TSI Incorporated 8587A Operation And Service Manual

LASER PHOTOMETER

MODEL 8587A

OPERATION AND SERVICE MANUAL

P/N 1980538, REVISION D

JULY 2015

LASER PHOTOMETER

MODEL 8587A

OPERATION AND SERVICE MANUAL

Introduction

1

Unpacking and

Setting Up the Laser

Photometer

2

Technical Description

3

Instrument Operation

4

Maintenance and

Service

5

Appendixes

Manual History

The following is a history of the Model 8587A Laser Photometer Operation

and Service Manual (Part Number 1980538).

Revision Date

A December 2005

B April 2008

C March 2009

D July 2015

iv

Warranty

Part Number

1980538 / Revision D / July 2015

Copyright

©TSI Incorporated / 2005-2015 / All rights reserved.

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA

Fax No.

651-490-3824

E-mail Address

particle@tsi.com

Limitation of Warranty

and Liability

(effective February 2015)

Seller warrants the goods, excluding software, sold hereunder, under normal use and service

as described in the operator's manual, to be free from defects in workmanship and material for

12 months, or if less, the length of time specified in the operator's manual, from the date of

shipment to the customer. This warranty period is inclusive of any statutory warranty. This

limited warranty is subject to the following exclusions and exceptions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other components

when indicated in specifications, are warranted for 90 days from the date of shipment;

b. Pumps are warranted for hours of operation as set forth in product or operator’s manuals;

c. Parts repaired or replaced as a result of repair services are warranted to be free from defects

in workmanship and material, under normal use, for 90 days from the date of shipment;

d. Seller does not provide any warranty on finished goods manufactured by others or on any

fuses, batteries or other consumable materials. Only the original manufacturer's warranty

applies;

e. This warranty does not cover calibration requirements, and seller warrants only that the

instrument or product is properly calibrated at the time of its manufacture. Instruments returned

for calibration are not covered by this warranty;

f. This warranty is VOID if the instrument is opened by anyone other than a factory authorized

service center with the one exception where requirements set forth in the manual allow an

operator to replace consumables or perform recommended cleaning;

g. This warranty is VOID if the product has been misused, neglected, subjected to accidental or

intentional damage, or is not properly installed, maintained, or cleaned according to the

requirements of the manual. Unless specifically authorized in a separate writing by Seller,

Seller makes no warranty with respect to, and shall have no liability in connection with, goods

which are incorporated into other products or equipment, or which are modified by any person

other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated

herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR PARTICULAR

PURPOSE OR MERCHANTABILITY IS MADE. WITH RESPECT TO SELLER’S BREACH OF

THE IMPLIED WARRANTY AGAINST INFRINGEMENT, SAID WARRANTY IS LIMITED TO

CLAIMS OF DIRECT INFRINGEMENT AND EXCLUDES CLAIMS OF CONTRIBUTORY OR

INDUCED INFRINGEMENTS. BUYER’S EXCLUSIVE REMEDY SHALL BE THE RETURN OF

THE PURCHASE PRICE DISCOUNTED FOR REASONABLE WEAR AND TEAR OR AT

SELLER’S OPTION REPLACEMENT OF THE GOODS WITH NON-INFRINGING GOODS.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR

BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES, INJURIES,

OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS BASED ON CONTRACT,

NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE) SHALL BE THE RETURN OF

GOODS TO SELLER AND THE REFUND OF THE PURCHASE PRICE, OR, AT THE

OPTION OF SELLER, THE REPAIR OR REPLACEMENT OF THE GOODS. IN THE CASE

OF SOFTWARE, SELLER WILL REPAIR OR REPLACE DEFECTIVE SOFTWARE OR IF

UNABLE TO DO SO, WILL REFUND THE PURCHASE PRICE OF THE SOFTWARE. IN NO

EVENT SHALL SELLER BE LIABLE FOR LOST PROFITS, BUSINESS INTERRUPTION, OR

ANY SPECIAL, INDIRECT, CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER

SHALL NOT BE RESPONSIBLE FOR INSTALLATION, DISMANTLING OR

REINSTALLATION COSTS OR CHARGES. No Action, regardless of form, may be brought

against Seller more than 12 months after a cause of action has accrued. The goods returned

under warranty to Seller's factory shall be at Buyer's risk of loss, and will be returned, if at all,

at Seller's risk of loss.

v

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are to our

customers, our service policy is designed to give prompt attention to any problems. If any mal-

function is discovered, please contact your nearest sales office or representative, or call TSI’s

Customer Service department at 1-800-874-2811 (USA) or (651) 490-2811.

LIABILITY, which contains the complete and exclusive limited warranty of Seller. This

LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or its terms

waived, except by writing signed by an Officer of Seller.

vi Model 8587A Laser Photometer

Laser Safety

W A R N I N G

The use of controls, adjustments, or procedures other than those

specified in this manual may result in exposure to hazardous optical

radiation.

W A R N I N G

Although the Laser Photometer is appropriate for monitoring inert

process gases such as nitrogen or argon, it should not be used with

hazardous gases such as hydrogen or oxygen. Using the Laser

Photometer with hazardous gases may cause injury to personnel and

damage to equipment.

Safety

This section provides instructions to ensure safe and proper operation and

handling of the Model 8587A Laser Photometer.

The Model 8587A Laser Photometer is a Class I laser-based instrument.

During normal operation, you will not be exposed to laser radiation.

However, you must take certain precautions or you may expose yourself to

hazardous radiation in the form of intense, focused visible light. Exposure

to this light can cause blindness.

Take these precautions:

Do not remove any parts from the Laser Photometer unless you are

specifically told to do so in this manual.

Do not remove the Laser Photometer housings or covers while power

is supplied to the instrument.

vii

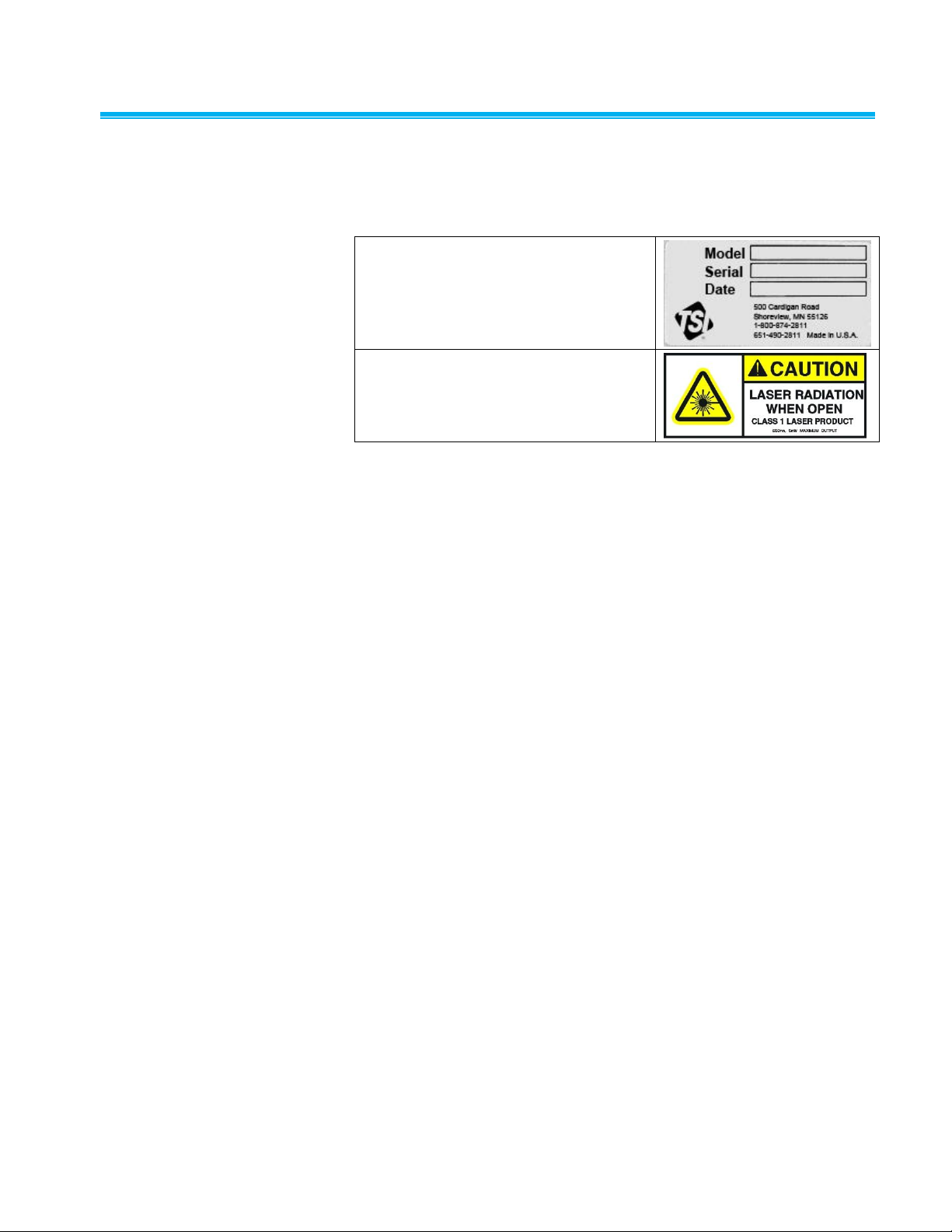

Description of Safety L a bels

C a u t i o n

Caution means be careful. It means if you do not follow the procedures

prescribed in this manual you may do something that might result in

equipment damage, or you might have to take something apart and start

over again. It also indicates that important information about the operation

and maintenance of this instrument is included.

W A R N I N G

Warning means that unsafe use of the instrument could result in serious

injury to you or cause irrevocable damage to the instrument. Follow the

procedures prescribed in this manual to use the instrument safely.

Warns you that uninsulated voltage within the instrument may

have sufficient magnitude to cause electric shock. Therefore,

it is dangerous to make any contact with any part inside the

instrument.

Warns you that the instrument contains a laser and that

important information about its safe operation and

maintenance is included. Therefore, you should read the

manual carefully to avoid any exposure to hazardous laser

radiation.

Warns you that the instrument is susceptible to electro-static

dissipation (ESD) and ESD protection procedures should be

followed to avoid damage.

Indicates the connector is connected to earth ground and

cabinet ground.

This section acquaints you with the advisory and identification labels on the

instrument and used in this manual to reinforce the safety features built into

the design of the instrument.

Caution

Warning

Caution or Warning Symbols

The following symbols may accompany cautions and warnings to indicate

the nature and consequences of hazards:

viii Model 8587A Laser Photometer

Labels

1. Serial Number Label (back panel)

2. Laser Radiation Label (located

internally on the optics housing)

Advisory labels and identification labels are attached to the outside of the

Laser Photometer housing and to the optics on the inside of the instrument.

Labels for the Model 8587A Laser Photometer are described below:

Safety ix

(This page intentionally left blank)

x Model 8587A Laser Photometer

Contents

Manual History ........................................................................................... iv

Warranty ...................................................................................................... v

Safety ......................................................................................................... vii

Laser Safety ......................................................................................... vii

Description of Safety Labels ................................................................ viii

Caution .............................................................................................. viii

Warning ............................................................................................. viii

Caution or Warning Symbols ............................................................ viii

Labels .................................................................................................... ix

Contents ..................................................................................................... xi

Figures ................................................................................................. xiii

Tables ................................................................................................. xiv

About This Manual ................................................................................... xv

Organization ......................................................................................... xv

Submitting Comments .......................................................................... xv

CHAPTER 1 Introduction ........................................................................ 1-1

Product Description ............................................................................. 1-1

How it Works ....................................................................................... 1-2

CHAPTER 2 Unpacking and Setting Up the Laser Photometer .......... 2-1

Unpacking ........................................................................................... 2-1

Packing List ..................................................................................... 2-1

AC Power Connection ......................................................................... 2-1

Vacuum Pump and Connection .......................................................... 2-2

Flow Check ...................................................................................... 2-2

Connecting the Sample Lines ............................................................. 2-3

CHAPTER 3 Technical Description ........................................................ 3-1

Cabinet ................................................................................................ 3-1

Front Panel .......................................................................................... 3-1

Keypad and LCD Display ................................................................. 3-1

Status Lights .................................................................................... 3-2

Back Panel .......................................................................................... 3-3

Upstream and Downstream Sample Ports ...................................... 3-4

Vacuum Port .................................................................................... 3-4

Analog Output BNC Connector ....................................................... 3-4

Serial Communications Port ............................................................ 3-5

USB Communication Port ................................................................ 3-5

Data Acquisition and Instrument Control ............................................ 3-6

Serial Communications Protocol ..................................................... 3-6

USB Communications ...................................................................... 3-6

USB Terminal Emulator Program .................................................... 3-6

Command Strings for Instrument Control and Data Acquisition ...... 3-7

Hex Data Retrieval ........................................................................... 3-8

Decimal Data Retrieval .................................................................... 3-8

DATA Averaging .............................................................................. 3-9

xi

Programming Note .......................................................................... 3-9

Flow System ....................................................................................... 3-9

Vacuum Pump .................................................................................... 3-9

Sensor (Scattering Chamber) ........................................................... 3-11

Laser Photometer Electronics........................................................... 3-13

Internal Instrument Components ...................................................... 3-14

Sensor Assembly ........................................................................... 3-15

Filters ............................................................................................. 3-15

Solenoid Valves ............................................................................. 3-15

Pressure Transducer ..................................................................... 3-16

Electronics Boards ......................................................................... 3-16

CHAPTER 4 Instrument Operation ........................................................ 4-1

Turning on the Laser Photometer ....................................................... 4-1

Keypad Pushbuttons ........................................................................... 4-1

Vacuum Pump Requirements ............................................................. 4-2

Connecting Sample Lines ................................................................... 4-3

Flow Setup .......................................................................................... 4-3

Fit Test Chamber Requirements ........................................................ 4-3

Performing Fit Tests ........................................................................... 4-4

Test Control ..................................................................................... 4-4

Performing a Fit Test Manually ....................................................... 4-4

Fit Test Under Computer Control .................................................... 4-5

Filter Testing Aerosol .......................................................................... 4-6

Performing a Filter Test ...................................................................... 4-7

CHAPTER 5 Maintenance and Service .................................................. 5-1

Filter Replacement .............................................................................. 5-1

Filter Replacement Instructions ....................................................... 5-2

Sensor Contamination ........................................................................ 5-2

Changing Sample Flow ....................................................................... 5-3

Technical Contacts ............................................................................. 5-4

Returning the Laser Photometer for Service ...................................... 5-5

APPENDIX A Specifications .................................................................. A-1

APPENDIX B Laser Photometer CD ..................................................... B-1

Accessing the Laser Photometer CD ................................................ B-1

USB Terminal Emulator Program ...................................................... B-2

Installing the USB Terminal Emulator ............................................ B-2

Connecting USB for the First Time .................................................... B-7

Installation Issues That May Arise ................................................ B-10

Stopping the Device ..................................................................... B-10

Uninstalling the Device ................................................................. B-10

Driver File Locations ..................................................................... B-10

Starting the Program .................................................................... B-11

Listing Available Devices .............................................................. B-11

Connecting to a Device ................................................................ B-11

Sending Commands ..................................................................... B-12

Disconnecting ............................................................................... B-12

Saving Input and Output ............................................................... B-12

Setting Timeouts ........................................................................... B-13

Setting the Buffer Size .................................................................. B-13

xii Model 8587 Laser Photometer

APPENDIX C Technical Information for Program Development

Using USB Communications .......................................................... C-1

Locating the Header File .................................................................... C-1

Locating the Library ........................................................................... C-2

Locating the Dynamic Link Library File .............................................. C-2

Using the Library ................................................................................ C-2

Error Values and Interpretation .......................................................... C-2

Troubleshooting Win32 Errors ........................................................ C-3

USB Command Status Errors ......................................................... C-4

Device Operation ............................................................................... C-4

Windows Registry Settings ................................................................ C-5

Connecting to the Attached Device.................................................... C-5

ListDevices...................................................................................... C-5

DeviceOpen .................................................................................... C-6

Communicating with the Attached Device ......................................... C-7

TsiUsbTerminalTransmit ................................................................. C-7

TsiUsbTerminalReceive .................................................................. C-8

Retrieving Error Strings .................................................................... C-10

TsiUsbGetStatusString ................................................................. C-10

TsiUsbGetWin32String ................................................................. C-11

Closing the Connection .................................................................... C-11

DeviceClose .................................................................................. C-11

Index

Reader’s Comments Sheet

Figures

1-1 Model 8587A Laser Photometer ....................................................... 1-2

3-1 Back Panel of the Model 8587A Laser Photometer .......................... 3-3

3-2 Serial Communications Port .............................................................. 3-5

3-3 Flow Schematic Model 8587A Laser Photometer ........................... 3-10

3-4 Sheath Air Flow System .................................................................. 3-12

3-5 General Location of Internal Components of the

Model 8587A Laser Photometer .................................................... 3-14

B-1 Introduction Screen .......................................................................... B-2

B-2 TSI USB Device Driver InstallShield Wizard Screen ....................... B-3

B-3 License Agreement Screen ............................................................. B-4

B-4 Choose Destination Location Screen .............................................. B-4

B-5 Begin Installation Screen ................................................................. B-5

B-6 Setup Status Screen ........................................................................ B-5

B-7 InstallShield Wizard Complete Screen ............................................ B-6

B-8 TSI USB Terminal Shortcut Icon ...................................................... B-6

B-9 Found New Hardware Wizard Screen ............................................. B-7

B-10 Hardware Wizard Installing Software ............................................... B-8

B-11 Unsigned Driver Warning Screen .................................................... B-8

B-12 Please Wait While Wizard Installs Software Screen ....................... B-9

B-13 Completing the Found New Hardware Wizard Screen .................... B-9

B-14 Terminal Program Screen .............................................................. B-11

B-15 Saving Input and Output ................................................................ B-12

Contents xiii

Tables

B-16 Set Device Timeout Screen ........................................................... B-13

B-17 Set Polling Buffer Size Screen ...................................................... B-13

2-1 Model 8587A Laser Photometer Packing List ................................... 2-1

3-1 Pin Function for Serial Communications Port ................................... 3-5

3-2 Laser Photometer ASCII Command Strings ..................................... 3-7

4-1 Example Fit Test Sequence .............................................................. 4-6

5-1 Filter Replacement Schedule ............................................................ 5-1

A-1 Model 8587A Laser Photometer Specifications .............................. A-1

xiv Model 8587 Laser Photometer

Organization

About This Manual

The following is a guide to the organization of this manual:

Chapter 1: Introduction

Describes the instruments and provides a brief overview of operation.

Chapter 2: Unpacking and Setting Up the Laser Photometer

Describes the unpacking of the instrumentation, physical setup of the

Laser Photometer, connection of sampling and vacuum line tubing.

Chapter 3: Technical Description

Provides significant detail on instrument components.

Chapter 4: Instrument Operation

Provides a guide to using the instrument for respirator fit tests and filter

testing.

Chapter 5: Maintenance and Service

Provides a guide to instrument maintenance and service.

Appendix A: Specifications

Provides instrument specifications.

Appendix B: Laser Photometer CD

Provides useful information and describes the software programs for

expanding the functionality of the instrument.

Appendix C: Technical Information for Program Development

Using USB Communications

Describes the software development library found on the Model 8587A

Laser Photometer CD-ROM supplied with the instrument.

Submitting Comments

TSI values your comments and suggestions on this manual. Please use

the comment sheet on the last page of this manual to send us your opinion

on the manual’s usability, to suggest specific improvements, or to report

any technical errors. If the comment sheet has already been used, please

mail your comments on another sheet of paper to:

TSI Incorporated

Particle Instruments

500 Cardigan Road

Shoreview, MN 55126

Fax: (651) 490-3824

E-mail Address: particle@tsi.com

xv

(This page intentionally left blank)

xvi Model 8587A Laser Photometer

C H A P T E R 1

Introduction

This chapter contains an introduction to the Model 8587A Laser

Photometer and provides a brief explanation of how the instrument

operates.

Product Description

The Model 8587A Laser Photometer measures aerosol concentrations for

determining the fit factor of particle protection respirators, and for

determining air filter efficiency.

To perform a fit factor test or filter efficiency test, aerosol is sampled from

two separate sampling ports. The sample ports are found at the back of the

instrument labeled UPSTREAM and DOWNSTREAM. When the Model

8587A is used for fit testing, the UPSTREAM port is used to sample

aerosol from the test chamber. The DOWNSTREAM port is used to sample

aerosol from within the mask.

For filter efficiency testing, the UPSTREAM port samples aerosol before it

passes through the filter, the “challenge aerosol”. The DOWNSTREAM port

is used to sample the aerosol concentration after passing through the filter.

The Model 8587A Laser Photometer sensor has special features which

make it unique from older light scattering devices using white light as their

light source. These features have dramatically improved sensitivity,

simplified operation and reduced maintenance. The special features of the

sensor are listed below:

Solid-state laser diode light source and photodiode detector

45 degree off-axis light collection angle

Sheath-air flow design

Fast purge mode capability

Microprocessor driven

Automatic gain selection (six decades)

Remote operation capability using a computer

Front panel switch for selecting between two sampling ports,

Downsteam and Upstream.

1-1

How it Works

Figure 1-1

Model 8587A Laser Photometer

The Model 8587A Laser Photometer determines aerosol concentration by

measuring the level of scattered light produced by aerosol particles as they

are passed through a collimated laser beam in the aerosol sensor

assembly. Scattered light is collected by a photosensitive detector, and a

voltage signal is produced. This signal, minus a small voltage offset, is

proportional to the aerosol mass concentration.

The Laser Photometer transmits signal voltage readings to the front panel

LCD display in scientific notation. Voltages can be accessed by a computer

too, connected to the RS-232 Serial or USB connectors using a

communications cable. Computer control enables automated respirator fit

and filter testing, in addition to other applications.

1-2 Model 8587A Laser Photometer

Unpacking

C H A P T E R 2

Unpacking and Setting

Up the Laser

Photometer

Use the information in this chapter to unpack the Model 8587A Laser

Photometer and set it up.

The following instruments and accessories comprise the Model 8587A

Laser Photometer.

Packing List

Table 2-1 shows the components shipped with your Model 8587A Laser

Photometer.

Table 2-1

Model 8587A Laser Photometer Packing List

Qty. Description Part No.

1 Operation manual 1980538

1 Power cord 110-120V 1303053

220-224V 1303075

1 Exhaust filter 1602230

1 Purge air filter 1602094

1 Sheath air filter 1602051

1 9-pin serial interface cable 6-foot 962002

1 6-foot USB interface cable 1303740

1 CD with USB terminal program 1031502

AC Power Connection

The Laser Photometer uses an on-board power supply capable of

operating with supplied AC power in the range of 100–240 VAC and

50-60 Hz. A detachable power cord is provided and is connected at the

cabinet back. Plug the power cord into a suitable voltage source.

2-1

Vacuum Pump and Conne c tion

N o t e

Stable airflows are extremely important in obtaining repeatable test

results. TSI strongly suggests the instrument be operated with a vacuum

greater than 55 kPa (8.0 psi). At a vacuum of greater than 55 kPa

(8.0 psi) an internal critical orifice limits and stabilizes the sample airflow

to 2.0 L/min (0.07 cfm). Repeatable test results will ONLY be obtained

with stable sample airflows.

The Laser Photometer requires the use of a high vacuum pump, sufficient

to draw >2 L/min (.07 cfm) at 55 kPa (8 psi) vacuum pressure and provide

a free flow of between 12 and 30 L/min (0.43–1.1 cfm).

The vacuum pump is connected to the back of the instrument at the

6.4 mm (¼ in.) tube connection labeled VACUUM. Use a plastic tube to

connect from the vacuum inlet port on the pump to the instrument. Use

tubing which will not collapse under the vacuum load >55 kPa (8 psi).

Flow Check

The Model 8587A verifies the airflow provided by an external vacuum

pump by monitoring the vacuum during upstream and downstream sample

modes. This ensures that a critical pressure is maintained during sampling,

and in turn, a critical airflow for sampling. An operating pressure and

airflow of >55 kPa at 2 L/min (8.0 psi at 0.07 cfm) are recommended. The

minimum vacuum and airflow required is 30 kPa at 1.79 L/min. (4.4 psi at

0.063 cfm) but at the minimum vacuum and airflow, the test data will not be

repeatable.

When the vacuum is greater than 30 kPa (4.4 psi), the FLOW STATUS

light on the front panel turns ON. An illuminated FLOW STATUS light

indicates proper operation. If the FLOW STATUS is BLINKING, the

vacuum is not sufficient and less than 30 kPa (4.4 psi). If the FLOW

STATUS is not ON or BLINKING, first check to make sure the unit is

operating in the UPSTREAM or DOWNSTREAM modes. The FLOW

STATUS is not functional in the PURGE mode. Second, check that there

are no leaks in the vacuum line. Third, if more than one Laser Photometer

shares the same vacuum source, make sure all instruments are connected

and none are in PURGE mode. If one instrument is in the PURGE mode, a

minimum vacuum of 30 kPa (4.4 psi) will not be maintained to the other

instruments.

To independently verify the vacuum, place the Laser Photometer in the

UPSTREAM mode and connect a vacuum gauge to a tee placed in the

vacuum line. If a differential gauge is used, connect to the low pressure

port of the gauge to the vacuum line. TSI strongly recommends a vacuum

of greater than 55 kPa (8 psi). The minimum vacuum must be greater than

30 kPa (4.4 psi).

2-2 Model 8587A Laser Photometer

Connecting the Sample L i n e s

Upstream and Downstream sample lines must be connected at the back of

each Laser Photometer. Tube stubs for tubing connections are labeled

accordingly; UPSTREAM and DOWNSTREAM. Clear ID 4.8 mm (316 in.)

vinyl tubing is recommended for the sample lines. The tubing must be

pushed completely over each tube stub. A touch of silicone grease applied

to the outside of the tube stub will simplify the connection.

Unpacking and Setting Up the Laser Photometer 2-3

(This page intentionally left blank)

2-4 Model 8587A Laser Photometer

Cabinet

C H A P T E R 3

Technical Description

This chapter identifies the basic features of your Model 8587A Laser

Photometer and provides general technical information. Detailed

instrument specifications are provided in Appendix A.

Cabinet dimensions (WDH): 17.8 cm 33.0 cm 25.4 cm

(7 in. 13 in. 10 in.)

Cabinet weight: 5.5 kg (12 lb.)

Front Panel

Front panel features include a 2-line liquid crystal display (LCD), a 3-button

membrane keypad and instrument status lights. The display presents the

photometer signal voltage and indicates the current operation mode, i.e.,

UPSTREAM, PURGE, DOWNSTREAM.

The keypad control buttons are found under the display and are used to

select the sampling mode indicated on the button face, UPSTREAM,

DOWNSTREAM, and PURGE. When sampling upstream or downstream,

the instrument draws sample from the respective sample port at the back

of the Laser Photometer (see the following section). When the photometer

is in the PURGE mode, particle free air is drawn at a high airflow rate into

the photometer’s laser optics chamber and through the purge air filter

shown in the schematic of Figure 3-3.

Keypad and LCD Display

The keypad enables manual switching for sampling from the different

sample ports (UPSTREAM and DOWNSTREAM) and to place the

instrument in a PURGE mode. The keypad buttons are labeled as to

function, UPSTREAM, UPSTREAM, and PURGE.

Note: When switching between UPSTREAM and DOWNSTREAM it is

necessary to pass through the PURGE mode by pressing the

PURGE keypad button.

3-1

Status Lights

OFF

During the PURGE mode, the FLOW STATUS is not

functional and will be off.

If the FLOW STATUS light is OFF during the UPSTREAM

or DOWNSTREAM modes, the instrument is

malfunctioning.

ON

An illuminated FLOW STATUS light indicates proper

operation.

The FLOW STATUS light is illuminated during the

UPSTREAM and DOWNSTREAM sampling modes if

more than 30 kPa (4.4 psi) of vacuum is being supplied to

the respective sample port. 30 kPa (4.4 psi) is the

minimum vacuum needed to obtain the sample airflow for

proper measurements.

BLINKING

A blinking FLOW STATUS light indicates the UPSTREAM

or DOWNSTREAM vacuum is less than what is required

to obtain proper measurements. The FLOW STATUS

light will blink if the UPSTREAM or DOWNSTREAM

vacuum is less than 30 kPa (4.4 psi). If the FLOW

STATUS light is blinking, check for leaks in the vacuum

system or a faulty vacuum pump.

The POWER light indicates the instrument is ON or OFF. An illuminated

POWER light indicates the power is ON.

The FLOW STATUS light has three indications.

3-2 Model 8587A Laser Photometer

(continued on next page)

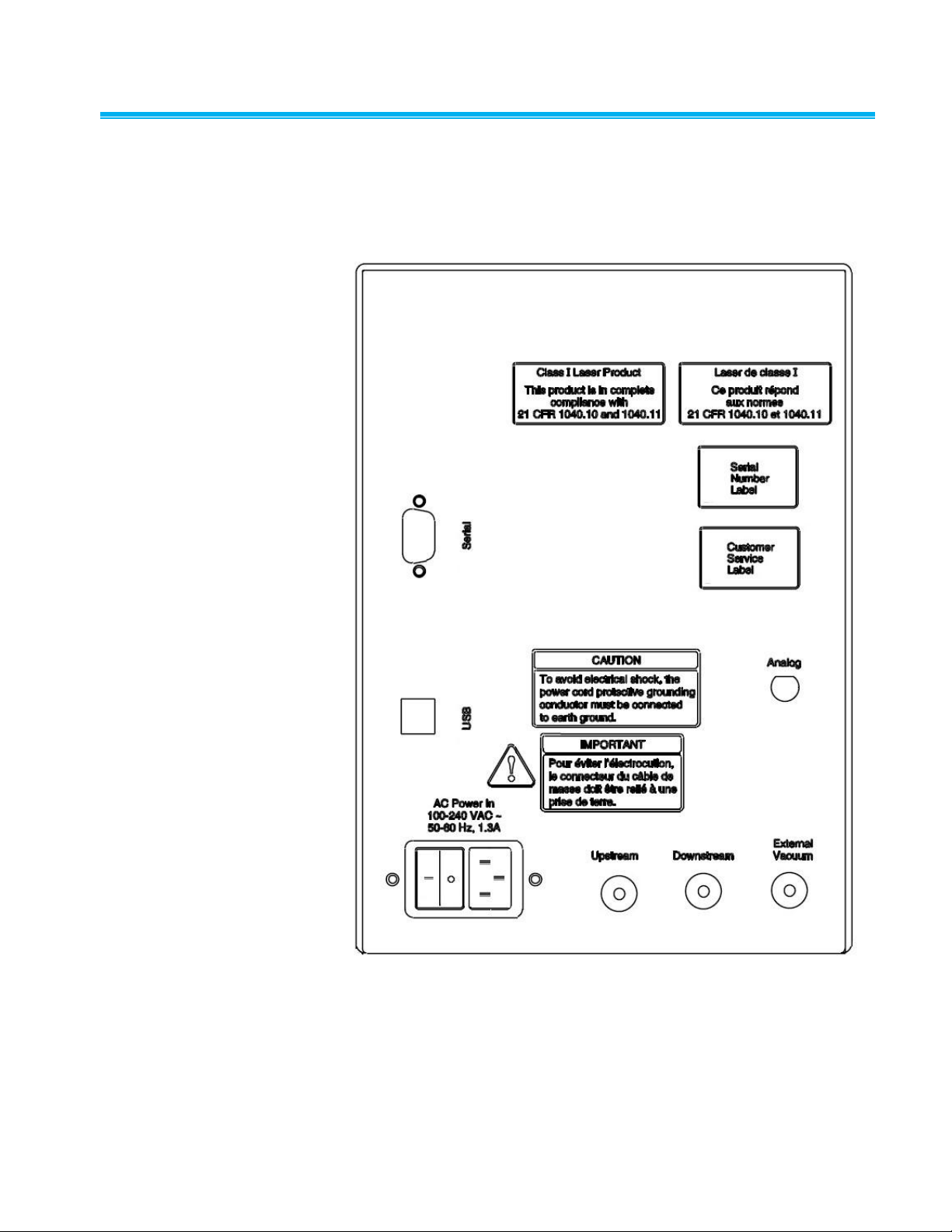

Back Panel

1 Upstream and downstream sample ports

4. 9-PIN D-type female serial connector

2. Port for external vacuum pump connection

5. USB type B connector

3. Power connection

6. Analog voltage BNC connector

The photometer back panel contains the DOWNSTEAM and UPSTREAM

sample and VACUUM ports, the AC power connection/main power switch,

the RS-232 serial port connection, the USB connection, the cabinet cooling

fan, and the analog output BNC connector. The back panel is shown

below:

Figure 3-1

Back Panel of the Model 8587A Laser Photometer

Technical Description 3-3

Upstream and Downstream Sample Ports

N o t e

Stable airflows are extremely important in obtaining repeatable test

results. TSI strongly suggests the instrument be operated with a vacuum

greater than 55 kPa (8.0 psi). At a vacuum of greater than 55 kPa

(8.0 psi), an internal critical orifice limits and stabilizes the sample airflow

to 2.0 L/min (0.07 cfm). Repeatable test results will ONLY be obtained

with stable sample airflows.

Internally the DOWNSTREAM and UPSTREAM sample ports are

connected via plastic tubing to a three-way solenoid valve that switches to

control which port is used.

Tubing is connected from the UPSTREAM sample port to a chamber or the

challenge aerosol side of a filter holder when performing quantitative

respirator fit testing or filter testing.

Tubing is connected from the DOWNSTREAM sample port to a mask or

downstream of the filter when performing fit testing or filter testing,

respectively.

Switching between sample ports is achieved manually by pressing the

appropriate front panel keypad button, or through the RS-232 or USB

interface connectors using computer control codes. It is necessary to select

PURGE as an intermediate step when switching between sampling modes.

Vacuum Port

A vacuum source (vacuum pump) is required to draw the sample airflow

into the photometer scattering chamber. The vacuum pump is connected to

the port labeled VACUUM on the back panel using flexible tubing pushed

over the tube stub. Tubing must be sufficiently rigid so it does not collapse

under the vacuum load.

The instrument is designed for a vacuum of >55 kPa (8 psi) which results in

a very stable sample airflow of 2 L/min (0.071 cfm). TSI strongly

recommends operation with a vacuum greater than 55 kPa (8.0 psi) in

order to obtain repeatable test results. The instrument will function with a

minimum vacuum and airflow of 30 kPa @ 1.79 L/min (4.4 psi @ 0.063

cfm) but the test data may not be repeatable.

Analog Output BNC Connector

The BNC electrical connector on the back panel can be used to monitor the

analog voltage from the Laser Photometer sensor. The output is 0–10 volts

at the minimum detector gain setting. The output has a limited usefulness

at lower signal voltages. Resolution is limited to .01 volts.

3-4 Model 8587A Laser Photometer

Loading...

Loading...