Manual Supplement

Model Number: 8636-N2

Product/System Title: Room Pressure Controller with Reheat

Control and N2 Communications Protocol

Contents of this manual supplement include:

1) Sequence of Operation

2) Menu configuration

3) Software items deleted

4) Variable Map

5) Description of variables

6) Wiring Diagram

N2 communications are installed on the Model 8636-N2 room pressure controllers. This document

provides the technical information needed for the host DDC system to communicate with 8636

units. This document assumes the programmer is familiar with the N2 protocol. Further technical

assistance is available from TSI if your question is related to TSI interfacing to a DDC system. If

you need further information regarding N2 programming in general, please contact Johnson

Controls.

Project:

Date:

Page 1 of 9 Released 10/03/01

Manual Supplement

Sequence of Operation

The Model 8636-N2 measures the room pressure differential and receives temperature information

from the temperature sensor. The 8636-N2 control algorithm modulates the supply and general

exhaust air to provide adequate supply air while maintaining the room pressure differential and

temperature control.

In occupied mode, the Model 8636-N2 has two supply flow set points: ventilation and temperature.

The ventilation setpoint is the minimum supply flow for the space, used when the heating and

cooling loads are met. The temperature supply set point is a higher flow, required to meet an

increased cooling load in the lab.

Laboratory temperature is continuously transmitted to the Model 8636-N2. When the laboratory

temperature is satisfied, the ventilation set point is maintained, unless additional supply air is

required for the room pressure balance. When the space temperature is more than 1°F above the

temperature setpoint, the 8636-N2 slowly will increase the supply air volume, to a maximum of the

temperature minimum supply flow, until the space temperature returns to setpoint. When the space

temperature is more than 1°F below the temperature setpoint, the 8636-N2 slowly will decrease the

supply air volume, to a minimum of the ventilation minimum supply flow, until the space

temperature returns to setpoint. If the supply volume is at the ventilation minimum supply flow, the

Model 8636-N2 will modulate the reheat valve to provide the necessary heating.

In unoccupied mode, the supply flow will remain at the unoccupied supply flow rate.

Supply air volumes will rise above the minimum setpoints, under all conditions, as required to

maintain space pressurization. Temperature control and occupied/unoccupied modes will only

affect the minimum supply flows, which are used, for example, when fume hood sashes are

lowered.

NOTE: The 8636-N2 will not allow the temperature minimum supply volume to be less than the

ventilation minimum supply volume.

Project:

Date:

Page 2 of 9 Released 10/03/01

Manual Supplement

Menu Configuration

SETPOINTS ALARM CONFIGURE CALIBRATION

SETPOINT

REM SETPOINT

UNOCC SETP

VENT MIN SET

TEMP MIN SET

TEMP SETP

CONTROL SUPPLY FLOW

SPEED

SENSITIVITY

CONTROL SIG

Kc VALUE

Ti VALUE

TEMP OUTPUT

TEMP CONTROL

TEMP Kc VAL

LOW ALARM

HIGH ALARM

REM LOW ALM

REM HIGH ALM

MIN SUP ALM

ALARM RESET

AUDIBLE ALM

ALARM DELAY

DOOR DELAY

MUTE TIMEOUT

SP1 DCT REA

SP2 DCT REA

SP1 FLO ZERO

SP2 FLO ZERO

FLO STA TYPE

TOP VELOCITY

SP LOW SETP

SP HIGH SETP

SP1 LOW CAL

SP1 HIGH CAL

SP2 LOW CAL

SP2 HIGH CAL

RESET CAL

UNITS

NET ADDRESS

ACCESS CODES

SENSOR SPAN

ELEVATION

TEMP CAL

DIAGNOSTICS

CONTROL SUP

CONTROL EXH

CONTROL TEMP

SENSOR INPUT

SENSOR STAT

DOOR SWITCH

UNOCC SWITCH

SUP1 FLOW IN

SUP2 FLOW IN

TEMP INPUT

ALARM RELAY

Software Item Deleted

The following software item has been deleted from the 8636-N2:

Menu Item

SETPOINTS MIN SUP DAMP

MAX SUP DAMP

MIN EXH DAMP

MAX EXH DAMP

CONFIGURE NET PROTOCOL

Project:

Date:

Page 3 of 9 Released 10/03/01

Manual Supplement

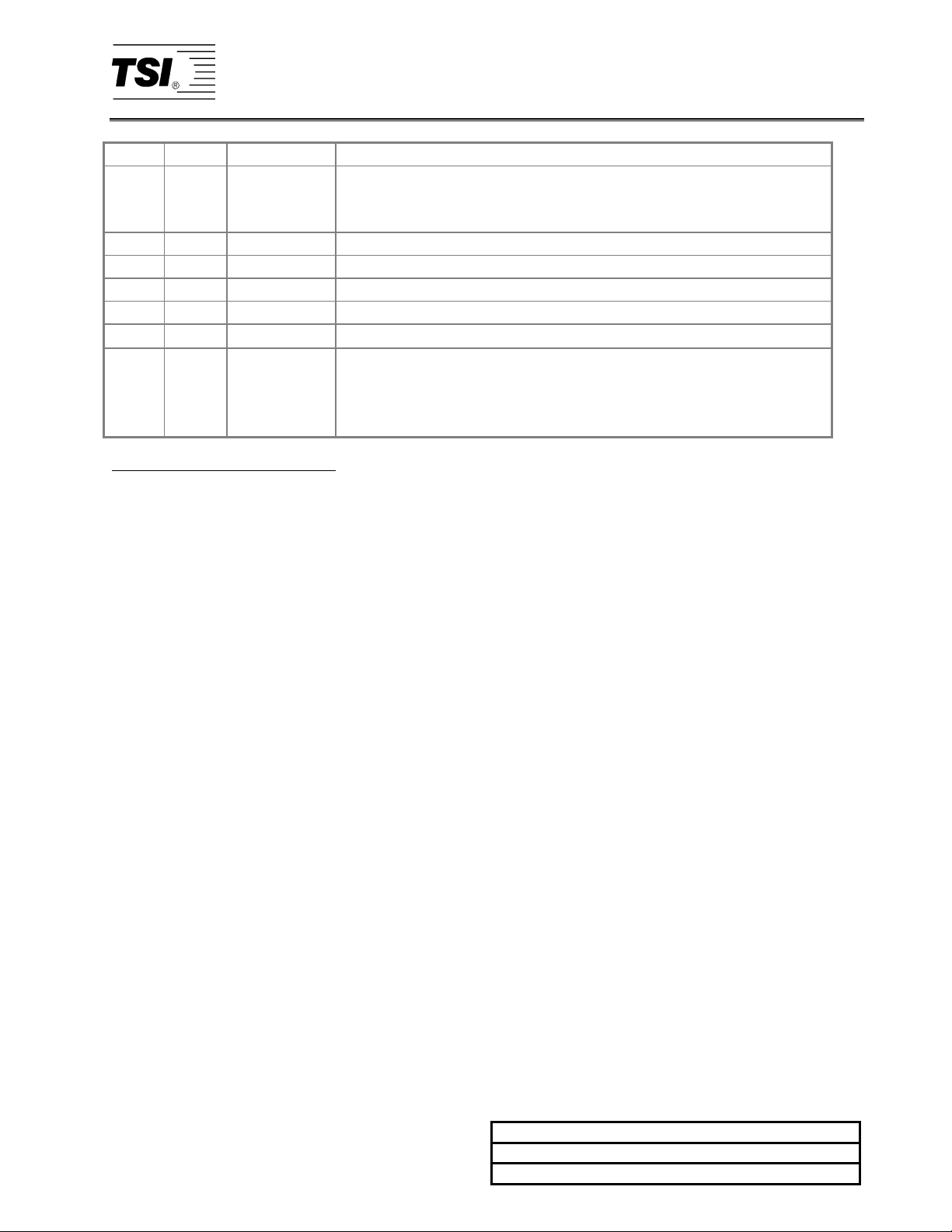

Variable Map

NPT NPA UNITS1 DESCRIPTION

AI 1 ft/min, m/s,

in. H2O, Pa,

mm H2O

AI 2 CFM, l/s Total Supply Flow Rate

AI 3

°F, °C

AI 4 ft/min, m/s,

in. H2O, Pa,

mm H2O

AI 5 CFM, l/s Minimum Supply Setpoint

AI 6 # Supply Control Output

AI 7 # Exhaust Control Output

AI 8 # Temperature Control Output

BI 1 Low Room Pressure Alarm 0=Normal

BI 2 High Room Pressure Alarm 0=Normal

BI 3 Min. Flow Alarm 0=Normal

BI 4 Emergency Mode 0=Normal

BI 5 Room Mode 0=Main

BI 6 Occupied/Unoccupied Mode 0=Occupied

BI 7 Data Error 0=Normal

AO 1 ft/min, m/s,

in. H2O, Pa,

mm H2O

AO 2 ft/min, m/s,

in. H2O, Pa,

mm H2O

AO 3 ft/min, m/s,

in. H2O, Pa,

mm H2O

AO 4 ft/min, m/s,

in. H2O, Pa,

mm H2O

AO 5 CFM, l/s Min. Supply Flow Alarm Setpoint

Room Pressure Value

Temperature

Control Setpoint

1=Low Alarm

1=High Alarm

1=Low Flow Alarm

1=Emergency Mode

1=Remote

1=Unoccupied

1=Data Error

Low Alarm Setpoint

High Alarm Setpoint

Remote Low Alarm Setpoint

Remote High Alarm Setpoint

Project:

Date:

Page 4 of 9 Released 10/03/01

Manual Supplement

NPT NPA UNITS1 DESCRIPTION

AO 6 ft/min, m/s,

Main Pressure Setpoint

in. H2O, Pa,

mm H2O

AO 7 CFM, l/s Remote Pressure Setpoint

AO 8 CFM, l/s Minimum Ventilation Rate Supply Flow Setpoint

AO 9 CFM, l/s Minimum Temperature Supply Flow Setpoint

AO 10 CFM, l/s Unoccupied Mode Minimum Supply Flow Setpoint

AO 11

°F, °C

Temperature Setpoint

AO 12 # Units 0=Feet per minute

1=Meters per second

2=Inches of H2O

3=Pascals

1

Units will correspond with choice in UNITS variable (AO #12). Flow rates will either be CFM or l/s, based on

whether UNITS variable is set for an english or metric unit type.

Project:

Date:

Page 5 of 9 Released 10/03/01

Manual Supplement

Description of Variables

NPT - Network Point Type

Variables are defined as analog inputs, binary inputs, and analog outputs. Analog inputs are current

control parameters and items that the controller is measuring. Binary inputs represent controller

states. Analog outputs are the programmable setpoints for the isolation room pressure controller

and monitor. These setpoints can be changed through the keypad or by overriding the current

setpoint.

NPA - Network Point Address

Address of the desired point.

Change of Status (COS) - Room Pressure Analog Input

The 8636-N2 has the ability to change control setpoints locally. The alarm setpoints need to be

based on the controller’s control setpoint (AI #4). For example the setpoint could go from -0.002

“H2O to +0.001 “H2O. If the COS alarm setpoints are not changed to accommodate you could get

low alarm or low warning messages when the unit is working correctly. If these alarm points are

set outside of the negative and positive setpoint values, incorrect alarm messages can be prevented.

Override Analog Input Command

Analog Input values can be set using the override command. These values will be reset to the

correct items when the Override is released. There is not a time-out on the override command.

Override Binary Input Command

Overriding a 1 to Emergency binary inputs enables that mode. To release the controller from

emergency state, override a 0 to the Emergency input or press either the emergency or reset key.

Releasing the override will return the controller to the Normal state. If the 8636-N2 had been put

into Emergency mode from the keypad, then it cannot be cleared remotely.

Overriding a 1 to Room Mode binary inputs enables Remote mode. To release the controller from

remote state, override a 0 to the Room Mode. Releasing the override will return the controller to

the Normal state.

Overriding a 1 to the Occupied/Unoccupied Mode binary inputs enables the unoccupied mode. To

release the controller from the unoccupied state, override a 0 to the Occupied/Unoccupied Mode.

The Occupied/Unoccupied Mode can only be accessed through N2 communications.

The alarm and data error variables can be overridden, but this will not affect the controller.

Overriding the low alarm variable will result in a change of status, but will not put the controller

into low alarm mode. The local alarm modes can only be controlled locally. Only override these

variables for diagnostic purposes, and release them for normal operation.

Project:

Date:

Page 6 of 9 Released 10/03/01

Manual Supplement

Binary Input Data Error

Data Error binary inputs are used to indicate if something has gone wrong with the controller. Data

Error indicates when some of the data stored on the device has been corrupted. The calibration and

setpoint values should be checked on the controller.

Override Analog Output Command

The analog output variables can be overridden to change their values. The overridden value will be

checked for validity. If invalid, the override command will be ignored, and the value will not

change. The override flag will not be set when the value is ignored. The override command will be

cleared when the variable is reset in the menus. The variable will not reset with the release

command.

Supported Commands

Command Response

Request Device ID Returns 0x10

Synchronize Time Command Acknowledged. There Is No Internal Clock To

Synchronize.

Poll Without/With Ack Message Any Change Of Status Is Returned

Read Analog Input Command Variable Value

Read Binary Input Command Variable Value

Read Analog Output Command Variable Value

Write Analog Input Acknowledge

Write Binary Input Acknowledge

Write Analog Output Acknowledge

Override Analog Input Command Acknowledge

Override Binary Input Command Acknowledge

Override Analog Output Command Acknowledge

Override Release Request Acknowledge

Identify Device Type Command Returns 0x10h

Note: Poll Without/With Ack Message will need to be sent twice in order to receive all of the

possible change of status variables.

Project:

Date:

Page 7 of 9 Released 10/03/01

Manual Supplement

Wiring Diagrams

MODEL 8636-N2 PRESSUR E CONTROLLER

MODEL 8636-N2

WIRING DIAGRAM - ELECTRIC

WIRING DIAG RAM - ELEC TRIC

28

27

26

25

24

23

22

21

Project:

Date:

Page 8 of 9 Released 10/03/01

Manual Supplement

MODEL 8636-N2 PRESSURE CONTROLLER

MODEL 8636-N2

WIRING DIAGRAM - PNEUMATIC

Project:

Date:

Page 9 of 9 Released 10/03/01

Loading...

Loading...