TS Industrie Saelen GS/VIPER50DS Operating Manual

TA B L E O F C O N T E N T S

INVENTION PATENT _________________________________ 5

INTRODUCTION__________________________________________

SAFETY PRECAUTIONS__________________________________________________

GUARANTEE____________________________________________________________

LOCATION OF THE SERIAL NUMBER ____________________________________

SAFETY ___________________________________________________________________

GENERAL SAFETY AND MEANING OF THE LABELS _______________________

SAFE USE________________________________________________________________

SAFE MAINTENANCE____________________________________________________

SAFE TRANSPORTATION_________________________________________________

GENERAL DESCRIPTION AND FUNCTIONS ______________________

OPERATION ____________________________________________________________

STARTING _______________________________________________

CHECKLIST ____________________________________________________________

STARTING _____________________________________________________________

STOPPING ______________________________________________________________

MAINTENANCE___________________________________________

RECOMMENDED LUBRICANTS___________________________________________

MAINTENANCE INTERVALS______________________________________________

LUBRICATION POINTS___________________________________________________

OIL LEVEL ______________________________________________________________

TENSION OF THE METAL BELT __________________________________________

VERIFICATION BELT AND SLIDING PLATE _______________________________

AIR INLETS OF THE ROTOR _____________________________________________

DISASSEMBLY TO REPLACE BLADES AND HAMMER INSERTS ____________

DISASSEMBLY TO CHECK THE COUNTERBLADES ________________________

ADJUSTMENT OF THE ROTOR BELTS ____________________________________

MAINTENANCE OF THE HYDRAULIC COUPLING _________________________

ADJUSTMENT OF THE BRAKES __________________________________________

DESCRIPTION AND MANIPULATION ______________________________

DASHBOARD ____________________________________________________________

TANKS __________________________________________________________________

SAFETY CAPS ___________________________________________________________

MAINTENANCE/WORK SWITCH__________________________________________

EMERGENCY STOPS _____________________________________________________

6-7

6-7

8

9

10

11-12

13

14

15

16-18

19

20

20

21

22

23

23

24

25-27

28

29

30

30

31-32

33

34

35

36

37

37

38

39

40

41

GS/VIPER50DS

TA B L E O F C O N T E N T S

ANTI-OBSTRUCTION SYSTEM "VarioStress": Description______________

ANTI-OBSTRUCTION SYSTEM: Programs _________________________________

ROTOR SENSOR ________________________________________________________

FUNCTIONING OF THE HYDRAULIC COUPLING AND ITS SAFETY

EQUIPMENT ____________________________________________________________

CO2 REDUCTION: (OPTION) Functioning __________________________________

CO2 REDUCTION: (OPTION) Starting ______________________________________

SPECIFIC FUNCTIONS OF CO2 RÉDUCTION_______________________________

DISCHARGE CHUTE _____________________________________________________

GENERAL PROBLEM-SOLVING_____________________________________

PROBLEM-SOLVING CO2 RÉDUCTION_____________________

SPECIFICATIONS_______________________________________________________

HYDRAULIC COUPLING AND CHANGING THE ENGINE OIL _______

HYDRAULIC SCHEDULE __________________________________

ELECTRICAL CIRCUIT VIPER standard________________________

ELECTRICAL CIRCUIT VIPER WITH CO2 REDUCTION_____

ELECTRICAL CIRCUIT CO2 RÉDUCTION_____________________

ELECTRICAL CIRCUIT MOTOR____________________________

SPECIFIC FUNCTIONS: Use of the machine in manual mode_____

CONFIRMATION OF CONFORMITY TS Industrie_____________

42

43-44

45

46

47

48-49

50

51

52-53

54

55

56

57

58

59

60

61-62

63

64

GS/VIPER50DS

PATENT FOR INVENTION

The General Manager of the National Institute of industrial property has decided

that invention patent # ##-##### the text of which is appended shall be delivered to:

SAELEN S.N.S. Company - FR

The delivery produces its effects for a period of twenty years starting on the date

of deposit of the application, under reserve of payment of the annual royalties.

Mention of the delivery is made in the Official Bulletin of industrial property ###/## of

##:##:## (publication # # ### ###).

Intellectual property law-Books VI

GRANTING DECISION

I N T R O D U C T I O N

Thank you for your purchase and your confidence in us.

It is important to read what follows in order for you to fully benefit from your purchase.

Although this machine is simple and easy to use, we recommend reading this manual be-

fore starting to use it.

In order to operate your multi-vegetation chipper in a safe, efficient and effortless manner,

you need to be familiar with the instructions for operation, maintenance and problemsolving that are described in this manual.

This manual describes all the functions of the VIPER chipper. Keep it within reach for later reference. Please contact your reseller for more information, technical data or if you

want to order an additional copy of this manual.

Safety precautions:

This machine is only suitable for chipping vegetable waste. It may not be operated by

persons younger than 16.

The machine should only be used by persons who have a good physical condition and a

certain technical knowledge.

Maintenance must be done by a qualified technician. All interventions for assembly, disassembly and/or specific maintenance must be handled by a recognized distributor. Before

working on the VIPER for maintenance or other purposes, please remove the ignition key.

Position of the operator: left, right, in front of and behind in this manual are as

seen by the operator from his work station, facing the hopper.

F Front

L

Left

R

Right

B Behind

GS/VIPER50DS

Safety instructions

This machine is only intended for crushing and shredding plants.

Besides shredding wood and plants, the VIPER shredder cannot be used

for any other purpose.

The shredder should only be used by people over 16 years of age.

I N T R O D U C T I O N

This machine can only be used by someone who is in good physical condition and who

has some technical knowledge.

Maintenance and repair work should be done by a qualified technician. Assembling,

disassembling and/or specific maintenance work should be performed by an authorized

dealer.

Before beginning work or proceeding to maintenance of the VIPER, always remove the

ignition key.

Proceed to maintenance by scrupulously following the instructions.

Eliminate pieces of metal, plastic, rubber or any other materials that may have been mixed

with the wastes.

Always use protection goggles, work gloves and protection against noise;

The machine can in no case be used to transport equipment, material or people.

The machine cannot be used to push or pull anything.

Battery acid is very corrosive. Avoid any contact with the eyes, skin and garments.

Immediately rinse eventual splashes with water and if the case arises, consult a doctor.

Before touching the electric circuit, always disconnect the cable connected to the battery’s +

terminal.

Always keep the battery out of reach of children.

When performing maintenance, do it in a sufficiently lit workshop.

Respect the safety standards prescribed in the motor’s user and maintenance manual.

Keep children away while the machine is in operation or when performing maintenance

work; Do not work in confined space. Do not run the motor in a non ventilated place (risk of

CO² intoxication)

GS/VIPER50DS

L O C AT I O N O F T H E

S E R I A L N U M B E R

When ordering spare parts for replacement or if you need technical information, please

always have with you the serial number of your VIPER 50 shredder.

TS Industrie manufacturer’s plate is on the front left chassis.

The serial number is located at the

place indicated on the photo.

Serial number

GS/VIPER50DS

G U A R A N T E E

The TS Industrie Company guarantees the parts of its VIPER shredders against any defect

that could affect their operating. The guarantee applies in all the cases where the damage is

not the result of improper use, abuse or negligence, accidental, act of God or any other

circumstance beyond the control of TS Industrie. This guarantee extends over a period of

one year starting on the date of delivery to the customer and is limited to the replacement of

defective parts and/or of labour.

GUARANTEE CLAIM

A claim in due form shall be presented to TS Industrie, by the origin purchaser for inspection

by an authorized representative of the company.

This guarantee does not apply to a shredder that has been modified out of our

workshops and that, according to TS Industrie standards, would be affected in its

operation, its safety and its service life.

This guarantee does not cover parts and accessories that are already under their

manufacturer’s guarantee and the servicing of which is covered by the latter’s

administration. Service items such as lubricants, belts, paint and similar are not subject to

guarantee.

USER MANUAL

The purchaser acknowledges having received instructions concerning the correct operation

of the shredder and also acknowledges that TS Industrie cannot assume any responsibility

resulting from the use of his product other than that described in the user manual supplied at

the time of the purchase.

DO NOT FORGET TO REGISTER YOUR GUARANTEE

OTHERWISE IT WILL BECOME INVALID.

www.ts-industrie.eu

Section: Services / Warranty

GS/VIPER50DS

SA FETY

You are responsible for the safe use and the maintenance of your plant shredder. You

should thus make sure that whoever uses, maintains and works with the appliance has

knowledge of the operating and maintenance methods as well as the safety measures to

apply as described in this manual. The user manual informs you on the security practices

to apply when using the plant shredder.

Remember that you are the person in charge of security. Efficient precautions will protect

you as well as those around you. Make sure that ANYONE working with this appliance

knows how to operate and maintain it. It is very important to prevent accidents. to avoid

injury, respect the security measures explained in this manual.

- Before using the plant shredder, an owner has the duty of giving the user

instructions to operators or eventual employees.

- This equipment’s most important safety device is a safe operator. It is an

operator’s duty to read and understand all the security and operating instructions and to

scrupulously follow them. The best way of avoiding accidents.

- No one is supposed to handle the MV VIPER shredder if they have not read and

understood the instructions on the subject. An operator without knowledge exposes

himself and others to risks of accidents.

- It is not allowed to modify the equipment in any way whatever. Any non

authorized modification could affect the operation or the security and eventually reduce

the equipment’s service life.

THINK CAUTION!

WORK IN COMPLETE SECURITY.

GS/VIPER50DS

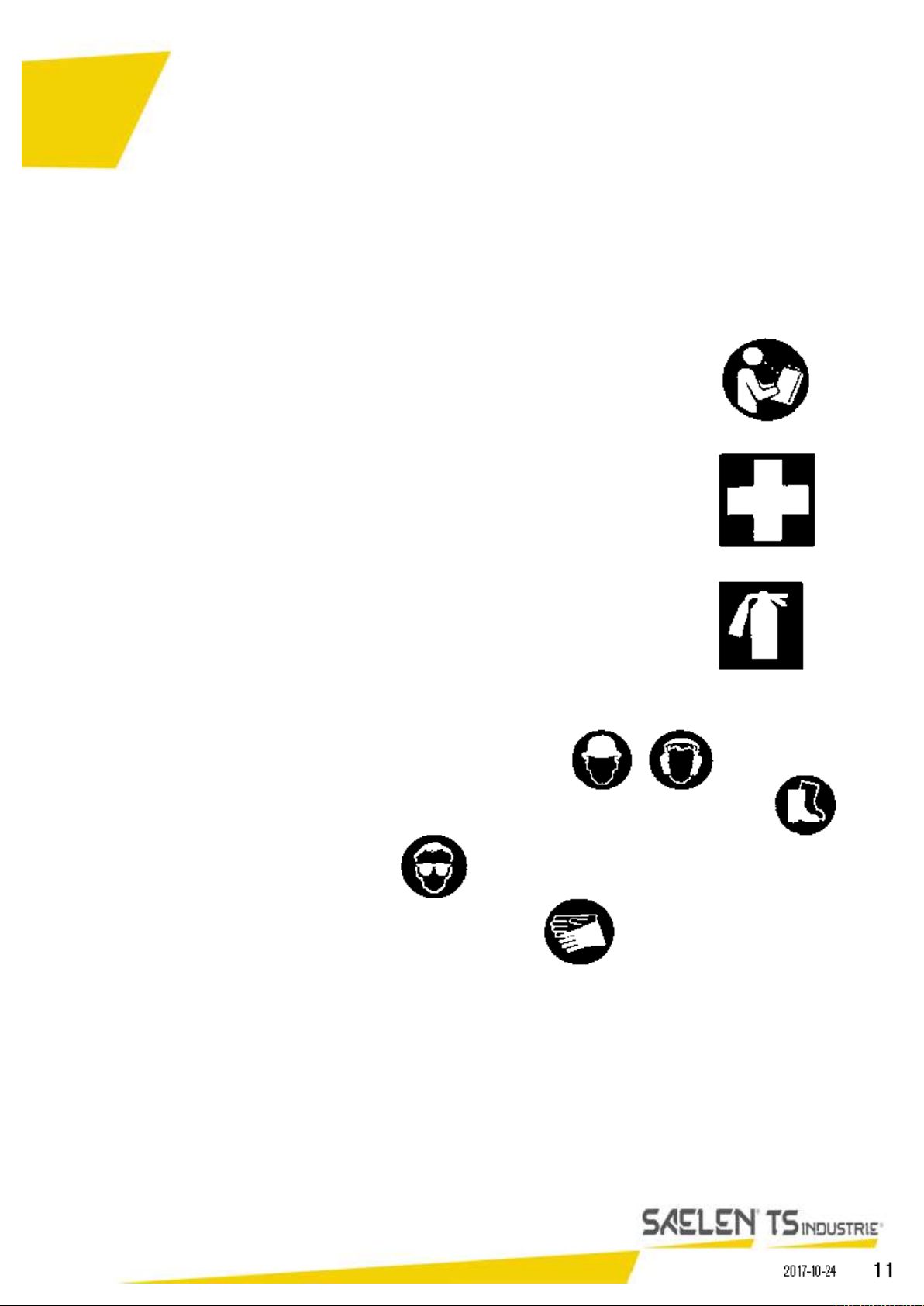

GE NERAL SAFET Y

1) Read and understand the user manual and all the

security symbols before operating, maintaining,

un-jamming or adjusting the shredder.

2) Keep a first aid kit in case of accident.

Keep it in a visible place.

3) Keep a fire extinguisher within reach in case of

need. Keep it in a visible place.

4) Use appropriate protection equipment. Here are a few suggestions,

but do not limit yourself just to this description:

-Helmet and ear protection

-Work shoes with steel non-skid soles

-Protective goggles

-Work gloves and waterproof

garments.

5) Never operate without the protector.

6) Keep people away and especially children, when you are using the

shredder

GS/VIPER50DS

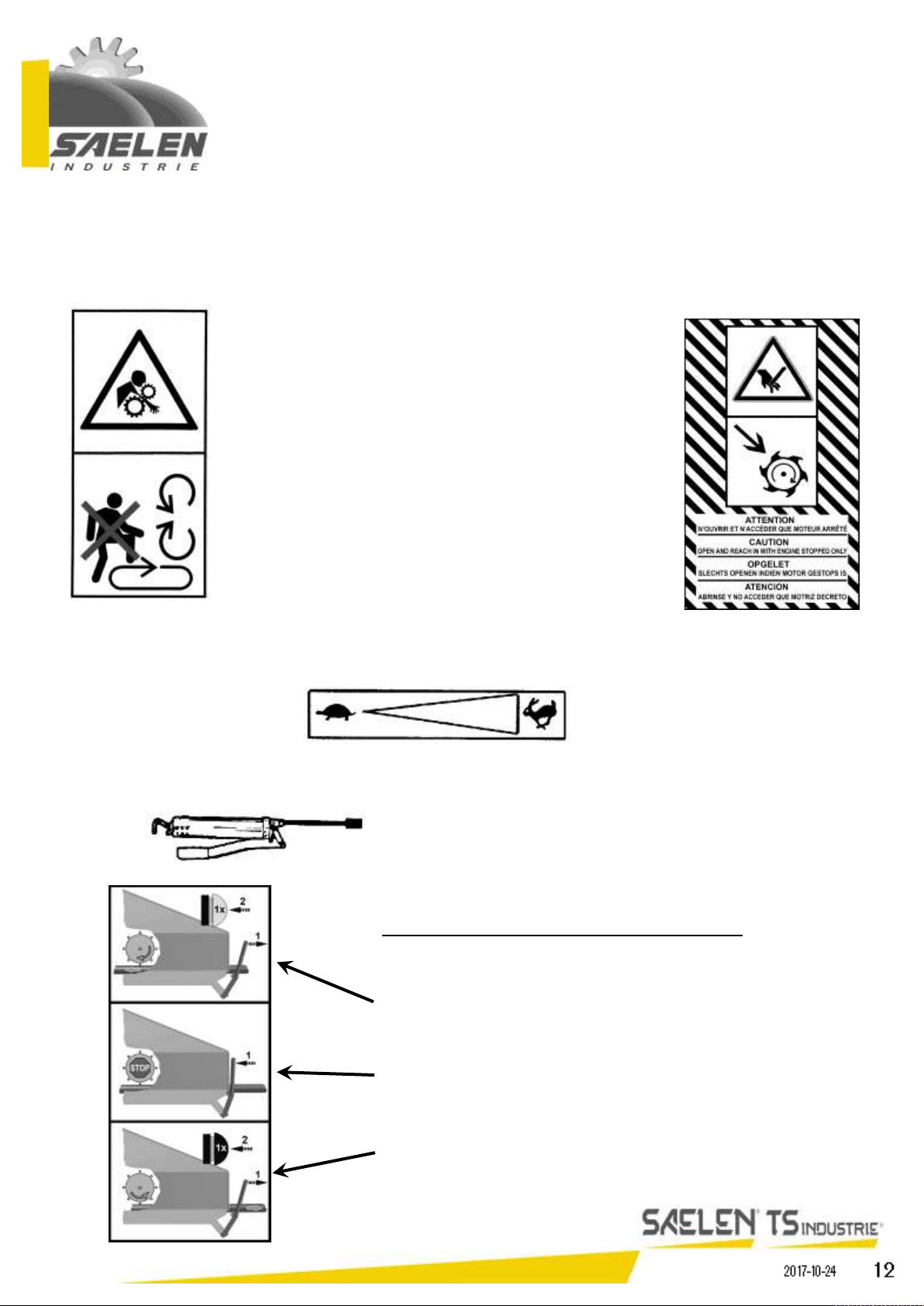

GE NERAL SAFET Y

Meaning of the labels (cont.)

Attention! Grip

wheel.

Never enter the

hopper when the

engine is running.

Never open or

remove the

inspection doors

and carters of the

cutting parts.

Minimum engine

speed

Maximum engine speed

Lubrication point

Rotation commands of the conveyor belt:

Chipping material (forward operation)

Stop the rotation of the feed rolls

Releasing material (backward)

GS/VIPER50DS

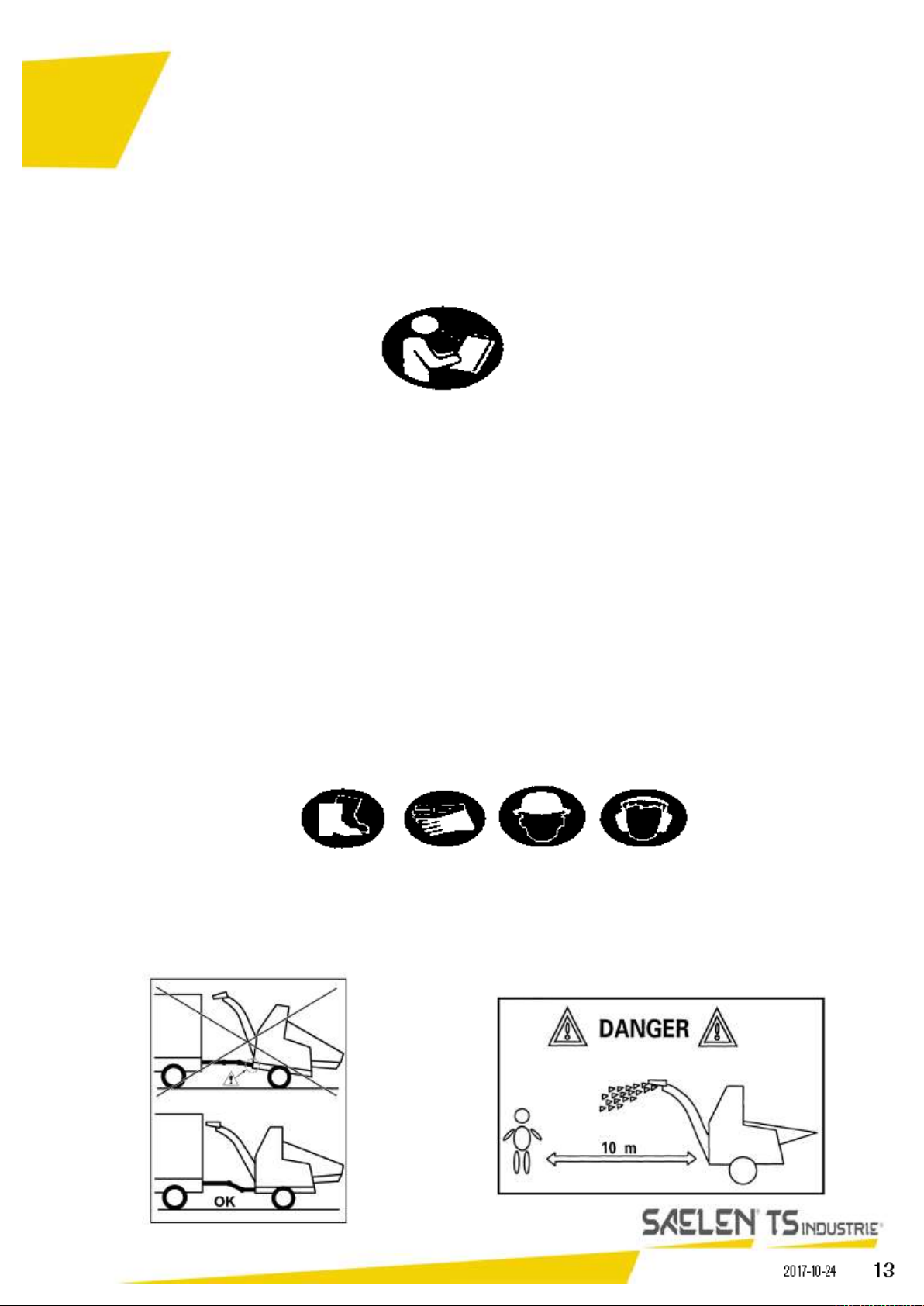

SA FE US E

1) Read and understand the user manual as well as all the security signs before any

operating, servicing, adjusting, repairing or un-jamming manoeuvre.

2) Install and make sure that all the protectors and guards are well fixed before starting

or working.

3) Keep hands, feet, hair as well as clothing out of reach of parts in movement.

4) Before performing maintenance, adjustments, repairs or un-jamming of the machine,

put the engine in idle speed with the accelerator handle, wait till all moving parts have

stopped, stop the engine.

5) Place all controls to neutral before starting the machine.

6) Keep people away, especially children before starting.

7) Use protections appropriate to the work to undertake.

8) Always couple the machine horizontally.

To avoid making the machine swing, always

work in a horizontal position if the machine

is unhitched.

9) when shredding, risk of projections of

chips within a 10 metres radius.

GS/VIPER50DS

SA FE MA INT EN ANC E

1) Follow all the indications in the user manual concerning operating, maintenance and

security.

2) Before performing any maintenance, adjustment, repair or un-jamming of the machine,

put the engine in idle speed with the accelerator handle, declutch the machine and wait till

all the parts in movement have stopped, stop the engine, remove the ignition key.

3) Make sure that all the protectors and guards are efficiently fixed after performing

maintenance or servicing the shredder.

4) Warning! Keep hands, hair and clothing out of reach of moving parts.

5) Install and make sure that all the protectors and all the guards are well fixed before

starting or working.

6) Never wear badly cut, too loose or shredded clothing when working on command system

components.

CONSIGNES DE FONCTIONNEMENT

Read the operating instructions before use

The fuel should be exempt of water and impurities.

Check the tightening of bolts after 30 h, then every 150 h.

Respect the lubricating periodicity

Do not un-jam the machine with the starter or the clutch.

GS/VIPER50DS

SA FE TR ANSPO RT

1) Follow the highway code in force.

2) Ensure that your equipment is always equipped with working signalling lights that are clean and visible

to other drivers.

3) Reduce your speed on country roads and bumpy surfaces.

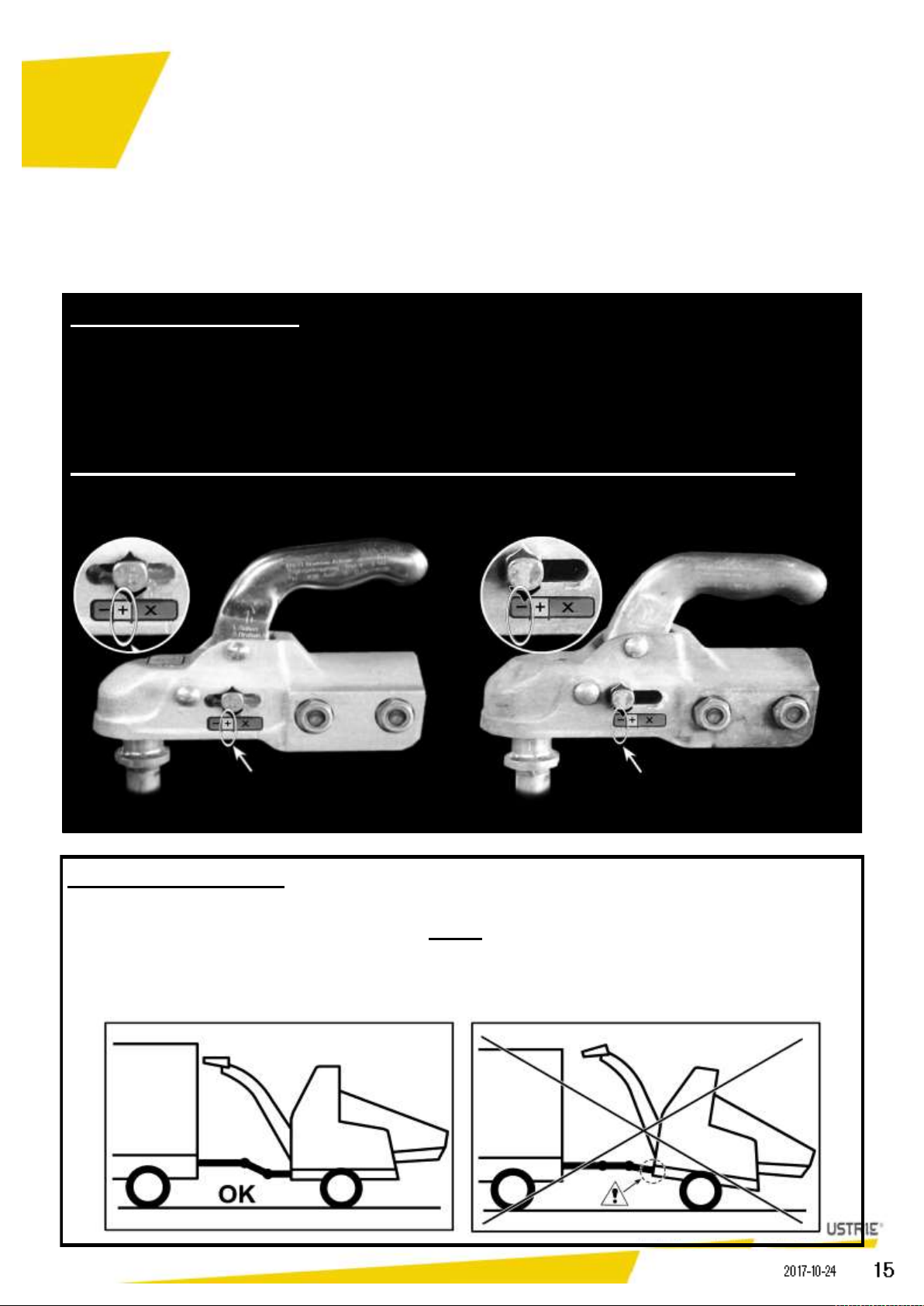

Wear of the coupling:

Check the wear indicator when coupling the machine.

Systematically repleace the had and/or the ball of the coupling of the

vehicle if the indicator is in the MINUS zone. You might loose the chipper

on a bump in the road or against a border.

YOU ARE RESPONSIBLE IN CASE AN ACCIDENT HAPPENS.

Head and/or ball of the

coupling OK

Head and/or ball worn

Hitching to a vehicle:

Always hitch the shredder in a horizontal position in order to prevent the

machine from tipping backwards AND check that the tow bar’s nut joints

are secure on a daily basis to prevent jolting which would damage the

hitch and tow system and reduce its lifespan.

GS/VIPER50DS

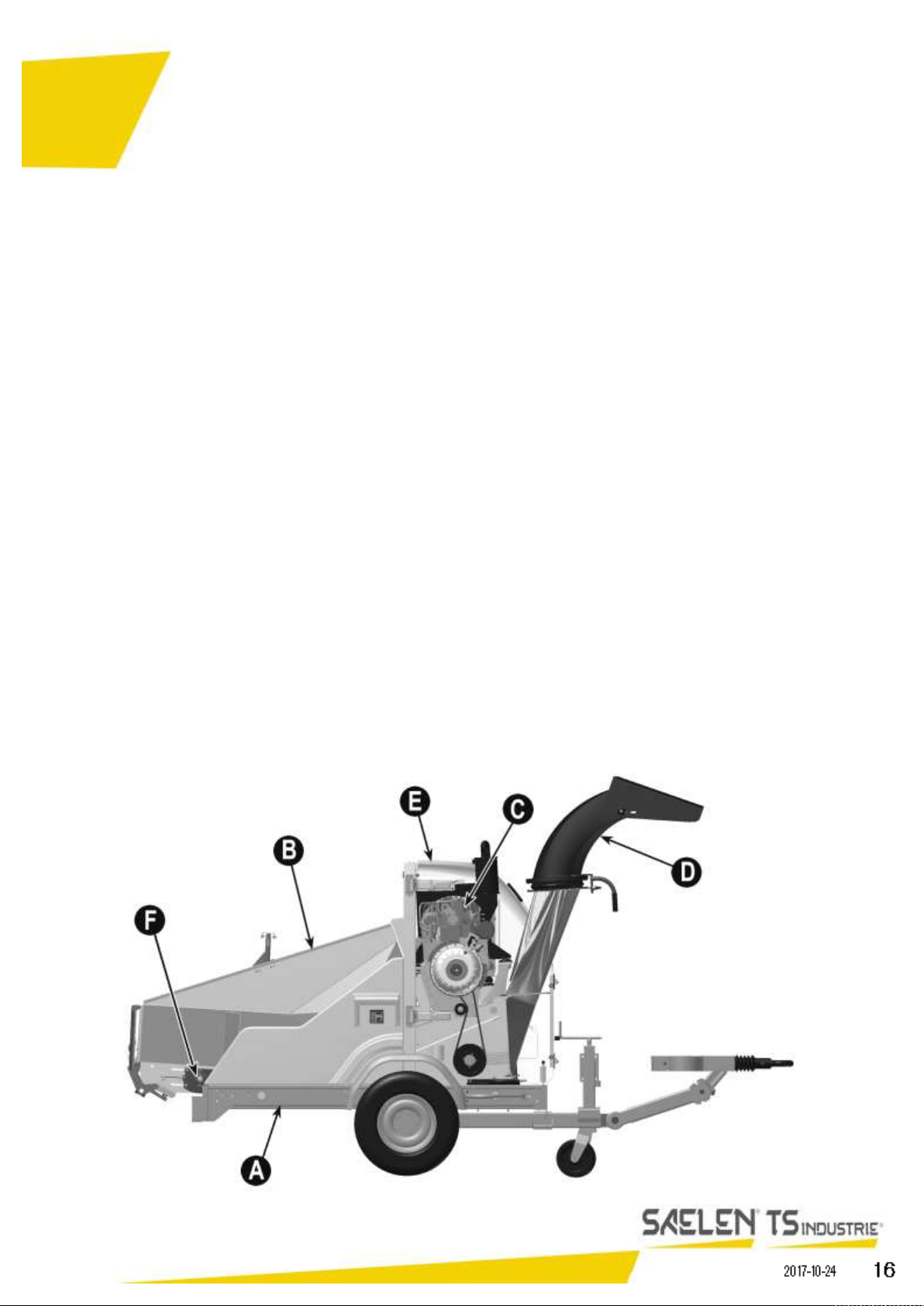

G E N E R A L D E S C R I PT I ON

A N D O P E R AT I ON

DESCRIPTION

The TS Industrie VIPER multi plant shredder is intended for the

shredding of plants and branches up to 6,70 inchs (170 mm) in

diameter.

The machine includes the following main components:

(A) : the chassis

(B) : the shredding unit

(C) : the engine and its various transmissions

(D) : the evacuation shaft

(E) : the soundproof cover

(F) : the metallic feed belt

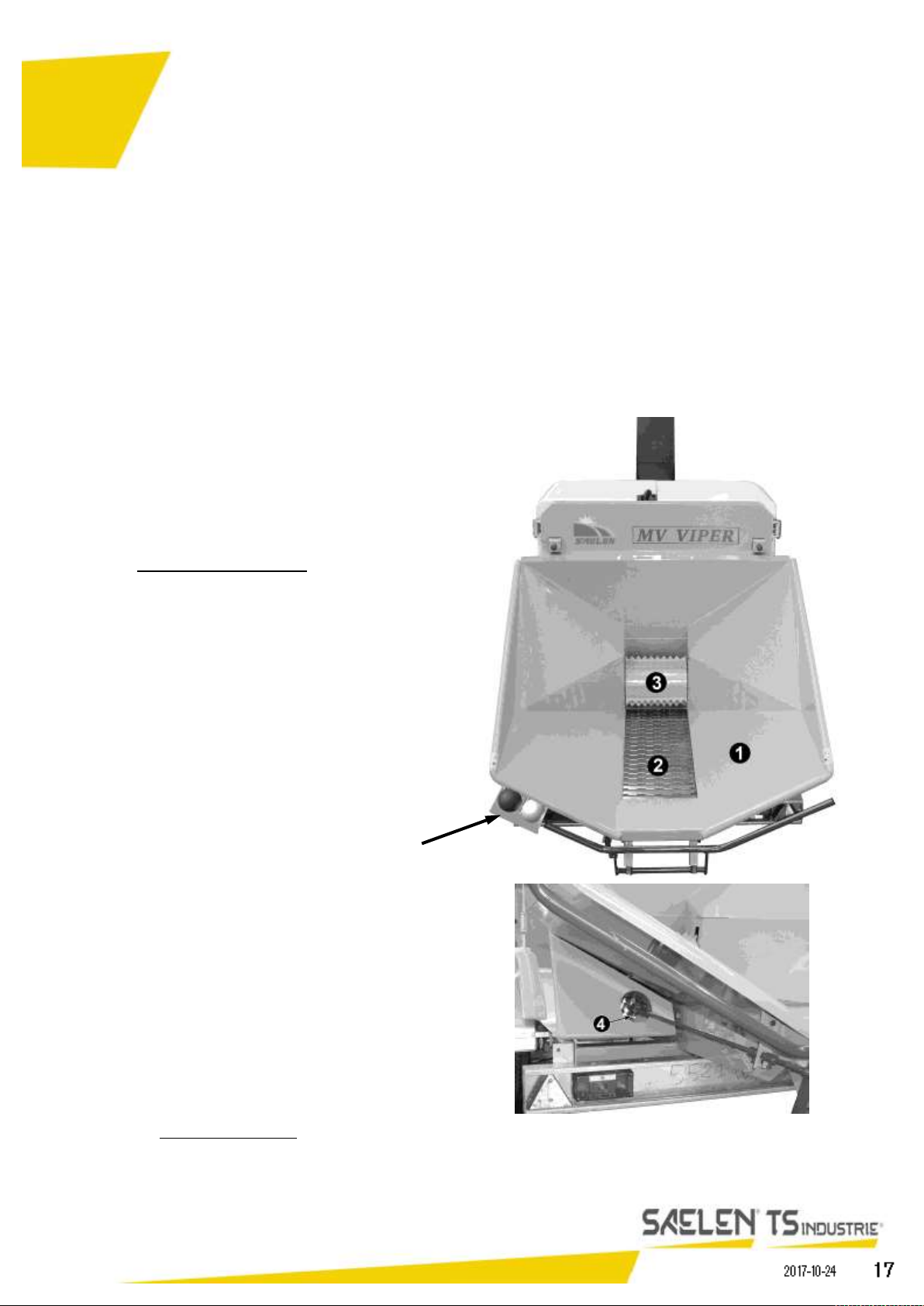

GS/VIPER50DS

G E N E R A L D E S C R I PT I ON

A N D O P E R AT I ON

A. The chassis.

The shredder’s chassis serves as support to the various components of the VIPER. It

allows moving the machine independently.

B. The shredding unit.

It is composed of a feed hopper (1), a metallic belt (2), a feed roller (3) with serrated bars and a rotor that shreds materials.

1) Feed belt and roller:

They lead the material at constant speed toward the shredding rotor.

An anti-jam system stops it when the ro-

tor’s speed descends too low (jamming at

shredding level), they are automatically

put in rotation when the rotor regains suf-

ficient speed to shred correctly.

They can be activated in both rotation directions (forward and reverse

run) With red or black and yellow push

buttons a the backside of the feed hopper

Their rotation speed is adaptable with a

tooth wheel (4) at the left backside of the

security cover and will depend on the di-

ameter of the material to shred

2) Shredding rotor:

Key element of the machine, it shreds the matter brought by the feed roller.

It is put in rotation by progressively activating the clutch levier.

Its speed is set.

GS/VIPER50DS

G E N E R A L D E S C R I PT I ON

A N D O P E R AT I ON

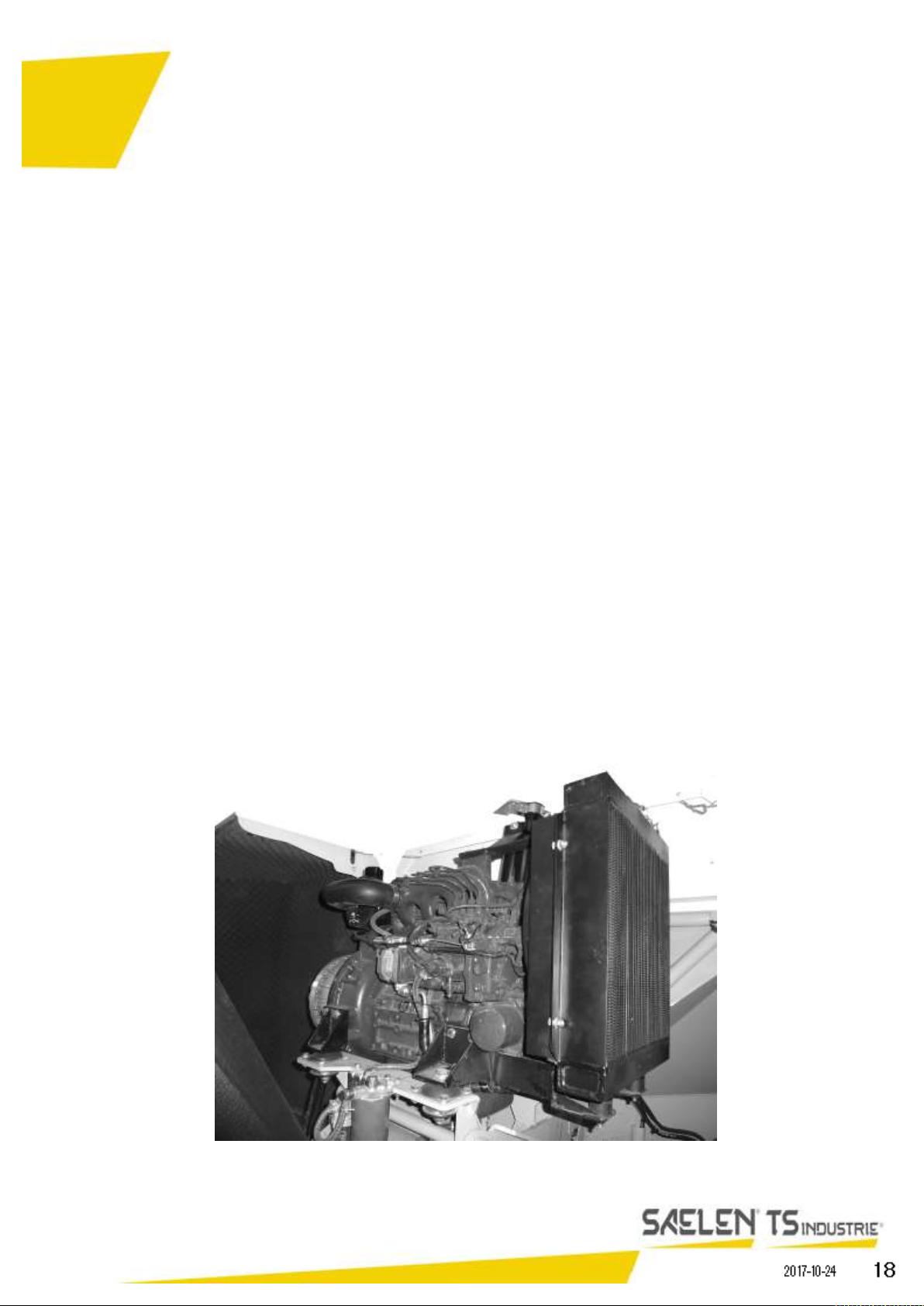

C. The engine and its drives

The diesel heat engine is located above the shredding unit, it supplies the energy needed to

drive the rotor and to drive the hydraulic circuit’s oil pump.

It is a four-cylinder Kubota diesel engine. It develops 50 HP at 2900 rpm. For any

additional information on this engine, please refer to the manufacturer’s manual.

The outlet shaft is equipped with a pulley activating 3 belts that drive the shredding rotor’s

rotation.

The hydraulic circuit’s oil pump located on the diesel engine; activates the hydraulic drives

of the belt/feeder unit.

GS/VIPER50DS

G E N E R A L D E S C R I PT I ON

A N D O P E R AT I ON

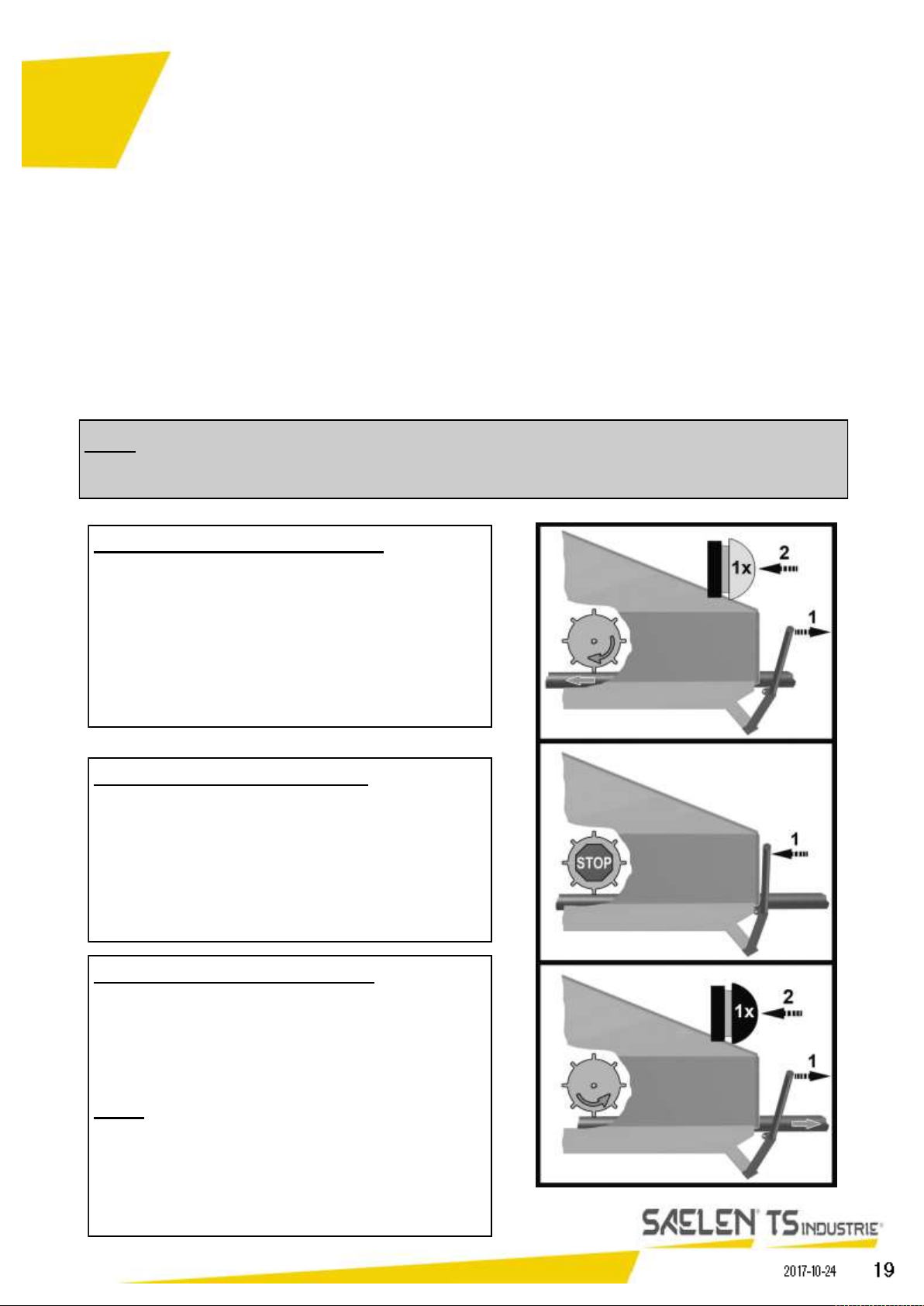

OPERATING OF FEEDER CONTROLS

The VIPER is equipped with an electric command hydraulic distributor activated by ‘mushroom’ pushbuttons for the forward and reverse drives and a

red ‘hand rail’ command bar for stopping the feed roller / belt unit.

REM: to make the feed roller / belt unit run in forward drive the en-

gine’s speed should be at its maximum

FORWARD RUN COMMAND

1: To make the feed roller run in forward

drive the red handrail should be pulled back-

ward

2: Press the yellow pushbutton to make the

feed roller run in forward drive

FEEDER STOP COMMAND

1: Push the red handrail to stop the feed roll-

er.

(the handrail can be locked in pulled position

and in pushed position)

REVERSE RUN COMMAND

1: To make the feed roller run in reverse

drive, first pull the handrail backward

2: And press the black pushbutton

REM: the feeding cell can be switched directly from forward to backward operation and vice versa without using the operating handle.

GS/VIPER50DS

S TA R T I N G

CHECK BEFORE STARTING

Every operator should read and understand all the inscriptions and should follow the safety

measures described in this section for sure and efficient shredder operating. A checklist

prior to use is supplied to the user. It is important to take it into account for the security of

all as well as to keep the machine in good condition.

The following points should be checked before using the machine:

1) Is the machine sufficiently lubricated according to the lubrication plan indicated in the

user’s manual.

2) Check the different levels for the engine, being:

the engine’s oil level

the radiator’s water level

the gas oil level

3) Check the hydraulic circuit’s oil level.

4) Make sure the air filter is clean.

5) Make sure the engine’s radiator is not clogged up.

6) Make sure the covers are all closed and locked.

GS/VIPER50DS

Loading...

Loading...