TSI Incorporated Alnor Balometer Jr. Owner's Manual

OWNER’S MANUAL

®

Balometer Jr.

LIMITATION

OF WARRANTY AND LIABILITY

Seller warrants the goods sold hereunder, under normal use and service as described in the operator's manual, shall be

free from defects in workmanship and material for twelve (12) months, or the length of time specified in the operator's

manual, from the date of shipment to the customer. This warranty period is inclusive of any statutory warranty. This

limited warranty is subject to the following exclusions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other components when indicated in

specifications, are warranted for 90 days from the date of shipment.

b. Parts repaired or replaced as a result of repair services are warranted to be free from defects in workmanship and

material, under normal use, for 90 days from the date of shipment.

c. Seller does not provide any warranty on finished goods manufactured by others or on any fuses, batteries or other

consumable materials. Only the original manufacturer's warranty applies.

d. Unless specifically authorized in a separate writing by Seller, Seller makes no warranty with respect to, and shall have

no liability in connection with, goods which are incorporated into other products or equipment, or which are modified

by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated herein. NO OTHER EXPRESS

OR IMPLIED WARRANTY OF FITNESS FOR PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR BUYER, AND THE LIMIT OF

SELLER'S LIABILITY FOR ANY AND ALL LOSSES, INJURIES, OR DAMAGES CONCERNING THE GOODS

(INCLUDING CLAIMS BASED ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE) SHALL

BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION OF

SELLER, THE REPAIR OR REPLACEMENT OF THE GOODS. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY

SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE RESPONSIBLE FOR

INSTALLATION, DISMANTLING OR REINSTALLATION COSTS OR CHARGES. No Action, regardless of form, may be

brought against Seller more than 12 months after a cause of action has accrued. The goods returned under warranty to

Seller's factory shall be at Buyer's risk of loss, and will be returned, if at all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND LIABILITY, which contains the

complete and exclusive limited warranty of Seller. This LIMITATION OF WARRANTY AND LIABILITY may not be

amended, modified or its terms waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are to our customers, our service

policy is designed to give prompt attention to any problems. If any malfunction is discovered, please contact your nearest

sales office or representative, or call Customer Service at (800) 424-7427 (USA) and (1) 651-490-2811 (International).

.

BALOMETER JR.

SECTION 1:

SECTION II:

SECTION III:

ENGLISH ....................................................................1

SPANISH ..................................................................25

FRENCH...................................................................53

TABLE

OF

CONTENTS

General

Using the Balometer Jr. Safely ............................................. 3

Preparation for

1.

2a. Setup of 2' x 2'

2b. Setup of 16" x 16"

3. Attaching Hood to Base ................................................... 5

4. Hood Support

5. Handle

6. LoFlow

Operation

Step by Step

Repacking

Performance Check ............................................................. 13

Calibration

General .............................................................................. 14

Equipment Required .......................................................... 14

Preparation.........................................................................

Calibration

Exchange of Calibrated

Appendix A: Theory of

Appendix B: Maintenance and Troubleshooting .............. 18

Maintenance.......................................................................

Troubleshooting .................................................................

Appendix C: Correction Factors for

Non-Standard

Repair

Instructions for

Ownership/Calibration Log ................................................. 23

Description

Unpacking ........................................................................

Attachment...........................................................

Adapter

................................................................................ 8

............................................................................. 12

Procedure

.......................................................................... 14

Hoods

Static

Manifold..........................................................................

Zero

Calibration

............................................................................. 18

Electricity

Adjustment

Information

............................................................... 2

Use

................................................................ 4

Hood

...................................................... 4

Hood

................................................. 4

System

................................................................ 7

Operation

.............................................................. 18

...................................................................... 18

Conditions

...............................................................

Return

...................................................... 6

...................................................... 11

..........................................................

Module

Operation

............................................................. 18

....................................................

........................................................

......................................... 15

.......................................

19

21

22

4

7

14

14

16

18

18

20

GENERAL

DESCRIPTION

The Alnor Balometer Jr. is designed to assist you in making rapid and

accurate measurements of air flow in heating, ventilating and air

conditioning systems. The Balometer Jr. directly reads average standard

air flow rate, for either supply or return diffusers, on the ceiling, wall or

floor. The use of this instrument eliminates the need for multipoint

velocity traverses, the resulting

as the use of K factors.

In use, air to be measured is captured by the hood assembly and then

directed past a square manifold which senses flow at 16 points. The

manifold is connected through the range selector to an Alnor Velometer

Jr. The meter is available in traditional units (cubic feet per minute

(cfm)*), or either of two metric units: cubic meters per hours (cmh),* or

liters per second (l/s).* The Balometer Jr. is capable of reading flows up

to 1400 cfm (2400 cmh, 660 l/s). The system is designed so that air flow

is sensed at either supply or return diffusers with equal accuracy.

A single knob to select both flow direction and range provides

control

ranges of 100 to 600, and 400 to 1400 cfm (200 to 1000, and 800 to 2400

cmh; 50 to 290, and 200 to 660 l/s). A LoFlow range is also available

of the Balometer Jr. for either supply or return diffusers on

which allows the instrument to read in the range of 0 to 200 cfm (0 to

340 cmh, 0 to 95 l/s) by using the included LoFlow adapter screen.

For increased flexibility, an optional 16" x 16" hood is available for

work with small diffusers or where the standard 2' x 2' hood will not

conveniently fit.

*Throughout this manual, the units cfm, cmh and l/s are used for simplicity. Note,

however, that the Balometer Jr. actually reads in standard cubic feet per minute (scfm),

standard cubic meters per hour (scmh), or standard liters per second (std. l/s). See the

Specifications section for more information.

averaging and

area calculations, as well

you

Figure 1: Typical usage

2

USING THE BALOMETER JR. SAFELY

When using the Balometer Jr. to check air flow at ceiling diffusers, make

certain that you can safely raise and hold the unit while making

measurements especially when working on a ladder.

Observe all necessary precautions so that the unit does not

caught

in moving machinery.

becom

e

The Balometer Jr. is not designed for gas mixtures other than air. Use

with corrosive or other dangerous or explosive gas mixtures is not

recommended, and is at the user’s risk.

Due to its size and shape, care should be taken when carrying the

assembled instrument from place to place so that it does not accidentally

bump into people or objects.

Special nylon material is used to manufacture the Balometer Jr. hoods

because of its impermeability and toughness. However, precautions

should be used so that it is not ripped by accidental contact with sharp

objects.

When the instrument is stored or otherwise not being used to

readings,

be certain to protect the meter movement by switching the

take

range selector to the OFF position.

The air flow sensing manifold can be damaged if subjected to excessive

stress. It is not repairable. Any air flow other than through the calibrated

sensing holes (even hairline cracks) will affect instrument accuracy.

Special manifold mounting springs are designed to cushion the assembly

and allow for some deformation of the base without affecting accuracy.

These springs should not be removed or altered in any way.

3

Figure 2:

Assembly of 16” x 16” frame top

4

PREPARATION

FOR USE

1. Unpacking

Before removing any parts from the carrying case, the arrangement of

various

items should be noted so that repacking can be done easily.

Depending on prior usage, either the 2' x 2' hood or the optional 16" x

16" hood may already be attached to the instrument base. If the entire

unit is to be lifted out as an assembly, caution must be exercised to

assure that the pieces do not separate, since dropping the instrument may

cause damage.

If your instrument was ordered with the optional 16" x 16" hood, it may

have been shipped in a separate carton. However, room has been set

aside in the instrument carrying case to store it when not in use. See

Repacking on page 12 for information.

2a. Setup of 2' x 2' Hood

Carefully remove the hood assembly from the case and unfold the hood

from around the frame. The frame itself is completely assembled, but

folded for storage. After the hood has been attached to the base (see

paragraph 3 on page 5), the assembly can be unfolded and deployed as

the hood is raised and attached to the hood support system (see page 6).

Proceed to step

3.

2b. Setup of 16" x 16" Hood

If the optional 16" x 16" hood is to be assembled, first locate the two ―L‖

shaped frame top sections packed to the left of the instrument base in the

carrying case. These sections are held together by an eyelet and slot

arrangement which mates with a similar eyelet and slot on the other

section. These pieces can be slid together, and are self locking by means

of a retention spring. For reference, the direction of sliding is marked by

an arrow on the appropriate corners of the frame sections. The assembled

frame should be square and solid. See Figure 2 for additional detail.

Now install the 16" x 16" hood to the frame top. This is most easily

accomplished by first stretching the hood around two corners of the

frame, and then pulling the hood into position around the other corners.

Make sure that the hood seams are located at the corners of the frame.

Finally, press the elastic

the frame. Assembly of the 16" x 16" hood is now complete.

cord

into the channel along each of the sides of

the

3. Attaching Hood to Base

If the hood size which is to be used is already attached to the base,

proceed to step 4.

First remove the hood which won’t be used by gently pulling the elastic

cord at the bottom of the hood out of its channel, working your way all

around

in the

the base.

When the hood is clear, carefully roll it up and place it

carrying case

to protect it from damage.

Next, attach the bottom of the hood which will be used to the base. This

is most easily accomplished by first stretching the hood around two

corners of the base, and then pulling the hood into position around the

other corners, keeping the hood seams in alignment with the corners of

the frame. Once this is done, the cord can be pressed into the channel to

keep the hood firmly attached and prevent air leaks. See Figure 3 for

details.

Figure 3:

Assembly of hood to base

5

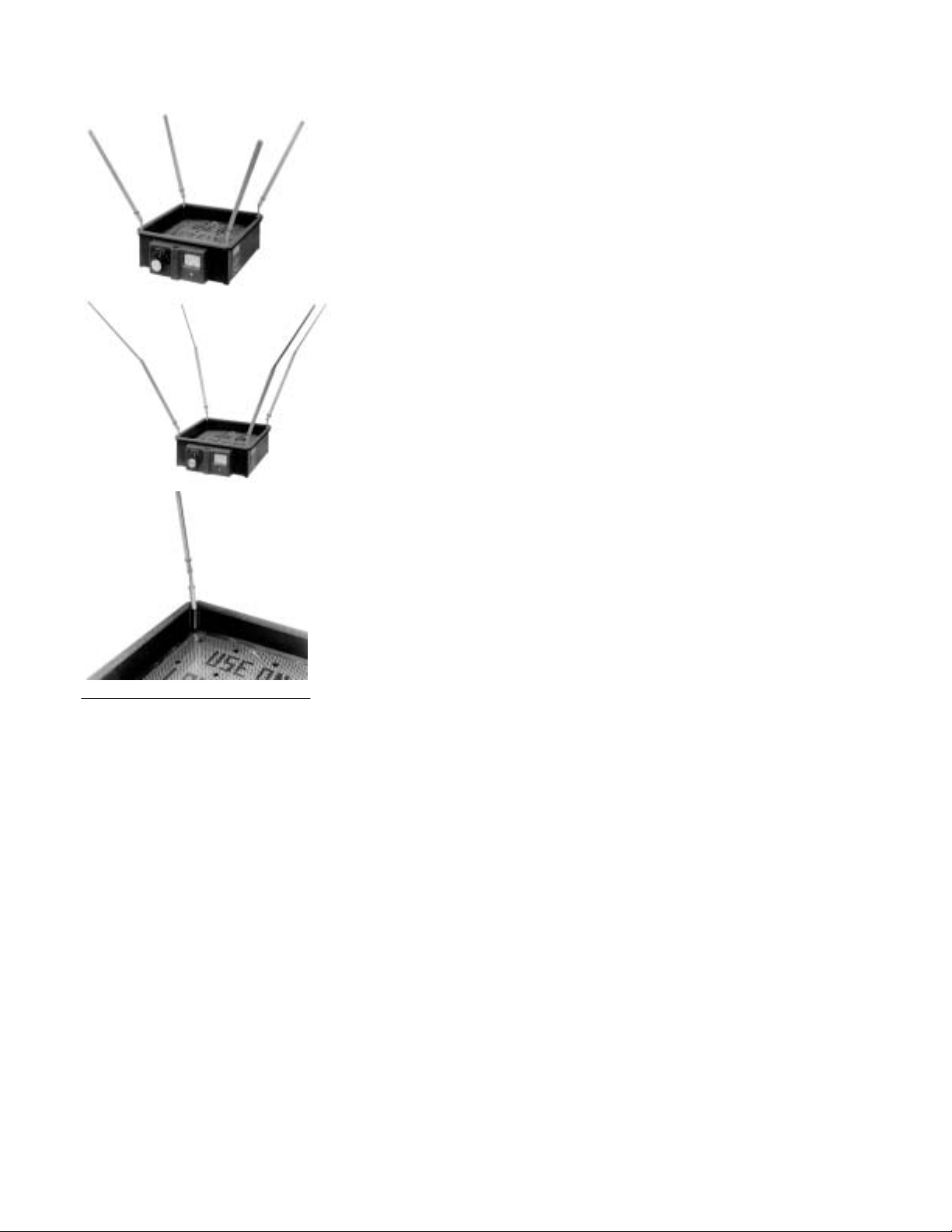

4. Hood Support System

Locate the four hood support rods which are packed behind the

instrument base in the carrying case. Insert one rod in each corner of the

base by pressing the round end of the rod into the square hole at the

inside base corner until the lip on the top of the round section is stopped

by the base. See Figure 4.

If the 16" x 16" hood is to be used, arrange the support rods so that the

tip of each rod is pointing away from the center of the base. See Figure 4.

If the 2' x 2' hood is to be used, the support rod must be extended to full

length. This is accomplished by pushing the retainer toward the base of

the support rod so that the end of the solid square extension is released

from the inside of the U-shaped section of the support rod assembly, and

is free to pivot on the hinge near the top of the U-shaped section. After

all the rods in all four corners are extended, they should be arranged so

that the open section of the U-channel is facing toward the center of the

base, and the tip of each rod is pointing away from the center of the base.

See Figure 4.

Once the support rods are properly located, the hood can be raised and

the

end

of the support rods inserted into the corners of the hood frame.

Proper tautness is achieved by the spring mechanism in the base of the

support rods.

Figure 4: Installation of

hood support system

6

Figure 5:

Handle location and installation

Figure 6: Installation of

LoFlow screen

5. Handle Attachment

Determine from the work to be done which handle arrangement will be

most convenient to use. Generally, if you are working from the floor, the

handle location near the bottom of the instrument will be most

convenient, while ladder work will be easiest with the handle installed on

the top of the range selector housing. Installation is accomplished by

simply turning the handle into

the threads

at either the top or bottom of

the range selector housing. Make sure that the handle is secure before

using. See Figure 5.

6. LoFlow Adapter

The LoFlow adapter screen can be used for measuring air volumes below

200 cfm (340 cmh, 95 l/s), but is strongly recommended for use only

when measuring very low flows, below 125 cfm (200 cmh, 60 l/s).

The LoFlow adapter is inserted by carefully pushing it into position

against the manifold on the side which the air will enter. (For example, if

the air will move through the hood to the base of the instrument, the

adapter goes on the ―hood‖ side of the manifold.) It is necessary that the

adapter be in very close

1

/16" may cause reading errors. Take care not to distort the manifold

contact with

the manifold. Gaps of more that

mounting springs or the adapter during installation or removal. See

Figure 6.

Do not forget to remove the adapter when the range selector is set to

either the medium or high range. The LoFlow adapter is not required

unless measurements of less than 100 cfm (200 cmh) are to be made. It is

strongly recommended that the adapter be used only when measuring

very low flows (up to 125 cfm, 200 cmh, 60 l/s).

This completes the assembly of the instrument. Proceed to the Operation

section for step by step instructions.

7

OPERATION

The operating controls for the Balometer Jr. are located on the front of the

instrument. These controls along with instrument features are illustrated

in Figures 7 and 8. A description of these controls and features is

provided in Tables 1 and 2.

8

Figure 7: Instrument controls and features—front view

(1) Foam Gasket

(2) Hood (2’ x 2’ shown)

(3) Handle (shown in top

position)

(7) Range Selector Switch

(8) Bezel

(5) Velometer Jr. Meter

(6) Zero Adjustment

(4) Lower Handle Position

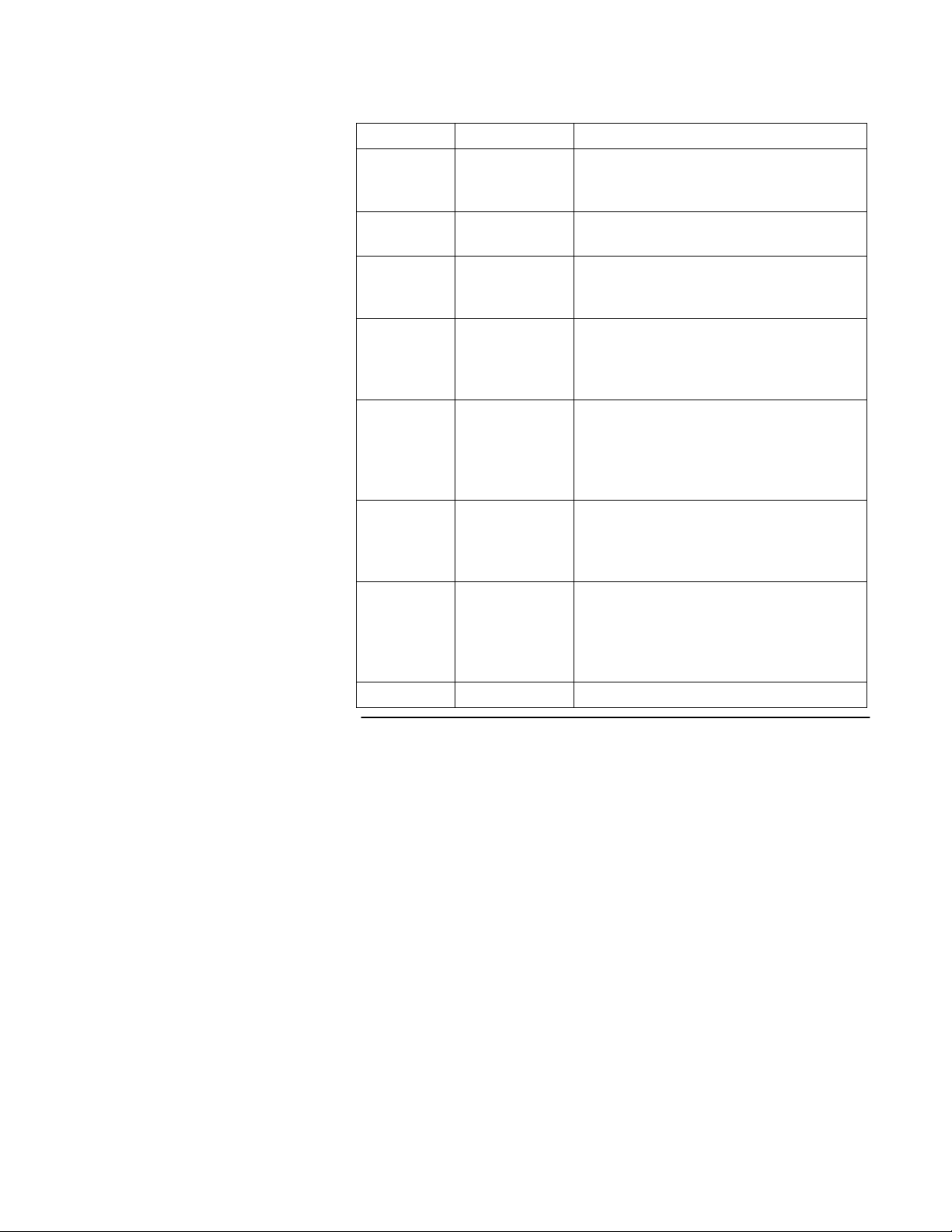

Index No.

Name

Description

1

Foam Gasket

This gasket is used to provide a good air

seal between the top of the hood and the

diffuser.

2

Hood

The hood captures the air and directs it

toward the manifold.

3

Handle (top

position)

Intended for use when the Balometer Jr. is

used in conjunction with a ladder. Allows

for easy one-hand support of unit.

4

Lower Handle

Position

Intended for use when the Balometer Jr. is

used without the aid of a ladder. Extended

reach allows easy access to many ceiling

diffusers while standing on floor.

5

Velometer Jr.

Meter

The meter is calibrated to provide flow

readings in either cubic feet per minute or

cubic meters per hour. Separate scales

corresponding to the position of the range

selector are provided.

6

Zero

Adjustment

Rotating this screw allows the meter to be

set at zero. This adjustment should only be

made with the range selector set to OFF and

with no airflow past the manifold.

7

Range Selector

Switch

The 7-position switch is used to select the

required flow range and operating mode

(supply or return). The OFF position

prevents flow from passing through the

meter.

8

Bezel

Covers range selector and meter system.

Table 1: Instrument controls and features description—front view

9

Index No.

Name

Description

1

Support Arms

These arms are used to support the hood.

They can be removed and folded for

packing.

2

Manifold

This plastic assembly is used to produce an

average of the air flow at the 16 intake and

exhaust points.

3

Manifold

Springs

These springs are used to hold the manifold

in position and absorb shocks during

transportation.

4

LoFlow

Adapter

Used for measuring low air volumes. The

screen should be placed against manifold

on side from which the air is entering.

Screen covers entire manifold; cut-away

view is for clarity only.

Figure 8: Instrument features—top view

(1) Support Arms

(2) Manifold

(3) Manifold Springs

(4) LoFlow Adapter

(Cut-away view)

10

Table 2: Instrument features—top view

Step By Step Operation

If the instrument has been stored at a temperature below 68°F (20°C) or

higher than 86°F (30°C) it should be allowed to stabilize at room

conditions (68°F to 86°F) in order to achieve specified accuracy.

1. Assemble the Balometer Jr. as described in the Preparation for Use

section of this manual.

2. Check the Velometer Jr. for zero adjustment by setting the range

selector to the 0 (OFF) position and verifying that the meter reads

zero. If

that the pointer

continue to read zero (within one division) regardless of how the unit

is

used.

3. Set the range selector to the highest range in the desired direction,

supply or return.

4. Bring the Balometer Jr. into contact with the perimeter of the diffuser

or grill to be measured. To assure maximum accuracy, the foam

gasket along the top of the frame must be firmly in contact with the

surface all around the opening. Take care to ensure that your body or

other material is not accidentally affecting the reading by blocking or

diverting the air flow at either the air entry or exit sides.

When using the Balometer Jr. to check air flow at ceiling diffusers,

make certain you can safely raise and hold the unit while making

measurement.

ladder. Make sure that the unit cannot be caught in moving

machinery.

5. If the reading is found to be below the full scale of the next lower

scale, the range selector may be switched to the next lower scale.

If the lowest (blue) scale is used, the Lo-Flow adapter screen must

be installed. See Preparation for Use section.

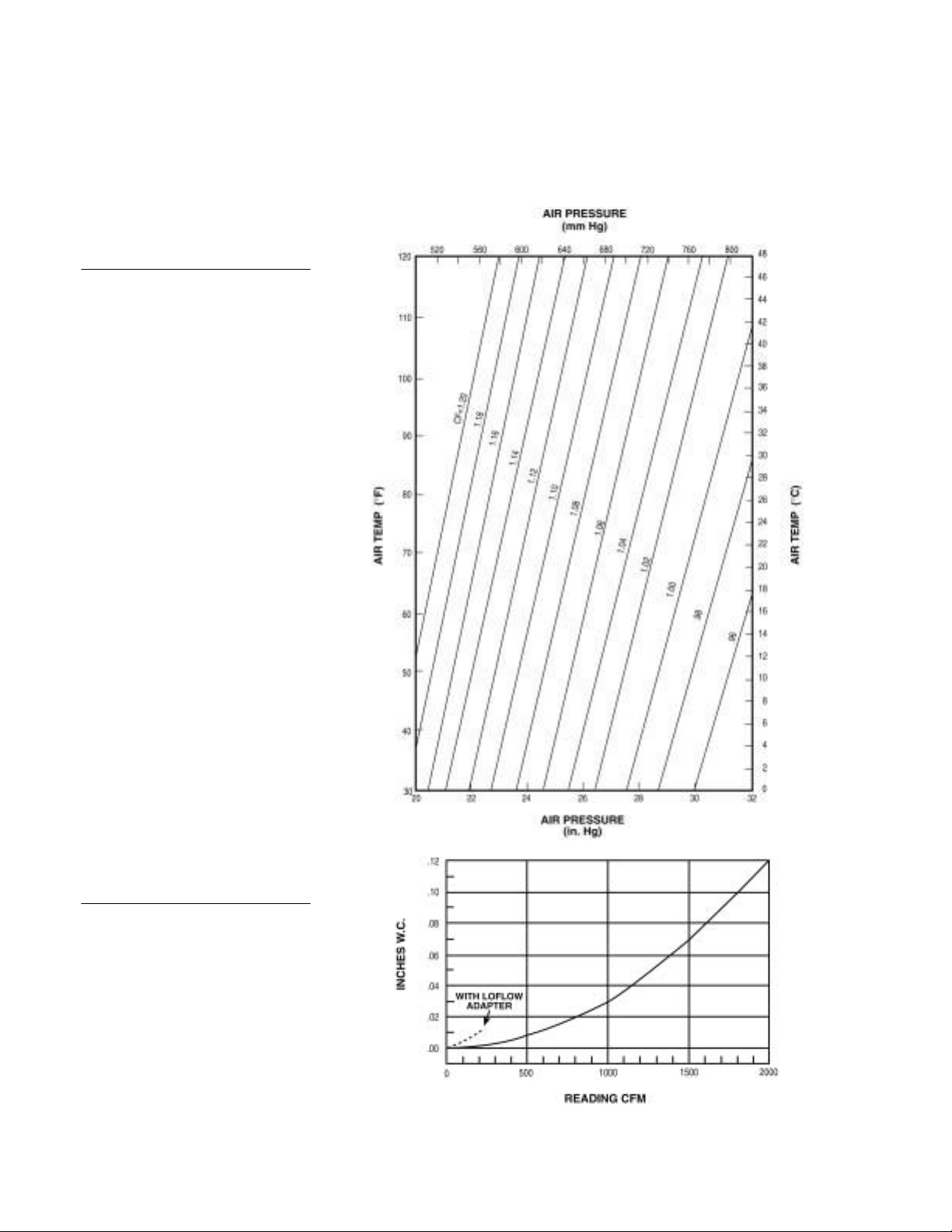

6. The reading from the Balometer Jr. is in cubic feet per minute or

cubic meters per hour, referenced to standard conditions of air

pressure and temperature (scfm or scmh). These standard conditions

are 70°F and 29.92 inches of mercury (21°C and 760 mm Hg). To

determine the true volume flow rate, multiply by the correction

factor shown in Figure 11. The correction factor is based on the static

pressure and air temperature at the manifold.

7. The additional system back pressure generated by the Balometer Jr.

may affect the output of an individual diffuser. Depending on system

design and balancing method, this may or may not be important.

When proportionally balancing a system of similar outlets, this is not

usually an important factor. If system design or other factors require

adjustment, Figure 12 is

necessary, use

held,

it is best to zero the meter in the position in which it will be

a small screwdriver to adjust the zero screw so

reads zero.

Although the meter will typically

This is especially important when working on a

included for

your reference.

the

11

Figure 9: Location of unit in

carrying case

12

REPACKING

The Balometer Jr. can be stored in the carrying case with either the 2' x 2'

or the optional 16" x 16" hood attached. The 16" x 16" hood may be

stored fully assembled, while the frame for the 2' x 2' hood must be

folded in half prior to storage. First, remove the handle by unscrewing it

from the top or bottom of the range selector/meter assembly. Store the

handle in its pocket on the left side of the carrying case.

Next, remove the hood support rods by gently pressing down on the rod

to compress the spring in the lower tube assembly, and release it from the

corner of the hood frame. Each of the four rods should be removed from

the base by gently pulling upward on the lower U-section until the lower

tube assembly is

free

from the square section on the base. The top solid

section of the rod should now be folded into the U-section if it is not

already placed there. This is accomplished by pushing the retainer

toward the end of the U-channel, swinging the center rod into the Uchannel, and then pushing the retainer back so that it holds the rod in

place.

Note: Use care not to pinch fingers when swinging rod closed. After all

four rods are closed, they should be placed in their pocket, at the rear of

the carrying case. The LoFlow adapter screen is simply pressed into

place on the top side of the base to secure it.

If storing the base with the 2' x 2' hood in place, the next step is to fold

the frame top. Fold the frame in half at its hinge points, being careful not

to pinch the hood material, and then wrap the material around the folded

frame assembly. The instrument base can now be placed in the case

(aligned so that range selector and meter fit into proper cut-out on left

side). The frame and hood can be placed around the sides and back so

that the short center sections fit into the pockets on the sides of the case.

See Figure 9.

If storing the base with the 16" x 16" hood in place, first make sure that

the 2' x 2' hood and frame is properly in place, with the center sections

located in the pockets along the sides of the carrying case. Next set the

base of the instrument into its pocket (aligned so that range selector and

meter fit into proper

frame in position, centered over base. See Figure 9.

cut-out on

the left side). Finally, place hood and

If the optional 16" x 16" hood is to be stored disassembled, first remove

the

hood

from the frame top by gently pulling the elastic cord out of its

channel, working your way around the entire top until the hood is free

from the frame. Next partially disassemble the frame top by pulling two

opposing

pieces in the

the base, and store

corner sections

foam cutout

the folded

apart, leaving two L-shaped pieces. Store these

to the left of the base, remove the hood from

hood by placing it under the base.

Before closing the case make sure that all items are securely in place, and

that no damage will occur.

PERFORMANCE

CHECK

When checking the performance of the Balometer Jr., first verify that the

unit has been properly adjusted to zero. If the calibration is to be

checked, a reference flow standard at least 5 times more accurate than the

Balometer Jr. should be used. Flow standards that may be used for this

purpose include orifice plates or laminar flow elements. These devices

require accurate pressure and temperature reading instruments to measure

actual flow volume.

If the Balometer Jr. is checked against a velocity standard such as a Pitotstatic probe or thermal anemometer, you should be aware that this may

introduce

errors.

If a velocity standard is used, the average velocity must

be obtained by taking a traverse.* The accuracy of the average reading is

dependent on the flow uniformity, the number of readings in the average

and the accuracy of

velocity reading must then be multiplied by the area over which

traverse

was taken. If this area is not accurately measured, additional

the velocity

reading instrument. This average

the

errors in the final flow volume reading will result.

Finally, air flow instrumentation is often dependent on environmental

conditions such as temperature, atmospheric pressure, humidity and even

turbulence. These conditions can have very different effects on various

instrument types. Caution must be exercised when making comparisons.

*

A traverse is a set of velocity readings taken in a prescribed geometric pattern which

will provide an overall velocity value when averaged together. Any of TSI’s velocity

measuring instruments can be used for this purpose. The owner’s manuals contain

instructions on how to perform the traverse.

13

CALIBRATION PROCEDURE

General

The Balometer Jr. is easily calibrated assuming that your calibration

facility has access to the proper equipment. Each range uses an easily set

single screw adjustment for calibration. However, the procedure should

be attempted only by persons who have the proper equipment. Note that

any attempt at recalibration voids all calibration certification provided

with instrument.

Equipment Required

Wind tunnel capable of providing controllable air flow in both supply

and exhaust directions from 50 to 1400 cfm (85 to 2400 cmh, 24 to

660 l/s); measurement standard for air volume in the same range;

measurement standard for air volume between 50 and 1400 cfm (85 to

2400 cmh, 24 to 660 l/s); 2' x 2' outlet air diffuser similar to ones

typically in use; 1/16" hex adjustment device at least 21/2" long (―ball end‖

device is useful).

The wind tunnel and measurement standard should be controllable and

accurate to within five times the accuracy of the scale being calibrated.

Preparation

1. Verify that there are no cracks in the manifold or leaks in the hoses

connecting the manifold to the range selector.

2. Connect wind tunnel, measurement standard, diffuser and Balometer

Jr. in such a way that the air which passes through the Balometer Jr.

has also passed through the measurement standard and diffuser.

Make sure there are no leaks in the system as any leaks will cause

errors in calibration.

3. Allow the Balometer Jr. and tunnel to stabilize at an air tem

between

68°F and 86°F (20–30°C) before attempting to calibrate the

instrument.

perature

Calibration

14

1. Set up Balometer Jr. with 2' x 2' hood.

2. Set up Balometer Jr. on wind tunnel so that air volume through unit

can be determined from measurement standard.

3. Turn off all air through Balometer Jr. and set range selector to OFF

position.

4. Using zero adjust screw, set Velometer Jr. meter to 0.

5. Turn on wind tunnel and set to 180 cfm (300 cmh, or 90 l/s).

Figure 10: Removing

meter/Range Selector unit

6. Set range selector for low range in proper direction for air flow

through the Balometer Jr. Install LoFlow adapter screen on the side

of the manifold against which the air pressure will be felt.

7. Insert hex adjustment tool into adjustment hole (See Figure 10),

adjust

until

meter reading agrees with wind tunnel setting, and then

remove adjustment tool. Also remove the LoFlow adapter.

8. Move range selector to mid range; set tunnel for 500 cfm (800 cmh,

250 l/s); adjust as in step 7 until meter reading agrees with wind

tunnel setting; then remove adjustment tool.

9. Move range selector to high range; set tunnel for 1200 cfm (2000

cmh, 600 l/s); adjust as in step 7 until meter reading agrees with

wind tunnel setting; then remove adjustment tool.

10. Verify calibration against standard as required.

11. Modify setup so that flow through Balometer Jr. is in opposite

direction. Again make sure there are no leaks in the system.

12. Repeat steps 5 through 10 for air flow in this direction.

Exchange of Calibrated Module

If complete calibration facilities are not available, you may exchange the

range selector/meter assembly for one calibrated at the factory. (See parts

list for proper item number.) You may maintain multiple selector/meter

assemblies if desired, to minimize down time between calibrations. To

separate the selector/meter assembly from the base, remove the

attachment screws (see Figure 10), and then carefully slide the hoses off

the manifold to remove the assembly. The hoses should then be removed

from the selector/meter assembly and saved with the screws for use in

reassembly. To reattach, slide the hoses on the selector/meter assembly

and then gently slide the hoses onto the manifold. Use the screws to

secure the assembly to the base. Make sure that the top manifold hose is

attached to the hose nipple on the range selector closest to the center of

the base. Also examine manifold to verify that there are no cracks or

other sources of leaks.

15

APPENDIX

A:

THEORY OF OPERATION

The Balometer Jr. is an adaptation of the Alnor Balometer and Velometer

Jr. systems which allow this instrument to be used for measurement of air

volume by reading average velocity as the air moves through a cross-

16

section of known constant dimension.

The Balometer Jr. consists of six major subassemblies which function as

a system to provide accurate air flow measurements:

1. Air Collection System—All the air issuing from or entering a

diffuser is collected through a cloth ―hood‖ which is chosen to fit a

specific diffuser at one end, and translates this variable size to a

standard opening which is slightly larger than one foot square. The

diffuser end of this hood is foam-edged to allow for a complete seal

around the opening.

2. Instrument Base—The base, in addition to housing the range

selector, manifold, and Velometer Jr., provides the standard crosssection through which the air is passed.

3. Manifold—This grid contains 16 calibrated holes in a 4 x 4 pattern

spaced within the standard base opening. It is actually two grids

back-to-back, with the pattern of holes in a separate network on each

side. Air can therefore enter the manifold from either side and be

discharged at

the

other. The amount of air which flow through the

manifold is directly proportional to the average velocity of the air

moving past the sensing holes. Therefore this velocity, which is

moving through a known cross-sectional area, is proportional to the

volume of air flow through the instrument.

4. Range Selector—By means of a single control, the range selector

provides for the measurement of air flow in either direction, and

provides calibrated orifices for three ranges, which effectively triples

the scale length of the meter. Accuracy of the measurement in either

direction is assured by providing similar flow paths regardless of

flow direction, and by separate calibration of each range in each

direction.

5. Velometer Jr.—TSI’s standard small swing vane anemometer is

provided with a special scale graduated either in standard cubic feet

per minute or standard cubic meters per hour. Because of the direct

proportion cited earlier, this velocity reading instrument can be

directly calibrated in volumetric terms.

6. LoFlow Adapter—This screen assembly makes use of the standard

area and velocity principles mentioned above. The adapter reduces

the effective area through which the air flows, causing a

corresponding increase in velocity past the manifold. The screen

blocks 50% of the standard

opening, increasing

the velocity to twice

the original. This means, for example, that with the adapter a volume

of 200 cfm will create the same velocity as 400 cfm without the

adapter. The lowest volume range on the Velometer Jr. is calibrated

to be used with the adapter, on the most sensitive range setting.

Note that the adapter provides higher sensitivity at low flow rates, but

can more easily upset the system being measured at flow rates above 125

cfm (200 cmh, 60 l/s) because of additional back pressure. It is therefore

suggested that measurements above these flows be taken without the

adapter.

17

APPENDIX

B:

MAINTENANCE AND TROUBLESHOOTING

18

Maintenance

Hoods

The hoods will last longer if hand washed periodically in cool water

with a mild detergent. When handling do not allow the cloth to come

in

contact with

puncture the material.

Static Electricity

Occasionally static electrical charges may be encountered, especially

in conditions of low humidity. If the Velometer Jr. will not hold a

zero setting, or gives erratic readings, it is suggested that you obtain

anti-static solution for use with the Balometer Jr. The solution may

be obtained from TSI as an accessory (see parts list on inside front

cover). To use, apply with a soft, lint-free cloth slightly moistened

with anti-static solution, rubbing gently over the outside surface of

the Velometer Jr. window.

Manifold

The manifold should be checked before using to be certain that the

sensing holes have not become clogged with dirt or dust particles.

Inspect for cracks which may cause air leaks. Also verify that a good

connection is made between the manifold and the range elector. The

manifold can be cleaned using mild detergent and warm water. Do

NOT immerse the entire manifold in water. It is recommended that

cleaning be done with the manifold in

Zero Adjustment

Periodically check that the Velometer Jr. pointer is at zero when the

range selector is off. If not, use the zero adjustment screw to bring

the pointer to zero in the position the instrument is used.

Calibration

Your Balometer Jr. may be returned to the factory for calibration, or

if proper facilities are available, may be calibrated using the

procedures outlined in the Calibration section of this manual.

When shipping the Balometer Jr. for factory recalibration, pack it

carefully, and follow the Instructions for Return in this manual.

sharp corners or other objects which can tear or

place,

and with extreme care.

Troubleshooting

Symptom

Possible Cause and Corrective

Action

Meter not at zero before use.

Velometer Jr. not adjusted. Use zero

adjustment screw.

Cannot zero meter.

Meter pointer not in balance. Return unit to

factory for rebalance.

Meter reading lower than

expected.

Hood frame not sealing properly around

diffuser or grill. Press hood evenly against

diffuser.

Hood torn. Replace, or repair tear with duct

tape or other non-porous material.

Range selector not properly set. Make sure

detent on switch is properly engaged.

Manifold is cracked. Replace manifold.

Manifold holes are plugged. Clean holes.

Meter/range selector out of calibration.

Recalibrate instrument.

LoFlow adapter not installed when using

lowest (blue) scale. Install adapter.

LoFlow adapter not close enough to

the manifold, or installed on wrong side

of manifold. (See Preparation for Use

section.)

Meter not indicating.

Range selector is switched to OFF. Position

switch to correct range.

Range selector incorrectly set. Position

switch to correct range.

Connection between manifold/range

selector/meter is broken. Repair.

Meter reading higher than

expected.

Meter/range selector out of calibration.

Recalibrate instrument.

LoFlow adapter mistakenly left installed.

19

Figure 11: Correction factors for

non-standard conditions

[Note: 1 (in. H20) x 7.36 (10-2)=

1 in. Hg]

Figure 12: Correction factors for

non-standard conditions

20

APPENDIX

FACTORS

STANDARD

C: CORRECTION

FOR NON-

CONDITIONS

REPAIR

INFORMATION

Contact TSI Incorporated before returning your Alnor Instrument to

factory.

See Instructions for Return. Follow the procedure carefully as it

will expedite processing. Failure to follow the procedure will/may cause

return of unit unrepaired. Send your instrument to the factory

transportation prepaid. To assure fast turnaround time, fill out this form

with as much detail as

RMA

Number

possible and

attach it to the instrument.

the

Instrument Model

Serial Number

Date

of

Purchase

Where Purchased

Describe

Malfunction

Describe Environment

Return Instrument to:

Nam

e

(Your name or company)

Address

Telephone

Address Correspondence to:

Name

Address

Telephone

21

Loading...

Loading...