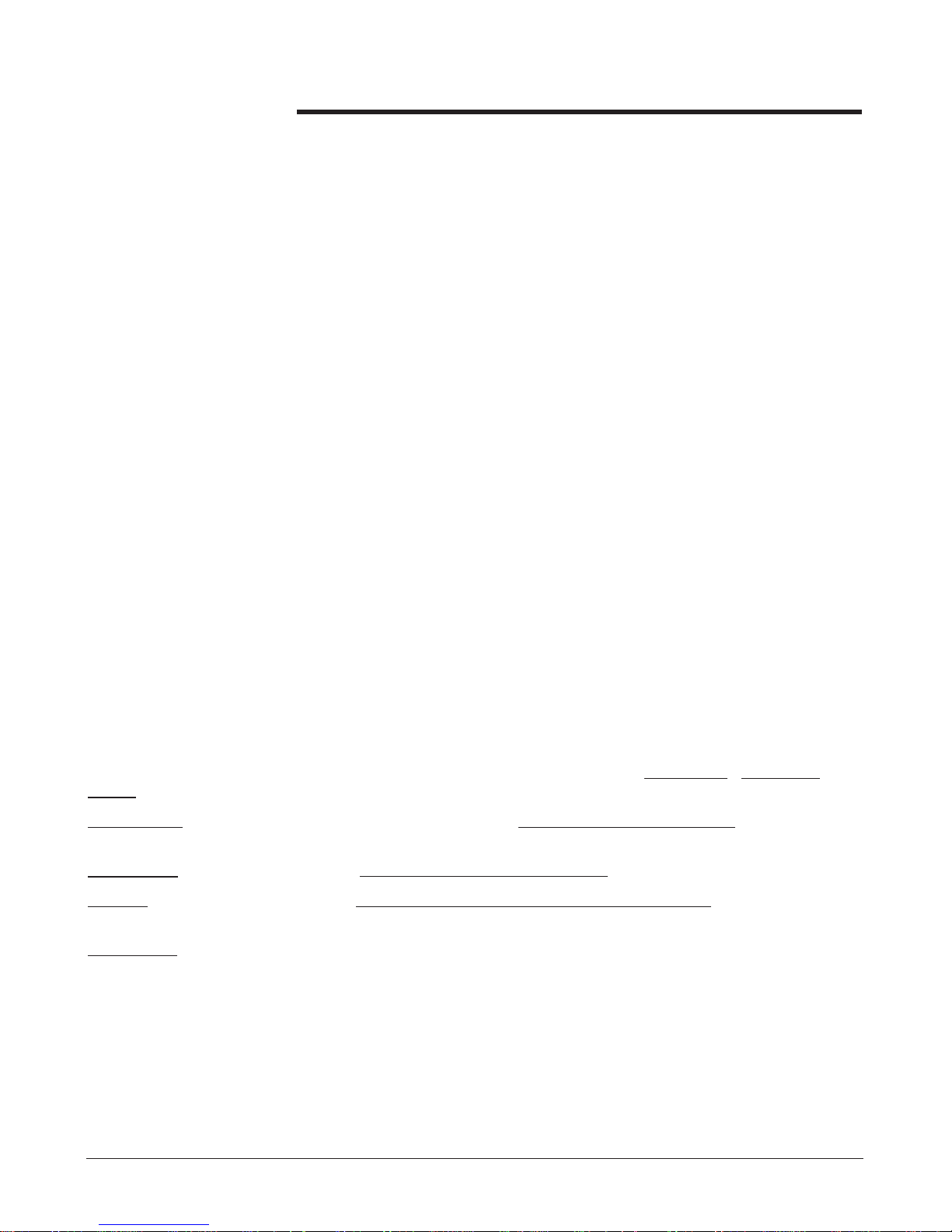

1-5 Performance Curves

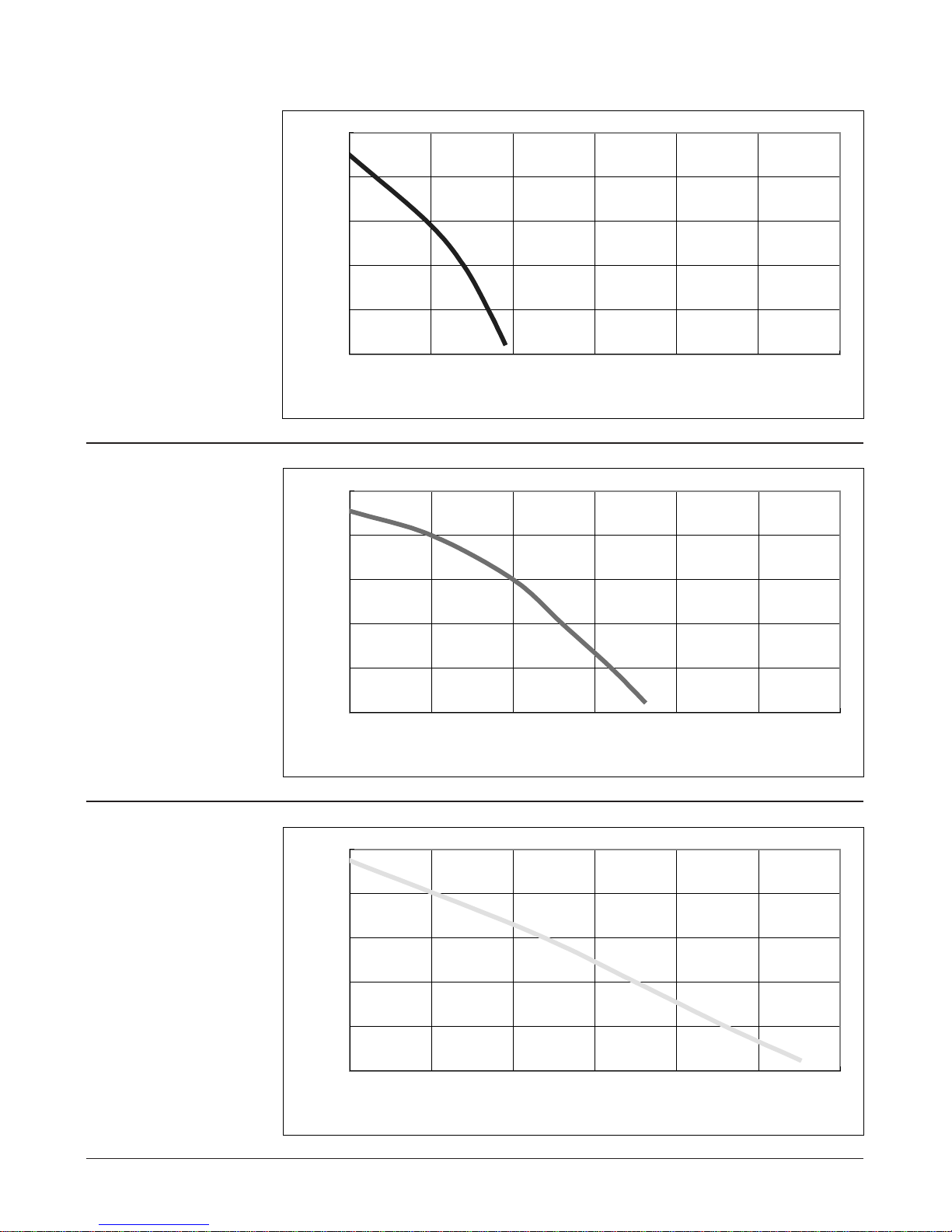

Refer to the performance curves for the pumping capacity of NPT3 series trash pumps.

Introduction Page 3

Tsurumi’s Operation, Service, and Repair Manual

AH001-3TPEAH08-3TPEAH05-3TPESLEDOM

Pump Output Gal./Min-to-Total Head See Performance Curve See Performance Curve See Performance Curve

elaM TPN 4elaM TPN 3elaM TPN 2sehcnIeziS noitcuS

PUMP

432sehcnIeziS egrahcsiD

Engine Models (Honda) - - - - GX160UT2WKT2 GX240UT2WKT2 GX340UT2WKT2

)mpr 0063( 0.11)mpr 0063( 0.8)mpr 0063( 5.5mpr/ph)mpr( PH .xaM

nI( CCtnemecalpsiD

3

) 163 (10) 242 (15) 337 (21)

7.16.159.0.slaGyticapaC knaT leuF

Noise Level (Rated Load) dB 64 dB 68 dB 72 dB

ENGINE

lioceRlioceRlioceR- - -metsyS gnitratS

Dimensions (L x W x H) Inches

23 x 18 x 17 27 x 20 _ x 25 30 _ x 20 x 26

SET

06163128.sbLthgieW gnippihS

EPT3-100HA

EPT3-80HA

0

20

40

60

80

100

0 100 200 300 400 500 600

QUANTITY(g.p.m.)

TOTAL HEAD(ft.)

EPT3-50HA

GROUP

PERFORMANCE

MODELS

EPT3-50HA

EPT3-80HA

EPT3-100HA

Page 4 Introduction

Tsurumi’s Operation, Service, and Repair Manual

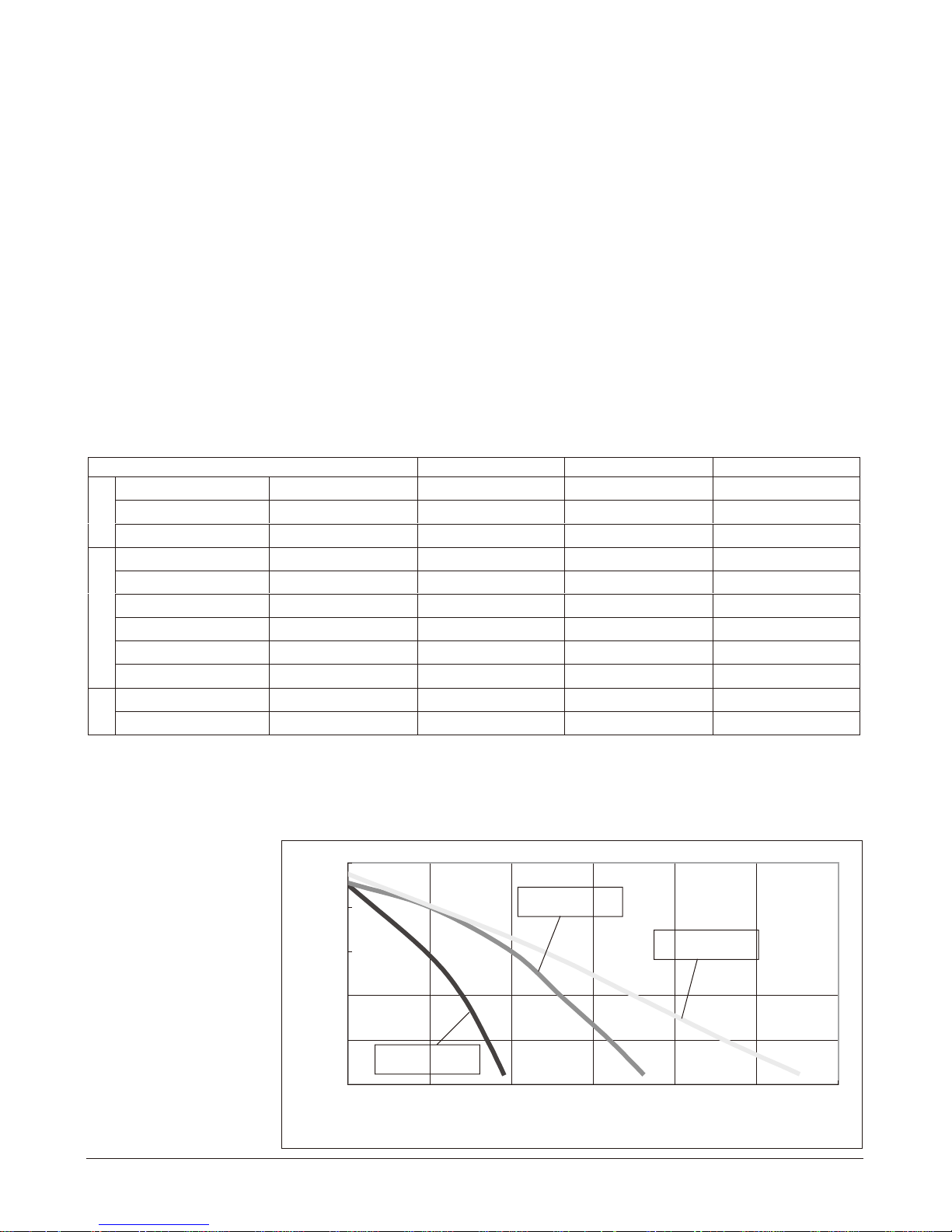

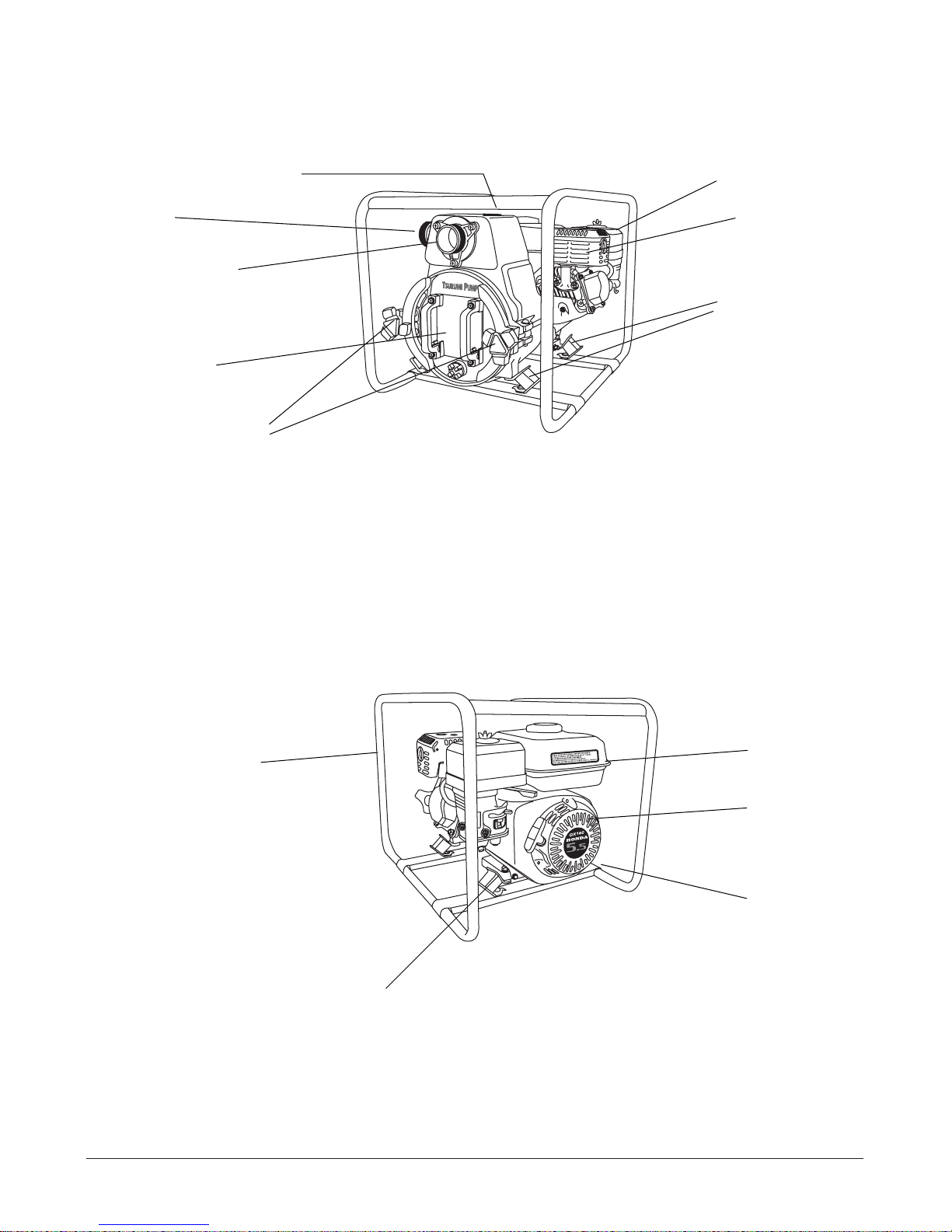

0

20

40

60

80

100

0 100 200 300 400 500 600

QUANTITY(g.p.m.)

TOTAL HEAD(ft.)

MODEL EPT3-50HA

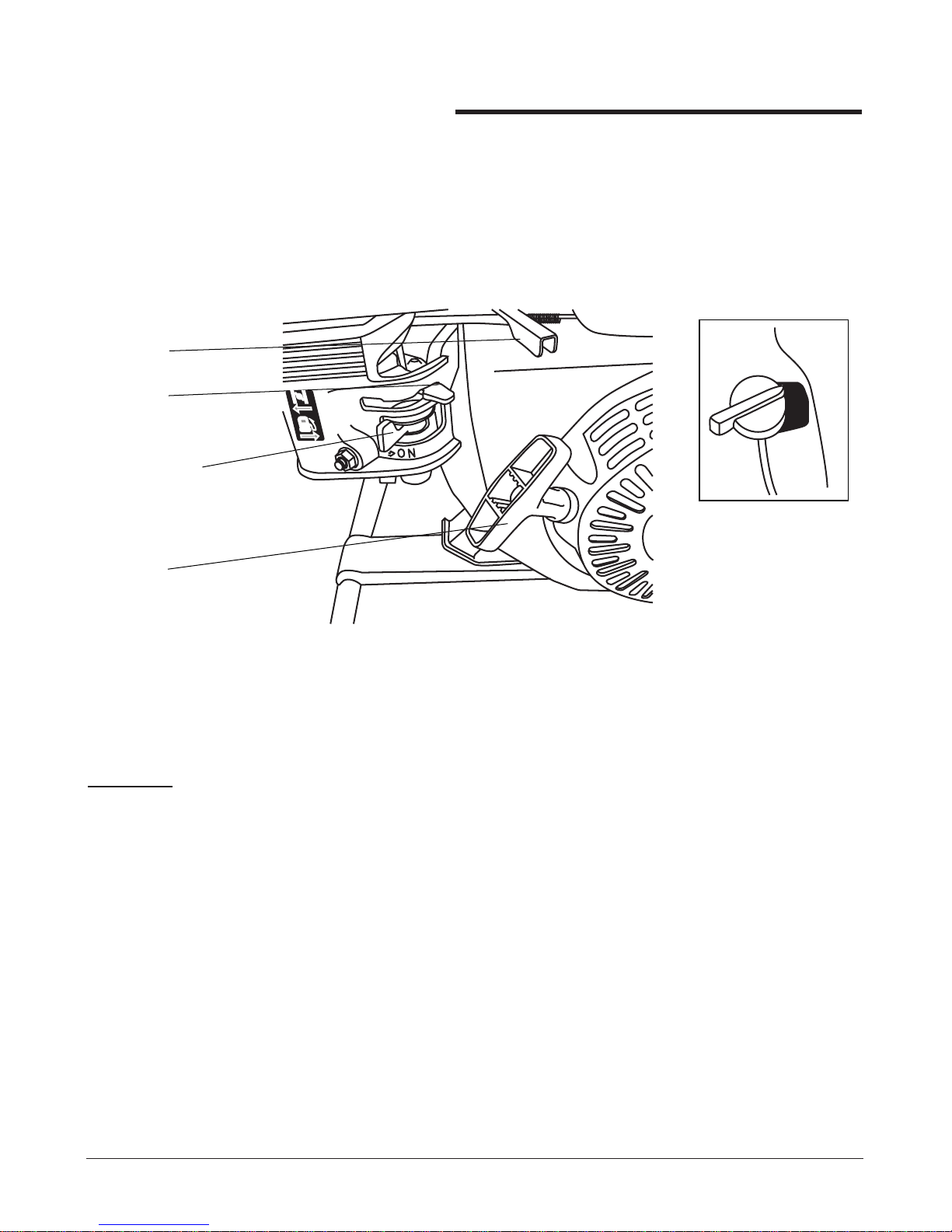

0

20

40

60

80

100

0 100 200 300 400 500 600

QUANTITY(g.p.m.)

TOTAL HEAD(ft.)

MODEL EPT3-80HA

0

20

40

60

80

100

0 100 200 300 400 500 600

QUANTITY(g.p.m.)

TOTAL HEAD(ft.)

MODEL EPT3-100HA

INDIVIDUAL

PERFORMANCE

MODEL

EPT3-50HA

INDIVIDUAL

PERFORMANCE

MODEL

EPT3-80HA

INDIVIDUAL

PERFORMANCE

MODEL

EPT3-100HA

Introduction Page 5

Tsurumi’s Operation, Service, and Repair Manual

Suction

Fitting

Discharge

Fitting

Priming

Plug

Engine Air

Filter

Vibration

Isolation Mounts

Clamping

Knobs

Casing

Cover

Recoil

Starter

Tubular

Frame

Engine

Controls

Fuel Tank

Honda

Engine

ENGINE END

Engine

Muffler

PUMP END

Figure 1: Key Features of the Trash Pump

OPERATING INSTRUCTIONS

2-1 Operating Controls

A. The trash pump operating controls are located on the engine.

B. The controls consist of a throttle lever (for speed control), choke lever (for cold weather

starting), fuel shutoff lever (to prevent fuel spills), and a recoil starter (to turnover engine by

hand). (Refer to Figure 2-1.)

2-2 Check the Engine Oil Level

CAUTION:

• ENGINE OIL IS A MAJOR FACTOR AFFECTING PERFORMANCE AND SERVICE LIFE.

NON-DETERGENT OILS AND 2-STROKE OILS ARE NOT RECOMMENDED BECAUSE

THEY HAVE INADEQUATE LUBRICATING CHARACTERISTICS

• CHECK THE OIL LEVEL WITH THE ENGINE ON A LEVEL SURFACE AND THE ENGINE

STOPPED.

A. The trash pump is controlled by the engine operating controls.

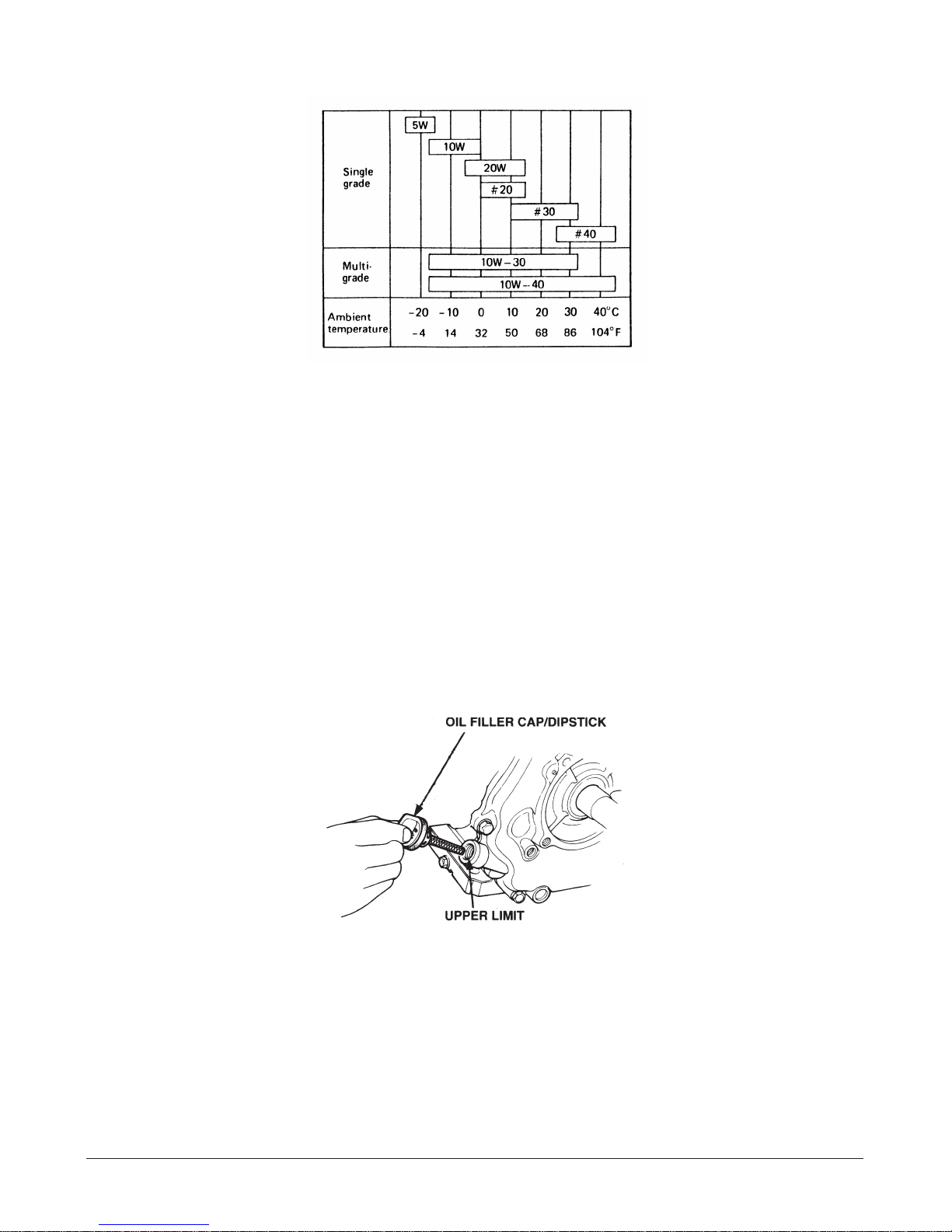

B. Use Honda 4-stroke oil, or use an equivalent high detergent, premium quality motor oil cer-

tified to meet or exceed U.S. automobile manufacturer’s requirements for Service

Classification SG, SF. Motor oils classified SG, SF will show this designation on the container. SAE 10W/30 is recommended for general, all-temperature use.

C. Other viscosity grades shown in Figure 2-2 may be used when the average temperature in

your area is within the indicated range.

Page 6 Operating Instructions

Tsurumi’s Operation, Service, and Repair Manual

Throttle

Lever

Choke

Lever

Recoil

Starter

Hand Grip

ON/OFF Switch

(Located on Recoil

Starter Shroud)

Figure 2-1: Operating Controls

Fuel Shutoff

Valve

OFF

ON

D. When checking oil, observe the following (refer to Figure 2-3): (Make sure the engine is in a level

position.)

(1) Remove the oil filler cap/dipstick and wipe it clean.

(2) Insert the filler cap/dipstick into the oil filler neck, but do not screw it in.

(3) Remove the filler cap/dipstick and check the oil level.

(4) If the level is low, fill to the top of the oil filler neck with the recommended oil.

(5) Reinstall the oil filler cap/dipstick.

Operating Instructions Page 7

Tsurumi’s Operation, Service, and Repair Manual

Figure 2-2: Oil Viscosity Grade-to-Temperature Recommendations

Loading...

Loading...