Page 1

OWNER’S MANUAL

Alnor® Electronic Balancing Tool

Models EBT720/EBT721

and

IRFLOW™ Instruments ProHood™

A

Capture Hood Models PH720/PH721

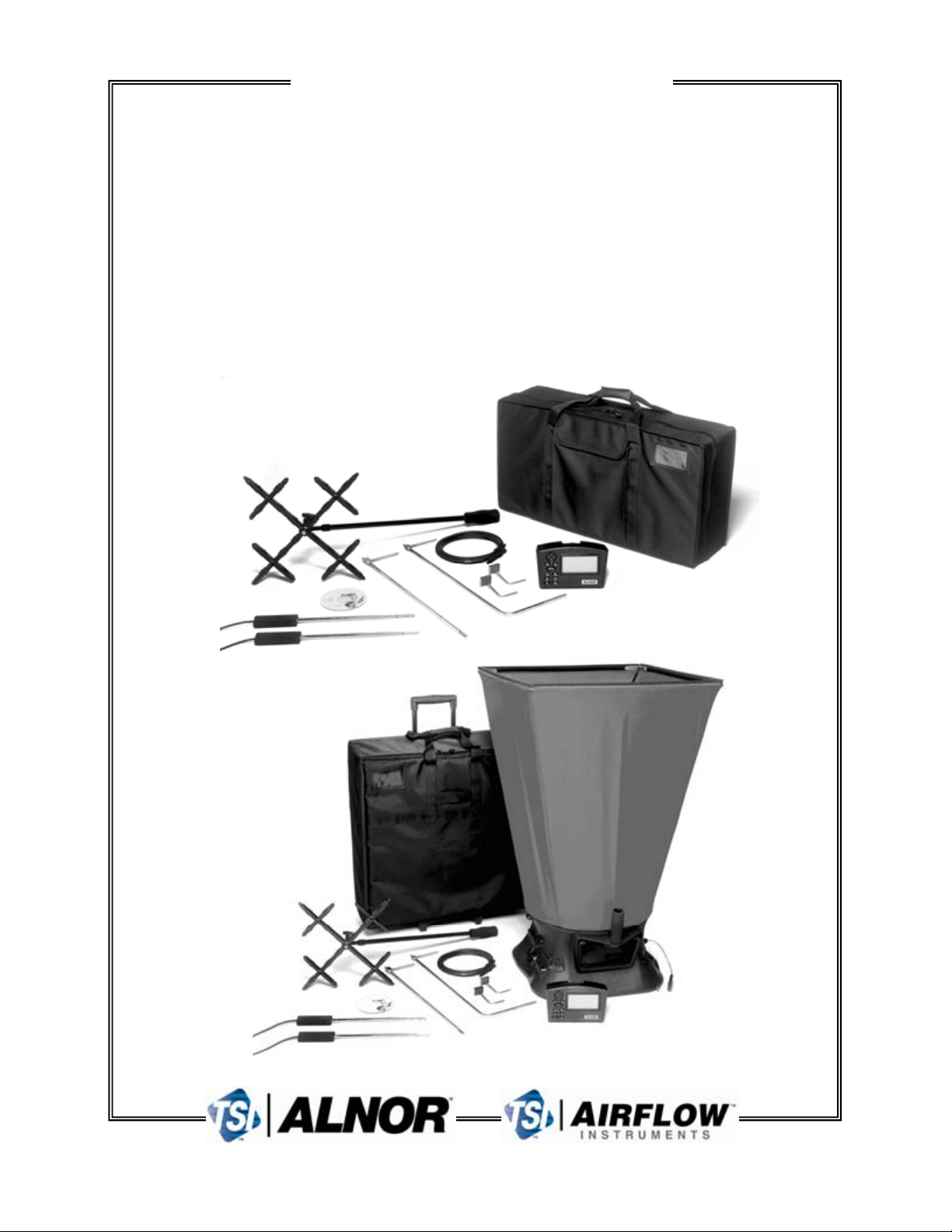

EBT720/PH720 Shown with all

accessory options

EBT721/PH721 Shown with

all accessory options

Page 2

LIMITATION OF WARRANTY AND LIABILITY

Copyright©

TSI Incorporated / 2005–2009 / All rights reserved.

LIMITATION OF WARRANTY AND LIABILITY (effective July 2000)

Seller warrants the goods sold hereunder, under normal use and service as described in the operator's

manual, shall be free from defects in workmanship and material for twenty-four (24) months, or the length

of time specified in the operator's manual, from the date of shipment to the customer. This warranty

period is inclusive of any statutory warranty. This limited warranty is subject to the following exclusions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other components when

indicated in specifications, are warranted for 90 days from the date of shipment.

b. Parts repaired or replaced as a result of repair services are warranted to be free from defects in

workmanship and material, under normal use, for 90 days from the date of shipment.

c. Seller does not provide any warranty on finished goods manufactured by others or on any fuses,

batteries or other consumable materials. Only the original manufacturer's warranty applies.

d. Unless specifically authorized in a separate writing by Seller, Seller makes no warranty with respect

to, and shall have no liability in connection with, goods which are incorporated into other products or

equipment, or which are modified by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated herein. NO

OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR PARTICULAR PURPOSE OR

MERCHANTABILITY IS MADE.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR BUYER, AND

THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES, INJURIES, OR DAMAGES

CONCERNING THE GOODS (INCLUDING CLAIMS BASED ON CONTRACT, NEGLIGENCE, TORT,

STRICT LIABILITY OR OTHERWISE) SHALL BE THE RETURN OF GOODS TO SELLER AND THE

REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR

REPLACEMENT OF THE GOODS. IN NO EVENT SHALL SELLER BE LIABLE FOR ANY SPECIAL,

CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE RESPONSIBLE FOR

INSTALLATION, DISMANTLING OR REINSTALLATION COSTS OR CHARGES. No Action, regardless

of form, may be brought against Seller more than 12 months after a cause of action has accrued. The

goods returned under warranty to Seller's factory shall be at Buyer's risk of loss, and will be returned, if at

all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND LIABILITY,

which contains the complete and exclusive limited warranty of Seller. This LIMITATION OF WARRANTY

AND LIABILITY may not be amended, modified or its terms waived, except by writing signed by an Officer

of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are to our customers,

our service policy is designed to give prompt attention to any problems. If any malfunction is discovered,

please contact your nearest sales office or representative, or call Customer Service department at

+44 (0) 149 4 459200 (UK), (800) 874-2811 (USA), or (1) 651-490-2811 (International).

Trademarks

®

, TSI logo, Alnor®, AIRFLOW™ Instruments, and ProHood™ are trademarks of TSI Incorporated.

TSI

.

Page 3

CONTENTS

About This Manual.....................................................................................................................iii

Formatting and Typography ....................................................................................................iii

Technical Assistance—Help! ..................................................................................................iii

Chapter 1. Introduction ..............................................................................................................1

Instrument Description ............................................................................................................ 1

Micromanometer ............................................................................................................... 2

Micromanometer ..................................................................................................................... 3

Standard Tools........................................................................................................................ 3

Pitot Tube..........................................................................................................................3

Static Pressure Probe .......................................................................................................3

Optional Tools......................................................................................................................... 3

Capture Hoods .................................................................................................................. 3

Velocity Matrix...................................................................................................................3

Air Flow Probe................................................................................................................... 3

Temperature Probe ........................................................................................................... 3

Temperature/Humidity Probe ............................................................................................3

Chapter 2. Unpacking and Setting Up....................................................................................... 5

Unpacking ............................................................................................................................... 5

Preparing the Instrument for Use ............................................................................................ 6

Power the Micromanometer with the AC Adapter .............................................................6

Power the Micromanometer with Batteries........................................................................ 6

Connecting the Pitot Tube to the Micromanometer................................................................. 8

Connecting the Static Pressure Port to the Micromanometer ................................................. 8

Attaching the Micromanometer to the Capture Hood Base..................................................... 9

Connecting the Velocity Matrix to the Micromanometer.................................................... 9

Connecting the Air Flow Probe to the Micromanometer .......................................................10

Connecting the Temperature Probe or Temperature and Humidity Probe to the

Micromanometer ............................................................................................................. 10

Chapter 3. Getting Started .......................................................................................................13

Keypad Operation ................................................................................................................. 13

Common Terms ....................................................................................................................14

Sample ............................................................................................................................ 14

Logging Interval............................................................................................................... 14

Test ID............................................................................................................................. 14

Step-By-Step Example Operation ......................................................................................... 15

Chapter 4. How To ....................................................................................................................17

Select a Tool ......................................................................................................................... 17

Set the Time and Date ..........................................................................................................19

Change the Currently Selected Test ID ................................................................................19

Recall Sample Data ..............................................................................................................19

Delete Sample Data ..............................................................................................................20

Delete all Sample Data ...................................................................................................20

Delete the Samples Stored in a Single Test ID............................................................... 20

Delete a Single Sample................................................................................................... 20

Select/Set a K-factor for a Tool............................................................................................. 21

i

Page 4

View/Set Standard Pressure and Temperature ....................................................................21

Set Units of Measure for Temperature, Pressure, Velocity/Flow and Humidity .................... 23

Select the RS232 Output Device (Computer or Printer) .......................................................23

Set the Baud Rate................................................................................................................. 24

Set the Format for Date and Decimal.................................................................................... 24

Set Display Mode for Running Average or Single.................................................................25

Select Discrete or Continuous Logging................................................................................. 25

Turn Back Pressure Compensation On and Off.................................................................... 26

Take Back Pressure Compensated Hood Readings............................................................. 26

Set Deadband On and Off..................................................................................................... 27

Calibrate the Micromanometer (User Calibration)................................................................. 27

Select User Calibration or Factory Calibration ...................................................................... 28

Connect and Download Data to an Optional Printer ............................................................. 28

Connect and Download Data to a Computer .................................................................. 29

Data Acquisition (Polling)......................................................................................................30

Chapter 5. Changing Flow Hoods ........................................................................................... 31

Flow Hood Parts Identification ..............................................................................................31

Hood Assembly..................................................................................................................... 31

Alternate Hood Installation .............................................................................................. 32

Direct Inflow Measurement Hood for Biological Safety Cabinets.................................... 37

Chapter 6. Flow Measurements Using the Capture Hood ..................................................... 43

Non-Backpressure Compensated Measurements ................................................................ 43

Single Measurements ...........................................................................................................43

Running Average Measurements.......................................................................................... 44

Backpressure Compensated Measurements ........................................................................ 44

Error Display ......................................................................................................................... 45

Chapter 7. Maintenance and Troubleshooting....................................................................... 47

Fabric Hood...........................................................................................................................47

Micromanometer ................................................................................................................... 47

Manifold.................................................................................................................................47

Cases .............................................................................................................................. 47

Calibration............................................................................................................................. 48

Error Code....................................................................................................................... 48

Appendix A. Back Pressure ..................................................................................................... 53

Verifying Flow Measurements...............................................................................................53

Appendix B. Actual vs. Standard Air Velocity and Flow Measurements ............................. 55

ii

Page 5

About This Manual

This manual explains how to set up, operate and maintain the Alnor EBT720/EBT721 and AIRFLOW™

Instruments PH720/PH721. Read it thoroughly before using the instrument.

Caution

CAUTION

W

HILE USING THE BALOMETER® AIR BALANCING INSTRUMENT TO TEST AIR

FLOW IN DUCTS

, POLLEN, MOLD, FUNGUS, OR OTHER AIRBORNE CONTAMINANTS. IF YOU

DUST

ARE OR MAY BE SENSITIVE TO DUST

AIRBORNE CONTAMINANTS

RESPIRATOR WHILE EMPLOYING THE

INSTRUMENT

Formatting and Typography

Step-by-step instructions are numbered in boldface type: 1, 2, 3, etc., set flush-left against the

margin.

References to keys on the micromanometer and the instrument's displayed readout are represented by

a typeface called Arial. In addition to the different typeface, displayed messages appear in quotes.

When reference is made to other sections of the manual, the section title is italicized.

, YOU MAY COME INTO CONTACT WITH OR BE EXPOSED TO

, POLLEN, MOLD, FUNGUS, OR OTHER

, ALWAYS USE AN APPROPRIATE MASK OR

BALOMETER

®

AIR BALANCING

.

Technical Assistance—Help!

For technical assistance or questions about the instrument, or if the instrument needs repair or

recalibration, call Customer Service at +44 (0) 149 4 459200 (UK), (800) 874-2811 (USA), or (1) 651490-2811 (International). Product application notes are available to provide more information on the

product. These application notes, as well as other related material, can be obtained by calling Customer

Service or by visiting the web site at

www.alnor.com or www.airflowinstruments.co.uk.

iii

Page 6

Page 7

Chapter 1. Introduction

The Electronic Balancing Tools EBT720/EBT721 and ProHood™ PH720/PH721 capture hoods are

lightweight and easy-to-use instruments packaged with a variety of accessories for measuring pressure,

temperature, humidity, air velocity, and air volume. Features of the micromanometer include:

Single-function keys for ease of use

Auto-zero for pressure measurements, auto-density correction, and back-pressure compensation when

used with a capture hood

User-selectable English and metric units

Conversions between actual and standard flow

Discrete or continuous display and data logging capabilities

Output port for downloading to a printer or a PC

Powered by AC adapter or batteries (rechargeable NiMH or alkaline)

Full field calibration

Designed for:

Test and balance professionals

Mechanical contractors

Industrial hygienists

Plant engineers and facilities maintenance personnel

Applications include:

Test, balance, or commission HVAC systems

Test clean rooms and biological safety cabinets

Measure fume hood or filter face velocity

Measure pressure, temperature, relative humidity, air velocity, or air flow

CAUTION

W

HILE USING THE BALOMETER® AIR BALANCING INSTRUMENT TO TEST AIR

FLOW IN DUCTS

, POLLEN, MOLD, FUNGUS, OR OTHER AIRBORNE CONTAMINANTS. IF YOU

DUST

ARE OR MAY BE SENSITIVE TO DUST

AIRBORNE CONTAMINANTS

RESPIRATOR WHILE EMPLOYING THE

INSTRUMENT

, YOU MAY COME INTO CONTACT WITH OR BE EXPOSED TO

, POLLEN, MOLD, FUNGUS, OR OTHER

, ALWAYS USE AN APPROPRIATE MASK OR

BALOMETER

®

AIR BALANCING

.

Instrument Description

The basic EBT720/PH720 includes a micromanometer, carrying case, 18 in. (46 cm) pitot tube, (2) static

®

pressure probes, (2) 8 ft (2.4 m) Norprene

downloading software and RS232 interface cable, neck strap, internal NiMH battery charger, (4) AA

NiMH batteries, AC adapter, and NIST traceable certificate.

®

Norprene is a registered trademark of Norton Performance Plastics, Akron, Ohio, USA.

tubing, user manual, CompuDat™ for Windows® data

1

Page 8

The basic EBT721/PH721 contains all of the EBT720/PH720 components plus 2 ft × 2 ft (610 mm × 610

A

A

mm) air capture hood, frame, and base. A variety of optional tools (see below) are also available to meet

your measurement needs.

The following paragraphs provide brief descriptions of the micromanometer and the various standard and

optional tools for use with the EBT/PH. Refer to Chapters

3 and 4 for more detailed information on using

the micromanometer and taking measurements with various sensors and probes.

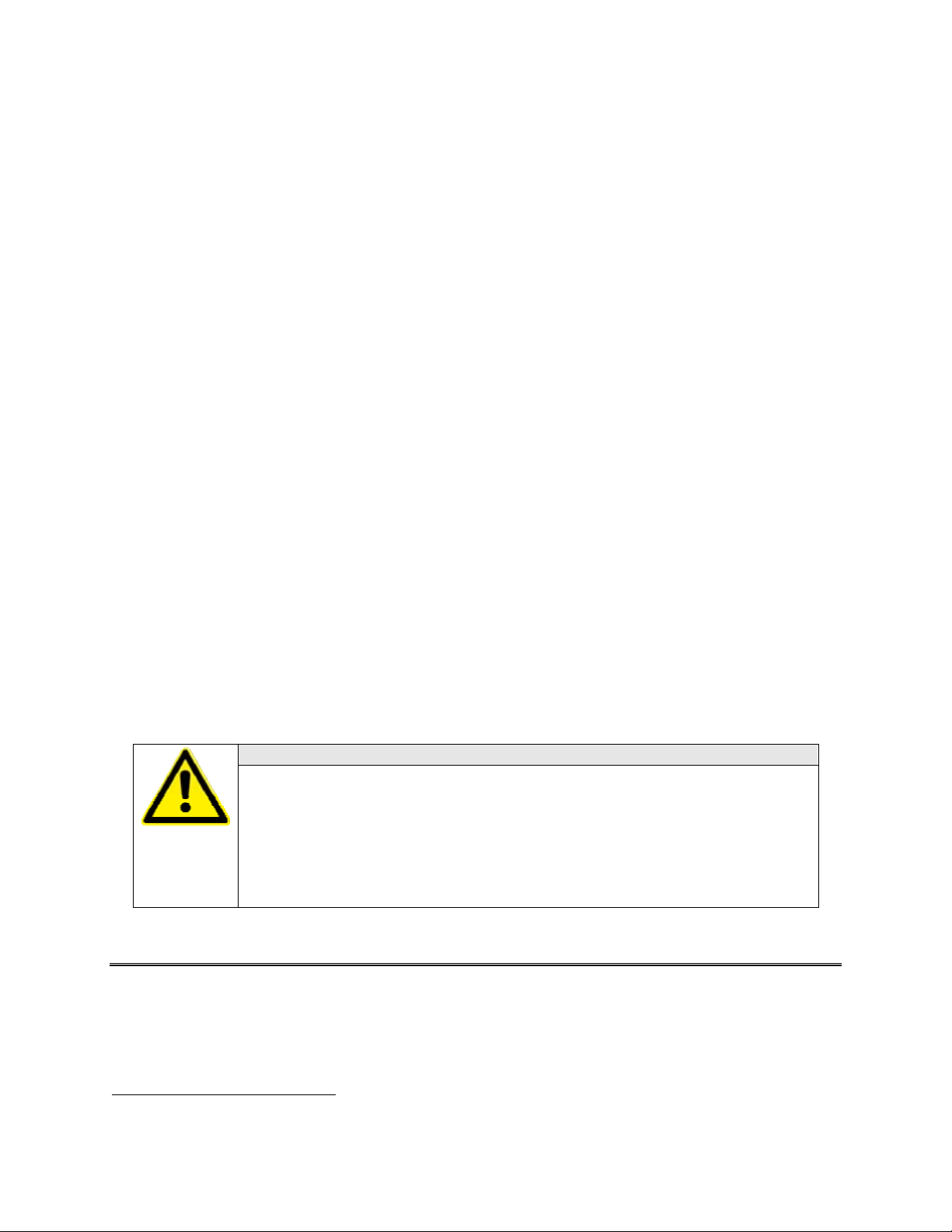

Micromanometer

Figures 1 and 2 show the features of the micromanometer used in the EBT720/EBT721 and

PH720/PH721.

Keypad

C Adapter

Connection

RS232 Port

For Future Use

Figure 1: Features of the EBT720/EBT721 and PH720/PH721 Micromanometer, Front View

irflow

Inlet/Outlet

Display

Headphone

Connection

Probe Connector

Battery

Compartment

Figure 2: Features of the EBT720/EBT721 and PH720/PH721 Micromanometer, Back View

2 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 9

Micromanometer

The micromanometer is a multifunction instrument useful in obtaining air velocity, air flow, absolute and

differential pressure, temperature, and humidity measurements when used with the tools listed below. The

lightweight micromanometer incorporates auto-zeroing for high-accuracy, low-end pressure

measurements.

Standard Tools

This section gives a brief description of standard tools for the micromanometer.

Pitot Tube

The pitot tube is primarily used to obtain air velocity, air volume, and velocity pressure measurements

within ductwork.

Static Pressure Probe

The static pressure probe is primarily used to obtain static pressure measurements within ductwork.

Optional Tools

This section gives a brief description of optional tools for the micromanometer.

Capture Hoods

Capture hoods are primarily used to obtain volumetric air flow measurements through diffusers, registers

and grilles. Capture hoods are available in a kit with one 2 ft × 2 ft (610 mm × 610 mm) fabric hood,

frame, and base assembly. Alternate hood sizes are available and descriptions and part numbers can be

found in

Table 2 of Chapter 2 in this manual.

Velocity Matrix

The velocity matrix is primarily used to obtain area-averaged multi-point air velocity measurements

useful in laboratory hood face velocity testing, filter face velocity testing, and other applications.

Air Flow Probe

The air flow probe is primarily used to obtain single point air velocity or air volume measurements in

ductwork.

Temperature Probe

The temperature probe is used to obtain temperature measurements over the range of -40 to 250°F (-40 to

121°C).

Temperature/Humidity Probe

The temperature/humidity probe is used to obtain temperature measurements over the range of 14 to

140°F (-10 to 60°C), humidity measurements over the range of 0 to 95% RH, along with calculated wet

bulb temperature of 40 to 140°F (4 to 60°C) and dewpoint temperature of 5 to 120°F (-15 to 49°C).

Chapter 1: Introduction 3

Page 10

Page 11

Chapter 2. Unpacking and Setting Up

This chapter describes unpacking and setting up (preparing) the Electronic Balancing Tool (EBT) or

ProHood

matrix measuring the face velocity on a laboratory hood.

Unpacking

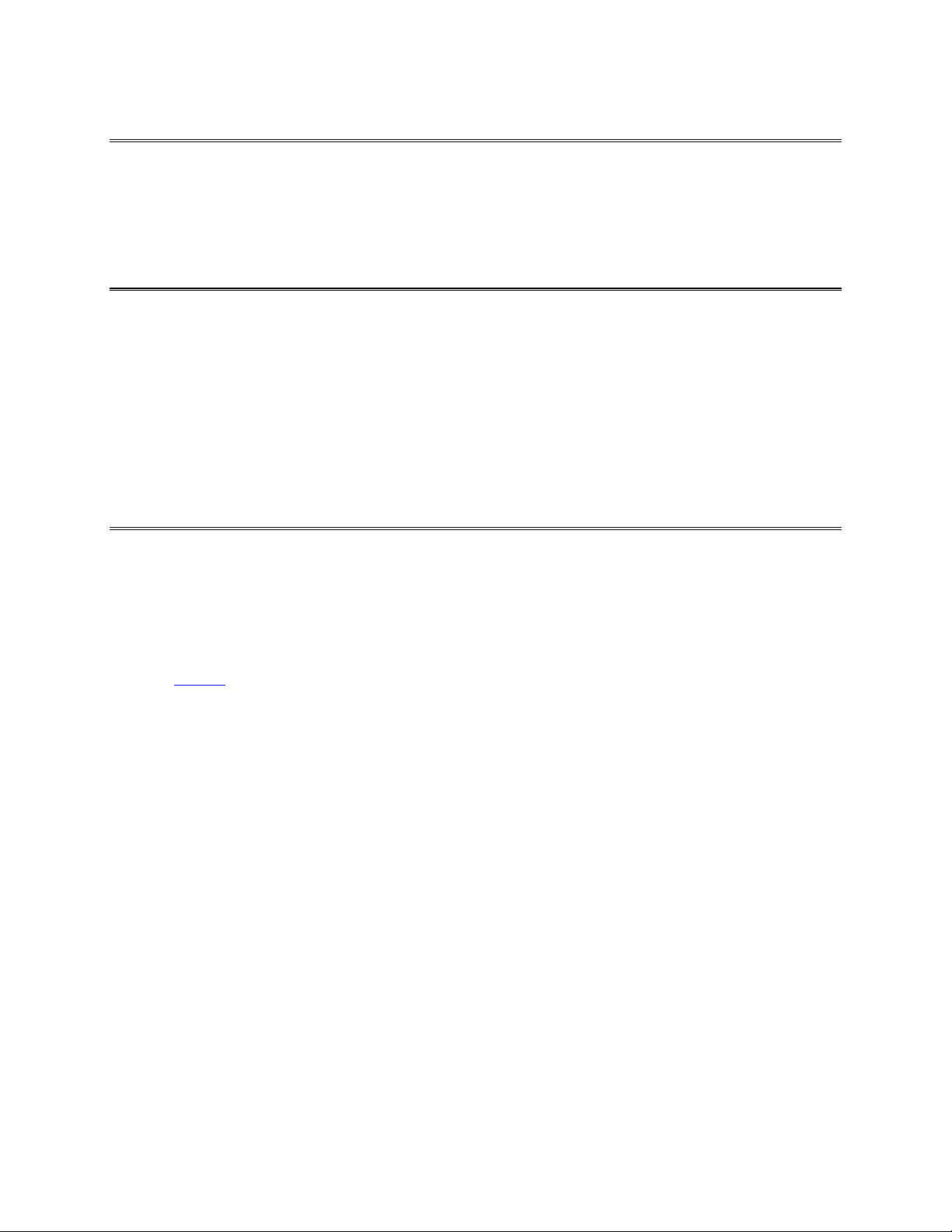

™ capture hood for use. Figure 3 shows a picture of the Model EBT720/PH720 with a velocity

Figure 3: Model EBT720/PH720 with Velocity Matrix

As you unpack the instrument and accessories, check the components against your packing list. If any

parts are missing or damaged, notify us immediately. Tables 1 and 2 list available standard and optional

components.

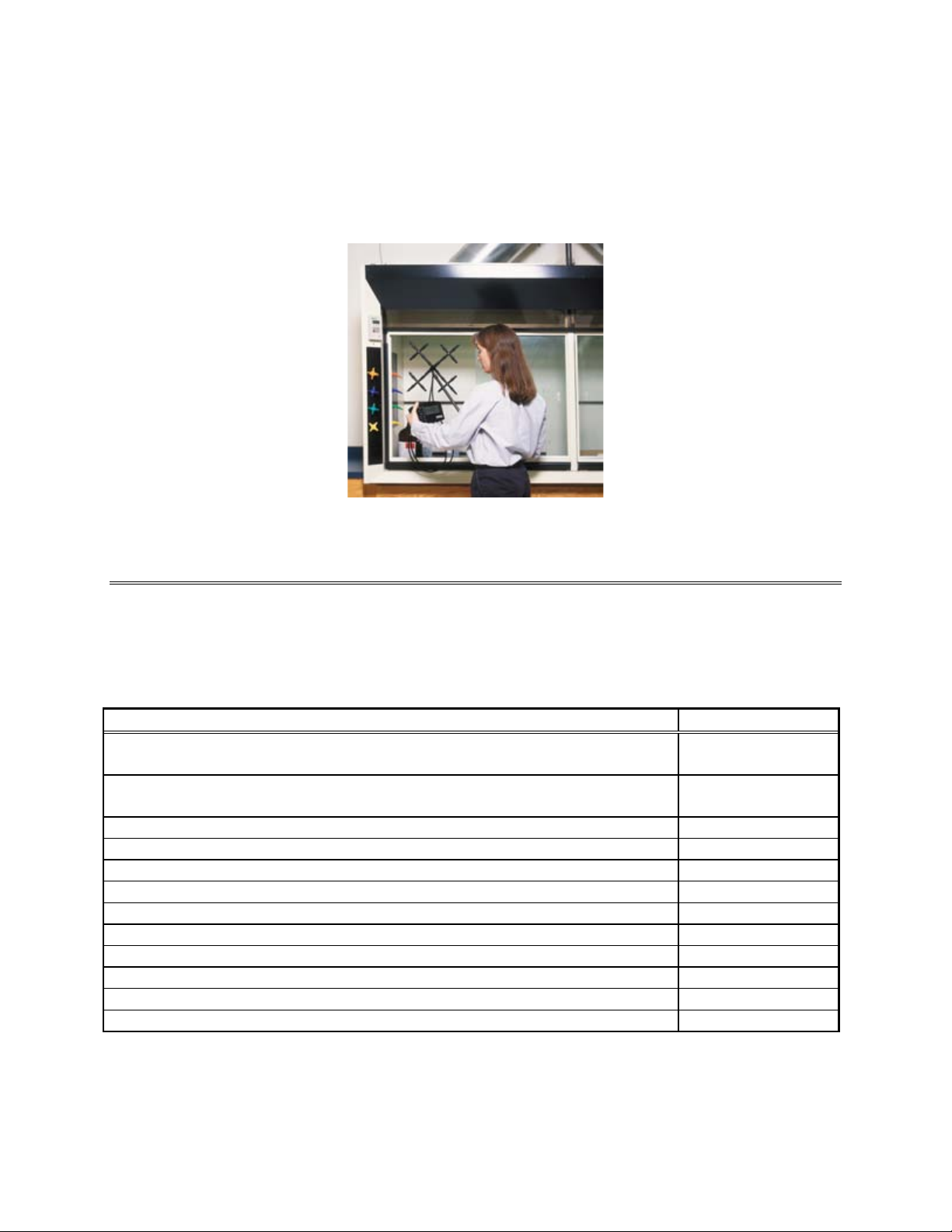

Table 1: List of Standard and Optional Components

Item Part No.

Models EBT720 and EBT721 Electronic Balancing Tools (Alnor)

Models PH720 and PH721 ProHood™ capture hood (AIRFLOW™ Instruments) PH720

Carrying case, EBT720/PH720 1319378

Carrying case, wheeled hood kit, EBT721 1319379

AA-size NiMH battery, four required 1208048

Operation and Service Manual 1980497

Velocity Matrix Add On Kit 801090

Air Flow Probe 800187

Temperature Probe (AIRFLOW™ Instruments) 800208

Temperature and Humidity Probe (AIRFLOW™ Instruments) 800209

Temperature Probe (Alnor) 800188

Temperature and Humidity Probe (Alnor) 800189

EBT720-XXX

EBT721-XXX

PH721

5

Page 12

Table 2: List of Optional Hood Components

Item Part No.

1 ft × 4 ft (305 mm × 1220 mm) and 2 ft × 4 ft (610 mm × 1220 mm) fabric hood

and frame kit

1 ft × 5 ft (305 mm × 1525 mm) and 3 ft × 3 ft (915 mm × 915 mm) fabric hood

and frame kit

1 ft × 4 ft (305 mm × 1220 mm) fabric hood and frame kit

2 ft × 4 ft (610 mm × 1220 mm) fabric hood and frame kit

1 ft × 5 ft (305 mm × 1525 mm) fabric hood and frame kit

3 ft × 3 ft (915 mm × 915 mm) fabric hood and frame kit

8 in. × 21 in. (203 mm × 533 mm) BSC fabric hood, frame, poles, and stand kit

10 in. × 21 in. (254 mm × 533 mm) BSC fabric hood, frame, poles, and stand kit

Please complete the registration card included with this product and mail it promptly. The card allows us

to inform you of product updates. If you prefer, register through the

Alnor web site or AIRFLOW web site.

801206

801207

801200

801201

801202

801203

801204

801205

Preparing the Instrument for Use

Before you can use the Electronic Balancing Tool, you must decide on a power source.

Power the Micromanometer with the AC Adapter

When the AC adapter is plugged into the micromanometer, the unit automatically turns on, runs a brief

diagnostic check, and briefly lights all segments of the display. It then displays the type of batteries the

unit is set to use (alkaline or rechargeable NiMH) and turns itself OFF.

Whenever the AC adapter is plugged into the micromanometer, the rechargeable batteries are recharged.

(Assuming you are using rechargeable batteries and the switch inside the battery compartment is set to

NiMH. See below.)

Power the Micromanometer with Batteries

When not using the AC adapter, the Electronic Balancing Tool or ProHood™ capture hood requires four

AA-size batteries to operate. These can be either alkaline batteries or rechargeable NiMH batteries. For

your convenience, four NiMH batteries are included with the EBT/PH.

To select the type of batteries you are using:

1. Turn the unit off and locate the battery cover on the back of the micromanometer (see Figure 4).

6 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 13

Figure 4: Battery Cover Removal

Press down on the compartment cover and slide it down. (The cover slides off.)

2.

3. Remove the battery holder by pulling up on the bottom (to loosen it) and then pulling the battery

holder free.

4. Refer to Figure 5 and set the battery selection switch to indicate the type of batteries you are using.

Battery Selection Switch

Figure 5: Location of Battery Type Selector Switch

5. Reinstall the battery holder and replace the battery compartment cover.

To install replacement batteries:

1. Turn the unit off and locate the battery cover on the back of the micromanometer (see Figure 4).

2. Press down on the compartment cover and slide it down. (The cover slides off.)

3. Remove the battery holder by pulling up on the bottom (to loosen it) and then remove the battery

holder.

Chapter 2: Unpacking and Setting Up 7

Page 14

4. Remove the old batteries and replace with fresh batteries (alkaline or rechargeable NiMH). Make

certain batteries are correctly oriented.

5. Verify the battery selection switch is correctly set (see Figure 5).

6. Reinstall the battery holder and replace the compartment cover.

Note: Make sure the battery holder is oriented so that its terminals make contact with the spring

contacts in the battery compartment.

If fresh, new alkaline batteries are used, the battery indicator will show 4 bars when first turned on.

With NiMH batteries, the indicator may show a lower value even when they are fully charged.

Notes: The percent power remaining will not be accurate for NiMH batteries because their voltage

does not decrease linearly with power use.

Due to the danger of battery leakage, remove batteries from the battery compartment before

storage. Never mix battery types.

The NiMH batteries should only be charged at room temperature. Starting with batteries that

are too cold or too warm can cause the charge cycle to stop early.

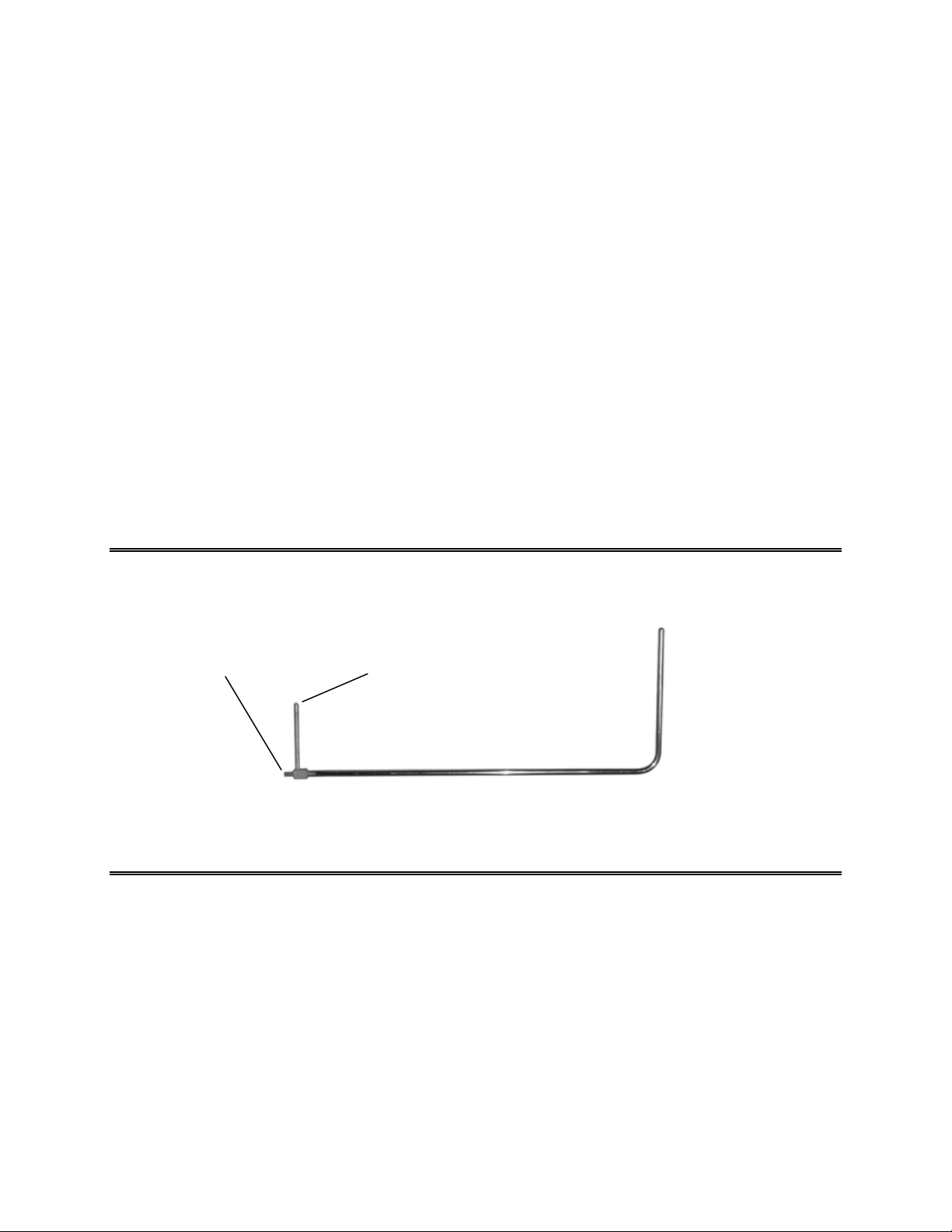

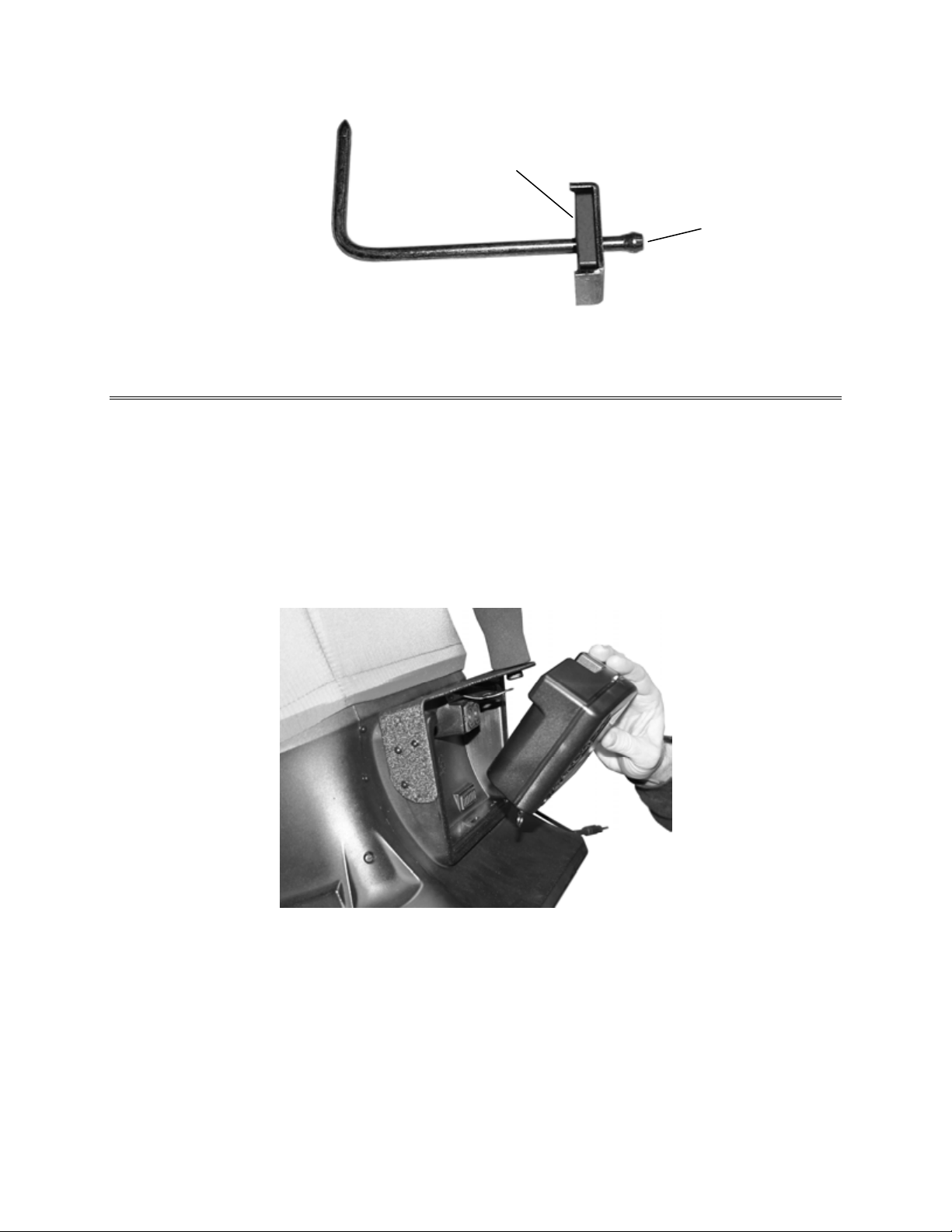

Connecting the Pitot Tube to the Micromanometer

The static pressure port (-) on the pitot tube will be connected to the negative pressure (-) port on the

micromanometer, and the total pressure port (+) on the pitot tube will be connected to the positive (+) port

on the micromanometer (see

Figure 6).

Total Pressure Port (+)

Static Pressure Port (–)

Figure 6: Pitot Tube

Connecting the Static Pressure Port to the Micromanometer

The static pressure port on the static pressure probe will be connected to the (+) port on the

micromanometer. The (-) port on the micromanometer will be open to atmosphere (see

Figure 7).

8 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 15

Magnet

Static Pressure Port

Figure 7: Static Pressure Probe

Attaching the Micromanometer to the Capture Hood Base

1. Tilt the meter forward and align the tabs in the base of the meter with the two matching slots in the

bottom of the recessed area at the front of the base (see

2. When the tabs are engaged in the slots, press firmly on the face of the meter above the display until

the tab in the top center of the meter “clicks” into the bent metal retaining clip in the base.

Figure 8).

3. Attach the temperature cable and the back pressure flap switch cable to the right side of the meter.

4. To remove the meter from the base, first disconnect the temperature cable and the back pressure flap

switch cable, then press upward on the metal retaining clip to release the meter from the base.

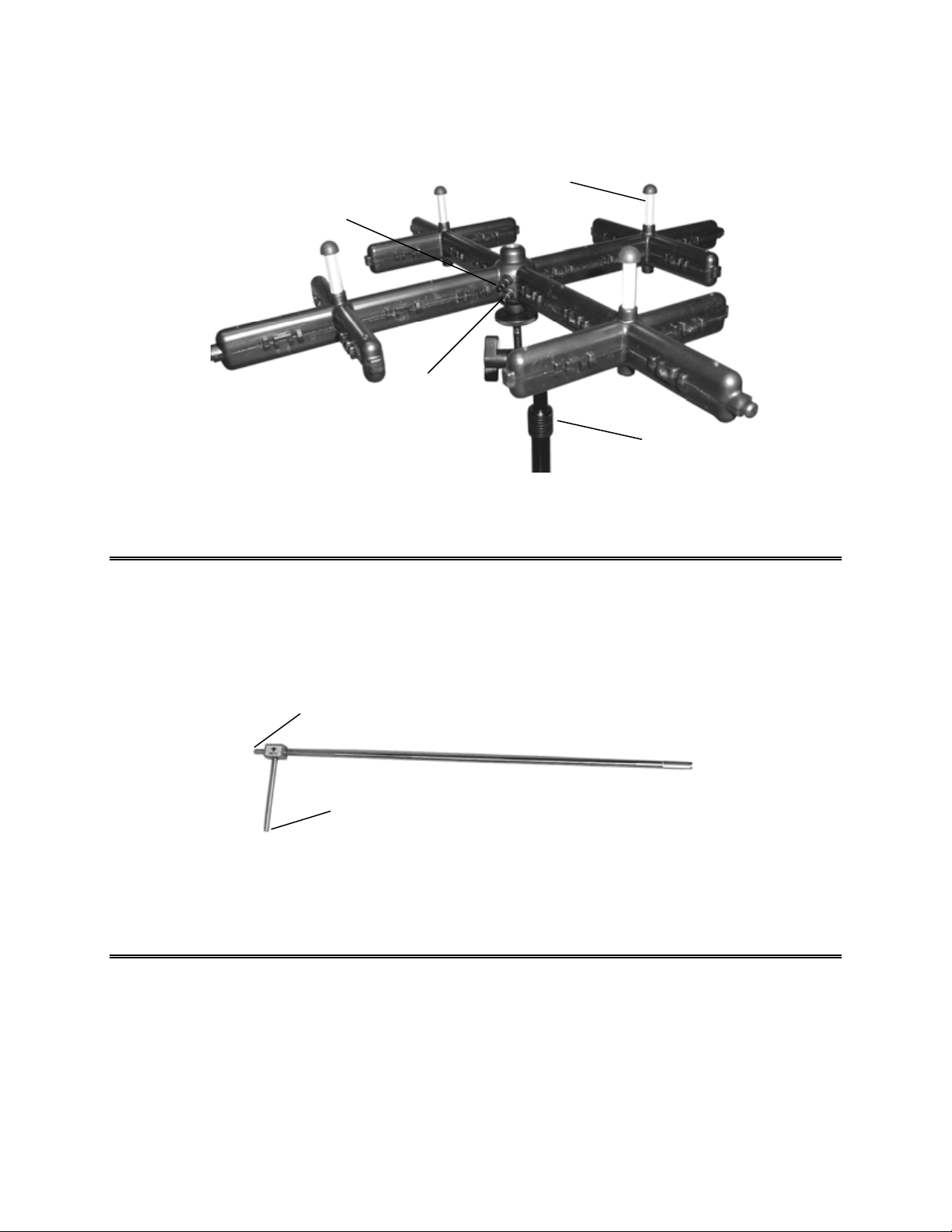

Figure 8: Attaching the Meter to the Capture Hood Base

Connecting the Velocity Matrix to the Micromanometer

The positive port (+) is located on the side of the Velocity Matrix that is opposite the handle assembly.

The positive port (+) on the Velocity Matrix will be connected to the (+) port on the micromanometer,

and the negative port (-) on the Velocity Matrix is connected to the (-) port on the micromanometer.

Standoffs can be screwed together to make different lengths and are used to maintain a fixed and level

orientation away from a filter. The standoffs are attached to the positive (+) side of the velocity matrix.

Chapter 2: Unpacking and Setting Up 9

Page 16

The handle assembly is attached to the downstream or negative (-) side in the center of the velocity matrix

Figure 9).

(see

Standoffs

Positive

Port (+)

Negative

Port (–)

Handle

Figure 9: Velocity Matrix

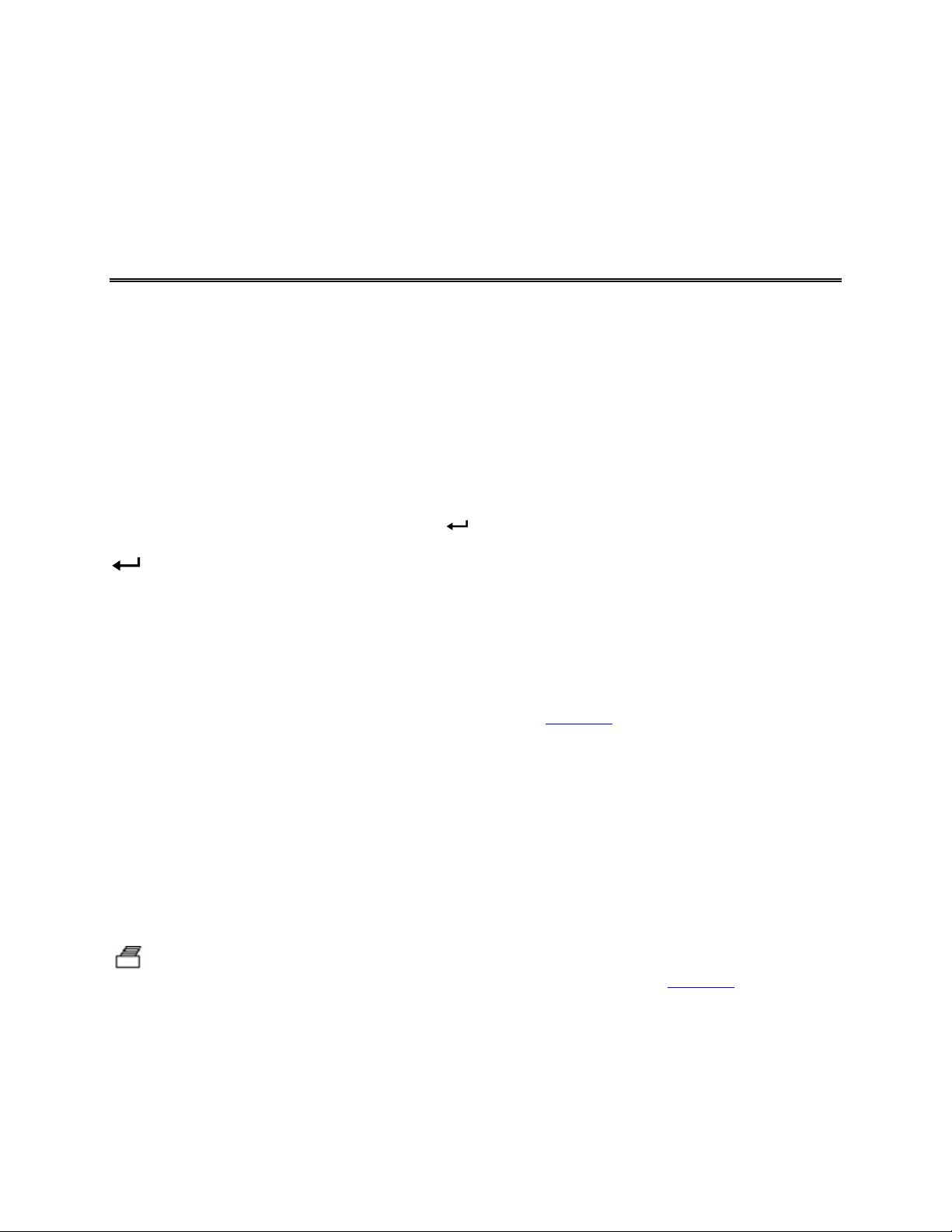

Connecting the Air Flow Probe to the Micromanometer

The static pressure port (-) on the Air Flow Probe will be connected to the negative pressure (-) port on

the micromanometer, and the total pressure port (+) on the Air Flow Probe will be connected to the

positive (+) port on the micromanometer (see

Figure 10).

Note: Observe the arrow indicator on the Air Flow Probe when taking air velocity or air volume

measurements.

Total Pressure Port (+)

Static Pressure Port (–)

Figure 10: Air Flow Probe

Connecting the Temperature Probe or Temperature and Humidity Probe to the Micromanometer

The Temperature probe and Temperature/Humidity probe attach to the 8-pin connector located on the

right hand side of the micromanometer. When connecting the probe to the meter, the dimple on the

connector must be aligned to fit the receptacle indentation on the meter (see

Figure 11).

10 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 17

Match key on plug to

detent on receptacle

Figure 11: Connector for the Temperature Probe or Temperature/Humidity Probe

Chapter 2: Unpacking and Setting Up 11

Page 18

Page 19

Chapter 3. Getting Started

This section provides information to help you quickly become familiar with the Models EBT720/EBT721

and PH720/PH721

Sample readings.

Keypad Operation

The keypad lets you enter information, initiate functions, and change values stored in the

micromanometer. It will be helpful before operating the micromanometer to understand more fully what

each of the keys do.

W X T andS

The arrow keys let you navigate through menus or select options. Generally only one set of arrow keys

(S,T or W,X are operational for any given operation. Use W and X to move through menus; use S and

T to increase or decrease a value.

ESC

The ESCAPE key is used to cancel or end an operation or back up to the last screen of displayed

information. The ESC key is useful if you press

The ENTER key is used to accept the present value or move to the next level of a menu.

READ

If the display mode is set to SINGLE, pressing the READ key begins a reading, which stops

automatically when the reading is done.

Micromanometer functions. It also includes step-by-step instructions for taking

and realize you meant to use one of the other keys.

If the display mode is set to RUNAVG, the micromanometer will measure continuously, and pressing

READ will alternately pause or resume the measurement. (See

to SINGLE or RUNAVG.)

There is a red button on the capture hood base that has the same function as the READ key.

Note: Pressing the READ key will not store any measurement to memory.

SAVE

The SAVE key is used to save the currently displayed measurement to the data logging memory.

NEXT TEST

The NEXT TEST key is used to select a new unused Test Id for saving Samples when logging data.

The PRINT key downloads data to an optional printer or to a computer. Refer to information on downloading data.

STATS

The STATISTICS key lets you display COUNT, MINimum, MAXimum and AVeraGe for the Test ID

currently selected for logging data.

Chapter 4 on how to set the display mode

Chapter 4 for

13

Page 20

I/O

The ON/OFF key is used to turn the micromanometer on or off.

The BACKLIGHT key turns the display’s backlighting on and off. Use backlighting only when working

in areas where you cannot read the display with existing light. Backlighting has a significant impact on

battery life.

Common Terms

In this manual there are several terms that are used in different places. The following is a brief

explanation of the meanings of terms.

Sample

A Sample consists of all of the measurement parameters stored each time the SAVE key is pressed, or

after each logging interval has passed. The maximum number of Samples is 1000.

Logging Interval

The Logging Interval is the frequency period that the micromanometer will log readings, when logging is

set to CONTIN (continuous). For example, if logging is set to CONTIN and the logging interval is set to

60 seconds, a Sample can be taken and saved automatically every 60 seconds. Refer to chapter 4 for more

information on continuous data logging.

Test ID

A Test ID consists of a group of Samples. A Test ID can contain up to 1000 Samples. The maximum

number of Test IDs is 255.

Any new Sample will be saved to the current Test ID. You can change the current Test ID at any time to

keep your data organized, refer to instructions in

The unit does not allow you to store Samples of different character in the same Test ID. If the READ key

is pressed after changes have been made to the Tool or display units or some other parameter, TEST ID

flashes on the display and a new unused TEST ID is selected.

In addition to the data for each Sample, the statistics that are available to view by TEST ID are:

SUM - The sum of all stored values in that TEST ID. (SUM is only available for hood flow or Diffuser

Flow [flow from pressure and K-Factor])

MINIMUM - The lowest value stored in that TEST ID

MAXIMUM - The highest value stored in that TEST ID

AVERAGE - The SUM divided by the number of Samples

COUNT - The number of Samples in that TEST ID

Once you have collected data in a Test ID, you can send it to a printer or a computer. See instructions for

downloading data in

Chapter 4.

Chapter 4.

14 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 21

Step-By-Step Example Operation

The quickest way to become acquainted with the operation of the Electronic Balancing Tool or

ProHood

To take Samples proceed as follows:

1. Connect the AC adapter to the micromanometer or install batteries in the micromanometer (see

2. Turn on the micromanometer by pressing the I/O key. The unit displays INIT (initializing) and runs a

™ capture hood is to take a few Samples while in the pressure mode.

CAUTION

W

HILE USING THE BALOMETER® AIR BALANCING INSTRUMENT TO TEST AIR

FLOW IN DUCTS

, POLLEN, MOLD, FUNGUS, OR OTHER AIRBORNE CONTAMINANTS. IF YOU

DUST

ARE OR MAY BE SENSITIVE TO DUST

AIRBORNE CONTAMINANTS

RESPIRATOR WHILE EMPLOYING THE

INSTRUMENT

, YOU MAY COME INTO CONTACT WITH OR BE EXPOSED TO

, POLLEN, MOLD, FUNGUS, OR OTHER

, ALWAYS USE AN APPROPRIATE MASK OR

BALOMETER

.

Chapter 2).

brief diagnostic test.

®

AIR BALANCING

3. If the display mode is set to SINGLE, the unit will stop and show READY on the display. Pressing

READ will begin a reading, which stops automatically when the reading is done. If the display mode

is set to RUNAVG, the micromanometer will start measuring continuously, and pressing READ will

pause and resume the measurement. (See

Chapter 4 on how to set the display mode to SINGLE or

RUNAVG.)

4. While the unit reads the measurements, it makes a “clicking” sound.

5. When data collection is finished, the display shows the pressure reading. Press the SAVE key to save

the displayed reading to the currently selected Test ID. (If the SAVE key is pressed before the

micromanometer has collected enough data to save, NO.DATA is displayed.)

6. Repeat steps 4-5 to save additional Samples.

Refer to Chapter 4 for detailed “

How To” information on recalling the saved Samples and many other

specific operations.

Chapter 3: Getting Started 15

Page 22

Page 23

Chapter 4. How To

This chapter explains how to perform a variety of operations:

Select a Tool/Probe

Set the Time and Date

Change the Currently Selected Test ID

Recall Sample Data

Delete Sample Data

Delete All Sample Data

Select/Set a K-factor

View/Set Standard Pressure and Temperature

Set Units of Measure for Temperature, Pressure, Flow and Humidity

Select the RS232C Output Device (Computer or Printer)

Set the Baud Rate

Set the Date and Decimal Format

Set Display Mode for Running Average or Single

Select Discrete or Continuous Logging

Turn Back Pressure Compensation On and Off

Take Back Pressure Compensated Hood Readings

Set Deadband On and Off

Calibrate the Micromanometer

Select User Calibration or Factory Calibration

Connect and Download to a Printer

Connect and Download to a Computer

Data Acquisition (Polling)

Note: The operations described below assume you are starting from the READY display. As you use the

instrument, you will find it unnecessary to return to the READY display each time. Press the ESC

key (one or more times) to return to the READY display.

Select a Tool

The instrument accepts a number of different measurement devices, referred to as Tools. The Tools are:

Capture hoods for measuring flow from grilles and diffusers.

A velocity matrix for area-averaged multi-point velocity measurements.

Pitot tubes for flow and velocity measurements.

Air Flow probes for flow and velocity measurements.

A Diffuser Flow tool which can calculate flow for diffusers equipped with differential pressure taps.

(The Diffuser Flow tool is a flow calculation method, not a physical device.) For the Diffuser Flow

tool, flow is calculated from the square root of pressure times a user entered K-factor.

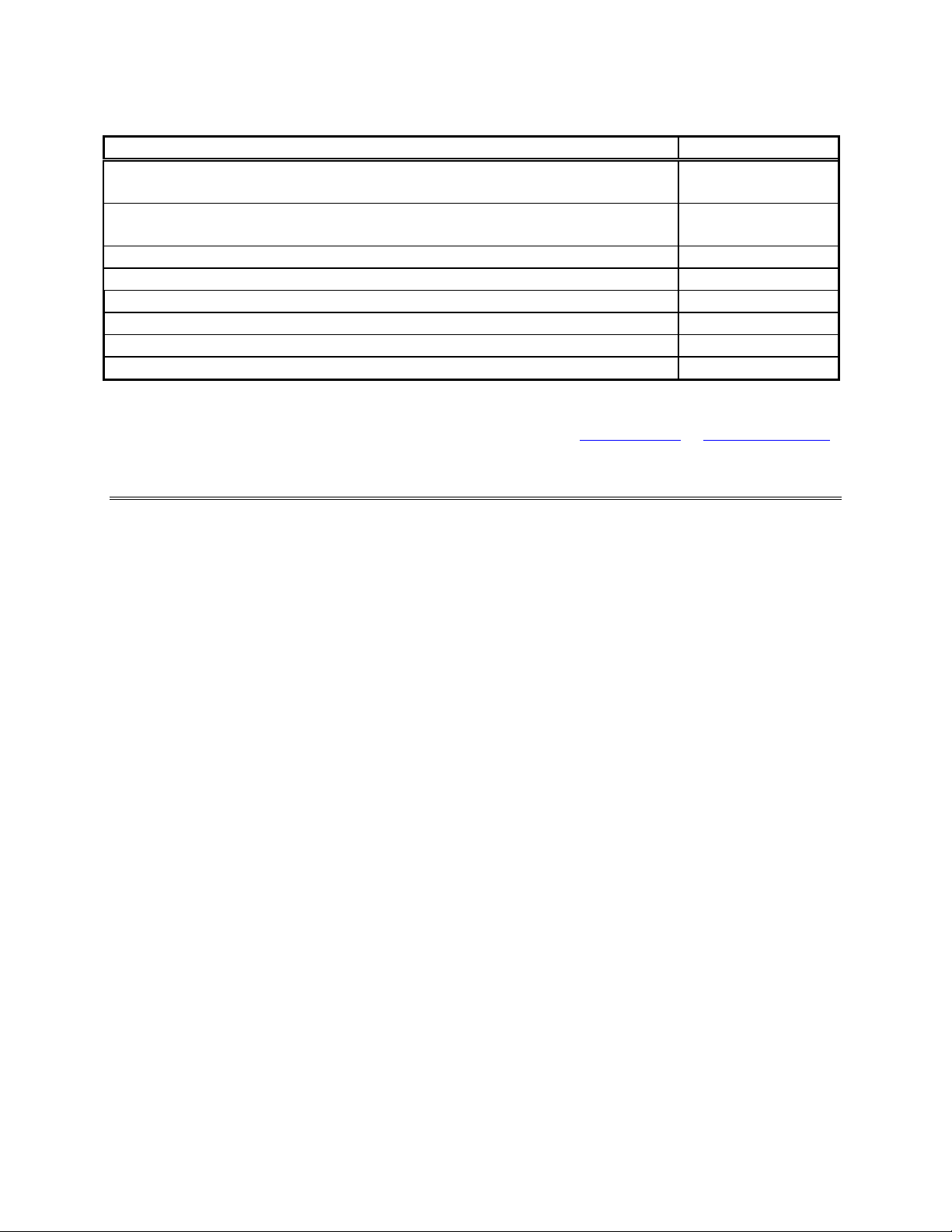

Table 3 identifies each Tool and the units of measure available for that tool.

17

Page 24

Table 3: Tool Selection Display

Display Shows Tool Units Available

Pressure units only Pressure in H2O, mm H2O, cm H2O, Pa, hPa, kPa,

mm Hg, cm Hg, in Hg,

3

Capture Hood l/s, m

/hr, m3/min, CFM

with flow units

Pressure units with K-

Diffuser Flow l/s, m3/hr, m3/min, CFM

factor and flow units

Air Flow Probe Flow l/s, m

3

/hr, m3/min, CFM

with flow units

Air Flow Probe Velocity ft/min, m/s

with velocity units

3

Pitot Tube Flow l/s, m

/hr, m3/min, CFM

with flow units

Pitot Tube Velocity ft/min, m/s

with velocity units

Velocity Matrix ft/min, m/s

To select a Tool, proceed as follows:

1. Press

to display CHANGE Test ID.

2. Press X until TOOL appears.

3. Press

. The display shows an icon and units (see Table 3 above) to indicate the currently selected

TOOL and the units selected for it.

4. Press S or T to scroll through the available TOOLs. See

5. When the TOOL you want to use is displayed, press

6. If you select “flow” using either a pitot tube or an Air Flow probe, the display will flash a

Table 3 above.

.

and

. This indicates that you need to enter the duct shape and duct size. Proceed with steps 7-10. If

you selected another TOOL, you will return to the TOOL menu.

Note: The only way to change the duct shape or size later is to re-enter the Tool select menu and

re-select the Tool.

7. Use S or T to select the duct shape and stop the flashing.

8. Press

. The display shows the currently selected duct size (flashing).

9. Use S or T to change the size. (If you selected a rectangular size, you need to enter/change the size

for both height and width, even if the duct is square. Change the x dimension first, then press

and

change the y dimension).

10. Press

to exit to the TOOL menu.

18 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 25

Set the Time and Date

1. Press to display CHANGE Test ID.

2. Press X until SETUP appears.

3. Press

4. Press X until TIME is displayed.

5. Press

6. Use W and X to move between values and S and T to adjust values.

7. Press

Note: You can change the date format (see “Set Format” below). Allowable formats are mm.dd and

.

. The display shows the current time and date. The hours value is flashing.

when you have set the time and date as desired.

dd.mm.

Change the Currently Selected Test ID

To change the Test ID in which Samples will be stored, proceed as follows:

1. Press

2. Press

3. Use S and T to select the Test ID you want to use.

Note: If you press S again after the highest numbered Test ID is displayed, you will add a new Test

to display CHANGE Test ID.

to display the current Test ID.

ID. (The Test ID is empty until you send Samples to it.) Also, if you press SAVE (or try to

automatically log data to a Test ID) and the Tool or display units or measurement

parameters are different from the information already stored in the currently selected Test

ID, the instrument will automatically change the currently selected Test ID to a new unused

Test ID. See the description of “

TEST IDs” in Chapter 3.

Recall Sample Data

To recall Sample data so that you can review it or send it to a printer or computer, proceed as follows:

1. Press

2. Press X until RECALL appears.

3. Press

4. Use S and T to select the Test ID you want to recall a Sample from.

5. Press

Test ID.)

Press S or T to display an entry in the selected Test ID. In addition to displaying individual Sample

values, you can also view the MAX, MIN, AVG, and SUM of the data in the Test ID. (SUM is only

available for hood flow or Diffuser Flow [flow from pressure and K-Factor].) Hold down S or T to

scroll quickly through the data.

Chapter 4: How To 19

to display CHANGE Test ID.

to display the current Test ID.

. The COUNT for the selected Test ID is displayed. (Count is the number of Samples in the

Page 26

Delete Sample Data

You can delete data in three ways: 1) delete all Sample data in all Test IDs, 2) delete all Sample data for a

single Test ID, and 3) delete only the last Sample currently stored in a Test ID.

Delete all Sample Data

1. Press to display CHANGE Test ID.

2. Press X until DELETE appears.

3. Press

4. Press

Note: This countdown gives you time to change your mind. If you decide not to delete all samples

. The display shows DELETE ALL.

. The instrument counts down from 3 to 0 and then deletes all Sample data.

after pressing

, press ESC before the count reaches 0. Samples will not be deleted.

Delete the Samples Stored in a Single Test ID

1. Press to display CHANGE Test ID.

2. Press X until DELETE appears.

3. Press

4. Press X. The display shows DELETE Test ID.

5. Press

6. Use S and T to display the Test ID whose Samples you want to delete.

7. Press

8. Repeat steps 6 and 7 to delete other Test IDs.

. The display shows DELETE ALL.

. The display shows the currently selected Test ID.

. “DELETE” flashes while all Samples for the selected Test ID are deleted.

Delete a Single Sample

1. Press to display CHANGE Test ID.

2. Press X until DELETE appears.

3. Press

4. Press X. The display shows DELETE Test ID.

5. Press X. The display shows DELETE #.

6. Press

7. Use S and T to display the Test ID containing the Sample you want to delete.

8. Press

9. Press

10. Repeat step 9 to delete other Samples in the selected Test ID.

20 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

. The display shows DELETE ALL.

. The display shows the currently selected Test ID.

. The display shows the last Sample in the Test ID.

. “DELETE” flashes while the last Sample of the selected Test ID is deleted.

Page 27

Select/Set a K-factor for a Tool

It is possible to enter K-Factors to adjust the calculations of the velocity and flow measurements.

For Hood Flow, Pitot Velocity, Pitot Flow, Air Flow Probe Flow, Air Flow Probe Velocity and Velocity

Matrix, the K-Factor is simply multiplied by the calculated velocity or flow in order to get the displayed

value. For these Tools, use of a K-Factor is optional and setting the K-Factor to 1.0 will turn it off. The

K-factor range for these Tools is 0.500 to 1.500.

For the Diffuser Flow Tool (Flow from Pressure and K-factor), the use of a K-Factor is mandatory. The

displayed flow for this tool is the square root of pressure times the entered K-Factor. The K-factor range

for this Tool is 0.001 to 9.999.

You can only enter a K-factor if you have selected a Tool that can use a K-factor. The Pressure Tool does

not use K-factors.

To select or set a K-factor, proceed as follows:

1. Press

2. Press X until K-FACT appears.

3. Press

4. Press X to scroll through the available K-factors or turn the K-factor Off. The instrument lets you set

four K-factors for each tool that uses a K-factor.

5. If you want to change the value of a K-factor, use S and T to change the K-factor to the value

desired.

6. Press

7. You can repeat steps 3–6 to select and/or adjust other K-factors for the Tool. Once you set a K-factor

it remains set until you change it.

to display CHANGE Test ID.

. The K-factor currently being used flashes on the display.

to accept the desired K-factor. K-FACT is displayed.

View/Set Standard Pressure and Temperature

Temperature and barometric pressure are used for calculating some of the flow and velocity

measurements shown by this instrument, as follows:

For the Pitot Flow, Pitot Velocity, Air Flow "Flow", Air Flow Velocity, Velocity Matrix, and Hood tools,

the instrument uses barometric pressure measured by an internal barometric pressure sensor.

For these tools, the instrument will also use temperature measured by a temperature sensor plugged into

the side of the meter.

The hood base temperature sensor, the accessory temperature sensor, or the accessory

temperature/humidity probe can be used for supplying this temperature measurement. If none of these

temperature sensors are plugged in, you will need to enter the flow temperature using the STP.SET

menu.

For the Diffuser Flow tool (Flow from Pressure and K-factor), temperature and barometric pressure are

not used for calculating flow. Therefore the user is not required to enter a temperature for this tool.

Chapter 4: How To 21

Page 28

To display the Barometric Pressure:

1. Press

to display CHANGE Test ID.

2. Press X until STP.SET appears.

3. Press

. ACT.STD is displayed.

4. Press X until B.PRESS appears. The measured barometric pressure is displayed. Barometric

pressure is not changeable by the user.

5. Press ESC to return to the STP.SET menu.

To view the Measured Temperature and set the Entered Temperature:

Note: Since the entered temperature is not used for the Diffuser Flow tool (Flow from Pressure and K-

factor), this ENT.MES menu screen is not available if that tool is selected.

1. Press

to display CHANGE Test ID.

2. Press X until STP.SET appears.

3. Press

. ACT.STD is displayed.

4. Press X until ENT.MES appears.

5. Press

. The display shows the user ENTered temperature on the left and the currently MEaSured

temperature on the right (If a temperature sensor is plugged in).

6. Adjust the user entered temperature using S and T, then press

to save it and return to the

STP.SET menu.

Note: To save time, if a temperature probe is installed, you can copy the measured temperature to the

entered temperature, by pressing READ.

ENTered temperature is used for density correction of velocity or flow values only if no

temperature probe is connected. If a temperature probe is connected during velocity or flow

measurement, MEaSured temperature will be used for density correction. For most accurate

density correction, be sure the connected temperature probe is exposed to the temperature of

the flow or velocity being measured.

To Select Actual Flow/Velocity or Standard Flow/Velocity:

(The Actual/Standard selection is used for all tools displaying flow and velocity except the Diffuser Flow

[Flow from Pressure and K-factor] tool.)

1. Press

to display CHANGE Test ID.

2. Press X until STP.SET appears.

3. Press

4. Press

. ACT.STD is displayed.

. The display shows the currently selected option (flashing). Options are ACTUAL and STD.

5. Use S or T to select the option you want to use.

6. Press

. ENT.MES is displayed.

7. Press ESC to return to the STP.SET menu.

22 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 29

Set Units of Measure for Temperature, Pressure, Velocity/Flow and Humidity

1. Press to display CHANGE Test ID.

2. Press X until SETUP appears.

3. Press

.

4. Press X until UNITS appears.

5. Press

6. Press

. The display shows TEMP.

. The display shows the current temperature units. Options are °F or °C.

7. Use S and T to select between options.

8. Press

when you have selected the desired units.

9. Press X until PRESS is displayed.

10. Press

. The display shows the current pressure units. Options are: in. H2O, cm. H2O, mm H2O, in.

Hg, cm. Hg, mm Hg, kPa, hPa, and Pa.

11. Use S and T to select between options.

12. Press

when you have selected the desired units.

13. Press X until VELFLO is displayed.

14. Press

. The display shows the current velocity/flow units. Options are ft/min for velocity with

CFM for flow, and m/s for velocity with either l/s, m

15. Use S and T to select between options. (If m

3

/h, or m3/min is selected for flow, m/s will be used for

velocity even though “m/s” is not shown on the display.)

16. Press

when you have selected the desired units.

3

/h, or m3/min for flow.

17. Press X until HUMID is displayed.

18. Press

. The display shows the current humidity units. Options are DEWPT, WETBULB, and

%RH.

19. Use S and T to select between options.

20. Press

when you have selected the desired units.

21. Press ESC twice to return to SETUP.

Select the RS232 Output Device (Computer or Printer)

1. Press to display CHANGE Test ID.

2. Press X until SETUP appears.

3. Press

4. Press X until COM.DEV appears.

5. Press

Chapter 4: How To 23

.

. The display shows the current selection: PRINTR or COMPU.

Page 30

6. Press S or T to change device.

7. Press

. COM.DEV is displayed.

8. Press ESC to return to SETUP.

Set the Baud Rate

Before transferring data to a computer or printer, you must set the baud rate to the speed at which your

printer or computer will accept information.

1. Press

to display CHANGE Test ID.

2. Press X until SETUP appears.

3. Press

.

4. Press X until BAUD appears.

5. Press

. The display shows the currently selected baud rate.

6. Press S or T to change the baud rate. Options are: 19200, 9600, 4800, 2400, and 1200.

7. Press

. BAUD is displayed.

8. Press ESC to return to SETUP.

Set the Format for Date and Decimal

The Format option lets you set the format for the date (mm/dd or dd/mm) and also for the delimiter (. or ,)

the instrument uses.

1. Press

to display CHANGE.

2. Press X until SETUP appears.

3. Press

.

4. Press X until FORMAT appears.

5. Press

. The currently selected format appears.

6. Press S or T to change the format. Options are:

Peri nndd (use a period for the delimiter and show date as month/day)

Peri ddnn (use a period for the delimiter and show date as day/month)

Conn nndd (use a comma for the delimiter and show date as month/day)

Conn ddnn. (use a comma for the delimiter and show date as day/month)

7. Press

to select the new format. FORMAT is displayed.

8. Press ESC to return to SETUP.

24 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 31

Set Display Mode for Running Average or Single

If Single is selected, the instrument will show READY on its display, and will not start taking readings

until READ is pressed.

If Running Average is selected, the instrument will constantly measure and display a running average.

The READ button can then be used to stop and start the running average.

1. Press

2. Press X until SETUP appears.

3. Press

4. Press X until DS.MODE appears.

5. Press

SINGLE.

6. Press S or T to change the display mode.

7. Press

8. Press ESC to return to SETUP.

to display CHANGE Test Id.

.

. The display shows the currently selected display mode. Options are: RUNAVG and

. DS.MODE is displayed.

Select Discrete or Continuous Logging

Discrete logging means you have to press SAVE each time you want to save a displayed reading.

Continuous logging means reading and saving is done automatically at the user-selectable Sample

Logging Interval. Then the continuous logging is started and stopped by pressing SAVE.

1. Press

2. Press X until SETUP appears.

3. Press

to display CHANGE.

.

4. Press X until LOG appears.

5. Press

6. Press S or T to change the logging option.

7. Press

CONTIN, the display shows LOG.INT to indicate you must enter a logging interval.

Note: Continuous logging is not available if backpressure compensation is turned on. In this case

8. Press S and T to select the logging interval. Options are (in sec.): 10, 15, 20, 30, 60, 120, 180, 240,

300, 360, 420, 480, 540, and 600.

9. Press

10. Press ESC to return to SETUP.

Chapter 4: How To 25

. The display shows the currently selected option. Options are: DISCRT and CONTIN.

. If you selected DISCRT, LOG is displayed. Continue with step 9. If you selected

the message TURN BP OFF is displayed and the change to continuous logging is not allowed.

Refer to the following section for instructions on how to turn backpressure compensation off.

. LOG is displayed.

Page 32

Turn Back Pressure Compensation On and Off

Back pressure caused by flow through the capture hood can lower the flow being measured, causing

measurement error. If it is desired to minimize this error, turn the back pressure compensation on.

1. Press

2. Press X until SETUP appears.

3. Press

4. Press X until BP.COMP appears.

5. Press

6. Press S or T to change the option. Options are: ON and OFF.

7. Press

8. Press ESC to return to the main display.

to display CHANGE Test ID.

.

. The display shows whether back pressure compensation is on or off.

. BP.COMP is displayed.

Take Back Pressure Compensated Hood Readings

When back pressure compensation is turned on, the sequence of taking flow readings with the capture

hood is somewhat different.

1. Open the flap in the capture hood base.

2. Hold the capture hood to the diffuser being measured to capture its air flow.

3. Press READ on the meter face or the red “Read Switch” on the left side of the hood base. READ

OPEn flashes on the display.

4. When the open-flap reading is done, CLOSE tHE FLAP is displayed.

5. Close the flap and press READ (or the Read Switch). READ CLOSEd flashes on the display.

6. When the closed-flap reading is done, the backpressure compensated flow is displayed.

7. If you want to save the flow reading to log memory, press SAVE now. STORE is shown on the

display, then the saved reading is shown.

8. Before pressing any more buttons, open the flap.

9. If the display mode is set to SINGLE, pressing READ now will start a new backpressure

compensated reading.

If the display mode is set to RUNAVG, pressing READ now will measure and display a running

average of non-backpressure-compensated readings. Press READ once more to start a new

backpressure compensated reading.

26 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 33

Set Deadband On and Off

The deadband determines the velocity or volume measurement threshold for displaying 0. If the deadband

is ON, readings below 18 fpm (0.0914 m/s) or 18 cfm (30.58 m

deadband is OFF, readings down to 0 will be displayed. The default is set to ON.

1. Press

2. Press X until SETUP appears.

3. Press

4. Press X until DEADbAnd appears.

5. Press

6. Press S or T to change the option. Options are: ON and OFF.

7. Press

8. Press ESC to return to the main display.

to display CHANGE Test ID.

.

. The display shows whether DEADbAnd is on or off.

. DEADbAnd is displayed.

3

/h, 8.49 l/s) will be displayed as 0. If the

Calibrate the Micromanometer (User Calibration)

A full instrument checkout and calibration with a calibration certificate is available from the factory.

However, some users prefer to calibrate their own instruments. Pressure, temperature and humidity can be

calibrated in the field.

1. Press

to display CHANGE Test ID.

2. Press X until CALIB appears.

3. Press

4. Press X until the desired measurement to calibrate is shown.

5. Press

left. If the current measurement is available for display, it will be shown on the bottom right.

6. Try to expose the sensor being calibrated to a condition close to the requested calibration condition

on the lower left. Press S or T to change the value shown on the lower left to the actual value you

want the display to read under that condition.

7. Press

shows DONE. If any errors are shown on the display it is because the user calibration data taken is

too much different from the factory calibration data. Error codes are explained at the end of

Chapter 7.

Note: The calibration for the accessory temperature/humidity probe is saved on an EEPROM in the

. The display shows CALIB plus which measurement is selected for calibration.

. The display shows SPAN and the requested calibration condition is shown on the bottom

. The display will show the next desired span condition. Repeat steps 6–7 until the display

probe. If that probe is unplugged and used in a different micromanometer, the calibration

will follow the probe. The calibration for the temperature probe and the hood base

temperature sensor is saved in the micromanometer. If those probes are unplugged and used

in a different manometer, the calibration will not follow the probe.

The hood flow calibration is an offset from the factory calibration. An offset of ±12% can be

applied to the hood flow measurement. With the hood icon on the display illuminated and the

display showing FACTOR, use the UP or DOWN key to adjust the offset facto, and press

Chapter 4: How To 27

Page 34

ENTER to accept. To return to the factory calibration, adjust the factor to 1.000 and press

ENTER to accept.

Select User Calibration or Factory Calibration

Performing a user calibration does not erase the factory calibration because the user calibration is saved in

a different place than the factory calibration. It is possible to re-select whether the micromanometer uses

the user or factory calibration at any time.

1. Press

2. Press X until CALIB appears.

3. Press

4. Press X until the display shows SOURCE U-F for the desired measurement.

5. Press

6. Press S or T to select USEr or FACt.

7. Press

Note: For the accessory temperature/humidity probe it is not possible to mix user and factory

to display CHANGE Test ID.

. The display shows CALIB plus which measurement is selected for calibration.

. The display shows SOURCE and whether USEr or FACt is selected for that measurement.

to save the selection.

calibrations for the different measurements. For example, USEr cannot be selected for

temperature with FACt selected for humidity.

The hood flow calibration factor is applied when the offset factor is changed. There is no

option to select USEr or FACt calibration for hood flow measurement. Set value to 1.000 to

restore factory calibration.

Connect and Download Data to an Optional Printer

To connect a printer, use the RS232 printer cable supplied with the optional printer. Note that the printer

interface cable is different from the computer interface cable.

The printer must be set to the same baud rate as the instrument. To change the baud rate of the printer,

refer to the printer’s operations manual. Always turn the instrument on before the printer. If the printer

prints question marks (??????), asterisks (******), or random characters, reset it by turning it off and then

on again.

Figure 12 illustrates the printout information for a single sample.

28 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 35

--------------------------MODEL: EBT721

SERIAL: 0404004

--------------------------TEST ID: 2

Sample: 1

02/16/04

15:14:31 1.00 CFM

Shape=Round

Dia = 4.0 in. ø

Entered Temp= 74.4 °F

Baro. Press= 29.16 in.Hg

15:14:31 28.5 %rh

Figure 12: Sample Print Out

The Models EBT720/EBT721 and Models PH720/PH721

allow printing of the entire memory, all

Samples stored within a particular Test ID, or an individual Sample.

To print the entire memory, press and hold the

key. This starts a countdown from 3 to 0 on the

display. When the display shows “0”, release the button. If you release the key at any time other than 0

during the countdown, nothing will print. The display will flash “Send dAtA” while printing.

To print all samples stored within a particular Test ID, first enter the RECALL menu. Select the desired

Test ID to print using the up/down arrow keys. Then press and release the

key. The display will

flash “Send dAtA” while sending.

To print an individual sample, first enter the RECALL menu. Select the Test ID containing the desired

sample using the up/down arrow keys and press

. Use the up/down arrow keys to scroll thru MIN,

MAX, etc until the desired Sample is displayed. Then press and release the (print icon) key. The display

will flash “Send dAtA” while sending.

Connect and Download Data to a Computer

Use the RS232 computer interface cable (provided) to connect the instrument to a COM port on the

computer. A 9-pin to 25-pin adapter will be required if your computer has a 25-pin serial port connector.

®

The program “HyperTerminal

sent by the micromanometer. To send data from the micromanometer, use the printing function of the

micromanometer, as shown above.

The program “CompuDat™” which comes with your micromanometer can be used to assist in

downloading data to a Windows

software, run the SETUP.EXE file on the CompuDat distribution disc. Once you open the program, it is

self-directing and provides all the necessary instructions for downloading data.

” which comes with Microsoft Windows® can be used for capturing data

®

-based computer and formatting that data. To install CompuDat

®

HyperTerminal is a registered trademark of Hilgraeve, Inc.

®

Windows is a registered trademark of Microsoft Corporation.

Chapter 4: How To 29

Page 36

Data Acquisition (Polling)

The micromanometer is designed to allow the user to perform polling through the use of a computer. The

computer must send an upper case ‘V’ to the micromanometer while the micromanometer is taking

measurements. The ‘V’ must be sent alone, without a carriage return or linefeed. The micromanometer

will then output the values of the last measurements read. Note that the ‘V’ polling command will not

start the micromanometer taking new measurements, therefore, it works much better if the

micromanometer display mode is set to RUNAVG.

You must write your own program to use the ‘V’ polling command. Therefore this command is only

designed for medium-to-advanced programmers who need real-time data acquisition. The ‘V’ polling

command cannot be used to request logged data.

30 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 37

Chapter 5. Changing Flow Hoods

This chapter identifies the flow hood parts and gives instructions for assembling the flow hood.

Flow Hood Parts Identification

Figure 13 identifies the major parts of the capture hood, which are described in the following paragraphs.

Before using the hood, please familiarize yourself with the various parts. You may also refer to

through

3.

1 Fabric hood - Basic hood assembly

2 Base allows micromanometer to be attached

3 Micromanometer with display

4 Flap Actuator

5 Read Switch

1

Tables 1

2

4

5

3

Figure 13: Flow Hood Components

Hood Assembly

The Flow Hood is shipped from the factory partially assembled with the 2 ft × 2 ft (610 mm × 610 mm)

nylon hood attached to the base. If you wish to use another hood size, see “Changing Hoods,” below.

To complete the assembly of the 2 ft × 2 ft (610 mm × 610 mm) hood, follow these six steps:

1. Place the base of the capture hood

2. Lift the top of the fabric. Insert one end of a support pole into its pole mount in the base. There is a

cup in each corner of the frame to accept the other end of each support pole.

3. Grasp the support pole. Bend the pole slightly to insert the top end of the pole into the support pole

cup located in the opposite corner of the fabric frame. The poles are connected to the frame corners in

a crisscross fashion as shown in

on the floor.

Figure 14.

31

Page 38

Figure 14: Installing a Support Pole

4. Insert the second support pole into the pole mount on the opposite side of the base.

5. Repeat step 3 for the second support pole.

6. Repeat steps 4 and 5 for the remaining two support poles.

Four other hood sizes are available from TSI and can be purchased separately. Available hood sizes are

identified by the dimensions of the frame structure at the top of the hood and include 2 ft × 4 ft (610 mm

× 1220 mm), 1 ft × 4 ft (305 mm × 1220 mm), 1 ft × 5 ft (305 mm × 1525 mm) and 3 ft × 3 ft (915 mm ×

915 mm).

To change hood sizes, first remove the hood currently attached to the base. To remove the attached hood,

first unlatch the cinch belt where the fabric is attached to the base. Then remove the fabric from its frame

structure by pulling the shock cord out of the aluminum frame. Finally, fold up the fabric you just

removed so that it can fit into one of the accessory pockets inside the carrying case. It is a good idea to

fold the fabric so that the tag identifying its size remains visible for future reference.

Alternate Hood Installation

Refer to Figures 15 through 18 to determine the frame channels needed to assemble any of the standard

sized frames. Select the pieces required for the frame size desired and assemble with the aid of the

appropriate figure. Each channel is labeled with its number for easy identification. Several sections

(numbers 1, 3, and 4) consist of a straight channel portion (each a different length) and a corner piece.

This corner piece has an eyelet and slot arrangement which mates with a similar eyelet and slot at the end

of the straight portion of the channel pieces (see

locking by means of a retention spring. The arrangement forms a rugged frame which is additionally

strengthened when the hood is attached.

Figure 19). These pieces can be slid together and are self

32 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 39

2

1

3

2

3

1

Figure 15: 1 ft × 4 ft (305 mm × 1220 mm) hood and frame. The support poles always cross as

pairs at the front and back of the fabric hood. For the 1 ft × 4 ft (305 mm × 1220 mm), the support

poles are inserted into the outside ferrule locations.

Chapter 5: Changing Flow Hoods 33

Page 40

2

4

1

1

4

2

Figure 16: 2 ft × 4 ft (610 mm × 1220 mm) hood and frame. The support poles always cross as

pairs at the front and back of the fabric hood. For the 2 ft × 4 ft (610 mm × 1220 mm), the support

poles are inserted into the inside ferrule locations.

The number 1 and 5 channels also have a wing nut at the straight end which will mate with an angle and

studs on the ends of numbers 2, 5 and 6 to form the longer frame sides (see

Figure 20).

34 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 41

2

5

1

1

5

3

2

3

Figure 17: 1 ft × 5 ft (305 mm × 1525 mm) hood and frame. The support poles always cross as

pairs at the front and back of the fabric hood. For the 1 ft × 5 ft (305 mm × 1525 mm), the support

poles are inserted into the inside ferrule locations.

Chapter 5: Changing Flow Hoods 35

Page 42

6

1

1

6

6

1

1

6

Figure 18: 3 ft × 3 ft (915 mm × 915 mm) hood and frame. The support poles always cross as pairs

at the front and back of the fabric hood. For the 3 ft × 3 ft (915 mm × 915 mm), the support poles

are inserted into the outside ferrule locations.

Figure 19: Frame Corner Assembly

36 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 43

Figure 20: Frame Side Coupler Assembly

Each hood is constructed in a trapezoidal shape, sewn together so that one open end forms a round

attachment to the base, and the other forms a square or rectangle large enough to fit its matching frame

assembly. Around the frame end of the hood, an elastic shock cord has been sewn into the hood. This

cord is of a size such that it can be pushed into the open side of the U-shaped channels of the frame.

In general, attach a hood to the frame first, and then to the base unit. By stretching around the frame

corners the cord is slightly reduced in diameter and is easier to press into the frame channel.

Note: The hood corners should always be aligned with the corners of the base, near the hood support

brackets. The base has rivets located in the corners which can be used as a guide for aligning the

hood corners.

Direct Inflow Measurement Hood for Biological Safety Cabinets

The BSC hood kits for the models EBT721/PH721 are designed to measure the inflow or exhaust flow

through a biological safety cabinet (see

Table 2 of this manual.

in

Figure 21: Direct Inflow Measurement Hood

Figure 21). Part numbers and description of each kit can be found

Chapter 5: Changing Flow Hoods 37

Page 44

The direct inflow BSC hood includes (see

Figure 22):

❑ Fixed frame assembly with four removable flaps

❑ Fabric hood

❑ Hood support poles

❑ Base mounting hardware (threaded insert, washer, and screw)

❑ Telescopic pole stand with case to freely hold the capture hood in a vertical position when mounted to

a biological safety cabinet or lab hood

Figure 22: Direct Inflow Measurement Hood Components

To complete the assembly of the BSC hood, follow these seven steps:

1. Remove the plug located at the back of the base assembly and insert the Philips screw with washer

into the hole from the inside of the base (see

Figure 23). Place the threaded insert on the outside of

the base opposite the screw and tighten with a Philips screwdriver.

Figure 23: Remove Plug Located at Back of Base Assembly

38 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 45

2. Attach the fabric hood and hood support poles to the frame and base assembly in the same manner as

previously described for the other hood sizes.

3. Insert the flaps into the slots from the side of the frame where the fabric hood is attached to the

U-channel of the frame (see

Figure 24). Use the different flap lengths to fit various cabinet widths.

Figure 24: Attach Fabric Hood and Hood Support Poles to Frame and Base Assembly

4. Mount the capture hood base to the telescopic stand by fastening the screw on the telescopic stand to

the threaded insert mounted on the base opposite the display/manometer (see

Figure 25).

Figure 25: Mount Hood Base to Telescopic Stand

5. Adjust the height and position of the telescopic stand so that the bottom part of the hood frame rests

against the cabinet opening, and the capture hood is horizontal to the cabinet (see

Figure 26).

Chapter 5: Changing Flow Hoods 39

Page 46

Figure 26: Adjust Height and Position of Telescopic Stand

6. Lower the sash of the cabinet until it rests on the foam lip of the hood frame (see

Figure 27).

Figure 27: Lower Sash of Cabinet Until it Rests on Foam Lip of Hood Frame

7. Adjust the flaps to cover the opening of the cabinet. Tape the edges of the flaps to the sash and frame

of the cabinet to create a tight fit. The unit is now ready to make measurements (see

Figure 28).

40 Electronic Balancing Tool EBT720/EBT721 and ProHood PH720/PH721

Page 47

Figure 28: Unit Ready to Make Measurements

Chapter 5: Changing Flow Hoods 41

Page 48

Page 49

Chapter 6. Flow Measurements Using the Capture Hood

There are two methods of making flow measurements using the capture hood: Non-Backpressure

Compensated and Backpressure Compensated methods (see “

explanation of the implications of capture hood-induced back pressure on the measured flow). Flows in

both “Supply” and “Return” flow direction can be taken with either non-backpressure compensated or

backpressure compensated mode.

Note: “Return” flows will be indicated by a negative flow number, as long as the tubes leading to the

Matrix manifold in the base are connected properly. The proper tube orientation is from the

upper portion of the Matrix manifold leading to the positive “+” port on the back of the meter.

CAUTION

W

HILE USING THE BALOMETER® AIR BALANCING INSTRUMENT TO TEST AIR

FLOW IN DUCTS

, POLLEN, MOLD, FUNGUS, OR OTHER AIRBORNE CONTAMINANTS. IF YOU

DUST

ARE OR MAY BE SENSITIVE TO DUST

AIRBORNE CONTAMINANTS

RESPIRATOR WHILE EMPLOYING THE

INSTRUMENT

, YOU MAY COME INTO CONTACT WITH OR BE EXPOSED TO

, ALWAYS USE AN APPROPRIATE MASK OR

.

Appendix A. Back Pressure,” for an

, POLLEN, MOLD, FUNGUS, OR OTHER

BALOMETER

®

AIR BALANCING

Non-Backpressure Compensated Measurements

To take non-backpressure compensated measurements, be sure the Back Pressure Compensation function

is turned “OFF” (see “

Turn Back Pressure Compensation On and Off” in Chapter 4).

Non-backpressure compensated measurements can only be made with the back pressure flap in the

“OPEN” position. If you attempt to make a non-backpressure compensated measurement with the flap

closed or partially closed, the meter will display the message “OPEN the FLAP”.

In the non-backpressure compensated mode, it is possible to take either single measurements or running

average measurements (see “