Indoor Air Quality

Q-T

Operation and Service Manual

Model 8550/8551

RAK

TM

IAQ Monitor

1980197, Revision K

October 2002

Model 8550/8551

™

Q-TRAK

IAQ Monitor

Operation and Service

Manual

October 2002

P/N 1980197, Rev. K

SHIP/MAIL TO:

TSI Incorporated

500 Cardigan Road

Shoreview, MN 55126-3996

USA

U.S.

Sales & Customer Service:

(800) 874-2811/(651) 490-2811

Fax:

(651) 490-3824

Sales & Customer Service:

E-mail address:

answers

http://www.tsi.com

INTERNATIONAL

(001 651) 490-2811

(001 651) 490-3824

@tsi.com

Web site:

Fax:

Copyright ©

TSI Incorporated / October 1997–2002 / All rights reserved.

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA

Fax No.

(651) 490-3824

Limitation of Warranty and Liability

Seller warrants the goods sold hereunder, under normal use and service as described in the

operator's manual, shall be free from defects in workmanship and material for twenty-four (24)

months, or the length of time specified in the operator's manual, from the date of shipment to the

customer. This warranty period is inclusive of any statutory warranty. T his limited warranty is

subject to the following exclusions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other

components when indicated in specifications, are warranted for 90 days from the date of

shipment.

b. Parts repaired or replaced as a result of repair services are warranted to be free from

defects in workmanship and material, under normal use, for 90 days from the date of

shipment.

c. Seller does not provide any warranty on finished goods manufactured by others or on any

fuses, batteries or other consumable materials. Only the original manufacturer's warranty

applies.

d. Unless specifically authorized in a separate writing by Seller, Seller m a kes no warranty

with respect to, and shall have no liability in connection with, goods which are

incorporated into other products or equipment, or which are modified by any person other

than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated

herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR

BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES,

INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS BASED

ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE) SHALL

BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE PURCHASE

PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR REPLACEMENT OF THE

GOODS. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE

RESPONSIBLE FOR INSTALLATION, DISMANTLING OR REINSTALLATION COSTS

OR CHARGES. No Action, regardless of form, may be brought against Seller more than 12

months after a cause of action has accrued. The goods returned under warranty to Seller's

factory shall be at Buyer's risk of loss, and will be returned, if at all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND

LIABILITY, which contains the complete and exclusive limited warranty of Seller. This

LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or its terms

waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are to our

customers, our service policy is designed to give prompt attention to any pr oblems. If any

malfunction is discovered, please contact your nearest sales office or representative, or call TSI's

Customer Service department at (800) 874-2811 (USA) or (001 651) 490-2811 (International).

CONTENTS

1. UNPACKING AND PARTS IDENTIFICATION ............................1

Unpacking the Q-T

RAK ..................................................................1

Parts Identification for the Q-TRAK ................................................2

2. SETTING-UP................................................................................. 3

Supplying Power to the Q-T

RAK .................................................... 3

Installing the Batteries.............................................................3

Using the AC Adapter............................................................. 3

Instrument Setup........................................................................... 3

Setting-up

TRAKPRO Data Analysis Software.......................... 3

Connecting the Q-TRAK to a Computer................................... 3

Set-Up the Communications Port........................................... 4

Setting the Real-Time Clock...................................................5

Programming the Date/Time Using TrakPro ..........................5

Manually Setting the Real-Time Clock ...................................6

Using the Probe Stand............................................................ 6

Connecting the Optional Model 8925 Portable Printer........... 6

3. OPERATION................................................................................. 7

Overview........................................................................................ 7

Keypad Functions.......................................................................... 7

ON/OFF Key..................................................................................7

Key......................................................................................... 8

CO

2

TEMP Key .....................................................................................8

HUMIDITY Key.............................................................................. 9

CO Key (Model 8551 Only)........................................................... 9

SAMPLE Key.................................................................................9

TIME CONSTANT Key.................................................................. 9

Programming the Available Time Constants...............................10

STATISTICS Key.........................................................................10

PRINT Key................................................................................... 11

SAMPLING MODE Key............................................................... 11

Survey Mode:........................................................................11

LOG Modes:.......................................................................... 12

CLEAR MEMORY Key................................................................12

LOGGING INTERVAL Key..........................................................12

Programming the Logging Intervals Using TRAKPRO ...............13

! and " Keys............................................................................. 14

Display/Keypad Lockout Switch.................................................. 14

Programming Advanced Modes: LOG 2 and LOG 3 ..................14

Sample Protocol for LOG 2 and LOG 3 Modes ..........................18

i

Things You Should Know About Taking Pre-Programmed

Samples ...................................................................................19

Memory Considerations...............................................................20

4. CALIBRATION AND MAINTENANCE.......................................21

Calibrating the CO

Concentration Measurement.......................21

2

Calibrating the Temperature or Relative Humidity

Measurement ...........................................................................23

Calibrating the CO Concentration Measurement

(Model 8551 only).....................................................................24

Replacing the CO Sensor............................................................26

Storage Precautions....................................................................27

5. TROUBLESHOOTING................................................................29

APPENDIX A: SPECIFICATIONS.....................................................31

APPENDIX B: INTERNAL DIP SWITCH SETTINGS.......................35

ii

Chapter 1

Unpacking and Parts Identification

Carefully unpack the Q-T

Use the tables and illustrations below to make certain that there are no

missing components. Contact TSI immediately if anything is missing or

damaged.

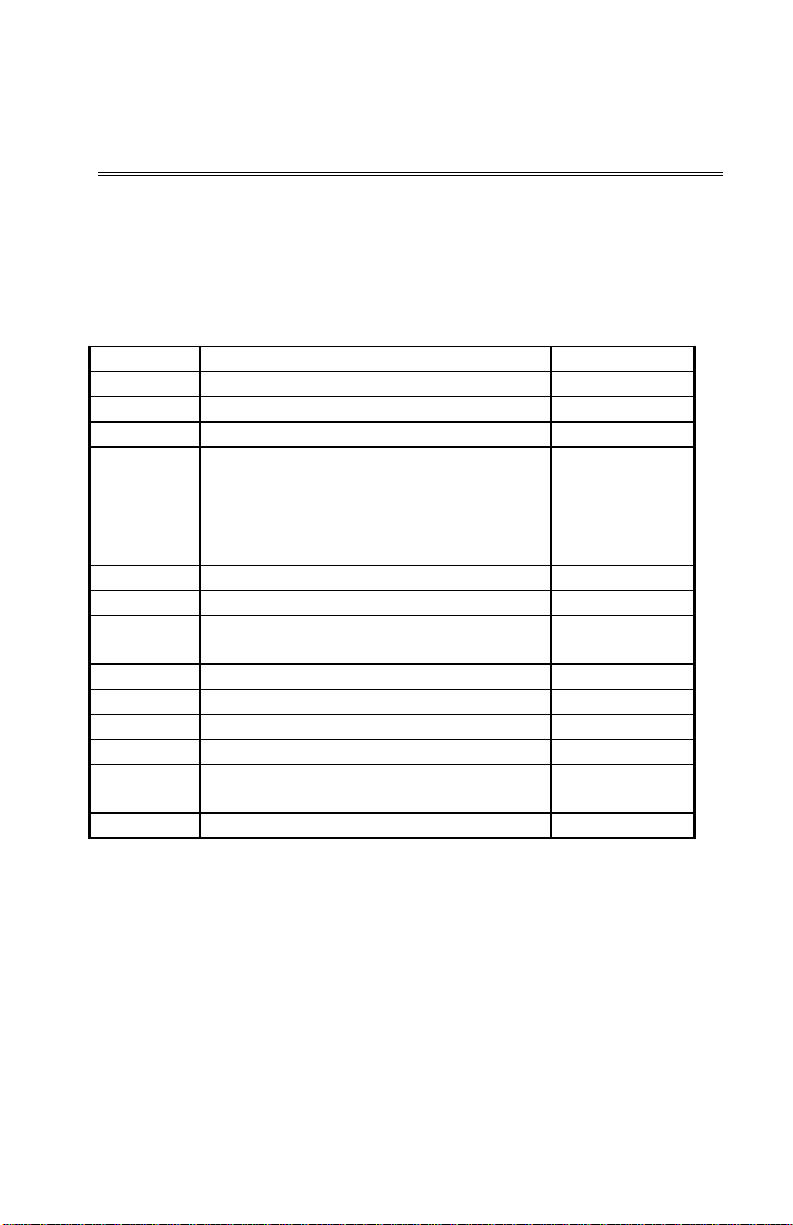

Packing List for the Model 8550/8551 Q-T

Quantity Item Description Part/Model

1 Q-TRAK IAQ Monitor 8550/8551

1 Carrying Case 800680

4 AA Alkaline Batteries 1206013

1 AC Adapter

115 V, NEMA-5

230 V, Eur., CEE 7/16

230 V, Great Britain

240 V, Australian

1 TRAKPRO Data Analysis Software 800700

1 CO2 Calibration Collar 800678

1 CO Calibration Adapter (Model 8551

only)

1 CO Sensor (Model 8551 only) 800695

1 Probe Stand 800679

1 Computer Interface Cable (RS-232) 800560

1 25-Pin to 9-Pin Serial Cable Adapter 1302690

1 Q-TRAK IAQ Monitor Operation and

Service Manual

1 Certificate of Calibration -

RAK IAQ Monitor from the shipping container.

RAK IAQ Monitor

2613033

2613078

800169

2613105

800696

1980197

1

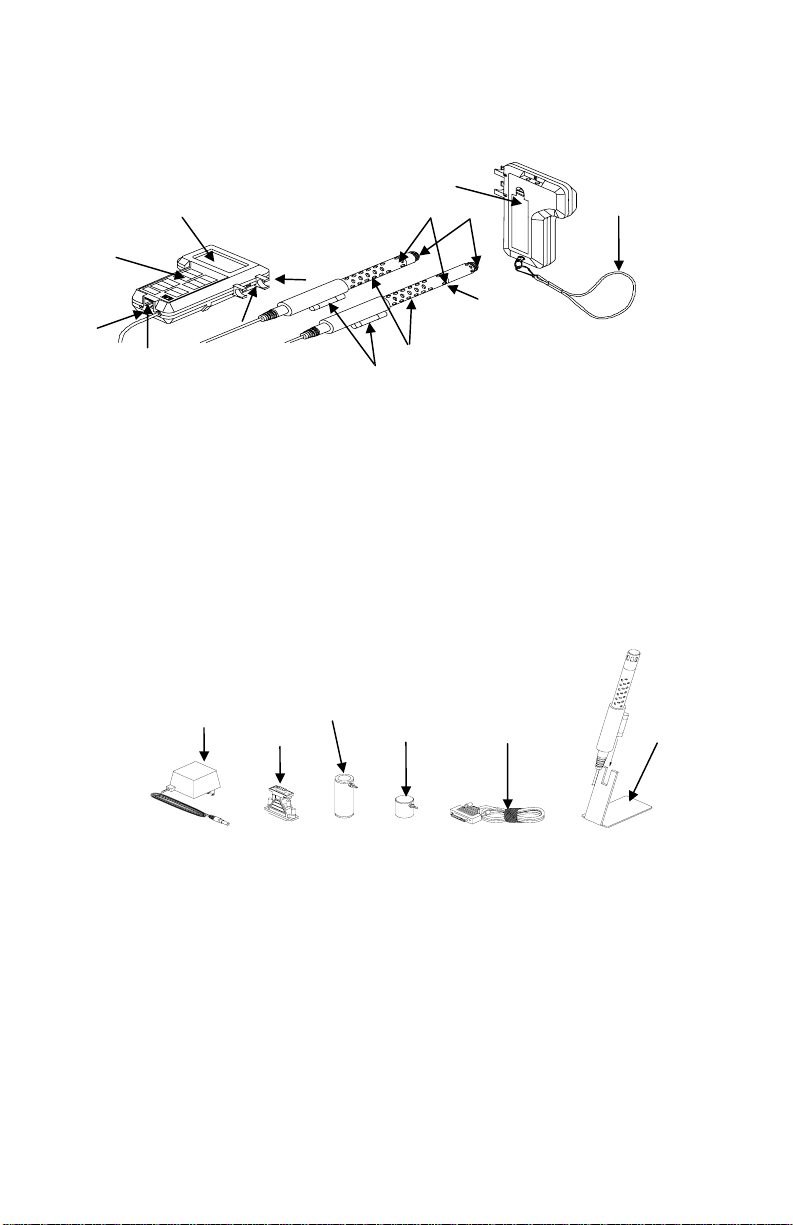

Parts Identification for the Q-T

Figures 1–1 and 1–2 identify the parts of the Q-T

RAK

RAK IAQ Monitor. Please

become familiar with these components before proceeding.

11

1

7

8

12

Model 8550

2

5

13

3

6

4

Figure 1–1: Q-T

10

9

Model 8551

RAK

1. Display 7. Location of Humidity Sensor

2. Keypad 8. Location of Temperature Sensor

3. External Power Socket 9. Location of CO

Sensor

2

4. Data Port RS-232 10. Probe Handle

5. Probe Mounting Clips 11. Battery Access Cover

6. Display/Keypad Lockout 12. Wrist Strap

Switch 13. Location of CO Sensor

(model 8551 only)

1

2

3

6

4

5

Figure 1–2: Q-T

RAK Accessories

1. AC Adapter 4. Computer Interface Cable

2. 25-Pin to 9-Pin Adapter 5. Probe Stand

Calibration Collar 6. CO Calibration adapter

3. CO

2

(Model 8551 Only)

Chapter 1

2

Chapter 2

Setting-Up

Supplying Power to the Q-T

The Q-T

RAK IAQ Monitor must be powered in one of two ways: four size

AA batteries or the supplied AC Adapter.

Installing the Batteries

Insert four size AA batteries as indicated by the diagram located on the

inside of the battery compartment. TSI ships the Q-T

batteries. NiCd rechargeable batteries may also be used.

Using the AC Adapter

The AC Adapter allows you to power the Q-T

outlet. When using the AC adapter, the batteries (if installed) will be

bypassed. The AC adapter is not a battery charger and will not charge

NiCd batteries.

The Q-T

RAK has an internal, non-user accessible battery that is used to

keep memory intact when power is turned off. Changing the AA-size

batteries or disconnecting the AC adapter will not cause data to be lost.

This battery is designed to last for years. TSI will install a new battery,

if necessary, when the unit is returned to the factory for service.

Instrument Setup

The Q-T

RAK comes with special software called TRAKPRO, which is

designed to provide you with maximum flexibility and power when using

the Q-T

RAK. The following sections describe how to install the software and

setup the computer.

Setting-up T

RAKPRO software contains a very comprehensive Help Function. This

T

RAKPRO Data Analysis Software

utility provides all the necessary information to guide you in all aspects

of software operation.

Connecting the Q-T

Each Q-T

RAK comes equipped with an RS-232 cable and a 25-pin to

9-pin serial cable adapter. One end of the cable is a 25-pin D

subminiature connector labeled COMPUTER; the other end is an RJ-45

modular connector that mates with the logging instrument. Serial port

connectors always have pins (male) on the computer side.

RAK

RAK with alkaline

RAK from an AC wall

RAK to a Computer

3

1. Locate an available serial port on your computer: COM1, COM2,

COM3, or COM4.

2. If the port has a 25-pin connector, you do not need the adapter. If

the port has a 9-pin connector, plug the 25-pin end of the adapter

into the RS-232 cable.

Connect the RS-232 cable to the available serial port on your

3.

computer.

Connect the RJ-45 connector to the Q-TRAK.

4.

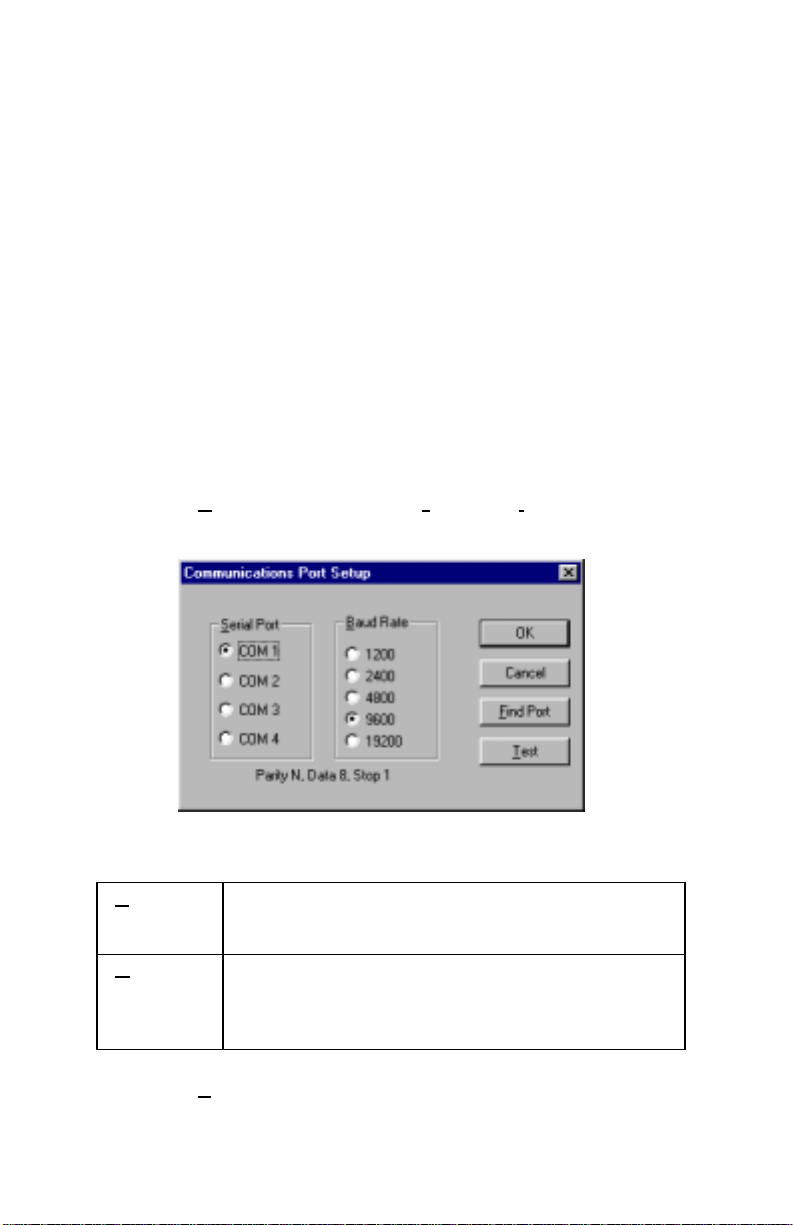

Set-Up the Communications Port

To communicate with the Q-T

the proper COM port. T

specific COM port, or it can automatically find a Q-T

RAK, the software must be configured for

RAKPRO can be manually set to operate on a

RAK that is

attached to any COM port. To set up the COM port, do the following:

1. Turn on the Q-T

2. Select C

following dialog is displayed:

Select the fo llowing:

3.

erial

S

Port

Baud

Rate

RAK and start TRAKPRO.

ommunications from the Instrument Setup menu. The

Select the name of the serial port to which the

logging device is connected: COM1, COM2, COM3,

or COM4.

Select the baud rate for the port. Higher baud rates

are recommended to transfer data at a faster rate.

Select a lower baud rate only if you are having

trouble communicating at a higher rate.

4. Select Test to verify that you have set up the communications port

properly. The system displays an informative message indicating

whether it was able to establish communications.

Chapter 2

4

5. As an alternate, you may select F

ind Port, to have TRAKPRO

search the available COM ports, looking for an attached Q-T

RAK.

6. Select

OK to accept the setup or Cancel to discard the changes.

Note: Some computers do not communicate reliably at baud rates

above 9600.

Setting the Real-Time Clock

The Q-T

RAK has an internal real-time clock that keeps track of the time

of day (the format is HH:MM where HH is the hour in 24-hour format

and the MM is minutes) and the date. It is very important for the

RAK to have the time and date correctly set; otherwise, date and time

Q-T

stamping of recorded data and calibrations will not be correct.

There are two ways to set the time and date. The first is to use the

supplied T

RAKPRO Data Analysis Software.

Programming the Date/Time Using TrakPro

To program the Q-T

1. Make sure the Q-T

2.

Select Parameters, then Clock from the Instrument Setup menu.

RAKPRO retrieves the current date and time settings from Q-TRAK

T

RAK date and time:

RAK is connected to the computer and turned on.

and displays them in the following dialog:

3. The system date and time (from the computer) may be transferred

to the Q-T

RAK using the “arrows” keys. Alternately, the date and

time may be manually entered into the dialog box.

4. Select Send to reprogram the Q-T

RAK.

5

Manually Setting the Real-Time Clock

To set the time and date with the keypad, you must press and hold the

SAMPLE key down while the Q-T

its power-up sequence. Release when the Q-T

RAK displays the time of day during

RAK “beeps.” You will

have an opportunity to view and/or change the hours, minutes, year,

month and day of month in sequence. Use the up and down arrow keys

(!") to change a setting. Use the SAMPLE key to store each setting

and advance to the next one.

Using the Probe Stand

For your convenience, the Q-T

RAK is supplied with a probe stand so

that the probe can be located above a table surface while unattended. To

use it, simply detach the probe from the Q-T

RAK mounting clips and

slide it onto the stand.

Connecting the Optional Model 8925 Portable Printer

To connect the Model 8925 printer to the Q-T

RAK, locate the Printer

Interface cable (supplied with optional printer) and connect the 9-pin

end labeled “PRINTER” to the printer and the other end to the data port

on the Q-T

RAK. Always turn the Q-TRAK on BEFORE the printer. If the

printer prints question marks (??????), asterisks (******), or random

characters, reset it by turning it off and then on again. If necessary, refer

to the Model 8925 Portable Printer Operation and Service Manual.

Chapter 2

6

Chapter 3

Operation

Overview

The Model 8550 and Model 8551 Q-T

temperature, and relative humidity. In addition the Model 8551 also

measures CO concentration. All parameters are measured simultaneously in

a single probe. The Q-T

RAK has four modes of operation, Survey, LOG 1,

LOG 2, and LOG 3. When the Q-T

mode which is used to display real-time readings and to determine statistics

such as average, minimum, and maximum readings. LOG 1 mode is used to

record individual data points for later analysis using a factory set protocol.

LOG 2 and LOG 3 modes have user-defined protocols, set up using

RAKPRO software. TRAKPRO software is used for analysis of data taken in

T

any of the three LOG modes, but cannot be used on samples taken in Survey

mode.

Keypad Functions

When pressing the keys on the front panel, the Q-T

the function. If you press a key and the Q-T

does not allow that function during the selected sampling mode. To disable

the beep, refer to Appendix B: “Internal DIP Switch Settings.”

ON/OFF Key

Use the ON/OFF key to turn the Q-T

first turned on it goes through a preprogrammed power-up sequence that

includes an internal self-check. First, all displayable items will appear for a

few seconds. If a problem is detected, the display shows the message

“SERVICE” along with a number to indicate that the Q-T

servicing. Refer to Chapter 5: “Troubleshooting” for information regarding

service numbers. If the “SERVICE” message appears, the Q-T

until any key is pressed.

When the Q-T

RAK completes its internal self-check, it will display the

approximate percentage of battery life remaining. The Q-T

+ –

battery symbol

when the battery voltage becomes very low. After the

battery symbol appears, the Q-T

before displaying the message “LO” (for a few seconds) and then

automatically turning off. This feature is accurate for alkaline batteries only.

The percentage life remaining will not be accurate for NiCd batteries. The

battery symbol appears when battery voltage becomes low, but the Q-T

RAK IAQ monitors measure CO

RAK is first turned on it will be in Survey

RAK will beep to confirm

RAK does not beep, the Q-TRAK

RAK on and off. When the instrument is

RAK requires

RAK pauses

RAK displays the

RAK runs for approximately 60 minutes

,

2

RAK

7

will run considerably less than 60 minutes before displaying the message

g

“LO” and turning off.

CO2 SAMPLE

CALIBRATE ZERO RECORDING

HR:MN:SEC TEST ID LOG 123

CO2 SAMPLE

ELAPSED TIME

PPM

°F°C

%RH

m

CONSTANT

AVERAGE

3

/m

% MEMORY

MIN MAX

SERVICE

Figure 3–1: Q-T

RAK Display With All Elements Shown

After displaying the percentage of battery life remaining, the current time set

on the internal real-time clock is displayed. When the self-check is complete,

the Q-T

RAK will be in Survey mode.

CO

Key

2

Press the CO

key to display CO2 readings. Carbon dioxide concentration

2

readings will be displayed in units of parts per million (ppm). Place the

sensor in the location where you want to take the measurement. The probe

must be fully exposed because the CO

sensor is located between the probe

2

tip and the handle, not at the tip.

Caution

!

TEMP Key

Press the TEMP key to display air temperature readings. The temperature

sensor is located near the tip of the probe. The Q-T

readings in either degrees Celsius (°C) or degrees Fahrenheit (°F) depending

on the DIP switch settings (refer to Appendix B).

Do not hold the probe close to your breathing zone. Humans

exhale CO

and this will influence the readings.

2

RAK displays temperature

Caution

!

Do not use the Q-TRAK to measure the temperature of liquids.

The sensor is not designed for submersion.

8

Chapter 3

HUMIDITY Key

Press the HUMIDITY key to display humidity readings. The humidity sensor

is located near the tip of the probe. The readings will be in u nits of percent

relative humidity (%rh).

Caution

!

CO Key (Model 8551 Only)

Press the CO key to display CO readings. Carbon monoxide concentration

readings are displayed in units of parts per million (ppm). The CO sensor is

located at the tip of the probe.

SAMPLE Key

Press the SAMPLE key to start/stop data sampling. The word “SAMPLE”

appears in the upper-right corner of the display while the Q-T

sample. When sampling is stopped, the Q-T

through statistics for the sample that just ended.

TIME CONSTANT Key

Momentarily press and release the TIME CONSTANT key to view the

current time-constant. To change the time-constant, press and hold the key

down. The available time-constant choices will sequence on the display.

When the desired value is displayed, immediately release the key.

The time-constant is actually an averaging period. The Q-T

always updated every second; however, the reading displayed is the average

reading over the last time-constant period. For example, if the current timeconstant is set to 10 seconds, the display shows readings averaged over the

previous 10 seconds, updated every second. This is also called a 10-second

“moving average.”

As configured at the factory, the available time-constant values are 2, 5, 10,

15, and 20 seconds. The internal list of time-constant values can be altered

using Q-T

of time constants allowed is 2–60 seconds. See the following instructions.

The humidity sensor is sensitive to the effects of water. Do not

expose the sensor to liquid water. This will damage the sensor.

Also, the humidity sensor will not function properly while

exposed to intense light, such as direct sunlight. Shade the

probe to avoid false readings.

RAK is taking a

RAK automatically scrolls

RAK display is

RAK Data Analysis Software supplied with the Q-TRAK. The range

Operation

9

Programming the Available Time Constants

To program the list of time constants using Q-T

RAK Data Analysis Software:

1. Make sure the Q-T

2.

Select Parameters, then Time Constants from the Instrument Setup

menu. T

Q-T

RAKPRO retrieves the current time constant settings from the

RAK and displays them in the following dialog:

RAK is connected to the computer and turned on.

Enter a value for each of the five available time constants. (The range is

3.

limited to 2–60 seconds.)

Select Send.

4.

The Q-T

RAK is reprogrammed to offer the time constants you have

specified.

STATISTICS Key

Use the STATISTICS key to sequentially view the average, minimum, and

maximum readings as well as the elapsed time of the most recently sampled

data. You may view sample statistics while the sample is in-progress;

however, one time-constant must have elapsed first. If one of the LOG

modes is active, a test identification number is displayed also. Press the

STATISTICS key once to display the average reading, again to display the

minimum reading, again to display the maximum reading, and again to

display the elapsed time for that sample (and again for the test ID if in LOG

mode). If you press the STATISTICS key a fifth time (sixth time if in LOG

mode), the Q-T

RAK switches back into the currently selected measuring

mode. You must sequence through all four statistic displays (i.e., press the

STATISTICS key five times, six if in LOG mode) before the Q-T

RAK goes

back into the currently selected measuring mode. All parameters are

10

Chapter 3

measured simultaneously. The display shows only the data for the current

measurement mode. The measurement mode may be changed at any time to

view statistics for the other measurements.

PRINT Key

Use the PRINT key to print information on the optional Model 8925

Portable Printer. The information printed will be different depending on

what the Q-T

RAK is currently doing.

When the Q-T

RAK is displaying real-time readings, pressing the PRINT key

will cause all parameters being measured to be printed along with the time

and date. Each time the PRINT key is pressed, one set of values prints. The

values printed reflect the current time-constant; therefore, they are the same

as would be displayed.

When the Q-T

RAK is displaying any statistic, pressing the PRINT key will

cause the current statistics to print. All statistics are printed as a set

regardless of which one is currently displayed.

When the Q-T

RAK is in one of the LOG modes and is idle (“%MEMORY” is

displayed), pressing the PRINT key will cause the logging setup for the

current LOG mode to print.

If you press and hold the PRINT key during the power-up sequence, and

you have the optional Model 8925 printer connected, a printout showing

certain system information occurs.

SAMPLING MODE Key

The SAMPLING MODE key allows you to select between the four

sampling modes: Survey, LOG 1, LOG 2, and LOG 3. Each time you press

the SAMPLING MODE key, the Q-T

When the Q-T

RAK is in Survey mode, the current measurement is shown on

RAK will sequence to the next mode.

the display. When one of the LOG modes is selected, the LOG mode

number, i.e., “LOG 1,” “LOG 2,” or “LOG 3” is displayed along with the

percentage of free memory available.

Survey Mode:

When the Q-T

Survey mode allows you to make simultaneous measurements of CO

RAK is first turned on, it will always be in Survey mode.

2

concentration, temperature, and relative humidity, and to obtain

statistics for each measurement when a sample is taken. The statistics

include the average, minimum, and maximum values, as well as the

elapsed time for that sample. Individual data points are not recorded

(this can be done in any of the LOG modes). Each new sample taken in

Survey mode clears the previous sample data from memory. Data taken

in Survey mode remains in memory until another sample is made, or

Operation

11

until samples are taken in one of the LOG modes. Turning the Q-T

RAK

off will not erase data. Use the SAMPLE key to start and stop a sample.

LOG Modes:

There are three LOG modes: LOG 1, LOG 2, and LOG 3. When one of

these modes is selected using the SAMPLING MODE key, the LOG

mode number is listed at the top of the display. The LOG modes allow

you to record data points for later retrieval and analysis using the

software provided with the instrument.

Use the SAMPLE key to start and stop recording. The word

“RECORDING” appears at the top of the display when recording is in

progress. Use the CO

, TEMP HUMIDITY, or CO keys to select which

2

measurement is displayed during recording.

The frequency that data is recorded can be set for LOG 1 mode with the

LOGGING INTERVAL key. Use T

RAKPRO software for LOG 2 and

LOG 3 modes.

Data recorded using one of the LOG modes can only be erased by using

the CLEAR MEMORY key. Turning the Q-T

RAK off will not erase

data. Recording another sample with one of the LOG modes, without

clearing memory first, causes new data to be added to the existing data

(using a new test ID).

CLEAR MEMORY Key

Use the CLEAR MEMORY key to erase all data. The CLEAR MEMORY

key will not respond unless the Q-T

RAK is first put into one of the three

LOG modes by using the SAMPLING MODE key.

Note: You should first download your data to your computer through the

RAKPRO software. There is only one block of memory in the

T

RAK. Clearing the memory for one LOG mode clears memory for

Q-T

all LOG modes.

To clear memory, press and hold the CLEAR MEMORY key until the

countdown reaches zero, then release quickly. This prevents accidental

erasure of data. Releasing the key too soon or too late prevents memory

from being cleared … try again.

LOGGING INTERVAL Key

Use the LOGGING INTERVAL key to view or set the frequency/averaging

period for recording data in LOG 1 mode or to view the current interval

setting in LOG 2 and LOG 3 mode. Use T

RAKPRO software to set the

logging interval for LOG 2 and LOG 3 mode. The LOGGING INTERVAL

12

Chapter 3

key will not respond unless the Q-T

RAK is first put into one of the three

logging modes. Press the LOGGING INTERVAL key momentarily to view

the current logging interval. Press and hold the LOGGING INTERVAL key

to sequence through the available choices and release the key when the

desired interval is on the display (LOG 1 mode only).

The logging interval is both a frequency and an averaging period. For

example, when the logging interval is set to 30 minutes, readings will be

recorded at 30-minute intervals. Each reading will be the average value

measured over that 30-minute interval.

As shipped from the factory, the available logging intervals for LOG 1 mode

are 1 second, 1 minute, 5 minutes, 15 minutes, and 30 minutes. Use the

RAKPRO data analysis software to alter these values.

T

Programming the Logging Intervals Using T

RAKPRO

To program the list of logging intervals available for LOG 1 mode:

1. Make sure the Q-T

2.

Select Parameters, then Logging Intervals from the Instrument

Setup menu. T

RAK and displays them in the following dialog:

Q-T

RAK is connected to the computer and turned on.

RAKPRO retrieves the current logging intervals from the

3.

Enter a value for each of the five available logging intervals (the range

is from 1 second to 59 minutes and 59 seconds).

Select Send.

4.

Operation

13

The Q-T

RAK is reprogrammed to offer the logging intervals you have

specified.

! and " Keys

The two arrow keys are used to adjust readings when calibrating the

RAK and for adjusting the time and date for the internal real-time clock.

Q-T

Display/Keypad Lockout Switch

Recording data over extended time periods often requires leaving the

RAK unattended. To reduce the risk of having an unauthorized person

Q-T

either intentionally or inadvertently interrupt the measurements, you can

lock the display and keypad.

This switch is located on the side of the Q-T

RAK between the probe

mounting brackets. It is a small slide switch and is recessed so that a pointed

instrument must be used to move it.

The instrument case is labeled next to the switch with the symbols “I” and

“0.” With the switch in the “I” or on (up) position, all keypad and display

functions will work normally. There are two ways to use the lockout switch.

You can lock the keypad (move the switch to the “0” position) after

recording starts, or you can put the switch into the lockout position prior to

when recording starts. If you select the second method, you will be able to

operate all functions normally until the SAMPLE key is pressed in one of

the LOG modes. At that time the keypad will automatically lock. When the

display and keypad are locked, the display shows the words “RECORDING

LOG X "” where “X” is the current LOG mode number.

Programming Advanced Modes: LOG 2 and LOG 3

Use LOG 2 or LOG 3 modes for unattended recording and setting user

protocols. With LOG 2 and LOG 3 modes you can set the start date, start

time, test length, logging interval, number of tests, and the time delay

between tests. All or selected parameters can be set.

To program a protocol for LOG 2 or LOG 3 mode:

1. Make sure the Q-T

RAK is connected to the computer and turned on.

2. Select Logging Setup from the Instrument Setup menu. T

retrieves the current settings for LOG 2 and LOG 3 modes from the

RAK and displays them in the following dialog:

Q-T

14

RAKPRO

Chapter 3

The following table summarizes the information displayed in the

Advanced Logging Modes dialog box:

Serial Number

Number of tests

logged

Available

Memory (%)

Displays the serial number of the logging

instrument.

Displays the number of tests currently logged

and stored in the logging instrument.

Displays the percent of available memory in

the logging instrument.

Operation

15

LOG 2 and LOG 3 Mode Protocols

Channels

Start Date

Start Time

Log interval

Test length

Number of tests

Time between

tests

Percent

memory

required.

Displays the channels selected for sampling in

LOG 2 and LOG 3 modes.

Displays the start date for LOG 2 and LOG 3

modes.

Displays the start time for LOG 2 and LOG 3

modes.

Displays the log interval for LOG 2 and LOG

3 modes.

Displays the test length for LOG 2 and LOG 3

modes.

Displays the number of tests for LOG 2 and

LOG 3 modes.

Displays the time between tests for LOG 2

and LOG 3 modes.

Displays the percent of logger memory

required to perform a LOG 2 or a LOG 3

mode sample. To store the results of a LOG 2

or LOG 3 mode sample, the Available

Memory must be equal to or greater than the

Percent memory required.

16

Chapter 3

3.

Enter the following for LOG 2 and LOG 3 modes:

Channels

Start Date

Start Time

Select the channels for which you want to log

data. In the case of the Q-T

channels to select: CO

RAK, there are four

, Temp, rh, and CO.

2

Enter the date and time to begin the sample:

• If you enter a blank for a start date, the

sample begins whenever the specified start

time occurs.

• If you enter a blank for the start time, both

start date and start time are ignored, and

the sample begins when the operator

manually starts the sample.

Log interval

Test length

Enter the log interval to use for the test.

Enter the length for the sample:

• If you enter a value, the instrument

automatically turns off when the last test is

complete.

• If you enter a blank, the operator must

manually stop the sample.

Number of tests

Time between

tests

Enter the number of tests to perform.

If you have specified more than one Number

of tests, enter the time between tests. If you

enter 0 or blank, the next test is started

immediately after the last test is complete.

While you are entering values for LOG 2 and LOG 3 modes, the

Percent Memory Required is dynamically updated to show the amount

of logger memory required to take the programmed sample. If the

protocol you have defined requires more than 100% of memory, you

can decrease the amount of memory required by manipulating the

following protocol parameters:

• Increase the logging interval.

• Decrease the length for the test.

• Decrease the number of tests.

• Decrease the number of channels.

The settings for each LOG mode must not require more than 100% of

the logger memory. Note also that if the Percent memory required is

greater than the Available memory, the logging instrument

automatically stops the test when memory is full.

Operation

17

4.

Wh en you have finished defining the parameters for LOG 2 and LOG 3

modes, select S

end.

5. You can now disconnect the Q-T

RAK and cable from the computer.

Sample Protocol for LOG 2 and LOG 3 Modes

The following steps describe how to program a sample protocol for LOG 2

or LOG 3 mode.

The sample protocol for LOG 2 is set to take unattended readings for one

day, 3/23/98. The logging sample begins at 8:00 a.m. and continues for

8 hours.

The sample protocol for LOG 3 is set up to take unattended readings for two

days, beginning on 3/24/98. The logging sample begins at 8:00 a.m. and

continues for 8 hours. The instrument is off for 16 hours, and then repeats

the 8 hours test on the following day.

The following graphic gives the appearance of the dialog box displayed in

RAKPRO, with these particular logging parameters.

T

To program this logging example, do the following:

1. Make sure the Q-T

RAK is connected to the computer and turned on.

18

Chapter 3

2. Select L

ogging Setup from the Instrument Setup menu. TRAKPRO

retrieves the current settings for LOG 2 and LOG 3 modes from the

RAK and displays them in the previous dialog.

Q-T

3. Enter the following for LOG 2 and LOG 3:

Setting

Channels

Start Date

Start Time

Log interval

Test length

Number of tests

Time between

LOG 2 LOG 3

CO

, Temp, rh, CO CO2, Temp, rh, CO

2

03/23/1998 03/24/1998

08:00 08:00

01:00 05:00

00:08:00 00:08:00

1 2

00:00:00 00:16:00

tests

4. Select Send. The logging instrument is programmed for the mode 2 and

mode 3 protocols.

5. Note that the LOG 2 test requires 3% of the available memory and LOG

3 requires 1% of the memory. A total of 98% of the memory is available

for use.

6. You can now disconnect your Q-T

RAK from the computer. Refer to

other sections of this Operation and Service Manual for details on

making measurements using LOG 2 and LOG 3 modes.

After programming the Q-T

take the Q-T

RAK to the desired location and turn it on. Put it into LOG 2 or

RAK with the TRAKPRO Data Analysis Software,

LOG 3 mode (whichever you programmed) using the SAMPLING MODE

key. Press the SAMPLE key to initiate the program.

If you have set a start time and/or date, the display toggles between the next

“TEST ID” and the “ELAPSED TIME 0” message. If the test start time is

greater than one minute away, the Q-T

the test start time. This indicates that the Q-T

RAK shuts off until one minute before

RAK is waiting until the

programmed start time and dates occur. You may want to lockout the display

and keypad at this time to prevent tampering.

Things You Should Know About Taking Pre-Programmed Samples

If you press the SAMPLE key during programmed recording, the

program terminates (unless the keypad is locked).

If the programmed start time and date has already passed, pressing the

SAMPLE key has no effect. The program never executes.

Operation

19

Setting the start time but no start date causes the Q-T

specified time regardless of the date.

RAK to start at the

If no start time is set, the Q-T

RAK waits for you to press the SAMPLE key

and starts sampling immediately.

If no test length is set, the Q-T

RAK samples continuously until the

SAMPLE key is pressed to stop sampling or until the memory is full.

When a pre-programmed test ends, the Q-T

RAK automatically shuts off.

When it is turned on again, it will be in Survey mode.

Memory Considerations

The Q-T

be concerned with running out. The Q-T

RAK has a great deal of memory and you will not normally have to

RAK has 128,000 bytes of internal

memory. This should be considered when selecting a logging interval.

Shorter logging intervals use memory more quickly than longer intervals.

A recorded data set consumes 6 bytes for Model 8550 and 8 bytes for

Model 8551 (2 each for CO

, CO, temperature and humidity.) In addition,

2

each test (labeled with a TEST ID number) needs 100 bytes for storing

statistics and setup information. (The formulas below ignore this 100 bytes

to keep the calculations simpler.) Based on this information, the Q-T

RAK is

capable of storing approximately 21,000 data sets for Model 8550 and

15,750 for Model 8551:

Note: LOG 2 and LOG 3 modes can be programmed to record any of the

measurements separately, i.e., only CO

, or CO2 and temperature

2

but not humidity, etc. If only one measurement is recorded, up to

63,000 data points could be stored. The discussion below assumes

four measurements are recorded.

ointsMax Data P =≈

000,128

8

000,16

Therefore 1% of memory is about 160 data sets. The maximum possible

duration of a data logging session is determined by the logging interval and

the available memory. The equation below can be used to determine any

memory, recording time or logging interval restraints.

Memory%

[]

≈

[][ ]

×

Time Elapsed

Interval Logging160

(Note: Elapsed Time and Logging Interval are in units of minutes.)

20

Chapter 3

Chapter 4

Calibration and Maintenance

The Q-T

The Q-T

Even so, we recommend that you return your Q-T

annually. For a reasonable fee, we will quickly clean and recalibrate the unit,

update software and firmware, and return it to you in “as new” working

condition along with a Certificate of Calibration and NIST Traceability. The

factory calibration is more precise than can be accomplished with the

procedures below. This “annual checkup” helps ensure that the Q-T

always in good operating condition.

Calibrating the CO

TSI recommends calibrating the Q-T

ensure accurate readings. The CO

changes in atmospheric pressure. Normal day-to-day variations due to local

weather conditions have little effect. However, changes in altitude can cause

more significant errors. For best accuracy, calibrate the Q-T

measurement for your local conditions or if conditions change.

To calibrate the CO

instructions can also be found on the calibration collar itself. You will need a

cylinder of pure air or nitrogen for the zero calibration and a cylinder of gas

with a known concentration of CO

local TSI distributor for available CO

Note: If using air for calibration, it must be specified to have less than

If necessary, you can select between the factory CO

calibration. Please refer to Appendix B: “Internal DIP Switch Settings.”

The calibration procedure can be aborted at any time by pressing the CO

TEMP, or HUMIDITY key.

If an error occurs during the CO

displays the message “ERR.” Press the CO

abort the calibration. Switching the zero gas with the span gas is an example

of a condition that causes the “ERR” message to come on.

RAK requires very little maintenance to keep it performing well.

RAK may be calibrated in the field using the instructions below.

RAK to TSI for calibration

RAK is

Concentration Measurement

2

10 ppm CO

RAK CO

concentration measurement is affected by

2

sensor, please follow the procedure below. Brief

2

for the span calibration. Contact your

2

2

. Ambient room air cannot be used.

2

calibration procedure, the Q-TRAK

2

measurement monthly to help

2

RAK CO

calibration kits.

calibration and a user

2

, TEMP, or HUMIDITY key to

2

2

,

2

21

1. Locate the calibration collar and slide it over the sensing probe. Make

sure that the collar completely covers the CO

diffusion holes. Refer to

2

Figure 4–1.

Figure 4–1: CO

Calibration

2

2. Install the regulator onto the zero calibration gas cylinder and connect

tubing from the cylinder to the fitting marked “GAS IN” and turn the

gas on (0.3 L/min). Make sure the cylinder is not empty. It should

quietly “hiss” when it is on.

3. To put the Q-T

RAK into CO

into Survey mode, and then press and hold the CO

calibration mode, first put the instrument

2

key. The display

2

begins to count down from five to zero. When the count reaches zero,

release the CO

key immediately. The words “CALIBRATE ZERO”

2

should appear on the display. If not, try again.

Note: DIP switch 2 must be set to the “User Calibration” (ON) position or

the Q-T

RAK will not go into CO

calibration mode. Please refer to

2

Appendix B: “Internal DIP Switch Settings.”

4. Press the SAMPLE key to take a zero measurement. The Q-T

RAK will

display a 60-second count-down. When the count-down is completed,

the display shows the word “CALIBRATE 1,” the next span

concentration (typically 1000 ppm), and the arrow symbols (!") will

be blinking. Turn off the regulator and disconnect the zero calibration

gas.

22

Chapter 4

5. Install the regulator onto the span calibration gas cylinder and attach a

tube from cylinder to the fitting marked “GAS IN.” Make sure the

cylinder is not empty, then turn the gas on (0.3 L/min). A CO

2

concentration of between 1000 and 5000 ppm should be used.

6. Use the arrow (!") keys on the Q-T

RAK keypad to adjust the display

to match the known span gas concentration. Press quickly and release

the arrow key to change the display 1 ppm at a time. Hold the arrow key

down to move more quickly. The span gas concentration value (ppm) is

marked on the gas container.

7. Press the SAMPLE key to take a span reading. The Q-T

RAK will

display a 60-second count-down. When the count-down reaches zero

the Q-T

RAK will go into Survey mode. Turn the instrument off.

8. Turn the instrument on and observe the reading displayed on the

RAK. It should be very close to the span gas concentration (within

Q-T

specifications: See Appendix A). If not, repeat the calibration.

9. If the displayed reading is accurate, turn the gas off and remove the

calibration collar and regulator. The calibration is now completed.

Calibrating the Temperature or Relative Humidity Measurement

To perform a temperature or humidity calibration on the Q-T

RAK you will

need a reference temperature or humidity device, preferably one that is more

accurate than the Q-T

so that both the Q-T

RAK. To obtain the best accuracy, care must be taken

RAK probe and the reference device are able to sense the

same air. Also, it’s best to calibrate at a temperature and humidity that is

near the range you typically measure. In most cases this will be room

temperature.

Caution

!

If necessary, you can select between the factory calibration and a user

calibration. Please refer to Appendix B: “Internal DIP Switch Settings.”

Never submerge the probe or Q-TRAK in water or any

other liquid. The sensor will be damaged.

1. Locate the Q-T

RAK probe and the reference device sensor so that they

“see” the same air conditions.

2. To put the Q-T

RAK into calibration mode, first put the instrument into

Survey mode and then press and hold the key, TEMP or HUMIDITY,

that you wish to calibrate. The display begins to count down from five

to zero. When the count reaches zero, release the key immediately. The

word “CALIBRATE” should appear on the display along with blinking

arrow symbols (!"). If not, try again.

Calibration and Maintenance

23

Note: DIP switch 3 or 4 must be set to the “User Calibration” (ON)

position or the Q-T

RAK will not go into calibration mode. Please

refer to Appendix B: “Internal DIP Switch Settings.”

3. Compare the reading on the Q-T

RAK with the reading from the

reference device. If they differ, use the arrow keys (!") on the

RAK to adjust the Q-TRAK display as needed so that the displayed

Q-T

measurement matches the measurement indicated by the reference

device. Press the arrow key briefly to change the display 0.1 degree or

0.1% at a time. Hold the arrow key down to change more quickly.

Note: If the two readings are the same, there is no need to proceed with the

calibration. Press the CO

, TEMP, or HUMIDITY key to terminate

2

the calibration procedure.

4. Press the SAMPLE key to take a measurement. The Q-T

RAK will

display a 15-second count-down. When the count-down is completed,

the Q-T

5. Observe the displayed reading on the Q-T

RAK will go back to survey mode.

RAK, it should agree with the

reference device within specifications (see Appendix A). If not, repeat

the calibration.

6. If the displayed reading is accurate, the calibration is completed.

Calibrating the CO Concentration Measurement (Model 8551 only)

TSI recommends calibrating the Q-T

RAK CO measurement monthly to help

ensure accurate readings. The CO concentration measurement is affected by

changes in temperature and atmospheric pressure. Normal day-to-day

variations due to local weather conditions have little effect. However,

changes in altitude can cause more significant errors. For best accuracy,

calibrate the Q-T

RAK CO measurement for your local conditions or if

conditions change.

To calibrate the CO sensor, follow the procedure below. You will need a

cylinder of pure air for the zero calibration and a cylinder of gas with a

known concentration of CO for the span calibration, 35 ppm or 200 ppm is

recommended. Contact your local TSI distributor for available CO

calibration kits.

Note: Calibration with CO gas should always be done in a well-ventilated

area.

If necessary, you can select between the factory CO calibration and a user

calibration. Please refer to Appendix B: “Internal DIP Switch Settings.”

24

Chapter 4

The calibration procedure can be aborted at any time by pressing the CO,

, TEMP, or HUMIDITY key.

CO

2

If an error occurs during the CO calibration procedure, the Q-T

display the message “ERR.” Press the CO, CO

, TEMP, or HUMIDITY key

2

RAK will

to abort the calibration. Switching the zero gas with the span gas is an

example of a condition that will cause the “ERR” message to come on.

Figure 4–2: CO Calibration

1. Locate the calibration adapter and slide it over the sensing probe. Make

sure that the adapter completely covers the CO diffusion holes at the tip

of the probe.

2. Install the regulator onto the zero calibration gas (must contain 0

, e.g.,

2

zero air) cylinder and connect tubing from the cylinder to the inlet of the

calibration adapter and turn the gas on (0.3 L/min). Make sure the

cylinder is not empty.

3. To put the Q-T

RAK into CO calibration mode, first put the instrument

into Survey mode, and then press and hold the CO key. The display

begins to count down from five to zero. When the count reaches zero,

release the CO key immediately. The words “CALIBRATE ZERO”

should appear on the display. If not, try again.

Note: DIP switch 7 must be set to the “User Calibration” (ON) position or

the Q-T

RAK will not go into CO calibration mode. Please refer to

Appendix B: “Internal DIP Switch Settings.”

4. Press the SAMPLE key to take a zero measurement. The Q-T

RAK will

display a 90-second count-down. When the count-down is completed,

the display shows the word “CALIBRATE 1” and the arrow symbols

(!") will be blinking. Turn off the regulator and disconnect the zero

calibration gas.

Calibration and Maintenance

25

5. Install the regulator onto the span calibration gas cylinder and attach a

tube from cylinder to the inlet fitting of the calibration adapter. Make

sure the cylinder is not empty, then turn the gas on.

6. Use the arrow (!") keys on the Q-T

to match the known span gas concentration. Quickly press and release

the arrow key to change the display 1 ppm at a time. Hold the arrow key

down to move more quickly. The span gas concentration value (ppm)

should be marked on the gas container.

7. Press the SAMPLE key to take a span reading. The Q-T

display a 90-second count-down. When the count-down reaches zero

the Q-T

8. Observe the reading displayed on the Q-T

the span gas concentration (within specifications: see Appendix A). If

not, repeat the calibration.

9. If the displayed reading is accurate, turn the gas off and remove the

calibration adapter. The calibration is now completed.

Replacing the CO Sensor

The electro-chemical CO sensor will need to be replaced approximately once

a year. Conditions that may indicate a sensor needs to be replaced are: 1) the

sensor will not hold calibration, or 2) the response is very unstable. Caution

must be taken when operating at very low or high temperatures. Exposing

the sensor to sub-freezing temperatures can cause permanent damage to the

sensor. Exposing the sensor to high temperature for long periods of time can

cause the sensor to dry out which will shorten the sensor life. The sensor has

a built in filter to eliminate interfering gasses. This filter will last the life of

the sensor under normal background gas levels. To replace the sensor follow

the procedure below.

RAK will go into Survey mode.

RAK keypad to adjust the display

RAK will

RAK. It should be very close to

WARNING

!

The CO sensor contains a corrosive material, avoid

contact with eyes and skin.

1. Unscrew cap from end of probe.

2. Carefully bend flex circuit assembly away from old CO sensor.

3. Remove old sensor by gently pulling sensor straight off the end of the

probe. Do not twist the sensor, this will damage the connector.

4. Obtain a new sensor, tear open foil pouch, and remove new sensor.

Inspect new sensor for visible signs of damage or leakage. Discard old

sensor.

26

Chapter 4

5. Line up notch on sensor with connector and gently push sensor onto the

connector.

6. While holding flex circuit against CO sensor, carefully thread thermistor

through cap and screw cap on probe.

7. Turn on Q-T

RAK. A one-time, 30-minute stabilization period is needed

only after sensor replacement. After the stabilization period, calibrate

the sensor by following the procedure above.

Storage Precautions

When storing the Q-T

RAK for more than 30 days, you should remove the

batteries. This prevents damage due to battery leakage.

This instrument must be stored in a location where the temperature remains

between -20 and 60°C (-4 and 140°F) and the relative humidity between

15% and 90%.

Calibration and Maintenance

27

28

Chapter 4

Chapter 5

Troubleshooting

The table below list the symptoms, possible causes and recommended

solutions for common problems encountered with the Q-T

Symptom Possible Cause Corrective Action

No Display. Unit not switched on.

Low or dead batteries.

Lockout switch enabled

Dirty battery contacts.

Battery

symbol is

displayed

(constant or

blinking).

Display

reads

“MEMORY

0%.”

Humidity

reading near

zero or not

believable.

Cannot enter

calibration

mode.

Incorrect

function

displayed.

Low battery charge.

Incorrect AC Adapter.

Low AC line Voltage.

Dirty battery contacts.

Memory is full. Download memory to a PC if

Probe exposed to intense

light.

DIP switch(s) set to

factory calibration.

Not in Survey mode.

Sample is in progress.

Two keys have been

pressed at the same time.

Switch unit on.

Replace the batteries or plug in

the AC adapter.

Disable lockout switch

Clean the battery contacts.

Replace batteries or use AC

Adapter.

Replace with the correct AC

Adapter.

Correct the AC line voltage or

use batteries.

Clean the battery contacts.

desired, then clear memory.

Shade the probe while taking

samples.

Change DIP switch setting. See

Appendix B.

Change to Survey mode.

Stop sample in progress.

Press only one key at a time.

RAK.

29

Symptom Possible Cause Corrective Action

No keypad

response.

“ERR”

Displayed

during

calibration

Display/Lockout switch

in lockout position.

A mistake has been made

such as switching the zero

and span gases.

Slide lockout switch to normal

position.

Press CO

, TEMP or

2

HUMIDITY key to abort

calibration. Review instructions

and try again.

procedure.

“SERVICE”

and “1”

displayed.

Memory has been cleared

due to temporary loss of

power from internal

Factory service required if

condition persists. Press any

key to bypass.

backup battery.

“SERVICE”

and “2”

displayed.

“SERVICE”

and “3”

Calibration memory error.

Internal calibration data

corrupted.

Temperature sensor

malfunction.

Factory service required.

Factory service required. Press

any key to bypass.

displayed.

“SERVICE”

and “4”

sensor malfunction. Factory service required. Press

CO

2

any key to bypass.

displayed.

“SERVICE”

and “5”

Humidity sensor

malfunction.

Factory service required. Press

any key to bypass.

displayed.

“SERVICE”

and “6”

displayed.

“SERVICE”

and “7”

displayed.

“SERVICE”

and “8”

displayed.

Low batteries are the

most common cause of

this error.

If error persists, infrared

light source malfunction

may have occurred.

Replace batteries or operate

with AC adapter. Press any key

to clear error. Turn instrument

off/on.

Factory service required to

replace light source. Press any

key to bypass error.

Backup battery low. Factory service required . Press

any key to bypass.

CO sensor not detected.

CO signal out of range.

CO sensor malfunction.

Check that CO sensor is

properly installed.

Recalibrate CO sensor.

Replace and recalibrate CO

sensor. Factory service possibly

required. Press any key to

bypass.

Chapter 5

30

Appendix A

Specifications

Specifications are subject to change without notice.

Specifications in parentheses () indicates English equivalents.

:

CO

2

Sensor type:............................. Non-Dispersive Infrared (NDIR)

Range:...................................... 0-5000 ppm

Accuracy: ................................. ±3% of reading ±50 ppm at 25°C

(77°F). [Add uncertainty of

±0.36% per °C (±0.2% of reading per

°F) for change in temperature.]

Resolution:............................... 1 ppm

Response time: ........................ 20 seconds (for 63% of final value for

500 ppm step change)

Temperature:

Sensor type:............................. Thermistor

Range:...................................... 0 to 50 °C (32 to 122 °F)

Accuracy: ................................. ±0.6 °C (1.0 °F)

Resolution:............................... 0.1 °C (0.1 °F)

Response time:........................ 30 seconds (90% of final value, air

velocity at 2 m/s)

Display units:............................ °C or °F (user selectable)

Humidity:

Sensor type:............................. Thin-film capacitive

Range:...................................... 5 to 95 %rh

Accuracy: ................................. ±3 %rh (includes ±1% hysteresis.)

Resolution:............................... 0.1 %rh

Response time: ....................... 20 seconds (for 63% of final value)

CO (Model 8551 only):

Sensor type:............................. Electro-chemical

Range:...................................... 0–500 ppm

Accuracy: ................................. ± 3% of reading or 3 ppm whichever

is greater [add ±0.5%/°C (0.28%/°F)

away from calibration temperature]

Resolution:............................... 1 ppm

Repeatability:........................... ± 2% of reading

Response time:........................ < 60 seconds to 90% of final value

31

Instrument Temperature Range:

Operating range:...................... 5 to 45 °C (41 to 113 °F)

Storage range: ......................... -20 to 60 °C (-4 to 140 °F)

Time Constant:

Range:...................................... Adjustable from 2 to 60 seconds

Data Logging:

Data points: .............................. 63,000 (14 days of logging

simultaneous CO

, Temperature,

2

and Humidity at 1-minute intervals).

Logging interval:....................... User adjustable from 1 second to

1 hour

Power Requirements:

Batteries: .................................. Four AA-size Alkaline or NiCd

or

AC adapter:.............................. 6 VDC nominal, 300 ma, [Q-T

RAK

mates with 5.5 mm OD x 2.1 mm ID

plug, center pin positive(+)]

Approx. battery Life:................. 13.5 hours (Alkaline), 4.75 hours

(NiCd)

Physical:

External dimensions:................ 107 mm x 183 mm x 38 mm

(4.2 in x 7.2 in x 1.5 in)

Probe length:............................ Model 8551: 17.8 cm (7.0 in)

Model 8550: 14.7 cm (5.8 in)

Probe diameter:........................ 1.9 cm (0.75

in)

Weight:..................................... 0.59 kg (1.3 pounds) (with batteries)

Display:..................................... 4-digit LCD, 15 mm (0.6 in) digit

height

Maintenance Schedule:

Factory calibration:................... Annually

User calibration:....................... As needed

Serial Interface:

Type: ....................................... RS-232

BAUD rate: .............................. 1200

Data bits:.................................. 8

Stop bits: .................................. 1

Handshaking:........................... None

Data format:.............................. ASCII

Appendix A

32

Calibration Gas

zero: ................................. Nitrogen or pure air (<10 ppm CO2)

CO

2

CO

span:................................. 1000–5000 ppm CO2

2

CO zero:................................... Pure air (<0.5 ppm CO)

CO span:.................................. 35–500 ppm CO

Gas flow rate:........................... 0.3 to 0.5 L/min

Specifications

33

Appendix A

34

Appendix B

Internal DIP Switch Settings

To access the DIP switches, remove the batteries from the battery

compartment. On the inside of the battery compartment, there is a window

with eight DIP switches The table below shows the functions for each

switch. Please refer to Figure B–1 for switch locations.

Caution

!

Switch OFF ON

* As shipped the user calibration is identical to the factory calibration

- Factory default settings are indicated with BOLD type.

- The ON position is away from the batteries and OFF is towards the

batteries.

- Switch 1 is towards the display and switch 8 is nearest to the data port.

Make certain that power is turned off before changing

DIP switch settings.

1 Degrees Celsius (°C)

2 Factory CO2 Cal.

3 Factory Temp. Cal.

4 Factory Humidity Cal.

5 Beep Disabled

6 Reserved

7 Factory CO Cal.

8 Reserved

Degrees Fahrenheit (°F)

User CO

User Temp. Cal.*

User Humidity Cal.*

Beep Enabled

Reserved

User CO Cal.*

Reserved

Cal.*

2

35

DIP SWITCH

ON

OFF

1

8

Figure B–1: DIP Switch Location

Appendix B

36

TSI Incorporated

500 Cardigan Road, Shoreview, MN 55126 U.S.A.

Web: www.tsi.com

Loading...

Loading...