TSI Incorporated 3563 Operation And Service

Particle Instruments

Integrating Nephelometer

Operation and Service Manual

Model 3563

P/N 1933563, Revision F

December 2005

Product Overview 1

Model 3563

Integrating Nephelometer

Operation and Service Manual

December 2005

Unpacking and

Setting Up the

Hardware

Operations Overview

Using NephLog

Software

Using Nephelometer

Software

Using Serial Data

Commands

2

3

4

5

6

Theory of Operation 7

Performing

8

Maintenance

Contacting

9

Customer Service

Appendixes

Manual History

The following is a history of the Model 3563 Integrating

Nephelometer Instruction Manual, part number 1933563.

Revision Date

Preliminary February 1994

Preliminary 1 August 1994

Preliminary 2 September 1994

Final November 1994

A May 1996

B April 1997

B1 July 1998

C December 2000

D April 2001

E October 2002

F December 2005

This manual was first published, in preliminary form, February

1994.

This manual was published as a preliminary 1 in August 1994.

This manual was published as a preliminary 2 in September

1994, additions of text and figures were made throughout

manual, Chapter 5 was added, and Chapter 8, “Troubleshooting

Guide,” was deleted.

The manual was published as a Final after Chapter 5, “Using

Nephelometer Software (Windows)” was added in November

1994.

In revision A, TSI’s “Limitation of Warranty and Liability” on

page iii was updated.

In revision B, Tables A-1 and A-2 in Appendix A were revised.

In revision B1, TSI’s area code changed from 612 to 651.

In revision C, TSI’s Limitation of Warranty and Liability and

TSI’s Software License were updated.

In revision D, Analog Outputs were removed.

In revision E, TSI’s phone numbers and address were updated

and schematics were removed from manual.

In revision F, Model 3550/3560 Series was changed to

Model 3563. Instructions were added for NephLog software and

Nephelometer software information was updated.

iv

Warranty

Part Number 1933563 / Revision F / December 2005

Copyright ©TSI Incorporated / 1994–2005 / All rights reserved.

Address TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA

Fax No. (651) 490-3824

Email Address particle@tsi.com

Limitation of Warranty

and Liability

(effective July 2000)

Seller warrants the goods sold hereunder, under normal use and service as

described in the operator's manual, shall be free from defects in workmanship and

material for (12) months, or the length of time specified in the operator's manual,

from the date of shipment to the customer. This warranty period is inclusive of any

statutory warranty. This limited warranty is subject to the following exclusions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other

components when indicated in specifications, are warranted for 90 days from

the date of shipment.

b. Parts repaired or replaced as a result of repair services are warranted to be free

from defects in workmanship and material, under normal use, for 90 days from

the date of shipment.

c. Seller does not provide any warranty on finished goods manufactured by others

or on any fuses, batteries or other consumable materials. Only the original

manufacturer's warranty applies.

d. Unless specifically authorized in a separate writing by Seller, Seller makes no

warranty with respect to, and shall have no liability in connection with, goods

which are incorporated into other products or equipment, or which are modified

by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS

stated herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER

OR BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES,

INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS BASED

ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE) SHALL

BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE PURCHASE

PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR REPLACEMENT OF THE

GOODS. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE

RESPONSIBLE FOR INSTALLATION, DISMANTLING OR REINSTALLATION COSTS

OR CHARGES. No Action, regardless of form, may be brought against Seller more

than 12 months after a cause of action has accrued. The goods returned under

warranty to Seller's factory shall be at Buyer's risk of loss, and will be returned, if at

all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY

AND LIABILITY, which contains the complete and exclusive limited warranty of

Seller. This LIMITATION OF WARRANTY AND LIABILITY may not be amended,

modified or its terms waived, except by writing signed by an Officer of Seller.

v

Software License (effective March 1999)

1. GRANT OF LICENSE. TSI grants to you the right to use one copy of the enclosed

TSI software program (the “SOFTWARE”), on a single computer. You may not

network the SOFTWARE or otherwise use it on more than one computer or

computer terminal at the same time.

2. COPYRIGHT. The SOFTWARE is owned by TSI and is protected by United States

copyright laws and international treaty provisions. Therefore, you must treat the

SOFTWARE like any other copyrighted material (e.g., a book or musical recording)

except that you may either (a) make one copy of the SOFTWARE solely for backup

or archival purposes, or (b) transfer the SOFTWARE to a single hard disk provided

you keep the original solely for backup or archival purposes.

3. OTHER RESTRICTIONS. You may not rent or lease the SOFTWARE, but you

may transfer the SOFTWARE and accompanying written material on a permanent

basis, provided you retain no copies and the recipient agrees to the terms of this

Agreement. You may not reverse-engineer, decompile, or disassemble the

SOFTWARE.

4. DUAL MEDIA SOFTWARE. If the SOFTWARE package contains multiple types of

media, then you may use only the media appropriate for your single-user

computer. You may not use the other media on another computer or loan, rent,

lease, or transfer them to another user except as part of the permanent transfer

(as provided above) of all SOFTWARE and written material.

5. U.S. GOVERNMENT RESTRICTED RIGHTS. The SOFTWARE and

documentation are provided with RESTRICTED RIGHTS. Use, duplication, or

disclosure by the Government is subject to the restrictions set forth in the “Rights

in Technical Data and Computer Software” Clause at 252.227-7013 and the

“Commercial Computer Software - Restricted Rights” clause at 52.227-19.

6. LIMITED WARRANTY. TSI warrants that the SOFTWARE will perform

substantially in accordance with the accompanying written materials for a period

of ninety (90) days from the date of receipt.

7. CUSTOMER REMEDIES. TSI’s entire liability and your exclusive remedy shall

be, at TSI’s option, either (a) return of the price paid or (b) repair or replacement of

the SOFTWARE that does not meet this Limited Warranty and which is returned

to TSI with proof of payment. This Limited Warranty is void if failure of the

SOFTWARE has resulted from accident, abuse, or misapplication. Any

replacement SOFTWARE will be warranted for the remainder of the original

warranty period or thirty (30) days, whichever is longer.

8. NO OTHER WARRANTIES. TSI disclaims all other warranties, either express or

implied, including, but not limited to implied warranties of merchantability and

fitness for a particular purpose, with regard to the SOFTWARE and the

accompanying written materials.

9. NO LIABILTY FOR CONSEQUENTIAL DAMAGES. In no event shall TSI be liable

for any damages whatsoever (including, without limitation, special, incidental,

consequential or indirect damages for personal injury, loss of business profits,

business interruption, loss of information or any other pecuniary loss) arising out

of the use of, or inability to use, this SOFTWARE.

Service Policy Knowing that inoperative or defective instruments are as detrimental to TSI as they

are to our customers, our service policy is designed to give prompt attention to any

problems. If any malfunction is discovered, please contact your nearest sales office

or representative, or call TSI’s Particle Instruments at 1-800-874-2811 (USA) or (651)

490-2811.

vi Model 3563 Integrating Nephelometer

!

!

!

Safety

This section gives instructions to promote safe and proper handling

of the Model 3563 Integrating Nephelometer.

Caution

High temperatures that can cause burns.

To avoid personal injury, disconnect power to the Nephelometer and allow the

halogen lamp and the lamp housing to cool before handling.

WARNING

High voltages that can shock or burn.

The box that houses the photomultiplier tubes (PMT) contains a high voltage

source. Components within this box should only be serviced by a qualified

technician. Disconnect all power to the Nephelometer and contact TSI personnel

before disassembling the PMT box.

Caution

Light sensitive components.

To avoid damage to the photomultiplier tubes (PMT), remove power from the

Nephelometer and open the PMT box in subdued lighting. Exposing the

photomultiplier tubes to direct light may affect tube performance.

WARNING

Moving parts that can cause serious personal injury.

Disconnect power to Nephelometer before inserting anything into the aerosol

inlet. The ball valve and position sensor are motorized and can move if power is

applied.

vii

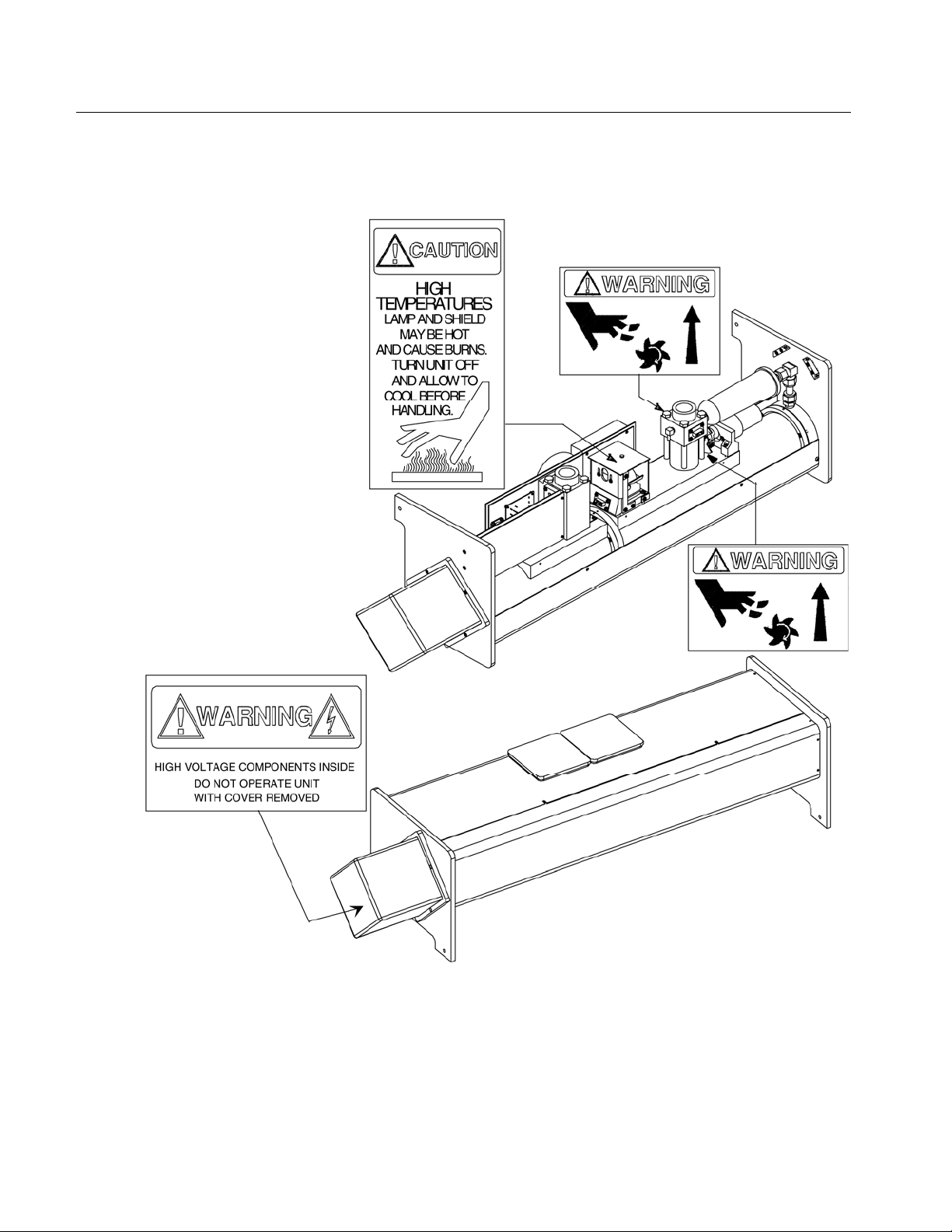

Labels

Figure 1 shows the special warning and caution labels and their

approximate location inside the Nephelometer.

Figure 1

Nephelometer Warning and Caution Labels

viii Model 3563 Integrating Nephelometer

Contents

Manual History .................................................................... iv

Warranty................................................................................v

Software License (effective March 1999) ................................ vi

Safety ................................................................................. vii

Labels ..................................................................................

About This Manual .............................................................xvii

Purpose...............................................................................

Reusing and Recycling ........................................................ xvii

Submitting Comments ........................................................ xvii

Notational Conventions ...................................................... xviii

viii

xvii

Chapters/Appendixes

CHAPTER 1 Product Overview............................................ 1-1

Product Description ............................................................ 1-1

Applications ........................................................................ 1-1

Beer-Lambert Law ............................................................ 1-2

How the Nephelometer Operates ......................................... 1-2

CHAPTER 2 Unpacking and Setting Up the Hardware ......... 2-1

Packing List ........................................................................ 2-1

Unpacking Instructions....................................................... 2-2

Connecting Power ............................................................... 2-2

Connecting Line Voltage to the Power Supply Module....... 2-2

Connecting the Power Supply Module to the

Nephelometer ................................................................ 2-

Using Another Power Supply ............................................ 2-3

Connecting a Computer ...................................................... 2-4

Mounting the Nephelometer ................................................ 2-4

Space Requirements......................................................... 2-6

Mounting Holes ................................................................ 2-6

Inlet and Outlet Ports ....................................................... 2-7

Environmental Concerns .................................................. 2-7

Connecting an External Blower ........................................... 2-8

Calibrating the Nephelometer .............................................. 2-9

3

CHAPTER 3 Operations Overview ....................................... 3-1

Serial Communications ....................................................... 3-

Hardware Components........................................................ 3-1

Power Failures ................................................................. 3-2

Lamp Power ..................................................................... 3-2

1

ix

Photomultiplier Tubes (PMTs)........................................... 3-2

Heater .............................................................................. 3-3

Blower Settings ................................................................ 3-3

Humidity and Temperature Sensors ................................. 3-3

Setting Up Parameters ........................................................ 3-4

Operating Parameters....................................................... 3-4

Time Parameters .............................................................. 3-7

Polled and Unpolled Communications .............................. 3-8

CHAPTER 4 Using NephLog Software ..................................4-1

Overview of NephLog Software............................................. 4-

1

Hardware and Software Requirements ................................ 4-1

Installing the NephLog Software .......................................... 4-2

Setting up the NephLog Software......................................... 4-4

CHAPTER 5 Using Nephelometer Software ..........................5-1

Overview of Nephelometer Software ..................................... 5-

1

Hardware and Software Requirements ................................ 5-2

Installing and Starting the Software .................................... 5-2

Quick Start ......................................................................... 5-4

Step 1. Verify COM Port .................................................. 5-5

Step 2. Start Data Collection ........................................... 5-5

Step 3. View Data and Nephelometer Status.................... 5-6

Step 4. Print a Graph ...................................................... 5-9

Step 5. Perform a Background (Zero Baseline)

Measurement ................................................................ 5-

9

Basic Nephelometer Operations...................................... 5-10

Clean Air Test ................................................................... 5-12

Menus and Commands: A Reference Guide ...................... 5-14

Using the File Menu ....................................................... 5-14

Using the Config Menu ................................................... 5-18

Using the View Menu ..................................................... 5-22

Using the Run Menu ...................................................... 5-35

Using the Window Menu................................................. 5-44

Using the Pause/Resume Menu ..................................... 5-44

Using the Help Menu...................................................... 5-45

CHAPTER 6 Using Serial Data Commands ........................... 6-1

Pin Connectors.................................................................... 6-

Baud Rate ........................................................................... 6-2

Parity (8-Bits Even) ............................................................. 6-2

Commands.......................................................................... 6-2

Set Commands................................................................. 6-5

Action Commands .......................................................... 6-18

Read Commands (Polled) ................................................ 6-21

Unpolled Commands ...................................................... 6-25

Unpolled Record Formats ............................................... 6-26

How to Input Commands and Troubleshoot the Results . 6-30

CHAPTER 7 Theory of Operation.........................................7-1

History ................................................................................ 7-

x Model 3563 Integrating Nephelometer

1

1

Construction ....................................................................... 7-2

Theory of Integration ........................................................... 7-4

Theory of Wavelength Dependence ...................................... 7-6

Signal Processing ................................................................ 7-8

Description....................................................................... 7-9

Equations/Calculations ................................................... 7-9

Detection Optics................................................................ 7-16

Calibration ........................................................................ 7-16

CHAPTER 8 Performing Maintenance ................................. 8-1

Removing Nephelometer Covers: Top, Bottom, and PMT ...... 8-

2

Removing the Top Cover ................................................... 8-2

Removing the Bottom Cover ............................................. 8-3

Removing the PMT Cover.................................................. 8-4

Calibrating the Nephelometer .............................................. 8-5

Cleaning Fan Filters............................................................ 8-6

Replacing the Main Microprocessor EPROM ........................ 8-7

Replacing the Motor Control Microprocessor ....................... 8-9

Replacing the Lamp........................................................... 8-

Replacing Aerosol Filters ................................................... 8-

11

13

Cleaning the Light Pipe Lens ............................................. 8-16

Checking for Leaks............................................................ 8-19

Cleaning the Reference Chopper........................................ 8-19

Cleaning the Light Pipe Outlet and the Backscatter

Shutter........................................................................... 8-

27

Cleaning the Flocked Paper ............................................... 8-35

Replacing a Temperature or Humidity Sensor ................... 8-40

Replacing a Photomultiplier Tube...................................... 8-42

Checking, Cleaning, and Replacing Bandpass Filters ........ 8-44

Cleaning the Lens ............................................................. 8-48

CHAPTER 9 Contacting Customer Service .......................... 9-1

Technical Contacts at TSI.................................................... 9-

1

Returning the Nephelometer for Service .............................. 9-1

APPENDIX A Specifications ................................................ A-1

APPENDIX B Bibliography .................................................. B-

Instrument Principles, Design and Calibration ................. B-

1

1

Applications of the Integrating Nephelometer to

Studies of Atmospheric Visibility ...................................B-

2

Light Scattering Measurements Related to Aerosol

Mass Concentration ...................................................... B-

3

Vertical Column and Horizontal Profile Studies with

the Integrating Nephelometer......................................... B-

4

Apportioning of Light Scattering Coefficient to

Chemical Species and to Sources .................................. B-

4

Use of the Integrating Nephelometer in Studies of

Physical and Chemical Properties of Aerosols ................B-

5

Observation of the Effects of Humidity on Light Scattering

Coefficient; Measurements on Fogs and Clouds ............. B-

Contents xi

6

Observation of Aerosols in Remote Locations with the

Integrating Nephelometer .............................................. B-

The Use of Integrating Nephelometer Data in Radiation

and Climate Studies ...................................................... B-

APPENDIX C Nephelometer Sensor Connectors ...................C-1

6

7

Figures

APPENDIX D Windows Program Files.................................. D-

Reader’s Comments

Index

1 Nephelometer Warning and Caution Labels ....................... viii

1-1 TSI Model 3563 Nephelometer .......................................... 1-

1-2 A Cross-Section View of the Nephelometer ........................ 1-

2-1 Power Supply Module ....................................................... 2-

2-2 Ventilation Requirements ................................................. 2-

2-3 COM Port Connector......................................................... 2-

2-4 Nephelometer Resting on its Feet...................................... 2-

2-5 Nephelometer in the Optimal Orientation ......................... 2-

2-6 As-Built Dimensions (Space Requirements) ...................... 2-

2-7 Blower Bracket ................................................................. 2-

2-8 Mounting the External Blower .......................................... 2-

3-1 Humidity and Temperature Sensor Locations ................... 3-

1

1

3

2

3

4

5

5

6

8

9

4

4-1 Start-up Screen ................................................................ 4-

4-2 Setup Options .................................................................. 4-

4-3 Selecting the Communications Port .................................. 4-

4-4 Communications Port Error .............................................. 4-

4-5 Open Data File Dialog....................................................... 4-

4-6 Data Display Options ....................................................... 4-

5-1 Start-up Screen ................................................................ 5-

5-2 The Main Menu of the Windows-Based Nephelometer

Program ........................................................................... 5-

5-3 The COM Port Setup Display ............................................ 5-

5-4 Choosing Data Collection from the Run Menu Starts

Data Collection................................................................. 5-

5-5 Select Data Display to View Data as it is Collected by

the Nephelometer ............................................................. 5-

5-6 The Nephelometer State Display Shows the Status of

the Nephelometer ............................................................. 5-

5-7 The Photon Frequency Display Shows the Current

Photon Frequency Calculations ........................................ 5-

5-8 The Graph Display Shows Current Data ........................... 5-

5-9 The Terminal Mode Display ............................................ 5-

3

4

5

6

8

9

3

4

5

6

7

7

8

8

10

xii Model 3563 Integrating Nephelometer

5-10 The Set Nephelometer Parameters Display Shows the

Current Parameters of the Nephelometer........................ 5-

5-11 Select a Filename After Choosing the Open Log File

Command ...................................................................... 5-

5-12 Select a Filename After Choosing the Log Data

Command ...................................................................... 5-

5-13 Select the Print Command from the File Menu................ 5-

5-14 Types of Graphs. Scatter Data Graph (top) and Status

Graph (bottom)............................................................... 5-

5-15 Choose Nephelometer from the Config Menu................... 5-

5-16 Use the COM Port Setup Display to Select the

Appropriate Communications Port ................................. 5-

5-17 The Data Display Shows Current (raw) Data Values

Collected by the Nephelometer ....................................... 5-

5-18 Graph Data of the Current Log Data File ........................ 5-

5-19 The Graph Options Window Lets You Customize Your

Graphs........................................................................... 5-

5-20 Photon Frequency Display .............................................. 5-

5-21 The Photon Frequency Graph Displays Current

Measurements................................................................ 5-

5-22 The Status of the Nephelometer is Displayed by Selecting

Neph State from the View Menu ..................................... 5-

5-23 Nephelometer Configuration Data is Displayed by

Selecting Neph Config Data from the View Menu ............ 5-

5-24 Display Log File Records in Tabular Format by Selecting

Log Data Table from the View Menu ............................... 5-

5-25 Select the Type of Graph from the Log Data Graph

Options .......................................................................... 5-

5-26 Operating Status Graph ................................................. 5-

5-27 Photon Counts (Calibrator) Graph .................................. 5-

5-28 Photon Counts (Dark) Graph .......................................... 5-

5-29 Photon Counts (Measure) Graph ..................................... 5-

5-30 Scattering Coefficients Graph ......................................... 5-

5-31 The Destination Dialog Box ............................................ 5-

5-32 The Nephelometer Calibration Data Display.................... 5-

5-33 Calibration Parameters Setup Screen ............................. 5-

5-34 Plugs for Inlet and Outlet and Gas Line With the Blue

DQ Filter ........................................................................ 5-

5-35 Selecting Data Collection from the Run Menu ................. 5-

5-36 Select Terminal Mode to Issue Serial Data Commands

to the Nephelometer ....................................................... 5-

5-37 The Help Contents Display Provides a List of Help

Topics ............................................................................ 5-

5-38 About Shows the Current Version of Your Software

and the Copyright Notice ................................................ 5-

13

15

16

17

18

19

22

23

25

25

27

27

28

29

31

32

33

33

33

34

34

35

36

37

42

43

44

45

46

6-1 COM Port Pin Designations............................................... 6-

6-2 Timelines for Data Measurement .................................... 6-

6-3 Comparison of Manual, Normal, and Air Chop Modes ..... 6-

Contents xiii

1

11

12

7-1 Nephelometer Schematic .................................................. 7-2

7-2 Reference Chopper Zones ................................................. 7-

7-3 Nephelometer Geometry.................................................... 7-

3

5

8-1 Nephelometer Showing Top, Bottom, and PMT Covers ...... 8-

8-2 Top Cover Screws, Bottom Cover Screws, Fan Cover Screws,

and I/O Panel Screws....................................................... 8-

8-3 PMT Cover ........................................................................ 8-

8-4 Fan Covers and Foam Inserts ........................................... 8-

8-5 Top Cover Screws ............................................................. 8-

8-6 Microprocessor and EPROM Locations on the Digital

Circuit Board ................................................................. 8-

8-7 Top Cover Screws ........................................................... 8-

8-8 Lamp Shield ................................................................... 8-

8-9 Top Cover Screws ........................................................... 8-

8-10 Bottom Cover Screws Securing End Plate ....................... 8-

8-11 White HEPA Filter........................................................... 8-

8-12 Blue DQ Filter ................................................................ 8-

8-13 Top Cover Screws ........................................................... 8-

8-14 Lamp Shield ................................................................... 8-

8-15 Light Pipe Lens ............................................................... 8-

8-16 Top Cover Screws, Bottom Cover Screws, Fan Cover

Screws, and I/O Panel Screws........................................ 8-

8-17 Circuit Board Mounting Screws ...................................... 8-

8-18 PMT End Plate Screws .................................................... 8-

8-19 Aperture Assembly ......................................................... 8-

8-20 Aperture Plates and Circuit Board .................................. 8-

8-21 Reference Chopper.......................................................... 8-

8-22 Top Cover Screws, Bottom Cover Screws, Fan Cover

Screws, and I/O Panel Screws........................................ 8-

8-23 Lamp Shield ................................................................... 8-

8-24 Disconnect Connectors and Tubing ................................ 8-

8-25 Nephelometer Sections Together ..................................... 8-

8-26 Nephelometer Sections Apart .......................................... 8-

8-27 Lamp Base ..................................................................... 8-

8-28 Removing the Lamp Base Assembly From the Sensor ..... 8-

8-29 Light Pipe Outlet and Backscatter Shutter ...................... 8-

8-30 O-ring on the Sensor Backbone ...................................... 8-

8-31 Top Cover Screws, Bottom Cover Screws, Fan Cover

Screws, and I/O Panel Screws........................................ 8-

8-32 Disconnect Connectors and Tubing ................................ 8-

8-33 Nephelometer Sections Together ..................................... 8-

8-34 Nephelometer Sections Apart .......................................... 8-

8-35 Flocked Paper Outside the Nephelometer........................ 8-

8-36 Top Cover Screws, Bottom Cover Screws, Fan Cover

Screws, and I/O Panel Screws........................................ 8-

8-37 Humidity and Temperature Sensor Locations ................. 8-

8-38 PMT Cover ...................................................................... 8-

8-39 Red, Blue and Green PMTs with Setscrews ..................... 8-

2

3

5

6

8

10

11

12

13

14

15

15

16

17

18

20

22

23

24

25

25

27

28

29

30

30

31

32

33

34

36

37

38

38

39

41

41

43

44

xiv Model 3563 Integrating Nephelometer

Tables

8-40 PMT Cover ...................................................................... 8-46

8-41 Red, Blue and Green PMTs with Setscrews ..................... 8-

8-42 Bandpass Filter .............................................................. 8-

8-43 PMT Cover ...................................................................... 8-

8-44 Red, Blue and Green PMTs with Setscrews ..................... 8-

2-1 Packing List with Accessories ........................................... 2-1

3-1 Typical Time Settings........................................................ 3-9

5-1 Basic Windows Nephelometer Operations ....................... 5-11

5-2 Nephelometer Setup Parameters ..................................... 5-20

5-3 Data Display Parameters ................................................ 5-23

5-4 Graph Options for the Graph Display ............................. 5-26

5-5 Nephelometer Configuration Data ................................... 5-30

5-6 Calibration Parameters ................................................... 5-37

5-7 Calibration Procedure ..................................................... 5-39

6-1 Signal Connections for RS-232 Configurations ................. 6-2

6-2 Serial Commands ............................................................. 6-4

47

48

49

50

7-1 Examples of Raw Count Data ........................................... 7-9

7-2 Comparisons Between Gate Width and Physical

Dimensions .................................................................... 7-

7-3 Counts Normalize to Photon Frequency (Hz) ................... 7-11

7-4 Boxcar Averages ............................................................. 7-11

8-1 Maintenance Overview...................................................... 8-1

A-1 Specifications for the Nephelometer Sensor ...................... A-1

10

Contents xv

About This Manual

Purpose

This is an operation and service manual for the Model 3563

Integrating Nephelometer.

Reusing and Recycling

As part of TSI Incorporated’s effort to have a minimal negative

impact on the communities in which its products are manufactured

and used:

This manual uses recyclable paper.

This manual has been shipped, along with the instrument, in a

reusable carton.

Submitting Comments

TSI values your comments and suggestions on this manual. Please

use the comment sheet, located on the last page of this manual, to

send us your opinion on the manual’s usability, to suggest specific

improvements, or to report any technical errors.

If the comment sheet has already been used, mail or fax your

comments on another sheet of paper to:

Particle Instruments

TSI Incorporated

500 Cardigan Road

Shoreview, MN 55126

Fax: (651) 490-3824

xvii

Notational Conventions

This manual uses the following conventions when describing

software:

<Enter> Denotes the “Return” or “Enter” key on the

keyboard.

<xx> Denotes an alphanumeric key on the keyboard. For

instance, <F4> means press the function “F4” on the

keyboard.

examples Examples of what you see on the screen and the text

you type are shown in monospace type resembling

computer output.

italic Variable information in computer responses,

commands, and options you must supply and type

are shown in italics in a font that resembles

computer font.

UPPERCASE Uppercase letters indicate names of programs, files

or commands.

Bold Bold type indicates names of fittings as they appear

on the instrument and commands appearing on the

display.

xviii Model 3563 Integrating Nephelometer

CHAPTER 1

Product Overview

This chapter contains a product description and a list of features

for the Model 3563 Integrating Nephelometer,

description of how the instrument works.

Product Description

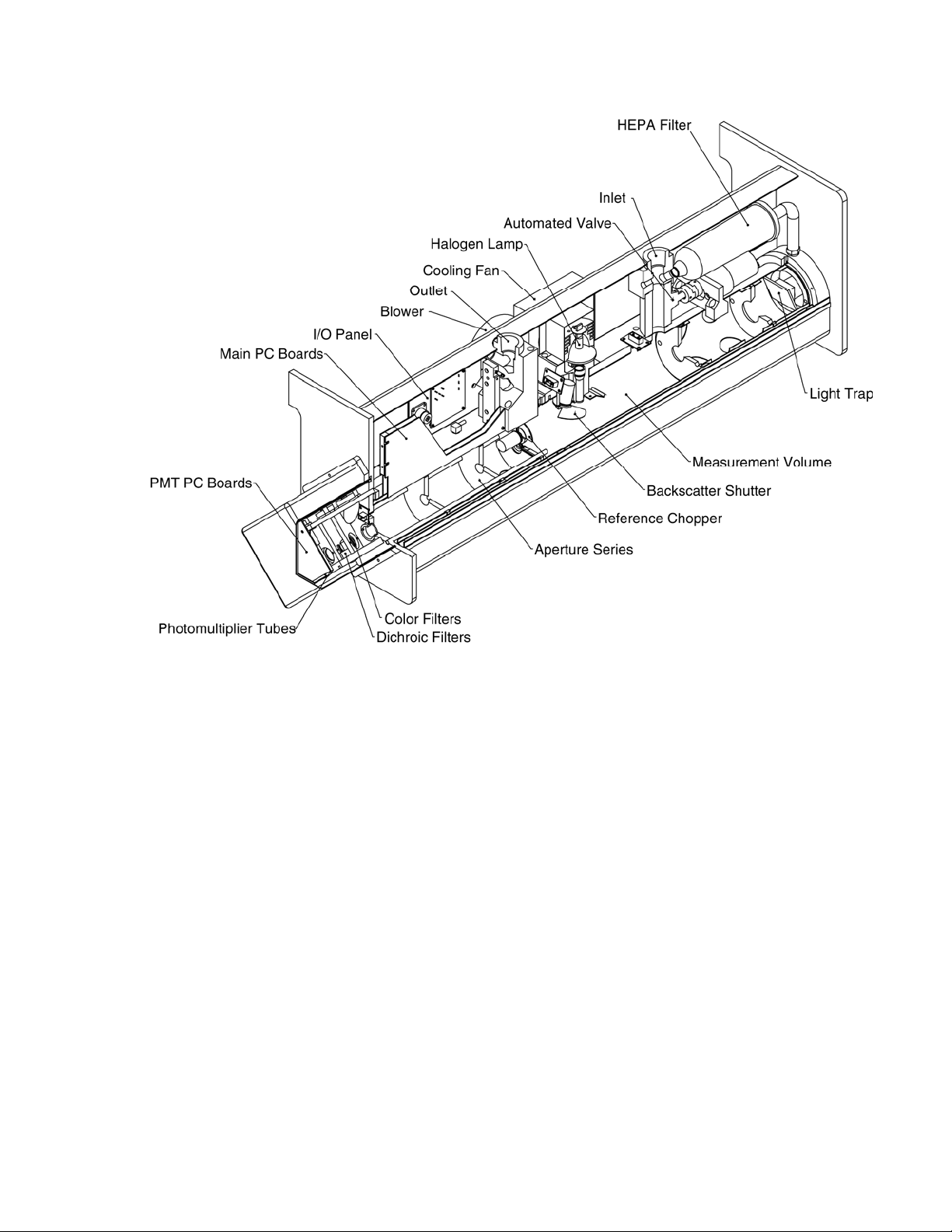

The Model 3563 Integrating Nephelometer, shown in Figure 1-1, is

designed for long-term monitoring of visual range and air quality in

ground-based and airborne studies. It continuously monitors the

light scattering coefficient of airborne particles.

*

as well as a brief

Applications

Figure 1-1

TSI Model 3563 Nephelometer

TSI Integrating Nephelometer is designed specifically for studies of

direct radiative forcing of the Earth’s climate by aerosol particles, or

studies of ground-based or airborne atmospheric visual air quality

in clean areas. It may also be used as an analytical detector for

aerosol particles whenever the parameter of interest is the lightscattering coefficient of the particles after a pretreatment step, such

as heating, humidification, or segregation by size.

*

The design of this instrument incorporates developments patented by the University of

Washington. Refer to United States Patent Numbers 3,563,661; 3,700,333; and 3,953,127.

1-1

The light-scattering coefficient is a highly variable aerosol property.

Integrating Nephelometer measures the angular integral of light

scattering that yields the quantity called the scattering coefficient,

used in the Beer-Lambert Law to calculate total light extinction.

Beer-Lambert Law

I/Io = e

where:

I

= intensity of light source

o

I = intensity of light after passing through atmospheric path

x = thickness of medium through which light passes

σ

= total extinction coefficient

(= scattering coefficient + absorption coefficient)

(-σx)

How the Nephelometer Operates

A small, turbine blower draws an aerosol sample through the large

diameter inlet into the measurement volume (

the sample is illuminated over an angle of 7 to 170° by a halogen

lamp directed through an optical light pipe and opal glass diffuser.

Figure 1-2). There,

The sample volume is viewed by three photomultiplier tubes (PMT)

through a series of apertures set along the axis of the main

instrument body. Aerosol scattering is viewed against the backdrop

of a very efficient light trap. The light trap, apertures, and a highly

light-absorbing coating on all internal surfaces of the instrument

combine to give a very low scatter signal from the walls of the

instrument.

Dichroic filters, in front of the PMT tubes, split and direct the light,

which has been scattered by aerosol. The light is directed into three

bandpass filters, blue, green and red. A constantly rotating

reference chopper has separate areas to provide three types of

signal detection. The first area gives a measure of the aerosol lightscattering signal allowed by an opening in the rotating chopper. The

second area blocks all light from detection and gives a

measurement of the PMT dark current that which is subtracted

from the measurement signal. The third area is a translucent

portion of the chopper, illuminated by the halogen lamp, which

provides a measure of the light-source signal. In this way, over

time, any change in the light source or in detector efficiency is

compensated.

1-2 Model 3563 Integrating Nephelometer

Figure 1-2

A Cross-Section View of the Nephelometer

In backscatter mode, the backscatter shutter rotates under the

lamp to block light in the 7 to 90° range. When light is blocked,

only light scattered in the backward direction is transmitted to the

PMT detectors. The backscatter signal can be subtracted from the

total signal to calculate forward-scattering signal data. When this

measurement is not of interest, the backscatter shutter can be

“parked” in the total scatter position.

Periodically, an automated valve built into the inlet can be activated

to divert all of the aerosol sample through a high-efficiency (HEPA)

filter. This gives a measure of the clean-air signal for the local

environment. This signal is subtracted, along with the PMT darkcurrent signal, from the aerosol-scatter signal to give only that

portion of the scatter signal provided by the sample aerosol.

Particle-scattering parameters for all three wavelengths of total and

backscatter signal are continuously averaged and passed to a

computer or data logger for permanent storage.

Product Overview 1-3

CHAPTER 2

Unpacking and Setting

Up the Hardware

Use the information in this chapter to unpack and set up the

hardware components of a Model 3563 Integrating Nephelometer.

This chapter contains these main sections:

Packing List

Unpacking instructions

Connecting power

Connecting a computer

Packing List

Mounting the Nephelometer

Connecting an external blower

Table 2-1 gives a packing list for the Nephelometer and the power

supply module. The packing list for the Data Analysis Center is

included in one of the two or three Data Analysis Center shipping

cartons.

Table 2-1

Packing List with Accessories

Qty Description Part Number

1 Nephelometer 3563

1 Power supply module 3590

1 Power supply cable 1303053*

1 Power cord (24 volts dc) 1035551

1 Blower bypass 1035545

1 Serial data cable (9-pin, 12 ft.) 962002

1 Serial cable adapter (25F-9M) 962003

1 Software CD 390107

1 Instruction manual 1933563

1 White HEPA filter 1602051

1 Blue DQ filter 1602080

1 Set (2) fan filters (foam inserts) 1602071

1 Lamp (halogen) 2201111

1 Vacuum grease 1701000

*Power cord listed is for USA use only.

2-1

Unpacking Instructions

The power supply module and power cord are in one box; the

Nephelometer sensor, power cable, manual, software CD, and other

accessories are in another box. Keep the packing material in case

you have to send the Nephelometer back to TSI.

The Nephelometer sensor comes fully assembled. If anything is

missing or appears to be damaged, contact your TSI representative,

or contact Customer Service at 1-800-874-2811 (USA) or (651) 490-

2811. Chapter 9, “

for returning the Nephelometer to TSI Incorporated.

Contacting Customer Service,” gives instructions

Connecting Power

This section describes connecting power to the power supply

module and connecting the power supply module to the

Nephelometer sensor, as well as using another power source for the

Nephelometer sensor.

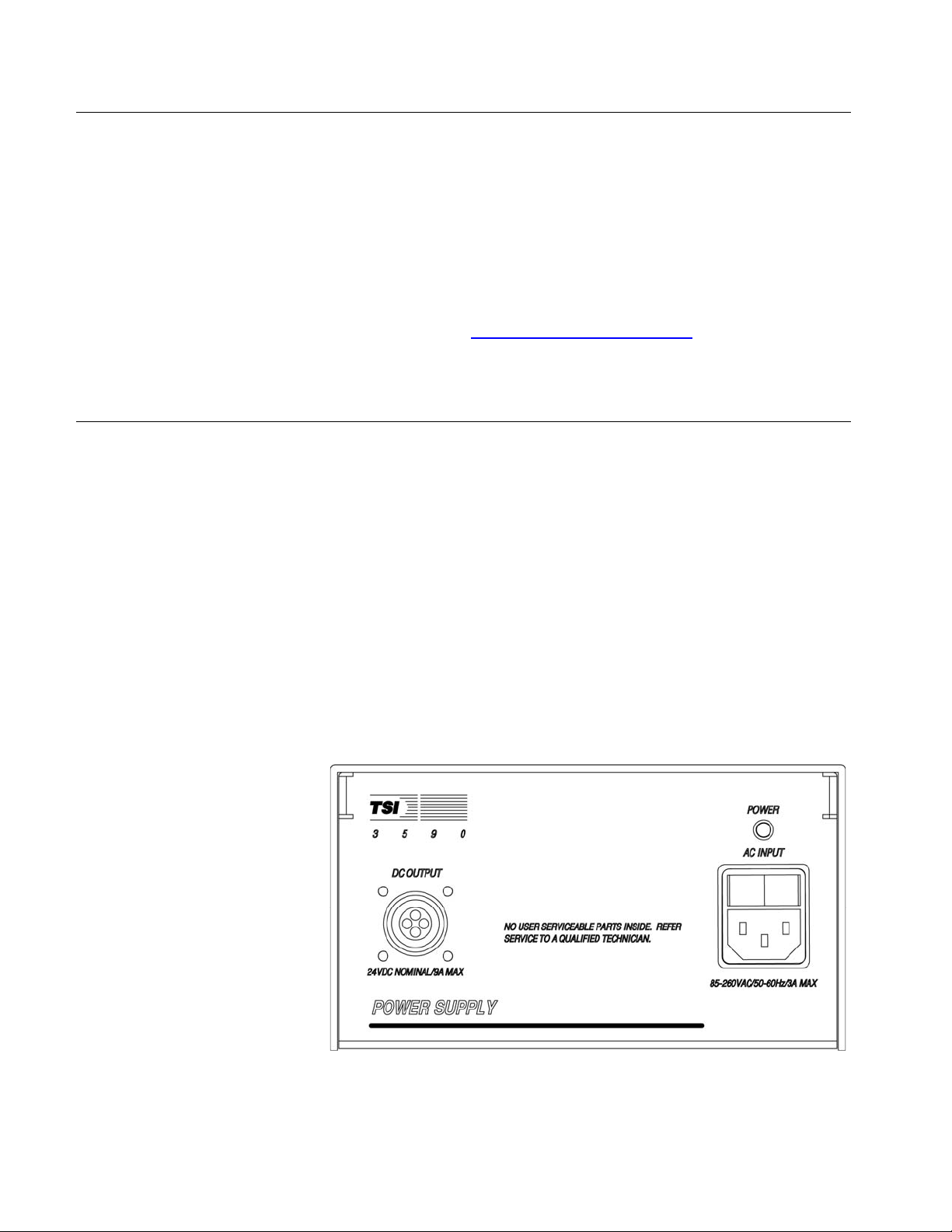

Connecting Line Voltage to the Power Supply Module

Use the line cord (supplied) to connect the TSI power supply

module to any line voltage from 85–260 volts AC at 50–60 Hz

(

Figure 2-1). The auto-switching power supply automatically

adjusts to the AC voltage provided.

Figure 2-1

Power Supply Module

2-2 Model 3563 Integrating Nephelometer

Connecting the Power Supply Module to the Nephelometer

The power supply module includes a 4-meter (12-ft.) cord with fourconductor, quarter-turn quick connectors. Before connecting the

cord, make sure the power switch is in the Off position. Connect

the pin end to the power supply and the socket end to the POWER

AC INPUT connector (

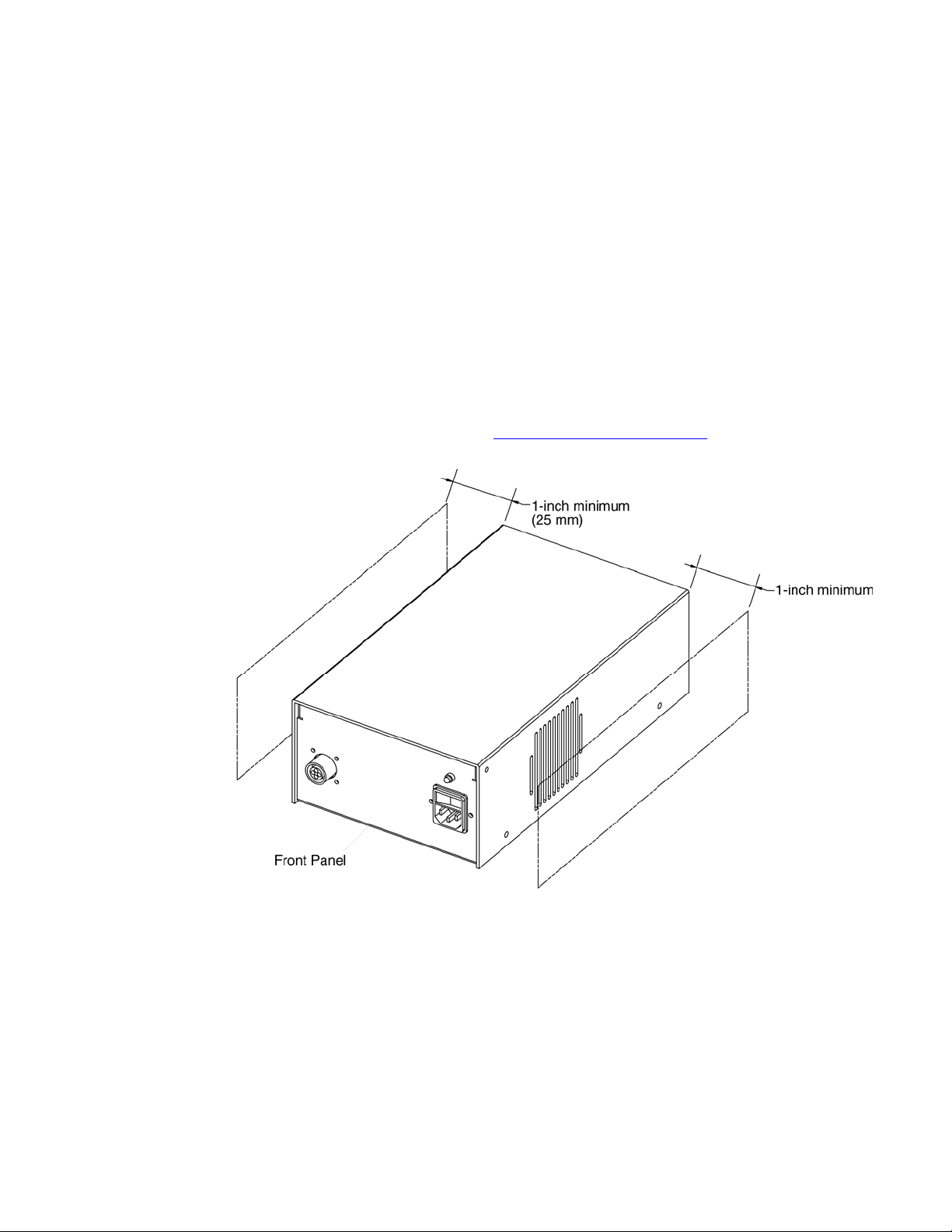

The TSI power supply module can be oriented in any direction, but

the cooling fan intake and exhaust vents should be free from

obstructions at all times (

Note: The power supply module contains no user-serviceable parts.

If the module is not operating properly, use the information in

Chapter 9, “

Figure 2-1) on the Nephelometer sensor.

Figure 2-2).

Contacting Customer Service,” to contact TSI.

Figure 2-2

Ventilation Requirements

Using Another Power Supply

As an option, you can connect the Nephelometer sensor to a 24–28

volts DC source. The lamp power is maximum at the higher end of

the DC range. You may order an extra cable (1035564) and wire

one end by connecting the red wire to +, the white wire to –, and the

green wire to chassis ground.

Unpacking and Setting Up the Hardware 2-3

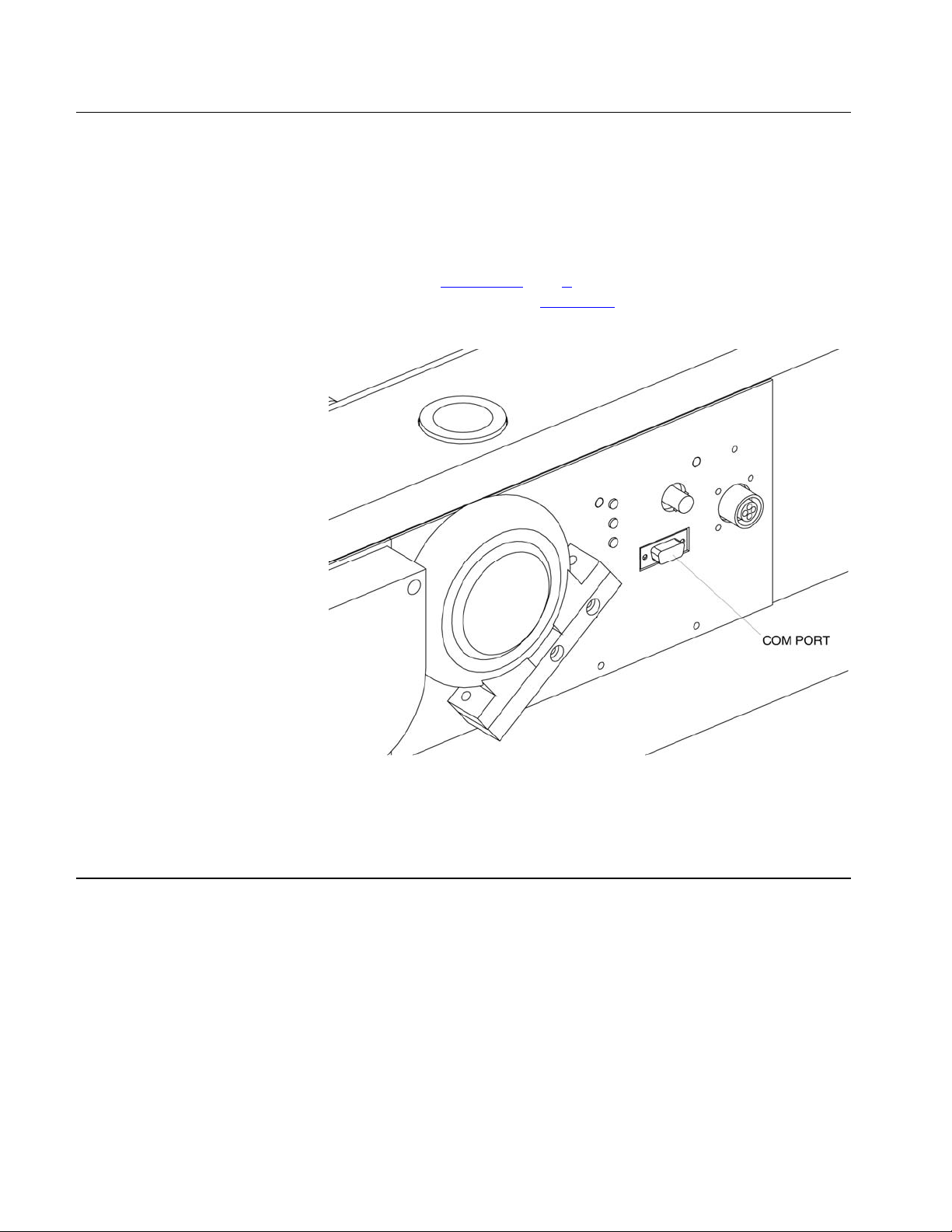

Connecting a Computer

Connect the serial port of an IBM-compatible computer to the

COM PORT connector on the Nephelometer sensor (

the 4-meter cable provided, and if you need additional length, use a

standard IBM 9-pin, serial extension cable.

Note: Refer to

software and refer to

data commands.

Chapters 4 and 5 for instructions on using TSI

Figure 2-3). Use

Chapter 6 for information on using serial

Figure 2-3

COM Port Connector

Mounting the Nephelometer

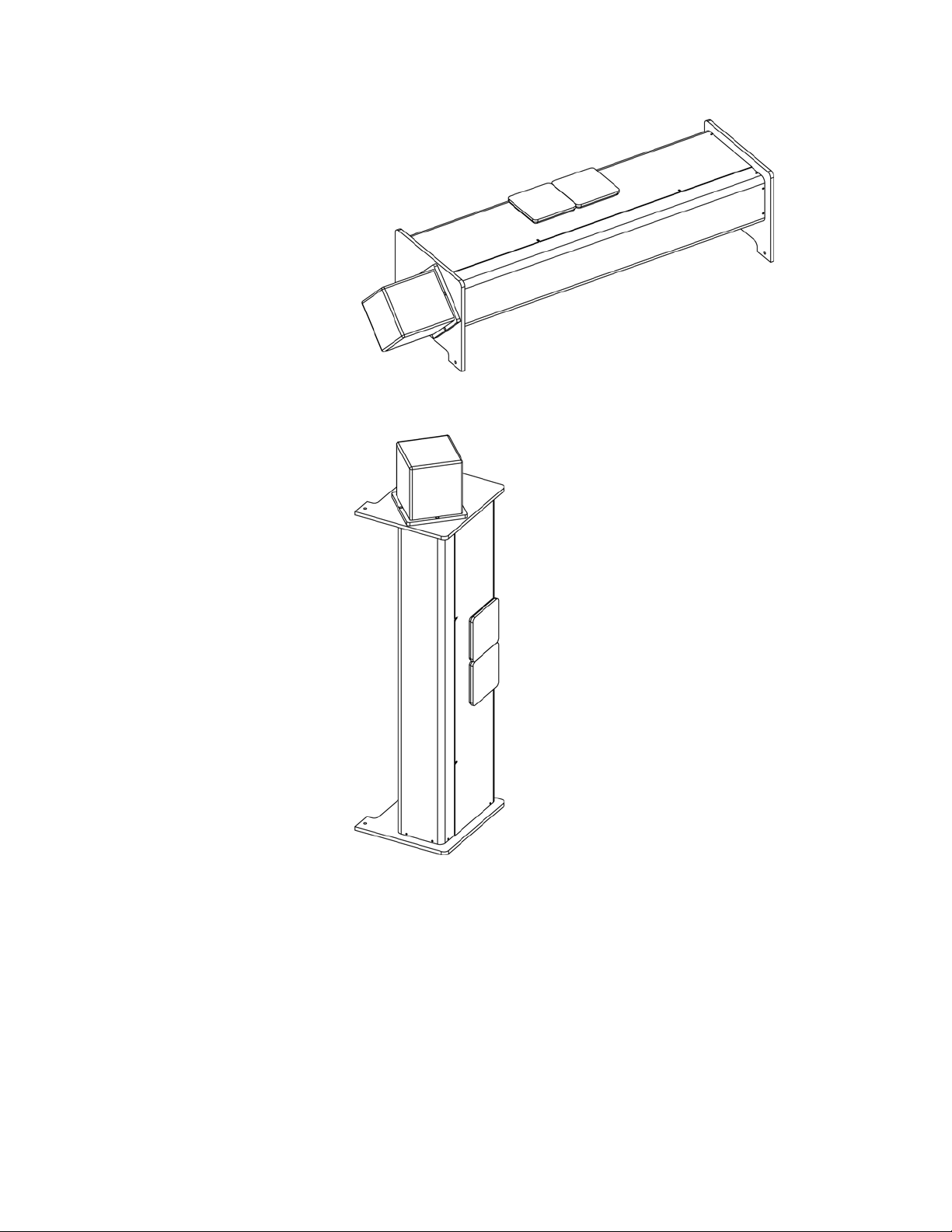

You can mount the Nephelometer in a variety of positions

depending on the application. Normally, the Nephelometer rests on

its feet (

the PMT box at the top and the light trap end at the bottom

(

Figure 2-5).

Note: Other positions are possible but consider dust collection

2-4 Model 3563 Integrating Nephelometer

Figure 2-4), but the best position is a vertical mount with

opposite the lamp or on the lens. Dust raises the background

noise level and necessitates cleaning more often.

Figure 2-4

Nephelometer Resting on its Feet

Figure 2-5

Nephelometer in the Optimal Orientation

Unpacking and Setting Up the Hardware 2-5

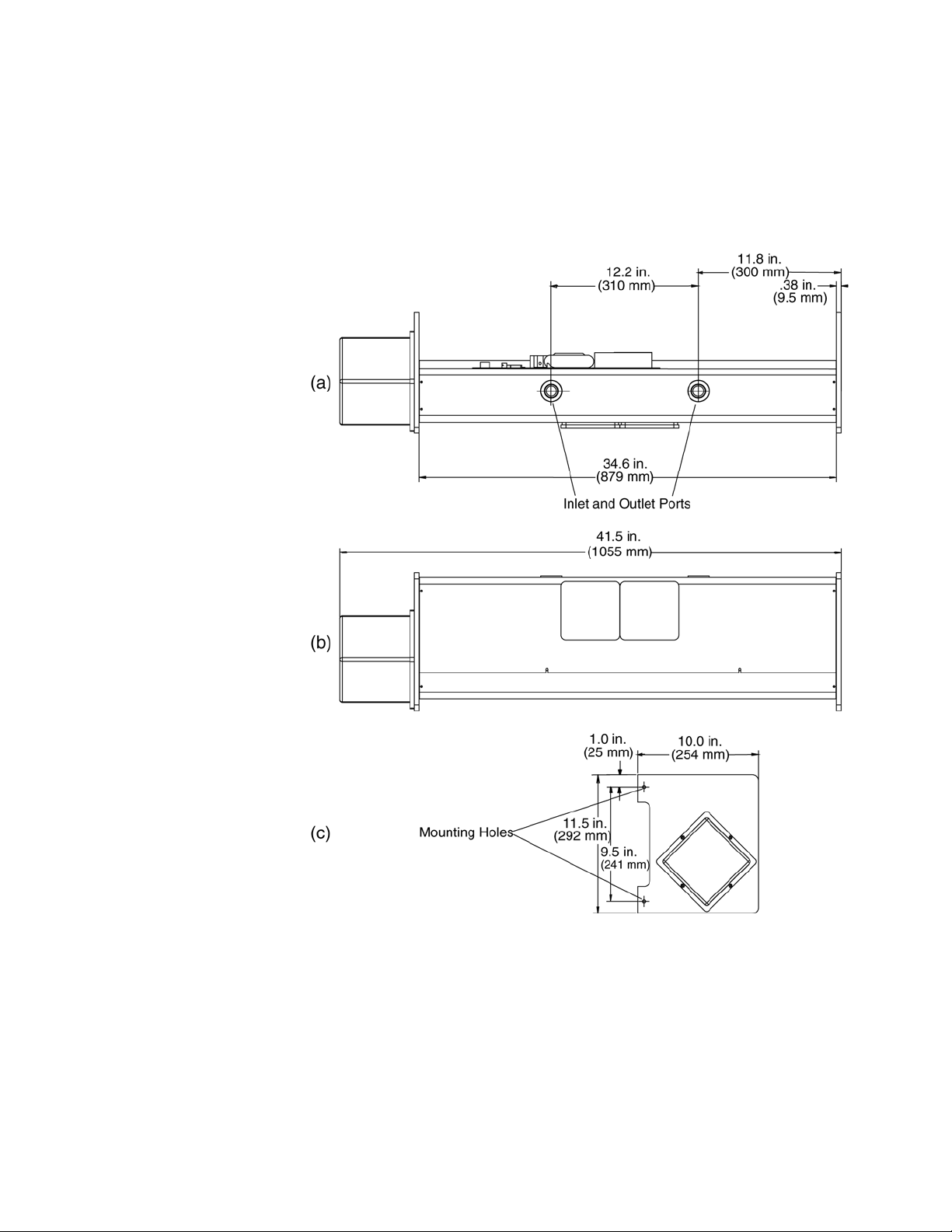

Space Requirements

The Nephelometer sensor requires a rectangular space (Figure 2-6).

You also need to allow room for the power supply module, air

ventilation, and a cable to reach the sensor. If you are using a

computer to set up the sensor, allow space for that as well.

Figure 2-6

As-Built Dimensions (Space Requirements)

Mounting Holes

Use the four mounting holes, two on each leg, to mount the

Nephelometer sensor (

bolts or screws to mount the instrument to a secure bracket, if

needed.

2-6 Model 3563 Integrating Nephelometer

Figure 2-6c). Use four 6 mm (¼ in.) diameter

Inlet and Outlet Ports

The inlet and outlet ports are 1 in. diameter female NPT (pipe

threaded) fittings (

adapters to mate to smaller or larger rigid tubing or can be fastened

directly to 1 in. pipe with a 1 in. NPT end. Rigid PVC tubing is often

used to bring a sample into the instrument and to exhaust the

sample from the instrument.

Keep in mind that the inlet and outlet tubing should have at least

8 inches of straight length to allow the cover to be easily removed

for maintenance.

Figure 2-6a). These fittings can be used with

Environmental Concerns

The Nephelometer is a highly sensitive instrument that detects

light-scattering from air (gas) molecules and particles present in the

sample chamber. The Nephelometer also detects undesirable

scatters from insects, birds, and rodents that may come into the

sampling chamber. Pests can severely limit the Nephelometer’s

ability to measure scattering from particles.

One way to minimize pests is to use insect screens, fly, or insect

traps in the upstream sampling line to prevent insects or small

pests from coming into the sampling chamber. Use metal screens to

prevent larger pests from coming into the sampling chamber.

It is good to keep in mind that humidity above 50–70% will enhance

scattering extinction (normally assumed to be small) by particles.

You may want to consider a heater or desiccant on the inlet flow to

keep the humidity below this level. Although the Nephelometer

incorporates a heater in the body, this is intended to compensate

for any cooling effects of the instrument body. It is not intended to

reduce the humidity through the instrument.

If the instrument will be used to sample from a warm, moist

environment, while located in a cooled enclosure, you should

consider insulating the inlet tubing and using the Nephelometer

heater feature (see H command in

In designing the inlet and plumbing systems, be aware that

changes in building pressure or a venturi effect caused by high

winds, can cause flow changes and reversals through the

Nephelometer.

Note: Minimize flow restrictions and particle loss when taking these

measures.

Chapter 6).

Unpacking and Setting Up the Hardware 2-7

Connecting an External Blower

)

You can use the Nephelometer with an external blower to move the

sample though the instrument. If you use an external blower, you

can remove the onboard blower and replace it with the blower

bypass fitting to reduce pressure drop through the sampling

volume.

Note: You need custom software to control the external blower. As of

this date, TSI software does not include an interface to control

an external blower.

To remove the onboard blower and install the external blower:

1. Remove the top cover of the Nephelometer using the

instructions in Chapter 8, "

2. Remove the two screws attaching the blower bracket to the

Nephelometer (

3. O-ring seals on the ports hold the blower in place. Firmly pull

the blower away from the mounting plate.

4. Insert the blower bypass fitting into the pair of holes previously

occupied by the blower.

Figure 2-7).

Performing Maintenance."

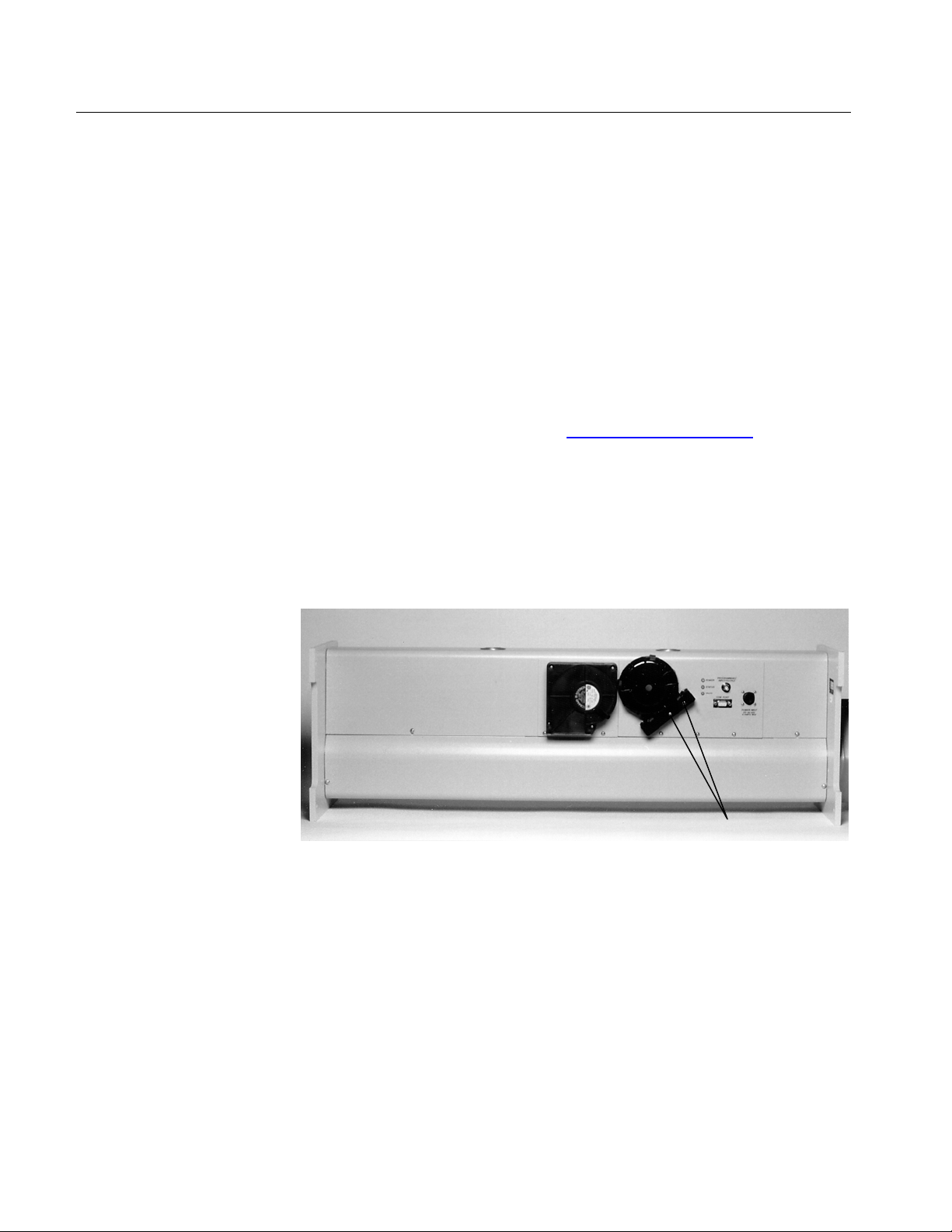

Figure 2-7

Blower Bracket

5. Install the external blower bypass fitting by pressing it into the

hole in the mounting plate (

blower bracket.

2-8 Model 3563 Integrating Nephelometer

Blower Bracket Screws (2

Figure 2-8) and reattaching the

Loading...

Loading...