Page 1

CERTIFIER® FA PLUS

TEST SYSTEM

OPERATOR’S MANUAL

P/N 1980560, REVISION J

FEBRUARY 2016

Page 2

Page 3

CERTIFIER® FA PLUS

TEST SYSTEM

OPERATOR’S MANUAL

P/N 1980560, REVISION J

FEBRUARY 2016

U.S. & INTERNATIONAL TSI Instruments Ltd. (UK)

Sales and Customer Service: Sales and Customer Service:

(800) 874-2811 / +1(651) 490-2811 +44 (0) 1494 459200

Fax: Fax:

+1(651) 490-3824 +44 (0) 1494 459700

Page 4

Page 5

Copyright TSI Incorporated / 2010-2016 / All rights reserved.

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA

Fax No.

(651) 490-3824

Caution

TSI flowmeters are not medical devices under FDA 510(k) and in no situation should be

used for human measurements.

LIMITATION OF WARRANTY AND LIABILITY (effective February 2015)

(For country-specific terms and conditions outside of the USA, please visit www.tsi.com.)

Seller warrants the goods, excluding software, sold hereunder, under normal use and service as described in the

operator's manual, to be free from defects in workmanship and material for 12 months, or if less, the length of

time specified in the operator's manual, from the date of shipment to the customer. This warranty period is

inclusive of any statutory warranty. This limited warranty is subject to the following exclusions and exceptions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other components when indicated

in specifications, are warranted for 90 days from the date of shipment;

b. Pumps are warranted for hours of operation as set forth in product or operator’s manuals;

c. Parts repaired or replaced as a result of repair services are warranted to be free from defects in workmanship

and material, under normal use, for 90 days from the date of shipment;

d. Seller does not provide any warranty on finished goods manufactured by others or on any fuses, batteries or

other consumable materials. Only the original manufacturer's warranty applies;

e. This warranty does not cover calibration requirements, and seller warrants only that the instrument or

product is properly calibrated at the time of its manufacture. Instruments returned for calibration are not

covered by this warranty;

f. This warranty is VOID if the instrument is opened by anyone other than a factory authorized service center

with the one exception where requirements set forth in the manual allow an operator to replace

consumables or perform recommended cleaning;

g. This warranty is VOID if the product has been misused, neglected, subjected to accidental or intentional

damage, or is not properly installed, maintained, or cleaned according to the requirements of the manual.

Unless specifically authorized in a separate writing by Seller, Seller makes no warranty with respect to, and

shall have no liability in connection with, goods which are incorporated into other products or equipment, or

which are modified by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated herein. NO OTHER

EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR PARTICULAR PURPOSE OR MERCHANTABILITY

IS MADE. WITH RESPECT TO SELLER’S BREACH OF THE IMPLIED WARRANTY AGAINST

INFRINGEMENT, SAID WARRANTY IS LIMITED TO CLAIMS OF DIRECT INFRINGEMENT AND EXCLUDES

CLAIMS OF CONTRIBUTORY OR INDUCED INFRINGEMENTS. BUYER’S EXCLUSIVE REMEDY SHALL BE

THE RETURN OF THE PURCHASE PRICE DISCOUNTED FOR REASONABLE WEAR AND TEAR OR AT

SELLER’S OPTION REPLACEMENT OF THE GOODS WITH NON-INFRINGING GOODS.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR BUYER, AND THE

LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES, INJURIES, OR DAMAGES CONCERNING

THE GOODS (INCLUDING CLAIMS BASED ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR

OTHERWISE) SHALL BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE PURCHASE

PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR REPLACEMENT OF THE GOODS. IN THE

i

Page 6

CASE OF SOFTWARE, SELLER WILL REPAIR OR REPLACE DEFECTIVE SOFTWARE OR IF UNABLE TO

DO SO, WILL REFUND THE PURCHASE PRICE OF THE SOFTWARE. IN NO EVENT SHALL SELLER BE

LIABLE FOR LOST PROFITS, BUSINESS INTERRUPTION, OR ANY SPECIAL, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE RESPONSIBLE FOR

INSTALLATION, DISMANTLING OR REINSTALLATION COSTS OR CHARGES. No Action, regardless of

form, may be brought against Seller more than 12 months after a cause of action has accrued. The goods

returned under warranty to Seller's factory shall be at Buyer's risk of loss, and will be returned, if at all, at

Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND LIABILITY, which

contains the complete and exclusive limited warranty of Seller. This LIMITATION OF WARRANTY AND

LIABILITY may not be amended, modified or its terms waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are to our customers, our

service policy is designed to give prompt attention to any problems. If any malfunction is discovered, please

contact your nearest sales office or representative, or call TSI's Customer Service department at (800) 8742811 / (1) 651 490-2811 (USA and International) or TSI Instruments in UK at: +44 (0) 1494 4 59200.

Trademarks

Certifier® is a registered trademark of TSI Incorporated.

ii Certifier® FA Plus Test System

Page 7

CONTENTS

1 INTRODUCTION ....................................................................................................... 1

1.1 Parts List ......................................................................................................... 2

1.2 Glossary .......................................................................................................... 6

1.2.1 Symbols on Display ............................................................................ 6

2 SETUP AND OPERATION ..................................................................................... 11

2.1 Keypad Functions ......................................................................................... 15

2.2 Power up ....................................................................................................... 16

2.3 Display Navigation ........................................................................................ 17

2.3.1 Measurement Selection .................................................................... 20

2.3.2 Graph Measurement Selection ......................................................... 21

2.3.3 Available Measurement Parameters ................................................. 22

2.3.4 Gas Conditions Selection Box .......................................................... 24

2.3.5 Averaging Setup Menu ..................................................................... 25

2.3.6 Breath Trigger Types ........................................................................ 26

2.3.7 Flow Triggering ................................................................................. 27

2.3.8 Saving/Loading Configurations ......................................................... 28

2.3.9 Print/Save Button .............................................................................. 29

2.3.9.1 Waveform Logging ..................................................................... 30

2.3.9.2 Continuous Logging ................................................................... 31

2.3.10 Setup Key ......................................................................................... 32

2.3.10.1 Advanced Features .................................................................... 33

2.3.10.1.1 Configuration Import/Export .................................................. 33

2.3.10.1.2 Format Settings ..................................................................... 34

2.4 Required Pre-test Calibrations ..................................................................... 35

2.4.1 Low Flow Module .............................................................................. 35

2.4.1.1 None required ............................................................................ 35

2.4.2 High Flow Module ............................................................................. 35

2.4.2.1 Zeroing the Flow Direction Sensor ............................................ 35

2.4.2.2 Low-Pressure and High-Pressure Transducer Zeroing ............. 35

2.4.2.3 Oxygen Sensor Calibration ........................................................ 36

3 TROUBLESHOOTING ........................................................................................... 37

iii

Page 8

4 MAINTENANCE ...................................................................................................... 41

4.1 Recharging the Batteries (as required) ......................................................... 41

4.2 Replacing the Oxygen Sensor ...................................................................... 41

4.3 Cleaning (as required) ................................................................................... 41

4.4 Factory Calibration (recommended yearly) ................................................... 42

4.5 Return Procedure .......................................................................................... 42

5 SPECIFICATIONS ................................................................................................... 43

5.1 Physical ......................................................................................................... 43

5.2 Environmental ............................................................................................... 43

5.3 Power ............................................................................................................ 43

5.4 Data Transfer and Storage ............................................................................ 44

5.5 Test Measurements (See notes at end of section. See Table 3 for

symbol definitions.) ....................................................................................... 44

5.6 Calibration Recommendations ...................................................................... 47

5.7 Compliance and Approvals ........................................................................... 47

APPENDIX A DATA FILE FORMATS ......................................................................... 49

LIST OF FIGURES

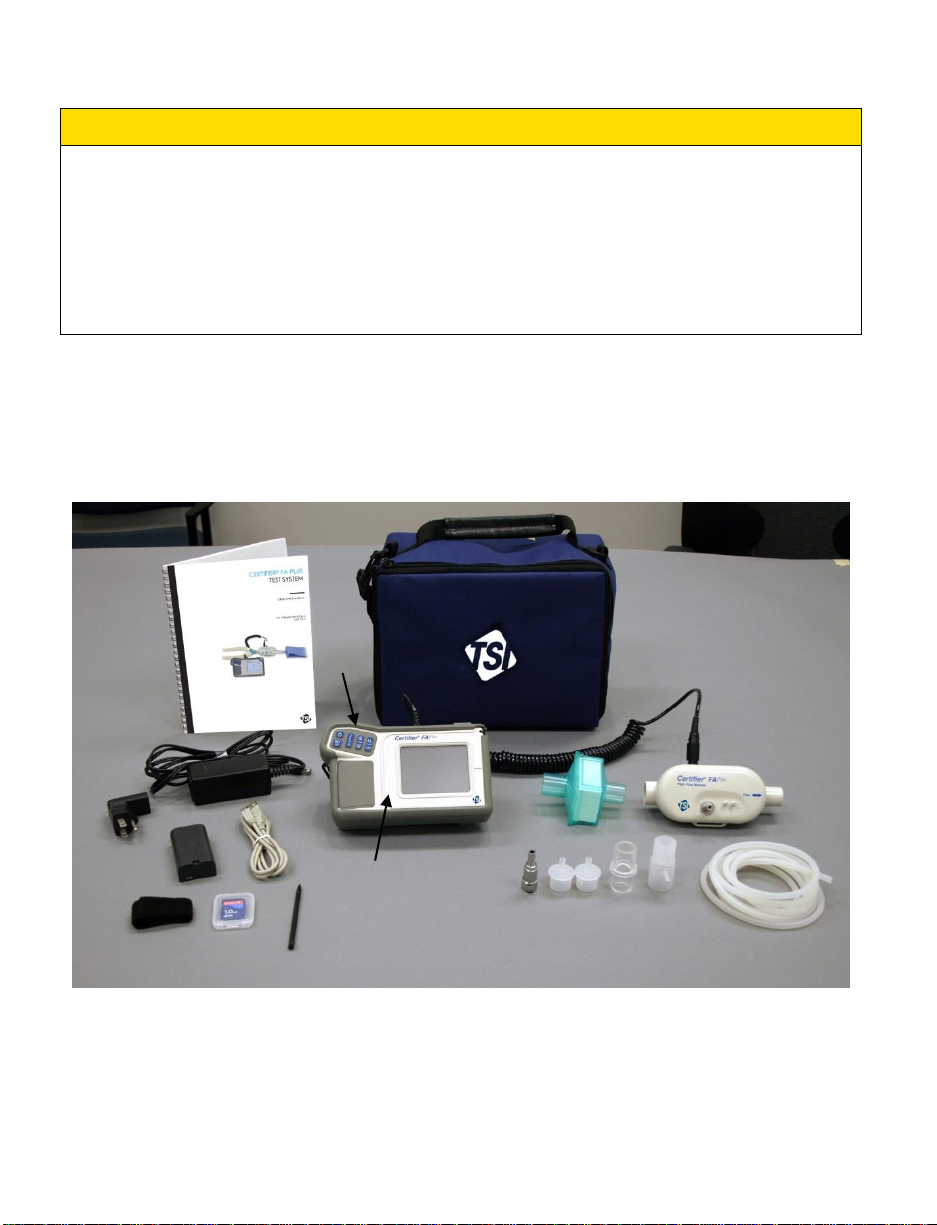

Figure 1. Certifier® FA Test System High Flow Standard Kit (4080) ............................... 2

Figure 2. Certifier® FA Test System Low Flow Module Kit (4082) ................................... 4

Figure 3. Certifier® FA Test System Oxygen Sensor Kit (4073) ...................................... 4

Figure 4. Certifier® FA Test System Extra Battery and Charger Kit (1208061) ............... 5

Figure 5. Interface Module ............................................................................................... 7

Figure 6. Back of Interface Module .................................................................................. 8

Figure 7. High Flow Module (arrow on module indicates positive flow direction) ........... 9

Figure 8. Low Flow Module .............................................................................................. 9

Figure 9. Oxygen Sensor Kit .......................................................................................... 10

Figure 10. Connecting the Interface Module to a Flow Module ..................................... 11

Figure 11. Installing a Flow Module into the Circuit for Measuring Bi-directional

Flow (flow direction Arrow should be towards test lung) .............................. 12

Figure 12. Test Circuit for Bi-Directional Flow ............................................................... 13

Figure 13. Removing Coupling ....................................................................................... 14

Figure 14. Interface Module Keypad .............................................................................. 15

Figure 15. Example of Parameter Screen ...................................................................... 17

iv Certifier

®

FA Plus Test System

Page 9

Figure 16. Example of Graph Screen ............................................................................ 17

Figure 17. Parameter Screen Features ......................................................................... 18

Figure 18. Graph Screen Features ................................................................................ 19

Figure 19. Measurement Selection Screen ................................................................... 20

Figure 20. Graph Measurement Selection Screen ........................................................ 21

Figure 21. Parameter Definitions ................................................................................... 23

Figure 22. Gas Conditions Selection Box ...................................................................... 24

Figure 23. Averaging Setup Menu ................................................................................. 25

Figure 24. Trigger Options Menu .................................................................................. 26

Figure 25. Configuration Save Screen .......................................................................... 28

Figure 26. Print/Save Options Screen ........................................................................... 29

Figure 27. Add Comments Screen ................................................................................ 30

Figure 28. Setup Menu .................................................................................................. 32

Figure 29. Advanced Function Menu ............................................................................ 33

Figure 30. Format Settings Screen ............................................................................... 34

LIST OF TABLES

Table 1. Certifier® FA Test System Parts List ................................................................. 3

Table 2. Keypad Functions ............................................................................................ 15

Table 3. Parameters (parameter list changes depending on module attached) ........... 22

Table 4. Troubleshooting the Certifier® FA Test System ............................................... 37

Table 5. Cleaning Recommendations ........................................................................... 41

Contents v

Page 10

(This page intentionally left blank)

vi Certifier

®

FA Plus Test System

Page 11

1 Introduction

The Certifier® Flow Analyzer (FA) Test System is a multi-functional pneumatic tester

designed specifically for the medical industry. Specific measurements for ventilator

testing are programmed and include flows, volumes, pressures, oxygen concentration,

and breath timing. The Certifier® FA Plus Test System is designed for hospital, home

care, field service, and laboratory settings.

Certifier® FA Test System components include:

Interface Module:

The keypad and touch screen display allow you to select test measurements and

units for display. The Interface Module connects to the High or Low Flow Module.

High Flow Module:

Measures air, oxygen (O2), nitrogen (N2) and carbon dioxide (CO2) flow rate over a

range of 0 to 300 standard liters per minute (0 to 40 standard L/min for CO2). A

150 PSI (10 Bar) gauge transducer, a barometric pressure transducer, and a

150 cm H2O differential pressure transducer are also in the High Flow Module.

Low Flow Module:

Measures air, O2, N2, CO2 and nitrous oxide (N2O) flow rate over a range of 0.01 to

20 standard L/min with greater accuracy than the High Flow Module at low flow

rates.

Oxygen Sensor:

Used with the High Flow module, allows the High Flow Module to measure O2

concentration and other measurements for any mixture of air and O2.

You can connect or disconnect the flow modules and oxygen sensor at any time during

normal operation without interrupting the operation of the instrument.

Lithium-Ion batteries or an AC adapter can be used to power the test system.

WARNING

To avoid the risk of explosion, do not use in the presence of flammable anesthetic

gases.

Only TSI qualified and trained service technicians are authorized to service the

Certifier® FA Test System.

1

Page 12

2

Caution

1 2 3 6 4

5

7

8 9 10

11

12

13

14

15

19

17

16

18

To avoid inaccurate test readings, do not obstruct tubing or inlet or exhaust ports,

and always use dry gas.

To avoid damage to the Certifier® FA Test System components, always use

bacteria filters upstream of the flow modules, and always cap flow module ports

when not in use.

The Certifier FA Plus is not a medical device under the Medical Device Directive or

FDA 510(k) and in no situation should be used for human measurements.

1.1 Parts List

Carefully unpack the test system components from the shipping container. Check the

individual parts against the packing list and notify TSI immediately if anything is missing

or damaged. Table 1 summarizes the Certifier® FA Test System components and part

numbers shown in Figure 1, 2, and 3.

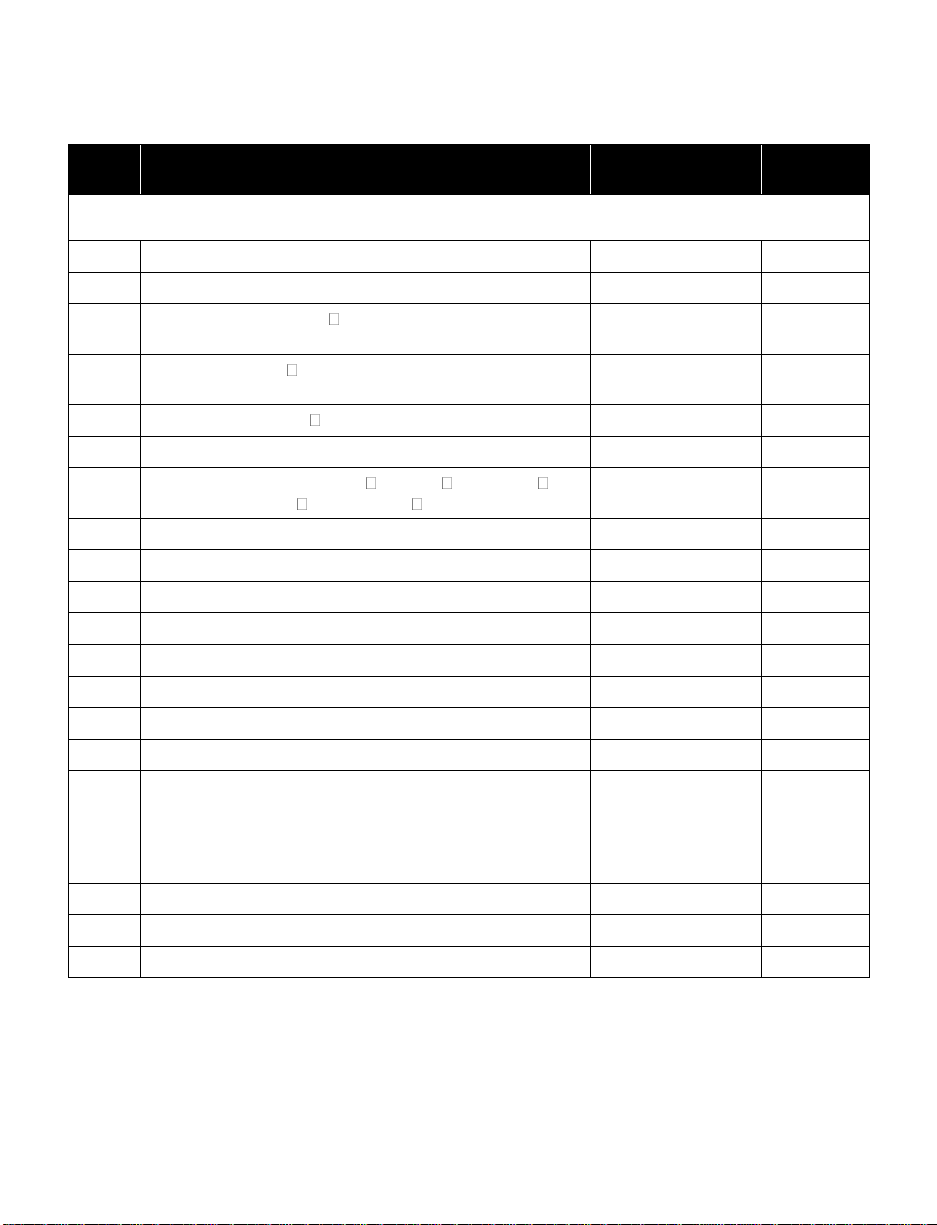

Figure 1. Certifier® FA Test System High Flow Standard Kit (4080)

Certifier® FA Plus Test System

Page 13

Table 1. Certifier® FA Test System Parts List

Item

No.

Description

Replacement

Part Number

Quantity

High Flow Standard Kit (part number 4080)

1 1

Interface Modulea

4088

1

2 2

High Flow Moduleb

4081

1

3 3

Bacteria filter, 22-mm 22-mm male/female, for use

with High Flow Module

1602341

1

4 7

Adapter, 22-mm 6-mm (for interfacing High Flow

Module to Low Flow filter)

1102091

2

5 5

Adapter, 15-mm ID 22-mm OD

1102093

1

6

Airway pressure fitting with screen

1611330

1

7 9

Pressure tubing, silicone, 18-in. ID ¼-in. OD

48-in. (3.2 mm ID 6.4 mm OD 122 cm)

3002053

1

8

Velcro strap for use on High Flow Module

2913133

1

9

Adapter, high pressure port

1611221

1

10

Cable, flow module

1040219

1

11 4

Soft carrying case

1319289

1

12

Power supply 90/260 VAC to +12 VDC

2613237

1

13

Stylus

1319420

2

14

Certifier® FA Test System Operator’s Manual

1980560

1

15

Battery—Lithium-Ion SBL-160

1208056

1

16

Connector, four types:

AC NORTH AM./IEC320, right angle

AC EURO/IEC320, right angle

AC UK/IEC320 fuse, right angle

AC AUST/IEC320, right angle

1302013

1302014

1302015

1302025

1

1

1

1

17

SD flash memory card

1500108

1

18

Protective Rubber boot for Interface module

6001503

1

19

Computer Cable—USB standard A to mini B

1303754

1

a

If ordering a 4088 for replacement, items 10 through 19 are included.

b

If ordering a 4081 for replacement, items 3 through 9 are included

1: Introduction 3

Page 14

4

Item

No.

Description

Replacement

Part Number

Quantity

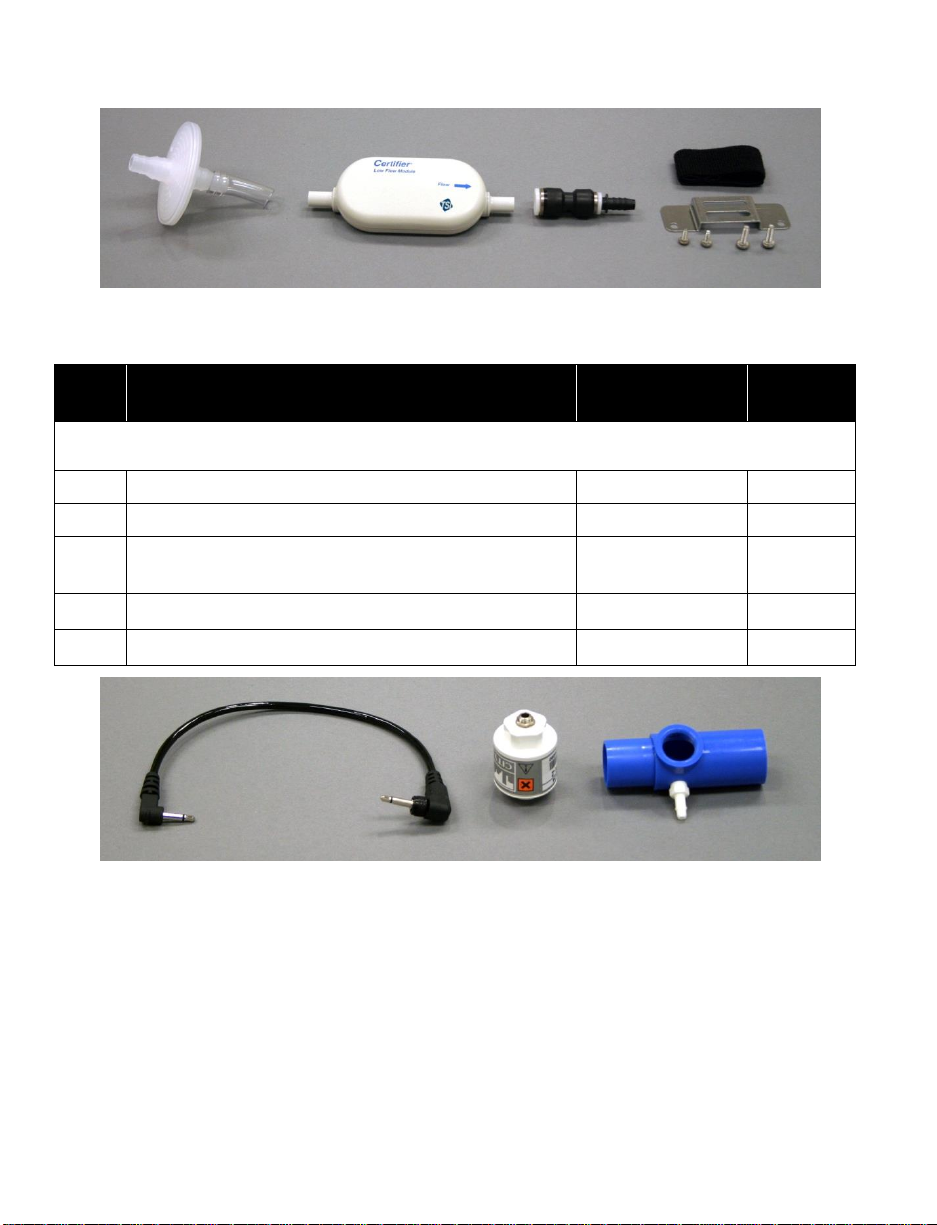

Low Flow Module Kit (optional—part number 4082)

20

Low Flow Module

4082

1

21

Bacteria filter, for use with Low Flow Module

1602342

1

22

Mounting bracket (includes bracket, screws, and

Velcro strap)

1040044

1

23

Coupling,

3

8 inch tube

1601180

1

24

Adapter,

3

8 inch tube to 38 inch barb

1601179

1

20

21

22

23

24

25

26

27

Figure 2. Certifier® FA Test System Low Flow Module Kit (4082)

Figure 3. Certifier® FA Test System Oxygen Sensor Kit (4073)

Certifier® FA Plus Test System

Page 15

Item

No.

Description

Replacement

Part Number

Quantity

Oxygen sensor kit (optional—part number 4073)

25

Oxygen sensor

2917019

1

26

Threaded tee

1313118

1

27

Oxygen sensor cable

1303741

1

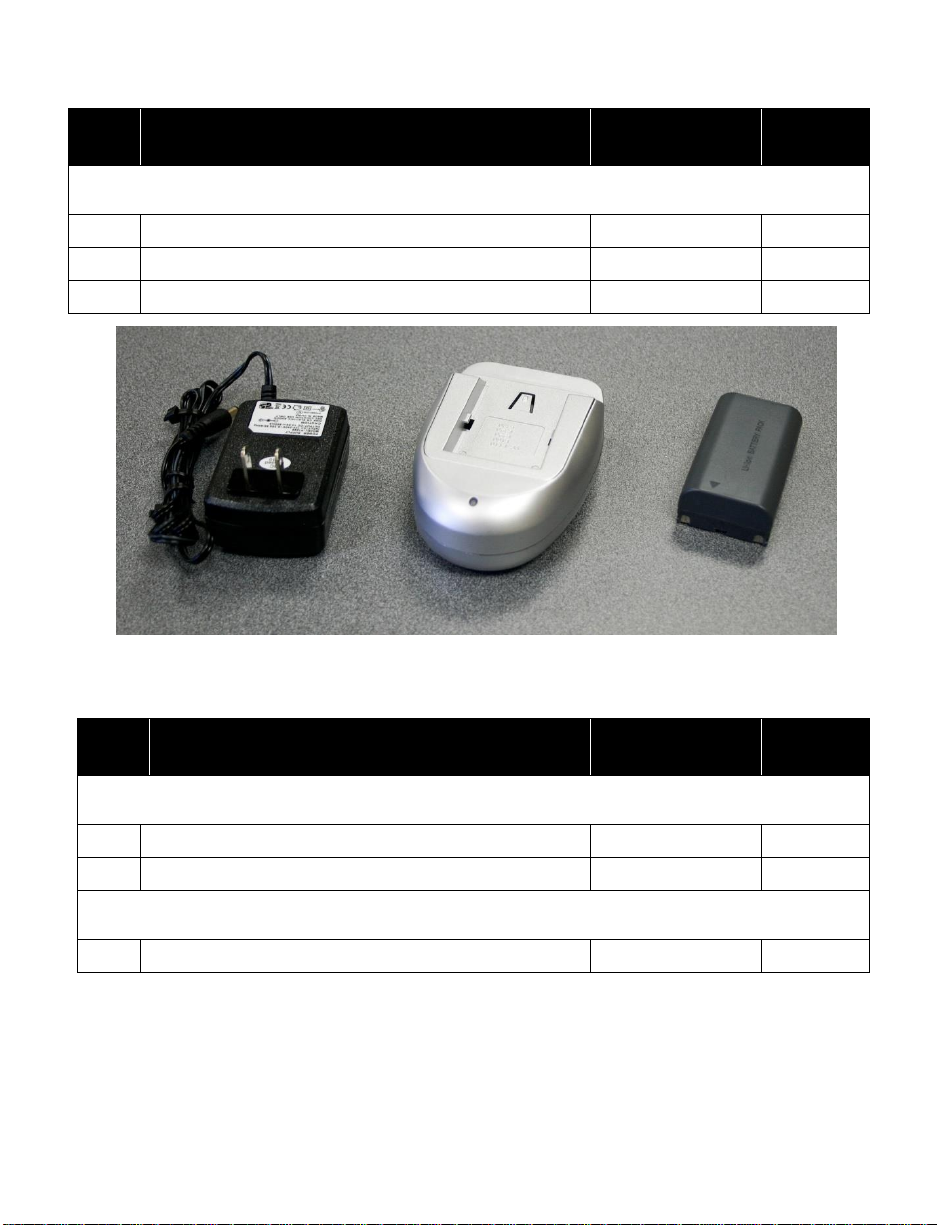

Figure 4. Certifier® FA Test System Extra Battery and Charger Kit (1208061)

Item

No.

Description

Replacement

Part Number

Quantity

Extra Battery and Charger Kit (optional kit – part number 1208061)

28

Battery—Lithium-Ion SBL-160

1208056

1

29

Battery Charger kit

1208059

1

Other accessories (optional)

Printer Cable—USB mini A to standard B

1303860

28

29

1: Introduction 5

Page 16

6

1.2 Glossary

Refer to manual: see Certifier® FA Test System Operator’s Manual for

important information.

CE marking of European Conformity for the Low Voltage Directive (LVD)

and the Directive for Electromagnetic Compatibility (EMCD).

WEEE Directive Label (Waste Electrical and Electronic Equipment). (Item

must be recycled properly.)

Warning symbol. Touch symbol for explanation.

Flow module is working in unidirectional mode. The module is not detecting

a significant amount of negative flows. When testing ventilators,

unidirectional flow is used when the flow module is connected to the To

Patient line

Flow module is in bi-directional flow mode. For ventilators bi-directional flow

is used when the module is between the Y fitting and the test lung.

Battery status symbol. This symbol will indicate how much the battery

charge is left. When no bars are showing instrument will shut off within

minutes.

Battery charging symbol.

>

Start graph or start displaying data on main parameter screen.

||

Pause graph or pause data being displayed on main parameter screen

These labels, terms, and symbols appear on the Certifier® FA Test System:

1.2.1 Symbols on Display

See Available Measurement Parameters in Table 3 for definitions of measurement

symbols and abbreviations that appear on the Certifier FA+ display.

Certifier® FA Plus Test System

Page 17

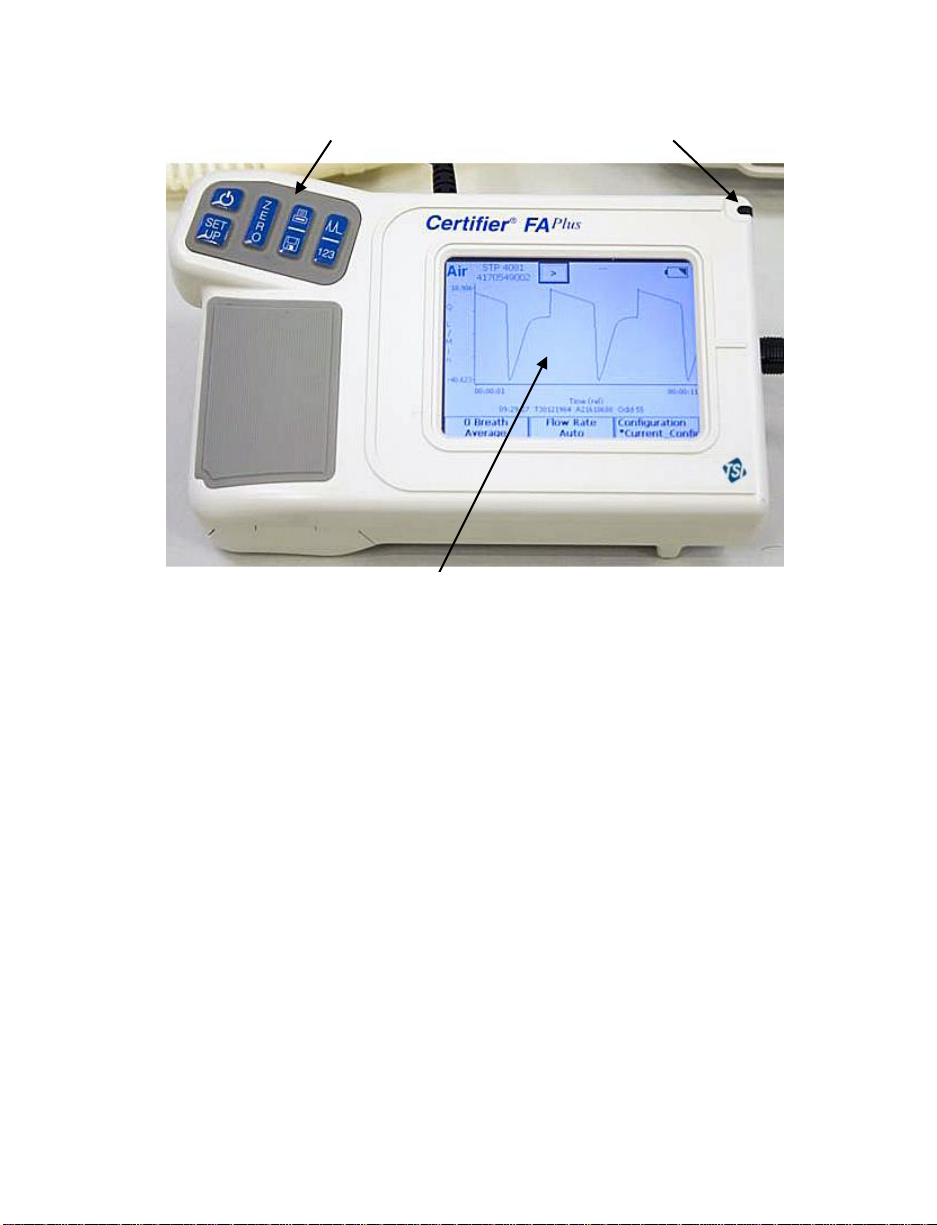

Touch Screen Display

Key Pad

Stylus

Figure 5. Interface Module

1: Introduction 7

Page 18

Certifier® FA Plus Test System

8

Module B Connector

(not used)

Module A Connector

USB Connector

SD Card Slot

DC

Power

Input

Flip Out Stand

Battery Cover

Wrist Strap

Figure 6. Back of Interface Module

Page 19

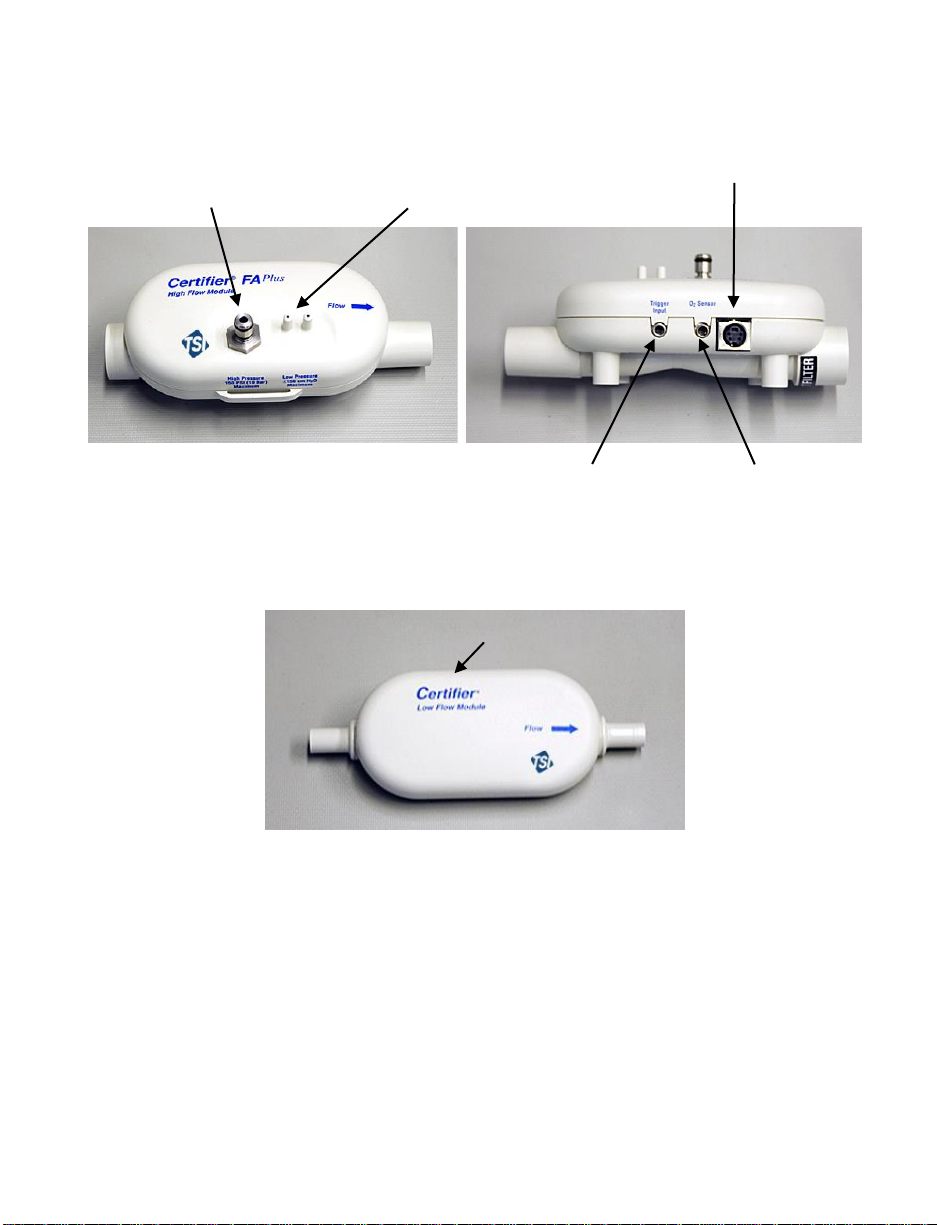

High Pressure

(150 PSIG, 10 bar)

Low Pressure (150 cmH2O

differential)

Use “+” port for airway

pressure.

Coiled Cable Connector

TTL Trigger Input

Oxygen Sensor

Connector

Coiled Cable Connector

Figure 7. High Flow Module

(arrow on module indicates positive flow direction)

Figure 8. Low Flow Module

1: Introduction 9

Page 20

10

Figure 9. Oxygen Sensor Kit

Certifier® FA Plus Test System

Page 21

2 Setup and Operation

Follow these steps to set up the Certifier® FA Test System:

Caution

To avoid damage to the Certifier® FA Test System components, always use bacteria

filters upstream of the flow modules, and always cap flow module ports when not in

use.

1. Install battery if not already installed. Connect AC adapter to DC power source

connector if desired. The battery will charge in the instrument when the AC adapter

is plugged in. Fully charge the battery overnight before using with battery alone.

2. Install SD flash memory card into card slot on top of the interface module. This step

is necessary only if planning to log data.

3. Connect the Interface Module to a flow module (Figure 10). To remove the cable,

pull its locking connector (not the cable) from the Interface Module.

Figure 10. Connecting the Interface Module to a Flow Module

Refer to the manufacturers test procedure for the device under test for

specific instructions on where to connect the Certifier® FA Plus flow module.

The manufacturer of the device under test will also specify which operating

parameters to test.

11

Page 22

4. Install the flow module into the test circuit. Align the flow direction arrow on the flow

module with the positive direction of flow through the circuit; for ventilator testing the

arrow should point towards the test lung or away from the “To Patient” port on the

ventilator.

Figure 11. Installing a Flow Module into the Circuit for Measuring

Bi-directional Flow

(flow direction Arrow should be towards test lung)

12 Certifier® FA Plus Test System

Page 23

Figure 12. Test Circuit for Bi-Directional Flow

Note: If using a test lung with a built in restrictor or a separate restrictor, place the

airway pressure fitting at least 15 cm of the 22 mm tubing between the restrictor

and the flow module. If this is not done, the flow direction sensor may not work

properly.

2: Setup and Operation 13

Page 24

The low flow module is used for testing oxygen concentrators and other low flow

devices. It is not designed for testing ventilators.

The low flow module includes a push-to-fit tube fitting. To install, push tubes into

coupling. To remove fittings, press or pry ring towards the coupling body with a small

screwdriver while pulling coupling away from flow module.

Figure 13. Removing Coupling

14 Certifier® FA Plus Test System

Page 25

Key

Primary Function

On/OFF key

Zeroing Key—Press this key to zero the high and low pressure

transducers.

Print/Save Key—Press this key to print and/or save data. See

Print/Save section (pg. 29) in this manual for more information.

Press this key to switch between the Parameter Screen and Graph

Screen.

Press this key to perform setup on the instrument.

2.1 Keypad Functions

Figure 14. Interface Module Keypad

Table 2. Keypad Functions

2: Setup and Operation 15

Page 26

2.2 Power up

If the device under test is running and creating flow or pressure, temporarily remove the

flow module from the test circuit during power up. This allows the flow direction sensor

on the high flow module to auto calibrate.

Press the I/O (on/off) key on the Interface Module to power up the Certifier® FA Plus

Test System (the Interface Module powers all of the attached Certifier FA Test System

components). At power up, the Interface Module shows information in this sequence

below. After this, return the flow module into the test circuit.

1. Logo screen appears on display for several seconds.

2. One of two types of screens will appear on the display: Graph Screen or

Parameter Screen (see Figures 15 and 16).

3. Wait 1 minute for pressure transducers and flow sensor to warm-up.

4. Perform the pre-test calibrations described in section 2.4.

5. Perform test per the device manufactures procedure (or other appropriate

procedure).

If the AC adapter is plugged into the instrument, the battery charging symbol will

appear on the display.

16 Certifier® FA Plus Test System

Page 27

2.3 Display Navigation

The main two screens are the Parameter Screen and the Graph Screen.

Figure 15. Example of Parameter Screen

Figure 16. Example of Graph Screen

2: Setup and Operation 17

Page 28

By touching on the active areas of the Parameter Screen, you can change the

Stops/Starts

data acquisition

configuration of the display by choosing which parameters to monitor, units of

measure, gas calibration, gas conditions, averaging, and triggering. You can also

save the display configuration to a file or load a previously saved configuration.

18 Certifier® FA Plus Test System

Figure 17. Parameter Screen Features

Page 29

By touching on the active areas of the Graph Screen, you can change the

Stops/Starts

graph

Y-axis setup

Y-axis setup

X-axis setup

configuration of the display by choosing which parameters to plot on the Graph,

units of measure, gas calibration, gas conditions, averaging, triggering, x and y axis

scale. You can also save the display configuration to a file or load a previously

saved configuration.

2: Setup and Operation 19

Figure 18. Graph Screen Features

Page 30

2.3.1 Measurement Selection

Figure 19. Measurement Selection Screen

To add a parameter to the Parameter Screen, touch the parameter and

then touch the right direction arrow. The available parameters change

depending on what module is attached.

To remove a parameter from the Parameter Screen, touch the parameter

and then touch the left direction arrow.

To move a parameter higher on the Parameter Screen, touch the

parameter and then use the up and down direction arrows.

To change the gas calibration used, touch the gas dropdown list and select

the desired gas.

Note: If the gas selection Air/O2 Mixture is selected but no oxygen sensor

is plugged into the Model 4081 high flow module, then the high flow

module will use the internal air calibration only. No corrections for

oxygen concentration will be made if the oxygen sensor is not

plugged into the flow module.

20 Certifier® FA Plus Test System

Page 31

2.3.2 Graph Measurement Selection

Figure 20. Graph Measurement Selection Screen

To add a parameter to Graph, touch the parameter on the left and then

touch the top right direction arrow. Only two parameters can be graphed at

one time. The available parameters change depending on what module is

attached.

To remove a parameter from the graph, touch the parameter and then

touch the top left direction arrow.

To change the gas calibration used, touch the gas dropdown list and select

the desired gas.

To add a parameter to the label section below the graph, touch the

parameter and then touch the bottom right direction arrow. Only four

parameters can be in this section.

To remove a parameter from the Parameter Screen, touch the parameter

and then touch the bottom left direction arrow.

After clicking OK, a prompt will appear to enter the units of measurement.

Note: Up to two parameters may be graphed simultaneously; whereas up

to four parameters may be viewed simultaneously on the Graph

page.

2: Setup and Operation 21

Page 32

Flow Rate. “Q” is used on the

Graph Screen.

High pressure transducer

(4081 only)

Peak Flow Rate—Peak Inhaled

Flow Rate. “Qpeak” is used on

the Graph Screen.

Absolute pressure in flow tube.

If flow tube open to

atmosphere, then this is also

the barometric pressure

Minimum Flow Rate—In BiDirectional Mode this is the

Negative of the Peak Exhaled

Flow Rate. “Qmin” is used on

the Graph Screen.

Oxygen concentration (with

both 4081 and 4073 only)

Inhaled tidal volume

Temperature of gas (accurate

for flows above 5 L/min)

Exhaled tidal volume (4081

only)

Frequency—Breath rate

V

Real-time volume (graphing

only)

Inspiratory time

Inhaled minute tidal volume

Inspiratory pause time (4081

only)

Low pressure transducer—

Airway pressure (4081 only)

Inspiratory time including the

pause time

Peak Inspiratory pressure (4081

only)

Expiratory time

Peak End Expiratory Pressure

(4081 only)

I to E ratio

Mean Airway Pressure (4081

only)

I to E ratio which includes

inspiratory pause time

Minimum low Pressure (4081

only)

Time of day

Delta low pressure—Delta

airway pressure (4081 only)

2.3.3 Available Measurement Parameters

Table 3. Parameters (parameter list changes depending on module attached)

2: Setup and Operation 22

Page 33

I:E = t

E

/ t

I

I:E

IP

= t

E

/ t

I+P

f = 1

/ (t

I+P

+ t

E

)

MV = V

TI

f

2: Setup and Operation 23

Figure 21. Parameter Definitions

Page 34

2.3.4 Gas Conditions Selection Box

STP

Standard Temperature and Pressure. The gas flow rate and volumes

are displayed in terms of what the gas flow rate and volume would be if

the gas was 21°C and 1 atmosphere (101.3 kPa) of pressure.

ATP

Actual Temperature and Pressure. The gas flow rate and volumes at

the actual temperature and pressure of the gas.

BTPS

Body temperature and Pressure Saturated. The gas flow rate and

volumes are displayed in terms of what the gas flow rate and volume

would be if the gas was changed to 37°C, the actual pressure, and also

saturated with water vapor.

BTPD

Body temperature and Pressure Dry The gas flow rate and volumes

are displayed in terms of what the gas flow rate and volume would be if

the gas was changed to 37°C, but maintaining the actual pressure.

STPxx

User defined Standard Conditions. The gas flow rate and volumes are

displayed in terms of what the gas flow rate and volume would be if the

gas was at the conditions entered in the boxes to the right.

Figure 22. Gas Conditions Selection Box

24 Certifier® FA Plus Test System

Page 35

2.3.5 Averaging Setup Menu

Number of Breaths

Averaged

All breath parameters are averaged over the selected

number of breaths.

Second Average for

Real-Time Values

All displayed transducer measurements are averaged over

the selected number of seconds. Transducer

measurements include: flow, low pressure, high pressure,

absolute pressure, oxygen concentration, and temperature.

Figure 23. Averaging Setup Menu

2: Setup and Operation 25

Page 36

2.3.6 Breath Trigger Types

Flow Rate

Start and end of the breath is determined by the specified

flow rate. If Auto-Triggering is selected, instrument tries to

determine trigger levels. In some cases you may need to

manually select the flow rates by looking at the flow

waveform on the Graph Screen.

Pressure

Start and end of the breath is determined by the specified

pressure levels. Positive slope changed through the first

value is used for the start of inspiratory and a negative

slope through the second value is used for the start of

expiratory. Note: This trigger type is intended to give

advance users additional setup options for special

circumstances, such as achieving basic breath

measurements from high frequency ventilators or other

setups in which flow rate or auto triggering are non-ideal.

TTL

Start and end of the breath is determined by a TTL voltage

signal given at the connector on the High Flow Module

labeled “Trigger Input”. This is only available for the 4081

High Flow Module. The connector is a 3.5 mm mono audio

jack plug.

This screen defines how the start of the inspiratory breath cycle and the expiratory

breath cycle are detected. Under most circumstances, it is recommended that the autotrigger be used.

Figure 24. Trigger Options Menu

26 Certifier® FA Plus Test System

Page 37

2.3.7 Flow Triggering

If auto-triggering is not providing reasonable results, consider using either manual flow

or manual pressure triggering. To use manual flow triggering, select the flow radio

button and uncheck the "Auto-Triggering" checkbox. Similarly, to use manual pressure

triggering, select the pressure radio button. For a breath to be detected, trigger settings

must be set appropriately for the waveform of interest. There are two suggested

methods for determining the appropriate start and end trigger values: 1) switch the

Certifier FA Plus Test System to the graphing screen and observe the flow or pressure

readings at the start and the end of inspiration and 2) observe the flow and pressure

wave form from the ventilator being tested. For robust flow and pressure triggering

always set the "End Trigger" level lower than the "Start Trigger". For example, a manual

flow trigger setting may be +5 L/min for a start trigger and -5 L/min for an end trigger

setting. These numbers can be optimized based upon your specific application.

2: Setup and Operation 27

Page 38

2.3.8 Saving/Loading Configurations

Configuration is saved

under current name and

location

Configuration of the values displayed, gas, conditions, triggering, and graph setup can

be saved and recalled. This allows the user to save configurations for different

equipment.

See section 2.3.10.1 to learn how to transfer configuration files from one instrument to

another using the SD memory card.

28 Certifier® FA Plus Test System

Figure 25. Configuration Save Screen

Page 39

2.3.9 Print/Save Button

Figure 26. Print/Save Options Screen

If the Print/Save button is pressed while viewing the Parameter Screen, the "Print/Save

Options" screen will appear. By selecting the various options on this screen you will be

able to:

Print the current data record without saving to a file.

Print the current data record and also save it to a file in a single operation.

Save the current data record to a file without printing.

Select Waveform logging function. This feature saves 15 seconds of "raw"

flowmeter data at a rate of 1 millisecond/reading to a file (requires an SD Flash

memory card).

Select Continuous logging function. This mode logs the Parameter Screen data

into a file at intervals of approximately 1 second until you command the logging to

stop (requires an SD Flash memory card).

When printing or saving, you can add custom comments to your data by selecting the

Add Comments option. When that option is selected, an on-screen keyboard appears,

allowing you to enter your comment text.

2: Setup and Operation 29

Page 40

Figure 27. Add Comments Screen

If the Print/Save button is pressed while viewing the Graph Screen, you will be able to

Save the currently displayed Graph data to a file to either the built-in Internal Memory or

to an SD Flash card inserted into the SD Card slot. You cannot print the Graph or the

Graph data and you cannot print or save a screen shot of the graph.

To retrieve data from the Certifier test system, simply connect the device to a PC using

an USB standard A to mini-B cable. Use the Setup function “Select Mass Storage

Target” (see section 2.3.10 “Setup Key”) to choose whether the host PC will access the

Certifier test system’s built-in memory, or an SD Flash card inserted in the card slot of

the Certifier test system.

All data files exported from Certifier test system use the ASCII character set and

"comma separated value" (CSV) format. This is a format that most spreadsheet and

database applications can import. See Advanced Features Menu for selecting file

delimeters other than commas.

2.3.9.1 Waveform Logging

The Waveform Logging feature logs 15 seconds of raw flowmeter data into a file on a

SD Flash card. The logging rate is about once per millisecond. The data is exported into

“comma separated value” (CSV) format, readable by many common spreadsheet and

database applications. See Advanced Features Menu for selecting file delimeters other

than commas.

The Waveform logging feature requires an SD Flash card.

30 Certifier® FA Plus Test System

Page 41

To initiate Waveform logging:

Press the Print/Save button on the Certifier test system keypad.

Select Waveform from the Logging Features section.

You may choose to Add Comments if you would like to annotate the data.

Click OK, add comments (if selected) and name the file.

The Certifier test system will collect 15 seconds of flowmeter waveform data and

then save it into the file.

Access the data by connecting the Certifier test system to a host computer via USB, or

by removing the SD Flash card from the Certifier test system and inserting it into a card

reader attached to a host computer.

2.3.9.2 Continuous Logging

The Continuous Logging feature will log snapshots of the same data being displayed on

the Certifier Parameter Screen and log it into a file on an SD Flash card. The logging

rate is once per second. Only data displayed on the Certifier Parameter Screen will be

logged. See section 2.3 on how to add or remove parameters. The data is exported into

“comma separated value” (CSV) format, readable by many common spreadsheet and

database applications. See Advanced Features Menu for selecting file delimeters other

than commas.

The Continuous logging feature requires an SD Flash card.

To initiate Continuous logging:

Press the Print/Save button on the Certifier test system keypad.

Select Continuous from the Logging Features section.

You may choose to Add Comments if you would like to annotate the data.

Click OK, add comments (if selected) and name the file.

The Certifier test system will continue to log data until the Print/Save button is

pressed again or until the SD Flash card fills up.

Access the data by connecting the Certifier test system to a host computer via USB, or

by removing the SD Flash card from the Certifier test system and inserting it into a card

reader attached to a host computer.

Note: If the pause button was pressed prior to continuous logging, a slight delay may

be noticed in the start of the data acquisition.

2: Setup and Operation 31

Page 42

2.3.10 Setup Key

Oxygen Sensor Calibration

See required pre-test section of this manual.

Set Time/Date

Sets the current time and date.

Touch Screen Calibration

Calibrates the touch screen of the interface module. Follow the instructions

on the display.

Lock Touch Screen

Disables the touch screen once the Setup Menu is closed. To enable the

touch screen, press the Setup button.

Lock Configuration

Disables the saving of configurations. The user will be able to load existing

configurations and change the current configuration, but not save it.

Advanced Features

See section 2.3.10.1 for a complete list of advanced features which can be

accessed through this menu.

About Device

Displays information about the Certifier Interface Module and any connected

flow module.

Figure 28. Setup Menu

32 Certifier® FA Plus Test System

Page 43

Select Mass Storage Target

When the Certifier test system is connected to a host computer via USB

interface, it appears to the host as a "mass storage" device, similar to a

"memory stick" or “thumb drive”. This function allows you to select whether

the host can access the Certifier's Internal Memory or an SD Flash memory

card. The Certifier test system supports SD flash cards up to 1 GB in size.

Restart the Certifier whenever a change if made when selecting between

internal flash RAM and SD flash card.

2.3.10.1 Advanced Features

Figure 29. Advanced Function Menu

2.3.10.1.1 Configuration Import/Export

This feature enables you to both download and upload configuration files to and from

the SD card. This is convenient when multiple Certifier FA+ units are in use where the

configuration files from one unit can be transferred to multiple Certifier units. This

eliminates the need to generate configuration files for each instrument.

This feature requires an SD card to be inserted in the instrument. If it is desired to view

the configuration file on a PC, be sure the Select Mass Storage Device setting is

configured to SD card as mentioned in section 2.3.10.

Press Export button to export the configuration file to the SD card.

Press Import to import the configurations from the SD card.

2: Setup and Operation 33

Page 44

Notes about exporting configuration files:

All data is saved to a single file called CertifierConfigurations.dat. If this file already

exists on the SD card, it will be overwritten each time the Export command is

executed.

It is not possible to generate a user-selectable filename for the exported

configurations.

Notes about importing configuration files:

Importing a configuration which already exists under the same name in the Certifier

memory will cause the configuration in memory to be overwritten.

Importing a configuration file will not erase existing configuration files which already

exist in memory but under a different configuration name.

This feature is not designed for creating configuration files on a PC. The feature is

primarily designed to transfer configuration files from one instrument to another.

2.3.10.1.2 Format Settings

Figure 30. Format Settings Screen

Different formats of the date can be selected from this menu. This information is used in

the file save mode as part of the filename and also stored internally within the file.

Different data delimeters used in the file save function can be selected through this

menu. This allows for greater flexibility for importing data in different regions of the

world.

34 Certifier® FA Plus Test System

Page 45

Caution

To ensure accurate measurements, wait one minute for the Certifier® FA Test

System to warm up. If environmental conditions have changed significantly, more

time may be necessary.

To avoid damage to the Certifier® FA Test System components, always use

bacteria filters upstream of the flow modules, and always cap flow module ports

when not in use.

If liquid has penetrated any of its components, do not use, and return to the factory

for calibration.

2.4 Required Pre-test Calibrations

2.4.1 Low Flow Module

2.4.1.1 None required

2.4.2 High Flow Module

2.4.2.1 Zeroing the Flow Direction Sensor

The model 4081, High Flow Module, has a sensor that is used to detect the direction of

flow. This sensor will normally auto-zero if there is no flow for a fraction of a second. If it

is unable to do this at power-up or at least every 10 minutes, a appears on the

screen. Touch the symbol on the display for an explanation of the warning. To manually

zero the direction sensor, remove the High Flow Module from the flow source and cover

one end of the flow tube for a couple of seconds.

2.4.2.2 Low-Pressure and High-Pressure Transducer Zeroing

Check the Low-pressure transducer zero and a High pressure transducer zero by

disconnecting the pressure tubing from the flow module before each pressure

measurement after initial power up to ensure the most accurate readings. If the low or

high pressure is not reading zero, perform the following steps to zero the transducers.

1. Disconnect the pressure tubing from the low and high pressure ports.

2. Press the key.

3. “Pressure Transducers Zeroing” appears on the display for one second. If the

transducers do not see a steady pressure or near zero pressure, an error appears.

NOTE: The barometric pressure transducer does not require a zero calibration.

2: Setup and Operation 35

Page 46

2.4.2.3 Oxygen Sensor Calibration

Follow these steps daily and following an altitude change or sensor replacement to

calibrate the oxygen sensor:

1. Power up the Certifier® FA Test System with the High Flow Module and oxygen

sensor attached, allow one minute to warm up.

2. Press the key and select the “Oxygen Calibration” box on the display. Follow

the directions on the screen. Note that either an “air only” or an “air and 100%

oxygen” calibration can be done. The two point air/100% oxygen calibrations

provide the best accuracy.

Note: The numeric value displayed during the stabilization process does not

necessarily represent the actual oxygen concentration. This numeric

stabilization value is there for you to determine if it is changing or not. Once

the reading stops changing then it is time to advance to the next step in the

oxygen sensor calibration process.

36 Certifier® FA Plus Test System

Page 47

Symptom

Possible Cause

Corrective Action

Interface Module won’t

turn on, or turns on

and off.

Batteries are depleted or

not installed.

Connect AC adapter or install

charged batteries.

Measurements are not

displayed even though

Interface Module is

turned on.

Flow module is not

connected to Interface

Module.

Connect flow module to Interface

Module. If connected, disconnect

and then reconnect.

Measurements are not

changing or graph is

not updating.

Pause button was

pressed.

Press the Play button at the

top of the screen.

“OOR” is shown on

display.

Measurement is out of

range.

Check range for displayed

measurement, and only make

measurements within that range.

Flow rate does not

read zero when no gas

flowing (Especially

when set to N2O or

CO2).

Meter was not purged

with gas displayed on the

Interface Module.

Purge meter with gas displayed

on Interface Module or press gas

select key to change to desired

gas.

Unable to disconnect

flow module from

Interface Module.

Pulling on the cable

rather than the connector.

Pull the locking connector (not

the cable) to disengage

connector lock.

3 Troubleshooting

Table 4 lists the symptoms, possible causes, and recommended corrective actions for

problems you may encounter with the Certifier® FA Test System. If the symptom is not

listed, or if none of the recommended corrective actions solve the problem, please visit

our website at http://service.tsi.com or contact TSI Customer Support at (800) 874-2811

or 651-490-2811.

Table 4. Troubleshooting the Certifier® FA Test System

37

Page 48

Symptom

Possible Cause

Corrective Action

Volume, minute

volume, peak flow,

peak pressure, PEEP,

respiratory rate, or I:E

ratio measurement are

not updated or

incorrect.

Less than two

consecutive full breaths

have been supplied to

flow module, or flow is not

supplied as a breathing

waveform.

Auto-trigger not optimized

for current waveform.

Airway restrictor causing

flow disturbance next to

flow module.

Flow condition causing

oscillations in the

waveform.

Wait for at least two consecutive

full breaths to be supplied to the

flow module.

Ensure that flow is supplied as a

breathing waveform.

Manually set flow trigger level.

Use the TSI Airway pressure

fitting which contains the screen

between the flow module and

the test lung (see Figure 12).

Minimize length of tubing

between the test lung and the

airway pressure fitting.

I:E ratio or I time

readings do not

appear correct.

It is possible the

inspiratory pause function

is turned on inside the

ventilator.

Select the I time parameter T

I+P

and ratio parameter I:EIP to be

on the display when the

inspiratory pause feature is

activated on the ventilator. See

section 2.3.3 for a description of

the difference between TI and

T

I+p

.

Another option is to turn off the

inspiratory pause feature on the

ventilator.

Can’t zero lowpressure or high

pressure transducer.

Transducer is connected

to a pressure source.

Disconnect pressure tubing from

flow module and then zero lowpressure transducer.

Can’t zero barometric

pressure transducer.

Barometric pressure

transducer does not

require a zero calibration.

Resume normal system

operation.

38 Certifier® FA Plus Test System

Page 49

Symptom

Possible Cause

Corrective Action

Oxygen sensor

calibration fails.

21% oxygen and/or 100%

oxygen not supplied for

calibration.

Oxygen sensor is

expired.

Non-steady flow or tidal

flows used.

Verify that calibration gases are

21% oxygen and 100% oxygen

and repeat calibration.

Replace oxygen sensor.

Use constant flow rates to

supply calibration gas.

Pressure trigger gives

erroneous results.

Pressure signal supplied

to high-flow module not

correct.

Change source of pressure

signal.

Pressure trigger optimized for

use with high-frequency

ventilators.

Host computer not

able to view internal

memory or SD flash

memory.

Certifier test system was

not restarted after

selecting mass storage

target location.

Turn Certifier off and then on

again.

3: Troubleshooting 39

Page 50

(This page intentionally left blank)

40 Certifier® FA Plus Test System

Page 51

Component

Cleaning

Interface Module

Flow modules

Carrying cases

Oxygen sensor

Oxygen sensor cables

Clean exterior as required with a clean cloth and

isopropyl alcohol, hydrogen peroxide (3%), or ammonia

(15%).

Tee

Adapters

Steam autoclave after contact with any non-sterile

breathing circuit components, and discard if any

damage is visible.

Single use filters (High

and Low Flow

Modules)

Discard after contact with any non-sterile breathing

circuit components or if damage is visible.

4 Maintenance

4.1 Recharging the Batteries (as required)

The batteries can be charged internally by connecting the AC adapter or they can be

charged externally with the optional battery charger. The fastest charging method is to

charge the battery in the instrument with the instrument turned off. The Certifier FA Plus

uses SBL-160, Lithium Ion Batteries, which are available from many battery supply

houses or TSI. Charging time is approximately 4 to 6 hours.

4.2 Replacing the Oxygen Sensor

The oxygen sensor will function for one or more years of normal operation if use begins

before the expiration date. Replace the oxygen sensor every year or two of normal use,

or if the sensor cannot be calibrated or sensor readings are erratic.

4.3 Cleaning (as required)

Table 5 summarizes recommended cleaning methods for Certifier® FA Test System

components.

Table 5. Cleaning Recommendations

41

Page 52

4.4 Factory Calibration (recommended yearly)

Certifier® FA Test System flow modules are designed for one year of normal use

following each factory calibration.

If the test system has been dropped or liquid has penetrated any of its components, do

not use, and return to the factory for calibration.

Recalibrated flow modules come with a certificate of calibration and a summary of

performance before and after the calibration. A factory calibration consists of pressure

transducer calibration over the full range of pressures and calibration over the full range

of flows. All calibration datum are stored in the flow modules, so the Interface Module

does not require calibration. Therefore, it is not necessary to return the Interface

Module for factory calibration.

Follow the steps in Section 4.5 to return Certifier® FA Test System flow modules for

factory calibration.

4.5 Return Procedure

Follow these steps to return Certifier® FA Test System flow modules for factory

calibration:

1. Obtain a Return Material Authorization (RMA) number using our online RMA form at

rma.tsi.com or contact one of the following offices to make service arrangements.

2. Package the flow modules carefully to avoid damage during shipping.

NOTE: It is not necessary to return the Interface Module for factory calibration.

U.S. & International United Kingdom

TSI Incorporated TSI Instruments Ltd.

500 Cardigan Road Tel: (44) 1494 459200

Shoreview MN 55126-3996 Fax: (44) 1494 459700

USA E-mail: tsiuk@tsi.com

Tel: (800) 874-2811 / Website: www.tsiinc.co.uk

+1(651) 490-2811

Fax: +1(651) 490-3824 Germany

E-mail: technical.service@tsi.com TSI GmbH

Website: www.tsi.com Tel: +49 241-52303-0

Fax: +49 241-52303-49

E-mail: tsigmbh@tsi.com

Website: www.tsiinc.de

42 Certifier® FA Plus Test System

Page 53

Dimensions

Interface module: 17.3 cm 10.5 cm 4.5 cm (6.8 in. 4.1 in.

1.8 in.)

High Flow Module: 15 cm 6.7 cm 6.1 cm (5.9 in. 2.7 in. 1.4 in.).

Low Flow Module: 12.7 cm 5.1 cm 2.8 cm (5.0 in. 2.0 in.

1.1 in.).

Flow

connectors

High Flow Module:

Flow inlet: 22-mm female ISO taper.

Flow outlet: 22-mm male ISO taper.

Low Flow Module:

Flow inlet: 3/8-in.

Flow outlet: 3/8-in.

Weight

Approximately 0.7 kg (1.5 lb), interface with high flow module and

cable.

Temperature

Operating: 5 to 40C (41 to 104F). 15 to 80% relative humidity from 5

to 31C decreasing linearly to 15 to 50% relative humidity at 40C.

Storage: -40 to 70C (-40 to 158F) at 10 to 90% relative humidity,

non-condensing

Atmospheric

Pressure

Operating: 57.1 to 106 kPa (8.28 to 15.37 psia).

Storage: 15000 meters

Conditions

Indoor Use

Operating Altitude up to 4000 m (13,000 ft)

Pollution degree I or II

Battery Life

3 to 6 hours typical

Battery Type

Lithium-Ion SBL160

AC Adapter

12 VDC 1A Minimum

5 Specifications

NOTE: Specifications are subject to change without notice.

5.1 Physical

5.2 Environmental

5.3 Power

43

Page 54

5.4 Data Transfer and Storage

Internal Memory

1 MB (500 typical records)

External Memory

SD Flash Card. Supports up to 1 GB cards.

Measurement

High Flow Module

Low Flow Module

Flows

Range

-200 to +300.0 SLPM air,

oxygen, and nitrogen

-40 to +40 SLPM carbon

dioxide

0 to 300 air/oxygen mixture

0.01 to 20.00 SLPM air, oxygen,

nitrogen, carbon dioxide, and

nitrous oxide

Accuracy

Air and oxygen: ±2% of reading

or ±0.075 standard L/min,

whichever is greater

Nitrogen and carbon dioxide:

±3% of reading or ±0.075

standard L/min, whichever is

greater

Air/Oxygen mixture: ±4% of

reading or ±0.100 standard

L/min, whichever is greater

Air and oxygen: ±2% of reading or

±0.010 standard L/min, whichever is

greater

Nitrogen and carbon dioxide: ±3%

of reading or ±0.010 standard

L/min, whichever is greater

Nitrous oxide: ±4% of reading or

±0.025 standard L/min, whichever is

greater

Volumes

Range

0.01 to 10 L STP

0 to 10 L STP

Accuracy

Air and oxygen: 2% of reading

plus 0.020 L

Air/oxygen mixtures: 4% of

reading plus 0.020 L STP

Air and oxygen: 2% of reading or

0.010 L, whichever is greater

Nitrous oxide: 4% of reading or

0.010 L STP, whichever is greater

5.5 Test Measurements (See notes at end of section. See Table 3 for symbol definitions.)

44 Certifier® FA Plus Test System

Page 55

Measurement

High Flow Module

Low Flow Module

Volumes

Range

0.01 to 10 L STP

Not applicable

Accuracy

Air and oxygen: 3% of reading

plus 0.030 L

Air/oxygen mixtures: 4% of

reading plus 0.040 L STP

Not applicable

Minute Volume

Range

0.01 to 100 L STP

0 to 10 L STP

Accuracy

3% of reading

3% of reading

Times

Range

0.04 to 30 seconds

0.04 to 30 seconds

Accuracy

2% of reading or 0.01

seconds, whichever is greater

2% of reading or 0.01 seconds,

whichever is greater

I:E Ratios

Range

1:100.0 to 100.0:1

1:100.0 to 100.0:1

Accuracy

4% of reading typical

4% of reading typical

Respiratory Rate

Range

1 to 1500 breaths per minute

1 to 1500 breaths per minute

Accuracy

2% of reading or 0.1 BPM,

whichever is greater

2% of reading or 0.1 BPM,

whichever is greater

Low Pressures

Range

-25.0 to 150.0 cmH2O.

(-18.4 to 110 mmHg)

Not applicable

Accuracy

0.5% of reading or

0.15 cmH2O (0.15 mmHg),

whichever is greater

Not applicable

5: Specifications 45

Page 56

46 Certifier® FA Plus Test System

Measurement

High Flow Module

Low Flow Module

High Pressure

Range

-10 to 150.0PSIG (-0.7 to 10

bar)

Not applicable

Accuracy

1% of reading or 0.1 PSI

(7 mbar), whichever is

greater.

Not applicable

Absolute Pressure

Range

375 to 1200 mmHg (500 to

1600 mbar)

375 to 1500 mmHg (500 to

2000 mbar)

Accuracy

8 mmHg (11 m bar)

8 mmHg (11 mbar)

Oxygen Concentration

Range

21 to 100%

Not applicable

Accuracy

2% concentration

Not applicable.

Temperature

Range

5 to 40°C

5 to 40°C

Accuracy

1°C When flow rates are

above 2 L/min

1°C When flow rates are above

2 L/min

Page 57

Measurement

High Flow Module

Low Flow Module

NOTES

1. Standard conditions are defined as 21.1C (70F) and 101.3 kPa (14.7 psia).

2. Flow and volume accuracy is applicable at these standard conditions (see note 1).

3. For the High Flow Module the temperature of the gas and the ambient air must be

within 10C (18F) of each other and the gas must be less than 30% relative

humidity at 21.1C (70F).

For the Low Flow Module the temperature of the gas and the ambient air must be

within 5C (9F) of each other and the gas must be less than 30% relative

humidity at 21.1C (70F).

4. Flow and volume accuracy de-rating: 0.075% of reading per 1C (1.8F) away

from 21.1C (70F); 0.015% of reading per 1.03 kPa (0.15 psia) above 101.3 kPa

(14.7 psia); 0.022% of reading per 1.03 kPa (0.15 psia) below 101.3 kPa (14.7

psia); 0.07% of reading per 1% relative humidity above 30% relative humidity.

The Low Flow Module has an additional flow rate accuracy de-rating of 0.0003

standard L/min per 1C (1.8F) and 1 kPa away from 21.1C (70F) and 101.3kPa.

5.6 Calibration Recommendations

Flow

Modules

Start with factory calibration every year for use under normal

conditions using the filter(s) provided.

Interface

Module

No calibration required.

Oxygen

Sensor

Check Daily, calibrate as needed.

Complies

with these

standards:

EN 55011 (1991) Class B, CISPR 11 (1990) Class B, FCC (CFR

47, Part 15) Class B: Emissions, Radiated and Conducted.

EMC Directive 89/336/ECC, EN 61326-1 (1997 plus Amendment

A1 1998), IEC 1000-4-2 (1995), EN 61000-4-2, IEC 1000-4-3

(1995), EN 61000-4-3: Immunity.

5.7 Compliance and Approvals

5: Specifications 47

Page 58

(This page intentionally left blank)

48 Certifier® FA Plus Test System

Page 59

Appendix A Data File Formats

Parameter Screen Single Sample and Continuous Logging Data

Format

Raw Text Example:

Filename:,\NV1FLASH\EXAMPLE.csv

Comments:,Custom comments here

Configuration:,*Current Configuration

Module A Model:,4081

Module A SN:,40810705010

Trigger Type:,Flow Rate

Start Trigger:,Auto

End Trigger:,Auto

Module A Conditions:,STP

Module A Gas:,AIR

Data Section:,,Module A,Module A,Module A

,,Flow Rate,Low Pressure,PEEP Pressure

Date,Time,L/Min,cmH2O,cmH2O

27/12/2007,12:03:20,0.00,-0.256,0.000

49

Page 60

As Formatted By spreadsheet application:

Filename:

\NV1FLASH\EXAMPLE.csv

Comments:

Custom comments here

Configuration:

*Current Configuration

Module A

Model:

4081

Module A SN:

40810705010

Trigger Type:

Flow Rate

Start Trigger:

Auto

End Trigger:

Auto

Module A

Conditions:

STP

Module A Gas:

AIR Data Section:

Module A

Module A

Module A

Flow Rate

Low

Pressure

PEEP

Pressure

Date

Time

L/Min

cmH2O

cmH2O

27/12/2007

12:03:20

-19.2

-0.256

0

Notes:

When Continuous logging is used, each additional reading is given on a separate,

appended text line.

Parameter value columns are formatted in the same order that they have been

configured on the display screen.

Parameter Screen Waveform Logging Data Format

Waveform Logging collects a 15-second snapshot of “raw” data from the connected

flow module. An example of the data collected in waveform logging is shown below.

50 Certifier® FA Plus Test System

Page 61

Raw Text Example (waveform logging):

Appendix A Data File Formats 51

Page 62

Graph Screen Data Format

The Graph Display data is formatted as 2 (1 parameter on Graph) or 3 (2 parameters

on Graph) columns of text. The first column is the X axis (relative time), the second and

third columns will contain the Graph data.

X Q L/Min P cmH2O

Total graph time: 10 seconds.

0 -0.421556 0.673527

0.041 -0.197457 0.678888

0.082 -0.095008 0.693449

0.123 -0.043302 0.699908

0.1639 -0.027286 0.712823

0.2049 -0.027088 0.723274

0.2459 -0.022927 0.730932

0.2869 -0.019958 0.736425

0.3279 -0.019294 0.738421

0.3689 -0.022878 0.740417

0.4098 -0.024059 0.744878

0.4508 -0.030267 0.744917

0.4918 -0.034957 0.747344

0.5328 -0.040919 0.74523

0.5738 -0.046022 0.740886

0.6148 -0.04976 0.749106

0.6557 -0.049111 0.743039

0.6967 -0.049844 0.742413

[up to 244 data points]

52 Certifier® FA Plus Test System

Page 63

USA Tel: +1 800 874 2811

UK Tel: +44 149 4 459200

France Tel: +33 1 41 19 21 99

Germany Tel: +49 241 523030

India Tel: +91 80 67877200

China Tel: +86 10 8219 7688

Singapore Tel: +65 6595 6388

TSI Incorporated – Visit our website www.tsi.com for more information.

P/N 1980560 Rev J Copyright © 2016 by TSI Incorporated Printed in U.S.A.

*1980560*

Loading...

Loading...