Page 1

VelociCalc®/

VelociCalc® Pro

Air Velocity Meter

Model 9600 Series

Operation and Service Manual

P/N 6016122, Revision C

August 2022

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 2

Start Seeing the Benefits

of Registering Today!

Thank you for your TSI® instrument purchase. Occasionally, TSI®

releases information on software updates, product enhancements and

new products. By registering your instrument, TSI® will be able to send

this important information to you.

As part of the registration process, you will be asked for your comments

on TSI products and services. TSI’s customer feedback program gives

customers like you a way to tell us how we are doing.

ii VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

Copyright

Address

Fax No.

E-mail Address

Limitation of Warranty

and Liability

(effective February 2015)

Warranty

Seller warrants the goods, excluding software, sold hereunder, under normal use

and service as described in the operator's manual, to be free from defects in

workmanship and material for 24 months, or if less, the length of time specified

in the operator's manual, from the date of shipment to the customer. This

warranty period is inclusive of any statutory warranty. This limited warranty is

subject to the following exclusions and exceptions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other

components when indicated in specifications, are warranted for 90 days from the

date of shipment;

b. Carbon monoxide (CO) Electro-chemical sensors are warranted for 12 months

from the date of shipment.

c. Pumps are warranted for hours of operation as set forth in product or

operator’s manuals;

d. Parts repaired or replaced as a result of repair services are warranted to be free

from defects in workmanship and material, under normal use, for 90 days from the

date of shipment;

e. Seller does not provide any warranty on finished goods manufactured by others or

on any fuses, batteries or other consumable materials. Only the original

manufacturer's warranty applies;

f. This warranty does not cover calibration requirements, and seller warrants

only that the instrument or product is properly calibrated at the time of its

manufacture. Instruments returned for calibration are not covered by

this warranty;

g. This warranty is VOID if the instrument is opened by anyone other than a

factory authorized service center with the one exception where

requirements set forth in the manual allow an operator to replace

consumables or perform recommended cleaning;

h. This warranty is VOID if the product has been misused, neglected, subjected

to accidental or intentional damage, or is not properly installed, maintained, or

cleaned according to the requirements of the manual. Unless specifically

authorized in a separate writing by Seller, Seller makes no warranty with

respect to, and shall have no liability in connection with, goods which are

incorporated into other products or equipment, or which are modified by any

person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the

LIMITATIONS stated herein. NO OTHER EXPRESS OR IMPLIED WARRANTY

OF FITNESS FOR PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE.

WITH RESPECT TO SELLER’S BREACH OF THE IMPLIED WARRANTY

AGAINST INFRINGEMENT, SAID WARRANTY IS LIMITED TO CLAIMS OF

DIRECT INFRINGEMENT AND EXCLUDES CLAIMS OF CONTRIBUTORY OR

INDUCED INFRINGEMENTS. BUYER’S EXCLUSIVE REMEDY SHALL BE THE

RETURN OF THE PURCHASE PRICE DISCOUNTED FOR REASONABLE

WEAR AND TEAR OR AT SELLER’S OPTION REPLACEMENT OF THE

GOODS WITH NON-INFRINGING GOODS.

iii

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 4

Service Policy

Trademarks

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE

USER OR BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND

ALL LOSSES, INJURIES, OR DAMAGES CONCERNING THE GOODS

(INCLUDING CLAIMS BASED ON CONTRACT, NEGLIGENCE, TORT, STRICT

LIABILITY OR OTHERWISE) SHALL BE THE RETURN OF GOODS TO SELLER

AND THE REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION OF

SELLER, THE REPAIR OR REPLACEMENT OF THE GOODS. IN THE CASE OF

SOFTWARE, SELLER WILL REPAIR OR REPLACE DEFECTIVE SOFTWARE

OR IF UNABLE TO DO SO, WILL REFUND THE PURCHASE PRICE OF THE

SOFTWARE. IN NO EVENT SHALL SELLER BE LIABLE FOR LOST PROFITS,

BUSINESS INTERRUPTION, OR ANY SPECIAL, INDIRECT, CONSEQUENTIAL

OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE RESPONSIBLE FOR

INSTALLATION, DISMANTLING OR REINSTALLATION COSTS OR CHARGES.

No Action, regardless of form, may be brought against Seller more than 12

months after a cause of action has accrued. The goods returned under warranty

to Seller's factory shall be at Buyer's risk of loss, and will be returned, if at all, at

Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF

WARRANTY AND LIABILITY, which contains the complete and exclusive limited

warranty of Seller. This LIMITATION OF WARRANTY AND LIABILITY may not

be amended, modified or its terms waived, except by writing signed by an Officer

of Seller.

Knowing that inoperative or defective instruments are as detrimental to TSI as

they are to our customers, our service policy is designed to give prompt attention

to any problems. If any malfunction is discovered, please contact your nearest

sales office or representative, or call Customer Service department

TSI, TSI logo, VelociCalc and VelociCalc Pro are registered trademarks of TSI

Incorporated in the United States and may be protected under other country’s

trademark registrations. Wi-Fi is a registered trademark of the Wi-Fi Alliance.

Find Quality Products Online at: sales@GlobalTestSupply.com

iv VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 5

Contents

WARRANTY ....................................................................................... III

SAFETY ............................................................................................ VII

Description of Caution/Warning Symbols ....................................... vii

Caution ......................................................................................... vii

Warning ........................................................................................ vii

Caution and Warning Symbols ...................................................... viii

Labels ............................................................................................. viii

RoHS ................................................................................................ ix

CE .................................................................................................... ix

Reusing and Recycling .................................................................... ix

Bluetooth® Safety and Compliance(9650) ....................................... ix

CHAPTER 1 UNPACKING AND PARTS IDENTIFICATION ............. 1

Standard Equipment ......................................................................... 1

Optional Plug In Probes .................................................................... 2

Optional Accessories and Replacement Parts ................................. 3

CHAPTER 2 SETTING UP THE VELOCICALC® METER ................. 5

Providing Power to the VelociCalc® Meter ........................................ 5

Installing the Batteries ................................................................... 5

Using the AC/DC Power Supply .................................................... 5

Case Magnets, Probe Holder and Wrist Strap .................................. 6

Connecting Ventilation or IAQ Probes .............................................. 6

Extending the Probe ...................................................................... 7

Retracting the Probe ...................................................................... 7

Differential Pressure Capable Models (9630, 9650 and 9650-NB) .. 7

Connecting the Static Pressure Probe .......................................... 8

Connecting an Optional Pitot Probe .............................................. 8

Thermocouple Port ............................................................................ 9

Connecting the Thermocouples ..................................................... 9

Connecting the Optional Bluetooth Portable Printer Device

(Model 9650 only) ........................................................................ 10

Connecting to a Computer .............................................................. 11

CHAPTER 3 OPERATIONAL OVERVIEW ...................................... 13

Keypad Button Names .................................................................... 13

Icons ................................................................................................ 13

Measurement Icons ..................................................................... 13

Dashboard Icons .......................................................................... 14

Soft Key Icons .............................................................................. 15

Programmable Soft Key Icons ..................................................... 15

Definitions ....................................................................................... 16

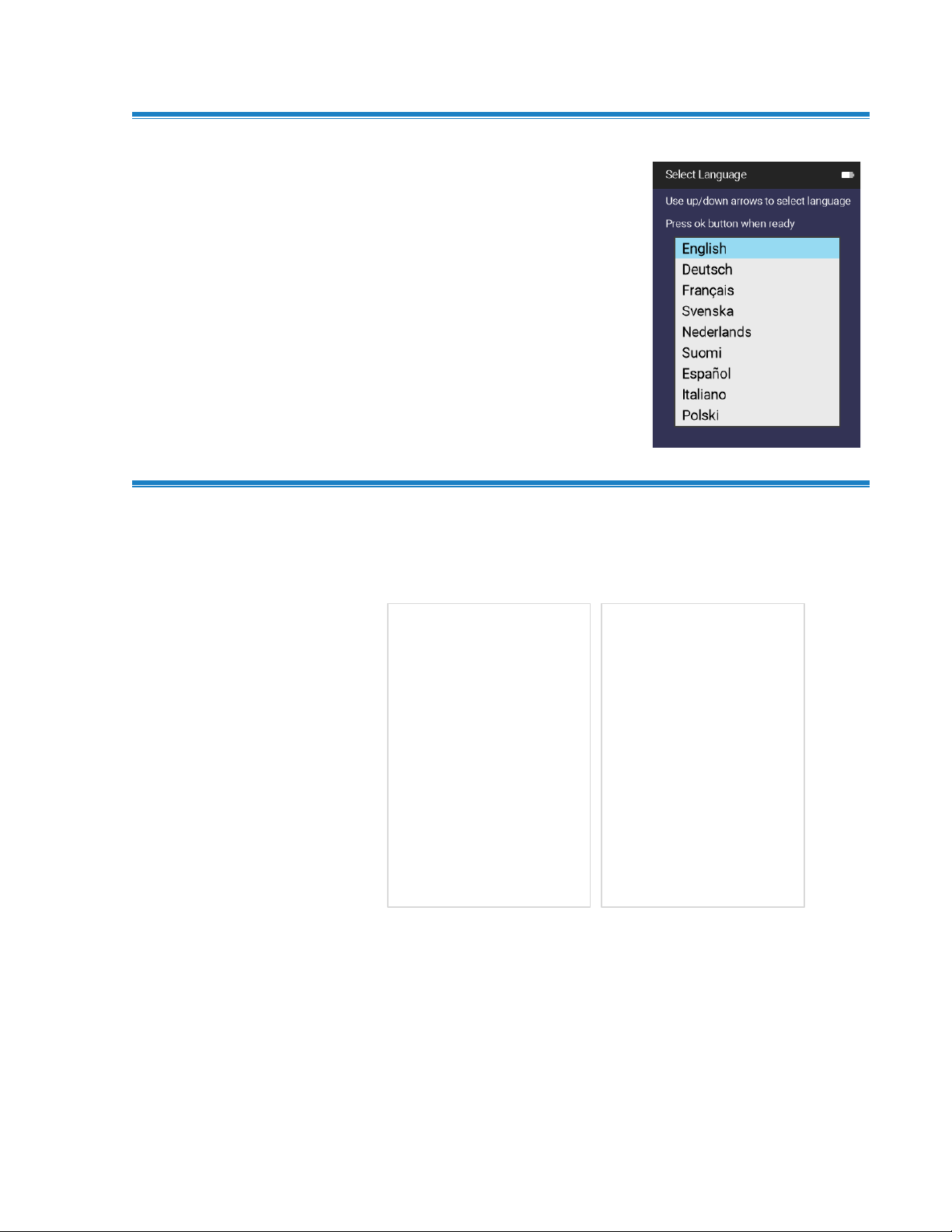

Language Selection ........................................................................ 17

Dashboard ....................................................................................... 17

Dashboard ................................................................................... 17

Assign Programmable Soft Keys .................................................... 18

Main Menu ...................................................................................... 19

v

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 6

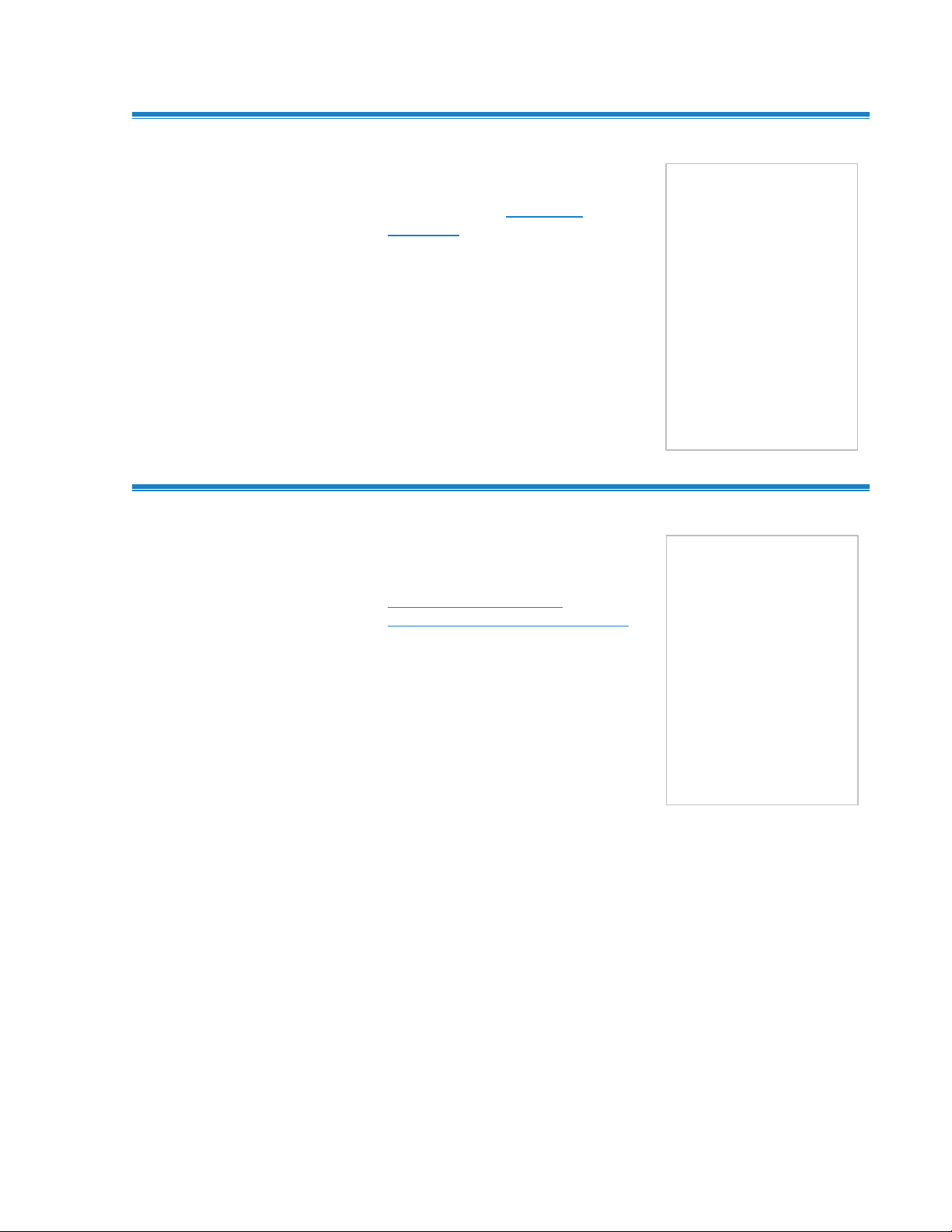

Zero Pressure ................................................................................. 19

Settings........................................................................................... 20

Flow Setup ..................................................................................... 20

Workflows ....................................................................................... 21

Logging Profile ............................................................................... 21

Manage Data .................................................................................. 22

CHAPTER 4 SETTINGS .................................................................. 23

Display Order ................................................................................. 23

Actual/Standard .............................................................................. 24

Calibration ...................................................................................... 24

General Settings ............................................................................. 26

Unit Settings ................................................................................... 27

Date and Time ................................................................................ 27

Display/Power ................................................................................ 28

Device Information ......................................................................... 28

CHAPTER 5 LOGGING PROFILE AND CUSTOM

TESTID LABELS .............................................................................. 29

Manual Mode Logging .................................................................... 29

Continuous Mode Logging ............................................................. 30

Customize TESTID Labels in Meter ............................................... 30

Customize TESTID Labels using TestID.csv ................................. 31

CHAPTER 6 MANAGE DATA ......................................................... 33

Viewing a Log File (TESTID) .......................................................... 33

Viewing Samples ............................................................................ 34

Delete Log Files ............................................................................. 34

Opening Log CSV Files on a PC .................................................... 34

CHAPTER 7 WORKFLOWS ............................................................ 35

Percent Outside Air (%OA) Calculation Procedure ........................ 35

Heat Flow Procedure ...................................................................... 36

Duct Traverse Procedure (9650, 9650-NB) ................................... 37

CHAPTER 8 MAINTENANCE ......................................................... 41

Cleaning/Disinfecting ...................................................................... 41

Bi-Annual Maintenance Checks ..................................................... 42

CHAPTER 9 TROUBLESHOOTING ............................................... 43

CHAPTER 10 HELP ........................................................................ 45

TSI® Technical Support/Service ..................................................... 45

APPENDIX A SPECIFICATIONS .................................................... 47

vi VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

W AR NI NG S

• The instrument must be used in the manner described in this

manual. Failure to follow all of the procedures described in this

manual can result in serious injury to you or can cause

irrevocable damage to the instrument.

• There are no user-serviceable parts inside the instrument. Refer

all repairs to a qualified factory-authorized technician.

• The VelociCalc® meter is not rated for intrinsic safety. DO NOT

operate the VelociCalc® meter under conditions where there is a

risk of fire or explosion.

C A U TI ON

CAUTION means that failure to follow the procedures prescribed in

this manual might result in irreparable equipment damage.

Important information about the operation and maintenance of this

instrument is included in this manual.

W AR NI NG

WARNING means that unsafe use of the instrument could result in

serious injury to you or cause damage to the instrument. Follow the

procedures prescribed.

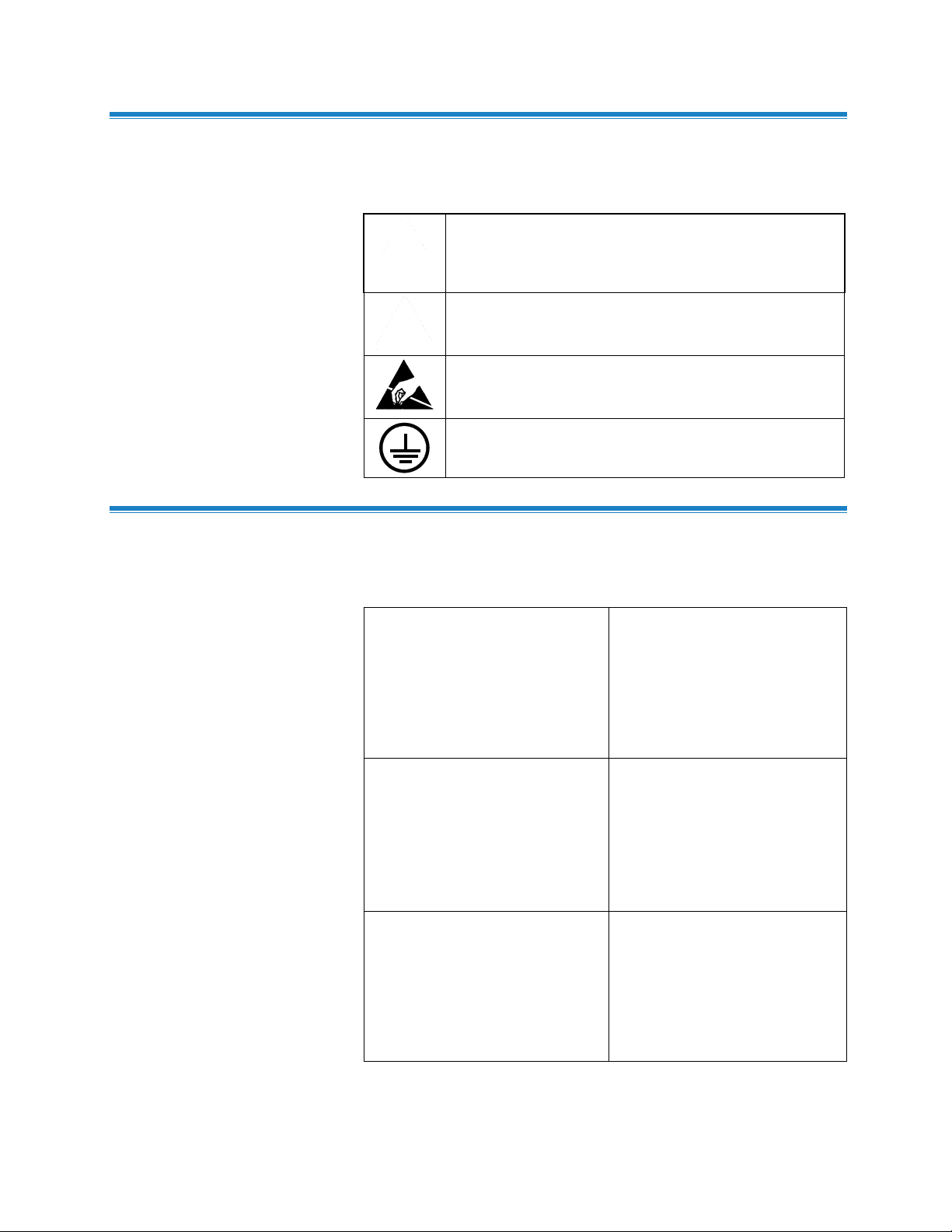

Safety

This section provides instructions to ensure safe and proper operation

of the VelociCalc® Air Velocity Meter Series 9600.

Description o f C a u t i o n / W a r n i n g S y m b o l s

Appropriate caution/warning statements are used throughout the

manual and on the instrument that require you to take cautionary

measures when working with the instrument.

Caution

Warning

Find Quality Products Online at: sales@GlobalTestSupply.com

vii

www.GlobalTestSupply.com

Page 8

Warns that uninsulated voltage within the instrument

may have sufficient magnitude to cause electric shock.

Therefore, it is dangerous to make contact with any

part inside the instrument.

Warns that the instrument contains a laser and that

important information about its safe operation and

maintenance is included in the manual.

Warns that the instrument is susceptible to electrostatic discharge (ESD) and ESD protection should be

followed to avoid damage.

Indicates the connector is connected to earth ground

and cabinet ground.

1. Example

2. Example

3. Example

4. Example

5. Example

6. Example

Caution an d W a r n i n g S y m b o l s

The following symbols may accompany cautions and warnings to

indicate the nature and consequences of hazards:

Labels

Advisory and identification labels or markings are attached to

the instrument.

Find Quality Products Online at: sales@GlobalTestSupply.com

viii VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 9

7. Example

8. Example

9. European symbol for nondisposable item. Item must

be recycled.

RoHS

VelociCalc® 9600 Series instruments are RoHS compliant.

CE

VelociCalc® 9600 Series instruments are CE compliant.

Reusing an d Re c y c l i n g

As part of TSI® Incorporated’s effort to have a minimal negative

impact on the communities in which its products are manufactured

and used:

DO NOT dispose of batteries in the trash. Follow local

environmental requirements for battery recycling.

If instrument becomes obsolete, return to TSI® for disassembly

and recycling.

Bluetooth® Safety a n d C o m p l i a n c e ( 9 6 5 0 )

This product uses Bluetooth® v4.2 to communicate with

software applications.

Hereby, TSI® Incorporated declares that this Bluetooth® test and

measurement instrument is in compliance with Directive 2014/53/EC.

Transmit Power Rating is +9 dBm, MAX @ 2.4 – 2.5 GHz.

Operation and Service Manual ix

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 10

NOT ICE

This device may not cause interference; this device must accept

any interference, including interference that may cause undesired

operation of the device.

l’appareil ne doit pas produire de brouillage; l’appareil doit

accepter tout brouillage radioélectrique subi, même si le brouillage

est susceptible d’en compromettre le fonctionnement.

NOT ICE

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to part 15 of the FCC

Rules (FCC ID: 2AC7Z-ESP32WROOM32E). These limits are

designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no

guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning

the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician

for help.

NOT ICE

This device complies with Industry Canada licence-exempt RSS

standard(s). Operation is subject to the following two conditions:

(1) this device may not cause interference, and (2) this device

must accept any interference, including interference that may

cause undesired operation of the device.

W A R N I N G

Changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to

operate the equipment.

Find Quality Products Online at: sales@GlobalTestSupply.com

x VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 11

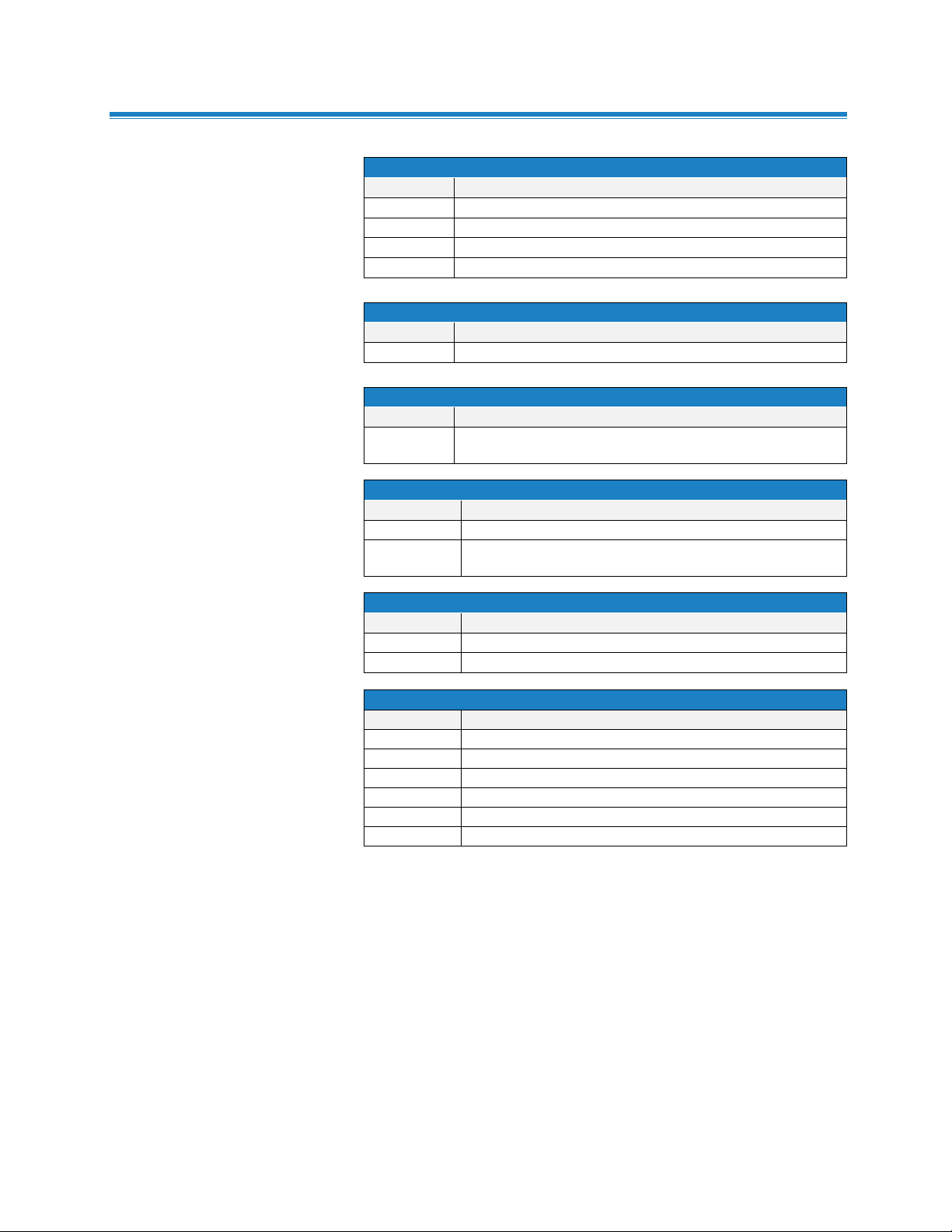

C H A P T E R 1

1. Carrying case

2. Instrument

3. USB cable

4. Static pressure tip (9630,

9650, 9650-NB)

5. Tubing (9630, 9650,

9650-NB)

6. Calibration certificate

7. Manual (English)

Model No.

Description

9600

Multi-Function Ventilation Meter

9630

Multi-Function Ventilation Meter with Differential Pressure

9650-NB

Multi-Function Ventilation Meter with Differential Pressure,

and Workflows

9650

Multi-Function Ventilation Meter with Differential Pressure,

Workflows, and Bluetooth® printing

Unpacking and Parts

Identification

Carefully unpack the instrument and accessories from the shipping

container. Check the individual parts against the list of components

below. If anything is missing or damaged, notify TSI® immediately.

Standard Equi p m e n t

All standard equipment can be purchased separately if needed.

This manual supports the following models:

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

1

Page 12

Telescopic Thermoanemometer Probes

Model No.

Description

960

Air Velocity and Temperature, Straight Probe

962

Air Velocity and Temperature, Articulating Probe

964

Air Velocity, Temperature, and Humidity, Straight Probe

966

Air Velocity, Temperature, and Humidity, Articulating Probe

Telescopic Thermohygrometer Probe

Model No.

Description

800220

Air temperature and relative Humidity

Rotating Vane Anemometer Probes

Model No.

Description

995

4 in. (100 mm) Rotating Vane, Air Velocity, and

Temperature

Indoor Air Quality (IAQ) Probes

Model No.

Description

980

Indoor Air Quality Probe, Temperature, Humidity, CO2

982

Indoor Air Quality Probe, Temperature, Humidity, CO2 and

CO K-alloy Thermocouple Probes

Model No.

Description

792

Surface Temperature Probe

794

Air Temperature Probe

Pitot Probes

Part No.

Description

634634000

Pitot Probe 12" (30 cm) - 5/16" (8 mm) diameter

634634001

Pitot Probe 18" (46 cm) - 5/16" (8 mm) diameter

634634002

Pitot Probe 24" (61 cm) - 5/16" (8 mm) diameter

634634003

Pitot Probe 36" (91 cm) - 5/16" (8 mm) diameter

634634005

Pitot Probe 60" (152 cm) - 5/16" (8 mm) diameter

634634004

Telescoping Pitot Probe - 8" to 38" (20 cm to 96 cm)

Optional P l u g I n P r o b e s

2 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

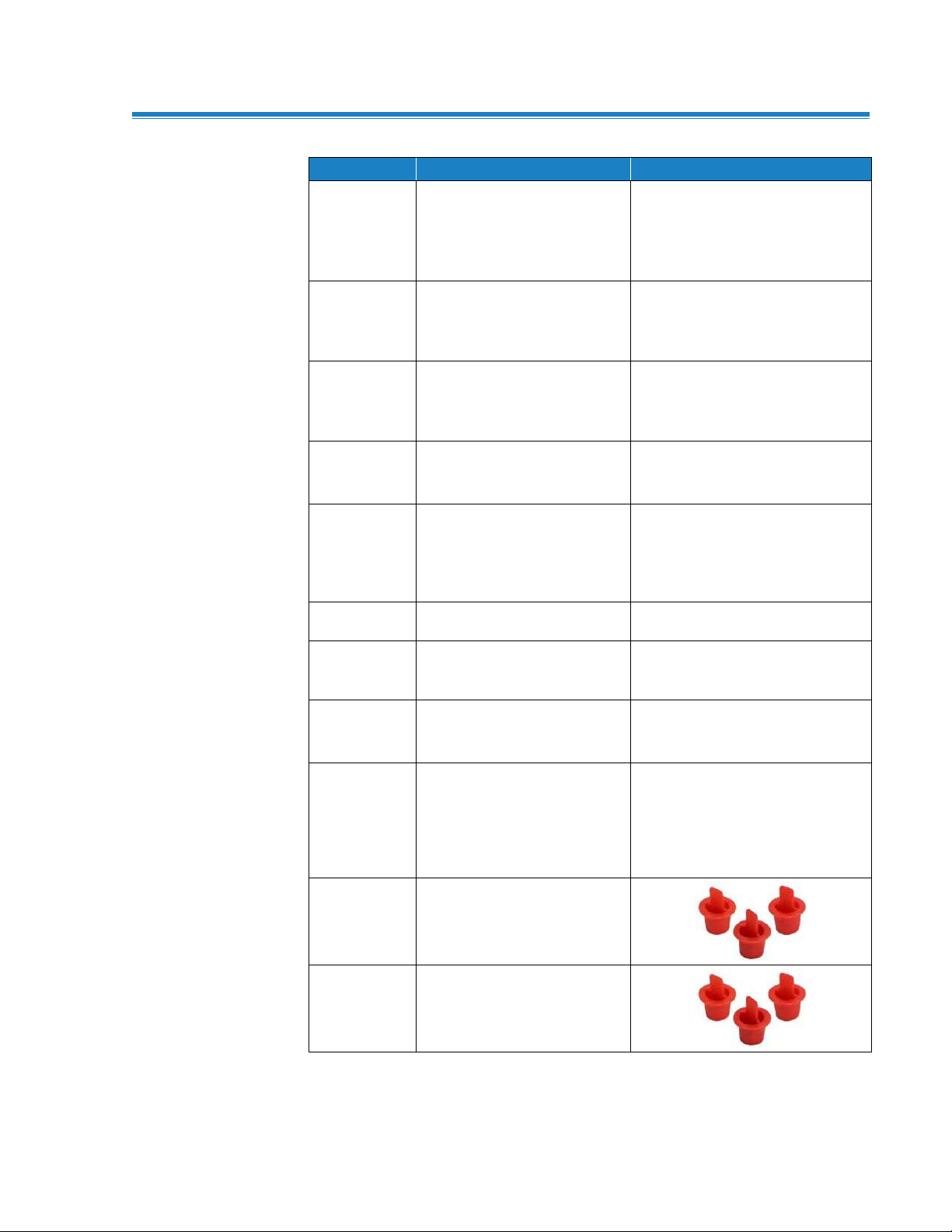

Page 13

Part No.

Description

Picture

800122

AC/DC Adapter/Power Supply

802241

USB Thermal Printer

801190

Bluetooth® Printer (9650 only)

80211

Printer paper (5 rolls)

800681

IAQ probe stand

801748

Telescopic, articulated

extension for 995 RV probe

372000000

8 ft. (2.5 m) tubing

3002017

Static pressure probe

800533

Static Pressure Probes and

Tubing Kit—contains two static

pressure probes and two 4 ft.

(1.2 m) lengths of tubing.

634650002

Duct plugs, 3/8" (9.5 mm)

diameter—1000 pieces

634650003

Duct plugs, 3/8" (9.5 mm)

diameter—5000 pieces

Optional Acces sories and Replacement Parts

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Operation and Service Manual 3

Page 14

Part No.

Description

Picture

800130

Carrying case, small:

Accommodates (1) meter and

up to (2) probes (IAQ or

thermoanemometer)

Find Quality Products Online at: sales@GlobalTestSupply.com

4 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 15

C A U T I O N

Use only the approved AC/DC power supply (TSI® part number

800122) and DO NOT substitute another adapter or use a computer

to supply power. Use of an incorrect power supply can cause the

measurements to be inaccurate.

AC/DC Power Supply Input

C H A P T E R 2

Setting Up the

VelociCalc® Meter

Providing Powe r t o t h e V e l o c i C a l c® Meter

The Model 9600 Series VelociCalc

powered in one of two ways: four (4) size AA batteries or the optional

AC/DC power supply.

Installing the Batteries

Insert four (4) size AA batteries as indicated by the diagram located

on the inside of the battery compartment.

®

Air Velocity Meter can be

Using the AC/DC Power Supply

The optional AC/DC power supply (800122) can be used to power the

instrument. Be sure to provide the correct voltage and frequency,

which is marked on the back of the AC/DC power supply.

When the AC/DC power supply is connected, the instrument will

automatically turn ON. To turn the instrument off, disconnect the

AC/DC power supply. If batteries are installed, press the power button

for 3 seconds.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

5

Page 16

“D” Shaped

mini-DIN connector

Magnets

Probe Holder

Wrist Strap

Location

Case M a g n e t s , P r o b e H o l d e r a n d Wrist Stra p

The back of the case features built-in magnets that allow for handsfree operation. Two small magnets are near the bottom of the case

and one large magnet in the top next to the serial number label. The

instrument can be affixed to metal components such as sheet metal

ductwork or frames of fume hoods. In addition, the case design

incorporates a probe holder and wrist strap connection.

Connecting Ve n t i l a t i o n o r I A Q P r o b e s

The ventilation and IAQ probes have a “D” shape overmolding on

the mini-DIN connector which must align with the connector at the

base of the 9600 series meter. This will ensure the probe is

properly connected and remains so during use. Once connected

and turned on, refer to the Display Order for displaying the

desired measurements.

6 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 17

N O T ICE

For temperature and humidity measurements, make sure that at

least 3 in. (7.5 cm) of the probe is in the flow to allow the

temperature and humidity sensors to be in the air stream.

W A R N I N G

DO NOT use the instrument or probes near hazardous voltage

sources since serious injury could result.

Negative (-) Pressure Port

Positive (+) Pressure Port

The telescoping probe contains the velocity, temperature, and

humidity sensors. When using the probe, make sure the

sensor window is fully exposed and the orientation dimple is

facing upstream.

Extending the Probe

To extend the probe, hold the handle in one hand while pulling on the

probe tip with the other hand. DO NOT hold the cable while extending

the probe as this prevents the probe from extending.

Retracting the Probe

To retract the probe, hold the handle in one hand while gently pulling

the probe cable until the smallest antenna section is retracted.

Differentia l P r e s s u r e C a p a b l e Models (9630, 9 6 5 0 a n d 9 6 5 0 - NB)

The 9630, 9650, and 9650-NB include pressure ports that can be

used to measure static and differential pressures in ductwork. For

more information, see Application Note TSI-107.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Operation and Service Manual 7

Page 18

The static pressure probe

included with differential

pressure capable meters is

connected to the “+” port using

the included tubing. The static

pressure probe is used to

measure the duct static

pressure and features a

magnet which holds the probe

to the ductwork.

N O T ICE

The pitot velocity needs a valid temperature to perform the standard

or actual velocity correction. This is accomplished in the

“Actual/Standard Setup” menu. If a thermocouple is plugged in, the

meter will use the temperature reading from the thermocouple. If no

thermocouple is plugged in, the meter will use the setting saved in

the “Actual/Standard Setup” menu.

For more information on entering the temperature manually, refer to

Chapter 4, Actual/Standard Setup section of this manual.

Connecting the Static Pressure Probe

Connecting an Optional Pitot Probe

When connected to a pitot probe, air velocity or air volume can be

measured. A pitot probe can be connected to the “+” and “-” pressure

ports on the pressure capable VelociCalc® meters using two pieces of

tubing of equal length. The total pressure port of the pitot probe

connects to the “+” port on the meter, and the static pressure port of

the pitot probe connects to the “-” port on the meter.

Find Quality Products Online at: sales@GlobalTestSupply.com

8 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 19

W A R N I N G

DO NOT use the instrument or probes near hazardous voltage

sources since serious injury could result.

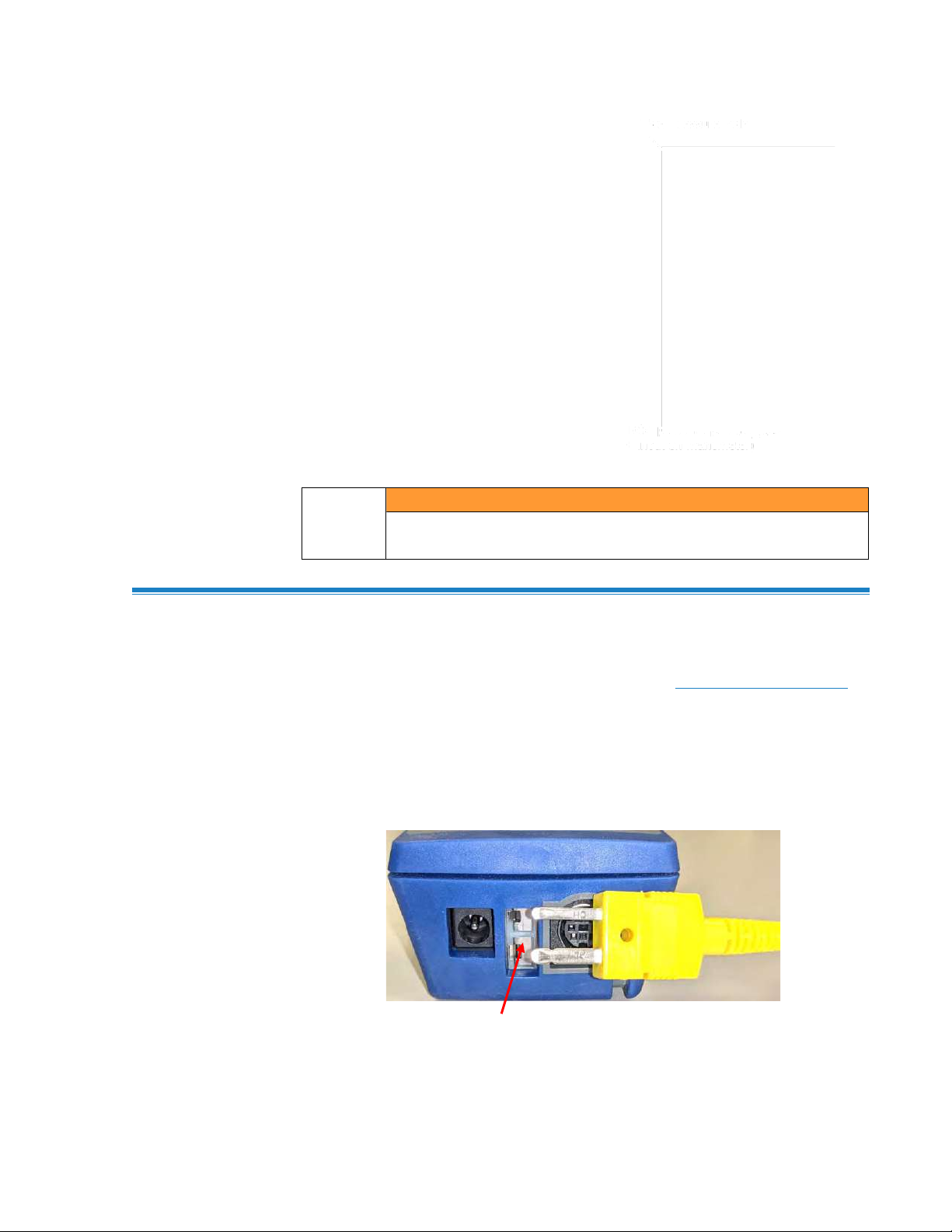

K-alloy Thermocouple

TC

Thermocouple Port

The 9600 Series VelociCalc® Air Velocity Meter includes a

thermocouple port at the base of the meter. Any K-alloy thermocouple

with mini-connector can be attached. See Chapter 4, Display Order

for displaying the thermocouple measurement.

Connecting the Thermocouples

The K-alloy thermocouple with mini-connector has one terminal wider

than the other. The wider terminal will be inserted into the bottom of

the TC connector port.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Operation and Service Manual 9

Page 20

W A R N I N G S

• Thermocouples from an alternate TSI® supplier must have the

metal sheath electrically isolated from the wires inside. Failure

to meet this requirement may result in false readings, electrical

shock, or fire hazard.

• DO NOT use the instrument or probes near hazardous voltage

sources since serious injury could result.

To connect the Bluetooth® printer to

the Model 9650, power on the unit

and the printer.

1. Navigate to Settings ->

Bluetooth and Enable

Bluetooth checkbox.

2. Highlight SCAN and

press Enter.

3. The unit will scan and find

compatible Bluetooth® printers.

4. Highlight printer and

press Enter.

5. The unit will display a message

of “Connected” when

successful.

Connecting the O p t i o n a l B l u e t o o t h® Portab l e Printer De v ic e ( M o d e l 9650 only)

Find Quality Products Online at: sales@GlobalTestSupply.com

10 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Bluetooth is a registered trademark of Bluetooth SIG.

www.GlobalTestSupply.com

Page 21

C A U T I O N

Protection provided by the instrument could be impaired if used in

a manner other than specified in this user manual.

USB Communications Port

Connecting to a C o m p u t e r

Use the Computer Interface USB Cable provided with the VelociCalc®

meter to connect the instrument to a computer for downloading

stored data.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Operation and Service Manual 11

Page 22

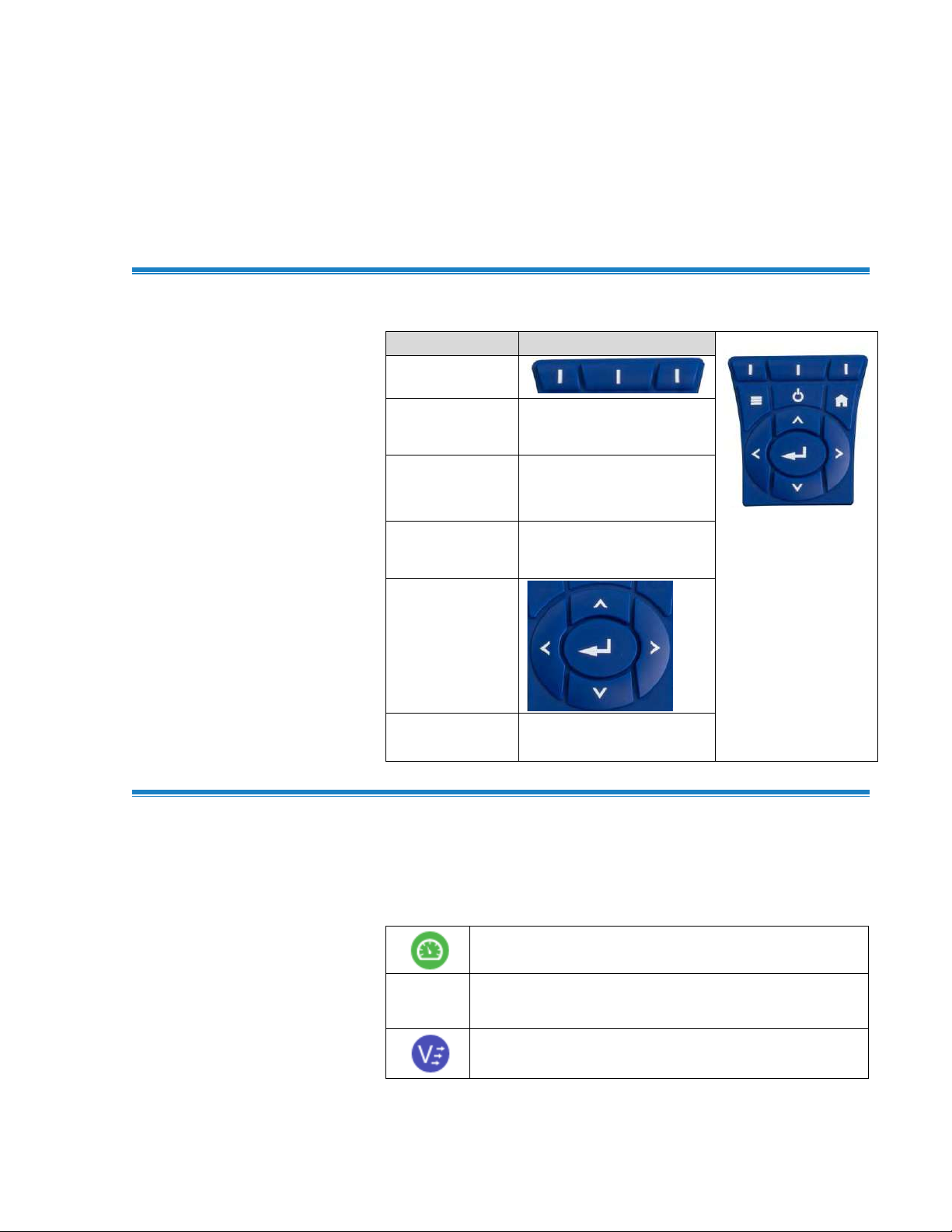

Button Names

Button Image

Programmable

Soft Keys

Main Menu

Power

Home

(Dashboard)

Navigation

Keys

Enter or OK

Barometric pressure

Temperature from thermocouple probe

Velocity from thermoanemometer or rotating vane

anemometer probe

C H A P T E R 3

Operational Overview

Keyp a d B u t t o n N a m e s

Icons

Measurement Icons

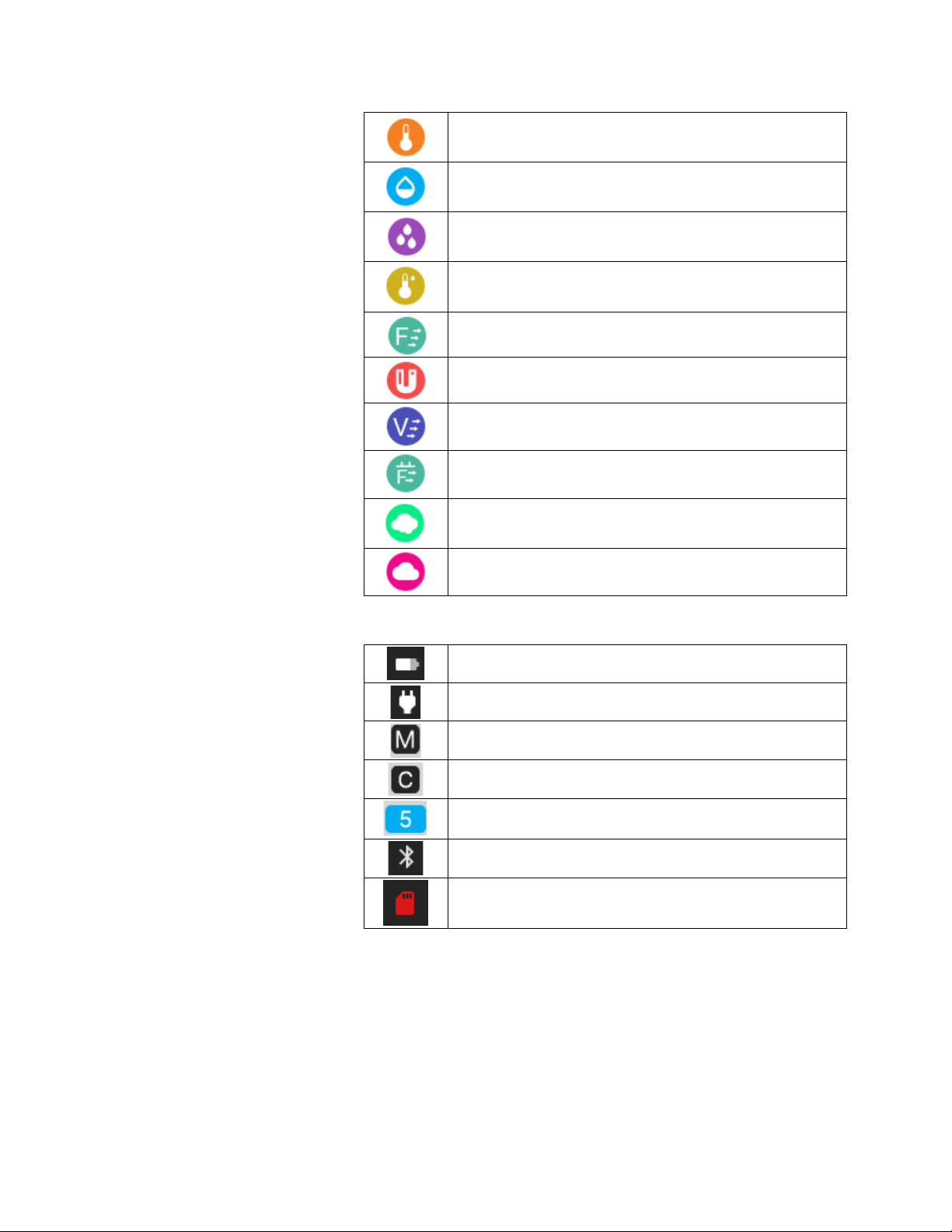

The visibility of the following icons are dependent on the type of meter

used and the probe connected.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

13

Page 23

Temperature

Relative humidity

Dew point temperature

Wet bulb temperature

Air flow from thermoanemometer or rotating vane

anemometer probe

Differential pressure

Velocity from pitot probe

Airflow from pitot probe or K-factor

Carbon dioxide

Carbon monoxide

Battery status

AC power

Manual Logging mode

Continuous Logging mode

Number of samples

Bluetooth enabled (9650 only)

Memory low warning when 90% full

Dashboard Icons

14 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 24

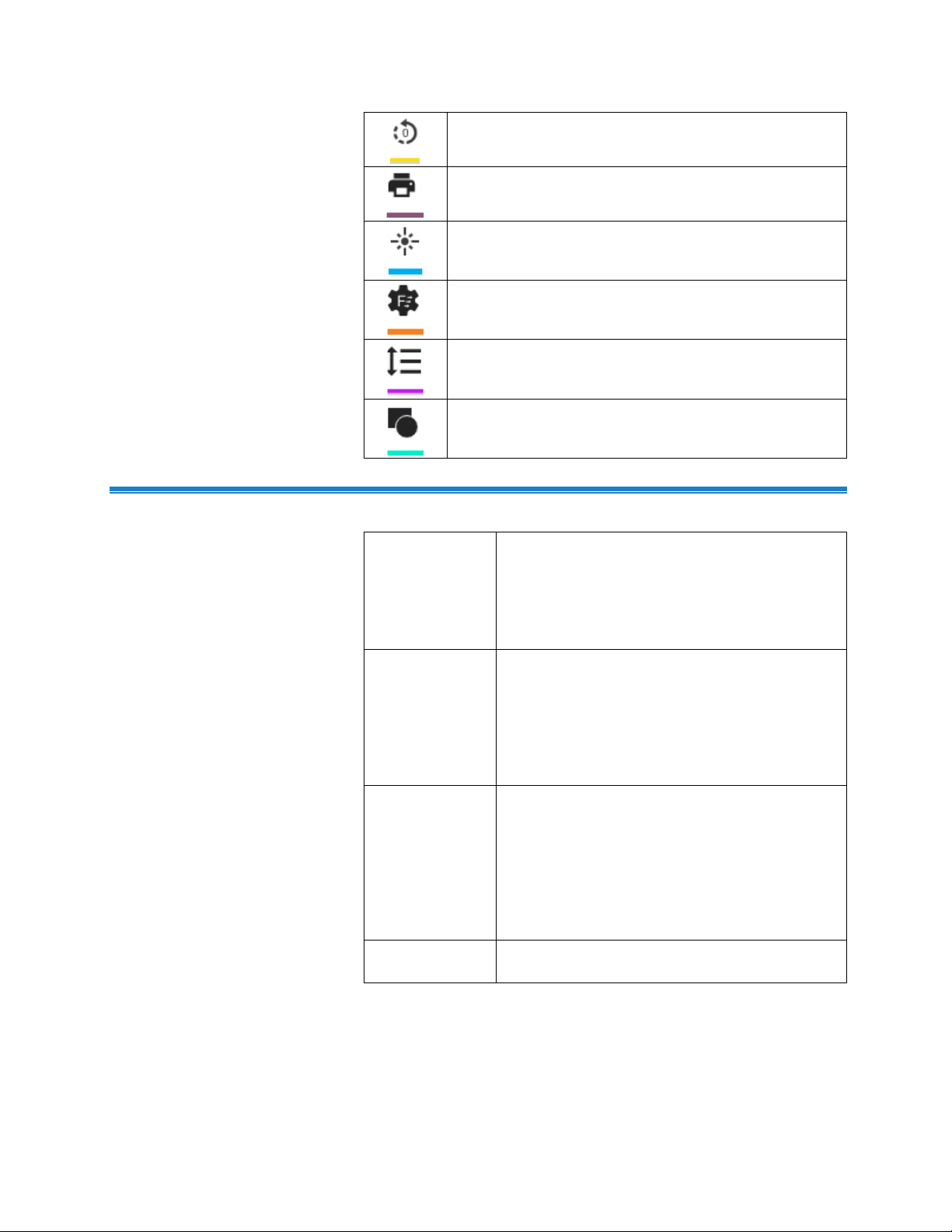

Save a sample

Cancel sample measurement in process

Closes a TestID and automatically increments to the

next available TestID

Display average measurements of current TestID

Close display of average measurements of

current TestID

Progress indicator

Go back to previous screen

Advance to next screen

Add a configuration

Delete

Delete all

Cancel and close Test ID

Restore factory calibration

Firmware update

Samples

Statistics

Manage data

Soft Key Icons

Programmable Soft Key Icons

Operation and Service Manual 15

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 25

Zero differential pressure (9630, 9650, 9650-NB)

Print

Logging profile

Flow setup

Display order

Duct traverse (9650, 9650-NB)

Definitions

Out-of-Range

(Calibration)

An Out-of-Range error during the calibration of

a sensor means the sensor’s offset or

calibration slope adjustment has drifted outside

of the TSI® recommended specification for

continued use. Sensor should be replaced or

sent to TSI® for recalibration.

Test Duration

The time over which the data will be logged

while in Continuous Save mode. The test

duration can be set from 0 seconds 0 hours and

0 minutes to 99 hours: 59 minutes: 59 seconds.

If set to 0 seconds, 0 hours, 0 seconds, the

meter will not stop logging in continuous save

mode until the user presses the enter key.

Sample

Duration /

Time Constant

The sample duration / time constant is the time

period where data is collected and averaged to

produce a single value. For example, if the

sample duration / time constant is set to

5 seconds, each 1 second sample will be

averaged over the 5 seconds in a single value.

The sample interval / time constant can be set

to 1, 5, 10, 20, 30, 60 or 90 seconds.

Sample Interval

The frequency that the meter will log data while

in Continuous Save mode.

Find Quality Products Online at: sales@GlobalTestSupply.com

16 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 26

A language selection list is

displayed the first time the

meter is powered on.

Language Sele c t i o n

Dashboard

Dashboard

This is the main page for viewing live readings and logging data.

Press the any time to return to the Dashboard (Home) page.

If ˅ or ˄ is displayed, press the Up or Down button on the keypad to

view additional measurements.

To change the dashboard to display more measurements in a list

view, press the left or right navigation button on the keypad.

Operation and Service Manual 17

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 27

NOT ICE

Measurements will only appear in the Dashboard page once they

have been configured as visible in the Display Order page.

The Dashboard offers a feature

called Programmable Soft Keys.

Programmable Soft Keys allows

you to create shortcuts to other

areas of interest in the meter.

Press and hold any of the top

3 keys (soft keys) for 3 seconds

to configure.

Programmable Soft Keys can be

configured to reach the following

screens or features with one

button press:

• Zero Pressure (9630,9650,

9650-NB only)

• Print

• Logging Profile

• Flow Setup

• Display Order

• Duct Traverse (9650 and

9650-NB)

• Samples

• Statistics

• Manage Data

Log Mode

Battery or AC Adapter

Current Test ID

Number of Samples

Air Density Setting

Measurements

Close Test ID

Display Average

of current test ID

Assign P r o g r a m m a b l e S o f t Keys

Find Quality Products Online at: sales@GlobalTestSupply.com

18 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 28

Main Menu

Press the button to bring up

the main menu.

NOT ICE

The Main Menu items

displayed are dependent on

the meter model and connected

probe. Zero Pressure will be

displayed on Models 9630,

9650 and 9650-NB. Zero CO

will be displayed if the 982

probe is connected to any

instrument model.

Zero Press ure

Select Zero Pressure from the Main Menu to zero the pressure

measurement.

Press to Cancel. When zeroing is complete, press or

to Save.

Zero Pressure applies to Models 9630, 9650, and 9650-NB.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Operation and Service Manual 19

Page 29

Settings

Select Settings from the

Main Menu, to view the Settings

page options. Refer to Chapter 4,

Settings for detailed information

about the device setting options.

Select Flow Setup to define duct

sizes and choose a duct shape.

Flow Setup is also used to set up

pressure K-factors on Models 9630

and 9650 or to select air cones

when the 995 probe is connected

to any meter model.

Flow Setup

20 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 30

Workflows

Select Workflows from the

Main Menu, to view the Workflow

options. Refer to Chapter 7,

Workflows for detailed information

about the device setting options.

Duct Traverse and Heat Flow are

only available on the 9650 and

9650-NB.

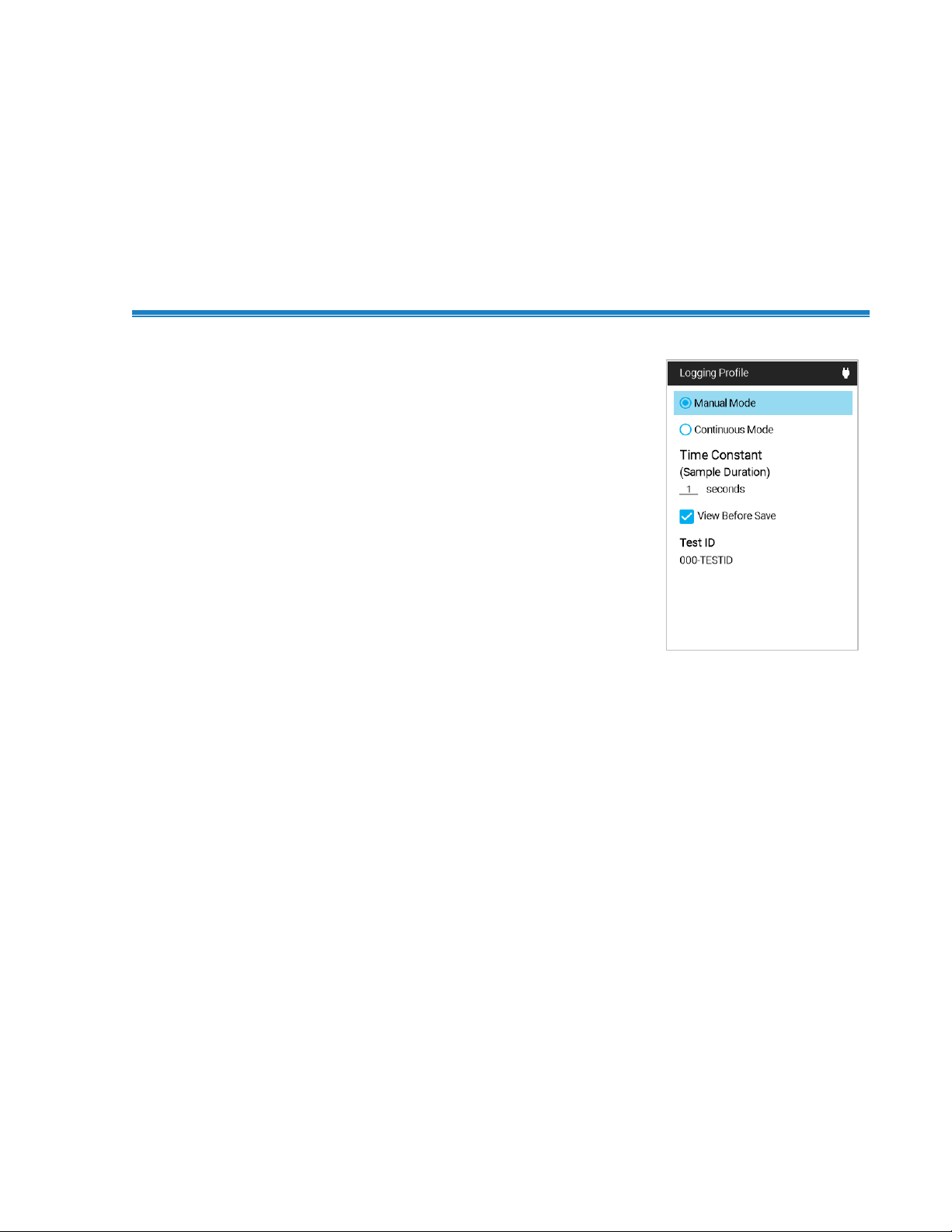

Select Logging Profile to select

between Manual Mode logging and

Continuous Mode logging. See

Chapter 5, Manual Mode

Logging/Continuous Mode Logging

for detailed information.

Logging Profile

Operation and Service Manual 21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 31

Manage Da t a

Select Manage Data to display

logged data stored in the device.

Refer to Chapter 6, Manage Data

for detailed information.

22 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 32

Navigate to the Settings page

by selecting Settings from the

Main Menu.

The Settings page options are:

• Display Order

• Actual/Standard

• Calibration

• General Settings

• Unit Settings

• Date and Time

• Display/Power

• Device Information

The Display Order screen is used to

configure what measurements are

displayed on the Dashboard page,

and the order they are displayed.

The list of measurements includes

the following information:

• A measurement icon and name.

• A toggle icon to enable or

disable the Visibility of the

measurement on the

Dashboard page.

• A positioning icon sets the

order of measurements

shown on the dashboard.

Use the buttons to

navigate the list and to

make adjustments.

C H A P T E R 4

Settings

Display Or der

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

23

Page 33

NOT ICE S

• The order of measurements on the Display Order page is the

order shown on the Dashboard page.

• Only those measurements configured as visible on the

Display Order page are logged to a TESTID.

Select Actual/Standard to

configure the settings used for

velocity and flow measurements.

The Calibration menu lists

measurement parameters that can

be adjusted in the field. The

appropriate detachable probes must

be attached to the VelociCalc® meter

before adjustments can be made.

Actual/Stan dar d

Calibration

Find Quality Products Online at: sales@GlobalTestSupply.com

24 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 34

Calibration Offset Adjustments Applicable Models

Temperature

Barometric Pressure

Relative Humidity

960, 962,

964, 966,

980, 982,

800220

9600, 9630, 9650,

9650-NB

964, 966, 980, 982, 995,

800220

You can apply offset adjustments

to temperature, relative humidity,

and barometric pressure. The

measurement displayed and

logged will be the raw

measurement added to the value

you specify here. Offsets will be

shown on the dashboard if the

value is other than 1. Enter 0 to

return to default.

Correction Factors Applicable Models

Pitot Velocity

Pitot Flow

Probe Flow

9630, 9650, 9650NB

9630, 9650, 9650-NB

960, 962, 964, 966,

995

You can apply correction factors to

pitot velocity, pitot flow and thermal

anemometer and rotating vane air

flows. The measurement displayed

and logged will be the raw

measurement multiplied by the

value you specify here. Correction

factors will be shown on the

dashboard if the value is other than

1. Enter 1.000 to return to default.

IAQ Probe Calibration Applicable Models

Carbon Dioxide (CO2)

Carbon Monoxide (CO)

980, 982

982

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Operation and Service Manual 25

Page 35

A probe calibration collar (included

with the 980 and 982 probes), zero

calibration gas, span calibration

gas, gas regulator and tubing are

required to perform the calibration.

The gas regulator used to control

the flow should be capable of

providing 0.3 L/min. Follow the onscreen instructions to complete the

calibration, the procedure is the

same for both carbon dioxide

(CO2) and carbon monoxide (CO).

The General Settings page is used

to configure the following functions:

• Language is used to select the

desired language shown on the

instrument.

• Number Format is used to

select the preferred decimal

separator.

• Time Constant (Sample

Duration) is used to adjust the

averaging period for all

measurements and to set the

sample duration for logging.

• When Sound Enabled is

active, the meter will sound

when any button is pressed.

General Se t t i n g s

Find Quality Products Online at: sales@GlobalTestSupply.com

26 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 36

NOT ICE

Time Constant is the display averaging period. The display will

update every second; however, the displayed reading will be the

average over the time constant period. For example, if the time

constant is 5 seconds, the display will update every second, but

the displayed reading will be the average of the last 5 seconds.

Unit Setti ngs

The Unit Settings page is used to

configure the desired unit of

measure for each measurement.

The Date and Time page is used to

configure the desired formats for

date and time and to set device

date and time.

Date and Time

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Operation and Service Manual 27

Page 37

The Display/Power page is used

to configure the following functions

• Screen Brightness adjusts the

brightness of the display.

• Automatic Shutdown enables

and disables automatic

shutdown. If enabled, the meter

will shut itself off after

20 minutes of inactivity.

To display general information

about the VelociCalc® Air Velocity

Meter, select Device Information

from the Settings Menu. The

Device Information page lists the

meter model number, serial

number, and many other

characteristics of the device,

including information about the

attached probe.

Display/Power

Device Info r m a t i o n

To update the VelociCalc® meter firmware, press the update firmware

soft key and follow the instructions provided.

28 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 38

To configure the meter to log when

the Enter button is pressed, select

Manual Mode.

View Before Save prompts you to

either SAVE or DISCARD once the

sample is complete.

The Time Constant (Sample

Duration) setting determines

how long all measurements are

averaged for.

C H A P T E R 5

Logging Profile and

Custom TESTID Labels

Manual Mode L o g g i n g

29

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 39

To configure the meter to log

continuously, select

Continuous Mode.

The Time Constant (Sample

Duration) setting determines how

long all measurements are

averaged for.

The Sample Interval sets the

frequency that the meter will log

measurements on the dashboard to

a TESTID.

The Test Duration sets how long the

meter will log data. If this setting is

set to 00:00:00, the meter will log

until the Enter button is pressed.

NOT ICE

On-board memory is capable of

storing data from all available

measurements for more than

30 days when sampling data once

a minute in continuous mode.

Continuous Mo de L o g g i n g

Find Quality Products Online at: sales@GlobalTestSupply.com

Custom i z e T E S T I D L a b e l s in Meter

To change a TESTID label, highlight the TESTID field and

press .

Then highlight the desired TESTID and press .

Use the navigation keys to update the test ID label.

Press the Check key to accept the new label.

Press the Cancel key to discard label changes.

30 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 40

NOT ICE

To scroll through the list of TESTIDs faster, press to page

down and to page up through the list.

Customize T ES T I D L a b e l s u s i n g T e s t I D . c s v

The VelociCalc® Air Velocity Meter also allows TESTID label updates

using Excel® spreadsheet program.

Plug the VelociCalc® meter into a computer using the supplied

USB cable.

Navigate to the “TSI9600_LOG” drive and open the TestIDs.csv file.

Modify labels in column B.

Save the new TestIDs.csv file to the “TSI9600_LOG” drive and close

the file. All TESTID labels that were changed will be updated in the

VelociCalc® meter when the USB cable is disconnected.

Operation and Service Manual 31

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 41

NOT ICE

TESTID labels are limited to 6 characters. Any additional

characters will be discarded.

32 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 42

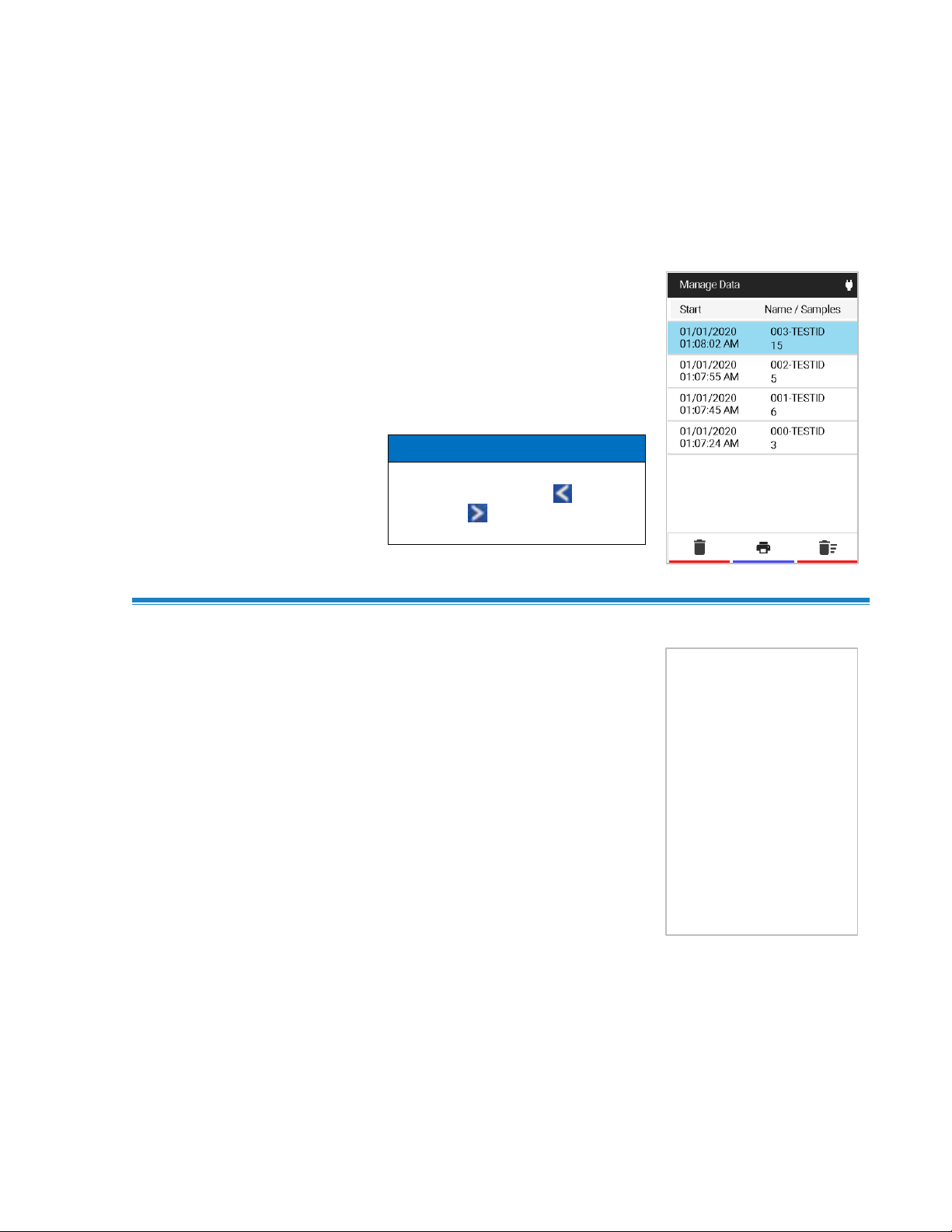

From the Main Menu, select

Manage Data.

The Manage Data page contains all

TESTIDs on the device. You can

select a log file for viewing or

deleting, as well as scroll through a

list of log files.

NOT ICE

To scroll through the list of

TESTIDs faster, press to page

down and to page up through

the list.

To view a log file (TESTID),

navigate to the log file on the

Manage Data list and press the

to open the Statistics page.

C H A P T E R 6

Manage Data

Viewing a L o g F i l e ( T E S T ID)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

33

Page 43

To view Samples in a log file

TESTID, navigate to the desired

measurement in the Statistics

page and press key.

NOT ICE

Deleted log files CANNOT be recovered.

Viewing Sa m p l e s

Delete Log F i l e s

Opening L o g C S V F i l e s on a PC

Select a log file then select the icon to delete it. Next select YES.

Log CSV files can be accessed on the VelociCalc® Series 9600

meters by connecting the meter to a computer using the supplied

USB cable.

Connect the VelociCalc® meter to a PC over the supplied USB cable.

A “please wait” message will appear on the VelociCalc® meter.

After the “please wait” message disappears, a TSI9600_LOG drive

will show up on the computer that looks like this:

Open the TSI9600_LOG drive to view or download TESTID CSV files:

34 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 44

NOT ICE

Displayed workflows are dependent on instrument model and

attached probe. Percent Outside air will be shown if a probe that

measures air temperature or CO2 is connected. Heat Flow will be

shown on the 9650 or 9650-NB if a 964 or 966 probe is attached.

Duct traverse will be shown on the 9650 or 9650-NB and is used

with the differential pressure sensor or a connected probe that

measures air velocity.

After selecting Workflows from the

Main Menu, select % Outside Air

to view the % Outside Air screen.

C H A P T E R 7

Workflows

Workflows step you through the measurement process and assist in

calculating and logging the measurement points.

The following workflows are available:

• Percent Outside Air (%OA) (9600, 9630, 9650, 9650-NB)

• Heat Flow (9650, 9650-NB with 964 or 966 probe)

• Duct Traverse (9650, 9650-NB)

Percent O u t s i d e A i r ( % OA) Calculation Procedure

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

35

Page 45

The Percent Outside Air feature

offers the choice between using

Temperature or CO2 for the Percent

Outside Air study if a probe that

supports either CO2 or Temperature

is plugged in.

Three measurements are necessary

for Percent Outside Air calculations:

Outside Air, Supply Air, and

Return Air.

The measurements may be taken in

any order by using the navigation

keys and . The Percent

Outside Air calculation is displayed

once the final measurement is taken.

IMP O R TANT NO TI CE

The VelociCalc® instrument is intended for indoor use only. Care

should be taken when taking Percent Outdoor Air measurements

so that the instrument is not exposed to rain, sleet, hail, snow, or

other inclement weather conditions as exposure to these elements

will void the factory warranty.

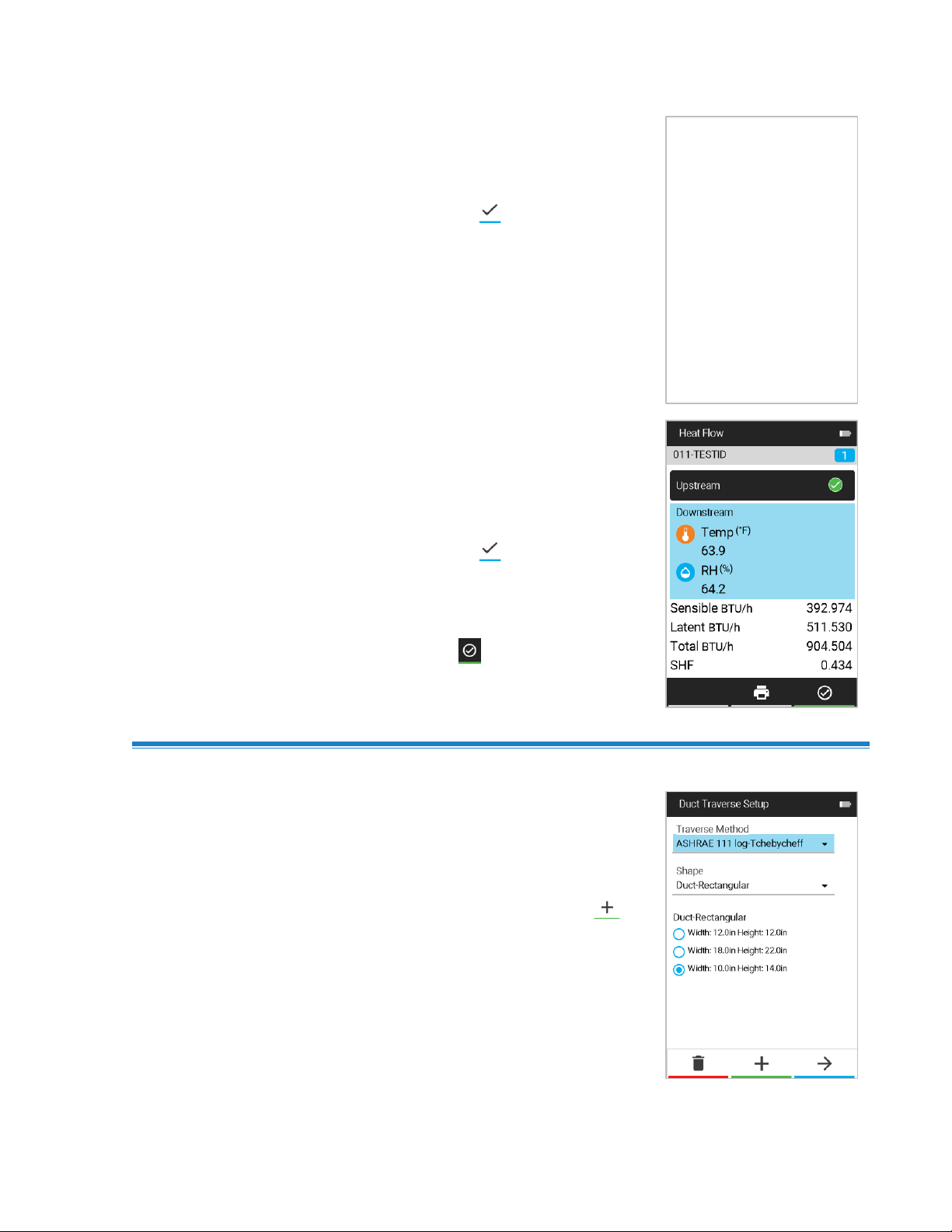

The instrument calculates heat flow

by making temperature, humidity, and

flow measurements upstream and

downstream of the coil in the duct.

The following steps are utilized to

make the heat flow measurement:

• Select Heat Flow under the

workflows menu.

NOT ICE

Heat Flow will only be available

with probes that measure Velocity,

Temperature, and Humidity (964

and 966 probes).

Heat Flow Proce dure

Find Quality Products Online at: sales@GlobalTestSupply.com

36 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 46

• Upstream measurements of Flow,

Temperature, and Humidity are

displayed. Press to capture

these upstream measurements.

o Press to accept the

upstream readings

o Press to retake

upstream readings

• After upstream measurement has

been accepted, place probe

downstream of the coil.

o Press to capture these

upstream measurements.

o Press to accept the

upstream readings

o Press to retake

upstream readings

• Press to save and close the

test ID.

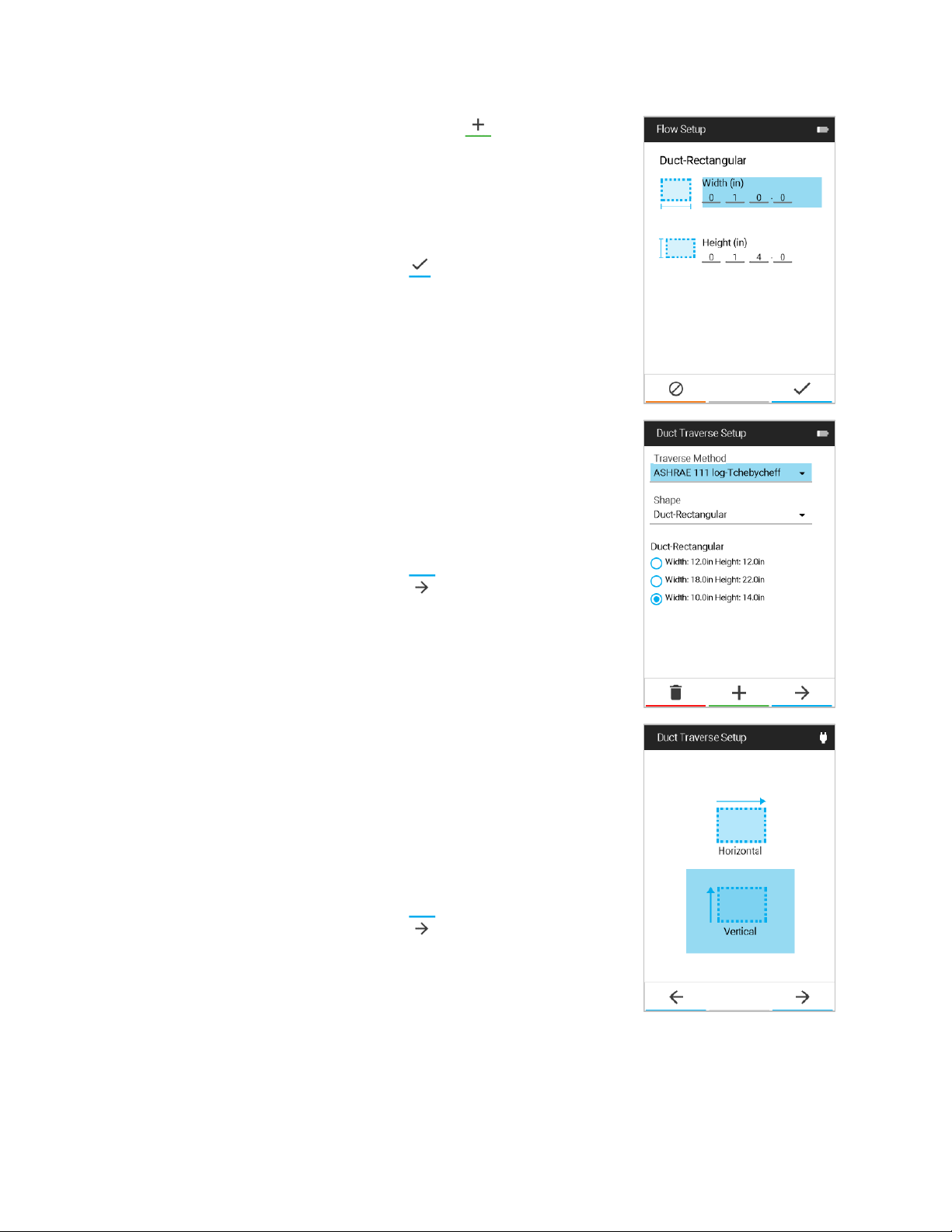

After connecting any TA Probe or

Pitot tube and selecting Workflows

from the Main Menu, select Duct

Traverse to view the Duct

Traverse Setup screen.

To add a new duct size press .

Duct Trave r s e P r o c e d u r e (9650, 9650 - NB)

Operation and Service Manual 37

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 47

After pressing to add a new

duct size, you are brought to the

Flow Setup page. To change the

dimensions, use the arrow keys to

navigate between Width and Height

then press to begin editing the

numbers by using the arrow keys.

Press to save the new duct size.

To create a circular duct, select

Duct-Circular on the Duct Traverse

Setup screen before adding a

duct size.

Creating a new duct size will bring

you back to the Duct Traverse

Setup screen. Select the desired

Traverse Method and Duct Shape

with the drop-down menus and

select the desired duct size using

the navigation keys.

Press to move onto the

next screen.

After choosing the traverse method

and duct shape and size, you will

select a traverse orientation

(rectangular only, screen is skipped

for circular ducts). For traverse

holes on the side of a rectangular

duct, select horizontal traverse. For

traverse holes on the bottom of a

rectangular duct, select vertical.

Press to move on.

Find Quality Products Online at: sales@GlobalTestSupply.com

38 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 48

After selecting the traverse

orientation (or after selecting

a circular duct), the Insertion

Depths screen will be shown.

Note these insertion depths

before proceeding.

Press to proceed to the

Duct Traverse working screen.

Insert your probe into the first

position indicated by the blue circle

(traverse starts in the bottom left of

the grid). If you prefer to start at a

different point, use the navigation

arrow keys to navigate to a

different spot in the grid first. To

take a velocity measurement,

press . The position will

automatically move up to the next

measurement point after taking a

measurement. Note that the

Previous measurement and the

Average of all measurements

taken will display across the

bottom. Pressing will display

flow measurements and to

display velocity measurements.

After taking a velocity

measurement at every grid

location, the traverse is complete

and you will be prompted to press

to accept the traverse. Before

accepting the traverse, you may go

back and retake any measurement

by navigating to that point with the

navigation keys. When you are

ready, press to complete and

accept the Duct Traverse. The

traverse will save to the TESTID

noted in the top left.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Operation and Service Manual 39

Page 49

C A U TI ON

DO NOT use strong solvents like ammonia to avoid damaging the

meter’s display.

DO NOT use paper-based cloths like paper towels to avoid

scratching surfaces.

DO NOT use disinfectants that contain phenol.

DO NOT clean with strong aromatic, chlorinated, ketone, ether, or

Esther solvents, sharp tools or abrasives.

C H A P T E R 8

Maintenance

Cleaning / D i s i n f e c t i n g

• Ensure the VelociCalc® meter is turned off and not plugged into

the AC/DC power supply.

• DO NOT spray directly onto the product.

• DO NOT get liquids inside the unit.

• For cleaning, wet a soft lint-free or microfiber cloth with a mild

soapy solution then wipe the screen and meter case in a gentle

motion to remove dust, oil, or fingerprint smudges.

• For disinfecting, the following is a recommended list of

disinfectant solutions:

o Household bleach solution (1/3 cup or 79 ml of bleach per

one (1) gallon or 3.8 L of water)

o Isopropyl alcohol (≤ 70% alcohol)

o 6% Hydrogen peroxide (H₂O₂)

• Hot water with soap can be used to remove sticky substances

when necessary.

• Wipe any moisture excess with a dry lint-free or microfiber cloth

to finish cleaning before turning the meter back on.

Find Quality Products Online at: sales@GlobalTestSupply.com

41

www.GlobalTestSupply.com

Page 50

Bi-Annual Ma i n t e n a n c e C h e cks

• Make sure there are no cracks on the meter case. Cracks can

create inconsistencies with how the electronics are supported

inside the case, which can lead to damages.

• Inspect the power supply and cable to make sure they have not

degraded. Replace if you find any cracks in the power supply or

cable as it might cause shorting.

42 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 51

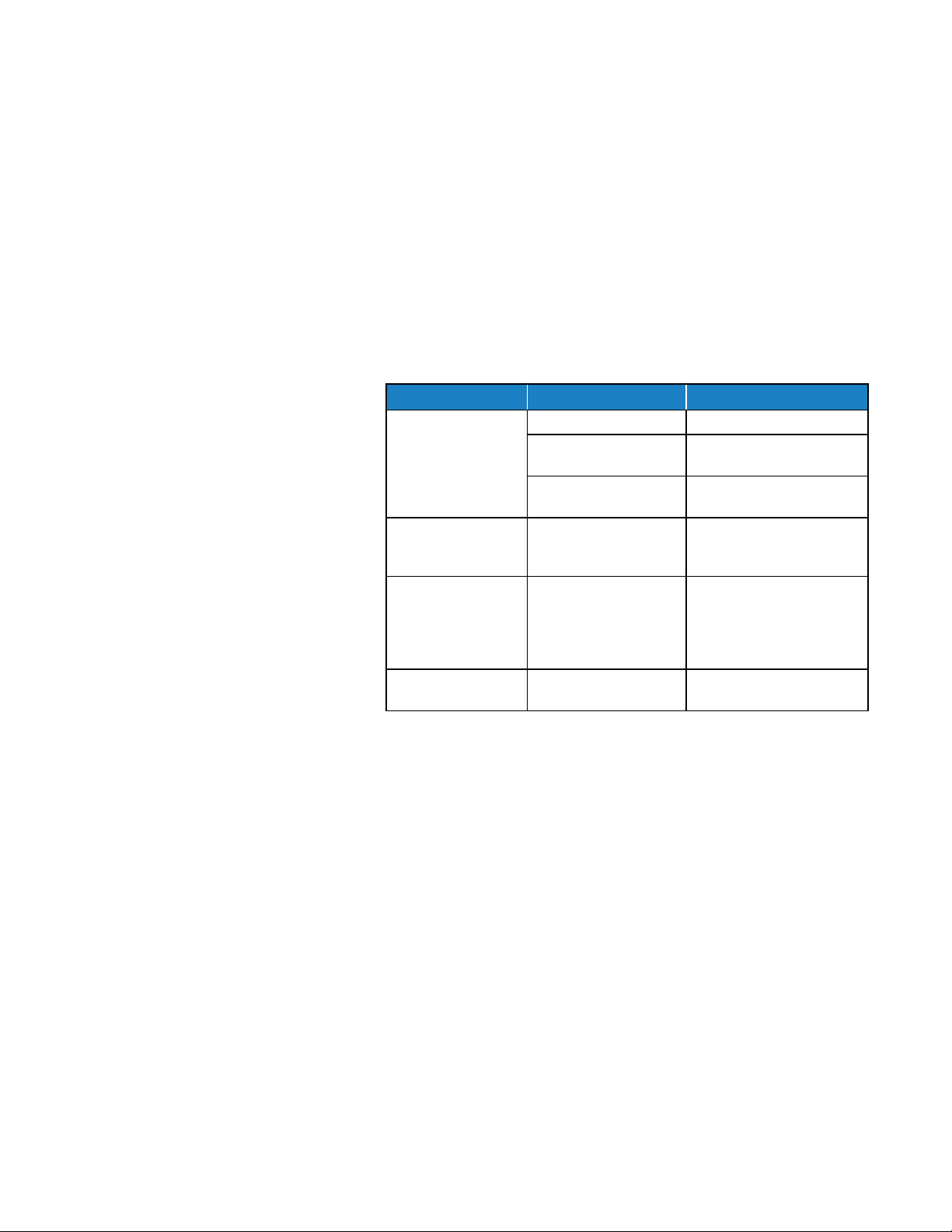

CH A P T E R 9

Symptom

Possible Causes

Corrective Action

No Display

Unit not turned on

Switch unit on.

Low or dead batteries

Replace batteries or plug

in AC/DC power supply.

Dirty battery contacts

Clean the battery

contacts.

Velocity reading

fluctuates unstable

Fluctuating flow

Reposition probe in less

turbulent flow or use

longer time constant.

Instrument shows a

memory full

message and

cannot log

more data

Memory is full

Download data if desired

then DELETE ALL memory.

Probe Error

message appears

Fault in probe

Factory service required

on probe.

Troubleshooting

Table 1 lists the symptoms, possible causes, and recommended

solutions for common problems encountered with the VelociCalc® Air

Velocity Meter. If your symptom is not listed, or if none of the

solutions solves your problem, please contact

Table 1. Troubleshooting the VelociCalc® Air Velocity Meter

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

43

Page 52

960 Thermoanemometer Straight Probe Velocity

and Temperature

Range: .....................

0 to 9999 ft/min (0 to 50 m/s), 0 to 200°F

(-18 to 93°C)

Accuracy: .................

±3% of reading or ±3 ft/min (±0.015 m/s),

whichever is greater1&2, ±0.5°F (±0.3°C)5

Resolution: ..............

1 ft/min (0.01 m/s), 0.1°F (0.1°C)

962 Thermoanemometer Articulating Probe Velocity

and Temperature

Range: .....................

0 to 9999 ft/min (0 to 50 m/s), 0 to 200°F

(-18 to 93°C)

Accuracy: .................

±3% of reading or ±3 ft/min (±0.015 m/s),

whichever is greater

1&2

, ±0.5°F (±0.3°C)5

Resolution: ..............

1 ft/min (0.01 m/s), 0.1°F (0.1°C)

964 Thermoanemometer Straight Probe Velocity, Temperature,

Humidity, Wet Bulb, and Dew Point

Range: .....................

0 to 9999 ft/min (0 to 50 m/s), 14 to 140°F

(-10 to 60°C), 5 to 95% RH

Accuracy: .................

±3% of reading or ±3 ft/min (±0.015 m/s),

whichever is greater

1&2

, ±0.5°F (±0.3°C)5,

±3% RH6

Resolution: ..............

1 ft/min (0.01 m/s), 0.1°F (0.1°C), 0.1% RH

966 Thermoanemometer Articulating Probe Velocity,

Temperature, Humidity, Wet Bulb, and Dew Point

Range: .....................

0 to 9999 ft/min (0 to 50 m/s), 14 to 140°F

(-10 to 60°C), 5 to 95% RH

Accuracy: .................

±3% of reading or ±3 ft/min (±0.015 m/s),

whichever is greater

1&2

, ±0.5°F (±0.3°C)5,

±3% RH6

Resolution: ..............

1 ft/min (0.01 m/s), 0.1°F (0.1°C), 0.1% RH

960 and 964 Thermoanemometer Probe Dimensions

Probe Length: ..................

40 in. (101.6 cm)

Probe Diameter of Tip: ....

0.28 in. (7.0 mm)

Probe Diameter of Base: .

0.51 in. (13.0 mm)

A P P E N D I X A

Specifications

Specifications are subject to change without notice.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

47

Page 53

962 and 966 Thermoanemometer Probe Dimensions (962, 966)

Probe Length: ...............................

40 in. (101.6 cm)

Probe Diameter of Tip: .................

0.28 in. (7.0 mm)

Probe Diameter of Base: ..............

0.51 in. (13.0 mm)

Articulating Section Length: ..........

6.0 in. (15.24 cm)

Diameter of Articulating Knuckle: .

0.38 in. (9.5 mm)

Thermoanemometer Response Time

Velocity: ...................

200 msec

Temperature: ...........

2 minutes (to 66% of final value)

Humidity: ..................

<1 minute (to 66% of final value)

995 Rotating Vane 4 in. (100mm) Probe Velocity and

Temperature

Range: .....................

50 to 6000 ft/min (0.25 to 30 m/s),

32 to 140°F (0 to 60°C)

Accuracy: .................

±1% + 4 ft/min (±0.02 m/s), ±2.0°F (±1.0°C)

Resolution: ...............

1 ft/min (0.01 m/s), 0.1°F (0.1°C)

980 IAQ Probe CO2, Temperature and Humidity

Range: .....................

0 to 5000 ppm CO2, 5 to 95% RH,

14 to 140°F (-10 to 60°C)

Accuracy: .................

±3% of reading or ±50 ppm CO2, whichever

is greater9, ±3% RH6, ±1.0°F (±0.5°C)5

Resolution: ...............

1 ppm CO2, 0.1% RH, 0.1°F (0.1°C)

982 IAQ Probe CO, CO2, Temperature and Humidity

Range: .....................

0 to 500 ppm CO, 0 to 5000 ppm CO2,

5 to 95% RH, 14 to 140°F (-10 to 60°C)

Accuracy: .................

±3% of reading or ±3 ppm CO, whichever is

greater8, ±3% of reading or ±50 ppm CO2,

whichever is greater9, ±3% RH6, ±1.0°F

(±0.5°C)5

Resolution: ...............

0.1 ppm CO, 1 ppm CO2, 0.1% RH, 0.1°F

(0.1°C)

980 and 982 Probe Response Time

Carbon Dioxide: .......

20 seconds to 90% of final value.

Carbon Monoxide: ...

<60 seconds to 90% of final value.

Temperature: ...........

30 seconds (90% of final value, air velocity

at 400 ft/min [2 m/s])

Relative Humidity: ....

20 seconds (for 63% of final value)

Find Quality Products Online at: sales@GlobalTestSupply.com

48 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Page 54

792 and 794 Thermocouple Probes Temperature

Range: .....................

-40 to 1200°F (-40 to 650°C)

Accuracy

5

:

................

±0.1% of reading +2°F

(±0.056% of reading +1.1°C)

Resolution: ..............

0.1°F (0.1°C)

Pitot Tubes (9630, 9650, 9650-NB)

Range3: ...................

250 to 15500 ft/min (1.27 to 78.7 m/s)

Accuracy4: ..............

±1.5% at 2000 ft/min (10.16 m/s)

Resolution: .............

1 ft/min (0.01 m/s)

Duct Size

Range: ....................

1 to 500 inches in increments of 0.1 in.

(2.5 to 1270 cm in increments of 0.1 cm)

Volumetric Flow Rate

Range: ....................

Actual range is a function of actual velocity,

pressure, duct size, and K-factor

Heat Flow (964 or 966 Probe with 9650, 9650-NB)

Range: ....................

Function of velocity, temperature, humidity,

and barometric pressure

Measurements

Available: ................

Sensible heat flow, latent heat flow, total

heat flow and sensible heat factor

Units Measured: .....

BTU/hr, kW

Static/Differential Pressure (9630, 9650, 9650-NB)

Range7: ...................

-15 to +15 in. H2O

(-28.0 to +28.0 mm Hg, -3735 to +3735 Pa)

Accuracy: .................

±1% of reading ±0.005 in. H2O

(±1 Pa, ±0.01 mm Hg)

Resolution: ..............

0.001 in. H2O (0.1 Pa, 0.01 mm Hg)

Barometric Pressure

Range: ............................

20.36 to 36.648 in. Hg (517.15 to

930.87 mm Hg)

Accuracy: ........................

±2% of reading

Instrument Temperature Range

Operating (Electronics): .

40 to 113°F (5 to 45°C)

Operating (Probe): ..........

14 to 140°F (-10 to 60°C)

Storage: ..........................

-4 to 140°F (-20 to 60°C)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Operation and Service Manual 49

Page 55

Instrument Operating Conditions

Altitude up to 4000 meters (only limited when plugged into the

AC/DC adapter)

Relative humidity up to 80% RH, non-condensing

Pollution Degree II

Overvoltage Category II

Data Storage Capabilities

Range: ............................

162,200 samples and 200 TESTIDs

(one sample can contain multiple

measurement types)

Logging Interval

Intervals: .........................

1 second to 1 hour

Time Constant

Intervals: .........................

User selectable

External Meter Dimensions

3.2 in. 9.5 in. 1.6 in. (8.1 cm 24.1 cm 4.1 cm)

Meter Weight

Weight with Batteries: .....

0.9 lbs (0.41kg)

Power Requirements

Four (4) AA-size batteries (included) or AC/DC power supply

P/N 6013125

Input: ...............................

100 to 240 VAC, 50 to 60 Hz, 1.0A

Output: ............................

12 VDC, 3.0A

1

Temperature compensated over an air temperature range of 40 to 150°F

(5 to 65°C).

2

The accuracy statement of ±3.0% of reading or ±3 ft/min (±0.015 m/s), whichever is

greater, begins at 30 ft/min through 9999 ft/min (0.15 m/s through 50 m/s).

3

Pressure velocity measurements are not recommended below 1000 ft/min (5 m/s) and

are best suited to velocities over 2000 ft/min (10.00 m/s). Range can vary depending

on barometric pressure.

4

Accuracy is a function of converting pressure to velocity. Conversion accuracy

improves when actual pressure values increase.

5

Accuracy with instrument case at 77°F (25°C), add uncertainty of 0.05°F/°F

(0.03°C/°C) for change in instrument temperature.

6

Accuracy with probe at 77°F (25°C). Add uncertainty of 0.1% RH/°F (0.2% RH/°C) for

change in probe temperature. Includes 1% hysteresis.

7

Overpressure range = 190 in. H2O (7 psi, 360 mmHg, 48 kPa).

8

At 77°F (25°C). Add uncertainty of ±0.2%/°F (0.36%/°C) for change in temperature.

9

At calibration temperature. Add uncertainty of ±0.28%/°F (0.5%/°C) for change

in temperature.

Find Quality Products Online at: sales@GlobalTestSupply.com

50 VelociCalc®/VeloCalc® Pro Air Velocity Meter 9600 Series

www.GlobalTestSupply.com

Loading...

Loading...