Model 3772

Model 3771

(discontinued)

CONDENSATION

PARTICLE COUNTER

MODEL 3772/3771

OPERATION AND SERVICE MANUAL

P/N 1980529, REVISION F

APRIL 2015

CONDENSATION

PARTICLE COUNTER

MODEL 3772/3771

OPERATION AND SERVICE MANUAL

Product Overview

1

Unpacking and

Setting Up the CPC

2

Instrument

Description

3

Instrument Operation

4

Technical

Description

5

Particle Counting

6

Computer Interface

and Commands

7

Maintenance and

Service

8

Appendixes

Manual History

The following is a history of the Model 3772/3771 Condensation Particle

Counter Operation and Service Manual (Part Number 1980529).

Revision Date

A February 2006

B April 2006

C April 2007

D December 2009

E July 2011

F April 2015

iv

Warranty

Part Number

1980529 / Revision F / April 2015

Copyright

©TSI Incorporated / 2006–2015 / All rights reserved.

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA

Fax No.

651-490-3824

E-mail Address

particle@tsi.com

Limitation of Warranty

and Liability

(effective February 2015)

Seller warrants the goods, excluding software, sold hereunder, under normal use and service

as described in the operator's manual, to be free from defects in workmanship and material for

12 months, or if less, the length of time specified in the operator's manual, from the date of

shipment to the customer. This warranty period is inclusive of any statutory warranty. This limited

warranty is subject to the following exclusions and exceptions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other components

when indicated in specifications, are warranted for 90 days from the date of shipment;

b. Pumps are warranted for hours of operation as set forth in product or operator’s manuals;

c. Parts repaired or replaced as a result of repair services are warranted to be free from defects

in workmanship and material, under normal use, for 90 days from the date of shipment;

d. Seller does not provide any warranty on finished goods manufactured by others or on any

fuses, batteries or other consumable materials. Only the original manufacturer's warranty

applies;

e. This warranty does not cover calibration requirements, and seller warrants only that the

instrument or product is properly calibrated at the time of its manufacture. Instruments

returned for calibration are not covered by this warranty;

f. This warranty is VOID if the instrument is opened by anyone other than a factory authorized

service center with the one exception where requirements set forth in the manual allow an

operator to replace consumables or perform recommended cleaning;

g. This warranty is VOID if the product has been misused, neglected, subjected to accidental

or intentional damage, or is not properly installed, maintained, or cleaned according to the

requirements of the manual. Unless specifically authorized in a separate writing by Seller,

Seller makes no warranty with respect to, and shall have no liability in connection with, goods

which are incorporated into other products or equipment, or which are modified by any person

other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated

herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR PARTICULAR

PURPOSE OR MERCHANTABILITY IS MADE. WITH RESPECT TO SELLER’S BREACH OF

THE IMPLIED WARRANTY AGAINST INFRINGEMENT, SAID WARRANTY IS LIMITED TO

CLAIMS OF DIRECT INFRINGEMENT AND EXCLUDES CLAIMS OF CONTRIBUTORY OR

INDUCED INFRINGEMENTS. BUYER’S EXCLUSIVE REMEDY SHALL BE THE RETURN OF

THE PURCHASE PRICE DISCOUNTED FOR REASONABLE WEAR AND TEAR OR AT

SELLER’S OPTION REPLACEMENT OF THE GOODS WITH NON-INFRINGING GOODS.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR

BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES, INJURIES,

OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS BASED ON CONTRACT,

NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE) SHALL BE THE RETURN OF

GOODS TO SELLER AND THE REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION

OF SELLER, THE REPAIR OR REPLACEMENT OF THE GOODS. IN THE CASE OF

SOFTWARE, SELLER WILL REPAIR OR REPLACE DEFECTIVE SOFTWARE OR IF UNABLE

TO DO SO, WILL REFUND THE PURCHASE PRICE OF THE SOFTWARE. IN NO EVENT

SHALL SELLER BE LIABLE FOR LOST PROFITS, BUSINESS INTERRUPTION, OR ANY

SPECIAL, INDIRECT, CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL

NOT BE RESPONSIBLE FOR INSTALLATION, DISMANTLING OR REINSTALLATION

COSTS OR CHARGES. No Action, regardless of form, may be brought against Seller more than

12 months after a cause of action has accrued. The goods returned under warranty to Seller's

factory shall be at Buyer's risk of loss, and will be returned, if at all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND

LIABILITY, which contains the complete and exclusive limited warranty of Seller. This

LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or its terms

waived, except by writing signed by an Officer of Seller.

v

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are to our

customers, our service policy is designed to give prompt attention to any problems. If any mal-

function is discovered, please contact your nearest sales office or representative, or call TSI’s

Customer Service department at 1-800-874-2811 (USA) or (651) 490-2811.

Trademarks

Scanning Mobility Particle Sizer and SMPS are trademarks of TSI Incorporated.

Aerosol Instrument Manager is a registered trademark of TSI Incorporated.

Microsoft and Windows are registered trademarks of Microsoft Corporation.

vi Model 3772/3771 Condensation Particle Counter

Laser Safety

W A R N I N G

The use of controls, adjustments, or procedures other than those

specified in this manual may result in exposure to hazardous optical

radiation.

Safety

This section provides instructions to ensure safe and proper operation and

handling of the Model 3772/3771 Condensation Particle Counter (CPC).

There are no user-serviceable parts inside the instrument. Refer all repair

and maintenance to a qualified technician. All maintenance and repair

information in this manual is included for use by a qualified technician.

The Model 3772/3771 CPC is a Class I laser-based instrument. During

normal operation, you will not be exposed to laser radiation. However, you

must take certain precautions or you may expose yourself to hazardous

radiation in the form of intense, focused visible light. Exposure to this light

can cause blindness.

Take these precautions:

Do not remove any parts from the CPC unless you are specifically told

to do so in this manual.

Do not remove the CPC housings or covers while power is supplied to

the instrument.

Chemical Safety

The Model 3772/3771 CPC uses n-butyl alcohol (butanol) as a working

fluid. Butanol is flammable. Butanol is also toxic if inhaled. Refer to a

Material Safety Data Sheet for butanol and take these precautions:

Use butanol only in a well-ventilated area. Under normal operating

conditions butanol is exhausted into the air at approximately 0.015 g

per minute.

Butanol vapor is identified by its characteristically strong odor and can

easily be detected. If you smell butanol and develop a headache, or

feel faint or nauseous, leave the area at once. Ventilate the area before

returning.

vii

C a u t i o n

Butanol is flammable. Butanol is also potentially toxic if inhaled. Use

butanol only in a well-ventilated area. If you smell butanol and develop a

headache, or feel faint or nauseous, leave the area at once. Ventilate the

area before returning.

W A R N I N G

Although the CPC is appropriate for monitoring inert process gases such

as nitrogen or argon, it should not be used with hazardous gases such

as hydrogen or oxygen. Using the CPC with hazardous gases may

cause injury to personnel and damage to equipment.

C a u t i o n

Caution means be careful. It means if you do not follow the procedures

prescribed in this manual you may do something that might result in

equipment damage, or you might have to take something apart and start

over again. It also indicates that important information about the operation

and maintenance of this instrument is included.

W A R N I N G

Warning means that unsafe use of the instrument could result in serious

injury to you or cause irrevocable damage to the instrument. Follow the

procedures prescribed in this manual to use the instrument safely.

Description of Safety L a bels

This section acquaints you with the advisory and identification labels on the

instrument and used in this manual to reinforce the safety features built into

the design of the instrument.

Caution

Warning

viii Model 3772/3771 Condensation Particle Counter

Caution or Warning Symbols

Warns you that uninsulated voltage within the instrument may

have sufficient magnitude to cause electric shock. Therefore,

it is dangerous to make any contact with any part inside the

instrument.

Warns you that the instrument contains a laser and that

important information about its safe operation and

maintenance is included. Therefore, you should read the

manual carefully to avoid any exposure to hazardous laser

radiation.

Warns you that the instrument is susceptible to electro-static

dissipation (ESD) and ESD protection procedures should be

followed to avoid damage.

Indicates the connector is connected to earth ground and

cabinet ground.

1. Serial Number label –

displayed on the back panel

2. Laser Radiation label –

located internally on the optics

housing

3. Electrical shock caution

label – displayed on back

panel

4. Laser device compliance

label – displayed on back

panel

The following symbols may accompany cautions and warnings to indicate

the nature and consequences of hazards:

Labels

Advisory labels and identification labels are attached to the outside of the

CPC housing and to the optics on the inside of the instrument. Labels for

the Model 3772/3771 CPC are described below:

Safety ix

5. Caution label

6. European Recycling Label –

displayed on the back panel

(indicates item is nondisposable and must be

recycled).

7. French language electrical

safety and laser compliance

labels – displayed on the back

panel

8. NRTL TÜV SÜD Mark –

displayed on the back panel.

This mark identifies the

product as meeting safety

regulations in the US, Canada

and Europe and further

identifies the product as one

for which ongoing production is

monitored for quality.

9. TSI Address and Service

Label – displayed on the back

panel

10. Saturator Wick Removal

caution label – displayed on

the bottom of the enclosure

x Model 3772/3771 Condensation Particle Counter

Contents

Manual History ........................................................................................... iv

Warranty ...................................................................................................... v

Safety ......................................................................................................... vii

Laser Safety ......................................................................................... vii

Chemical Safety ................................................................................... vii

Description of Safety Labels ................................................................ viii

Caution .............................................................................................. viii

Warning ............................................................................................. viii

Caution or Warning Symbols ............................................................. ix

Labels .................................................................................................... ix

About This Manual ................................................................................. xvii

Purpose ............................................................................................... xvii

Organization ........................................................................................ xvii

Related Product Literature ................................................................. xviii

Submitting Comments ......................................................................... xix

CHAPTER 1 Product Overview .............................................................. 1-1

Product Description ............................................................................. 1-1

How it Works ....................................................................................... 1-2

CHAPTER 2 Unpacking and Setting up the CPC ................................. 2-1

Packing List ......................................................................................... 2-1

Unpacking ........................................................................................... 2-2

Setting Up ........................................................................................... 2-3

Remove Protective Caps ................................................................. 2-3

Mounting the Bracket and Fill Bottle ................................................ 2-3

Filling the Fill Bottle with Butanol ..................................................... 2-4

Connecting the Butanol Drain Bottle ............................................... 2-4

Apply Power to the CPC .................................................................. 2-4

Supply External Vacuum to the CPC ............................................... 2-5

Positioning the CPC ......................................................................... 2-5

CHAPTER 3 Instrument Description ...................................................... 3-1

Model 3772 Front Panel ...................................................................... 3-1

LCD Display and Keypad ................................................................. 3-1

Aerosol Inlet ..................................................................................... 3-2

Status Light ...................................................................................... 3-2

Particle Light .................................................................................... 3-2

Flash Memory Card Slot .................................................................. 3-2

Model 3771 Front Panel ...................................................................... 3-3

Model 3772/3771 Back Panel ............................................................. 3-3

AC Connector and Switch ................................................................ 3-3

USB Communication Port ................................................................ 3-3

RS-232 Serial Connections ............................................................. 3-4

Analog Inputs ................................................................................... 3-5

DMA/Analog Output and Pulse Output ............................................ 3-5

Ethernet Communication Port.......................................................... 3-6

xi

Butanol Fill Port ............................................................................... 3-6

External Vacuum Port ...................................................................... 3-6

Drain Port ........................................................................................ 3-7

Instrument Cooling Fan ................................................................... 3-7

Cover .................................................................................................. 3-7

Bottom Panel ...................................................................................... 3-7

Internal Instrument Components ........................................................ 3-8

Water Removal Pump ..................................................................... 3-8

Filters ............................................................................................... 3-9

Valves .............................................................................................. 3-9

Pressure Transducers ..................................................................... 3-9

Electronics Boards ........................................................................... 3-9

Basic Instrument Functions .............................................................. 3-10

Concentration Measurement ......................................................... 3-10

Total Count Mode (3772 only) ....................................................... 3-11

Water Removal .............................................................................. 3-11

Internal Data Logging (3772 only) ................................................. 3-11

Remote Access of Instrument ....................................................... 3-11

External Vacuum Pump or Source ................................................ 3-11

Flow Rate Control .......................................................................... 3-12

Temperature Control ..................................................................... 3-12

Inlet Pressure Measurement ......................................................... 3-12

CHAPTER 4 Instrument Operation ........................................................ 4-1

Operating Precautions ........................................................................ 4-1

Power Switch ...................................................................................... 4-1

Warm-up ............................................................................................. 4-1

Status Indicator ................................................................................... 4-2

Particle Indicator ................................................................................. 4-2

Communication ................................................................................... 4-2

Model 3772 LCD Display and Keypad ............................................ 4-3

Model 3772 Keypad Navigation ...................................................... 4-3

Concentration ..................................................................................... 4-4

Total Count Mode (3772 only) ............................................................ 4-5

User Settings ...................................................................................... 4-5

Data Logging (3772 only) ................................................................ 4-6

Water Removal ................................................................................ 4-6

Totalizer Time (3772 only) ............................................................... 4-7

Auto Fill ............................................................................................ 4-7

Analog Out ....................................................................................... 4-7

Data Averaging (3772 only) ............................................................. 4-8

Drain ................................................................................................ 4-8

Status .................................................................................................. 4-8

Saturator Temp (Temperature) ....................................................... 4-9

Condenser Temp (Temperature) ..................................................... 4-9

Optics Temp (Temperature) ............................................................ 4-9

Cabinet Temp (Temperature) .......................................................... 4-9

Ambient Pressure ............................................................................ 4-9

Orifice Pressure ............................................................................. 4-10

Nozzle Pressure ............................................................................ 4-10

Laser Current ................................................................................. 4-10

Liquid Level ................................................................................... 4-10

Analog Inputs ................................................................................. 4-10

Flash Status (3772 only) ............................................................... 4-10

xii Model 3772/3771 Condensation Particle Counter

USB Status .................................................................................... 4-10

Firmware Version ........................................................................... 4-11

Using the Flash Memory Card (3772 only) ....................................... 4-11

Aerosol Instrument Manager® Software ............................................ 4-13

Moving and Shipping the CPC .......................................................... 4-13

CHAPTER 5 Technical Description ........................................................ 5-1

Theory ................................................................................................. 5-1

History ................................................................................................. 5-2

Adiabatic Expansion CNC ............................................................... 5-2

Two-Flow Mixing CNC ..................................................................... 5-3

Diffusional Thermal CNC ................................................................. 5-3

Design of the CPC .............................................................................. 5-5

Sensor .............................................................................................. 5-5

Critical Flow ..................................................................................... 5-7

Counting Efficiency and Response Time of the 3772/3771 CPC ....... 5-8

CHAPTER 6 Particle Counting ............................................................... 6-1

Optical Detection ................................................................................. 6-1

Total Count Accuracy .......................................................................... 6-2

Live-Time Counting ............................................................................. 6-2

Coincidence Correction for Pulse Output ........................................ 6-3

Particle Size Selector .......................................................................... 6-4

CHAPTER 7 Computer Interface and Commands ................................ 7-1

Computer Interface ............................................................................. 7-1

USB .................................................................................................. 7-1

Ethernet ........................................................................................... 7-1

Flash Memory Card Specification (3772 only) ................................. 7-5

RS-232 Serial Communications ...................................................... 7-6

Commands .......................................................................................... 7-7

CHAPTER 8 Maintenance and Service .................................................. 8-1

Replacement Parts Kits ...................................................................... 8-2

Draining Butanol from the Butanol Reservoir ..................................... 8-4

Changing the Filters ............................................................................ 8-5

Butanol Fill and Drain Filters ............................................................ 8-5

Micro Pump Filter ............................................................................. 8-6

Removing and Installing the Saturator Wick ....................................... 8-7

Verifying Flow Rate ........................................................................... 8-10

Calibration ......................................................................................... 8-10

Correcting Flooded Optics ................................................................ 8-11

Viewing Analog Pulses ..................................................................... 8-12

Calibration Reminder ........................................................................ 8-14

False Count Check ........................................................................... 8-14

Error Messages and Troubleshooting ............................................... 8-15

Technical Contacts ........................................................................... 8-17

Returning the CPC for Service .......................................................... 8-18

APPENDIX A Specifications .................................................................. A-1

APPENDIX B Firmware Commands ...................................................... B-1

READ Commands .............................................................................. B-1

SET Commands ................................................................................. B-5

MISC (MISCELLANEOUS) Commands ............................................ B-8

HELP Commands .............................................................................. B-9

Contents xiii

Figures

APPENDIX C References ....................................................................... C-1

Index

Reader’s Comments Sheet

1-1 Model 3772 Condensation Particle Counter ..................................... 1-2

1-2 Model 3771 Condensation Particle Counter ..................................... 1-2

2-1 View of Fill Bottle Bracket Mounting ................................................. 2-3

3-1 View of the Model 3772 Front Panel ................................................. 3-1

3-2 View of the Model 3771 Front Panel ................................................. 3-3

3-3 Back Panel of the Model 3772/3771 CPC ........................................ 3-4

3-4 Sample Digital Pulse from Pulse Output Port at the Back Panel

of the CPC ........................................................................................ 3-6

3-5 Bottom Panel Showing Removable Saturator Base ......................... 3-7

3-6 Internal Components of the Model 3772/3771 CPC ......................... 3-8

3-7 Electronics Boards inside the Model 3772/3771 CPC .................... 3-10

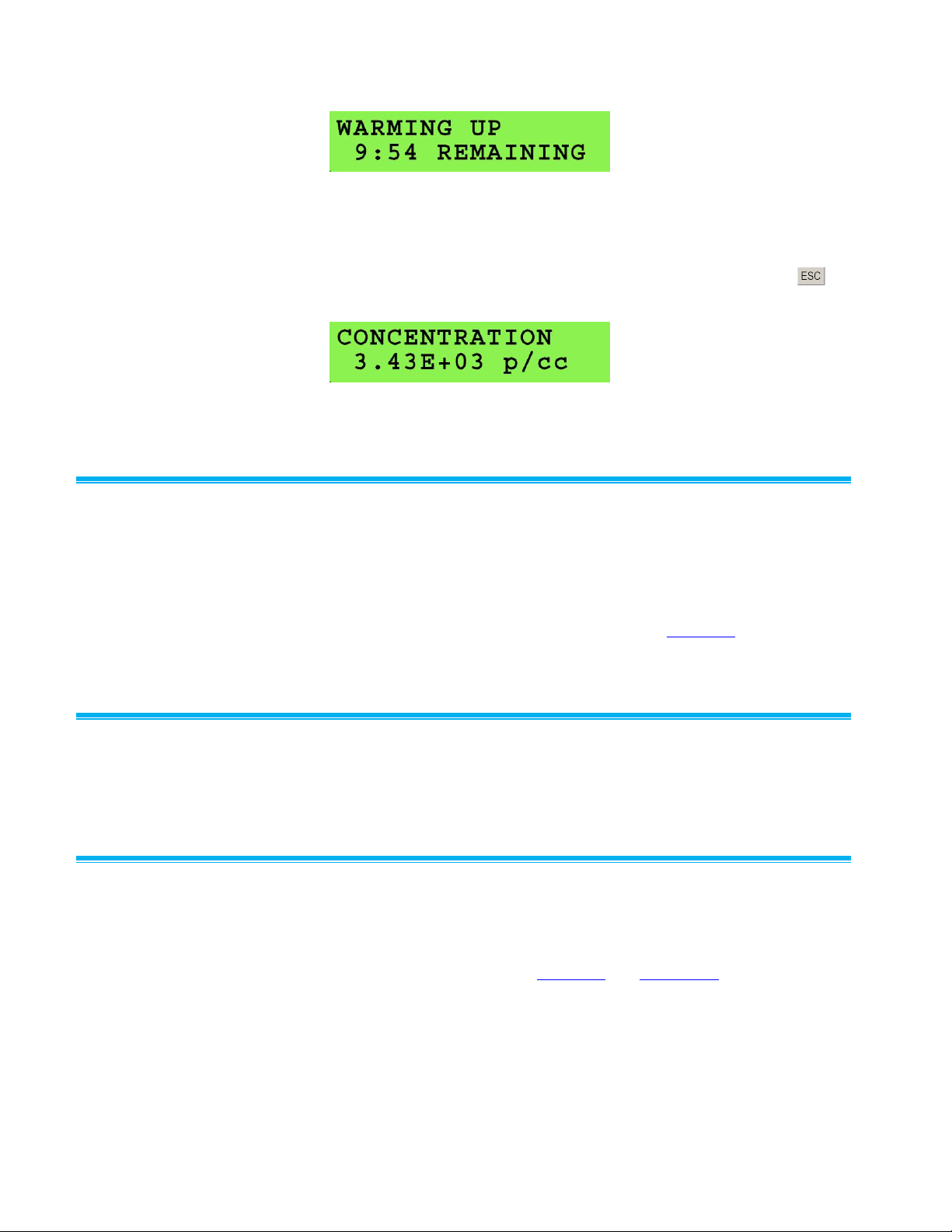

4-1 Model 3772 Display During Warm-Up .............................................. 4-2

4-2 Model 3772 Display After Warm-Up is Completed ........................... 4-2

4-3 Model 3772 Front Panel LCD Display and Keypad .......................... 4-3

4-4 Total Count Mode Data Screen ........................................................ 4-5

4-5 Initial Total Mode Data Screen .......................................................... 4-5

4-6 User Settings Display ........................................................................ 4-5

4-7 Status Display ................................................................................... 4-9

4-8 Status Parameter Display for Diagnostics ........................................ 4-9

4-9 Reformatting the Flash Memory Card ............................................. 4-12

5-1 Flow Schematic of the Model 3772/3771 CPC ................................. 5-6

5-2 Counting Efficiency Curve of 3772/3771 CPC .................................. 5-8

5-3 Response Time of 3772/3771 CPC ................................................ 5-10

7-1 Digi Device Discovery Screen ........................................................... 7-2

7-2 Configure Network Settings Screen .................................................. 7-3

7-3 Digi Connect ME Configuration and Management Screen ............... 7-3

7-4 Main Screen HTML Page .................................................................. 7-4

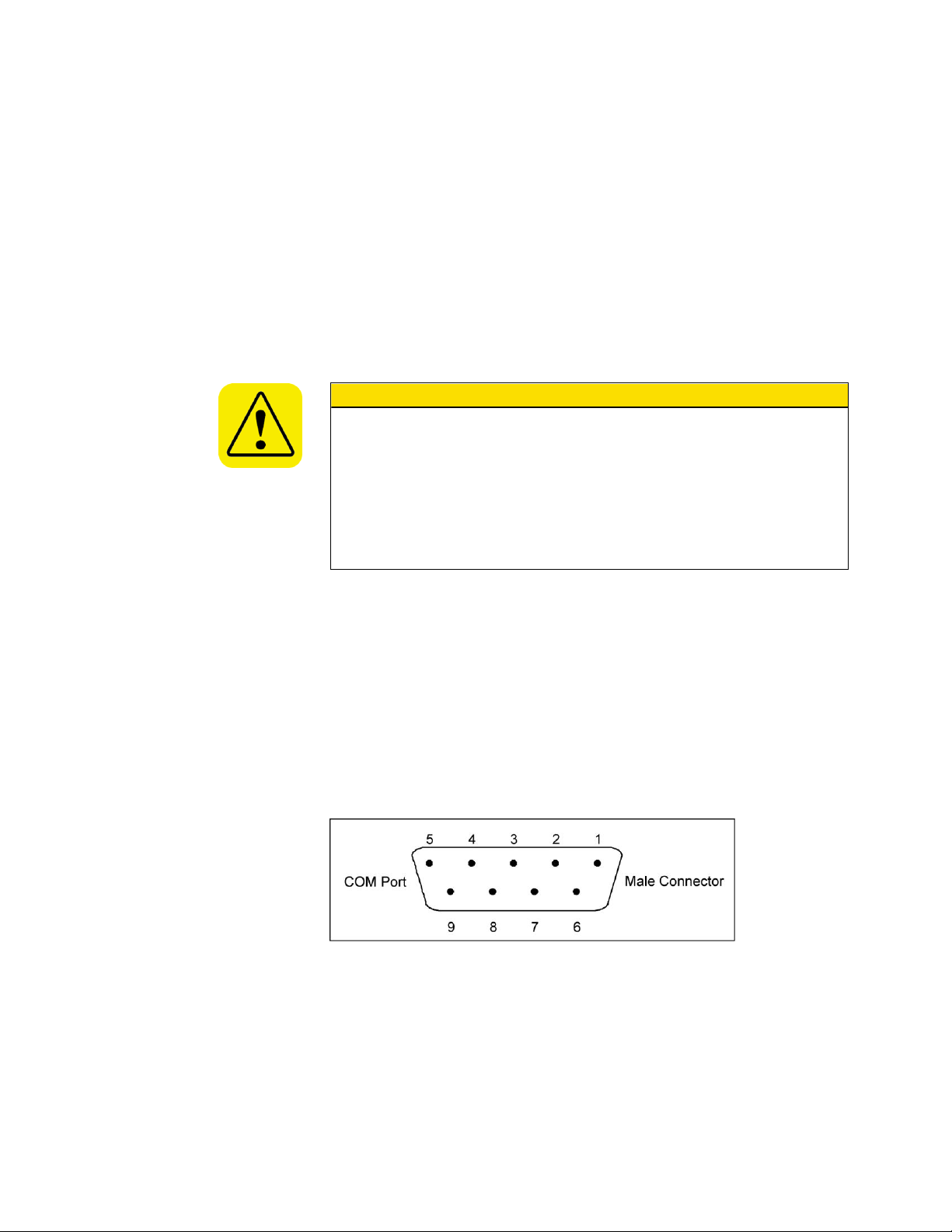

7-5 RS-232 Connector Pin Designations ................................................ 7-6

8-1 Vacuum Drain Cap Assembly ........................................................... 8-4

8-2 Replacing the Butanol Fill and Drain Filters ...................................... 8-5

8-3 Replacing the Micro Pump Filter ....................................................... 8-6

8-4 Inlet Tube .......................................................................................... 8-7

8-7 O-Rings on Saturator Base (P/N 2501172 and 2501569) ................ 8-9

8-8 O-Rings on Saturator Base (P/N 2500021) ...................................... 8-9

8-9 Connecting SMC Plug to Detector Board ....................................... 8-13

8-10 Typical Analog Pulse Trace ............................................................ 8-13

xiv Model 3772/3771 Condensation Particle Counter

Tables

2-1 Model 3772 CPC Packing List .......................................................... 2-1

2-2 Model 3771 CPC Packing List .......................................................... 2-2

6-1 Coincidence Levels Based on 0.35 µsec Pulse Width ...................... 6-3

7-1 Signal Connections for RS-232 Configurations ................................ 7-7

8-1 3772/3771 CPC Maintenance and Replacement Kits ....................... 8-2

8-2 Troubleshooting ............................................................................... 8-15

A-1 Model 3772/3771 CPC Specifications ............................................. A-2

Contents xv

(This page intentionally left blank)

xvi Model 3772/3771 Condensation Particle Counter

Purpose

Organization

About This Manual

This is an operation and service manual for the Model 3772/3771

Condensation Particle Counter (CPC).

The following is a guide to the organization of this manual:

Chapter 1: Product Overview

This chapter gives an introduction to the Model 3772/3771

Condensation Particle Counter, a list of features, and a brief

description of how the instrument works.

Chapter 2: Unpacking and Setting Up the CPC

This chapter gives a packing list and the step-by-step procedure for

getting the CPC ready to operate.

Chapter 3: Instrument Description

This chapter describes features and controls that run the CPC,

including the components on the front-panel, back-panel, bottompanel, cover and inside the instrument. It also covers the basic

functions of the instrument.

Chapter 4: Instrument Operation

This chapter describes the operation of the instruments.

Chapter 5: Technical Description

This chapter details the principle of operation, theory, and performance

of the condensation nucleus counter.

Chapter 6: Particle Counting

This chapter describes the particle counting modes.

Chapter 7: Computer Interface and Commands

This chapter describes the computer interface hardware, associated

firmware commands, and flash memory card.

Chapter 8: Maintenance and Service

This chapter describes the recommended practices and schedule for

routine cleaning, checking and calibration.

Appendix A: Specifications

This appendix lists the specifications of the Model 3772/3771

Condensation Particle Counter.

xvii

Appendix B: Firmware Commands

This appendix lists all the serial commands for communications

between the CPC and the computer.

Appendix C: References

This chapter lists all of the references that have been used within the

text of the manual. In addition, a general list of references pertaining to

condensation nucleus counters is included.

Related Product Lite r ature

Model 3007 Condensation Particle Counter Operation and Service

Manual (part number 1930035) TSI Incorporated

Model 3775 Condensation Particle Counter Operation and Service

Manual (part number 1980527) TSI Incorporated

Model 3776 Ultrafine Condensation Particle Counter Operation

and Service Manual (part number 1980522) TSI Incorporated

Model 3783 EPC™ Environmental Particle Counter™ Monitor

Operation and Service Manual (part number 6003653) TSI

Incorporated

Model 3785 Water-based Condensation Particle Counter

Operation and Service Manual (part number 1933001) TSI

Incorporated

Model 3786 Ultrafine Water-based Condensation Particle Counter

Operation and Service Manual (part number 1930072) TSI

Incorporated

Model 3787 General Purpose Water-based Condensation Particle

Counter Operation and Service Manual (part number 6003712) TSI

Incorporated

Model 3788 Nano Water-based Condensation Particle Counter

Operation and Service Manual (part number 6003713) TSI

Incorporated

Model 376060 Particle Size Selector Instruction Manual (part

number 1930013) TSI Incorporated

This manual contains operating instructions for the Model 376060

Particle Size Selector, an accessory for the Model 3772, 3771, and

3781 CPCs. The Model 376060 is a separating device that removes

small particles from an aerosol while passing larger particles.

Aerosol Instrument Manager® Software for CPC and EAD

Instruction Manual (part number 1930062) TSI Incorporated

This manual contains operating instructions for Aerosol Instrument

Manager Software for CPC and EAD, a software program that

monitors, calculates, and displays particle concentration data collected

by a CPC or an EAD.

xviii Model 3772/3771 Condensation Particle Counter

Submitting Comments

TSI values your comments and suggestions on this manual. Please use

the comment sheet on the last page of this manual to send us your opinion

on the manual’s usability, to suggest specific improvements, or to report

any technical errors.

If the comment sheet has already been used, please mail your comments

on another sheet of paper to:

TSI Incorporated

Particle Instruments

500 Cardigan Road

Shoreview, MN 55126

Fax: (651) 490-3824

E-mail Address: particle@tsi.com

About This Manual xix

(This page intentionally left blank)

xx Model 3772/3771 Condensation Particle Counter

C H A P T E R 1

Product Overview

This chapter contains an introduction to the Model 3772/3771

Condensation Particle Counter (CPC) and provides a brief explanation of

how the instrument operates.

Product Description

The Model 3772/3771 Condensation Particle Counter is a compact,

rugged, and full-featured instrument that detects airborne particles down to

10 nanometers in diameter at an aerosol flow rate of 1.0 liter per minute,

over a concentration range from 0 to 104 particles per cubic centimeter.

These CPCs are ideally suited for applications that do not require

measurement of high concentrations, such as basic aerosol research, filter

and air-cleaner testing, particle counter calibration, environmental

monitoring, mobile aerosol studies, particle shedding and component

testing, and atmospheric and climate studies. The Model 3772 CPC is also

compatible with TSI Scanning Mobility Particle SizerTM (SMPSTM)

spectrometers for particle size distribution measurements.

The successor to the Model 3010, 3760A, and 3762 CPCs, the Model 3772

and 3771 CPCs offer many new features and improvements:

Fast response to rapid changes in aerosol concentration (T

seconds)

Butanol-friendly features, including anti-spill design, water-removal

system, and improved resistance to optics flooding

Removable saturator wick for easy transport and maintenance

USB and Ethernet available

Auto recovery from power failure

The Model 3772 CPC offers the following additional features:

Built-in SMPS

Particle concentration, total counts, instrument status or user settings

shown on enhanced front panel LCD display

Built-in data logging and storage capability with removable memory

card

TM

spectrometer compatibility

95

3

1-1

Figure 1-1 Figure 1-2

Model 3772 Condensation Particle Counter Model 3771 Condensation Particle Counter

(discontinued)

How it Works

In the Model 3772/3771 Condensation Particle Counter (CPC), an aerosol

sample is drawn continuously through a heated saturator in which butanol

is vaporized and diffuses into the sample stream. Together, the aerosol

sample and butanol vapor pass into a cooled condenser where the butanol

vapor becomes supersaturated and ready to condense. Particles present in

the sample stream serve as condensation nuclei. Once condensation

begins, particles that are larger than a threshold diameter quickly grow into

larger droplets and pass through an optical detector where they are

counted easily.

The Model 3772/3771 CPC detects particles as small as 10 nanometer in

diameter and employs single-particle-count-mode operation to measure

concentrations up to 104 particles per cubic centimeter. The detector

counts individual pulses produced as each particle (droplet) passes

through the sensing zone. A high signal-to-noise ratio and continuous, livetime coincidence correction provide great measurement accuracy, even at

very low concentrations. An external vacuum pump is required to draw the

1-2 Model 3772/3771 Condensation Particle Counter

aerosol sample into the CPC. The 1.0 L/min aerosol flow rate is controlled

accurately and reliably using an internal critical orifice.

The CPCs use a laser-diode light source and diode photodetector to collect

scattered light from particles. An internal microprocessor is used for

instrument control and data processing.

Model 3772 CPC has a two-line LCD display which presents real-time

number concentration, totalizer function, and enables easy-to-use menus

for control operation functions and presents instrument status information

and user settings. A variety of communication options for computer data

acquisition are available. The 3772 CPC also includes on-board data

logging and storage using a removable flash memory card. Model 3771

has no display and no memory card.

Product Overview 1-3

(This page intentionally left blank)

1-4 Model 3772/3771 Condensation Particle Counter

Packing List

Qty.

Description

Model/

Part Number

1

Model 3772 CPC and Operation Manual

1980529

1

Power cable

(based on

destination)

1

Aerosol Instrument Manager® Software

390065

1

Fill Bottle

1035590

1

Drain Bottle

1035591

1

Bottle Bracket

1503475

1

Vacuum Drain Bottle Cap

1031526

1

RS-232 Cable (A-pin M/F, 12 ft)

962002

1

USB I/O Cable A/B 6 ft

1303740

1

SanDisk ImageMate 5-in-1 Card Reader

1500208

1

Data Memory Card

1500108

1

Saturator Wick CPC 3772

1600047

2

Water Removal Filter Inline, 25 micron 116" barb

1500192

3

Butanol Fill/Drain Filter Inline, 73 micron 18" barb

1602088

2

Saturator Base O-Ring FVMQ 1-010

2500021

1

Saturator Base O-Ring FVMQ 1-030

2501172

2

Saturator Base O-Ring EPDM 1-027

2501569

1

Krytox

®

O-ring Grease

1701154

1

Checkout Data Sheet

N/A 1 Certificate of Conformance

N/A

C H A P T E R 2

Unpacking and Setting

up the CPC

Use the information in this chapter to unpack the Model 3772/3771

Condensation Particle Counter (CPC) and set it up.

Tables 2-1 and 2-2 show the components shipped with the Model 3772

and 3771 CPCs.

Table 2-1

Model 3772 CPC Packing List

Krytox® is a registered trademark of DuPont.

2-1

Table 2-2

Qty.

Description

Model/

Part Number

1

Model 3771 CPC and Operation Manual

1980529

1

Power cable

(based on

destination)

1

Aerosol Instrument Manager® Software

390065

1

Fill Bottle

1035590

1

Drain Bottle

1035591

1

Bottle Bracket

1503475

1

Vacuum Drain Bottle Cap

1031526

1

RS-232 Cable (A-pin M/F, 12 ft)

962002

1

USB I/O Cable A/B 6 ft

1303740

1

Saturator Wick CPC 3771

1600047

2

Water Removal Filter Inline, 25 micron 116" barb

1500192

3

Butanol Fill/Drain Filter Inline, 73 micron 18" barb

1602088

2

Saturator Base O-Ring FVMQ 1-010

2500021

1

Saturator Base O-Ring FVMQ 1-030

2501172

2

Saturator Base O-Ring EPDM 1-027

2501569

1

Krytox® O-ring Grease

1701154

1

Checkout Data Sheet

N/A 1 Certificate of Conformance

N/A

Model 3771 CPC Packing List

Unpacking

Note: Some items in the lists above and those for future maintenance are

available for purchase as kits from TSI. A complete list of

replacement part kits is included in the maintenance section in

Chapter 8.

The Model 3772/3771 CPC comes fully assembled with protective

coverings on the inlet sample port, exit ports, and analog connectors. The

CPC comes packaged with the accessory kit. Use the packing list

(Table 2-1 or Table 2-2) to make certain that there are no missing

components.

The CPC box contains special foam cutouts designed to protect the

instrument during shipment. Save the original packaging materials for

future use should you need to ship the instrument or return the instrument

to TSI for service. Also keep the protective coverings for ports for shipping.

To avoid contaminating the instrument or the environment the CPC is

monitoring, do not remove the protective covers until you are ready to

install the instrument.

If anything is missing or appears to be damaged, contact your TSI

representative or contact TSI Customer Service at 1-800-874-2811 (USA)

or (651) 490-2811. Chapter 8, “Maintenance and Service,” gives

instructions for returning the CPC to TSI Incorporated.

2-2 Model 3772/3771 Condensation Particle Counter

Setting Up

This section contains instructions for setting up the Model 3772/3771 CPC.

Follow the instructions in the order given.

Remove Protective Caps

Remove all protective caps from the inlet sample port and exit flow ports at

the back of the instrument, also remove covers from the BNC connectors.

Mounting the Bracket and Fill Bottle

Mount the black anodized aluminum Bottle Bracket to the back panel using

two 8-32 38-inch screws and two no. 8 lock-washers found in the

mounting hole locations. Refer to the location of the bottle bracket shown in

Figure 2-1.

Find the Fill Bottle in the accessory kit. Connect the bottle tube fitting to the

Butanol Fill port at the back panel of the instrument. Position the bottle with

the fitting oriented for minimal stress on the tubing connector on the back

panel and place the bottle in the bracket. Both mated fittings are leak-tight

when disconnected.

Figure 2-1

View of Fill Bottle Bracket Mounting

Unpacking and Setting Up the CPC 2-3

Filling the Fill Bottle with Butanol

C a u t i o n

Butanol is flammable. Butanol is also potentially toxic if inhaled. Use

butanol only in a well-ventilated area. If you smell butanol and

develop a headache, or feel faint or nauseous, leave the area at

once. Ventilate the area before returning.

The Model 3772/3771 CPC uses reagent-grade n-butyl alcohol (butanol)

as the working fluid for particle growth. Pour the butanol into the Fill Bottle

to at least one-third full. Because of the leak-tight fittings and internal

solenoid valve, liquid will not flow into the CPC until the connections are

made, the instrument is switched on, and warm-up cycle is complete.

Note: Due to shipping regulations on flammable materials, n-butyl alcohol

(butanol) is not supplied with the CPC. Butanol may be purchased

from scientific chemical supply houses. Reagent grade of butanol is

required.

Connecting the Butanol Drain Bottle

A drain bottle should be connected to the Liquid Drain port at the back

panel of the CPC. The drain bottle collects butanol drained from the CPC

prior to transport and holds condensed water and butanol removed from

the condenser when the water removal system is turned on (see note

below). Draining butanol is described in Chapter 8 “Maintenance and

Service”.

Note: The water removal system will not work without a drain bottle

connected to the drain port. Refer to Chapter 4 for more details on

water removal system.

Apply Power to the CPC

Plug the power cord into the receptacle on the back panel of the CPC and

then plug it into the AC power source. The instrument uses a universal

power supply that accepts a variety of input voltages identified below.

Power 100 – 240 VAC, 50/60 Hz, 200 W maximum

Note: Make certain the power cord is plugged into a grounded power

outlet. Position the CPC so the power connector and switch are

easily accessible in case an emergency disconnect is required.

Apply power to the CPC by turning on the switch next to the power cord on

the back panel.

The instrument begins a warm-up sequence which typically lasts ten

minutes at room temperature. On the 3772, a ten-minute countdown is

displayed on the front panel. Particle concentration will not be accurately

measured during warm-up. After warm-up completes, the fluid begins to fill

the internal butanol reservoir in the saturator.

2-4 Model 3772/3771 Condensation Particle Counter

Supply External Vacuum to the CPC

An external vacuum port is located in the lower right-hand corner of the

CPC back panel. An external vacuum must be connected to this port

before the CPC can count particles. Vacuum source, either a central

building vacuum or a stand-alone vacuum source (e.g., TSI Model 3032

Vacuum Pump), should provide at least 60 kPa (18 in. Hg) vacuum and

1.0 L/min critical flow at the inlet of each CPC. Details of vacuum

specifications are given in Chapter 5.

Positioning the CPC

Place the CPC on a level surface. Ensure the cooling fan on the back

panel of the CPC is exposed to ambient air.

Note: If the CPC has n-butyl alcohol (butanol) in the reservoir, be very

careful when moving the CPC. See “Moving and Shipping the CPC”

section for details.

Unpacking and Setting Up the CPC 2-5

(This page intentionally left blank)

2-6 Model 3772/3771 Condensation Particle Counter

C H A P T E R 3

Instrument Description

Use the information in this chapter to become familiar with the location and

function of controls, indicators, and connectors on the Model 3772 and

3771 Condensation Particle Counters (CPC).

Model 3772 Front Panel

The main components of the 3772 front panel include the two-line LCD

display, six-key push button keypad, flash memory card slot, aerosol inlet,

two LED indicator lights (particle and status). These are identified in Figure

3-1 and described below.

LCD Display and Keypad

The two-line backlit LCD provides continuous real-time display of sample

data and is used in conjunction with the keypad to display option menus,

instrument status information, and user settings. Refer to Chapter 4 for

details on how to make selections and change options on the menus.

Figure 3-1

View of the Model 3772 Front Panel

3-1

Aerosol Inlet

The aerosol inlet is located on the front panel. The inlet consists of a ¼”

OD tube suitable for use with common tube fittings. Permanent fittings with

metal locking ferrules should be avoided since this can deform the tube

when overtightened, leading to leaks.

Status Light

The status light indicates the working status of the CPC. It will light only

when the key performance parameters of the CPC fall within an acceptable

range. More information on the status light is provided in Chapter 4.

Particle Light

The particle light flashes each time a particle is detected. At high particle

counting levels (>10 counts per second) the light appears continuously on.

Flash Memory Card Slot

The Model 3772 CPC provides storage of particle concentration data using

a standard flash memory card. A flash memory card is included. Refer to

Using the Flash Memory Card in Chapter 4 for more on how to use the

Flash Memory Card. Technical information is also found in Chapter 7.

3-2 Model 3772/3771 Condensation Particle Counter

Model 3771 Front Pane l

The main components of the 3771 front panel include the aerosol inlet and

two LED indicator lights (particle and status). These are identified in

Figure 3-2 and operate the same as described above for the 3772.

Figure 3-2

View of the Model 3771 Front Panel

Model 3772/3771 Back Panel

As shown in Figure 3-3, the back panel of the 3772/3771 CPC has power

and data connections, analog input/output connections, external vacuum

port, butanol fill and drain ports, and cooling fan. The function of the ports

and connectors are clearly labeled.

AC Connector and Switch

Plug the supplied AC power cable into this receptacle. The instrument

power switch is integrated into this AC receptacle at the top.

USB Communication Port

The Model 3772/3771 CPC provides a USB port for use with the TSI

Aerosol Instrument Manager® software included with the instrument. When

USB communications are used with the software, the computer

automatically recognizes the CPC as a TSI instrument. Additional

information on USB communications is found in Chapter 7 and also in the

Aerosol Instrument Manager® software manual.

Instrument Description 3-3

Note: Up to three CPCs can be simultaneously connected to one

computer running Aerosol Instrument Manager® software with USB

connections.

Figure 3-3

Back Panel of the Model 3772/3771 CPC

RS-232 Serial Connections

The Model 3772/3771 CPC provides two standard A-pin RS-232 serial

ports that allow communication between a computer and the CPC. Serial

commands are sent to and from the computer to monitor instrument status

information, to retrieve and monitor data, and to provide a variety of control

functions such as turning the water removal system on and off (Serial 1

only). Aerosol Instrument Manager® software may be used with Serial 1 as

well as USB. Information on RS-232 communications can be found in

Chapter 7, “Computer Interfaces and Commands”.

3-4 Model 3772/3771 Condensation Particle Counter

Analog Inputs

The CPC can monitor the analog voltages from two external sources via

the analog input BNC connectors on the back panel, labeled Analog Input

1 and Analog Input 2. The input voltage range for these ports is 0 to 10

volts. On the 3772 the analog voltages can be displayed on the LCD

display and saved to the removable Flash Memory Card or a computer.

Voltages from external pressure, flow, or temperature transducers can be

correlated to particle concentration in real time.

Amplification must be supplied by the user to bring low voltage signals to

the appropriate 0 to 10 volt range for best resolution.

DMA/Analog Output and Pulse Output

The DMA/Analog Output port provides an analog 0–10 V signal linearly

proportional to particle concentration. This particle concentration is

corrected for coincidence and equals the concentration displayed on the

front panel of the CPC and the concentration saved to the Flash Memory

Card or computer. Refer to Chapter 4 for details. In addition, on the 3772

this port can be configured by the Aerosol Instrument Manager® software to

provide the ramped voltage signal needed when the 3772 CPC is used as

part of the Scanning Mobility Particle SizerTM (SMPSTM) spectrometer.

Although this port on the 3771 is also labeled DMA/Analog Output, the

DMA function is not available for the 3771.

Pulse Output port provides a 5-volt (50-ohm termination) digital pulse for

each particle detected. This enables you to use your own counting

electronics hardware or provides a particle trigger for special applications.

The width of the pulse depends on both the shape of the photodetector

pulse and the trigger-level of the pulse threshold. Typical (nominal) pulse

widths are 350 nanoseconds (see Figure 3-4) for the 3772/3771 CPC. To

provide accurate pulse counts, use a counter that is capable of counting

pulses with a width of 50 nanoseconds or less.

Particle concentrations calculated based on the particle counts from the

counting electronics hardware are not corrected for particle coincidence.

Thus, the concentration obtained this way might be slightly lower than the

displayed concentration when particle concentration is high. Refer to

Chapter 6 “Particle Counting” for coincidence correction for pulse output.

The Pulse Output is a way to get raw particle count information. This

information is also available through serial command. Using the SSTART,2

command, described in Appendix B, you can read raw, uncorrected,

particle counts. TSI recommends using the SSTART,2 command for raw

counts as then all the information is shipped which is used to calculate the

corrected concentration, and there are no issues with the counters ability to

accurately count the pulses.

Instrument Description 3-5

Figure 3-4

Sample Digital Pulse from Pulse Output Port at the Back Panel of the CPC

Ethernet Communication Port

Instrument status including particle concentration of the Model 3772/3771

CPC can be monitored remotely from a local area network or over the

internet using the Ethernet communication port. Ethernet communications

are described further in Chapter 7, “Computer Interfaces and Commands”.

Butanol Fill Port

Butanol is supplied from the butanol fill bottle to the instrument at the

Butanol Fill port quick connect fitting.

External Vacuum Port

By attaching an external vacuum to this port, critical flow is established

through the critical orifice described in Chapter 5. The flow through this port

contains butanol vapor so the external vacuum must be properly vented

away from work areas or use charcoal filter to absorb the butanol vapor.

Charcoal filters can be ordered through TSI (P/N 1031492 and P/N

1031493). See Chapter 8 “Maintenance and Service.”

3-6 Model 3772/3771 Condensation Particle Counter

Cover

The bottom portion of the

chassis provides access to the

saturator wick. As shown in

Figure 3-5, the saturator base,

which is attached to the wick,

is visible above the centrally

located 2.5-inch diameter hole

on the bottom panel. The base

and wick can be removed for

maintenance, as described in

Chapter 8.

Figure 3-5

Bottom Panel Showing Removable Saturator

Base

Drain Port

This port is used to drain the working fluid (butanol) from the 5 cm3 liquid

reservoir and is used when collecting water extracted using the Water

Removal system. See Chapters 3 and 4 for more on the water removal

feature.

Instrument Cooling Fan

This fan cools internal electronics and dissipates heat generated during

cooling of the condenser. The fan is provided with a guard and a

removable filter that should be cleaned of dust periodically.

The cover refers to the removable section of the chassis covering the top

and sides of the CPC. It is secured to the chassis with four screws on the

bottom and two on the top and it can be removed for access to the interior

of the Model 3772/3771 CPC. Refer to Chapter 8 for details.

Bottom Panel

Instrument Description 3-7

Internal Instrument C o m ponents

1. Sensor assembly

5. Critical orifice

2. Water removal pump

6. Pressure transducers

3. Butanol fill filter

7. Power supply

4. Fan

Internal components are described in this section and identified in

Figure 3-6 and Figure 3-7.

Figure 3-6

Internal Components of the Model 3772/3771 CPC

Water Removal Pump

The Model 3772/3771 CPC uses a micro-flow Water Removal Pump to

remove condensate from the condenser. The Water Removal Pump draws

condensed butanol and water from the condensate collection reservoir.

Water removal prevents contamination of the butanol during operation in a

high humidity environment. When activated, the pump runs continuously. A

drain bottle must be connected for water removal to occur. For information

on operating the water removal pump refer to Chapter 4, “User Settings.”

3-8 Model 3772/3771 Condensation Particle Counter

Filters

The CPCs use three liquid filters. One liquid filter is used to filter butanol

supplied from the fill bottle while a second filters the butanol drain line. The

third is used to filter the condensed water and butanol mixture before it

passes through the Water Removal Pump.

Valves

Solenoid fill and drain valves enable butanol to be added or removed from

the liquid reservoir. The fill valve is actuated when the Auto-Fill is turned

ON and the level sensor indicates a low butanol level in the liquid reservoir.

When the butanol fill bottle is connected, butanol flows into the reservoir

until the level sensor indicates a full state. On the 3772, the drain valve is

activated through the front panel or through serial command. On the 3771,

the drain valve is activated through serial command. Butanol is drained

prior to shipment or removal of the saturator wick. See “User Settings” in

Chapter 4 and “Maintenance and Service” in Chapter 8.

Pressure Transducers

The Model 3772/3771 CPC uses three pressure transducers for monitoring

instrument flows. The differential pressure across the Critical Orifice is

measured to verify that a critical pressure is maintained across the orifice.

Differential pressure across the nozzle is measured and verifies the nozzle

in the optics block is free from obstruction. The ambient pressure is also

measured. These pressure transducers are mounted to the main PC

board. On the 3772, pressure information is viewable via the front panel

display. On both 3772 and 3771 CPCs, pressure information is available

through serial commands.

Electronics Boards

Four electronics boards identified in Figure 3-7, are used in

Model 3772/3771 CPC. The boards include main PC board, laser board,

detector board, and communication connector board. The 3772 also

includes a fifth board—flash memory board.

Instrument Description 3-9

Figure 3-7

1. Main PC board

4. Communication connector board

2. Laser board

5. Flash memory board (3772 only)

3. Detector board

Electronics Boards inside the Model 3772/3771 CPC

Basic Instrument Fu n c tions

This section describes basic instrument functions.

Concentration Measurement

Particle concentration is presented as particles per cubic centimeter (p/cc).

For the 3772, the particle concentration is displayed on the front panel LCD

in numeric form. For both CPCs, data is collected using the Aerosol

Instrument Manager® software or other terminal program (such as

HyperTerminal). Particle concentration is determined from the count rate

(particles counted per tenth of a second) and the aerosol flow rate,

nominally 1000 cubic centimeters per minute (cm3/min). The concentration

is also live-time corrected for coincidence. Refer to Chapter 6 “Live-Time

Counting” for more information.

3-10 Model 3772/3771 Condensation Particle Counter

Total Count Mode (3772 only)

Total Count Mode (also called totalizer mode) counts number of particles in

a given time period. This mode is used to improve counting resolution at

very low particle concentrations. Time and number of counts are shown on

the front panel display of the 3772.

Water Removal

When the aerosol sample has a dew point above the condenser

temperature of 22°C, water vapor may condense on the walls of the

condenser and run back into the saturator, contaminating the butanol over

time. Unlike its predecessor, the Model 3010, 3760A, or 3762 CPC, the

Model 3772/3771 CPC is able to capture condensed water vapor and

remove it, significantly reducing butanol contamination in high humidity

environment. The water removal process increases the butanol

consumption. For additional information refer to Chapter 4.

Internal Data Logging (3772 only)

A removable Flash Memory Card can be inserted in the slot on the 3772

front panel to store data including particle concentration and analog input

data. Data can then be transferred to a computer for further data

processing. Refer to Chapter 4 for more details. It is not recommended you

use a Flash Memory Card and Aerosol Instrument Manager® software or

terminal program to collect data simultaneously to avoid data transfer

interference.

Remote Access of Instrument

The Model 3772/3771 CPC provides an Ethernet port to connect the

instrument to a network for monitoring status information. Status

information includes saturator, condenser, optics temperatures, laser

power, and particle concentration, etc. The data is updated once every five

seconds. Refer to Chapter 7 for more details.

External Vacuum Pump or Source

The external vacuum pump or source must provide sufficient vacuum to

maintain a critical pressure across the critical orifice, while providing an

aerosol flow of 1.0 L/min. At an atmospheric pressure of 100 kPa (1 atm),

an external pump or other vacuum source must provide at least 60 kPa

(18 in. Hg) of vacuum and 1.0 L/min inlet volumetric flow for each CPC

supported. TSI offers Model 3032 Vacuum Pump for one CPC and Model

3033 Vacuum Pump for multiple CPCs. Contact TSI technical support for

more information on use of an external vacuum pump.

Instrument Description 3-11

Flow Rate Control

The Model 3772/3771 CPC uses a critical orifice to accurately control the

air flow in the instrument. The critical orifice operates at or below a critical

pressure to control the 1.0 L/min volumetric aerosol flow. More is found in

Chapter 5 “Technical Description.”

Problems with the aerosol flow can be detected by monitoring the pressure

drop across the nozzle, and verifying that the critical orifice pressure is

maintained.

Temperature Control

The temperatures of the condenser, saturator, and optics are maintained at

22 °C, 39 °C, and 40 °C, respectively, with specified ambient temperatures

in the operating range of 10 to 35 °C. The temperatures are controlled

through feedback circuits on the main electronics board and are viewable

via firmware commands. For the 3772, the temperatures are also viewable

with the Status display screen. If the temperatures are out of range on

either CPC, the status indicator LED on the front panel will be off. For

ambient temperatures outside the instrument operating range, the

instrument temperature performance may not be maintained. Moderate

increases in saturator temperature and optics are tolerated in some

instances, depending on measurement requirements.

Inlet Pressure Measurement

With adequate external vacuum, the instrument is capable of operating at

inlet pressures in the range of 75 to 105 kPa. The inlet pressure is

measured by an absolute pressure sensor, and is essentially the

barometric pressure if no inlet restriction is present. Inlet Pressure is

accessible through firmware commands on both 3772 and 3771 CPCs and

it is also viewable via the Status display screen for the 3772. Refer to

Chapter 4 for more details.

3-12 Model 3772/3771 Condensation Particle Counter

W A R N I N G

Although the Condensation Particle Counter is appropriate for monitoring

inert process gases such as nitrogen or argon, it should not be used with

hazardous gases such as hydrogen or oxygen. Using the CPC with

hazardous gases may cause injury to personnel and damage to equipment.

C H A P T E R 4

Instrument Operation

This chapter describes the basic operation of the Model 3772/3771

Condensation Particle Counter (CPC) and provides information on the use

of controls, indicators, and connectors found on the front and back panels.

Operating Precautions

Read the following before applying power to the 3772/3771 CPC:

Review the operating specifications for the CPC in Appendix A.

Do not operate the CPC outside the range of 10 to 35 C. If the CPC is

operated outside this range, the displayed concentration may be

inaccurate.

Power Switch

Warm-up

If the CPC reservoir contains butanol, be very careful when moving the

CPC. Refer to “Moving and Shipping the CPC” for more details.

The power switch is found on the back panel of the CPC. The switch is

combined with the power cord receptacle.

When the CPC is turned on, the saturator, condenser, and optics have to

reach set operating temperatures. This “warm-up interval” takes about 10

minutes at room temperature. The Status LED indicator on the front panel

will remain unlit during this time. Under extremes in ambient temperature, it

may take considerably longer for the instrument to warm-up.

On the 3772 front panel display, a countdown is also displayed during the

warm-up time, as shown in Figure 4-1.

4-1

Figure 4-1

Model 3772 Display During Warm-Up

When warm-up is complete, the concentration is automatically displayed

for the 3772 as shown in Figure 4-2. The concentration can also be

displayed before the warm-up is complete by pressing the ESC key at

any time.

Figure 4-2

Model 3772 Display After Warm-Up is Completed

Status Indicator

A status LED indicator on the front panel of the Model 3772/3771 CPC

indicates the overall status of the CPC. It will remain unlit if a key

parameter falls outside of the acceptable operating range. Parameters

monitored include instrument temperatures, pressures, and liquid level.

Generally it will light after warm-up time is complete, an external vacuum is

applied, and butanol has filled the reservoir. See Chapter 8 for

troubleshooting instructions if the Status indicator LED does not turn on.

Particle Indicator

A particle LED indicator light on the front panel of the CPCs indicates

particle counts.

Communication

CPC measurement data, instrument status, and user settings are available

through firmware communication for both Models 3771 and 3772 and also

viewable through the front panel for Model 3772. For more information on

firmware communication, see Chapter 7 and Appendix B.

4-2 Model 3772/3771 Condensation Particle Counter

Model 3772 LCD Display and Keypad

In addition to firmware communication, Model 3772 presents measurement

data, instrument status, and user settings on a 2-line, 16-character,

alphanumeric LCD display. You can navigate the menu options using the

six-button keypad. The display and keypad are shown in Figure 4-3.

Figure 4-3

Model 3772 Front Panel LCD Display and Keypad

Model 3772 Keypad Navigation

As shown in Figure 4-3, the keypad has six keys: scroll left , scroll right

, scroll up , scroll down , Enter , and ESC . Detailed

navigation instructions are described below. Generally,

The up and down arrows are used to scroll through a given menu.

The left and right arrows are used to configure user settings. The new

setting becomes active immediately after the setting is selected.

The Enter

The ESC

key displays submenus.

key returns the display out of a submenu.

The control menu has a two-tier hierarchy. There are four primary

functions: Concentration, User Settings, Status, and Total Count Mode. By

pressing the up or down arrow, the display will scroll through

these four functions.

Two of the primary functions, User Settings and Status, have submenus. A

submenu can be accessed by pressing the Enter key. Once inside a

submenu, the up or down arrow can be used to scroll through the

features. The submenu for User Settings contains all the options for

configuring the CPC. The submenu for Status contains all the parameters

for monitoring the CPC. The primary functions are summarized below

along with their submenus. These are described in detail in the following

sections.

Instrument Operation 4-3

Primary Function

Secondary Submenu

Concentration

Aerosol concentration

measured in [p/cc]

No submenu available.

User Settings

Displays features available

for configuration

Data Logging, Water Removal, Totalizer Time,

Auto Fill, Analog Out, Data Averaging, and Drain.

Status

Displays operating

parameters and status of

CPC

Saturator Temperature, Condenser

Temperature, Optics Temperature, Cabinet

Temperature, Ambient Pressure, Orifice

Pressure, Nozzle Pressure, Laser Current, Liquid

Level, Analog Input 1, Analog Input 2, Flash

Status, USB status, Firmware Version

Total Count Mode

Accumulates particle counts

and clock time

No submenu available.

Concentration

The CPC measures aerosol concentration in particles per cubic centimeter.

The 3772 displays a Concentration screen as shown in Figure 4-3. This is

the default display. Pressing ESC twice from any other screen returns

the display to Concentration screen. The LCD is updated once per second.

For both 3771 and 3772, concentration data can be accessed through

firmware communication using “RD” command. Refer to Chapter 7 and

Appendix B for more information on firmware commands. The maximum

concentration limit for the 3772/3771 is 10,000 particles/cm3.

When concentration exceeds 10,000 particles/cm3 for a 3772, two

exclamation marks appear on the LCD main display, one in front of the

concentration value and one after. For both 3772 and 3771 CPCs,

measurements with concentrations that exceed 10,000 are flagged and the

status LED will be turned off.

4-4 Model 3772/3771 Condensation Particle Counter

Total Count Mode (3772 only)

Total Count Mode allows particle counts to be accumulated and displayed

as shown in Figure 4-4. Total Count Mode is generally useful for tests at

very low particle concentrations (e.g., below 10.0 particles/cm3), such as

evaluation of high efficiency filters.

To access Total Count Mode from the default Concentration screen, press

the down arrow once. When first accessed, the display appears as

shown in Figure 4-5. By pressing Enter , the screen changes to

Figure 4-5. Pressing Enter again at this screen will cycle between

Start, Stop, and Reset. The CPC will count time and total particles once

Start is set. The sample automatically stops when the time is equal to the

Totalizer Time. Totalizer Time can be set in the User Setting submenu.

Figure 4-4

Total Count Mode Data Screen

Figure 4-5

Initial Total Count Mode Data Screen

User Settings

User settings can be configured through firmware commands on both 3772

and 3771. Refer to Chapter 7 and Appendix B for information on firmware

commands. On the 3772, User Settings is also accessible from the front

panel display. It is a primary function accessible from the default

Concentration screen by pressing the up arrow once. The screen

appears as in Figure 4-6. Pressing Enter once brings up the

submenu. Once inside the submenu, the up or down arrow can

be used to scroll through a list of configurable settings. To change a

setting, use the left or right arrow. The setting takes effect

immediately after it is selected. Pressing ESC once returns the display

to User Settings as shown in Figure 4-6. User settings in the menu are

described under individual headings below, beginning with the Data

Logging.

Figure 4-6

User Settings Display

Instrument Operation 4-5

Data Logging (3772 only)

Imp ort a nt Note

The Drain Bottle must be connected for the water removal system to work

properly.

Butanol

Consumption

The water removal feature removes condensed

butanol as well as water, increasing butanol

consumption. The operator may elect not to use

water removal in cool/dry environments to preserve

butanol. When water removal is not used, butanol is

recycled. A full bottle of butanol (1 liter) lasts

approximately 7 days with the water removal system

ON and last 15 days with the water removal system

OFF.

Data can be saved on a Flash memory card on the 3772. By default Data

Logging is “OFF.” To initiate data logging, switch the Data Logging user

setting to “ON” by pressing the left or right arrow once. Logging

will begin immediately. Press the arrow again to toggle Data Logging to

“OFF” to stop. More information on data logging is provided under “Using

the Flash Memory Card.” Use the Data Averaging option in User Settings

to set the data averaging interval for data collection.

Water Removal

The Water Removal option provides ON/OFF control for the water removal

feature of the CPC. The default setting is “OFF.” On the 3772 it can be set

from the Water Removal option in the submenu of User Settings. Pressing

the left

either 3772 or 3771 CPC, it can be turned on using the “SAWR” firmware

command. See Chapter 7 and Appendix B for information on firmware

commands.

Water Removal system is used in hot/humid environments to eliminate

contamination of the butanol working fluid by condensed water vapor.

Water removal keeps the CPC operating at peak performance.

or right arrow toggles Water Removal system on or off. On

Water removal is achieved by collecting all condensate from the cooled

condenser before it has a chance to return and remix with the butanol in

the heated saturator. The collected condensate is pumped to the Drain port

and flows into the supplied Drain Bottle.

4-6 Model 3772/3771 Condensation Particle Counter

Totalizer Time (3772 only)

Option

Concentration Range for Analog Output 0–10 V

Relation

OFF

0 V independent of concentration

-

1E+1

0 to 10 particles/cm3

linear

1E+2

0 to 100 particles/cm3

linear

1E+3

0 to 1,000 particles/cm3

linear

1E+4

0 to 10,000 particles/cm3

linear

OFF

0 V independent of concentration

-

The Totalizer Time feature is available from the User Settings submenu.

Use this feature with the Total Count Mode function to select the time

period for accumulating counts. Three options are available: 1 minute,

60 minutes, and Continuous. The default setting is “Continuous.” Pressing

the left