Page 1

Anemometers

Alnor® Velometer Jr.®

Anemometer

Owner’s Manual

Page 2

LIMITATION OF WARRANTY AND LIABILITY

Copyright

TSI Incorporated / 2010 / All rights reserved.

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA

LIMITATION OF WARRANTY AND LIABILITY (effective July 2000)

Seller warrants the goods sold hereunder, under normal use and service as described in the

operator's manual, shall be free from defects in workmanship and material for twelve (12)

months, or the length of time specified in the operator's manual, from the date of shipment to

the customer. This warranty period is inclusive of any statutory warranty. This limited

warranty is subject to the following exclusions:

a. Batteries and certain other components when indicated in specifications, are warranted

for 90 days from the date of shipment.

b. With respect to any repair services rendered, Seller warrants that the parts repaired or

replaced will be free from defects in workmanship and material, under normal use, for a

period of 90 days from the date of shipment to the customer

c. Seller does not provide any warranty on finished goods manufactured by others or on

any fuses, batteries or other consumable materials. Only the original manufacturer's

warranty applies.

d. Unless specifically authorized in a separate writing by Seller, Seller makes no warranty

with respect to, and shall have no liability in connection with, goods which are

incorporated into other products or equi pment, or which are modified by any person

other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated

herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER

OR BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES,

INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS BASED

ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHER WISE) SHALL

BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE PURCHASE

PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR REPLACEMENT OF THE

GOODS. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE

RESPONSIBLE FOR INSTALLATION, DISMANTLING OR REINSTALLATION COSTS

OR CHARGES. No Action, regardless of fo rm, may be brought against Seller more than 12

months after a cause of action has accrued. The goods returned under warranty to Seller's

factory shall be at Buyer's risk of loss, and will be returned, if at all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND

LIABILITY, which contains the complete and exclusive limited warranty of Seller. This

LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or its

terms waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective in struments are as detrimental to TSI as they are to our

customers, our service policy is designed to give prompt attention to any problems. If any

malfunction is discovered, please contact your nearest sales o ffice or representative, or call

Customer Service department at (800) 874-2811 (USA) or (1) 651-490-2811 (International).

Page 3

TABLE OF CONTENTS

FEATURES .......................................................................................... 2

Zero Adjustment ............................................................................ 2

Range Change .............................................................................. 2

ALNOR TYPE 8125 “AirGard®” VELOMETER JR®

ANEMOMETER. .................................................................................. 3

Step By Step Calibration Instructions ............................................ 4

MAINTENANCE .................................................................................. 5

SERVICE INFORMATION ................................................................... 5

Service and Repair ........................................................................ 5

Instructions for Return ................................................................... 6

Damaged in Transit ....................................................................... 6

1

Page 4

FEATURES

The Alnor® Velometer Jr.® Anemometer is a direct reading air

velocity measuring instrument.

This precision instrument is ruggedly built and will serve for many

years if given reasonable care.

You can use this instrument to measure air velocities fr om grilles and

registers and to locate drafts. Balancing of a domestic heating

installation is made simple when using the Alnor

Anemometer.

Hold the instrument so the air blows directly into the calibrated

orifice and read the velocity as indicated by the pointer.

Zero Adjustment

®

Velometer Jr.®

Hold the palm of your hands over the two openings in the sides of the

Velometer Jr.

®

Anemometer and note whether the pointer indicates

Zero. If not, turn the Zero Adjuster screw on the front of the case

slightly until the pointer does read zero. (See fig. 1.)

Orifice Fitting

Zero Adjuster

Figure 1

Range Change

Change range by turning orifice fitting on double r ange i nstr um ents .

(Small orifice for high range—large orifice for low range.) (See fig.1.)

2

Page 5

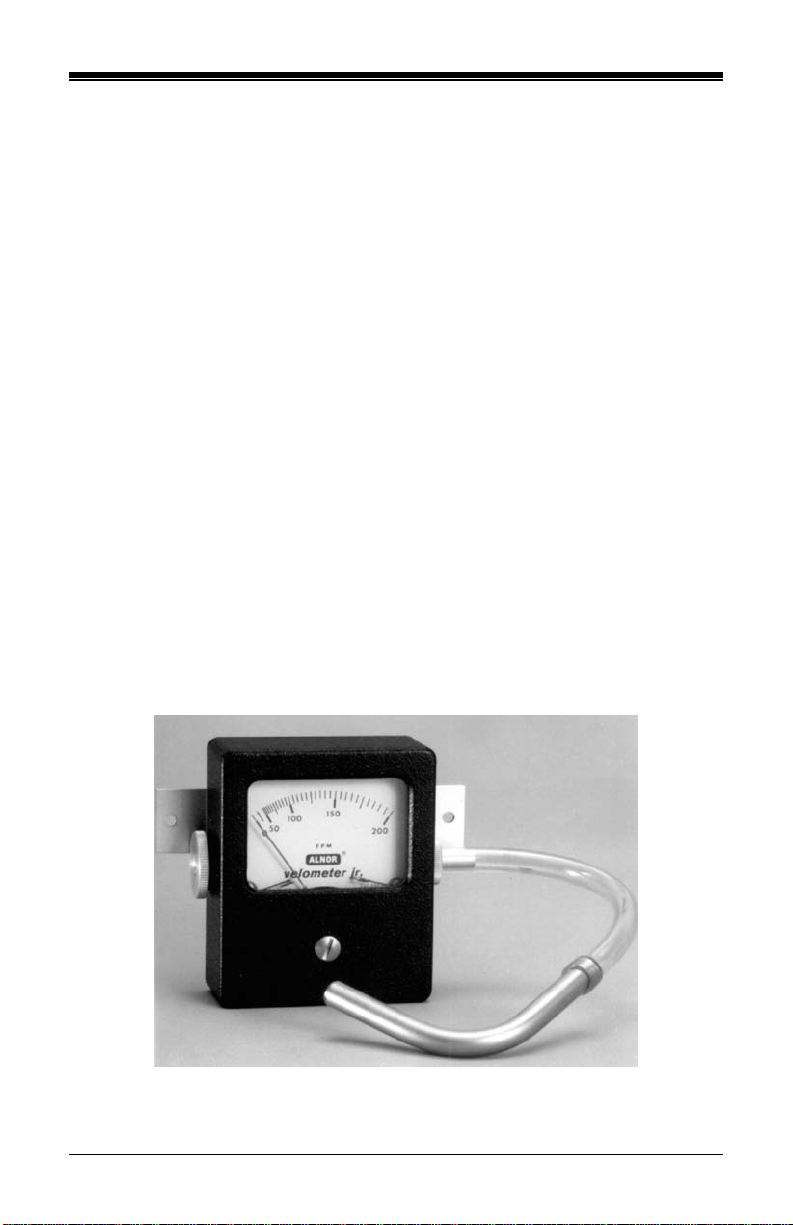

ALNOR TYPE 8125 “AirGard®”

VELOMETER JR.® ANEMOMETER

The AirGard® Face Velocity Monitor is designed to indicate, by

correlation, the average velocity at the face of a ventilation hood. To

ensure that the average face velocity indicated by the AirGard

is correct, the AirGard

can be verified with a properly calibrated thermo-anemometer. Also, the

AirGard

®

monitor should be mounted at a location where local drafts are

®

monitor should be mounted at a location where it

very low and the curved probe will not interfere with the work area.

The calibration procedure follows four basic steps:

1. Make sure the AirGard

®

monitor attachments which were shipped

with the instrument are available—the curved probe and flexible

tube.

2. Zero the AirGard

®

monitor.

3. Measure the average face velocity of the hood using a properly

calibrated thermo-anemometer.

4. Find the right location to mount the AirGard

®

monitor by moving it

along the face of the hood until the meter indicates the same value as

measured with the thermo-anemometer.

®

monitor

Figure 2

3

Page 6

Step By Step Calibration Instructions

1. Connect the curved probe to the AirGard® monitor using the flexible

tube.

2. Cover the inlet orifice on the left hand side of the AirGard

®

monitor

(the operator’s finger can be used for this purpose).

3. With the inlet covered, the AirGard

®

monitor should indicate zero

fpm. If it does not, adjust the pointer to zero using the screw on the

front of the case.

4. Using a properly calibrated thermo-anemometer, determine the

velocity through the face of the hood by taking a detailed velocity

traverse. Divide the face area of the hood into equal increments. A

six-inch grid is recommended for an accurate traverse.

5. Position the AirGard

®

monitor at a location for mounting where local

drafts are very low and the curved pr obe will not interfere with the

work area.

6. Attach the probe to the hood so the open end is inside the hood and

faces downstream.

7. Verify that the AirGard

at the face of the hood in step 4. If the reading by the AirGard

monitor does not match the reading measured in step 4, move the

AirGard

®

monitor along the face of the hood until it indicates the

®

monitor reads the same velocity measured

®

same value as measured with the thermo-anemometer.

8. When the AirGard

®

monitor’s indication matches the value measured

with the thermo-anemometer, mount it in place using the mounting

screws and the curved probe using the fitting provided.

4

Page 7

MAINTENANCE

Handle the Velometer Jr.® Anemometer as you would a watch. It is

composed of precision parts and is carefully balanced and calibrated.

If due to accident, the Velometer Jr.

®

Anemometer requires repair,

return to manufacturer for factory qual ity service. Other instrument

laboratories may not have proper calibrating equipment.

A partially plugged orifice will result in a low reading and, therefore,

we suggest occasional cleaning of the orifice. A toothpick is a good

tool for this purpose. Do not use any wire or other hard tool for this

purpose.

SERVICE INFORMATION

Service and Repair

Please return your Product Registration Card immediately. This

allows us send you service reminders, special offers, and important

information about your product.

Before sending your instrument for calibration or repair, you should

call Customer Service. The Service Department will provi de you with

the cost of service or calibration, Return Material Authorization

(RMA) number, and shipping instructions.

Please have the following information available when you call:

Owner’s Name, address, and phone number

Billing address, if different and applicable

Instrument Name or Model

Serial Number

Date of Purchase

Where Purchased

TSI recommends that you keep a ‘calibration log’ and keep all

records of service on your instrument.

5

Page 8

Instructions for Return

Send the instrument prepaid. Securely package your instrument in a

strong container surrounded by at least two inches (5 cm) of suitable

shock-absorbing material. Include the Purchase Order showing

instrument model number, cost of service and/or calibration, and the

RMA number. Mark the outside of the shipping container with the

RMA number. This will expedite processing of your instrument when

we receive it.

Please note that instruments received improperly marked or without

an accompanying Purchase Order may be return ed at your expense.

See back cover for factory addresses.

Damaged in Transit

All orders are carefully packed for shipment. On receipt, if the

shipping container appears to have been damaged during shipment,

the instrument should be thoroughly inspected. The delivering

carrier’s papers should be signed n oting the apparent damage. DO

NOT DISCARD THE BOX.

If the instrument itself has been damaged, a claim should be promptly

filed against the carrier by the custo mer. The selling agent will assist

the customer by supplying all pertinent shipping information;

however, the claim must be filed by the insured. If the instrument is

damaged beyond use, a new order should be placed with TSI while

awaiting reimbursement from the carrier for the damaged instrument.

Call TSI directly for assistance if necessary .

6

Page 9

CONTENIDO

ESPECIFICACIONES DEL VELOMETER JR. ................................... 8

CARACTERÍSTICAS ........................................................................... 9

Calibracion a Cero ......................................................................... 9

Cambio de Rangos ...................................................................... 10

VELOMETER JR. “AirGard” DE ALNOR TIPO 8125 ..................... 10

Instrucciones Detalladas de Calibracion ..................................... 11

MANTENIMIENTO ............................................................................. 12

INFORMACIÓN SOBRE SERVICI O ................................................. 13

Servicio y Reparación ................................................................. 13

Instrucciones de Devolución ....................................................... 13

Daños en Tránsito ....................................................................... 14

7

Page 10

ESPECIFICACIONES DEL VELOMETER JR.

Precision ±5% de la Escala Completa

Tiempo de Lectura 4–8 Segundos

Dimensiones 3

Lista de Modelos

3

" x 3

/4

1

" x 1

/8

1

"

/8

Número de Parte

Rango

634-110-018 0–200 y 0–800 fpm

634-110-025 0–400 y 0–1600 fpm

634-110-032 0–500 y 0–2500 fpm

634-111-013 0–1.0 y 0–4.0 mps

634-111-020 0–2.0 y 0–8.0 mps

634-111-038 0–2.5 y 0–12.5 mps

634-112-019 0–8 y 0–40 mph

AirGard Modelo 8125

634-112-080 0–200 fpm

8

Page 11

CARACTERÍSTICAS

El Velometer Jr. de Alnor es un instrumento que toma medidas

directas de la velocidad del aire.

Este instrumento de precisión le será de utilidad por muchos años si

se le proporciona con los cuidados necesarios.

Puede emplear el instrumento para tomar medidas de las velocidades

del aire de registros y parrillas, asi como también para localizar fugas

de aire. El uso del Velometer Jr. de Alnor hace que el balanceo de las

instalaciones de calefacción domésticas sean simples.

Sujete el intrumento de tal manera que el aire pase directamente por el

orificio calibrado y lea la velocidad tal y como señala el indicador.

Calibracion a Cero

Sujete el Velometer por las dos aberturas que se local izan a los lados

del instrumento, cubriéndolas con la palma de su mano, fíjese cuando

el indicador señale cero. Si no señala cero, r ote ligeramente el tornillo

ajustador que se encuentra en la parte frontal del instrumento hasta

que el indicador señale cero.

Tornillo de

Orifice

Tornillo

Adjustador

Figura 1

9

Page 12

Cambio de Rangos

Cambie los rangos cambiando la posición de los orificios en los

instrumentos de doble rango. (El orificio pequeño es para rangos altos

y el orificio grande es para rangos bajos.)

VELOMETER JR. “AirGard”

DE ALNOR TIPO 8125

El Velometer “AirGard” de Alnor fue diseñado para indicar por

correlación, los promedios de velocidad a la entrada de una caperuza

de ventilación. Para asegurarse de que el promedio de velocidades

indicada por el AirGard es la correcta, el AirGard d eberá ser montado

en un lugar donde pueda ser verificado con un termoanemómetro

debidamente calibrado. También, el AirGard deberá ser montado en

un lugar en donde las ráfagas locales sean mínimas y la sonda

curveada no interfiera con el área de trabajo.

Para los procedimientos de calibración siga los cuatro siguientes

puntos:

1. Asegúrese de que los aditamentos del AirGard con los cuales fue

empacado se encuentren a disposición: la sonda curveada y el

tubo flexible.

2. Calibre a CERO el AirGard.

3. Mida el promedio de velocidad de la entrada de la caperuza,

empleando un termoanemómetro debidamente calibrado.

4. Localize el lugar adecuado para instalar/montar el AirGard

moviendo el instrumento alrededor de la caperuza, hasta que la

lectura obtenida del AirGard sea la misma obtenida po r el

termoanemómetro.

10

Page 13

Figura 2

Instrucciones Detalladas de Calibracion

1. Conecte la sonda curveada al AirGard empleando el tub o flexible.

2. Cubra el orificio de entrada de la parte izquierda del AirGard (se

pueden usar los dedos del operador con este propósito).

3. Con el orificio de entrada cubierto, el AirGard deberá indicar

CERO fpm. Si no es de esta manera, ajuste el indicador a cero

empleando el tornillo ajustador locali zado en la parte delantera

del instrumento.

4. Empleando un anemómetro debidamente calibrado, determine la

velocidad de la entrada de la caperuza midiend o velocidades

detalladas traversas. Divida el area de entrada de la caperuza en

incrementos iguales. Se recomiendan distancias de 6 pulgadas

para una medición precisa.

5. Posicione el AirGard en un lugar en donde las ráfagas locales

sean mínimas y la sonda curveada no interfiera con el área de

trabajo.

6. Conecte la sonda a la caseta de manera que el extremo abierto se

encuentre dentro de la caseta y esté de frent e a la contracorriente.

11

Page 14

7. Verifique que la lectura del AirGard sea la misma velocidad

medida a la entrada de la caperuza del paso 4. Si la lectur a del

AirGard no corresponde a la lectura tomada en el paso 4, mueva

el instrumento a lo largo de la caperuza hasta que encuentre el

punto en donde las lecturas sean iguales a las del

termoanemómetro.

8. Cuando las indicaciones del AirGard corr espondan a los valores

medidos con el termoanemómetro, instale el instrumento

empleando los tornillos de montaje, y la sonda curveada,

empleando los aditamentos proporcionados.

MANTENIMIENTO

Maneje este instrumento como lo haría con un reloj de mano. Está

construido de partes de precisión y ha sido cuidadosamente calibrado

y balanceado.

Si debido a un accidente, requiere de r eparación, envíelo al fabricante

para que obtenga un servicio de calidad. Cualquier otro laboratorio de

instrumentación puede no tener el equipo adecuado de calibración.

Si tiene un orificio parcialmente tapado, obtendrá lecturas bajas y por

lo tanto, sugerimos que limpie el orificio de vez en cuando. Un palillo

de dientes puede ser una herramienta adecuada par a lograr dicho

propósito. No utilize ningún tipo de alambre o herramientas pesadas

con el mismo propósito.

12

Page 15

INFORMACIÓN SOBRE SERVICIO

Servicio y Reparación

Sírvase devolver su Tarjeta de registro d el producto inmediatamente.

Esto nos permitirá enviarle recordatorios d e ser vicio, ofertas

especiales e información importante sobre su prod ucto.

Antes de enviar el producto para su calibración o reparación, deberá

llamar al Servicio de atención al cliente de TSI. El Departamento de

servicio le proporcionará el valor d el costo del servicio o de la

calibración, el número de Autorización de devolución de material

(RMA, por sus siglas en inglés) y las instrucciones de envío.

Sírvase tener la información siguiente disponible al realizar la

llamada:

Nombre del propietario, dirección y número de teléfono

Dirección de envío de la factura, si fuera di f er ente y aplicable

Nombre del instrumento o modelo

Número de serie

Fecha de compra

Lugar de compra

TSI le recomienda que mantenga un ‘registro de calibración’ y que

guarde todos los documentos de servicio del instrumento.

Instrucciones de Devolución

Envíe el instrumento con el franqueo pre-pagado. Embale el

instrumento con seguridad en un contenedor resistente envuelto en, al

menos, 2 pulgadas (5 cm) de material de protección contra golpes

apropiado. Incluya la Orden de compra con el número de modelo del

instrumento, el costo del servicio y/o calibración, y el número de

Autorización de devolución de material (R MA). Marque el exterior

del contenedor de envío con el n úmero de RMA. Esto acelerará el

procesamiento de su instrumento cuando lo recibamos.

Tenga en cuenta que los instrumentos que se reciban marcados de

manera inapropiada o sin la correspondiente Orden de compra

podrían ser devueltos con los gastos a su cargo. Vea la cubierta

trasera de este manual para obtener las direcciones de fábrica.

13

Page 16

Daños en Tránsito

Todos los pedidos son embalados cuidadosamente para su envío. Una

vez recibido, si el contenedor de envío aparenta haber sido dañado

durante su envío, el instrumento deberá ser inspeccionado

meticulosamente. Los documentos de la compañía tran sportista

deberán firmarse haciendo constar el daño aparente. NO SE

DESHAGA DE LA CAJA.

Si el instrumento ha sufrido daños, el cliente deberá presentar una

queja inmediatamente contra la compañía transportista. El agente

vendedor asistirá al cliente proporcionando toda la información de

envío pertinente; sin embargo, la reclamación d eberá ser presentada

por la parte asegurada. Si el instrumento está d añado sin remedio, se

deberá hacer un nuevo pedido a TSI mientras se espera el reembolso

por parte de la compañía transportista por el instrumento dañado.

Llame a TSI directamente si necesita asistencia.

14

Page 17

TABLE DES MATIÈRES

FICHE TECHNIQUE .......................................................................... 16

CARACTÉRISTIQUES ...................................................................... 17

Réglage du Zéro .......................................................................... 17

Changement d’Amplitude ............................................................ 18

ALNOR TYPE 8125 “AirGard” VELOMETER JR. .......................... 18

Proceudre de Calibrage .............................................................. 19

ENTRETIEN ....................................................................................... 20

RENSEIGNEMENTS DE SERVICE .................................................. 21

Service et Réparations ................................................................ 21

Instructions de Retour à l’Usine .................................................. 21

Dommages en Transit ................................................................. 22

15

Page 18

FICHE TECHNIQUE

Precision ±5% de la valeur inscrite

Temps De Lecture 4 à 8 Secondes

Dimensions 9.525 CM x 7.93 CM x 2.858 CM

Liste des Modeles

No de Serie

634-110-018 0–200 et 0–800 fpm

634-110-025 0–400 et 0–1600 fpm

634-110-032 0–500 et 0–2500 fpm

634-111-013 0–1.0 et 0–4.0 mps

634-111-020 0–2.0 et 0–8.0 mps

634-111-038 0–2.5 et 0–12.5 mps

634-112-019 0–8 et 0–40 mph

AirGard Model 8125

634-112-080 0–200 fpm

Capacite de Mesure

16

Page 19

Ajustement du

CARACTÉRISTIQUES

Le Velometer Jr. d’Alnor est un appareil de mesure de la vitesse de

l’air à lecture directe.

Cet instrument de précision et sa fabrication de qualité vous

donneront entière satisfaction pen dant de nombreuses années s’il est

utilise avec soin.

Vous pouvez utiliser cet appareil pour mesurer la vitesse

d’écoulement de l’air â la sortie d’une bouche de ventilation ou pour

localiser des courants d’airs. L’équilibrage d’une installation de

chauffage devient simple en utilisant le “Velo meter Jr.” d’Alnor.

Positionnez l’instrument de facon à ce que l’air passe directement par

l’orifice de mesure et lisez la vitesse indiquée p ar l’index.

Réglage du Zéro

Obstruez les deux orifices de chaque côté d u “Velometer Jr.” avec la

paume de la main et vérifiez si l’index indique bien zéro. Si tel n’est

pas le cas, tournez doucement la vis de mise à zéro située sur l e

devant de l’appareil jusqu’à ce que l’index soit sur zéro.

Raccord de

l’Orifice

Zéro

Figure 1

17

Page 20

Changement d’Amplitude

Sur les appareils à double capacité de mesure, vous pouvez changer

de calibrage en tournant la mollette de réglage de dimension de

l’orifice. (Petit orifice pour une grande amplitude—Grand orifice

pour une petite amplitude).

ALNOR TYPE 8125

“AirGard” VELOMETER JR.

Le model “AirGard” d’Alnor a été conçu pour indiquer, par

correlation, la vitesse moyenne á la sortie d ’une hotte de ventilation.

Pour être sûr que la vitesse moyenne de sortie indiquée est correcte,

“l’AirGard” doit être installé à un endr oit ou la vitesse peut être

verifiée avec un thermoanémomètre convenablement calibré. De pl us

l’AirGard doit être installé à un endroit ou les courants locaux sont

très faibles et de façon à ce que la sonde courbe ne gêne pas la zone

de travail.

La procédure de calibrage passe par les quatres ét apes suivantes:

1. Verifiez que les accessoires AirGard ont bien été liv r és avec

l’appareil (sonde courbe et tubes souples).

2. Ajustez l’AirGard sur zéro.

3. Mesurez la vitesse moyenne de sortie d’air avec le

thermoanémomètre.

4. Trouvez le bon endroit pour installer l’AirGard en le déplacant le

long de la hotte Jusqu’à ce que l’appareil indique la valeur

mesurée avec le thermoanémomètre.

18

Page 21

Figure 2

Proceudre de Calibrage

1. Connectez la sonde courbe à l’AirGard en utilisant les tubes

souples.

2. Obstruez l’orifice d’entrée situe sur la gauche de l’AirGard.

(l’operateur pourra utiliser son doigt pour cela).

3. Une fois l’orifice d’entrée obstrué, l’AirGard doit indiquer zéro

fpm. Si tel n’est pas le cas, reglez l’index sur zéro en tournant la

vis de réglage située sur le devant de l’appareil.

4. En utilisant un thermoanémomètre convenablement calibré,

determinez la vitesse de l’air qui passe à travers la hotte

en effectuant une traverse de vitesse

précise. Divisez la surface de

sortie de la hotte en parties égales. Nous reco mmendons un

quadrillage de six inch (15 cm) pour obtenir une traverse précise.

5. Installez l’AirGard à un endroit ou les courants locaux sont très

faibles et où la sonde courbe ne gêne pas la zone de travail.

6. Attachez la sonde à la hote de facon à ce que la p artie ouverte de

la sonde soit à l’interieur de la ho tte et en aval du courrant d’air.

7. Verifez que l’AirGard indique la même vitesse d’écoulement que

celle mesurée à la sortie de la hotte à l’étape 4. Si la valeur

mesurée par l’AirGard n’est pas la même que celle mesurée à

l’etape 4, déplacez l’AirGard le long de la hotte jusqu’à ce qu’il

indique la même valeur que celle relevée avec le

thermoanémomètre.

19

Page 22

8. Quand la mesure de l’AirGard correspond à la valeur mesurée par

le thermoanémomètre, installez le définitivement en utilisant les

vis de montage. Installez la sonde courbe en utilisant le materiel

de montage fourni.

ENTRETIEN

Manipulez cet appareil comme si vous manipuleriez une mont r e. Il est

compose de pièces de précision et a été equilibré et calibré avec les

plus grands soins.

Si par accident, des réparations étaient nécessai r es, renvoyez

l’appareil au service apres vente d’usine du fabricant. D’autres

laboratories de réparation n’auraient pas forcement les appareils de

calibrage nécessaires.

Un orifice partiellement obstrué donnera des val eurs de mesure

minorées, c’est pourquoi nous recommendons un nettoyage régulier

de l’orifice. Pour cela, vous pouvez utiliser un cure-dent. Ne jamais

utiliser de fil de fer ou n’importe quel autre outil trop dur pour le

nettoyage de l’orifice.

20

Page 23

RENSEIGNEMENTS DE SERVICE

Service et Réparations

Prière de retourner sans délai votre carte d’enregistrement de produit,

ce qui permettra à TSI de vous faire parvenir des rappels de service,

des offres spéciales et des renseignements importants concernant

votre produit.

Avant d’expédier votre instrument pour étalonnage ou pour

réparation, il est préférable de téléphoner au Service à la clientèle

d’TSI, qui vous communiquera le coût de la réparation ou de

l’étalonnage, le numéro d’autorisation de retour de matériel (RMA) et

les instructions de retour à l’usine.

Prière d’avoir les renseignements suivants sous la main lors de votre

appel :

Nom, adresse et numéro de téléphone du propriétaire

Adresse de facturation, si différente et applicable

Nom ou modèle de l’instrument

Numéro de série

Date d’achat

Place d’achat

TSI vous recommande de tenir un « registre d’étalonnage » et de

conserver tous les dossiers de service concern ant votre instrument.

Instructions de Retour à l’Usine

Expédier l’instrument port payé. Emballer soigneu sement

l’instrument dans un contenant robuste, enveloppé d’au moins 5 cm

(2 po) de matériel amortisseur approprié. Inclure le bon de commande

indiquant le numéro de modèle de l’instrument, le coût du service et

(ou) de l’étalonnage et le numéro d’autorisation de retour de matériel

(RMA). Indiquer le numéro RMA au crayon feutre sur l’extérieur du

contenant d’expédition, ce qui accélérera le traitement dès réception

de votre instrument.

Prière de noter que les instruments reçus sans les indications

appropriées ou sans bon de commande pourraient être retournés à vos

frais. Voir l’adresse de l’usine sur la co uverture arrière de ce manuel.

21

Page 24

Dommages en Transit

Toutes les commandes sont soigneusement emballées avant

l’expédition. Dès réception, si le contenant d’expédition semble avoir

été endommagé pendant le transport, l’instrument doit être examiné

avec soin. Indiquer les dommages apparents sur les documents du

transporteur livreur avant de les signer. NE PAS JETER LA BOÎTE.

Si l’instrument a été endommagé, le client doit immédiatement

présenter une réclamation au transporteur. L’agent vendeur aidera le

client en fournissant tous les détails d’expédition pertinents; la

réclamation, cependant, doit être déposée p ar l’assuré. Si l’instrument

est endommagé au point d’être inutilisable, le client devrait passer

une nouvelle commande auprès d’TSI en attendant d’être remboursé

par le transporteur pour l’instrument endommagé.

Appeler TSI directement pour obtenir de l’aide, au besoin.

22

Page 25

VELOMETER JR.

®

SPECIFICATIONS

Accuracy ±5% of Full Scale

Read-out Time 4–8 Seconds

Dimensions 3

3

" x 3

/4

1/

" x 1

8

1

/8

List of Models

"

Part Number

Range

634-110-018 0–200 and 0–800 fpm

634-110-025 0–400 and 0–1600 fpm

634-110-032 0–500 and 0–2500 fpm

634-111-013 0–1.0 and 0–4.0 mps

634-111-020 0–2.0 and 0–8.0 mps

634-111-038 0–2.5 and 0–12.5 mps

634-112-019 0–8 and 0–40 mph

AirGard® Model 8125

634-112-080 0–200 fpm

Page 26

Alnor Products, TSI Incorporated –

500 Cardigan Road, Shoreview, MN 55126-3996 U.S.A

USA Tel: +1 800 874 2811 E-mail: customerservice@alnor.com

Contact your local ALNOR Distributor or visit our website www.alnor.com for more detailed s pec ifications.

P/N 116049007-09 Copyright © 2010 by TSI Incorporated Printed in U.S.A.

Loading...

Loading...