Page 1

VOLATILE ORGANIC COMPOUND

PROBES

MODELS 984, 985, 986 AND 987

OPERATION AND SERVICE MANUAL

P/N 6007661, REVISION A

FEBRUARY 2014

Page 2

Page 3

Copyright

TSI Incorporated / 2014 / All rights reserved.

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA

Fax No.

(651) 490-3824

LIMITATION OF WARRANTY AND LIABILITY (effective June 2011)

(For country-specific terms and conditions outside of the USA, please visit www.tsi.com.)

Seller warrants the goods sold hereunder, under normal use and service as described in

the operator's manual, shall be free from defects in workmanship and material for 24

months, or if less, the length of time specified in the operator's manual, from the date of

shipment to the customer. This warranty period is inclusive of any statutory w arranty . This

limited warranty is subject to the following exclusions and exceptions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other

components when indicated in specifications, are warranted for 90 days from the date

of shipment;

b. Pumps are warranted for hours of operation as set forth in product or operator’s

manuals;

c. Parts repaired or replaced as a result of repair services are warranted to be free from

defects in workmanship and material, under normal use, for 90 days from the date of

shipment;

d. Seller does not provide any warranty on finished goods manufactured by others or on

any fuses, batteries or other consumable materials. Only the original manufacturer's

warranty applies;

e. Unless specifically authorized in a separate writing by Seller, Seller makes no warranty

with respect to, and shall have no liability in connection with, goods which are

incorporated into other products or equipment, or which are modified by any person

other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated

herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE. WITH RESPECT TO

SELLER’S BREACH OF THE IMPLIED WARRANTY AGAINST INFRINGEMENT, SAID

WARRANTY IS LIMITED TO CLAIMS OF DIRECT INFRINGEMENT AND EXCLUDES

CLAIMS OF CONTRIBUTORY OR INDUCED INFRINGEMENTS. BUYER’S EXCLUSIVE

REMEDY SHALL BE THE RETURN OF THE PURCHASE PRICE DISCOUNTED FOR

REASONABLE WEAR AND TEAR OR AT SELLER’S OPTION REPLACEMENT OF

THE GOODS WITH NON-INFRINGING GOODS.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR

BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES,

INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS BASED

ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE) SHALL

BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE PURCHASE

PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR REPLACEMENT OF THE

GOODS. IN THE CASE OF SOFTWARE, SELLER WILL REPAIR OR REPLACE

DEFECTIVE SOFTWARE OR IF UNABLE TO DO SO, WILL REFUND THE PURCHASE

PRICE OF THE SOFTWARE. IN NO EVENT SHALL SELLER BE LIABLE FOR LOST

PROFITS OR ANY SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER

SHALL NOT BE RESPONSIBLE FOR INSTALLATION, DISMANTLING OR

REINSTALLATION COSTS OR CHARGES. No Action, regardless of form, may be

brought against Seller more than 12 months after a cause of action has accrued. The

goods returned under warranty to Seller's factory shall be at Buyer's risk of loss, and will be

returned, if at all, at Seller's risk of loss.

i

Page 4

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND

LIABILITY, which contains the complete and exclusive limited warranty of Seller. This

LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or its terms

waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are

to our customers, our service policy is designed to give prompt attention to any

problems. If any malfunction is discovered, please contact your nearest sales office or

representative, or call TSI's Customer Service department at (800) 874-2811 (USA) or

(001 651) 490-2811 (International) or visit www.tsi.com.

ii

Page 5

CONTENTS

INTRODUCTION ................................................................................. V

CHAPTER 1 UNPACKING AND PARTS IDENTIFICATION ............ 1

CHAPTER 2 SETTING-UP ................................................................. 3

Connecting the VOC Probe to Instrument ...................................... 3

Using the Probe .............................................................................. 3

Configuring the Probe and Instrument ........................................... 4

DISPLAY SETUP ................................................................................. 4

SETTINGS ......................................................................................... 5

VOC SETUP ....................................................................................... 6

DATA LOGGING ................................................................................. 7

Measurements ........................................................................... 7

CHAPTER 3 RESPONSE FACTORS ................................................ 9

CHAPTER 4 FIELD TESTING AND CALIBRATION ....................... 19

Overview ....................................................................................... 19

Probe Verification ......................................................................... 19

TSI Recommended Accessories for Testing or Calibrating

PID Probes ................................................................................... 20

Example 1 (ppb) ...................................................................... 20

Example 2 (ppm) ..................................................................... 20

PID Probe Calibration ................................................................... 21

Accessing the Calibration Menu ................................................... 21

Calibrate VOC ............................................................................... 22

Calibrate CO2 ................................................................................ 23

Requirements ............................................................................... 23

Calibrate Temp ............................................................................. 25

Calibrate %RH .............................................................................. 26

RESTORE FACTORY CAL ..................................................... 26

CHAPTER 5 PROBE MAINTENANCE ............................................ 27

Removing the Electrode Stack and Lamp .................................... 27

Cleaning the PID Lamp................................................................. 29

PID Lamp Cleaning Kit P/N 801782 ............................................. 30

Hazard identification: .................................................................... 30

Storage: ........................................................................................ 30

Handling: ....................................................................................... 30

Replacing the Lamp ...................................................................... 30

Replacing the Electrode Stack ..................................................... 31

iii

Page 6

Discarding the Electrode Stack ..................................................... 31

Refitting Electrode Stack and Lamp ............................................. 31

Spare Components ....................................................................... 32

Recalibration ................................................................................. 32

CHAPTER 6 TROUBLESHOOTING ................................................ 33

APPENDIX A SPECIFICATIONS ..................................................... 35

iv

Page 7

Introduction

TSI measures Volatile Organic Compounds (VOCs) in air by using

Photo-Ionization Detection (PID). A PID sensor uses an ultraviolet

(UV) light source to break down VOCs in the air into positive and

negative ions. The PID sensor then detects or measures the charge

of the ionized gas, with the charge being a function of the

concentration of VOCs in the air.

TSI VOC probes are designed for evaluating or investigating indoor

air quality (IAQ) conditions and are best suited for ambient, nonhazardous conditions. Common passive sensor monitoring

applications include evaluating off-gassing of new building

construction materials, point source location, comparing complaint to

non-complaint areas and sensitization investigations.

The potential for adverse health effects depends on the type of

chemical, concentration in air, time of exposure, and personal

sensitivity to any specific VOC.

v

Page 8

(This page intentionally left blank)

vi

Page 9

Model 984

Low concentration (ppb) VOC and temperature

Model 985

High concentration (ppm) VOC and temperature

Model 986

Low concentration (ppb) VOC, temperature, CO2 and

humidity

Model 987

High concentration (ppm) VOC, temperature, CO2

and humidity

Chapter 1

Unpacking and Parts Identification

Carefully unpack the probe from the shipping container. Check the

individual parts against the list of components below. If anything is

missing or damaged, notify TSI immediately.

1. Probe

2. VOC calibration collar

3. CO2 calibration collar (included with Models 986 and 987)

4. Calibration certificate

5. Manual

1

Page 10

2

(This page intentionally left blank)

Chapter 1

Page 11

“D” Shaped

mini-DIN connector

Chapter 2

Setting-up

Connecting the VOC Probe to Instrument

The VOC probes have a “D” shape overmolding on the mini-DIN

connector which must align with the connector at the base of the

multi-functional instrument models 9565-X, 9565-P, TA465-X,

TA465-P and 7575-X. This will ensure the probe is properly

connected and remains so during use.

Using the Probe

The sensing probe relies on the diffusion of air. For best results, try to

keep the sensing probe surrounded by moving air. Do not breathe on

the probe.

Humans exhale CO2 levels exceeding 10,000 ppm and it may take

time for the probes that measure CO2 to re-stabilize, and high

humidity from your breath can cause condensation on the UV light

source in the PID sensor.

3

Page 12

Configuring the Probe and Instrument

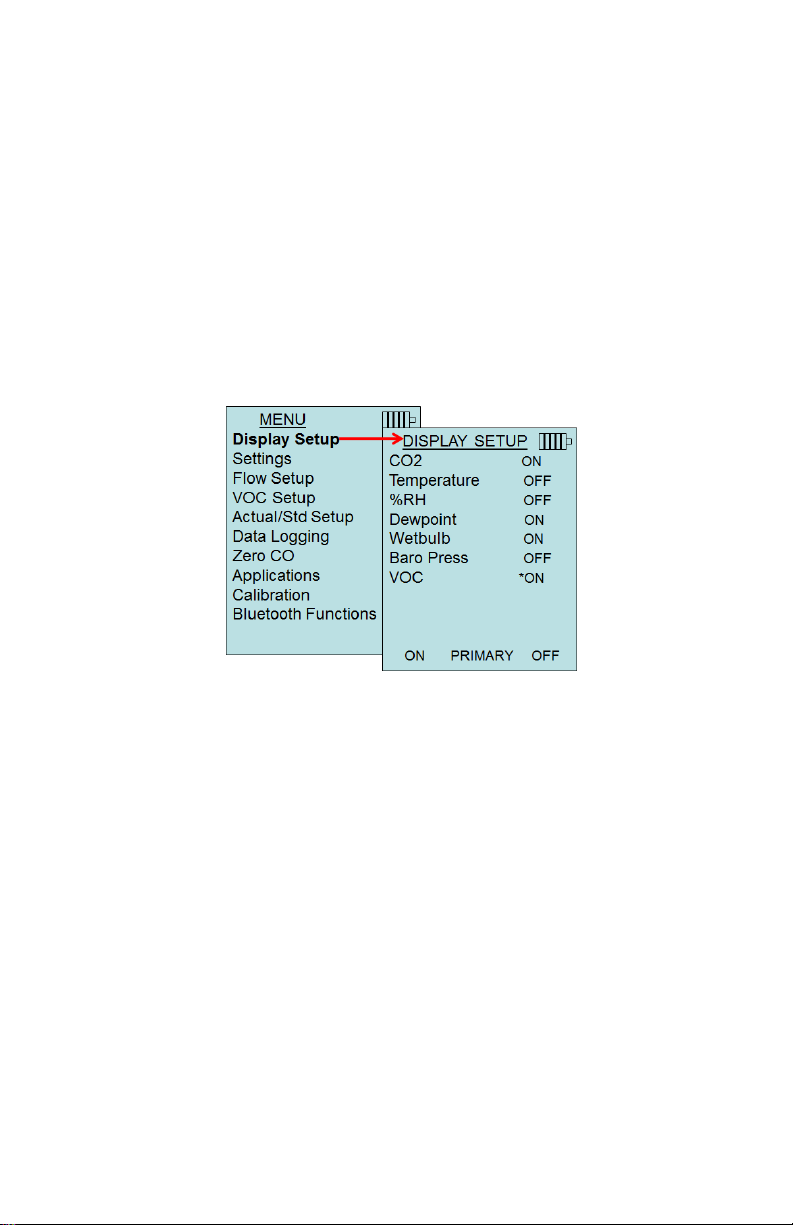

DISPLAY SETUP

Display Setup menu is where you will setup the desired parameters to

be displayed on the instrument screen. With a parameter highlighted

you can then use the ON soft key to have it show up on the instrument

screen or select the OFF soft key to turn off the parameter. Use

PRIMARY soft key to have a parameter show up on the instrument

screen in a larger display. A total of 5 parameters can be shown on

the display, 1 primary (large font) and 4 secondary. Parameters

shown in the Display Setup screen are dependent on the type of

probe currently connected.

4 Chapter 2

Page 13

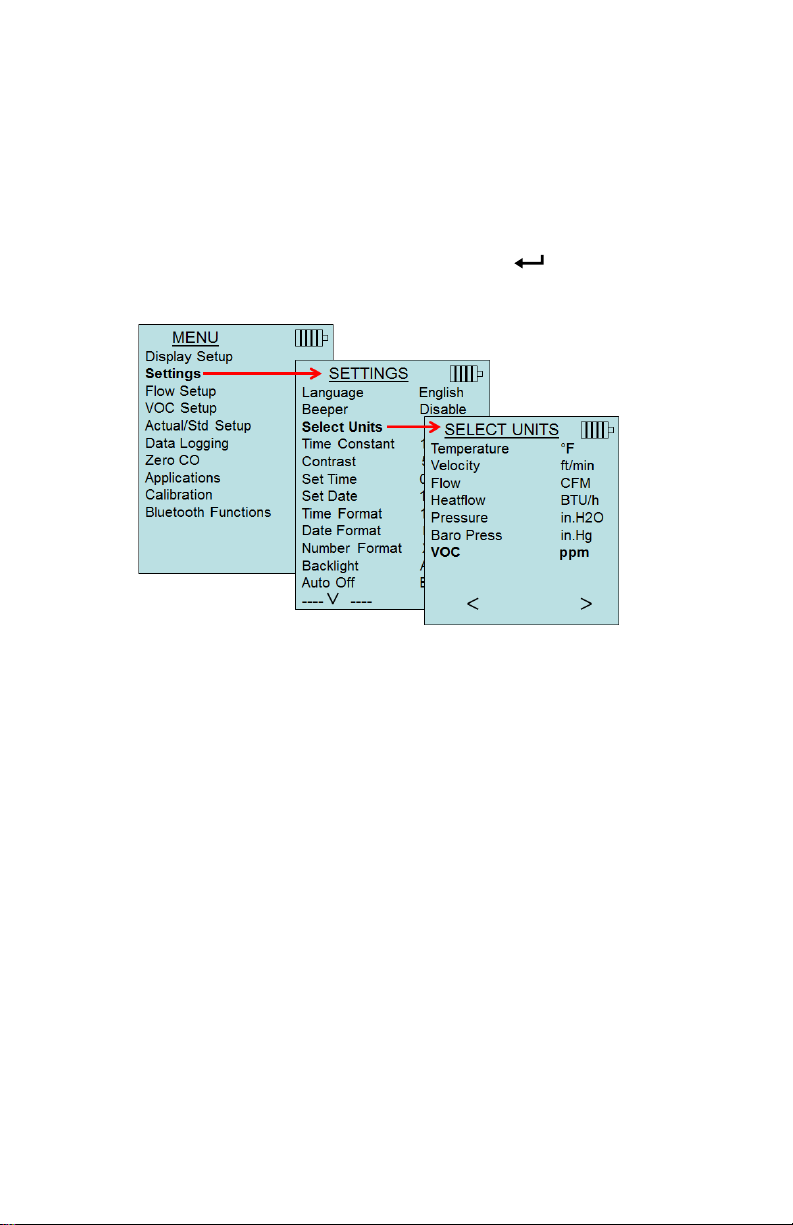

SETTINGS

Settings menu is where you can set the general settings. These

include Language, Beeper, Select Units, Time Constant, Contrast,

Set Time, Set Date, Time Format, Date Format, Number Format,

Backlight, and Auto Off.

Use the or keys to select an option, and the or soft keys to

change the settings for each option. Press the key to accept

settings.

Setting-up 5

Page 14

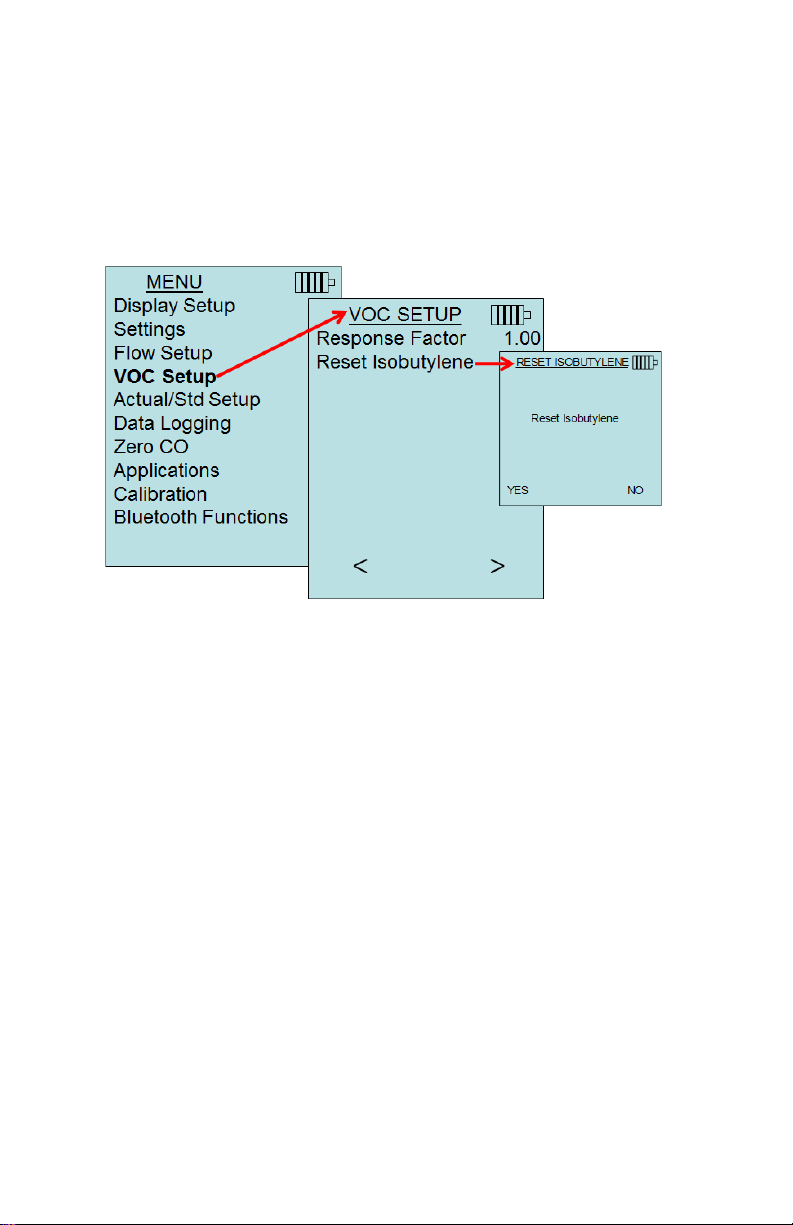

VOC SETUP

The Response Factor of a specific gas can be inputted by the user.

The response Factor is used to calculate the actual concentration

of a specific VOC.

Reset Isobutylene will restore the factory to factory conditions for

Isobutylene (56.11).

6 Chapter 2

Page 15

DATA LOGGING

Measurements

Measurements to be logged to memory are independent of

measurements on the display, and must therefore be selected under

DATA LOGGING Measurements.

When set to ON, measurement will be logged to memory.

When set to DISPLAY, measurement will be logged to memory if

it is visible on the main running screen.

When set to OFF, measurement will not be logged to memory

Refer to the instrument manual (Chapter 3: Data Logging →

“LogMode/Log Settings”) for information on the different logging

formats available.

Setting-up 7

Page 16

(This page intentionally left blank)

8 Chapter 2

Page 17

Gas/ VOC

The most common name for the VOC.

CAS No.

Find the VOC using the CAS No.

Formula

To assist in identifying the VOC and to determine

the VOC’s molecular weight.

Response

Factor (RF)

Multiply the displayed concentration by the

Response Factor to calculate the actual

concentration of the VOC.

NOTE: The Response Factor (RF) can be

programmed into the instrument via the VOC

SETUP menu.

Chapter 3

Response Factors

TSI Volatile Organic Compound (VOC) probes are calibrated using

isobutylene, but the sensor’s Photo Ionization Detector (PID) is a

broadband VOC detector with a sensitivity that differs for each VOC

compound.

PID lamps can be created with a number of gasses, each of which

has different photon energy. TSI’s PID probes use Krypton gas, with

photon energy of 10.6 eV (Electron Volt) that offers a long lamp life

and responds to a wide range of gases.

If you know what VOC you are measuring, the table in this section will

allow you to calculate the real concentration for your specific VOC

that responds to a 10.6 eV lamp source.

NOTE: These are approximate values, so for best accuracy, you

should calibrate with the relevant VOC.

NOTE: TSI PID sensors cannot measure all VOCs or gases. VOCs

that have an electron-volt potential greater than or equal (≥) to

10.6 eV will give no response since they cannot be ionized by the

10.6 eV lamp source. Semi-Volatile Organic Compounds (SVOC)

cannot be measured if the vapor pressure is too low (a few ppm at

20°C) to volatize the compound.

The table includes four columns:

9

Page 18

10 Chapter 3

Gas/VOC

CAS No.

Formula

Response Factor

Acetaldehyde

75-07-0

C2H4O

4.9

Acetic Acid

64-17-7

C2H4O2

36.2

Acetic Anhydride

108-24-7

C4H6O3

4.0

Acetone

67-64-1

C3H6O

0.7

Acrolein

107-02-8

C3H4O

4.0

Acrylic Acid

79-10-7

C3H4O2

2.7

Allyl alcohol

107-18-6

C3H6O

2.1

Allyl chloride

107-05-1

C3H5Cl

4.5

Ammonia

7664-41-7

H3N

8.5

Amyl acetate, n-

628-63-7

C7H14O2

1.8

Amyl alcohol

71-41-0

C5H12O

3.2

Aniline

62-53-3

C6H7N

0.5

Anisole

100-66-3

C7H8O

0.5

Arsine

7784-42-1

AsH3

2.5

Asphalt, petroleum fumes

8052-42-4

C6H6

1.0

Benzaldehyde

100-52-7

C7H6O

0.9

Benzene

71-43-2

C6H6

0.5

Benzenethiol

108-98-5

C6H5SH

0.7

Benzonitrile

100-47-0

C7H5N

0.7

Benzyl alcohol

100-51-6

C7H8O

1.3

Benzyl chloride

100-44-7

C7H7Cl

0.6

Benzyl formate

104-57-4

C8H8O2

0.8

Biphenyl

92-52-4

C12H10

0.4

Bis(2,3-epoxypropyl) ether

2238-07-5

C6H10O3

3.0

Bromine

7726-95-6

Br2

20.0

Bromobenzene

108-86-1

C6H5Br

0.7

Bromoethane

74-96-4

C2H5Br

5.0

Bromoethyl methyl ether, 2-

6482-24-2

C3H7OBr

2.5

Bromoform

75-25-2

CHBr3

2.8

Bromopropane, 1-

106-94-5

C3H7Br

1.3

Butadiene

106-99-0

C4H6

0.8

Butadiene diepoxide,1,3-

1464-53-5

C4H6O2

4.0

Butane, n-

106-97-8

C4H10

46.3

Butanol, 1-

71-36-3

C4H10O

4.0

Buten-3-ol, 1-

598-32-3

C4H8O

1.2

Butene, 1-

106-98-9

C4H8

1.3

Butoxyethanol, 2-

111-76-2

C6H14O2

1.1

Butyl acetate, n-

123-86-4

C6H12O2

2.4

Butyl acrylate, n-

141-32-2

C7H12O2

1.5

Butyl lactate

138-22-7

C7H14O3

2.5

Butyl mercaptan

109-79-5

C4H10S

0.5

Butylamine, 2-

513-49-5

C4H11N

0.9

Butylamine, n-

109-73-9

C4H11N

1.0

Camphene

565-00-4

C10H16

0.5

Carbon disulfide

75-15-0

CS2

1.4

Carbon tetrabromide

558-13-4

CBr4

3.0

Page 19

Response Factors 11

Gas/VOC

CAS No.

Formula

Response Factor

Carvone, R-

6485-40-1

C10H14O

1.0

Chlorine dioxide

10049-04-4

ClO2

1.0

Chloro-1,3-butadiene, 2-

126-99-8

C4H5Cl

3.2

Chlorobenzene

108-90-7

C6H5Cl

0.5

Chloroethanol, 2-

107-07-3

C2H5ClO

10.0

Chloroethyl methyl ether, 2-

627-42-9

C3H7ClO

2.6

Chlorotoluene, o-

95-49-8

C7H7Cl

0.5

Chlorotoluene, p-

108-41-8

C7H7Cl

0.5

Chlorotrifluoroethylene

79-38-9

C2ClF3

1.0

Citral

5392-40-5

C10H16O

1.0

Citronellol

26489-01-0

C10H20O

1.0

Cresol, m-

108-39-4

C7H8O

1.1

Cresol, o-

95-48-7

C7H8O

1.1

Cresol, p-

106-44-5

C7H8O

1.1

Crotonaldehyde

4170-30-3

C4H6O

1.0

Cumene

98-82-8

C9H12

0.6

Cyclohexane

110-82-7

C6H12

1.3

Cyclohexanol

108-93-0

C6H12O

2.9

Cyclohexanone

108-94-1

C6H10O

1.1

Cyclohexene

110-83-8

C6H10

0.8

Cyclohexylamine

108-91-8

C6H13N

1.0

Cyclopentane

287-92-3

C5H10

4.0

Decane, n-

124-18-5

C10H22

1.0

Diacetone alcohol

123-42-2

C6H12O2

0.8

Dibenzoyl peroxide

94-36-0

C14H10O4

0.8

Dibromochloromethane

124-48-1

CHBr2Cl

10.0

Dibromoethane 1,2-

106-93-4

C2H4Br2

2.0

Dibutyl hydrogen phosphate

107-66-4

HC8H18PO4

4.0

Dichloro-1-propene, 2,3-

78-88-6

C3H4Cl2

1.4

Dichloroacetylene

7572-29-4

C2Cl2

5.0

Dichlorobenzene o-

95-50-1

C6H4Cl2

0.5

Dichloroethene, 1,1-

75-35-4

C2H2Cl2

1.0

Dichloroethene, cis-1,2-

156-59-2

C2H2Cl2

0.8

Dichloroethene, trans-1,2-

540-59-0

C2H2Cl2

0.7

Dichloroethylene 1,2-

540-59-0

C2H2Cl2

0.8

Dichloromethane

75-09-2

CH2Cl2

39.0

Dicyclopentadiene

77-73-6

C10H12

0.9

Diesel Fuel

68334-30-5 0.8

Diethyl ether

60-29-7

C4H10O

0.9

Diethyl maleate

141-05-9

C8H12O4

2.0

Diethyl phthalate

84-66-2

C12H14O4

1.0

Diethyl sulphate

64-67-5

C4H10SO4

3.0

Diethyl sulphide

352-93-2

C4H10S

0.6

Diethylamine

109-89-7

C4H11N

1.0

Diethylaminoethanol, 2-

100-37-8

C6H15ON

2.7

Diethylaminopropylamine, 3-

104-78-9

C7H18N2

1.0

Page 20

Gas/VOC

CAS No.

Formula

Response Factor

Dihydrogen selenide

7783-07-5

H2Se

1.0

Dihydroxybenzene, 1,2

120-80-9

C6H6O2

1.0

Dihydroxybenzene, 1,3

108-46-3

C6H6O2

1.0

Diisobutylene

107-39-1

C8H16

0.6

Diisopropyl ether

108-20-3

C6H14O

0.7

Diisopropylamine

108-18-9

C6H15N

0.7

Diketene

674-82-8

C4H4O2

2.2

Dimethoxymethane

109-87-5

C3H8O2

1.4

Dimethyl cyclohexane, 1,2-

583-57-3

C8H16

1.1

Dimethyl disulphide

624-92-0

C2H6S2

0.2

Dimethyl ether

115-10-6

C2H6O

1.3

Dimethyl phthalate

131-11-3

C10H10O4

1.0

Dimethyl sulphide

75-18-3

C2H6S

0.5

Dimethylacetamide N,N-

127-19-5

C4H9NO

1.3

Dimethylamine

124-40-3

C2H7N

1.4

Dimethylaminoethanol

108-01-0

C4H11NO

1.5

Dimethylaniline, NN-

121-69-7

C8H11N

0.6

Dimethylbutyl acetate

108-84-9

C8H16O2

1.6

Dimethylethylamine, NN-

598-56-1

C4H11N

0.8

Dimethylformamide

68-12-2

C3H7NO

0.9

Dimethylheptan-4-one, 2,6-

108-83-8

C9H18O

0.8

Dimethylhydrazine, 1,1-

57-14-7

C2H8N2

1.0

Dinitrobenzene, m-

99-65-0

C6H4N2O4

3.0

Dinitrobenzene, p-

100-25-4

C6H4N2O4

5.0

Dinonyl phthalate

84-76-4

C26H42O4

1.0

Dioxane 1,2-

C4H8O2

1.5

Dioxane 1,4-

123-91-1

C4H8O2

1.5

Dipentene

138-86-3

C10H16

0.9

Diphenyl ether

101-84-8

C12H10O

0.8

Disulphur dichloride

10025-67-9

S2Cl2

3.0

Di-tert-butyl-p-cresol

2409-55-4

C11H16O

1.0

Divinylbenzene

1321-74-0

C10H10

0.4

Dodecanol

112-53-8

C12H26O

0.9

Epichlorohydrin

106-89-8

C3H5ClO

8.0

Epoxypropyl isopropyl ether,

2,3-

4016-14-2

C6H12O2

1.1

Ethanol

64-17-5

C2H6O

8.7

Ethanolamine

141-43-5

C2H7NO

3.0

Ethoxy-2-propanol, 1-

1569-02-4

C5H10O2

2.0

Ethoxyethanol, 2-

110-80-5

C4H10O2

29.8

Ethoxyethyl acetate, 2-

111-15-9

C6H12O3

3.0

Ethyl(S)-(-)-lactate

97-64-3

C5H10O3

3.0

Ethyl acetate

141-78-6

C4H8O2

3.6

Ethyl acrylate

140-88-5

C5H8O2

2.0

Ethyl amine

75-04-7

C2H7N

1.0

Ethyl benzene

100-41-4

C8H10

0.5

12 Chapter 3

Page 21

Gas/VOC

CAS No.

Formula

Response Factor

Ethyl butyrate

105-54-4

C6H12O2

1.0

Ethyl chloroformate

541-41-3

C3H5O2Cl

80.0

Ethyl cyanoacrylate

7085-85-0

C6H7O2N

1.5

Ethyl decanoate

110-38-3

C12H24O2

1.8

Ethyl formate

109-94-4

C3H6O2

30.0

Ethyl hexanoate

123-66-0

C8H16O2

2.6

Ethyl hexanol, 2-

105-76-7

C8H18O

1.5

Ethyl hexyl acrylate, 2-

103-11-7

C11H20O2

1.0

Ethyl mercaptan

75-08-1

C2H6S

0.7

Ethyl octanoate

106-32-1

C10H20O2

2.3

Ethylene

74-85-1

C2H4

8.0

Ethylene glycol

107-21-1

C2H6O2

20.0

Ethylene oxide

75-21-8

C2H4O

15.0

Ferrocene

102-54-5

C10H10Fe

0.8

Formamide

75-12-7

CH3ON

2.0

Furfural

98-01-1

C5H4O2

1.4

Furfuryl alcohol

98-00-0

C5H6O2

2.0

Gasoline vapors

8006-61-9 1.1

Gasoline vapors92 octane

8006-61-9 0.8

Germane

7782-65-2

GeH4

10.0

Glutaraldehyde

111-30-8

C5H8O2

0.9

Heptan-2-one

110-43-0

C7H14O

0.7

Heptan-3-one

106-35-4

C7H14O

0.8

Heptane n-

142-82-5

C7H16

2.1

Hexamethyldisilazane,

1,1,1,3,3,3-

999-97-3

C6H19NSi2

1.0

Hexamethyldisiloxane

107-46-0

C6H18OSi2

0.3

Hexan-2-one

591-78-6

C6H12O

0.8

Hexane n-

110-54-3

C6H14

4.2

Hexene, 1-

592-41-6

C6H12

0.9

Hydrazine

302-01-2

H4N2

3.0

Hydrogen peroxide

7722-84-1

H2O2

4.0

Hydrogen sulfide

7783-06-4

H2S

4.0

Hydroquinone

123-31-9

C6H6O2

0.8

Hydroxypropyl acrylate 2-

999-61-1

C6H10O3

1.5

Iminodi(ethylamine) 2,2-

111-40-0

C4H13N3

0.9

Iminodiethanol 2,2'-

111-42-2

C4H11NO2

1.6

Indene

95-13-6

C9H8

0.5

Iodine

7553-56-2

I2

0.2

Iodoform

75-47-8

CHI3

1.5

Iodomethane

74-88-4

CH3I

0.4

Isoamyl acetate

123-92-2

C7H14O2

1.6

Isobutane

75-28-5

C4H10

8.0

Isobutanol

78-83-1

C4H10O

3.5

Isobutyl acetate

110-19-0

C6H12O2

2.3

Isobutyl acrylate

106-63-8

C7H12O2

1.3

Response Factors 13

Page 22

Gas/VOC

CAS No.

Formula

Response Factor

Isobutylene

115-11-7

C4H8

1.0

Isobutyraldehyde

78-84-2

C4H8O

1.2

Isodecanol

25339-17-7

C10H22O

0.9

Isononanol

2452-97-9

C9H20O

1.5

Isooctane

565-75-3

C8H18

1.1

Isooctanol

26952-21-6

C8H18O

1.7

Isopentane

78-78-4

C5H12

6.0

Isophorone

78-59-1

C9H14O

0.8

Isoprene

78-79-5

C5H8

0.7

Isopropanol

67-63-0

C3H8O

4.4

Isopropyl acetate

108-21-4

C5H10O2

2.2

Isopropyl chloroformate

108-23-6

C4H7O2Cl

1.6

Jet Fuel JP-4

0.8

Jet Fuel JP-5

0.7

Jet Fuel JP-8

0.7

Ketene

463-51-4

C2H2O

3.0

Maleic anhydride

108-31-6

C4H2O3

2.0

Mercaptoacetic acid

68-11-1

C2H4O2S

1.0

Mesitylene

108-67-8

C9H12

0.3

Methacrylic acid

79-41-4

C4H6O2

2.3

Methacrylonitrile

126-98-7

C4H5N

5.0

Methanol

67-56-1

CH4O

200.0

Methoxyethanol, 2-

109-86-4

C3H8O2

2.7

Methoxyethoxyethanol, 2-

111-77-3

C5H12O3

1.4

Methoxymethylethoxy-2propanol

34590-94-8

C7H16O3

1.3

Methoxypropan-2-ol

107-98-2

C4H10O2

3.0

Methoxypropyl acetate

108-65-6

C6H12O3

1.2

Methyl acetate

79-20-9

C3H6O2

5.2

Methyl acrylate

96-33-3

C4H6O2

3.4

Methyl bromide

74-83-9

CH3Br

1.9

Methyl cyanoacrylate

137-05-3

C5H5O2N

5.0

Methyl ethyl ketone

78-93-3

C4H8O

0.8

Methyl ethyl ketone

peroxides

1338-23-4

C8H18O2

0.8

Methyl isobutyl ketone

108-10-1

C6H12O

0.8

Methyl isothiocyanate

556-61-6

C2H3NS

0.6

Methyl mercaptan

74-93-1

CH4S

0.7

Methyl methacrylate

80-62-6

C5H8O2

1.6

Methyl propyl ketone

107-87-9

C5H10O

0.8

Methyl salicylate

119-36-8

C8H8O3

1.2

Methyl sulphide

75-18-3

C2H6S

0.5

Methyl t-butyl ether

1634-04-4

C5H12O

0.8

Methyl-2-propen-1-ol, 2-

51-42-8

C4H8O

1.1

Methyl-2-pyrrolidinone, N-

872-50-4

C5H9NO

0.9

Methyl-4,6-dinitrophenol, 2-

534-52-1

C7H6N2O5

3.0

14 Chapter 3

Page 23

Gas/VOC

CAS No.

Formula

Response Factor

Methyl-5-hepten-2-one, 6-

110-93-0

C8H14O

0.8

Methylamine

74-89-5

CH5N

1.4

Methylbutan-1-ol, 3-

123-51-3

C5H12O

3.4

Methylcyclohexane

108-87-2

C7H14

1.1

Methylcyclohexanol, 4-

589-91-3

C7H14O

2.4

Methylcyclohexanone 2-

583-60-8

C7H12O

1.0

Methylheptan-3-one, 5-

541-85-5

C8H16O

0.8

Methylhexan-2-one, 5-

110-12-3

C7H14O

0.8

Methylhydrazine

60-34-4

CH6N2

1.3

Methyl-N-2,4,6tetranitroaniline, N-

479-45-8

C7H5N5O8

3.0

Methylpent-3-en-2-one, 4-

141-79-7

C6H10O

0.7

Methylpentan-2-ol, 4-

108-11-2

C6H14O

2.8

Methylpentane-2,4-diol, 2-

107-41-5

C6H14O2

4.0

Methylpropan-2-ol, 2-

75-65-0

C4H10O

3.5

Methylstyrene

25013-15-4

C9H10

0.5

Mineral oil

8042-47-5 0.8

Mineral spirits

64475-85-0 0.8

Naphthalene

91-20-3

C10H8

0.4

Nitric oxide

10102-43-9

NO

8.0

Nitroaniline 4-

100-01-6

C6H6N2O2

0.8

Nitrobenzene

98-95-3

C6H5NO2

1.7

Nitrogen dioxide

10102-44-0

NO2

10.0

Nitrogen trichloride

10025-85-1

NCl3

1.0

Nonane, n-

111-84-2

C9H20

1.3

Norbornadiene, 2,5-

121-46-0

C7H8

0.6

Octachloronaphthalene

2234-13-1

C10Cl8

1.0

Octane, n-

111-65-9

C8H18

1.6

Octene, 1-

111-66-0

C8H16

0.7

Oxydiethanol 2,2-

111-46-6

C4H10O3

4.0

Paraffin wax, fume

8002-74-2 1.0

Paraffins, normal

64771-72-8 1.0

Pentacarbonyl iron

13463-40-6

FeC5O5

1.0

Pentan-2-one

107-87-9

C5H10O

0.8

Pentan-3-one

96-22-0

C5H10O

0.8

Pentandione, 2,4-

123-54-6

C5H8O2

0.8

Pentane, n-

109-66-0

C5H12

7.9

Peracetic acid

79-21-0

C2H4O3

2.0

Petroleum ether

64742-82-1

C6H14

0.9

Phenol

108-95-2

C6H6O

1.2

Phenyl propene, 2-

98-83-9

C9H10

0.4

Phenyl-2,3-epoxypropyl

ether

122-60-1

C9H10O2

0.8

Phenylenediamine, p-

106-50-3

C6H8N2

0.6

Phosphine

7803-51-2

PH3

2.0

Picoline, 3-

108-99-6

C6H7N

0.9

Response Factors 15

Page 24

Gas/VOC

CAS No.

Formula

Response Factor

Pinene, alpha

80-56-8

C10H16

0.3

Pinene, beta

127-91-3

C10H16

0.3

Piperidine

110-89-4

C5H11N

0.9

Piperylene

504-60-9

C5H8

0.7

Prop-2-yn-1-ol

107-19-7

C3H4O

1.3

Propan-1-ol

71-23-8

C3H8O

4.8

Propane-1,2-diol, total

57-55-6

C3H8O2

10.0

Propene

115-07-1

C3H6

1.4

Propionaldehyde

123-38-6

C3H6O

1.7

Propionic acid

79-09-4

C3H6O2

8.0

Propyl acetate, n-

109-60-4

C5H10O2

2.5

Propylene oxide

75-56-9

C3H6O

7.0

Propyleneimine

75-55-8

C3H7N

1.3

Pyridine

110-86-1

C5H5N

0.8

Pyridylamine 2-

504-29-0

C5H6N2

0.8

Styrene

100-42-5

C8H8

0.4

Terphenyls

C18H14

0.6

Terpinolene

586-62-9

C10H16

0.5

Tert-butanol

75-65-0

C4H10O

2.6

Tetrabromoethane, 1,1,2,2-

79-27-6

C2H2Br4

2.0

Tetracarbonylnickel

13463-39-3

NiC4O4

1.0

Tetrachloroethylene

127-18-4

C2Cl4

0.7

Tetrachloronaphthalenes,all

isomers

20020-02-4

C10H4Cl4

1.0

Tetraethyl orthosilicate

78-10-4

C8H20O4Si

2.0

Tetrafluoroethylene

116-14-3

C2F4

1.0

Tetrahydrofuran

109-99-9

C4H8O

1.6

Tetramethyl succinonitrile

3333-52-6

C8H12N2

1.0

Therminol

1.0

Toluene

108-88-3

C7H8

0.5

Toluene-2,4-diisocyanate

584-84-9

C9H6N2O2

1.6

Toluenesulphonylchloride, p-

98-59-9

C7H7SO2C

l

3.0

Toluidine, o-

95-53-4

C7H9N

0.5

Tributyl phosphate

126-73-8

C12H27O4

P

5.0

Tributylamine

102-82-9

C12H27N

1.0

Trichlorobenzene 1,2,4-

120-82-1

C6H3Cl3

0.6

Trichloroethylene

79-01-6

C2HCl3

0.7

Trichlorophenoxyacetic acid,

2,4,5-

93-76-5

C8H5O3Cl3

1.0

Triethylamine

121-44-8

C6H15N

0.9

Trimethylamine

53-50-3

C3H9N

0.5

Trimethylbenzene, 1,3,5-

108-67-8

C9H12

0.3

Turpentine

8006-64-2

C10H16

0.6

TVOC

1.0

16 Chapter 3

Page 25

Gas/VOC

CAS No.

Formula

Response Factor

Undecane, n-

1120-21-4

C11H24

0.9

Vinyl acetate

108-05-2

C4H6O2

1.1

Vinyl bromide

593-60-2

C2H3Br

1.0

Vinyl chloride

75-01-4

C2H3Cl

2.1

Vinyl-2-pyrrolidinone, 1-

88-12-0

C6H9NO

0.9

Xylene mixed isomers

1330-20-7

C8H10

0.4

Xylene, m-

108-38-3

C8H10

0.4

Xylene, o-

95-47-6

C8H10

0.6

Xylene, p-

106-42-3

C8H10

0.6

Xylidine, all

1300-73-8

C8H11N

0.7

Response Factors 17

Page 26

(This page intentionally left blank)

18 Chapter 3

Page 27

Chapter 4

Field Testing and Calibration

Overview

Due to the nature of the PID sensor and the presence of VOCs in air

along with other environmental factors such as altitude, temperature

and relative humidity, the zero value of the VOC probe will shift over

time. TSI recommends testing the probe performance each time

the instrument is used to make measurements. This is a common

practice within the gas measurement community which includes IAQ

consultants and industrial hygienists.

Probe Verification

Verifying the probe performance

can easily be accomplished in

the field by comparing it to

certified zero and span

calibration gases. To do this,

attach the probe with the

calibration collar to a bottle of

Zero Gas and compare to the

instrument readings (also

referred to as a “Bump Test”). If

the probe reads any number

other than 0, the PID sensor has

drifted and needs to be

re-calibrated.

NOTE: With probe attached, power on the instrument for 10 minutes

before verifying performance. This allows the instrument and probe

electronics to stabilize to produce best results.

19

Page 28

TSI Recommended Accessories for Testing or Calibrating PID Probes

Zero Gas—80% Nitrogen/20% Oxygen

Span Gas—1 ppm Isobutylene in balance Nitrogen—use with

ppb probe

Span Gas—10 ppm Isobutylene in balance Nitrogen—use with

ppb probe

Span Gas—20 ppm Isobutylene in balance Nitrogen—use with

ppm probe

Span Gas—100 ppm Isobutylene in balance Nitrogen—use with

ppm probe

0.3 to 0.5 L/min flow rate Continuous Flow Regulator

Tygon® tubing 0.250 in. (6.35 mm) OD, 0.125 in. (3.175 mm) ID

VOC probe calibration collar (included with probe)

When spanning with an isobutylene gas, select a concentration value

that is closest to the desired measurement range. This will result in

maximum accuracy of the PID sensors readings.

Example 1 (ppb)

If you have a ppb PID probe and want to measure VOCs in the low

ppb range, span calibrating with a 1 ppm isobutylene gas will give

more accurate results than span calibrating with a 10 ppm

isobutylene gas. If you would like to measure VOCs in the mid to

upper range of the PID sensor, calibrating with 10 ppm isobutylene

span gas would be appropriate.

Example 2 (ppm)

If you have a ppm PID probe and want to measure VOCs in the low

ppm range, span calibration with a 20 ppm isobutylene gas will give

more accurate results, than span calibrating with 100 ppm

isobutylene gas will. If you would like to measure VOCs in the mid to

upper range of the PID sensor, calibrating with 100 ppm isobutylene

span gas would be appropriate.

Zero, Span gasses and regulators that meet TSI’s requirements are

available internationally from PortaGas at www.portagas.com in 103

liter bottle configurations.

20 Chapter 4

Page 29

PID Probe Calibration

NOTES

With probe attached power on the instrument for 10 minutes

before calibrating the probe. This allows the instrument and

probe electronics to stabilize to produce best results.

Field calibration is required if a new replacement PID sensor is

installed on the probe.

Restore to Factory Calibration before performing field

calibration.

After restoring Factory Calibration, try the “Bump Test” again at

0 ppm and/or at a known concentration of Isobutylene in balance

Nitrogen gas. If readings are still out of tolerance, then proceed

with field calibration procedure.

MENU

Zero Press

Display Setup

Settings

Flow Setup

VOC Setup

Actual/Std Setup

Data Logging

Zero CO

Applications

Calibration

Bluetooth Functions

CALIBRATION

Calibrate Temp

Calibrate Vel

Calibrate %RH

Calibrate B.P.

Calibrate CO2

Calibrate CO

Calibrate VOC

Restore Factory Cal

If the probe reads any number other than 0 when tested against a

zero gas, the PID sensor has drifted and needs to be re-calibrated

using the following instructions. These instructions are also applicable

if the PID sensor has been replaced in the field.

Accessing the Calibration Menu

To access the CALIBRATION menu, press the MENU key and scroll

down to CALIBRATION and press ENTER. Highlight Calibrate VOC

and then press ENTER.

Field Testing and Calibration 21

Page 30

NOTE

The measurement capabilities of the instrument and probe will

determine what appears in the main MENU and CALIBRATION

menu. Instrument models using detachable probes must have the

probe attached to perform field calibrations. This screen display

above is from the 9565-P VelociCalc® Multi-Function Ventilation

Meter with VOC probe attached.

Calibrate VOC

Step 3—Zero Calibration.

After pressing ENTER with the zero

calibration gas connected, the instrument

begins to take data. A bar graph will

appear showing the time remaining. The

time allocated by the instruments

firmware for zero is sufficient for zeroing.

CALIBRATE VOC

Connect zero gas

then press

ENTER

CALIBRATE VOC

0.00 ppm

A probe calibration collar (included with probe), zero calibration gas,

span calibration gas, gas regulator and tubing are required to perform

the calibration. The gas regulator used to control the flow should be

capable of providing 0.3 L/min. Follow the on-screen instructions to

complete the calibration.

Step 1—Grasp probe handle and pull PID sensor protective cap off.

Step 2—Slide calibration collar onto probe and attach to gas cylinder

using tubing.

22 Chapter 4

Page 31

Step 4—Span Calibration.

For best results, run the span gas with

the probe attached for 60 seconds before

pressing the ENTER button to conduct

the span calibration.

After pressing ENTER with the span

calibration gas connected, the instrument

begins to take data. A bar graph will

appear showing the time remaining.

CALIBRATE VOC

Connect span gas

then press

ENTER

CALIBRATE VOC

9.41 ppm

Step 5—Span Adjustment

Once the countdown is complete, the

VOC concentration as measured by the

probe is displayed along with the percent

of adjustment.

In this example, the span gas is rated at

10 ppm. Use the UP or DOWN arrow

keys to adjust offset to match the span

gas concentration. Press ENTER to

accept and to return to the

CALIBRATION menu.

CALIBRATE VOC

9.41 ppm

0.0 % Adjustment

CALIBRATE VOC

10.00 ppm

6.3 % Adjustment

Calibrate CO2

This calibration option applies to meters and probes capable of

measuring CO2. A probe calibration collar, zero calibration gas, span

calibration gas, gas regulator and tubing are required to perform the

calibration. The gas regulator used to control the flow should be

capable of providing 0.3 L/min. Follow the on-screen instructions to

complete the calibration.

Requirements

Probe calibration collar (included

with IAQ and VOC probes)

Span calibration gas, 5000 ppm

maximum

Zero Gas – 80% Nitrogen /

20% Oxygen

0.3 L/min flow rate Continuous

Flow Regulator

Tygon tubing 0.250 in. (6.35 mm) OD, 0.125 in. (3.175 mm) ID

Field Testing and Calibration 23

Page 32

NOTE

If probe measures VOC gasses, remove VOC sensor first.

Step 2— Bump Test

Measure concentration with 0 ppm calibration gas flowing through the

calibration collar. Do the same with the Span Gas. If readings are out

of tolerance, Restore CO2 Factory Calibration (see RESTORE

FACTORY CAL) and then perform the Bump Test again at 0 ppm and

Span. If readings are still OOT, proceed with Field Calibration.

Step 3—Zero Calibration.

After pressing ENTER with the zero

calibration gas connected, the instrument

will begin to take data. A bar graph will

appear showing the time remaining.

Step 4—Span Calibration.

After pressing ENTER with the span

calibration gas connected, the instrument

will begin to take data. A bar graph will

appear showing the time remaining.

Pull PID sensor protective cap off

Remove PID sensor

Unscrew collar

Gently remove small PCB

Step 1—Slide calibration collar onto probe and attach to gas cylinder

using tubing.

24 Chapter 4

Page 33

Step 5—Span Adjustment.

Once the countdown is complete, the

CO2 concentration as measured by the

probe is displayed along with the percent

of adjustment.

In this example, the span gas is rated at

1000 ppm. Use the UP or DOWN arrow

keys to adjust offset to match the span

gas concentration. Press ENTER to

accept and to return to the

CALIBRATION menu.

Calibrate Temp

This calibration option applies to all meters and probes capable of

measuring temperature. The temperature calibration can be adjusted

±6.0°F (±3.3°C). Compare the instruments temperature reading to a

reference standard and make changes as required.

Step 1—Use the UP or DOWN arrow keys to adjust offset.

Step 2—Press ENTER to accept and to return to CALIBRATION

menu.

In this example, the temperature measured by the probe is 75.3°F

and the reference temperature is 73.6°F. Adjusting the offset by

-1.7°F allows the probe to match the reference standard.

Field Testing and Calibration 25

Page 34

Calibrate %RH

RESTORE FACTORY CAL

Restore Temp

Restore Vel

Restore %RH

Restore Press

Restore B.P.

Restore CO2

Restore CO

Restore VOC

RESTORE VOC

Are you Sure?

YES NO

This calibration option applies to meters and probes capable of

measuring relative humidity. Compare the instruments relative

humidity reading to a reference standard and make changes as

required. The Offset can be adjusted ±12.0% RH.

Step 1—Use the UP or DOWN arrow keys to adjust offset.

Step 2—Press ENTER to accept and to return to CALIBRATION

menu.

In this example, the relative humidity measured by the probe is

30.5 %RH and the reference humidity is 31.6 %RH. Adjusting the

offset by 1.1% allows the probe match the reference standard.

RESTORE FACTORY CAL

This option resets the field calibration for any measurement

parameter back to the last factory calibration. To restore the last

factory calibration for any measurement parameter, the probe must

be attached to the meter on models with detachable probe.

26 Chapter 4

Page 35

Condition

Recommended Action

Sensitivity has dropped too much (note the

change required when checking calibration)

Clean lamp

The baseline is climbing after you zero the PID

Replace electrode stack

The PID becomes sensitive to humidity

Replace electrode stack

The baseline is unstable or shifts when the PID

is moved

Replace electrode stack

Chapter 5

Probe Maintenance

The electronics in the PID sensor in the VOC probes are not

accessible. However, periodic sensor maintenance of the electrode

stack and lamp may be needed for optimal performance.

The PID lamp will need cleaning from time to time. How often

depends on the environment you are measuring in. If you are

measuring indoor air quality where the VOC concentrations are low

and there are few particulates, then a monthly or even less frequent

cleaning may be adequate. However, if you are measuring high VOC

concentrations and particulates are present in high concentrations,

check calibration frequently and clean the lamp. When the PID has

lost sensitivity, change the stack as explained below in the sections

entitled “Removing Electrode Stack and Lamp” and “Refitting

Electrode Stack and Lamp”.

The PID needs maintenance if:

Removing the Electrode Stack and Lamp

CAUTION: Always use the Electrode Stack Removal Tool (included

with replacement stack); any other tools may damage your PID and

void the warranty.

1. Remove cap and PID sensor from VOC probe, as shown in

Figure 1.

2. Gently pull the sensor from the probe.

3. Place the PID, top side down, onto a clean surface.

4. Insert electrode stack removal tool into the two slots on the sides

of the PID (as shown in Figure 2) and squeeze together until

electrode stack and lamp are released.

27

Page 36

CAUTION: Electrode stack and lamp may jump off sensor and

become lost if removed when the PID is right-side up.

5. Carefully lift the PID body away from the electrode stack and

lamp.

Figure 1. Removing Cap and PID Sensor from VOC Probe

NOTES:

If the lamp lodges in the sensor, use tweezers to carefully

remove it.

If the spring behind the lamp also comes out, replace it in the

sensor housing.

Figure 2. Using Electrode Stack Removal Tool

28 Chapter 5

Page 37

Cleaning the PID Lamp

Cleaning the PID lamp is recommended as a first step for PIDs

needing service. Use the procedure described below. Recalibrate the

sensor after cleaning the lamp.

To check for a lamp that needs cleaning, hold it in front of a light

source and look across the window surface as shown in Figure 3. A

dirty lamp will have a “blue hue” on the detection window.

Figure 3. Checking Lamp for Contamination

Only clean the lamp using the lamp cleaning kit (P/N 801782) while

following the instructions below. To avoid contaminating the sensor

and affecting accuracy, do not touch the lamp window with bare

fingers. You may touch the body of the lamp with clean fingers.

1. Remove Electrode Stack and Lamp from sensor and probe.

2. Open the container of alumina polishing compound. With a clean

cotton swab, collect a small amount of the powder.

3. Use this cotton swab to polish the PID lamp window. Use a

circular action, applying light pressure to clean the lamp window,

as shown in Figure 4. Do not touch the lamp window with fingers.

4. Continue polishing until an audible “squeaking” is made by the

cotton swab moving over the window surface. Squeaking usually

occurs within 15 seconds.

Probe Maintenance 29

Page 38

Remove the residual powder from the

lamp window with a clean cotton swab.

Care must be taken not to touch the

tips of cotton swab that are to be used

to clean the lamps as this may

contaminate them with finger oil.

Ensure the lamp is completely dry and

any visible signs of contamination are

removed before replacing.

Figure 4. Cleaning Lamp

Window

PID Lamp Cleaning Kit P/N 801782

The vial of cleaning compound contains alumina (CAS Number

1344-28-1) as a very fine powder. Key safety issues are identified

below.

Hazard identification:

May cause irritation of respiratory tract and eyes.

Storage:

Keep container closed to prevent water adsorption and

contamination.

Handling:

• Do not breathe in the powder. Avoid contact with skin, eyes and

clothing.

• Wear suitable protective clothing.

• Follow industrial hygiene practices: Wash face and hands

thoroughly with soap and water after use and before eating,

drinking, smoking or applying cosmetics.

• The powder carries a TVL (TWA) limit of 10 mg/m3.

Replacing the Lamp

A PID lamp will last a long time, typically a few thousand hours.

However, the sensitivity of the PID sensor is approximately

proportional to the lamp light intensity. As the bulb ages and loses

intensity, the response to a gas concentration decreases and may

become noisier. If cleaning the window does not restore sensitivity,

replace the lamp. Recalibrate the sensor after replacing the lamp.

30 Chapter 5

Page 39

Replacing the Electrode Stack

1. Place the lamp inside the

O-ring seal in the electrode

stack as shown in Figure 5.

Twisting the lamp slightly

during insertion will help to

ensure the lamp window is

snug against the pellet’s

front electrode. The lamp

should be freely supported

by the O-ring.

Figure 5. Inserting Lamp into

Electrode Stack

While the PID electrode stack can last the lifetime of the PID if used

in clean environments, it may only last a month if used in heavily

contaminated sites. Therefore, TSI recommends having a

replacement electrode stack if you are working in dirty environments.

Replace the electrode stack if the sensor shows signs of

contamination after the lamp window has been cleaned or is known to

have been subjected to severe contamination. Recalibrate the sensor

after replacing the electrode stack.

Discarding the Electrode Stack

Discard the contaminated electrode stack. The electrode stack does

not have any toxic components unless contaminated in the field by

toxic materials.

Refitting Electrode Stack and Lamp

WARNING: Do not refit a damaged lamp.

2. Continuing to hold the electrode stack between forefinger and

thumb, carefully insert the lamp into recess in the sensor

ensuring that the lamp remains in position. Press the electrode

firmly, to ensure that the wing clips are engaged, and the top

faces of the electrode stack and sensor housing are flush.

3. Refit the sensor into the VOC probe and replace the sensor

cover.

4. Re-calibrate the gas detector.

Probe Maintenance 31

Page 40

Spare Components

800706

10 ppm Cal Gas (for ppb probe)

800707

100 ppm Cal Gas (for ppm probe)

801780

Replacement Lamp

801781

Replacement Electrode Stack (for ppm Sensor) and Tool

801786

Replacement Electrode Stack (for ppb Sensor) and Tool

801782

Lamp Cleaning Kit with Spring

801783

Replacement ppm sensor

801784

Replacement ppb sensor

U.S.

International

TSI Incorporated

TSI GmbH

500 Cardigan Road

Neuköllner Strasse 4

Shoreview MN 55126-3996

52068 Aachen GERMANY

Tel: +1-800-874-2811 (USA)

Tel: +49 241-52303-0

+1 (651) 490-2811

Fax: +49 241-52303-49

Fax: (651) 490-3824

E-mail: tsigmbh@tsi.com

E-mail: technical.service@tsi.com

Web: www.tsiinc.de

Web: www.tsi.com

TSI Instruments Ltd.

Stirling Road

Cressex Business Park

High Wycombe, Bucks

HP12 3ST UNITED KINGDOM

Tel: +44 (0) 149 4 459200

Fax: +44 (0) 149 4 459700

E-mail: tsiuk@tsi.com

Web: www.tsiinc.co.uk

If you need spare components, then order the necessary parts listed

below:

Recalibration

To maintain a high degree of accuracy in your measurements, TSI

recommends that you return your VOC probe to TSI for annual

recalibration. Please contact one of TSI’s offices or your local

distributor to make service arrangements and to receive a Return

Material Authorization (RMA) number. To fill out an online RMA form,

visit TSI’s website at http://service.tsi.com.

32 Chapter 5

Page 41

Symptom

Possible Causes

Corrective Action

No Display

Unit not turned on

Switch unit on.

Low or dead batteries

Replace batteries or plug

in AC adapter.

Dirty battery contacts

Clean the battery

contacts.

No measurements

shown on display

DISPLAY SETUP

measurement parameters

set to OFF

Set measurement

parameters to ON.

No response to

keypad

Keypad locked out

Unlock keypad by

pressing keys

simultaneously.

Instrument Error

message appears

Memory is full

Download data if desired,

then DELETE ALL memory.

Fault in instrument

Factory service required

on instrument.

Probe Error

message appears

Fault in probe

Factory service required

on probe.

Probe is plugged in,

but the instrument

does not recognize

it

Probe was plugged in

when the instrument was

ON

Turn instrument OFF and

then turn it back ON.

Chapter 6

Troubleshooting

Table 6-1 lists the symptoms, possible causes, and recommended

solutions for common problems encountered with the instrumentation.

If your symptom is not listed, or if none of the solutions solves your

problem, please contact TSI.

Table 6-1: Troubleshooting instrument and VOC probes

Remove the probe from excessive temperature immediately:

excessive heat can damage the sensor. Operating temperature limits

can be found in Appendix A, Specifications.

W A R N I N G !

33

Page 42

(This page intentionally left blank)

34 Chapter 6

Page 43

Appendix A

Specifications

Specifications are subject to change without notice.

Model 984 Low Concentration (ppb) VOC and Temperature

Range 10 to 20,000 ppb,

14 to 140°F (-10 to 60°C)

Accuracy ±1.0°F (±0.5°C)1

Resolution Up to 10 ppb, 0.1°F (0.1°C)

Model 985 High Concentration (ppm) VOC and Temperature

Range 1 to 2,000 ppm,

14 to 140°F (-10 to 60°C)

Accuracy ±1.0°F (±0.5°C)

Resolution Up to 10 ppm, 0.1°F (0.1°C)

Model 986 Low Concentration (ppb) VOC, Temperature, CO2, and

Humidity

Range 10 to 20,000 ppb VOC, 0 to 5,000 ppm CO2

14 to 140°F (-10 to 60°C), 5 to 95% RH

Accuracy ±3% of reading or 50 ppm CO22, whichever is greater

±1.0°F (±0.5°C)1, ±3% RH3

Resolution Up to 10 ppb VOC, 0.1 ppm CO

0.1°F (0.1°C), 0.1% RH

Model 987 High Concentration (ppm) VOC, Temperature, CO2,

and Humidity

Range 1 to 2,000 ppm VOC, 0 to 5,000 ppm CO2

14 to 140°F (-10 to 60°C), 5 to 95% RH

Accuracy ±3% of reading or 50 ppm CO

±1.0°F (±0.5°C)1, ±3% RH3

Resolution Up to 10 ppm VOC, 0.1 ppm CO2,

0.1°F (0.1°C), 0.1% RH

1

2

,

2

2

, whichever is greater

2

Temperature Range:

Operating (Electronics): 40 to 113°F (5 to 45°C)

Operating (Probe): 14 to 140°F (-10 to 60°C)

Storage: -4 to 140°F (-20 to 60°C)

35

Page 44

Probe Dimensions

Length 7.0 in. (17.8 cm)

(excluding handle)

Base Diameter 0.75 in. (1.9 cm)

Tip Diameter 1.0 in. (2.54 cm)

Note: The 984 and 986 probes are designed to measure ppb concentrations of VOCs.

The 10 to 20,000 ppb range corresponds to 0.01 to 20 ppm.

1

Accuracy with instrument case at 77°F (25°C), add uncertainty of 0.05°F/°F

(0.05°C/°C) for change in instrument temperature.

2

Accuracy with probe at 77°F (25°C). Add uncertainty of ±0.2%/°F (±0.36%/°C) away

from calibrated temperature

3

Accuracy with probe at 77°F (25°C). Add uncertainty of 0.1% RH/°F (0.2% RH/°C) for

change in probe temperature. Includes 1% hysteresis.

TSI, the TSI logo and VelociCalc are registered trademarks of TSI Incorporated.

36 Appendix A

Page 45

USA Tel: +1 800 874 2811

UK Tel: +44 149 4 459200

France Tel: +33 4 91 11 87 64

Germany Tel: +49 241 523030

India Tel: +91 80 67877200

China Tel: +86 10 8219 7688

Singapore Tel: +65 6595 6388

TSI Incorporated – Visit our website www.tsi.com for more information.

P/N 6007661 Rev. A ©2014 TSI Incorporated Printed in U.S.A.

Loading...

Loading...