Page 1

ANALOG BALANCING TOOL

MODELS ABT701, ABT703,

ABT711, ABT713

OWNER’S MANUAL

P/N 6002462, REV E

FEBRUARY 2016

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

LIMITATION OF WARRANTY AND LIABILITY

Copyright©

TSI Incorporated / 2009-2016 / All rights reserved.

LIMITATION OF WARRANTY AND LIABILITY (effective February 2015)

Seller warrants the goods, excluding software, sold hereunder, under normal use and service as described in the

operator's manual, to be free from defects in workmanship and material for 24 months, or if less, the length of time

specified in the operator's manual, from the date of shipment to the customer. This warranty period is inclusive of any

statutory warranty. This limited warranty is subject to the following exclusions and exceptions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other components when indicated in

specifications, are warranted for 90 days from the date of shipment;

b. Pumps are warranted for hours of operation as set forth in product or operator’s manuals;

c. Parts repaired or replaced as a result of repair services are warranted to be free from defects in workmanship and

material, under normal use, for 90 days from the date of shipment;

d. Seller does not provide any warranty on finished goods manufactured by others or on any fuses, batteries or other

consumable materials. Only the original manufacturer's warranty applies;

e. This warranty does not cover calibration requirements, and seller warrants only that the instrument or product is

properly calibrated at the time of its manufacture. Instruments returned for calibration are not covered by this warranty;

f. This warranty is VOID if the instrument is opened by anyone other than a factory authorized service center with the one

exception where requirements set forth in the manual allow an operator to replace consumables or perform

recommended cleaning;

g. This warranty is VOID if the product has been misused, neglected, subjected to accidental or intentional damage, or

is not properly installed, maintained, or cleaned according to the requirements of the manual. Unless specifically

authorized in a separate writing by Seller, Seller makes no warranty with respect to, and shall have no liability in

connection with, goods which are incorporated into other products or equipment, or which are modified by any

person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated herein. NO OTHER

EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR PARTICULAR PURPOSE OR MERCHANTABILITY IS

MADE. WITH RESPECT TO SELLER’S BREACH OF THE IMPLIED WARRANTY AGAINST INFRINGEMENT, SAID

WARRANTY IS LIMITED TO CLAIMS OF DIRECT INFRINGEMENT AND EXCLUDES CLAIMS OF CONTRIBUTORY

OR INDUCED INFRINGEMENTS. BUYER’S EXCLUSIVE REMEDY SHALL BE THE RETURN OF THE PURCHASE

PRICE DISCOUNTED FOR REASONABLE WEAR AND TEAR OR AT SELLER’S OPTION REPLACEMENT OF THE

GOODS WITH NON-INFRINGING GOODS.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR BUYER, AND THE LIMIT OF

SELLER'S LIABILITY FOR ANY AND ALL LOSSES, INJURIES, OR DAMAGES CONCERNING THE GOODS

(INCLUDING CLAIMS BASED ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE) SHALL

BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION

OF SELLER, THE REPAIR OR REPLACEMENT OF THE GOODS. IN THE CASE OF SOFTWARE, SELLER WILL

REPAIR OR REPLACE DEFECTIVE SOFTWARE OR IF UNABLE TO DO SO, WILL REFUND THE PURCHASE

PRICE OF THE SOFTWARE. IN NO EVENT SHALL SELLER BE LIABLE FOR LOST PROFITS, BUSINESS

INTERRUPTION, OR ANY SPECIAL, INDIRECT, CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL

NOT BE RESPONSIBLE FOR INSTALLATION, DISMANTLING OR REINSTALLATION COSTS OR CHARGES. No

Action, regardless of form, may be brought against Seller more than 12 months after a cause of action has accrued. The

goods returned under warranty to Seller's factory shall be at Buyer's risk of loss, and will be returned, if at all, at Seller's

risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND LIABILITY, which contains the

complete and exclusive limited warranty of Seller. This LIMITATION OF WARRANTY AND LIABILITY may not be

amended, modified or its terms waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are to our customers, our service

policy is designed to give prompt attention to any problems. If any malfunction is discovered, please contact your

nearest sales office or representative, or call Customer Service department

Trademarks

Alnor, TSI, Balometer, and the TSI logo are registered trademark of TSI Incorporated.

.

iii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

CONTENTS

About This Manual ...................................................................................................................................... v

Caution ................................................................................................................................................... v

Technical Assistance—Help! .................................................................................................................. v

Chapter 1. Introduction ............................................................................................................................. 7

Chapter 2. Unpacking and Hood Set Up .................................................................................................. 9

Unpacking ............................................................................................................................................... 9

Hood Setup ........................................................................................................................................... 10

Models ABT701, ABT711—2 ft x 2 ft (610 mm x 610 mm)............................................................ 10

Models ABT703, ABT713—16 in 16 in (406 mm 406 mm) ..................................................... 10

Attaching and Detaching the ABT Meter to the Capture Hood Base ................................................... 11

Power the Meter with Batteries ............................................................................................................ 12

Meter Zero Adjustment ......................................................................................................................... 12

Detachable Handle ............................................................................................................................... 13

Chapter 3. Getting Started ....................................................................................................................... 15

Analog Meter Operation ....................................................................................................................... 15

Hold Switch ........................................................................................................................................... 16

Step-By-Step Example Operation ........................................................................................................ 17

Chapter 4. Changing Flow Hoods ........................................................................................................... 19

Hood Assembly .................................................................................................................................... 19

Alternate Hood Installation ............................................................................................................. 19

Chapter 5. Maintenance and Troubleshooting ...................................................................................... 25

Fabric Hood .......................................................................................................................................... 25

Analog Meter ........................................................................................................................................ 25

Manifold ................................................................................................................................................ 25

Cases .................................................................................................................................................... 25

Calibration ............................................................................................................................................. 25

Appendix A. Actual vs. Standard Air Flow Measurements ................................................................... 27

Specifications* .......................................................................................................................................... 29

iv

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 5

About This Manual

C A U T I O N

WHILE USING THE BALOMETER

®

AIR BALANCING INSTRUMENT TO TEST AIR FLOW IN

DUCTS, YOU MAY COME INTO CONTACT WITH OR BE EXPOSED TO DUST, POLLEN, MOLD,

FUNGUS, OR OTHER AIRBORNE CONTAMINANTS. IF YOU ARE OR MAY BE SENSITIVE TO

DUST, POLLEN, MOLD, FUNGUS, OR OTHER AIRBORNE CONTAMINANTS, ALWAYS USE AN

APPROPRIATE MASK OR RESPIRATOR WHILE EMPLOYING THE BALOMETER® AIR

BALANCING INSTRUMENT.

This manual explains how to set up, operate and maintain the Alnor ®ABT Balometer® Capture Hood

Models ABT701, ABT703, ABT711, and ABT713. Be sure to read it thoroughly before using the

instrument.

Caution

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

v

Page 6

7

C A U T I O N

The ABT Balometer® capture hood is not designed for gas mixtures other than

air. Any use with corrosive or other dangerous or explosive gas mixtures is not

recommended, and is at the user’s risk.

C A U T I O N

WHILE USING THE BALOMETER

®

AIR BALANCING INSTRUMENT TO TEST AIR FLOW IN

DUCTS, YOU MAY COME INTO CONTACT WITH OR BE EXPOSED TO DUST, POLLEN, MOLD,

FUNGUS, OR OTHER AIRBORNE CONTAMINANTS. IF YOU ARE OR MAY BE SENSITIVE TO

DUST, POLLEN, MOLD, FUNGUS, OR OTHER AIRBORNE CONTAMINANTS, ALWAYS USE AN

APPROPRIATE MASK OR RESPIRATOR WHILE EMPLOYING THE BALOMETER® AIR

BALANCING INSTRUMENT.

Chapter 1. Introduction

The Alnor® Analog Balancing Tool (ABT) Balometer® capture hood Models ABT701, ABT703, ABT711, and

ABT713 are productivity instruments designed to quickly measure the air flow directly from supply diffusers

and return/exhaust grilles mounted in a ceiling, wall or floor with equal accuracy. The ABT consists of:

fabric hood

hood frame

support rods

molded plastic base (which contains the meter and a flow sensing manifold).

Air flowing through the hood is measured by a hot-film sensor located in the central hub of the flow sensing

manifold. The twenty-four pairs of flow sensing ports in the manifold are strategically located so that the ABT

provides a high degree of measurement accuracy, even in non-uniform flow conditions.

The ABT Models are temperature-compensated to display a standard flow rate in CFM (ft3/min.) or

CMH (m3/hr) depending on the model ordered. Standard flow rate is defined as the volumetric flow rate at

standard conditions of 70°F (21.1°C) and 29.92 inHg (760 mm Hg) barometric pressure.

For increased flexibility, additional hood sizes are available to fit interchangeably on the instrument base.

These additional hoods are used with frame pieces which must be assembled by the user. Instructions for

assembly can be found in this manual (see Chapter 2, “Hood Setup” and Chapter 4, “Hood Assembly”) for the

following sizes:

1 ft 4 ft (305 mm 1220 mm)

2 ft 4 ft (610 mm 1220 mm)

3 ft 3 ft (915 mm 915 mm)

1 ft 5 ft (305 mm 1525 mm)

16 in 16 in (406 mm 406 mm).

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

Chapter 2. Unpacking and Hood Set Up

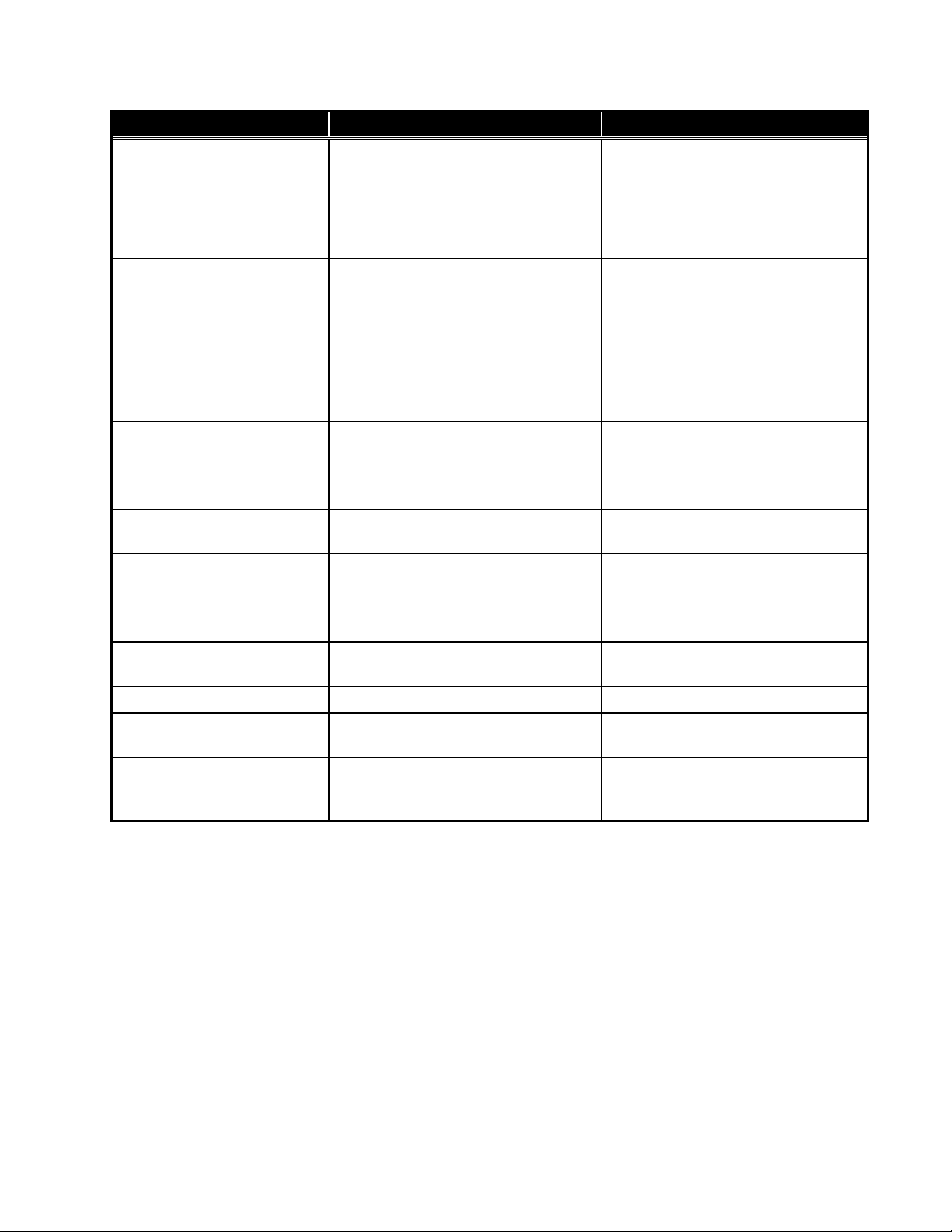

Item

Part No.

Model ABT701—30 to 1000 CFM with 2 ft 2 ft (610 mm 610 mm) hood

ABT701

Model ABT711—50 to 2000 CMH with 2 ft 2 ft (610 mm 610 mm) hood

ABT711

Model ABT703—30 to 1000 CFM with 16 in 16 in (406 mm 406 mm) hood

ABT703

Model ABT713—50 to 2000 CMH with 16 in 16 in (406 mm 406 mm) hood

ABT713

Wheeled Carrying case

1319379

AA-size alkaline battery, four required

1208013

Operation and Service Manual

6002462

Center handle

534593173

1 ft 4 ft (305 mm 1220 mm) and 2 ft 4 ft (610 mm 1220 mm) fabric hood and

frame kit

801206

1 ft 5 ft (305 mm 1525 mm) and 3 ft 3 ft (915 mm 915 mm) fabric hood and

frame kit

801207

1 ft 4 ft (305 mm 1220 mm) fabric hood and frame kit

801200

2 ft 4 ft (610 mm 1220 mm) fabric hood and frame kit

801201

1 ft 5 ft (305 mm 1525 mm) fabric hood and frame kit

801202

2 ft 2 ft (610 mm 610 mm) fabric hood and frame kit

801097

16 in 16 in (406 mm 406 mm) hood and frame kit

801209

This chapter describes unpacking and setting up (preparing) the ABT Balometer® capture hood for use.

Unpacking

As you unpack the instrument and accessories, check the components against your packing list. If any parts

are missing or damaged, notify us immediately. Table 1 lists available standard and optional components.

The ABT Models ship with the hood and frame attached to the instrument base and must be removed from the

case as a set before the instrument base can be lifted out. Caution must be exercised to assure that the pieces

do not separate, since dropping the instrument may damage the instrument.

Table 1: List of Standard and Optional Components

9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 8

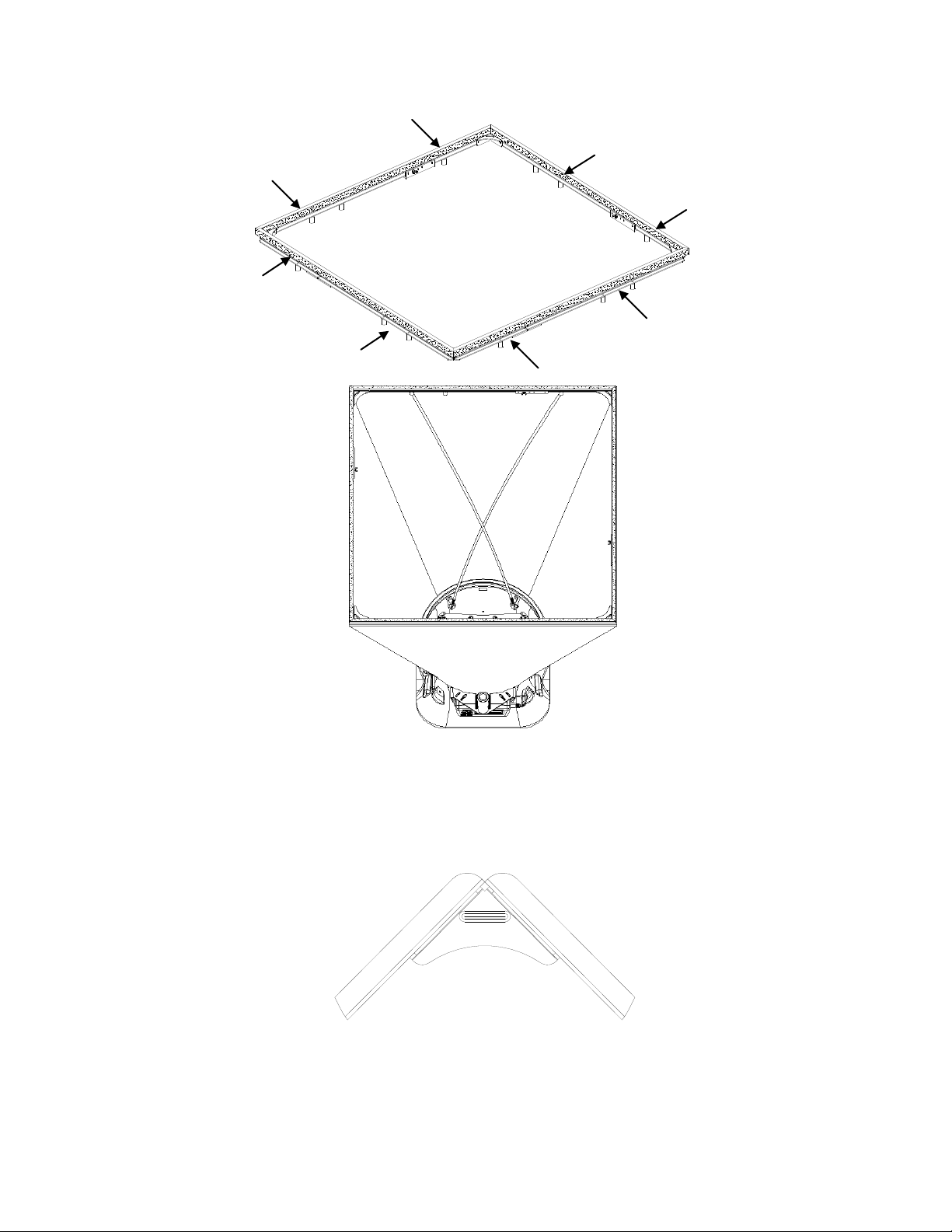

1. Place the base of the capture hood on the floor.

2. Lift the top of the fabric. Insert one end of a support

pole into its pole mount in the base. There is a cup in

each corner of the frame to accept the other end of

each support pole.

3. Grasp the support pole. Bend the pole slightly to insert

the top end of the pole into the support pole cup

located in the opposite corner of the fabric frame. The

poles are connected to the frame corners in a

crisscross fashion as shown in Figure 1.

4. Insert the second support pole into the pole mount on

the opposite side of the base.

5. Repeat step 3 for the second support pole.

6. Repeat steps 4 and 5 for the remaining two support

poles.

Figure 1

Installing a Support Pole on a 2 ft 2 ft

(610 mm 610 mm) Hood

Hood Setup

The ABT Balometer® capture hood is shipped from the factory partially assembled with the 2 ft 2 ft

(610 mm 610 mm) or 16 in 16 in (406 mm 406 mm) nylon hood attached to the base. If you wish to use

another hood size, see Chapter 4. Changing Flow Hoods.

Models ABT701, ABT711—2 ft x 2 ft (610 mm x 610 mm)

To complete the assembly of the 2 ft 2 ft (610 mm 610 mm) hood, follow these steps:

Models ABT703, ABT713—16 in 16 in (406 mm 406 mm)

To complete the assembly of the 16 in 16 in (406 mm 406 mm) hood, follow these steps:

1. Place the base of the capture hood on the floor.

2. For storage purposes, the 16 in 16 in (406 mm 406 mm) frame sits around the top lip of the base. To

assemble, lift one of the front hood corners on an angle to remove the frame from the stowed position.

See Figure 2.

Removing the 16 in x 16 in (406 mm x 406 mm) Hood from Stowed Position

Figure 2

Find Quality Products Online at: sales@GlobalTestSupply.com

10 Alnor® Analog Balancing Tool Models ABT701/ABT703/ABT711/ABT713

www.GlobalTestSupply.com

Page 9

3. Insert one end of a support pole into its pole mount in

the base. There are two cups on the frame to accept

the other end of each support pole.

4. Grasp the support pole. Bend the pole slightly to insert

the top end of the pole into the support pole cup

located on the opposite side of the fabric frame. The

poles are connected to the frame corners in a

crisscross fashion as shown in Figure 3.

5. Insert the second support pole into the pole mount on

the opposite side of the base.

6. Repeat step 4 for the second support pole.

7. Repeat steps 5 and 6 for the remaining two support

poles.

Figure 3

Installing the Support Poles on a 16 in 16 in

(406 mm 406 mm) Hood

1. Tilt the meter forward and align the tabs in the

base of the meter with the two matching slots in

the bottom of the recessed area at the front of

the base (see Figure 4).

2. When the tabs are engaged in the slots, press

firmly on the face of the meter above the display

until the tab in the top center of the meter

“clicks” into the bent metal retaining clip in the

base.

3. Attach the sensor cable and the hold switch

cable to the right side of the meter.

4. To remove the meter from the base, first

disconnect the sensor cable and the hold switch

cable, then press upward on the metal retaining

clip to release the meter from the base.

Figure 4

Attaching the Meter to the Capture Hood Base

Attaching and Detaching the ABT Meter to the Capture Hood Base

Find Quality Products Online at: sales@GlobalTestSupply.com

Chapter 2. Unpacking and Hood Set Up 11

www.GlobalTestSupply.com

Page 10

To install batteries:

1. Turn the unit off and locate the battery cover on

the back of the meter (see Figure 5).

2. Press down on the compartment cover and slide it

down (the cover slides off).

3. Remove the battery holder by pulling up on the

bottom (to loosen it) and then remove the battery

holder.

4. Remove the old batteries and replace with fresh

batteries. Make certain batteries are correctly

oriented.

5. Reinstall the battery holder and replace the

compartment cover.

Figure 5

Battery Cover Removal

N o t e

Make sure the battery holder is oriented so that its terminals make contact with the spring contacts

in the battery compartment.

C A U T I O N

Due to the danger of battery leakage, remove batteries from the battery compartment before

storage. Never mix battery types.

Power the Meter with Batteries

The ABT requires four AA-size alkaline batteries to operate. For your convenience, four alkaline batteries are

included with the ABT.

Meter Zero Adjustment

Check to see that the pointer of the Meter is at zero each time the meter is put into service. The zero adjust

screw enables the user to align the pointer to the zero mark on the scale. With the meter turned off, use a

screwdriver to bring the pointer to zero. It should read zero regardless of how the Balometer® capture hood is

held (see Figure 7).

Find Quality Products Online at: sales@GlobalTestSupply.com

12 Alnor® Analog Balancing Tool Models ABT701/ABT703/ABT711/ABT713

www.GlobalTestSupply.com

Page 11

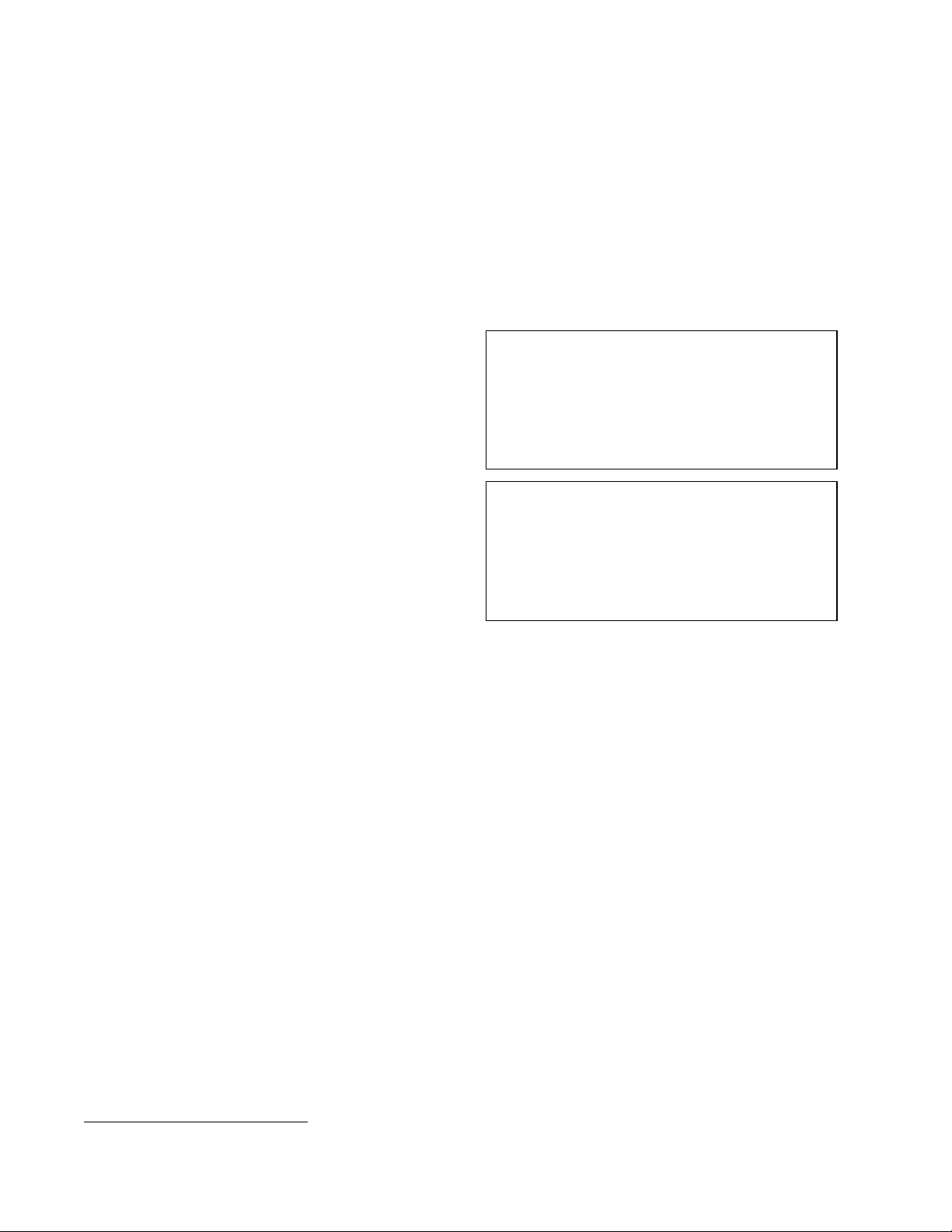

For maximum flexibility in using or carrying the Balometer® capture

hood, install the detachable handle (see Error! Reference source

not found.). Simply screw it “hand tight” into its mating thread on

the support plate above the meter.

Figure 6

Center Handle

N o t e

Check the tightness of this handle each time before use to ensure

it doesn’t loosen while the instrument is being used to take

readings or being carried from place to place.

Detachable Handle

Find Quality Products Online at: sales@GlobalTestSupply.com

Chapter 2. Unpacking and Hood Set Up 13

www.GlobalTestSupply.com

Page 12

I/O Key

Press and release to turn the ABT meter on. Press and hold for 2 seconds to

turn the ABT meter off.

During the power-up sequence, all the LEDs will be briefly illuminated and the

indicator needle will deflect to full scale and then back to zero. Once the

indicator is back to zero, the instrument is ready to take measurements.

Note: If the indicator needle does not deflect to full-scale position during the

power-up sequence, the meter may be damaged and may not read flow

accurately. See the “Maintenance and Troubleshooting” section of this

manual for further details.

Supply and Return

Flow (▲▼) Keys

Press to switch between supply (▼) flow and return (▲) flow measurement.

Range Selection

Press to switch between the low, medium, and high measurement range.

Note: If unsure of the flow, set the ABT to the highest range first.

Supply Flow

Return Flow

On/Off

Range Selector

Battery Indicator

Sensor Cable

Hold Switch

Zero Adjust

Chapter 3. Getting Started

This section provides information to help you quickly become familiar with the ABT Model functions.

Analog Meter Operation

The analog meter lets you initiate functions and view flow measurements. Prior to operating the instrument,

read this section to more fully understand what each of the keys do (see Figure 7).

Figure 7

Analog Meter Components

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

15

Page 13

Battery indicator

The battery indicator remains OFF when battery levels are in the normal

operating range.

When the batteries are becoming depleted, the battery indicator will flash,

indicating that the batteries should be changed soon.

When the batteries are fully depleted, the battery indicator will remain

constant ON, and after a few minutes the ABT meter will automatically poweroff. At this stage, the batteries must be replaced to resume normal operation.

Meter zero adjust

The zero adjust screw aligns the pointer to the zero mark on the scale. With

the meter turned off, use a screwdriver to bring the pointer to zero in the

position it will be used in with no flow.

Sensor Cable

The sensor cable must be plugged into the ABT meter to perform flow

measurement. If the sensor cable is not plugged in or is loose, the Supply and

Return indicator LEDs will flash to indicate this condition.

To “hold” a particular value on the display,

momentarily press and release the red

trigger button located on the left side of the

base (see Figure 8). To restart the

measurements from a “held” value, simply

press and release the red trigger button

again.

Figure 8

Red Hold Switch Location

N o t e

While the reading is being “held”, the LED

corresponding to the currently selected range

on the range selector indicator will be

blinking signifying the hold function is active.

Hold Switch

Find Quality Products Online at: sales@GlobalTestSupply.com

16 Alnor® Analog Balancing Tool Models ABT701/ABT703/ABT711/ABT713

www.GlobalTestSupply.com

Page 14

Step-By-Step Example Operation

If the instrument has been stored at a temperature below 68°F (20°C) or above 86°F (30°C), it should be

allowed to stabilize at room conditions (between 68°F and 86°F) in order to achieve specified accuracy.

1. Assemble the Balometer® capture hood as described in Chapter 2, “Unpacking and Hood Set Up,” of this

manual.

2. With the meter turned off, check the meter for zero adjustment by placing the instrument away from any air

flow and verify that the meter reads zero. If necessary, use a screwdriver to adjust the zero screw so that

the pointer reads zero. Although the meter will typically read zero regardless of how the unit is held, it is

best to zero the meter in the position in which it will be used.

3. Turn the meter on by pressing the I/O key. During the power up sequence, all the LEDs will be illuminated

and the indicator needle will peg to full scale and then return to zero. The instrument is now ready for use.

4. Select supply or return mode and set the range to the highest scale. This technique is to ensure the meter

will not be damaged by an over range condition when flow is unknown.

5. Place the Balometer® capture hood into contact with the perimeter of the diffuser or grill to be measured. To

assure maximum accuracy, the foam gasket along the top of the frame must be firmly in contact with the

surface all around the opening.

6. If the reading is found to be below the full scale of the next lower scale, the range can be switched to the

next lower scale.

Chapter 3. Getting Started 17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 15

Chapter 4. Changing Flow Hoods

This chapter identifies the flow hood parts and gives instructions for assembling the flow hood.

Hood Assembly

Four other hood sizes are available from TSI and can be purchased separately. Available hood sizes are

identified by the dimensions of the frame structure at the top of the hood and include 2 ft 4 ft (610 mm

1220 mm), 1 ft 4 ft (305 mm 1220 mm), 1 ft 5 ft (305 mm 1525 mm) and 3 ft 3 ft (915 mm 915

mm).

To change hood sizes, first remove the hood currently attached to the base. To remove the attached

hood:

1. Unlatch the cinch belt where the fabric is attached to the base.

2. Remove the fabric from its frame structure by pulling the shock cord out of the aluminum frame.

3. Fold up the fabric you just removed so that it can fit into one of the accessory pockets inside the

carrying case. It is a good idea to fold the fabric so that the tag identifying its size remains visible for

future reference.

Alternate Hood Installation

Refer to Figure 9 through Figure 14 to determine the frame channels needed to assemble any of the

standard sized frames. Select the pieces required for the frame size desired and assemble with the aid of

the appropriate figure. Each channel is labeled with its number for easy identification. Several sections

(numbers 1, 3, and 4) consist of a straight channel portion (each a different length) and a corner piece.

This corner piece has an eyelet and slot arrangement which mates with a similar eyelet and slot at the

end of the straight portion of the channel pieces (see Figure 9). These pieces can be slid together and

are self locking by means of a retention spring. The arrangement forms a rugged frame which is

additionally strengthened when the hood is attached.

19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 16

2 1 3 1 2

3

Figure 9

1 ft 4 ft (305 mm 1220 mm) hood and frame. The support poles always cross as pairs at the

front and back of the fabric hood. For the 1 ft 4 ft (305 mm 1220 mm), the support poles are

inserted into the outside ferrule locations.

20 Alnor® Analog Balancing Tool Models ABT701/ABT703/ABT711/ABT713

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

2 1 4 1 2

4

Figure 10

2 ft 4 ft (610 mm 1220 mm) hood and frame. The support poles always cross as pairs at the

front and back of the fabric hood. For the 2 ft 4 ft (610 mm 1220 mm), the support poles are

inserted into the inside ferrule locations.

The number 1 and 5 channels also have a wing nut at the straight end which will mate with an angle and

studs on the ends of numbers 2, 5 and 6 to form the longer frame sides (see Figure 11).

Chapter 4: Changing Flow Hoods 21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 18

2 1 3 1 2

3

5

5

Figure 11

1 ft 5 ft (305 mm 1525 mm) hood and frame. The support poles always cross as pairs at the

front and back of the fabric hood. For the 1 ft 5 ft (305 mm 1525 mm), the support poles are

inserted into the inside ferrule locations.

22 Alnor® Analog Balancing Tool Models ABT701/ABT703/ABT711/ABT713

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 19

1

6

6 1 6 1 6

1

Figure 12

3 ft 3 ft (915 mm 915 mm) hood and frame. The support poles always cross as pairs at the front

and back of the fabric hood. For the 3 ft 3 ft (915 mm 915 mm), the support poles are inserted

into the outside ferrule locations.

Figure 13

Frame Corner Assembly

Chapter 4: Changing Flow Hoods 23

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 20

N o t e

The hood corners should always be aligned with the corners of the base, near the hood support

brackets. The base has rivets located in the corners which can be used as a guide for aligning

the hood corners.

Figure 14

Frame Side Coupler Assembly

Each hood is constructed in a trapezoidal shape, sewn together so that one open end forms a round

attachment to the base, and the other forms a square or rectangle large enough to fit its matching frame

assembly. Around the frame end of the hood, an elastic shock cord has been sewn into the hood. This

cord is of a size such that it can be pushed into the open side of the U-shaped channels of the frame.

In general, attach a hood to the frame first, and then to the base unit. By stretching around the frame

corners the cord is slightly reduced in diameter and is easier to press into the frame channel.

24 Alnor® Analog Balancing Tool Models ABT701/ABT703/ABT711/ABT713

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

Chapter 5. Maintenance and Troubleshooting

The Alnor® Analog Balancing Tool Models ABT701/ABT703/ABT711/ABT713 are designed for long-term field

use. If used with reasonable care, they should be able to make precise measurements over a long time

period. Some of the components can be cleaned periodically. When cleaning the components, please follow

the instructions given below.

Fabric Hood

The hoods can be washed with mild detergent and cold water. When washing the hood, keep the hood away

from objects with sharp corners or sharp edges. Careless cleaning may cause damage.

If the fabric gets ripped it should be replaced or repaired. Duct tape can be placed over the rip on both sides

of the fabric for temporary repair.

To replace a damaged fabric or to order a different fabric size, contact your local TSI®/Alnor® distributor.

Analog Meter

The analog meter case, display screen and keys can be cleaned using a damp cloth with mild detergent

solution. Do not immerse it in water. Wipe the unit dry before use.

Manifold

If you observe the flow sensing taps of the manifold becoming clogged with dust or other material, clean them

with a damp cloth. The manifold should be kept in place during cleaning. Do not apply excessive forces on

the grid of the manifold. If any part of the grid is damaged, please contact Customer Service for repair

information

Cases

If the instrument case or storage case needs cleaning, wipe it off with a soft cloth and isopropyl alcohol or a

mild detergent.

Calibration

TSI recommends an annual calibration for the instrument. For a nominal fee, we will calibrate the unit and

return it to you with a certificate of calibration and NIST traceability. This “annual checkup” assures you of

consistently accurate readings. To calibrate the instrument, please ship the complete package that includes

the meter, the base, the manifold and any fabrics used. The meter and base are calibrated as a set and must

be returned together for calibration. Everything should be packed carefully within the carrying case and then

inside a shipping box. The original shipping box is preferred. Before sending your instrument for calibration or

repair, obtain a Return Material Authorization (RMA) number by visiting our website or contacting customer

service. When obtaining an RMA number, you will also learn the cost of service or calibration and receive

shipping instructions.

Table 2 lists the symptoms, possible causes, and recommended solutions for common problems encountered

with the instrument. If your symptom is not listed, or if none of the solutions solves your problem, please

contact the factory.

25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 22

Symptom

Possible Causes

Corrective Action

No LEDs light up.

Unit not turned on.

Low or dead batteries.

Dirty battery contacts.

Meter may be damaged and need

repair.

Press I/O key.

Replace the batteries.

Clean the battery contacts.

Return to factory for service.

Meter needle does not move

with flow stimulus.

Unit not turned on.

Low or dead batteries.

Dirty battery contacts.

Meter is in flow “Hold” condition (if 1

Range LED is also blinking).

Meter may be damaged and need

repair.

Press I/O key.

Replace the batteries.

Clean the battery contacts.

Press and release the hold button

to resume normal flow reading.

Return to factory for service.

During power-on sequence,

meter needle does not

deflect to full-scale position.

Meter needle zero is out of

adjustment.

Meter may be damaged and need

repair.

Verify correct meter needle zero

adjustment.

Return to factory for service.

1 Range LED is blinking.

Meter is in flow “Hold” condition.

Press and release the hold button

to resume normal flow reading.

Supply and Return LEDs

blink On and Off.

Sensor cable disconnected from

meter.

Flow sensor or cabling may be

damaged and need repair.

Verify sensor cable is connected.

Return to factory for service.

All 3 Range LEDs blink On

and Off.

Meter may be damaged and need

repair.

Return to factory for service.

Battery indicator is blinking.

Batteries are becoming depleted.

Replace the batteries.

Battery indicator is constant

On.

Batteries are fully depleted.

Replace the batteries.

Unit powers On, but

automatically turns itself Off

shortly thereafter.

Batteries are fully depleted.

Replace the batteries.

Table 2: Troubleshooting the Instrument

Find Quality Products Online at: sales@GlobalTestSupply.com

26 Alnor® Analog Balancing Tool Models ABT701/ABT703/ABT711/ABT713

www.GlobalTestSupply.com

Page 23

Appendix A. Actual vs. Standard Air Flow Measurements

Thermo-anemometer sensors measure mass air flow velocity which is a measurement of the air mass moving

past the sensor and is displayed as standard velocity. Air mass is what gives air its heat holding capacity.

Since thermal anemometers measure air mass and display it as standard velocity, many people doing

measurements on indoor air are more concerned with standard air velocity.

Standard readings can be converted to actual air velocity to compensate for temperature and barometric

pressures. Actual or standard measurements will give the same readings at standard conditions (using a

reference of 70°F [21.1°C] and 29.92 in. Hg [101.4 kPa]), but not if pressure or temperature stray from

standard conditions.

To calculate actual air velocity, multiply the standard velocity reading indicated by the thermoanemometer by

the following density correction factor:

Actual Velocity = (Standard Velocity) [(460 + T) / (460 + 70)] * 29.92 / Pm

or

Actual Velocity = (Standard Velocity) [(273 + Tm) / (273 + 21.1)] * 101.4 / P

Where:

T = Ambient temperature in degrees Fahrenheit

Pm = Ambient pressure in inches of Hg.

Tm = Ambient temperature in degrees Centigrade

P = Ambient pressure in kPa

27

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

Specifications*

Supply and Exhaust Ranges

ABT701/ABT703 30 to 1,000 CFM (ft3/min)

ABT711/ABT713 50 to 2,000 CMH (m3/hr)

Accuracy

ABT701/ABT703 ±3% of full scale selected +5 CFM (ft3/min)

ABT711/ABT713 ±3% of full scale selected +10 CMH (m3/hr)

Units

CFM (ft3/min) Models ABT701 and ABT703

CMH (m3/hr) Models ABT711 and ABT713

Scale Divisions (Supply/Exhaust)

CFM (ft3/min)

5 from 30 to 250

10 from 200 to 500

20 from 400 to 1000

CMH (m3/hr)

10 from 50 to 500

20 from 400 to 1000

40 from 800 to 2000

Power Requirements

Four AA-size cells alkaline

Battery Life (continuous)

200 CFM ( 340 CMH) 29.2 hours

800 CFM (1360 CMH) 21.3 hours

1000 CFM (1700 CMH) 20.4 hours

Weight with Batteries

7.4 lb (3.4 kg)

Operating Temperature Range

32 to 140°F (0 to 60°C)

Storage Temperature Range

-40 to 140°F (-40 to 60°C)

Model Description

ABT701 30 to 1000 CFM (ft3/min) with 2 ft 2 ft (610 mm 610 mm) hood

ABT703 30 to 1000 CFM (ft3/min) with 16 in 16 in (406 mm 406 mm) hood

ABT711 50 to 2000 CMH (m3/hr) with 2 ft 2 ft (610 mm 610 mm) hood

ABT713 50 to 2000 CMH (m3/hr) with 16 in 16 in (406 mm 406 mm) hood

Optional Hood and Frame Kits

801097 2 ft 2 ft (610 mm 610 mm)

801201 2 ft 4 ft (610 mm 1220 mm)

801200 1 ft 4 ft (305 mm 1220 mm)

801202 1 ft 5 ft (305 mm 1525 mm)

801203 3 ft 3 ft (915 mm 915 mm)

801209 16 in 16 in (406 mm 406 mm)

*

Specifications are subject to change without notice.

Find Quality Products Online at: sales@GlobalTestSupply.com

29

www.GlobalTestSupply.com

Loading...

Loading...