Tsurumi Pump C series, 80C215, 100C222, 100C411, 100C415 Operation Manual

17236427/B-10008-11

INTRODUCTION

Thank you for selecting the Tsurumi C Submersible Sewage & Wastewater Pumps.

This equipment should not be used for applications other than those listed in this manual. Failure to observe

this precaution may lead to a malfunction or an accident. In the event of a malfunction or an accident, the

manufacturer will not assume any liability. After reading this Operation Manual, keep it in a location that is

easily accessible, so that it can be referred to whenever information is needed while operating the equipment.

CONTENTS

1. BE SURE TO READ FOR SAFETY ............................... 1

2. PART NAMES.................................................................. 4

3. PRIOR TO OPERATION ............................................... 4

4. INSTALLATION ............................................................. 5

5. ELECTRICAL WIRING .................................................... 8

6. OPERATION .................................................................... 12

7. MAINTENANCE AND INSPECTION ............................... 15

8. DISASSEMBLY AND REASSEMBLY PROCEDURE ...... 17

9. TROUBLESHOOTING ..................................................18

TSURUMI MANUFACTURING CO., LTD.

Submersible Sewage & Wastewater Pumps

OPERATION MANUAL

with Cutter Impeller

C Series

-1-

1

BE SURE TO READ FOR YOUR SAFETY

:

The mark indicates an action that must be taken, or instructs how to perform a task. The symbol

inside the mark describes the precaution in more detail ("provide ground work", in the case of the

example on the left).

:

The mark indicates a WARNING or CAUTION item. The symbol inside the mark describes the

precaution in more detail ("electrical shock", in the case of the example on the left).

●

: Operating the equipment improperly by failing to observe this precaution may possibly

cause injury to humans and other physical damage.

: Operating the equipment improperly by failing to observe this precaution may possibly

lead to death or injury to humans.

: Gives information that does not fall in the WARNING or CAUTION categories.

●

:

The mark indicates a prohibited action. The symbol inside the mark, or a notation in the vicinity of

the mark describes the precaution in more detail ("disassembly prohibited", in the case of the

example on the left).

Be sure to thoroughly read and understand the SAFETY PRECAUTIONS given in this section before using

the equipment in order to operate the equipment correctly.

The precautionary measures described in this section are intended to prevent danger or damage to you or

to others. The contents of this manual that could possibly be performed improperly are classified into two

categories:

WARNING

, and

CAUTION

. The categories indicate the extent of possible damage

or the urgency of the precaution. Note however, that what is included under

CAUTION

may at times

lead to a more serious problem. In either case, the categories pertain to safety-related items, and as such,

must be observed carefully.

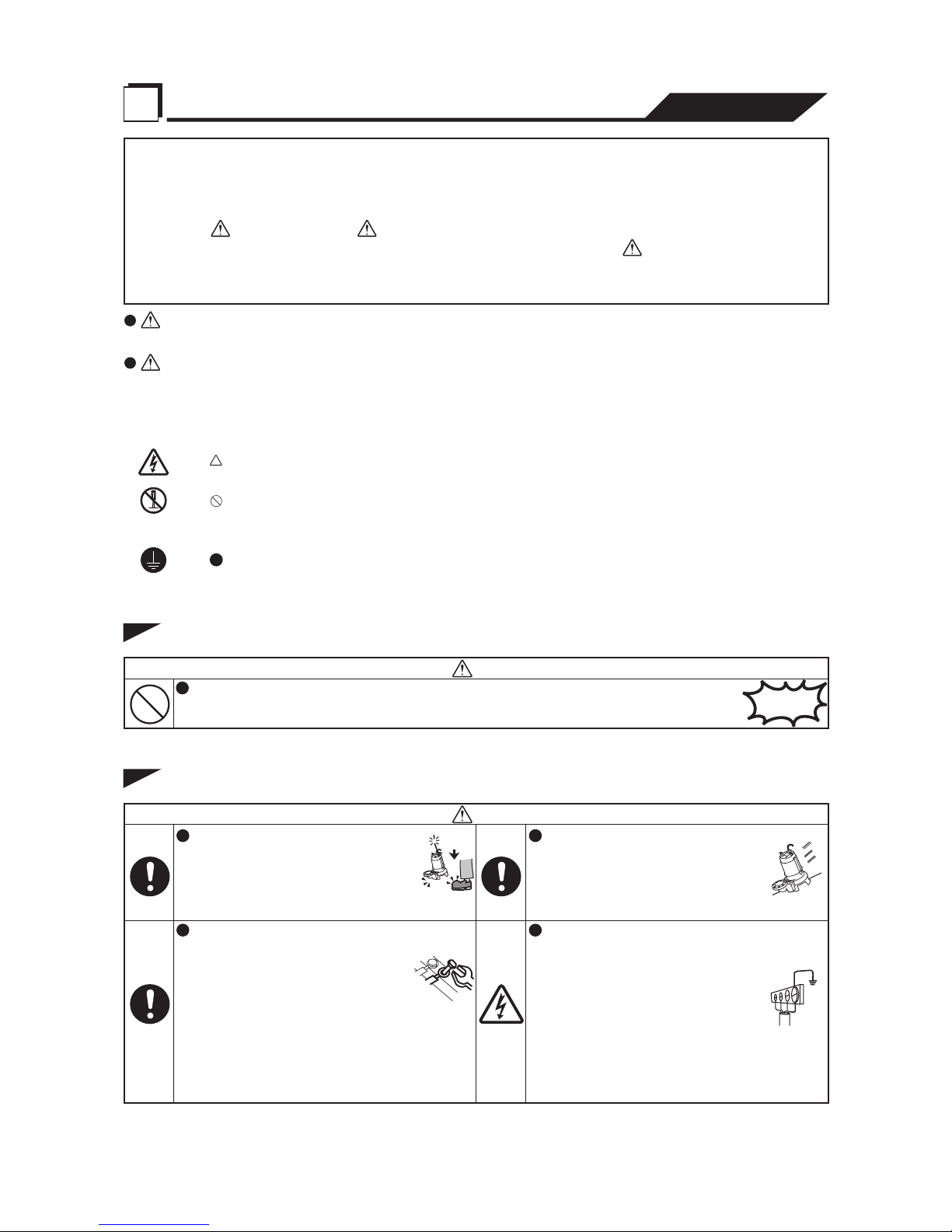

WARNING

CAUTION

NOTE

Explanation of Symbols:

PRECAUTIONS TO THE PRODUCT SPECIFICATIONS

Do not operate the product under any conditions other than those for which it is specified. Failure to observe the precaution can lead to electrical leakage, electrical

shock, fire, or water leakage, etc.

CAUTION

Frequency

Voltage

PRECAUTIONS DURING TRANSPORT AND INSTALLATION

WARNING

When transporting the product, pay

close attention to its center of

gravity and mass. Use an appropriate lifting equipment to lift the unit.

Improper lifting may result in the

product damage, injury, or death.

Electrical wiring should be

performed in accordance with all

applicable regulations in your

country. Absolutely provide a

dedicated earth leakage circuit

breaker and a thermal overload

relay suitable for the product

(available on the market). Imperfect wiring or improper protective

equipment can lead to electrical

leakage, fire, or explosion in the

worst case.

Install the product properly in

accordance with this instruction

manual. Improper installation

may result in electrical leakage,

electrical shock, fire, water

leakage, or injury.

Provide a secure grounding

dedicated for the product. Never

fail to provide an earth leakage

circuit breaker and a thermal

overload relay in your starter or

control panel (Both available on

the market). If an electrical

leakage occurs due to a

product failure, it may cause

electrical shock.

-2-

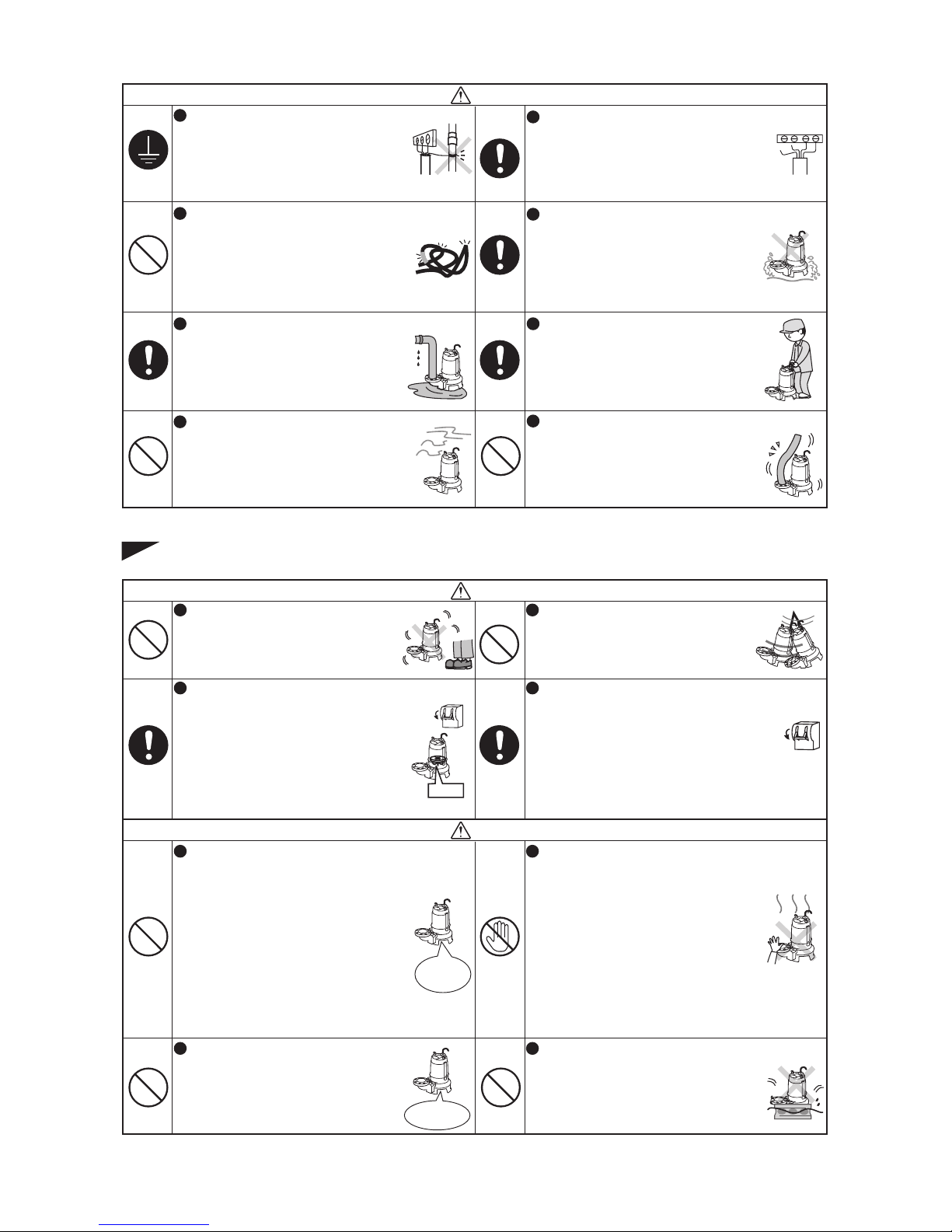

PRECAUTIONS DURING TEST OPERATION AND OPERATION

CAUTION

WARNING

Never try to operate the pump if

somebody is present in the pump

sump. If an electrical leakage

occurs, it can cause electrical

shock.

When changing power connection is

needed to correct the direction of

rotation, be sure to turn off the

power supply (earth leakage circuit

breaker, etc.), and perform the work

after making sure that the impeller

has stopped completely. Failure to

do so may lead to electrical

shock, short-circuit, or injury.

Never start the pump while it is

suspended, as the unit may jerk

and could lead to injury.

When inspecting the pump, be sure

to turn off the power supply (earth

leakage circuit breaker, etc.) so that

the pump may not start accidentally. Failure to do so may lead to a

serious accident.

Do not operate the product under

any voltage other than described

on the nameplate with the voltage

tolerance limit within ±5%. If it is

operated with a generator, it is

strongly suggested not to operate

other equipment with the same

generator. Failure to observe

this caution may cause

malfunction and breakdown of

the product, which may lead to

electrical leakage or electrical

shock.

Do not touch the product with bare

hands during or immediate after

the operation, as the product may

become very hot during operation.

Failure to observe this caution

may lead to burn.

Do not use the product in a liquid

other than water. Use in oil, salt

water or organic solvents will

damage it, which may lead to

electrical leakage or electrical

shock.

Do not run the product dry or

operate it with its valve (sluice or

gate valve) closed, as doing so

will damage the product, which

may lead to electrical leakage or

electrical shock.

For water

only

Rated

Voltage

STOP

OFF

OFF

CAUTION

Do not scratch, fold, twist, make

alterations, or bundle the cable, or

use it as a lifting device. The cable

may be damaged, which may

cause electrical leakage, shortcircuit, electrical shock, or fire.

Be sure to provide a ground wire

securely. Do not connect the

ground wire to a gas pipe, water

pipe, lightening rod, or telephone

ground wire. Improper grounding

could cause electrical shock.

Do not use the cabtyre cable if it is

damaged. Connect every conductor

of the cabtyre cable securely to the

terminals. Failure to observe this

can lead to electrical shock,

short-circuit, or fire.

Install the discharge piping

securely so that no water leakage

may occur. Failure to do so may

result in damage to nearby

walls, floors, and other equipment.

When the product needs to be

carried by hand, decide the

number of persons considering

the mass of the product.

This pump is neither dust-proof nor

explosion-proof. Do not use it at a

dusty place or at a place where

toxic, corrosive or explosive gas is

present. Use in such places

could cause fire or explosion.

If a hose is used for the discharge

line, take a measure to prevent the

hose from shaking. If the hose

shakes, you may be wet or

injured.

Provide a countermeasure against

overflow, like installation of a

stand-by pump. If it is insuffi-

cient, the overflow may damage

nearby wall, floor and other

equipment.

-3-

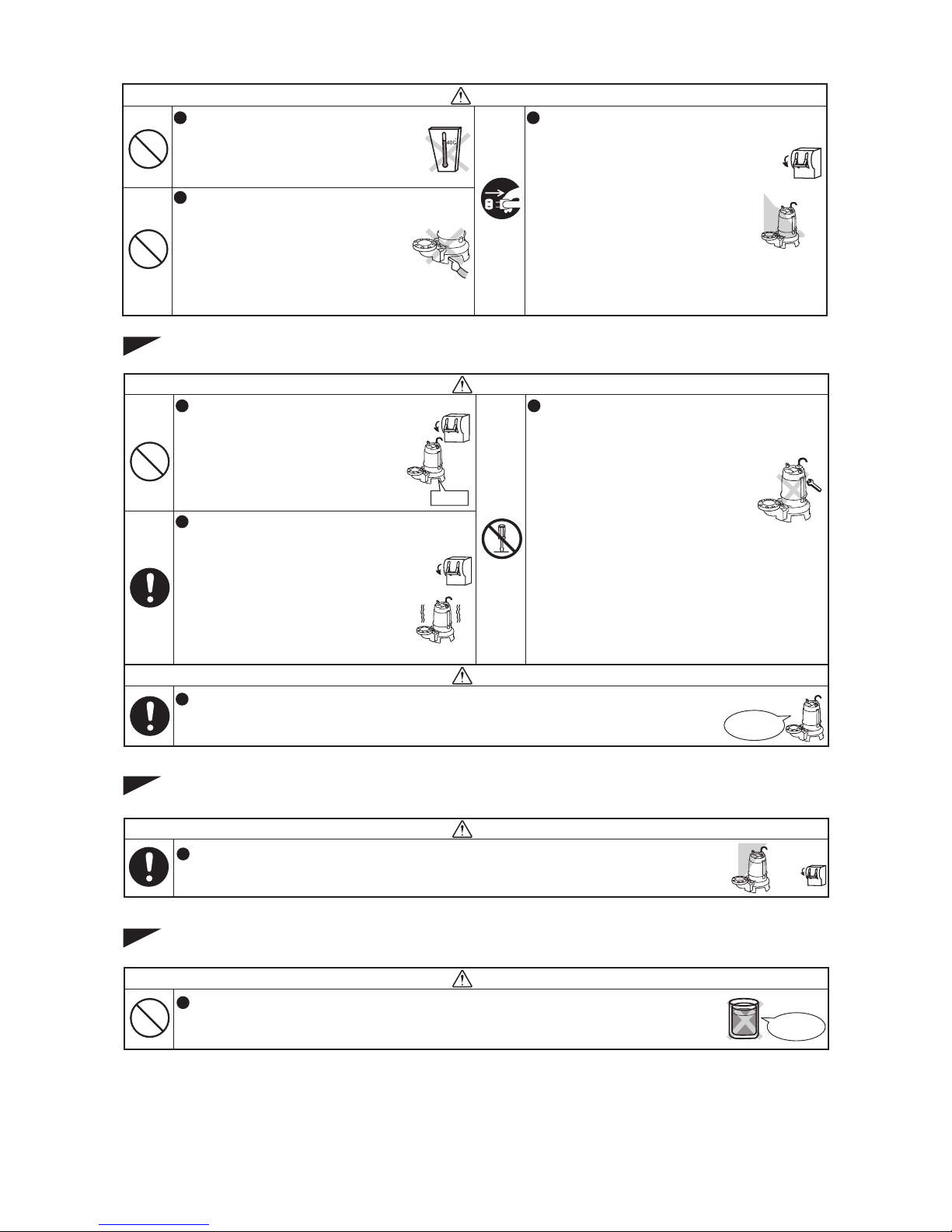

PRECAUTIONS DURING MAINTENANCE AND INSPECTION

CAUTION

WARNING

Absolutely turn off the power

supply before starting maintenance

or inspection. Do not work with wet

hands. Failure to observe these

cautions may lead to electrical

shock or injury.

After reassembly, always perform a test operation before resuming use of the product. Improper assembly can result in electrical leakage, electrical shock, fire,

or water leakage .

In case any abnormality (excessive

vibration, unusual noise or odor) is

found in the operation, turn the

power off immediately and consult

with the dealer where it was

purchased or Tsurumi representative. Continuing to operate the

product under abnormal conditions may result in electrical

shock, fire, or water leakage.

Do not disassemble or repair any

parts other than those designated

in the operation manual. If repairs

are necessary in any other than

the designated parts, consult with

the dealer where it was

purchased or Tsurumi representative. Improper repairs can

result in electrical leakage,

electrical shock, fire, or water

leakage.

Test

operation

STOP

OFF

OFF

PRECAUTION TO POWER OUTAGE

In case of power outage, turn off the power supply. The product will resume

operation when the power is restored, which presents serious danger to

people in the vicinity.

WARNING

power

outage

OFF

CAUTION

Do not allow foreign objects (metal

objects such as pins or wires) to

enter the suction inlet of the pump.

Failure to observe this caution

could cause it to malfunction or

to operate abnormally, which

may lead to electrical leakage or

electrical shock.

Do not use the product for hot or

warm liquid over 40℃, as doing so

will damage the product, which

may lead to electrical leakage or

electrical shock.

When the product will not be used

for an extended period, be sure to

turn off the power supply (earth

leakage circuit breaker, etc.).

Deterioration of the insulation

may lead to electrical leakage,

electrical shock, or fire.

OFF

OTHER PRECAUTION

CAUTION

Never use the product for potable water. It may present a danger to human

health.

Potable

Water

-4-

After unpacking, verify the contents.

Product Inspection

Inspect the product for damage during shipment, and make sure all bolts and nuts are tightened properly.

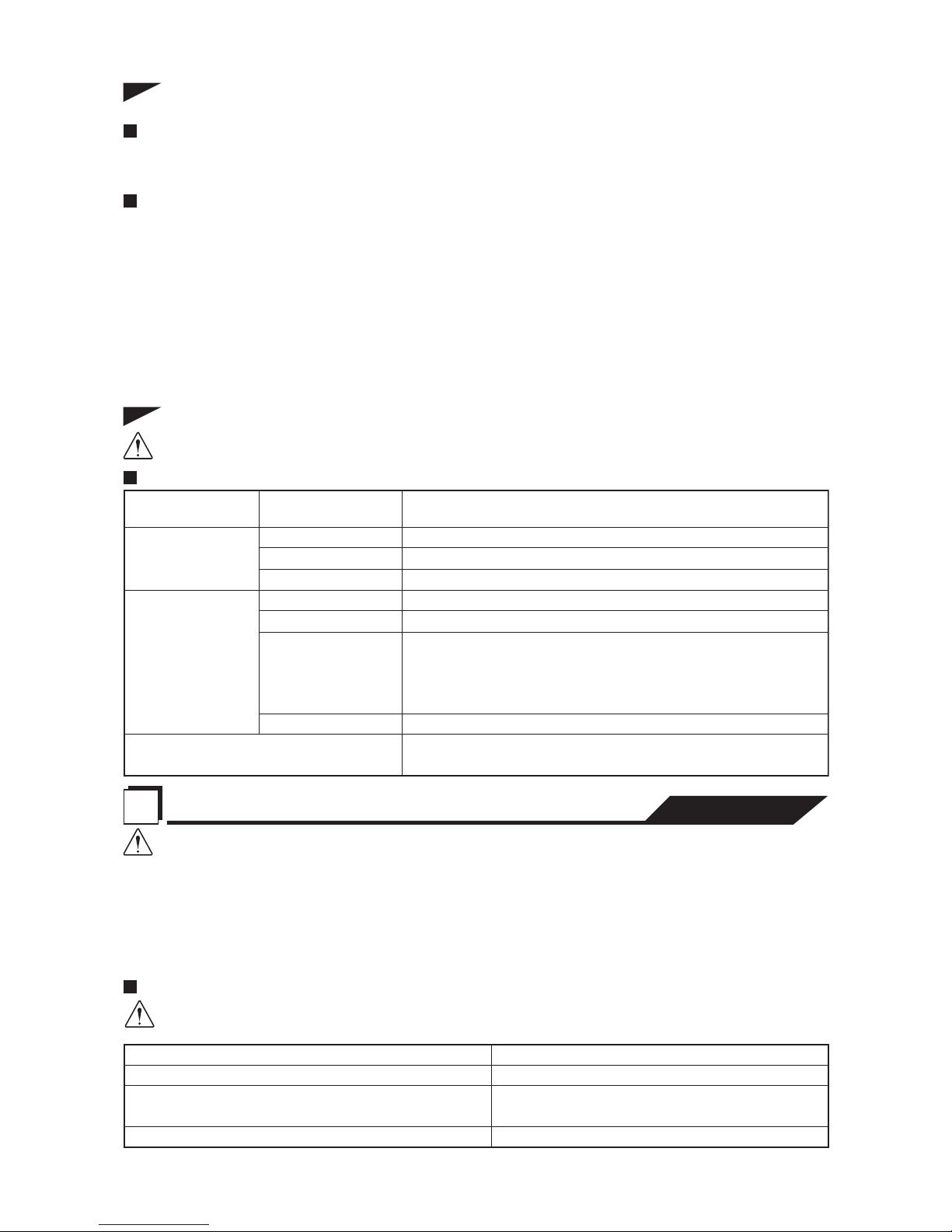

Specication Check

Check the nameplate of the unit to verify that it is the product that you have ordered. Pay particular attention

to its voltage and frequency specications.

Example

2

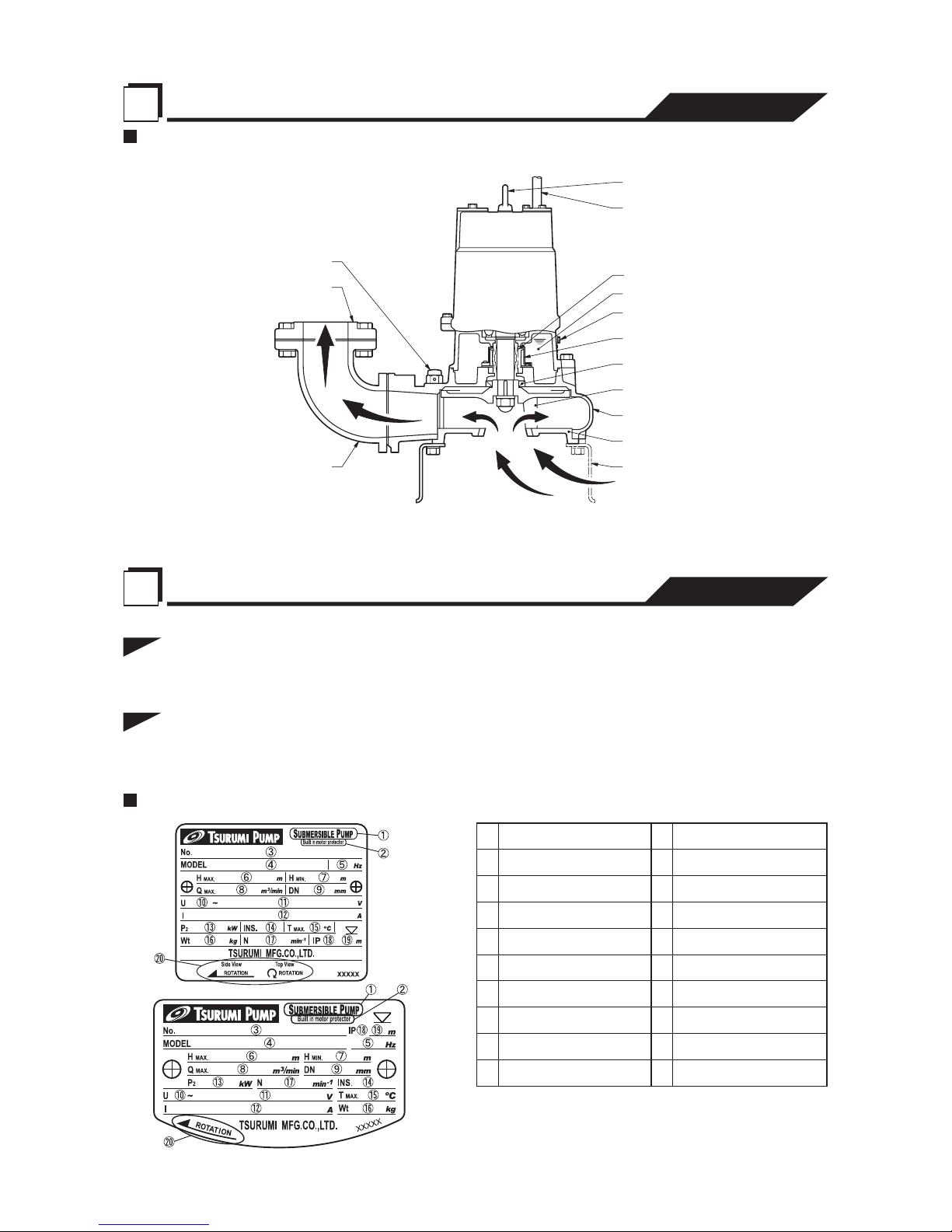

PART NAMES

3

PRIOR TO OPERATION

Discharge Bend

Screwed Flange

Air Release V

alve

Mechanical Seal

Oil Lifter

Oil Plug

Lubricant

Pump Casing

Oil Seal

Impeller

Suction Cover

Stand

EyeBolt

Cabtyre Cable

Example of nameplate

1

2

3

4

5

6

7

8

9

10

11Submersible pump

Built in motor protector

Serial number

Model

Frequency

Max. total head

Min. total head

Max. flow rate

Discharge bore

Phase

Rated voltage

12

13

14

15

16

17

18

19

20

Rated current

Rated output power

Insulation class

Max. liquid temperature

Weight without cable

Speed of rotation

IP degree of protection

Max. immersion depth

Direction of rotation

-5-

Accessory Check

Verify that all accessory items are included in the package.

If you discover any damage or discrepancy in the product, please contact the dealer where this equipment

was purchased or the Tsurumi sales of ce in your area.

Note:

Bend Type

• Discharge Bend (with bolts and packings) ..................................1 set

• Screwed Flange (with bolts and packings) ..................................1 set

• Operation Manual .........................................................................1

Guide-Rail Type

• Guide Support (with bolts) .............................................................1 set

• Duck-Foot Bend (with bolts) ..........................................................1 set

• Guide Hook (with bolts) .................................................................1 set

• Chain for lifting up/down the pump (with shackle) .........................1 set

• Guide Connector (with bolts) .........................................................1 set

• Screwed Flange *1 ........................................................................1 set

• Operation Manual ..........................................................................1

*1 : Some of the models are not provided.

Foundation Bolts are not provided.

Product Specications

Do not operate this product under any conditions other than those that have

been specied.

CAUTION

Major Standard Specications

Applicable Liquids

Waste water, sewage, and liquid carrying waste and

solid matters ; 0 ~ 40℃

Pump

Impeller Channel type (with Cutter Mechanism)

Shaft Seal Double Mechanical Seal

Bearing Shielded Ball Bearing

Specifications Dry Type Submersible Induction Motor, 2-Pole, 4-Pole, 6-Pole

Insulation

Class E, B, and F

Protection System

(built-in)

Circle thermal protector (7.5kW max.)

Miniature protector (11kW minimum, and some models with

5.5kW and 7.5kW)

Float type Leak Sensor (2P-15kW, 2P-22kW)

Turbine oil VG32 (non-additive)Lubricant

Discharge Connection

Special screwed flange (1.5kW max.)

JIS10K flange (above 2.2kW minimum and guide-rail type)

Motor

Property

• Do not use the pump for pumping liquids other than water, such as oil, salt

water, or organic solvents.

• Use with a power supply voltage tolerance within ± 5% of the rated voltage.

• The water temperature for operating the pump should be between 0 ~ 40℃.

Failure to observe the precautions given above could cause the pump to

malfunction, which may lead to current leakage or electrical shock.

CAUTION

Critical Use Pressure

Do not operate the pump in an area that is exposed to a water pressure that

exceeds the values given below.

CAUTION

To use the pump for a special solution, contact the dealer where it was purchased, or the Tsurumi sales of

-

ce in your area.

Note:

4

INSTALLATION

Models with output of 7.5kW and below, 2P-11kW 0.3MPa(3kgf/cm

2

) − discharge pressure during use

Models with output of 4P-11kW, 4P-15kW, 2P-22kW,

6P-11kW and 6P-15kW

0.4MPa(4kgf/cm2) − discharge pressure during use

Models with output of 2P-15kW

0.5MPa(5kgf/cm2) −

discharge pressure during use

Applicable Pump Critical Use Pressure

Loading...

Loading...