Combustion Analysis

Series 6200

TM

CA-CALC

Combustion Analyzers

Operation and Service Manual

1980431 Rev. F

January 2004

Series CA-6200

CA-CALC

TM

Combustion Analyzers

Operation and Service

Manual

January 2004

P/N 1980431 Rev. F

U.S. AND CANADA OTHER COUNTRIES

Sales & Customer Service:

(800) 874-2811/(651) 490-2811 (001 651) 490-2811

Fax:

Fax:

(651) 490-3824 (001 651) 490-3824

MAIL/SHIP TO: E-Mail

TSI Incorporated answers@tsi.com

ATTN: Customer Service

500 Cardigan Road WEB SITE

Shoreview, MN 55126 www.tsi.com

USA

Sales & Customer Service:

Copyright ©

TSI Incorporated / 2001–2004 / All rights reserved.

Part Number

1980431 / Revision 5

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA

Fax No.

(651) 490-3824

LIMITATION OF WARRANTY AND LIABILITY (effective July 2000)

Seller warrants the goods sold hereunder, under normal use and service as described in the operator's manual, shall

be free from defects in workmanship and material for twenty-four (24) months, or the length of time specified in the

operator's manual, from the date of shipment to the customer. This warranty period is inclusive of any statutory

warranty. This limited warranty is subject to the following exclusions:

a. Batteries are warranted for 90 days from the date of shipment to the customer. Electrochemical gas sensors are

warranted for a period of twelve (12) months from the date of shipment to the customer.

b. Parts repaired or replaced as a result of repair services are warranted to be free from defects in workmanship and

material, under normal use, for 90 days from the date of shipment.

c. Seller does not provide any warranty on finished goods manufactured by others or on any fuses, batteries or

other consumable materials. Only the original manufacturer's warranty applies.

d. Unless specifically authorized in a separate writing by Seller, Seller makes no warranty with respect to, and shall

have no liability in connection with, goods which are incorporated into other products or equipment, or which

are modified by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated herein. NO OTHER

EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR PARTICULAR PURPOSE OR

MERCHANTABILITY IS MADE.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR BUYER, AND

THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES, INJURIES, OR DAMAGES

CONCERNING THE GOODS (INCLUDING CLAIMS BASED ON CONTRACT, NEGLIGENCE, TORT,

STRICT LIABILITY OR OTHERWISE) SHALL BE THE RETURN OF GOODS TO SELLER AND THE

REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR

REPLACEMENT OF THE GOODS. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE RESPONSIBLE FOR

INSTALLATION, DISMANTLING OR REINSTALLATION COSTS OR CHARGES. No Action, regardless of

form, may be brought against Seller more than 12 months after a cause of action has accrued. The goods returned

under warranty to Seller's factory shall be at Buyer's risk of loss, and will be returned, if at all, at Seller's risk of

loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND LIABILITY, which

contains the complete and exclusive limited warranty of Seller. This LIMITATION OF WARRANTY AND

LIABILITY may not be amended, modified or its terms waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are to our customers, our service

policy is designed to give prompt attention to any problems. If any malfunction is discovered, please contact your

nearest sales office or representative, or call TSI's Customer Service department at (800) 874-2811.

ii

CONTENTS

Introduction ..............................................................................................................................................vii

Manual Purpose .................................................................................................................................. vii

Using This Manual...............................................................................................................................vii

Warnings and Cautions.......................................................................................................................vii

Chapter 1. Instrument Description...........................................................................................................1

Gas Sampling Probes............................................................................................................................1

Chapter 2. Unpacking................................................................................................................................3

List of Standard Components................................................................................................................3

Optional Accessories.............................................................................................................................3

Chapter 3. Component Identification.......................................................................................................5

The Gas Sensors...................................................................................................................................6

Optional Combustion Supply Air Thermocouple Probe.........................................................................7

On-Board Temperature Measurement..................................................................................................7

Diaphragm Pump...................................................................................................................................7

Draft Sensor...........................................................................................................................................7

Water Trap.............................................................................................................................................7

Stack Probe Thermocouple...................................................................................................................7

Emission Probe (Supplied with Models CA-6213 and CA-6215 ).........................................................7

CO Diversion Valve...............................................................................................................................8

Mounting Magnets.................................................................................................................................8

Schematic Representation of CA-CALC.................................................................................................8

Chapter 4. Getting Started ........................................................................................................................9

Supplying Power....................................................................................................................................9

Installing Batteries...........................................................................................................................9

Connecting the AC Adapter............................................................................................................9

Connecting the Sampling Probe............................................................................................................9

Setting CO Diversion Valve................................................................................................................ 10

Connecting the Optional Combustion Supply Air Temperature Probe............................................... 10

Connecting the Optional Portable Printer........................................................................................... 10

Connecting to a Computer.................................................................................................................. 10

Default Instrument Settings................................................................................................................ 11

Factory Defaults (U.S.)....................................................................................................................... 11

Factory Defaults (Non-U.S.)............................................................................................................... 11

Default Settings For Different Model Letter Designations ........................................................... 12

Chapter 5. Basic Operation.................................................................................................................... 13

Quick Start.......................................................................................................................................... 13

Steps to Quick Startup................................................................................................................. 13

Baseline Calibration........................................................................................................... ..........13

The Data Display Screen.................................................................................................................... 14

Available Measurements.................................................................................................................... 15

Buttons and Button Operations .......................................................................................................... 16

ON-OFF Control Button (red)....................................................................................................... 16

The ENTER Control Button.......................................................................................................... 16

The ESC Control Button .............................................................................................................. 16

Arrow Control Buttons.................................................................................................................. 16

Icon Buttons................................................................................................................................. 17

Labeled Buttons........................................................................................................................... 17

Selecting Menu Items .................................................................................................................. 18

Changing a Number Value................................................................................................................. 18

Changing Units................................................................................................................................... 19

Entering and Changing Names.......................................................................................................... 19

iii

Using the Sampling Probe.................................................................................................................. 19

Gas and Temperature Measurements......................................................................................... 19

Making a Draft Measurement............................................................................................................. 21

Auto Draft Meas. Feature............................................................................................................. 21

Printing to the Portable Printer and to a Computer............................................................................ 21

Printing.........................................................................................................................................21

Printing to a Computer.................................................................................................................21

Chapter 6. MENU Selections and Menu Items ..................................................................................... 23

Zoom Settings..................................................................................................................................... 24

Instrument Setup................................................................................................................................ 24

Calibrate Sensors............................................................................................................................... 27

Restore Factory Cal............................................................................................................................ 28

Set Contrast........................................................................................................................................ 28

Set Time and Date.............................................................................................................................. 28

Select Fuel Type................................................................................................................................. 28

Fuel Setup .......................................................................................................................................... 29

Fuel Setup When Siegert Loss Calculation Used.............................................................................. 30

Restore Fuel Settings......................................................................................................................... 30

Erase Logged Data............................................................................................................................. 31

Chapter 7. Saving Data and LOGGING FUNCTIONS........................................................................... 33

Overview............................................................................................................................................. 33

Saving Data When no Site or Device is Selected .............................................................................. 34

Saving Data to Selected Site or Device ............................................................................................. 34

LOGGING FUNCTIONS .................................................................................................................... 36

Sites ............................................................................................................................................. 36

Devices ........................................................................................................................................ 37

Samples....................................................................................................................................... 38

Chapter 8. Calibrations........................................................................................................................... 39

Gas Sensors....................................................................................................................................... 39

The Calibration Setups....................................................................................................................... 40

Calibrating the O2 Sensor................................................................................................................... 40

Calibration Steps.......................................................................................................................... 40

Calibration of the CO (Hydrogen Compensated) Sensor................................................................... 40

Calibration Steps.......................................................................................................................... 40

Calibration of NO, NO2, SO2 and COhi (High Concentration) Sensors.............................................. 41

Calibration Steps.......................................................................................................................... 41

Draft Sensor Calibration..................................................................................................................... 41

Calibration Procedure.................................................................................................................. 41

Stack and Supply Air Thermocouple Calibration................................................................................ 42

Calibration Procedure.................................................................................................................. 42

Chapter 9. Maintenance and Troubleshooting..................................................................................... 43

Emptying Water Trap.......................................................................................................................... 43

Changing the Water Trap Filter................................................................................................. .........44

Cleaning the Sample Probe................................................................................................................ 44

High Concentration Overload.............................................................................................................44

Adding or Replacing a Gas Sensor.................................................................................................... 44

Gas sensors are warranted for one year, however sensors (O2 excluded) typically last two or three years.44

Sensor Positions.......................................................................................................................... 44

Replacing a Sensor...................................................................................................................... 45

Adding a New Sensor......................................................................................................................... 47

Troubleshooting Chart........................................................................................................................ 48

iv Series CA-6200 CA-CALC Combustion Analyzer

Appendix A. Calculations....................................................................................................................... 49

O2 Reference Concentration Calculation ........................................................................................... 49

Excess Air Calculation........................................................................................................................ 49

Calculating Combustion Efficiency..................................................................................................... 49

Determining CO2 Using the O2 Concentration ................................................................................... 50

Emission Rate Calculations Using Emission Factors......................................................................... 50

A General Equation for the Combustion of a Simple Hydrocarbon in Air .......................................... 51

Calculating CO2 Max From the Carbon Content................................................................................ 51

Calculation of Combustion Air............................................................................................................ 51

Appendix B. Series CA-6200 CA-CALC Combustion Analyzers Detailed Specifications................. 53

TÜV Reg. No. 213 *

* Instruments supplied with the Model 801940, 41 Sampling Probe have been approved for

measurements of O

probe do not meet the temperature response requirement.

.

, temperature, CO and NO. Instruments supplied with the Model 80151,52 Emission

2

Contents v

Introduction

Manual Purpose

This manual describes the operation and maintenance of TSI Series CA-6200 CA-CALCTM portable combustion

analyzers (Models 6210, 6211, 6212, 6213, 6214, 6215 and 6216).

Using This Manual

Before using the CA-CALC combustion analyzer for the first time, review this manual in its entirety.

The manual assumes that you have a basic understanding of combustion analysis and are thoroughly familiar with

your fuel burning equipment. When performing equipment adjustments, rely on good judgment and experience

along with the measured data. This is especially important where safety issues are of concern. Equipment

adjustments must always coincide with the fuel burning equipment manufacturer’s recommendations.

Warnings and Cautions

WARNING

High temperatures and toxic gases are produced when fossil fuels are burned. Only

!

Note: Best results are obtained if the CA-C

temperature of the test environment before using.

!

qualified individuals, thoroughly familiar with operating and adjusting fuel-burning

equipment, should use combustion analysis instrumentation for the purpose of

making equipment adjustments.

Always use the water trap when sampling. Check the trap frequently during operation

to prevent overfilling with condensed water. Empty often.

This device is not intended for use as a continuous monitor or as a safety indicator.

ALC combustion analyzer is allowed to stabilize at the

Caution

WARNING

!

Note: To reduce sensor exposure to gas and to reduce build up of water vapor in the sampling lines

and water trap, turn the pump off when not making measurements.

vii

Chapter 1. Instrument Description

The CA-CALCTM combustion analyzer is a portable instrument measuring combustion gases, combustion gas and

supply air temperatures and draft pressure for evaluating the performance of burners in boilers, furnaces, and hot

water tanks. From the measured data, the CA-C

parameters including excess air, CO

level, and combustion efficiency. When fitted with NO, NO2, and SO2 gas

2

sensors, emission rates and NOX are calculated. Combustion data is presented on a large display screen, making it

possible to display multiple parameters simultaneously. This data can be saved or printed with the p ress of a button.

The basic CA-C

ALC analyzer Model 6210 comes standard with two electrochemical gas sensors for stack gas

measurements, one sensor for measuring oxygen (O

the model ordered, your CA-C

ALC may have one or two additional electrochemical gas sensors. The table below

shows the available models and sensor combinations. It is also possible to add additional gas sensors later to

upgrade your CA-C

ALC combustion analyzer.

Model Gas Sensors

CA-6210 O2, CO

CA-6211 O2, CO, NO

CA-6212 O2, CO, CO(high concentration)

CA-6213 O2, CO, NO, SO2

CA-6214 O2, CO, NO, CO(high concentration)

CA-6215 O2, CO, NO, NO2

CA-6216 O2, CO, SO2 , NO2

ALC combustion analyzer calculates a variety of combustion

), and one for measuring carbon monoxide (CO). Depending on

2

Gas Sampling Probes

One of two basic gas sampling probe types is provided with the CA-CALC, depending on the model chosen. For

instruments measuring O

sampling tube, and has an exposed thermocouple tip for fast-response temperature measurements. For instruments

supplied with NO

2

tube to limit loss of the reactive gases. The Emission Probe also has a sintered metal filter on the probe tip to reduce

soot buildup in the sample line.

, CO, and NO, the standard Sampling Probe is provided. This probe has an unlined

2

or SO2 gas sensors, the Emission Probe is supplied. This probe has a non-reactive “lined” sample

1

Chapter 2. Unpacking

Carefully unpack the CA-CALCTM combustion analyzer and accessories from the carrying case. Check the individual

parts against the list of components in the table below. If items are missing or damaged, notify TSI immediately.

List of Standard Components

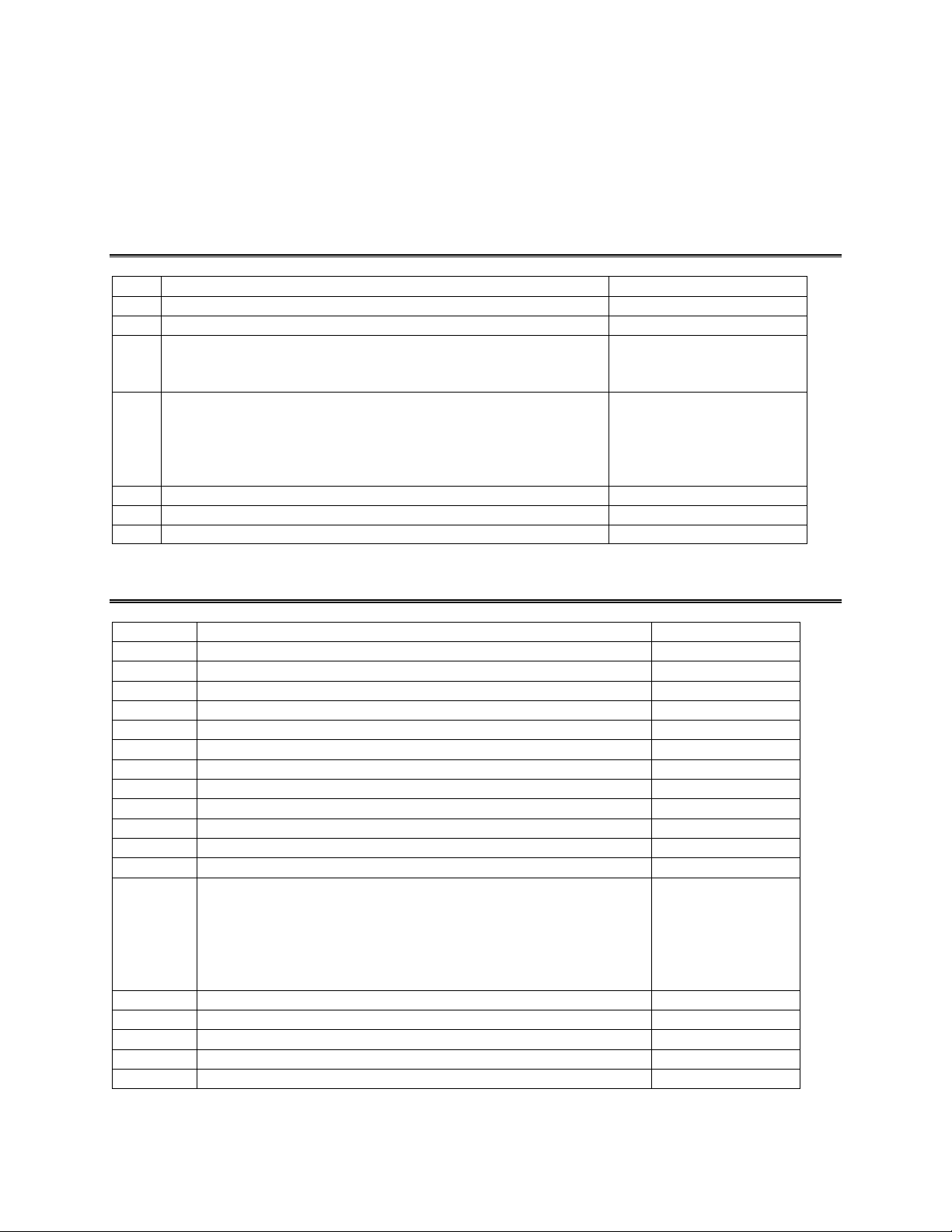

Qty. Item Part/Model

1 Series CA-6200 CA-CALC combustion analyzer CA-62XX (XX = 10-16)

1 Carrying case 1319319

1 Standard probe 12” with water trap or 801940

Emission probe 12” with water trap or 801951

Other probe and hose lengths available (24” probe, 25’ hose) Consult factory

1 Power supply 7.2V

120V or

230V European, or

230V Great Britain, or

240V Australian

1 Calibration certification

4 C cell alkaline batteries

1 Operation and Service manual 1980431

2613033

2613078

800169

2613106

Optional Accessories

Item Part/Model

Combustion supply air thermocouple, Type K 3013003

Portable printer 801994

Carrying strap tether 2913011

Computer cable 8940

NO sensor 802266

NO

sensor 802267

2

CO sensor (high concentration) 802265

O

replacement sensor 802263

2

CO (hydrogen compensated) replacement sensor 802264

SO

sensor 802268

2

Water trap filters 801947

Replacement kit, emission probe filter 801944

Gas Calibration kits (U.S. only)

CO (hydrogen compensated)

NO

NO

2

SO

2

O

zero calibration kit (N2)

2

801923

801937

801938

801936

801939

Probe adapter kit 801970

Probe heat shield 801969

Replacement filter kit 801944

Water trap replacement 802215

Lithium battery 1208028

3

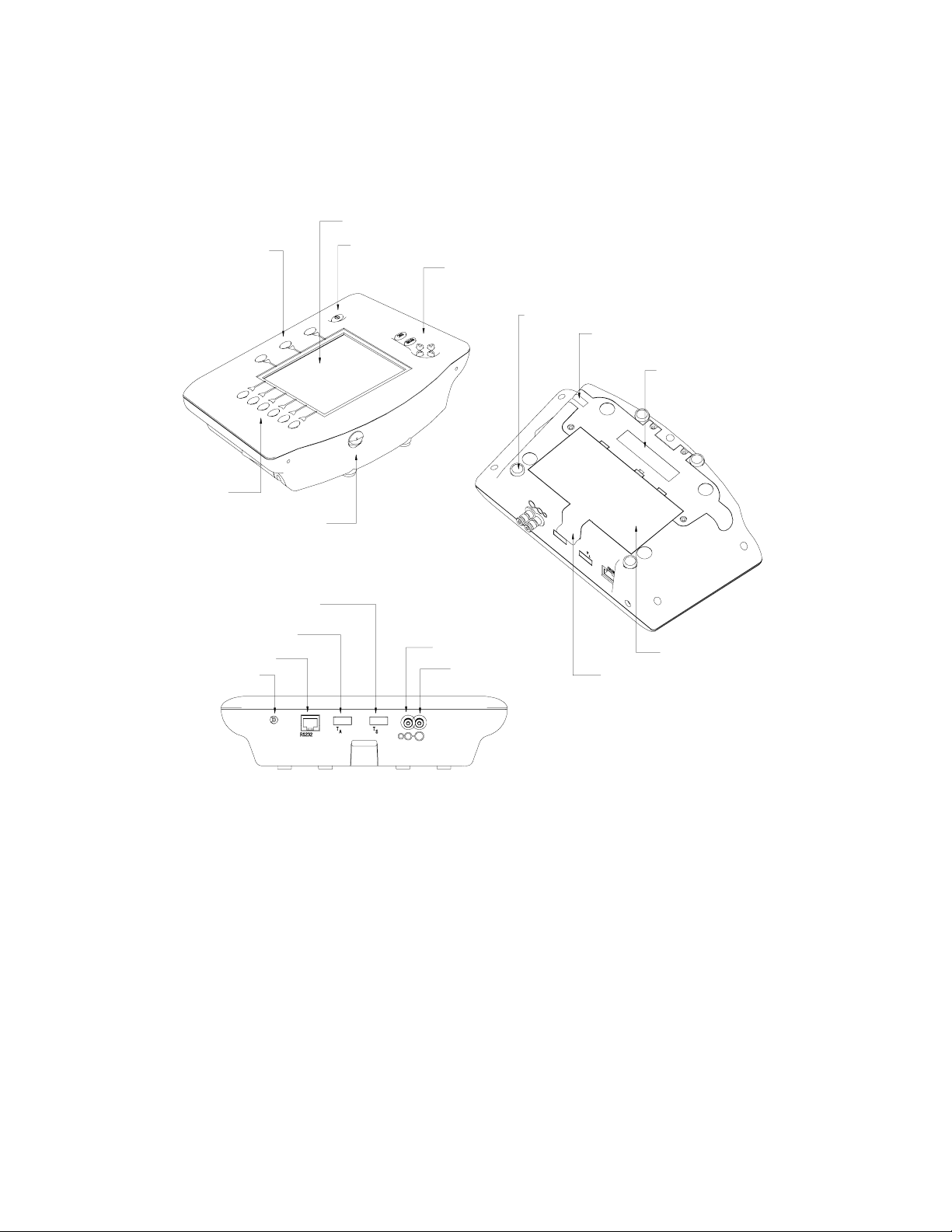

Chapter 3. Component Identification

Key components of the CA-CALCTM combustion analyzer and sampling probe are identified in Figures 1 and 2 and

under section headings in the text that follows.

2

1

5

3

4

7

8

9

6

12

13

14

15

1. Label buttons 10. Battery cover

2. LCD display 11. Battery cover tab

3. On-Off button 12. Port for stack gas thermocouple probe

4. Control buttons 13. Port for combustion supply air thermocouple, type K

5. Icon buttons 14. RS232 serial port

6. CO diversion valve 15. Power connection

7. Magnets 16. Draft sample port

8. Vent 17. Gas sample port

9. Sensor cover

Figure 1: CA-C

16

17

ALC Combustion Analyzer Components

11

10

5

1

9

2

3

4

10

5

7

8

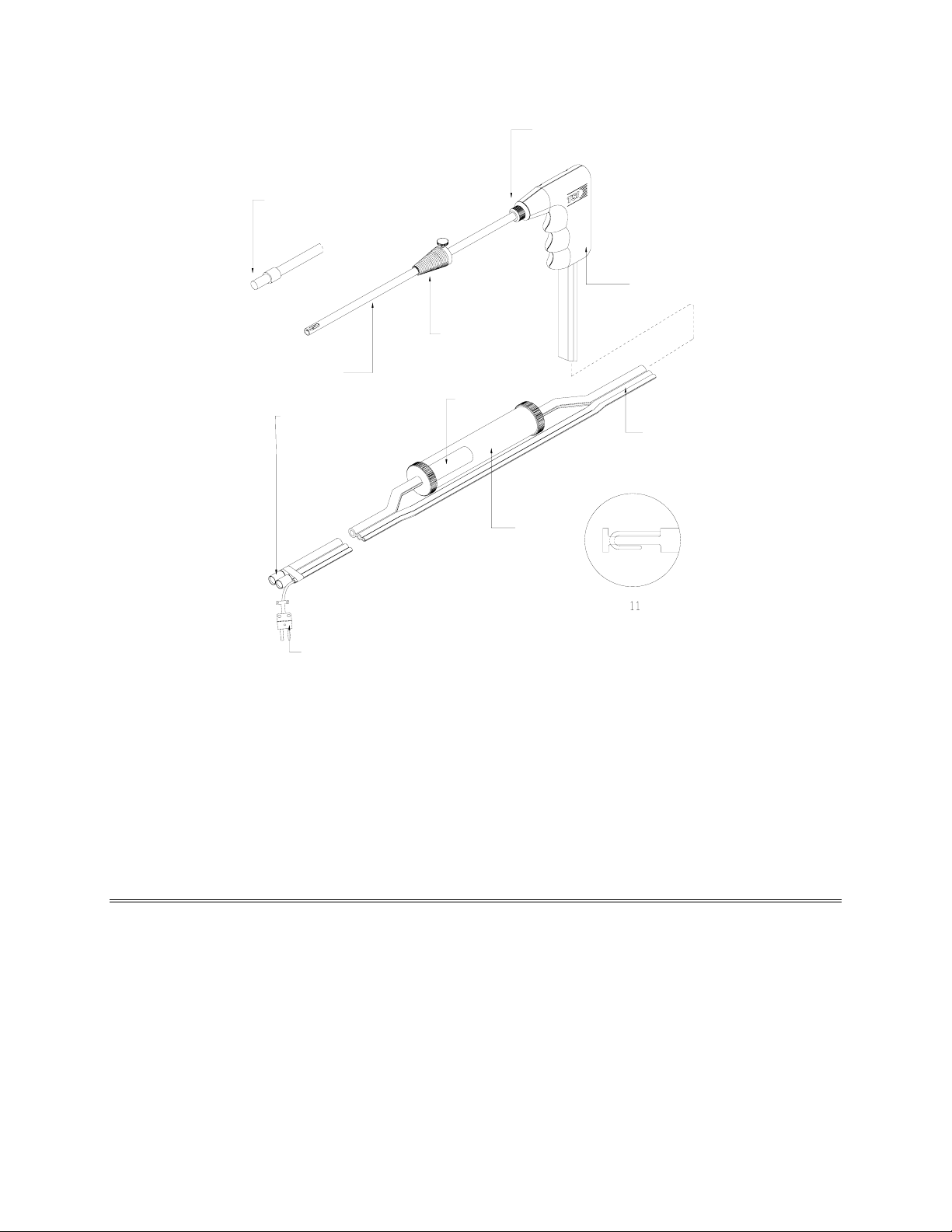

6

1. Sample tube retaining fitting 7. Tri-plex tubing

2. Probe handle 8. Water trap

3. Position collar 9. Emission Probe for NO2, SO2, with SS filter

4. SS sampling tube 10. Plastic filter

5. Sample and Draft connectors 11. Detail of standard probe tip

6. Thermocouple connector

Figure 2: CA-C

ALC Sampling Probe Components

The Gas Sensors

The CA-CALC analyzer holds up to four electrochemical gas sensors. Oxygen (O2) and hydrogen compensated

carbon monoxide [CO(H

Two of the following sensors can also be added: nitric oxide (NO), nitrogen dioxide (NO

and high concentration carbon monoxide (COhi). The gas sensors are found under the sensor cover identified in

Figure 1 above.

)] sensors are standard, included with all Series CA-6200 CA-CALC combustion analyzers.

2

), sulfur dioxide (SO2)

2

6 Series CA-6200 CA-CALC Combustion Analyzer

Optional Combustion Supply Air Thermocouple Probe

A measurement of the Combustion Supply air temperature is made using an optional thermocouple accessory probe

(TSI PN 3013003). This probe is connected to the supply air temperature port.

Combustion supply air temperature is an important value used in the determination of flue losses and efficiency.

On-Board Temperature Measurement

The CA-CALC analyzer uses an on-board resistance temperature detector (RTD) to provide the combustion supply

air temperature when no supply-air accessory probe is present.

Diaphragm Pump

The CA-CALC analyzer samples exhaust gases from the flue and delivers them to the electrochemical sensors using

a long-life diaphragm sampling pump.

Draft Sensor

A differential pressure transducer in the CA-CALC analyzer is used to measure draft pressure. The transducer has a

measurement range of ±30” of H

O (7.47 kPa).

2

Water Trap

The water trap shown in Figure 2 is used to remove moisture that collects in the sample tubing when combustion

gases are sampled. Water must be prevented from entering the instrument through the sample port. The water trap

uses two chambers and a hydrophobic coalescing filter to maximize water removal.

Stack Probe Thermocouple

The type K thermocouple probe extends through the SS sampling tube to its tip, where stack temperatures are

measured. The thermocouple probe measures temperatures up to 1800 degrees F.

The yellow thermocouple connector plugs into the stack thermocouple port (see Figure 1).

Emission Probe (Supplied with Models CA-6213 and CA-6215 )

An “Emission” gas sample probe (Model 801951) is required when NO2 and SO2 gases are measured. This gas

sampling probe has an internal liner (TFE), which does not absorb NO

a sintered stainless steel filter at the probe tip to reduce soot buildup in the sampling lines. Soot, combined with

moisture from condensation, readily absorbs NO

Emission probe slows the response of the temperature sensor.

Note: When making temperature measurements, maintain the position of the probe in the flue until the

temperature reading has stabilized. For faster temperature measurement, when determining combustion

efficiency, a Model 801940 Sampling Probe is recommended.

and SO2. Note that the sintered metal filter on the tip of the

2

and SO2 gases. The Emission Probe also has

2

Chapter 3. Component Identification 7

CO Diversion Valve

The CO diversion valve is used to divert high concentrations of carbon monoxide (>5000 ppm) away from the

hydrogen compensated CO sensor. High CO concentrations cause the sensor baseline value to shift upward.

Although the effect is temporary, it may take ten minutes or longer for the sensor to recover. A shift upward in the

sensor baseline means the CO sensor indicates a concentration that is higher than the true concentration.

Mounting Magnets

The CA-CALC combustion analyzer can be adhered to a flat metal surface using the magnets on the case bottom.

This orients the instrument for convenient viewing and button operation. When mounted in this way it is advisable

to use the optional strap/tether (see optional accessories) as a safety harness in case the instrument is pulled away

from the metal surface. Metal surface must not be hot.

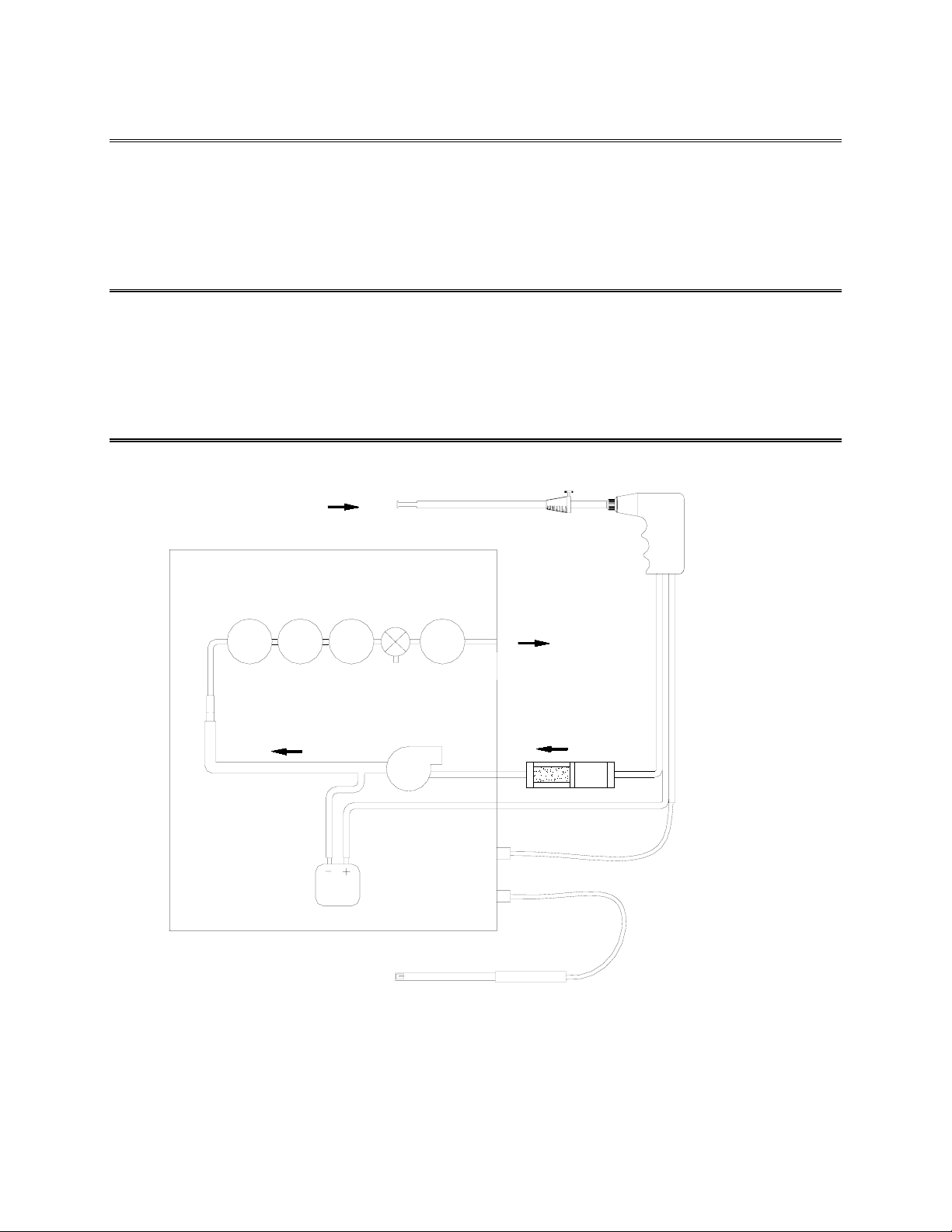

Schematic Representation of CA-CALC

Sampling Probe

Gas Sensors [S1 & S2; NO, NO

COhigh (optional))

O2

Orifice

Probe for Combustion

Air Temperature

(optional)

S1

Draft

Sensor

S2

CO Diversion

Valve

Pump

, SO2,

2

CO

Exhaust

Water Trap

Flue Gas

Temperature

Thermocouple

8 Series CA-6200 CA-CALC Combustion Analyzer

Chapter 4. Getting Started

Supplying Power

The CA-CALC

Quality alkaline batteries enable the instrument to operate for 24 hours. Use of the plug-in AC adapter conserves

battery life and can be substituted for batteries.

TM

portable combustion analyzer operates using 4 C-cell batteries or using the AC adapter provided.

Installing Batteries

Turn the combustion analyzer over and remove the battery cover by lifting up and

out on the battery cover tab shown to the right. Remove the old batteries.

Note: It is not necessary to remove the battery holder when removing or

installing batteries. Best results are obtained if the batteries opposite

the contact springs are removed first.

Install four new C-cell batteries, noting the battery orientation depicted on the base of the battery holder. Install

spring-side batteries first.

Connecting the AC Adapter

Find the supplied 7.2-volt AC Adapter included with the instrument. Connect the corresponding connector plugs to

the AC wall source and instrument power connection located on case bottom (see Figure 2). When using the power

supply, the batteries are bypassed.

Note: The CA-C

ALC analyzer does not charge rechargeable batteries.

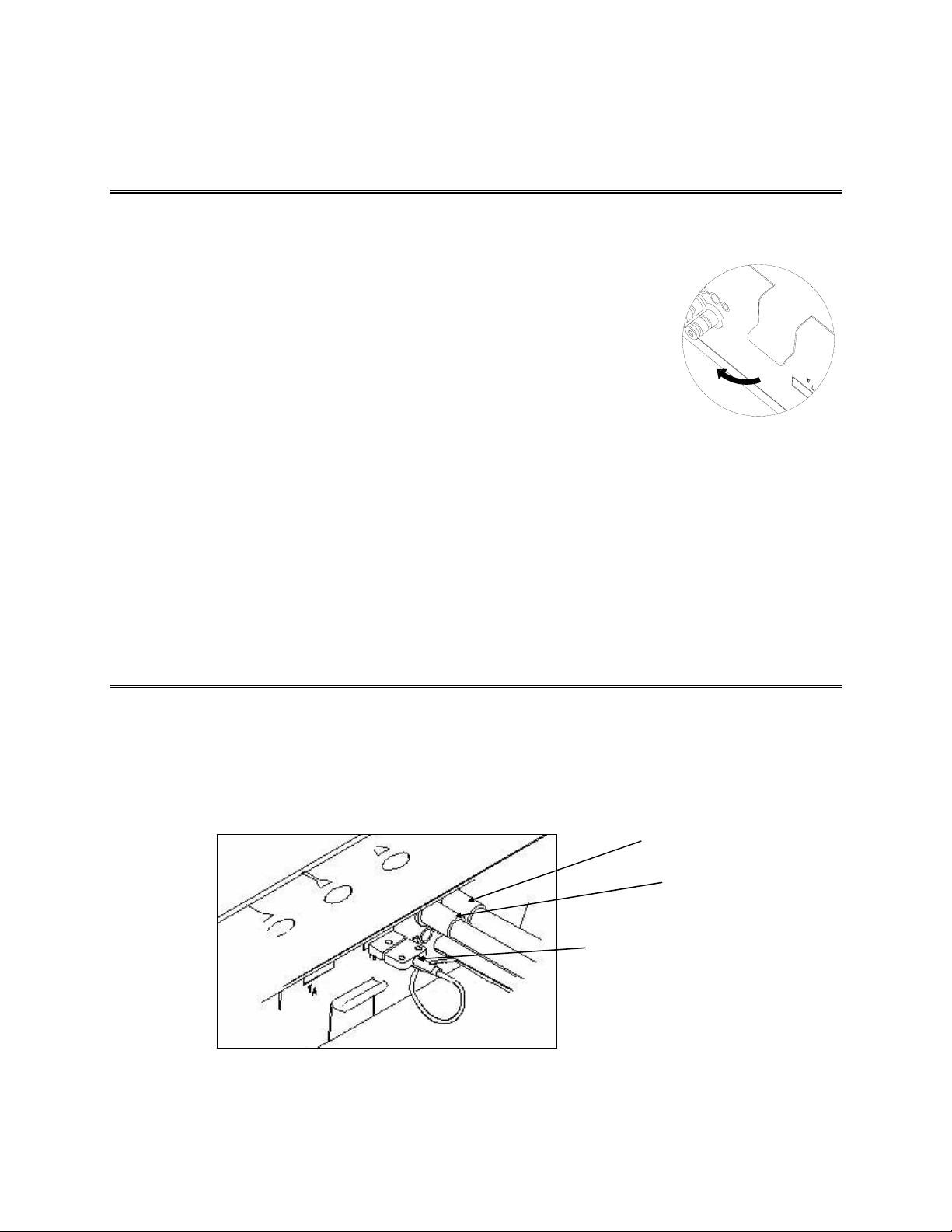

Connecting the Sampling Probe

The sampling probe depicted in Figure 2 is connected to the instrument by pushing the sample and draft connectors

over the bulkhead ports on the instrument. Refer to Figure 3 below showing the probe connection. Make sure the

connectors are pushed fully over the bulkhead ports. Finish the connection by plugging the yellow thermocouple

connector into the Stack temperature thermocouple port. The thermocouple plugs in only one way. Don’t force the

connector.

Thermocouple Connector

Figure 3: Sampling Probe Connection

Sample Connector

Draft Connector

9

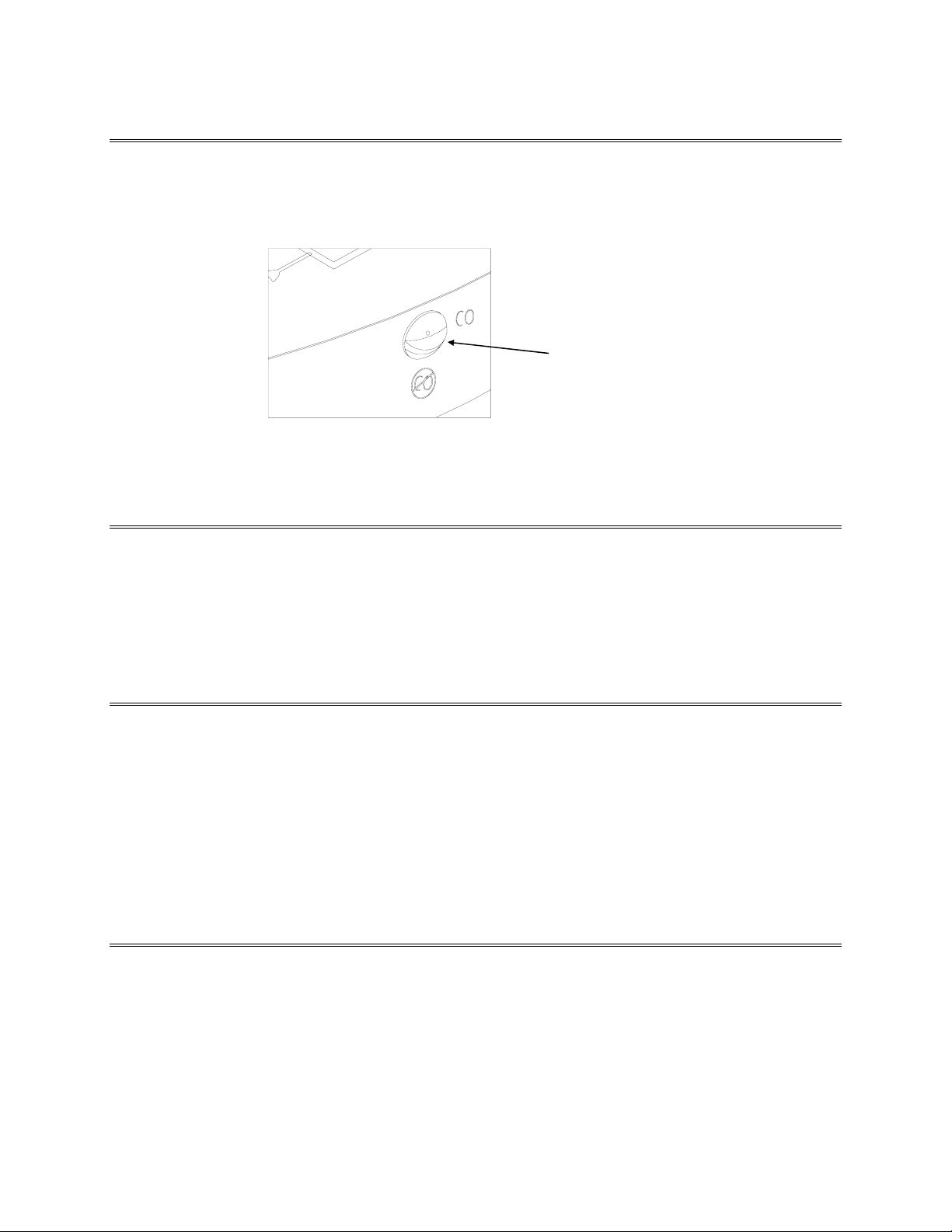

Setting CO Diversion Valve

Set the CO diversion in the orientation shown in the figure below. In this position, the valve is open, allowing gas to

flow to the CO sensor. Only under conditions where the CO level is very high (above 5000 ppm), should the valve

be closed. To close the valve, turn it 90 degrees counterclockwise.

Figure 4: Normal CO Diversion Valve Orientation

Normal Orientation for the

CO Diversion Valve

Connecting the Optional Combustion Supply Air Temperature Probe

An optional type K thermocouple probe (TSI PN 3013003) is used to measure the temperature of the air supplied to

the burner; the Combustion Supply air. When a probe is not used, the supply air temperature is measured using the

on-board resistance temperature detector (RTD). Connect the optional supply air thermocouple (see “Optional

Accessories”) to the supply air thermocouple port depicted in Figure 1. The thermocouple plugs in only one way.

Do not force the connector.

Connecting the Optional Portable Printer

Find the printer interface cable included with the Model 8925 portable printer. Connect the large 9-pin connector on

the cable to mating connector on the printer. Connect the opposite end to the instrument’s RS232 communications

and printer port. See Figure 1 for port location.

The printer and CA-C

different, the printer will print random characters, question marks or asterisks. Printer settings are described in the

printer manual, along with illustrations identifying the correct DIP-switch configuration. You will also need to set

the RS232 Device setting to Printer. To set the CA-C

“MENU Selections and Menu Items.”

ALC combustion analyzer have both been factory set for a baud rate of 1200. If baud rates are

ALC baud rate and device settings, refer to Chapter 6,

Connecting to a Computer

Use the optional computer interface cable, Model 8940, to transfer (download) data serially from the CA-CALC

analyzer to a computer. Connect the large 9-pin connector on the computer interface cable to the 9-pin serial

connector on your computer. Connect the opposite end to the instrument’s RS232 communications and printer port.

See Figure 1 for port location.

10 Series CA-6200 CA-CALC Combustion Analyzer

You will need to do two things before you can successfully communicate with a computer. First make sure the baud

rate of the CA-C

ALC analyzer matches that of the computer. Second, make sure the RS232 Device setting is set to

Computer and not Printer. To set the Device, refer to “Instrument Setup” in Chapter 6, “MENU Selections and

Menu Items.”

Default Instrument Settings

The CA-CALC combustion analyzer uses a number of standard settings for presenting the data, performing

calculations, and controlling instrument operation. These include the units displayed, the fuel used, the baud rate

and so on. When shipped, these have factory pre-set Default settings. The default settings are listed below. Default

settings can be changed as described in Chapter 6, “MENU Selections and Menu Items.”

Factory Defaults (U.S.)

Gas Concentrations

Temperature

Fuel*

O2REF

O2

Draft:

Excess Air:

Effc./Loss

Fuel Heat

Auto Draft Meas.

Baud Rate

RS232 Device

CO Shutoff level

NO Shutoff level

PPM (parts per million), applicable for CO, NO, NO

Degrees F

Natural Gas

OFF (do not incorporate O

reference in calculation of gas concentration)

2

Reference level: 3% (not used if OFF selected above)

Inches H

O

2

%EA

Net Efficiency

High heating value used in calculations, units are BTU

OFF

1200

Printer, configured for output to printer rather than to computer

2000 ppm. Turns the pump off if the CO level exceeds this set level

1000 ppm. Turns the pump off if the NO level exceeds this set level

, SO2 sensors

2

*Defaults extend to include factory set fuel parameter values for eight fuels. These fuels are; natural gas, propane,

#2 fuel oil, #6 fuel oil, coal, wood, baggasse, coke.

Factory Defaults (Non-U.S.)

Instruments sold outside the U.S. are often set up with default units and settings different than those identified in th e

table above. The defaults installed depend upon the letter designation present in the instrument’s Model number.

For example a -D in Model number CA-6210–D indicates that Germany is the destination country and has

appropriate units and settings installed. Other letter designations have the following meanings: -EU European,

-M metric units, -UK United Kingdom, -AU Australia. The following table shows defaults relating to the instrument

designations. Remember it is always possible to change the default settings.

Chapter 4. Getting Started 11

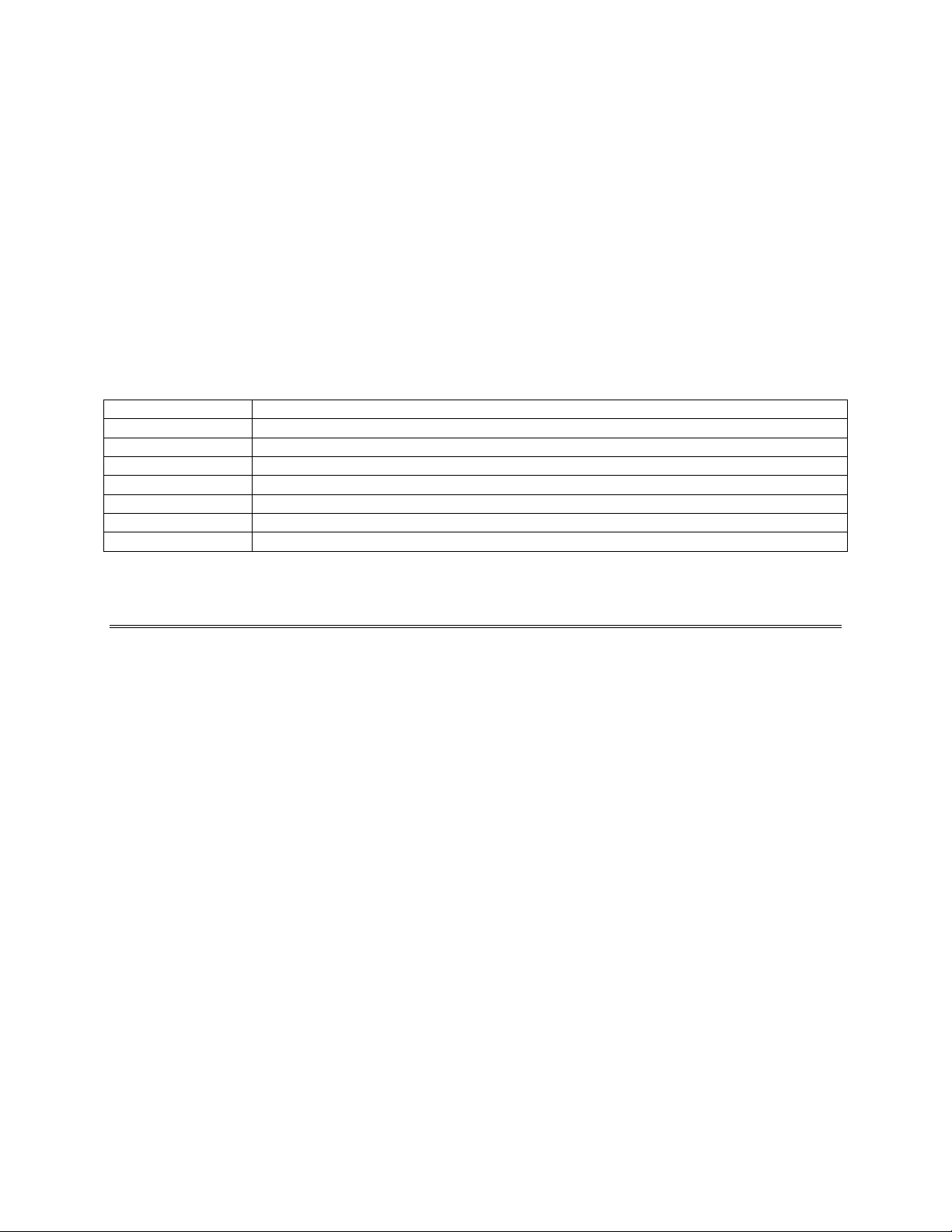

Default Settings For Different Model Letter Designations

Instrument Model

number

O2

O2 ref.

ref.

Level Draft Temp

Excess

Air

Effc / Loss

Basis

Effc / Loss Fuel heat

Gas

Conc. Decimals Fuel Setup

CA-621X off 3% " H20 F %EA ASME/heat

loss

CA-621X – D off 0% mbar C lambda Siegert qA NA PPM commas Siegert fuel

CA-621X - EU off 0% mbar C lambda Siegert qA NA PPM commas Siegert fuel

CA-621X - M off 0% kPa C %EA ASME/heat

loss

CA-621X - UK off 0% kPa C %EA ASME/heat

loss

CA-621X - AU off 0% kPa C %EA ASME/heat

loss

Net

Efficiency

Net

Efficiency

Gross

Efficiency

Gross

Efficiency

BTU HHV PPM periods fuel

composition

parameters

parameters

parameters

kJ/kg HHV PPM periods fuel

composition

parameters

kJ/kg LHV PPM periods fuel

composition

parameters

kJ/kg LHV PPM periods fuel

composition

parameters

12 Series CA-6200 CA-CALC Combustion Analyzer

Chapter 5. Basic Operation

Quick Start

This chapter describes the steps needed to start making basic measurements. When used for the first time, the

CA-C

different instrument parameter settings refer to “Instrument Setup” in Chapter 6, “MENU Selections and Menu Items.”

TM

ALC

combustion analyzer parameter settings match the Defaults listed in the previous chapter. To select

Steps to Quick Startup

1. Review Chapter 4, “Getting Started.” Perform the necessary hardware setups.

2. Turn the instrument on using the red ON-OFF button identified in Figure 1.

3. Verify that you have adequate battery life for your measurement needs. A 50% reading for example, indicates 8 to

12 hours of additional operating life.

4. Press the ENTER button. A brief initialization follows.

If the Error screen appears, refer to Chapter 9, “Maintenance and Troubleshooting.”

5. Review the Pre-Test screen. The O

near 0 ppm. The draft reading should be 0.

6. Press ESC to bypass the baseline calibration.

sensor should indicate approximately 20.9% and other gas sensors indicate

2

Baseline Calibration

To perform a baseline calibration press ENTER from the Pre-Test screen. A baseline calibration reestablishes

baseline levels for the electrochemical sensors and draft sensor. When performing a new baseline calibration, make

sure the probe is in air free of exhaust gases (or disconnected). The baseline calibration takes about 40 seconds. To

abort the baseline calibration, press ESC. The data display screen app ears when the baseline calibration is complete or

bypassed.

Figure 5: Schematic Illustration of Quick Start Process

13

The Data Display Screen

Refer to the figure below to identify the key components of the main Data Display screen.

Site name for data logging

Device name for data logging

Date and time

O2 reference status

Site: Not Selected

Device: Not Selected Bat:99%

15:00:00 01/01/00 Fuel: NAT GAS

O2REF: OFF

Message area

O2 20.9 % TAint 77 °

CO 1 PPM C O r 0.0000

NO 0 PPM CO2 0.0

NOx 0 PPM EA

SO2 0 PPM Effc

TS 500 °

Draft - 0.00

LOGGING

FUNCTION

F

inH2O

ZERO

DRAFT

OVER %

OVER %

Button label for instrument setups. See Chapter 6.

F

%

MENU

Battery life indication

Fuel type

Button Icons

Button label for re-zeroing the draft sensor.

Button label for data saving and management

functions. See Chapter 7.

Measured and calculated data. Updated in

real-time.

Figure 6: The Main Data Display Screen

14 Series CA-6200 CA-CALC Combustion Analyzer

Available Measurements

The CA-CALC analyzer automatically detects the sensors installed. Only measurements for detected sensors appear on

the display. For example, if no carbon monoxide sensor is present, CO will not appear on the display. For values that

are calculated, such as efficiency (Effc), sensors that provide data for the calculation must be present. If the O

data or stack temperature data is missing, efficiency will not be calculated and Effc will not be displayed on the Data

Display.

The following table presents a list of the measurements and calculations made by the CA-C

ALC analyzer. These will

appear on the Data Display if the appropriate sensors are present.

O

2

CO

Oxygen concentration. 0–25%

Carbon monoxide concentration measurement made using the hydrogen compensated CO

sensor. 0–5000 ppm

sensor

2

NO (optional)

NO2 (optional)

NOX (optional)

SO2 (optional)*

COhi (optional)

TA (optional)

TAint

TS

Draft

CO2

COr

EA%

Nitric oxide concentration 0–4000 ppm

Nitrogen dioxide concentration. 0–500 ppm

Concentration combining NO and NO

the NO

if the NO

concentration is assumed to be 5% of the NO concentration. No NOX is displayed

X

sensor alone is present

2

concentrations. When a NO2 sensor is not present,

2

Sulfur dioxide concentration. 0–4000 ppm

Measurement of carbon monoxide made using the high concentration CO sensor. 0–20000

ppm

The combustion supply air temperature. Only present when the accessory probe is used. –

20–392 °F (0–200°C)

The temperature measured using the on-board RTD.

Stack temperature. Displayed when thermocouple is plugged in. 32–1800°F (0–1000°C)

The Draft measurement. Only updated when the pump is off. ±30” H

The carbon dioxide concentration in %. Based upon the O

measurement and fuel CO2

2

O (80 mbar)

2

Max parameter.

The ratio of CO to CO

. ppm CO/(%CO2 x 10000)

2

% Excess air.

Lambda (λ)

Effc

Loss

Alternative excess air representation to %.

Combustion Efficiency, Net or Gross and (100 – qA)

Dry gas loss and Siegert (qA).

Special note: The SO

concentration. The CA-C

present. A correction is also performed for the effects of NO

the NO

sensor to NO

concentration is assumed to be 5% of the NO measured concentration. The response of each SO2

2

is determined at the factory as part of the SO2 sensor calibration.

2

sensor has a negative response to NO2 gas which is proportional to the NO2

2

ALC analyzer corrects for the effect of NO

2

on the SO2 sensor if an NO2 sensor is

2

when a NO sensor is installed. In this case,

Chapter 5. Basic Operation 15

Buttons and Button Operations

ON-OFF Control Button (red)

Turns the instrument on and off. Pressing this button is accompanied by a beep.

The ENTER Control Button

Press the ENTER button to execute a command, such as selecting a menu item. Most instrument display screens have

a message indicating the ENTER button function.

Note: Pressing ENTER does not cause entered values to be saved to the instrument memory. Buttons

with display labels such as SAVE & EXIT or ACCEPT are designed for saving.

The ESC Control Button

Press the ESC button to exit the current screen and operation, in most cases returning to the previous screen.

Arrow Control Buttons

The arrow buttons are used for three purposes:

Purpose 1. To move the display cursor to a menu item for selection using the ENTER key. The display cursor appears

as a dark background over light characters. Example: Instrument Setup

Purpose 2. To move the character cursor to a character or character space.

Example:

Name: NAT GAS Character cursor on letter T.

Purpose 3. To increment a numerical value or select a character from the character menu.

When a blinking cursor box is present, the arrow keys cause the value in the box to change; ON toggles to OFF, a

Name character steps through a set of characters, or a number value increases or decreases.

16 Series CA-6200 CA-CALC Combustion Analyzer

Icon Buttons

Button Icons appear on the right side of the display and are connected to an Icon button by an indicator line. The

button icons correspond to the button functions described below. You will see that some icons change when the button

is pressed, indicating a change in a current status (e.g., pump on/off), or indicate that a new operation will be

performed when the button is pressed again. This is true of the Display button that changes from the graph icon to the

zoom icon to the un-zoom icon.

Icons

Print a Sample. Press the button to the right of this icon to output the current data

displayed on the Data Display screen through the serial port to the portable printer

or a computer.

Draft Measurement. Press this key to take a draft measurement. This causes the

pump to stop. A countdown begins during which time the draft reading is stabilized

and taken.

Icon Description

Back Light button icon. Left icon indicates light off, right icon indicates

light on.

Pump On-Off button icon. Left icon indicates pump off, right icon

indicates pump on.

Display Icons. Button to the right toggles from the Graph

display to the Zoom display to the Un-zoomed, standard

Data Display.

Save Data. Save (log) current data on the Data Display screen.

Labeled Buttons

Button labels appear in boxes such as those shown below. The labels have tabs that connect to a button, performing

the labeled function, by an indicator line. Examples are shown in the illustration below.

Chapter 5. Basic Operation 17

Label Box

Button

Indicator Line

Tab

If no tab is present on a box, it is not linked to a button and is a message box. A good example of a message box is

shown below.

Message Box

Selecting Menu Items

Menus are lists of items or options you select to perform a needed operation. Selection of a menu item begins by

moving the display cursor to the item and pressing the ENTER button. The display cursor is moved using the Arrow

buttons.

Example: Display Cursor

Zoom Settings

Instrument Setup

Calibrate Sensors

Restore Factory Cal

Set Contrast

.

.

Once the ENTER button is pressed, a new menu may appear with a new list of option items, or you may see a

blinking cursor indicating that a number value, or unit value can be changed. If you want to back-out of a selection,

simply press the ESC button.

Display Cursor

Changing a Number Value

The CA-CALC combustion analyzer has a variety of number values that are changeable. Examples are the Contrast

level, Time and Date, O

becomes changeable when a blinking cursor box surrounds it.

Example: Changeable number value.

Contrast:

Use the Arrow buttons to increase or decrease the indicated value. Note—there are upper and lower limits on values.

When an upper or lower limit is reached, the numbers wrap around.

Use the SAVE & EXIT button to install the new value.

Reference, and so on. Press the ENTER button on the list item to initiate a change. A value

2

Blinking cursor indicates value can be changed using

50

the Arrow buttons.

18 Series CA-6200 CA-CALC Combustion Analyzer

Changing Units

Data displayed by the CA-CALC analyzer can be presented in different units. To change units, first select Instrument

Setup from the main MENU. Use the Arrow buttons to select from the list of available units. Press ENTER to make

a selection. A blinking cursor box over the selected unit indicates that it is changeable. Use the Arrow buttons to

change between available units. Press ENTER once the desired units are shown, then use the SAVE & EXIT button

to install the new unit.

Refer to “Instrument Setup” in Chapter 6, “MENU Selections and Menu Items,” for specific information on unit types.

Entering and Changing Names

Names include the fuel types and data saving identifications: Sites, Devices and Samples. To create or edit a name,

use the Arrow buttons to move the cursor to the desired character space and press the ENTER button (see the

example below). The blinking cursor indicates that a character can be changed or added if none exists.

Note: A character table is displayed when ENTER is pressed. Use the Arrow buttons to choose any

character in the table. Press ENTER to install the selected character. Repeat this process to enter

all your required characters.

When the entries are complete, press the SAVE & EXIT button to install the name.

Example: Name entry

Name: __ __ __ __ __ __ __ __ __ __ __ __

A B C D

Name: __ __ __ __ __ __ __ __ __ __ __ __

Finish by pressing the SAVE & EXIT button to install new name.

To select an item from a menu list use the Arrow buttons to highlight the item, then press ENTER.

A B C D

Move character cursor with Arrow buttons. Select

using the ENTER button.

Blinking cursor after ENTER. Change character with the

Arrow buttons. Use ENTER to accept character.

Using the Sampling Probe

Gas and Temperature Measurements

Connect the sampling probe to the CA-Calc as described in Chapter 4.

Place the Sampling probe through a hole in the exhaust flue, following recommendations presented below. Placement

of the probe is important, and certain considerations must be given when choosing a sampling location.

To ensure that the gas measurements are not diluted or cooled by outside air, place the probe before any draft damper

or regulator as illustrated in Figure 7. Tilt the probe tip up slightly so vapor condensing in the sampling tube does not

run back to the probe tip and cool the thermocouple tip. Important: Twist sampling tube to ensure that the

thermocouple tip is exposed directly to exhaust flow (see figure below).

Chapter 5. Basic Operation 19

2

3

1

Minimum 2” (5 cm)

4

Rotate the tube to window to

ensure proper thermocouple

exposure. Models CA-6210,

CA-6211, CA-6212, CA-6214

1. Sampling probe 3. Exhaust flue

2. Draft regulator 4. Hot exhaust gases

Figure 7: Sampling Probe Location

Stack temperature measurement is extremely important to establish the heat loss from the exhaust gases and

determine combustion efficiency. The Sampling Probe with its integral thermocouple measures temperature at the

probe tip. The tip should be placed at the point of highest exhaust gas temperature when determining efficiency. This

means at the base of the flue, before heat is lost to the flue side-walls, and towards the center, especially for small

ducts. If the stack gas temperature is underestimated, the operating efficiency will be overstated. When an

economizer or air heater is used, the stack temperature is measured after these devices.

Note: When an Emission Probe is used, allow adequate time for the temperature to stabilize before

accepting the combustion efficiency measurement (5–10 minutes).

Cautions

Hot probe! When removed, the sampling probe will be extremely hot. Avoid touching

!

20 Series CA-6200 CA-CALC Combustion Analyzer

the probe tip, and avoid placing the probe on or near plastic materials such as the

instrument case. These will melt. Maintain a minimum 2” (5 cm) clearance between

the probe handle and position collar when the probe is mounted in flue.

Empty Water Trap! Watch the water trap and empty it frequently to prevent the

possibility of flooding the instrument. See Chapter 9 for instructions.

Making a Draft Measurement

Before making a draft measurement, zero the draft pressure transducer by pressing the ZERO DRAFT option button

in the Data Display. For zeroing, make sure the sampling probe is out of the flue, or that the d raft and sample fittings

are disconnected from the instrument. Once zeroed, reinsert the sample probe and press the Draft Measurement

icon button to initiate a draft measurement.

During the draft measurement, the sampling pump is automatically turned off.

When the draft measurement is complete, the pump turns on again.

Note: Draft readings are also taken continuously whenever the pump is turned off. When the pump is

turned on again, the current draft reading is captured, and remains displayed until the next time the

pump is turned off or the Draft Measurement icon button is pressed.

Auto Draft Meas. Feature

The Auto Draft Meas. feature is used so that a draft reading is automatically taken whenever a sample is saved using

the Save Data icon button. To activate automatic draft saving, set the Auto Draft Meas. item to On from the

Instrument Setup menu.

Printing to the Portable Printer and to a Computer

Printing

Instrument data can be output through the RS232 serial port to the optional Model 8925 portable printer. First refer to

“Connecting the Optional Portable Printer” in Chapter 4, “Getting Started.” Make sure the baud rate is set correctly.

To print the information on the Data Display, press the Print a Sample icon button.

The printer responds immediately once the button is pressed, producing a printout. Example printouts are shown in

Figure 8.

Data is also printed using the logging functions accessed by pressing the LOGGING FUNCTIONS option button.

The logging functions enable you to print saved data as a single Sample, or as many Samples saved under a Site or

Device name. Chapter 7, “Saving Data and LOGGING FUNCTIONS,” identifies the buttons used to perform these

printing operations.

When data is printed from LOGGING FUNCTIONS, the Site and Device names are presented as well as the

Sample name. In addition, fuel parameters used in the calculations are also printed. An example of a Sample

printout from LOGGING FUNCTIONS is shown on the right in Figure 8.

Printing to a Computer

Use the print buttons and print functions to output data to a computer as well as to the portable printer. First refer to

“Connecting a Computer” in Chapter 4, “Getting Started.” Make sure the RS232 Device is properly set to

Computer, and that the baud rate is set correctly.

Data transferred to a computer is the same as that output to a printer (see Figure 8); however, it is formatted differently

and uses the Windows

combustion analyzer how to output the data. Data transferred to a computer is tab-delimited so it can be more

conveniently parsed when using spreadsheet applications such as Microsoft Excel

®

Windows and Excel are a registered trademarks of Microsoft Corporation.

®

character set rather than DOS characters. Setting the RS232 Device tells the CA-CALC

®

.

Chapter 5. Basic Operation 21

Data can be downloaded to a terminal emulator program such as the HyperTerminal, which accompanies the

Windows

®

operating system program. Look for HyperTerminal in the Accessories folder. In HyperTerminal,

use the Capture Text option from the Transfer menu for recording instrument data.

Communications Protocol

Baud rate 1200 (default)

Data bits 8

Parity none

Stop bit 1

Flow none

DATE: 01/01/99

TIME: 15:00:18

Fuel: Nat Gas

O2REF: Off

O2 6.0

CO 5 PPM

NO 0 PPM

NO2 0 PPM

NOx 0 PPM

TA 70 °F

TS 300 °F

Draft 0.01 inH2O

CO2 8.4 %

Lambda OVER

Effc 84%

Printout using the Icon button.

Site: 1( site name

Device: 1( device name

Sample: 1(sample name)

DATE: 01/01/99

TIME: 15:00:18

O2REF: Off

Fuel: Nat Gas

Fuel Parameters:

Carbon wt.: 79.9%

CO2 max vol.: 11.8%

Sulfur wt. 0.0%

Moisture. 0.0%

HHV(BTU/lb): 21869

O2 6.0

CO 5 PPM

NO 0 PPM

NO2 0 PPM

NOx 0 PPM

TA 70 °F

TS 300 °F

Draft 0.01 inH2O

CO2 8.4 %

Lambda OVER

Effc 83.8 %

Printout from LOGGING FUNCTIONS.

Figure 8: Example Printouts

22 Series CA-6200 CA-CALC Combustion Analyzer

Chapter 6. MENU Selections and Menu Items

Select from items in the main menu to perform setup operations. Access the main menu by pressing the button

labeled MENU. Following is a list of the main menu items and the underlying menus. In this chapter, main menu

items are described in sections in the order they appear in the menu, beginning with the Zoom Settings followed

by Instrument Setup and so on.

It will be useful to review sections of the previous chapter dealing with selecting menu items, changing number

values, units and names before proceeding. Recognize that for most operations, the procedure is as follows: use the

Arrow buttons to highlight a menu item, use the ENTER button to select the menu item, use the Arrow buttons

make modifications, and finally use SAVE & EXIT to implement the change.

(MENU main menu)

Zoom Settings

Instrument Setup

Calibrate Sensors

Restore Factory Cal

Set Contrast

Set Time and Date

Select Default Fuel

Fuel Setup

Restore Fuel Settings

Erase All logged Data

CALIBRATE SENSORS

O2

CO

NO

NO2

SO2

TS

TA

Draft

SELECT FUEL TYPE

Nat GAS

Propane

Oil #2

Oil #6

Coal

Wood(dry)

Bagasse

Coke

User Type

User Type

User Type

User Type

User Type

ZOOM SETTINGS

O2

CO

NO

NO2

NOX

SO2

TS

TA

Draft

CO2

EA

RESTORE FACTORY CAL

O2

CO

NO

NO2

SO2

TA

TS

Draft

FUEL SETUP

Nat GAS

Propane

Oil #2

Oil #6

Coal

Wood (dry)

Bagasse

Coke

User Type

User Type

User Type

User Type

User Type

INSTRUMENT SETUP

O2REF

O2REF Level

Temp:

Draft:

Excess Air

Effc./Loss

Fuel Heat

Gas Conc.

Decimals:

Auto Draft Meas:

Baud rate:

RS232 Device

CO Alarm Level

NO Alarm Level:

Effc/Loss Basis

SET DATE AND TIME

Date:

Time:

23

Zoom Settings

In the Zoom Settings screen you can select two parameters to be displayed in large characters. The large character

display appears when the Zoom Display Icon button is pressed.

NO -0 PPM CO2 0.0 %

NOx -0 PPM EA OVER %

SO2 -0 PPM Effic OVER %

TS 500 °F

TA 75 °F

Draft - 0.00 inH2O

O2 20.9 %

CO 1

LOGGING

FUNCTIONS

ZERO

DRAFT

PPM

MENU

ZOOM SETTINGS

= Measurement Zoomed

*

* O2

* CO

NO

NOx

SO2

Figure 9: Example Zoom Display and Zoom Settings Screen

To set the parameters for large display select Zoom Settings from the MENU items.

Choose a parameter from the list in the Zoom Settings menu by moving the cursor to a list item using the Arrow

buttons, and pressing ENTER. An asterisk appears by the selected parameter. Two parameters can be chosen.

Instrument Setup

Below is a list of Instrument Setup options. These are discussed on the following pages. Some of the items

below are calculated. Refer to Appendix A, “Calculations,” later in this manual for information.

REF

O

2

REF Level

O

2

Temp:

Draft:

Excess Air

Effc./Loss

Fuel Heat

Gas Conc.

Decimals:

….more….

Auto Draft Meas:

Baud rate:

RS232 Device

CO Alarm Level

NO Alarm Level:

Effc/Loss Basis

This indicates additional items are available

beyond those currently displayed. Use the

down Arrow button to access these items.

24 Series CA-6200 CA-CALC Combustion Analyzer

Instrument Setup

Item Description Options

REF:

O

2

Enable or disable the O

reference calculation. The O2

2

reference applies to the CO, NO, NO

and SO2

2

Select between:

On

Off

measurements. Refer to the next item below.

reference level can be adjusted between 0 and

O2REF Level:

This option is used to set a value for the O

reference

2

The O

18%.

2

level used in the reference calculation. Refer to

Appendix A, “Calculations,” at the back of this

manual.

Temp:

This option is used to select temperature units for

display.

Temperature units are:

Degrees Fahrenheit, °F

Degrees centigrade, °C

Draft:

This option is used to select draft units for display.

Optional Draft units are:

O

inH

2

kPa

mbar

hPa

Excess Air:

This option is used to select between options for the

display of excess air.

Options for displaying excess air are:

%EA

Lambda,(

Effc./Loss:

Choose to display Net Efficiency, Gross Efficiency

Loss or qA and Effic. for the Data Display. Options

for display will depend upon the Effc/Loss Basis

selected (ASME or Siegert).

Refer to the Fuel Setup section and Appendix A,

“Calculations,” later in this manual.

To change the Effc/Loss Basis, refer to the item

description found later in this section.

Fuel Heat:

This option allows you to select whether the high

heating value (HHV) of the fuel, or the low heating

value (LHV) of the fuel. Fuel heating value is used

when calculating combustion efficiency or loss. Units

for fuel heat are also selectable between BTUs/lb. and

kJ/kg.

The options for the display of fuel combustion

efficiency are:

ASME

Effc. Net,

Effc Gross,

Loss

Siegert

qA

Effic. = 100 – qA

Fuel heat options:

BTU/lb HHV

BTU/lb LHV

kJ/kg HHV

kJ/kg LHV

Note: Emission factors will change to metric

units when kJ/kg fuel heat units selected (see

Appendix A).

λ)

Chapter 6. MENU Selections and Menu Items 25

Instrument Setup (continued)

Item Description Options

Gas Conc.:

Change gas concentration units for display gas

concentration using this option. The selections of

units applies to all gases accept the O

and CO2.

2

These are expressed as percent only.

Units relating the weight of the gas to the fuel energy

input use the conversion factors, FNOx, FSO

, FCO

2

displayed in the Fuel Parameters screen.

Decimals:

Select between periods or comas to use when

expressing decimal notation.

Auto Draft Meas:

When On is selected, this option causes the

instrument to automatically take a new draft

measurement each time the Save Data icon button is

pressed.

Baud Rate:

This option is used to select the baud rate for the

serial output to an attached computer or printer. The

default baud rate is 1200, which matches the default

printer setting.

If the baud rate is changed in the instrument, make

sure it is also changed for your computer or printer.

RS232 Device:

Select the Device (printer or computer) receiving the

serial data. Sending data to the wrong Device results

in the presence of bad characters.

CO Shutoff Level:

Extended CO sensor exposures above the stated

maximum overload concentration of 4000 PPM can

cause temporary shifts in the CO readings. To help

avoid this, the instrument automatically turns the

pump off and displays a warning when the Shutoff

level is exceeded for three seconds.

NO Shutoff Level:

Extended NO sensor exposures to NO concentrations

above the recommended maximum overload

concentration (5000 PPM) can cause temporary shifts

in NO sensor measurements. To avoid this, the

instrument turns the pump off when concentrations

remain over the Shutoff level for three seconds.

Select units for concentration display from the

following:

PPM parts per million

g/MWh grams per megawatt hour

mg/MJ milligrams per mega-joule

ng/J nanogram per Joule

mg/kJ milligrams per kilo-joule

#/Mbu pounds per million Btus

mg/m3 milligrams per cubic meter

g/bhph grams per brake horsepower hour

mg/kWh milligrams per kilowatt hour

g/kWh grams per kilowatt hour

Select from:

Commas

Periods

Chose between:

On

Off

Select from the following baud rates.

1200

2400

4800

9600

19200

Choose device to receive serial data:

Printer

Computer

The CO shutoff level can be set over the range:

1000-5000 PPM:

The default level is set to 2000 PPM.

See Chapter 9, “High Concentration Overload”..

The NO shutoff level can be set over the range:

1000-5000 PPM:

The default shutoff level is 1000 PPM

See Chapter 9, “High Concentration Overload”.

26 Series CA-6200 CA-CALC Combustion Analyzer

Instrument Setup (continued)

Item Description Options

Effc/Loss Basis:

Efficiency and loss are calculated based upon heat-

loss (ASME) or Siegert calculations. Select between

ASME or Siegert using the Effc/Loss Basis

instrument setup option.

Select from the following options:

ASME

Siegert

In the U.S. select the ASME calculation to determine

Net Efficiency. Use the high fuel heating value

(HHV). Use the Siegert formula in Europe. Refer to

the Default Instrument Setting section in

Chapter 2.

Note: Depending upon the basis selected for

the efficiency and loss calculations, default fuels

and fuel parameters in the Fuel Setup menu

change. Refer to the Fuel Setup section later in

this chapter and Appendix A for more

information.

Note: If you use this option to change the basis

of your efficiency/loss calculations, it is

necessary to use the Restore Fuel Setting

following the change. Select YES for both factory

and user fuels.

Calibrate Sensors

Calibrate Sensors is the third selection in the main MENU. This is used when performing calibrations of the on-

board sensors. Gas sensors, thermocouples and the draft sensor can all be calibrated. When the Calibrate Sensors

option is selected, the display menu appears as in the example below (Figure 10). Only installed sensors are listed.

Select the sensor for calibration using the Arrow buttons and ENTER.

For specific information regarding calibrations, refer to Chapter 8, “Calibrations,” found later in this manual.

Calibration:

Name Reading Units Serial Last cal

O2 20.9

CO -1 PPM 01200002

NO -1 PPM 01200003 01/02/99

NO2 -1 PPM 01200004 01/02/99

SO2 -1 PPM 01200005 01/02/99

TS 75 F 01/02/99

TA 75 F 01/02/99

Draft inH20 01/02/99

<--> move cursor

<ENTER> to calibrate

% 01020001 01/02/99

Figure 10: Screen to Select Sensor for Calibration

Chapter 6. MENU Selections and Menu Items 27

Restore Factory Cal

In the event that a sensor calibration is performed in error, or the calibration(s) becomes corrupted, the initial sensor

calibration performed at the factory can be re-installed. This is possible because factory calibration data is saved,

either in the gas sensor electronics, or in the instrument. The initial data is never discarded. Calibrations are restored

for individual sensors by selecting the appropriate sensor from the list in the Restore Factory Cal screen, and

pressing ENTER.

Set Contrast

The Set Contrast option is used to lighten or darken the display, improving visibility. Once Set Contrast is

selected with ENTER, set the contrast using the Arrow buttons to increase (darken), or decrease (lighten) the

contrast value. The default is value is 50. Use the SAVE & EXIT button to save the new contrast setting.

Set Time and Date

Once selected from the main MENU using ENTER, a blinking cursor in the Set Time and Date screen indicates

the number field is changeable. The up/down ( ) Arrow buttons are used to increase or decrease the indicated

value. To move between entry fields use the left/right ( ) Arrow buttons. Time and date have the following

format:

Date: Month/Day/Year

Time: Hour:Min.:Sec.

Use the SAVE & EXIT button to save new settings.

Select Fuel Type

Use this selection from the main MENU to choose the type of fuel being burned. When you select a fuel type, you

install fuel parameters for this fuel. Fuel parameters are used to perform calculations of CO

loss, and emission rates. These calculated values are not correct if the wrong fuel is specified! The fuel list includes

eight standard fuel types (five when Siegert basis used), with nominal fuel parameter values, and five User fuels.

More information on fuels is included in the next section “Fuel Setup.”

, combustion efficiency,

2

28 Series CA-6200 CA-CALC Combustion Analyzer

Fuel Setup

This menu selection lets you change fuel parameters for existing fuel types and add new fuel types to the fuel list.

When the Fuel Setup is selected from the main MENU, the fuel list is displayed together with a table of fuel

parameters. Use the Arrow buttons to move to a fuel in the fuel list. The fuel parameters in the table automatically

update for the highlighted fuel. See the example display in Figure 11 below.

Fuel Setup

Nat Gas

Propane…....

Oil #2

Oil #6

Coal

Wood(dry)

Bagasse

Coke

User 1

User 2

User 3

User 4

User 5

Figure 11: Fuel Setup Screen—Selecting Fuel to Change Parameter

To modify parameters for the highlighted fuel, Press ENTER. The fuel parameters screen appears as in Figure 12

below.

Use the Arrow buttons to move the cursor to the field to be changed. This can be a letter in the fuel name, or a fuel

parameter with a number value. Press the ENTER button to choose the highlighted field. A blinking cursor appears,

indicating that the field is changeable.

Use the Arrow buttons to increase or decrease a value in the chosen field, or select a character from the character

table. The character table appears when a character in the fuel name is highlighted and ENTER is pressed. A fuel

name can be comprised of any character in the character table.

Press the SAVE & EXIT to install your new entries. ESC will abort any changes.

Fuel parameters

Carbon wt.: 81.8 %

Hydrogen wt.: 18.2 %

CO2 max vol.: 13.8 %

Sulfur wt.: 0.00 %

HHV(BTU/lb): 21669

LHV(BTU/lb) 19693

Moisture: 0.0%

F.SO2: 0.00145

F.NOx: 0.00104

F.CO: 0.00063

Table of fuel parameters for

highlighted fuel (Propane).

Chapter 6. MENU Selections and Menu Items 29

Figure 12: Fuel Parameters Screen—Select and Change Fuel Parameters

Fuel Parameters:

Name: PROPANE

Carbon wt…: 81.8 % Moisture 0.0%

Hydrogen wt.: 18.2 %

CO2 max vol.: 13.8 % Emission Factors:

Sulfur wt.: 0.00 % FSO2: 0.00145

HHV(BTU/lb): 21669 FNOx: 0.00104

LHV(BTU/lb) 19693 FCO 0.00063

move cursor

<ENTER> = select

<ESC> = exit

SAVE & EXIT

Fuel Setup When Siegert Loss Calculation Used

When Siegert is selected from the Effc/Loss Basis option, flue losses and fuel efficiency are calculated using

the Siegert formula (see Appendix A). The fuel parameters are different than those identified in the section above.

The Siegert formula for flue gas loss uses constants A1 and B, replacing the weight percents of C, H, S and the

fuel heating values (HHV and LHV). These constants are derived from the fuel’s composition and incorporate the

low heating value into the loss calculation.

To change these values, or enter values for new fuel types, follow the same procedur e outlined in the previous

sections above. Remember to use the SAVE & EXIT button when complete. For information on the Siegert

calculation, refer to Appendix A.

Restore Fuel Settings

Fuels one through eight (1-8) in the fuel list are set at the factory, together with their fuel parameters. These fuel

values are saved in the instrument, and can be changed if desired using the Fuel Setup option. Fuels 1-8 can also

be restored to the initial factory setting if needed. To return values to the factory settings after changes have been

made, select Restore Fuel Settings from the main MENU. Choose the YES option button when required.

Restore Fuel Settings does not affect the User fuels (9-13), however, you are given a chance to clear your user

fuels by selecting YES when requested. Skip this process by selecting NO or pressing ESC.

Remember to use this option after changing the Effc/Loss Basis.

30 Series CA-6200 CA-CALC Combustion Analyzer

Erase Logged Data

Use the Erase Logged Data function to clear the instrument’s logging memory. When this option is selected,

press YES to perform the clean-up operation. Choose NO or ESC to abort the erasing process.

Caution

This option permanently erases all user entered Sites, Devices and Samples from

!

the CA-CALC combustion analyzer logging memory.

Chapter 6. MENU Selections and Menu Items 31

Chapter 7. Saving Data and LOGGING FUNCTIONS

A key feature of the CA-CALCTM combustion analyzer is the ability to save combustion and emission test data to

memory in the instrument. This data can be retrieved later for printouts, downloaded to a computer, or used for

comparison with other tests. Data is maintained by power supplied from a 2-year lithium battery on-board the

instrument. There is the possibility that if the instrument is dropped, lithium battery power could be lost with

subsequent loss of data. Important data stored on-board should be saved periodically to a computer or printed for a

permanent record.

Overview

The CA-CALC analyzer saves data Samples when the Save Data icon button is pressed. A Sample is a snapshot

or log of the data appearing on the Data Display screen.

The Save Data icon button