Page 1

OWNER’S MANUAL

Velometer® Jr.

®

A TSI Company

®

Page 2

TABLE OF CONTENTS

Features 2

Zero Adjustment 2

Range Change 2

®

Alnor Type 8125 AirGard

Step by Step Calibration Instructions 4

Maintenance 5

Service Information 5

Service and Repair 5

Instructions for Return 6

Damaged in Transit 6

Velometer Jr. 3

1

Page 3

FEATURES

The Alnor Velometer Jr. is a direct reading air velocity measuring

instrument.

This precision instrument is ruggedly built and will serve for

many years if given reasonable care.

You can use this instrument to measure air velocities from grilles

and registers and to locate drafts. Balancing of a domestic heating

installation is made simple when using the Alnor Velometer Jr.

Hold the instrument so the air blows directly into the calibrated

orifice and read the velocity as indicated by the pointer.

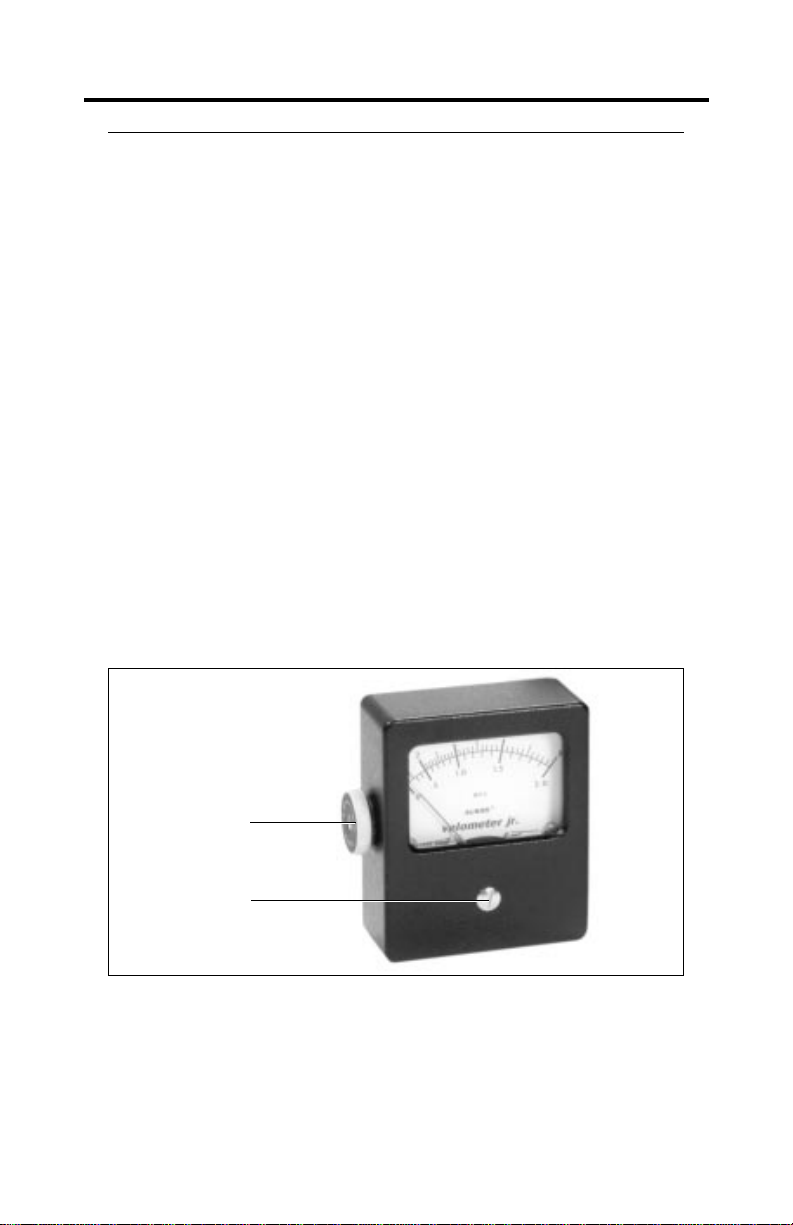

Zero Adjustment

Hold the palm of your hands over the two openings in the sides

of the Velometer Jr. and note whether the pointer indicates Zero.

If not, turn the Zero Adjuster screw on the front of the case

slightly until the pointer does read zero. (See fig. 1)

Orifice Fitting

Zero Adjuster

Figure 1

Range Change

Change range by turning orifice fitting on double range instruments.

(Small orifice for high range—large orifice for low range.) (See fig.1)

2

Page 4

ALNOR TYPE 8125 “AirGard”

VELOMETER JR.

The Alnor AirGard is designed to indicate, by correlation, the

average velocity at the face of a ventilation hood. To ensure that

the average face velocity indicated by the AirGard is correct, the

AirGard should be mounted at a location where it can be verified

with a properly calibrated thermo-anemometer. Also, the AirGard

should be mounted at a location where local drafts are very low

and the curved probe will not interfere with the work area.

The calibration procedure follows four basic steps:

1. Make sure the AirGard attachments which were shipped

with the instrument are available—the curved probe and

flexible tube.

2. Zero the AirGard.

3. Measure the average face velocity of the hood using a

properly calibrated thermo-anemometer.

4. Find the right location to mount the AirGard by moving it

along the face of the hood until the meter indicates the

same value as measured with the thermo-anemometer.

Figure 2

3

Page 5

Step By Step Calibration Instructions

1. Connect the curved probe to the AirGard using the flexible

tube.

2. Cover the inlet orifice on the left hand side of the AirGard

(the operator’s finger can be used for this purpose).

3. With the inlet covered, the AirGard should indicate zero

fpm. If it does not, adjust the pointer to zero using the

screw on the front of the case.

4. Using a properly calibrated thermo-anemometer, determine

the velocity through the face of the hood by taking a

detailed velocity traverse. Divide the face area of the hood

into equal increments. A six inch grid is recommended

for an accurate traverse.

5. Position the AirGard at a location for mounting where local

drafts are very low and the curved probe will not interfere

with the work area.

6. Attach the probe to the hood so the open end is inside the

hood and faces downstream.

7. Verify that the AirGard reads the same velocity measured at

the face of the hood in step 4. If the reading by the AirGard

does not match the reading measured in step 4, move the

AirGard along the face of the hood until it indicates the

same value as measured with the thermo-anemometer.

8. When the AirGard’s indication matches the value measured

with the thermo-anemometer, mount it in place using the

mounting screws and the curved probe using the fitting

provided.

4

Page 6

MAINTENANCE

Handle the Velometer Jr. as you would a watch. It is composed of

precision parts and is carefully balanced and calibrated.

If due to accident, the Velometer Jr. requires repair, return to

manufacturer for factory quality service. Other instrument

laboratories may not have proper calibrating equipment.

A partially plugged orifice will result in a low reading and,

therefore, we suggest occasional cleaning of the orifice. A

toothpick is a good tool for this purpose. Do not use any wire or

other hard tool for this purpose.

SERVICE INFORMATION

Service and Repair

Please return your Product Registration Card immediately.

This allows us send you service reminders, special offers, and

important information about your product.

Before sending your instrument for calibration or repair, you

should call Alnor Customer Service. The Service Department

will provide you with the cost of service or calibration, Return

Material Authorization (RMA) number, and shipping instructions.

Please have the following information available when you call:

Owner’s Name, address, and phone number

Billing address, if different and applicable

Instrument Name or Model

Serial Number

Date of Purchase

Where Purchased

Alnor recommends that you keep a ‘calibration log’ and keep all

records of service on your instrument.

5

Page 7

Instructions for Return

Send the instrument prepaid. Securely package your instrument

in a strong container surrounded by at least two inches (5 cm)

of suitable shock-absorbing material. Include the Purchase Order

showing instrument model number, cost of service and/or

calibration, and the RMA number. Mark the outside of the

shipping container with the RMA number. This will expedite

processing of your instrument when we receive it.

Please note that instruments received improperly marked or

without an accompanying Purchase Order may be returned at

your expense. See back cover for factory addresses.

Damaged in Transit

All orders are carefully packed for shipment. On receipt, if

the shipping container appears to have been damaged during

shipment, the instrument should be thoroughly inspected. The

delivering carrier’s papers should be signed noting the apparent

damage. DO NOT DISCARD THE BOX.

If the instrument itself has been damaged, a claim should be

promptly filed against the carrier by the customer. The selling

agent will assist the customer by supplying all pertinent shipping

information; however, the claim must be filed by the insured. If

the instrument is damaged beyond use, a new order should be

placed with Alnor while awaiting reimbursement from the carrier

for the damaged instrument.

Call Alnor directly for assistance if necessary.

6

Page 8

WARRANTY

Alnor Instrument Company (Alnor) warrants this product to be free of

defects in material and workmanship for a period of two years from the

date of original purchase. If the product should become defective during

the warranty period, Alnor will repair it or elect to replace it free of charge

under the following conditions:

1.Product is returned postpaid per the instructions for return, located in the

owner’s manual.

2.Owner submits proof of original date of purchase.

3.Alnor will inspect product for defects in material and workmanship.

Alnor’s decision as to existence of defect, and in the case of defect, to

repair or replace will be final.

THIS WARRANTY IS EXCLUSIVE. THERE ARE NO OTHER WARRANTIES

EITHER EXPRESSED OR IMPLIED. SPECIFICALLY AND WITHOUT

LIMITATION, THERE IS NO WARRANTY, EXPRESSED OR IMPLIED, OF

MERCHANTABILITY OR FITNESS FOR PARTICULAR PURPOSE.

This warranty is void if product is misused, used contrary to procedures set

forth in the owner’s manual, or if product is serviced by anyone other than

Alnor’s authorized service. This warranty does not cover consumables such

as light bulbs, paper, batteries, etc.

Alnor’s liability for this product is limited to the above stated warranty and

shall not in any event exceed the cost of the product. In no event will Alnor

be liable for any direct or consequential damages, including but not limited

to lost profits, loss of use, inaccuracies, loss of data, dismantling or

reinstallation.

ALNOR INSTRUMENT COMPANY

7555 North Linder Avenue

Skokie, Illinois 60077 USA

Toll-Free (800) 424-7427 June 1998

Telephone (847) 677-3500 Printed in USA

Fax (847) 677-3539 Part No. 116-049-007 Rev.6

www.alnor.com © Copyright 1998 Alnor Instrument Company

7

Loading...

Loading...