Page 1

POSITIVE AND NEGATIVE

DUCT ACCREDITATION

(PANDA) SYSTEM

AIRFLOW™ INSTRUMENTS

MODEL PAN300 SERIES

OPERATION AND SERVICE MANUAL

P/N 6005447, REV B

MARCH 2021

Page 2

Page 3

Copyright

TSI Incorporated / 2011-2021 / All rights reserved.

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA

Fax No.

(651) 490-3824

LIMITATION OF WARRANTY AND LIABILITY (effective February 2015)

(For country-specific terms and conditions outside of the USA, please visit www.tsi.com.)

Seller warrants the goods, excluding software, sold hereunder, under normal use and

service as described in the operator's manual, to be free from defects in workmanship

and material for 24 months, or if less, the length of time specified in the operator's

manual, from the date of shipment to the customer. This warranty period is inclusive of

any statutory warranty. This limited warranty is subject to the following exclusions and

exceptions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other

components when indicated in specifications, are warranted for 90 days from the date

of shipment;

b. Pumps are warranted for hours of operation as set forth in product or operator’s

manuals;

c. Parts repaired or replaced as a result of repair services are warranted to be free from

defects in workmanship and material, under normal use, for 90 days from the date of

shipment;

d. Seller does not provide any warranty on finished goods manufactured by others or on

any fuses, batteries or other consumable materials. Only the original manufacturer's

warranty applies;

e. This warranty does not cover calibration requirements, and seller warrants only that

the instrument or product is properly calibrated at the time of its manufacture.

Instruments returned for calibration are not covered by this warranty;

f. This warranty is VOID if the instrument is opened by anyone other than a factory

authorized service center with the one exception where requirements set forth in the

manual allow an operator to replace consumables or perform recommended

cleaning;

g. This warranty is VOID if the product has been misused, neglected, subjected to

accidental or intentional damage, or is not properly installed, maintained, or cleaned

according to the requirements of the manual. Unless specifically authorized in a

separate writing by Seller, Seller makes no warranty with respect to, and shall have no

liability in connection with, goods which are incorporated into other products or

equipment, or which are modified by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS

stated herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE. WITH RESPECT TO

SELLER’S BREACH OF THE IMPLIED WARRANTY AGAINST INFRINGEMENT,

SAID WARRANTY IS LIMITED TO CLAIMS OF DIRECT INFRINGEMENT AND

EXCLUDES CLAIMS OF CONTRIBUTORY OR INDUCED INFRINGEMENTS.

BUYER’S EXCLUSIVE REMEDY SHALL BE THE RETURN OF THE PURCHASE

PRICE DISCOUNTED FOR REASONABLE WEAR AND TEAR OR AT SELLER’S

OPTION REPLACEMENT OF THE GOODS WITH NON-INFRINGING GOODS.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER

OR BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES,

INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS

BASED ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR

OTHERWISE) SHALL BE THE RETURN OF GOODS TO SELLER AND THE

REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION OF SELLER, THE

REPAIR OR REPLACEMENT OF THE GOODS. IN THE CASE OF SOFTWARE,

Page 4

SELLER WILL REPAIR OR REPLACE DEFECTIVE SOFTWARE OR IF UNABLE TO

DO SO, WILL REFUND THE PURCHASE PRICE OF THE SOFTWARE. IN NO

EVENT SHALL SELLER BE LIABLE FOR LOST PROFITS, BUSINESS

INTERRUPTION, OR ANY SPECIAL, INDIRECT, CONSEQUENTIAL OR

INCIDENTAL DAMAGES. SELLER SHALL NOT BE RESPONSIBLE FOR

INSTALLATION, DISMANTLING OR REINSTALLATION COSTS OR CHARGES. No

Action, regardless of form, may be brought against Seller more than 12 months after a

cause of action has accrued. The goods returned under warranty to Seller's factory

shall be at Buyer's risk of loss, and will be returned, if at all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY

AND LIABILITY, which contains the complete and exclusive limited warranty of Seller.

This LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or

its terms waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are

to our customers, our service policy is designed to give prompt attention to any

problems. If any malfunction is discovered, please contact your nearest sales office or

representative, or call TSI's Customer Service department at (800) 680-1220 (USA) or

(001 651) 490-2860 (International) or visit www.tsi.com.

Trademarks

TSI and TSI logo are registered trademarks of TSI Incorporated in the United States

and may be protected under other country’s trademark registrations.

Page 5

iii

CONTENTS

CHAPTER 1 UNPACKING AND PARTS IDENTIFICATION ............. 1

CHAPTER 2 PREPARING PAN300 SYSTEM FOR

AIR DUCT LEAK TESTING ................................................................ 5

CHAPTER 3 PERFORMING A DUCT LEAKAGE TEST ................ 11

Measuring Duct Static Pressure ................................................... 11

Measuring Duct Leakage Flow ..................................................... 12

Turning on the PAN300 Duct Leakage Tester.............................. 12

Using Leakage Test Application in the Model TA465-P ............... 13

Troubleshooting Guide ................................................................. 16

APPENDIX A SPECIFICATIONS ..................................................... 17

APPENDIX B LEAKAGE TESTING STANDARDS HIGHLIGHTS ... 21

Standards Supported .................................................................... 21

EU Standards ............................................................................... 22

US Standards ............................................................................... 25

APPENDIX C TYPICAL SETUP....................................................... 29

APPENDIX D PROCEDURE FOR USING SMOKE PELLETS

IN LEAKAGE TESTERS ................................................................... 31

Page 6

iv

(This page intentionally left blank)

Page 7

1

Chapter 1

Unpacking and Parts Identification

Carefully unpack the PANDA system and instrument cases from the

shipping container. Check the individual parts against the list of

components below. If anything is missing or damaged, notify TSI®

Incorporated (TSI®) immediately.

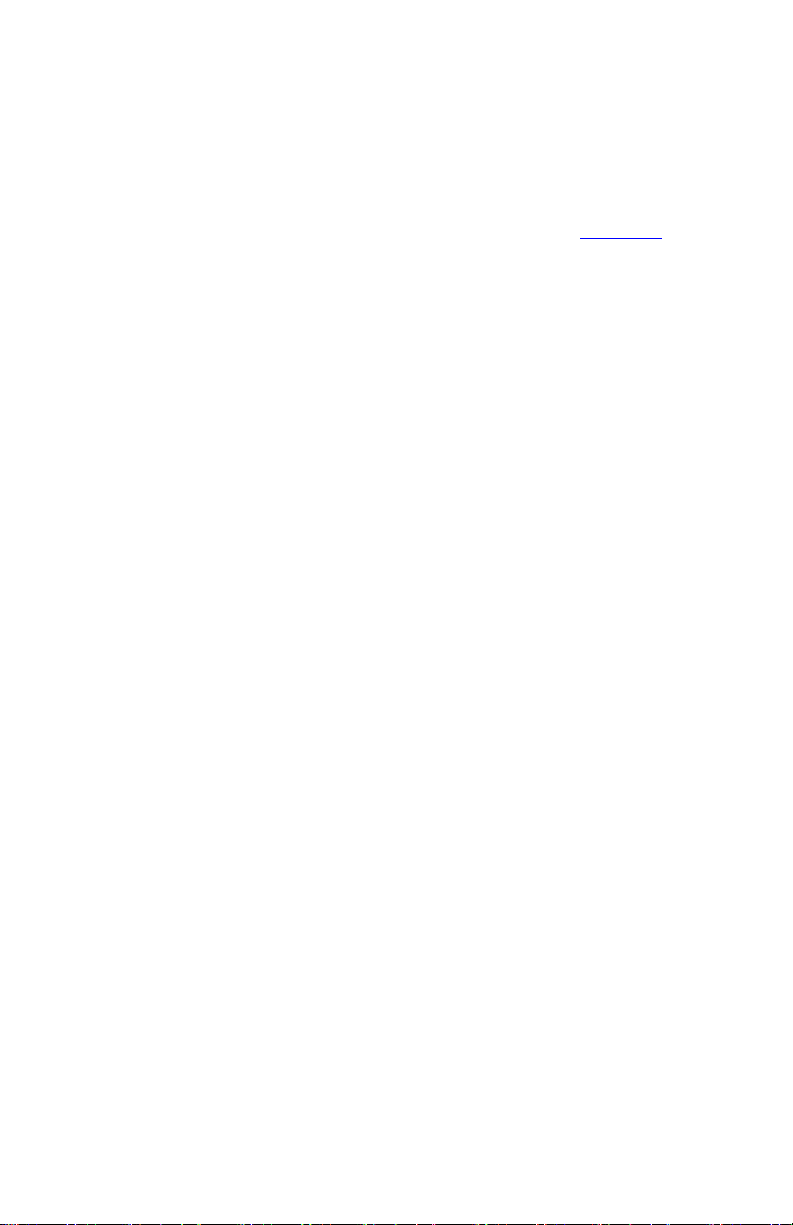

The PANDA system consists of the following:

Qty

Description

Part Number

Reference Picture

1

Low flow nozzle

6002598

1

Primary duct adapter

spigot plus rubber bung

(to fit to test duct)

6002638

1

Cam lock primary spigot

(to connect flexi-duct to

PANDA)

6002607

2

Ø4-in. (100-mm)

adjustable over lock

straps

6002683

1

13-ft (4-m) long

Ø4-in. (100-mm) plastic

flexible duct

6002667

2

20-in. (500-mm)

silicone tubes (red)

AFL9020004

Page 8

2 Chapter 1

Qty

Description

Part Number

Reference Picture

2

20-in. (500-mm) silicone

tubes (blue)

AFL9020005

1

16-ft (5-m) silicone tube

(blue)

AFL9020005

1

Smoke cap holder

assembly

AFL71549801

1

Smoke pellets

AFL9004167

1

K-type thermocouple

probe

AFL82859201

3

Instrument adapter

AFL82859401

1

Operation and User’s

manual

6005447

Page 9

Unpacking and Parts Identification

3

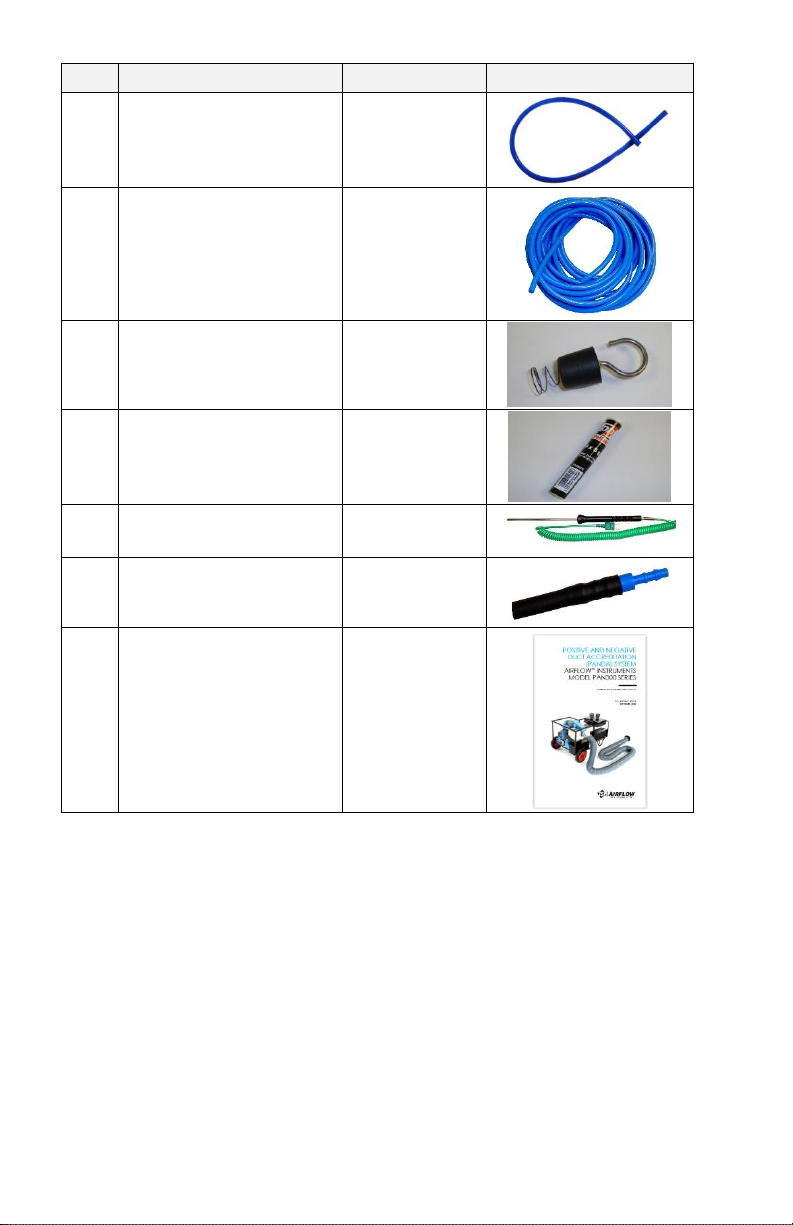

The following two instruments should be used in conjunction with the

PANDA unit:

TA465-P Multifunction Instrument

Refer to TA465 Operation and

Service Manual supplied with the

instrument for additional parts

supplied as standard.

PVM620

Micromanometer

Refer to PVM620 Operation and

Service Manual supplied with the

instrument for additional parts

supplied as standard.

IMPORTANT—

Read Before Using the PANDA for the First Time

It is IMPORTANT that the PANDA be connected to the power supply

using a 30 mA residual-current device (RCD) or Ground Fault Circuit

Interrupter (GFCI).

It is IMPORTANT that the 110V PANDA (yellow power socket) be

connected only to 110V to 120V supplies. Connecting it to a higher

voltage supply will permanently damage the inverter.

The 220V/240V PANDA (blue power socket) should only be

connected to 200V to 240V power supplies.

When storing the PANDA in a vertical position, please ensure that the

straps holding the instrument box are in place and tightened first.

The PANDA is designed so that the instrument box and duct carry

tube are removable to lighten the load when lifting.

DANGER

Turn the isolation switch to the OFF position and wait 10 minutes

prior to disconnecting power.

Page 10

4 Chapter 1

(This page intentionally left blank)

Page 11

5

Chapter 2

Preparing PAN300 System for Air Duct Leak

Testing

The following procedure should be followed carefully so that safe and

accurate leakage testing can be achieved:

Successfully completing a duct leakage test requires certain

information be compiled prior to starting the test. Refer to

Appendix B for a discussion of standards relating to duct

leakage testing. The list below indicates the information

required:

• Type of leakage test to be performed (Positive or

negative).

• Leakage standard to be followed.

• Air tightness/leakage class to be achieved

• Amount of ductwork to be tested, such as the complete

system or a statistical sample.

1. Select the section of the ductwork to be tested.

2. Calculate the surface area of the ductwork of the section to

be tested.

3. Temporarily seal the all openings of the ductwork except one,

which will be connected to the PAN300 duct leakage tester.

4. Position the PAN300 unit as close to the remaining opening in the

ductwork as possible to minimize the flexible tubing needed.

Minimize bends in the flexible tubing to reduce the pressure loss,

giving the best performance.

5. Make sure the Fan Control Switch on the Fan Speed Controller is

in the OFF position and the multi-turn Fan Speed Control

potentiometer is fully turned counter-clockwise using the pictures

of the VFD in Figure 1 as a reference. Plug the cord into the

PANDA unit as shown in Figure 2 and Figure 3. Then connect the

other end of the cord to a suitable electrical supply.

Page 12

6 Chapter 2

CAUTION

Remove the power cord from the PANDA duct leakage tester

before tilting it to the vertical position to avoid damaging the cord.

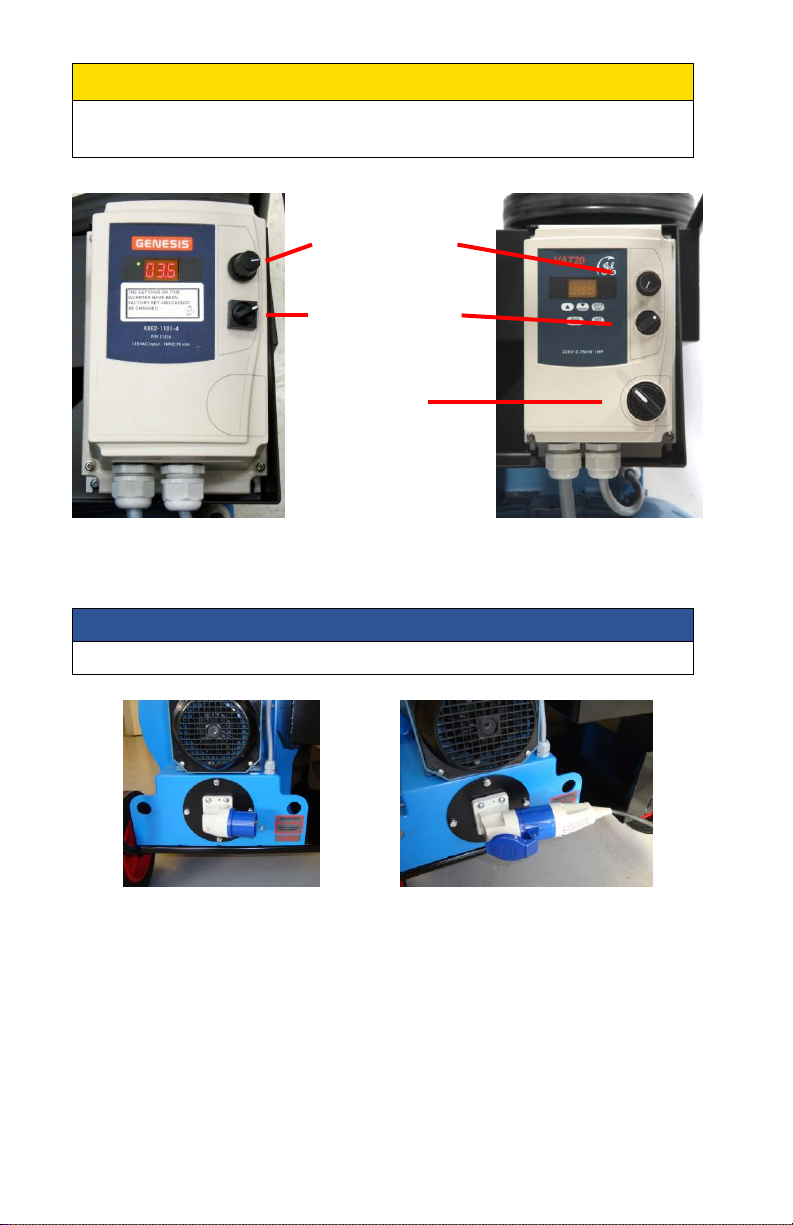

110 V 230 V

Figure 1. 110V and 230V Fan Speed Controllers

NOTE

The control pad on the Fan Speed Controller has been disabled.

Figure 2. Receptacle for

Power Cord

Figure 3. Connected Power Cord

Fan Speed

Control

Fan Control

Switch

On/Off

Switch

Page 13

Preparing PAN300 System for Air Duct Leak Testing

7

6. Fit the primary duct adapter

spigot (black sheet metal

with rubber bung) to one end

of the 4-in. (100-mm)

diameter flexi-tube. Make an

air-tight seal using one of the

over lock straps and leverlocking cam provided as

shown in Figure 4. Adjust

the fit of the over lock strap

with a screwdriver.

7. Securely attach the black

primary duct adapter

spigot/flexi-tube assembly to

the opening on the ductwork

to be pressure tested.

Figure 4. Flex Ductwork

Connected to Primary Adapter

Spigot. Bung not shown.

8. If the static pressure tap on

the black Primary Duct

Adapter is open to the duct,

connect the 16-ft (5-m) long

blue silicone tube to it as

shown in Figure 5.

If the static pressure tap on

the black Primary Duct

Adapter is not open to the

duct, drill a 4-mm hole in the

duct and insert about 6

inches (10 mm) of the

silicone tube into the duct.

Seal around the hole

with putty.

9. Connect the other end of the

4-in. (100-mm) flexi-tube to

Figure 5. Connecting Pressure

Tubing to Tap on Primary Duct

Adapter. Bung not shown.

the cam lock connector (grey cast aluminum without nozzle).

Make an airtight seal using the other over lock strap and leverlocking cam provided. Adjust the fit of the over lock strap with

a screwdriver.

10. Determine if you are going to perform a high- or low-flow testing

and positive or negative testing. Set-up the duct leakage

tester by:

Page 14

8 Chapter 2

a. For positive pressure,

high-flow testing,

remove the low flow

nozzle if it is installed.

Then, connect the grey

cast-aluminum cam

lock connector to the

outlet side of the

blower per Figure 6.

Close both cam lock

arms at the same time

to ensure proper fit.

Connect the free end of

the 16-ft (5-m) silicone

Figure 6. Positive Pressure,

High-Flow Set-Up

tube to the pressure tap marked DUCT PRESSURE P3 (+)

on the black square box.

Finally, verify that the FLOW GRID MODE pressure taps on

the inlet tubes are connected to the FLOW GRID pressure

taps, i.e., P1 (+) to P1 (+) and P2 (-) to P2 (-).

b. For positive pressure,

low-flow testing, add

the low-flow nozzle to

the blower inlet if it is

not installed per

Figure 7. Then,

connect the grey castaluminum cam lock

connector to the outlet

side of the blower per

Figure 6. Close both

cam lock arms at the

same time to ensure

proper fit.

Figure 7. Positive Pressure,

Low-Flow Set-Up

Connect the free end of the 16-ft (5-m) silicone tube to the

pressure tap marked DUCT PRESSURE P3 (+) on the black

square box.

Fan

Outlet

Cam Lock

Connector

Low Flow

Nozzle

Fan Inlet

Page 15

Preparing PAN300 System for Air Duct Leak Testing

9

c. For negative pressure,

high-flow testing,

remove the low flow

nozzle if it is installed.

Then, connect the grey

cast aluminum cam

lock connector to the

inlet side of the blower

per Figure 8. Close

both cam lock arms at

the same time to

ensure proper fit.

Connect the free end of

Figure 8. Negative Pressure,

High-Flow Set-Up

the 16-ft (5-m) silicone tube to pressure tap marked DUCT

PRESSURE P4 (-) on the black square box.

Finally, verify that the FLOW GRID MODE pressure taps on

the inlet tubes are connected to the FLOW GRID pressure

taps, i.e., P1 (+) to P1 (+) and P2 (-) to P2 (-).

d. For negative pressure,

low-flow testing, add

the low-flow nozzle to

the blower inlet if it is

not installed. Then,

connect the grey cast

aluminum cam lock

connector to the lowflow nozzle per

Figure 9. Close both

cam lock arms at the

same time to ensure

proper fit.

Connect the free end of

Figure 9. Negative Pressure,

Low-Flow Set-Up

the 16-ft (5-m) silicone tube to pressure tap marked DUCT

PRESSURE P4 (-) on the black square box.

Fan

Inlet

Cam Lock

Connector

Fan

Inlet

Low Flow

Nozzle

Cam Lock

Connector

Page 16

10 Chapter 2

(This page intentionally left blank)

Page 17

11

Chapter 3

Performing a Duct Leakage Test

The PAN300 duct leakage test system includes a Model PVM620

Micromanometer and a Model TA465-P Ventilation Meter. During duct

leakage testing, the Model PVM620 Micromanometer measures the

duct static pressure while the Model TA465-P Ventilation Meter

measures the airflow rate.

Refer to the Operation and Service Manuals for the Model PVM620

Micromanometer and the Model TA465-P Ventilation Meter to use

these instruments in other applications. If you do not have the

manuals, download them from TSI® Incorporated’s website

www.tsi.com.

Measuring Duct Static Pressure

1. Turn ON the Model PVM620.

2. Zero the Model PVM620 pressure sensor with both ports open to

the atmosphere.

3. Connect the (+) port on the Model PVM620 to P3 (+) to measure

the duct static pressure (see Figure 6).

4. Leave the (-) port on the Model PVM620 open to the atmosphere.

NOTE

Refer to the Model PVM620 Operation and Service Manual for

instructions on using data logging to automatically record the duct

static pressure.

Page 18

12 Chapter 3

Measuring Duct Leakage Flow

Turning on the PAN300 Duct Leakage Tester

1. Switch the PANDA unit on.

a. For 230V models position the Mains Power switch of the

inverter to the ON position to power the Inverter speed

controller. The Fan motor is not energized.

b. 110V models DO NOT include a separate power switch. The

PANDA unit is turned on when the power cord is plugged in.

2. Position the Fan Control switch to the RUN position to energize

the fan.

3. Increase the fan to the desired speed by turning the Fan Speed

Controller clockwise. To decrease the fan speed, turn the Fan

Speed controller counter-clockwise.

1. Turn ON Model TA465-P.

2. Zero the Model TA465-P

pressure sensor with both

ports open to the

atmosphere.

3. Connect the Model TA465-P

to the PAN300 by connecting

the (+) and (-) ports on the

Model TA465-P to the P1 (+)

and P2 (+) ports located

inside the black box of the

PAN300 as shown in

Figure 10.

Figure 10. Connecting Instruments

to PANDA Tester in

High Flow Mode

4. Connect the thermocouple to

the Model TA465-P.

5. Insert the thermocouple

probe into the blower inlet

through the hole marked TC1

as shown in Figure 11.

Figure 11. Thermocouple

Insertion Hole

Thermocouple

Hole

Page 19

Performing a Duct Leakage Test

13

Using Leakage Test Application in the Model TA465-P

CAUTION

The Model PVM620 and Model TA465-P meters must be zeroed

before entering the Leakage Test Application.

1. Press the MENU key to access

the menu system on the

Model TA465-P.

2. Use the keys to highlight

the Applications item.

3. Press the (ENTER) key to

access the Applications menu.

MENU

Zero Press

Display Setup

Settings

Flow Setup

Actual/Std Setup

Data Logging

Zero CO

Applications

Calibration

Discover Printer

4. Select Leakage Test and

press key.

APPLICATIONS

Draft Rate

Heatflow

Turbulence

% Outside Air

Leakage Test

5. Select either the EN Standard

or SMACNA leakage test.

LEAKAGE TEST

EN Standard

SMACNA

Page 20

14 Chapter 3

Instrument Operation if EN Standard Test Protocol is Selected

1. Enter key parameters:

a. Surface Area of ductwork

section to be tested.

b. Static Pressure of test, as

measured by Model

PVM620 micromanometer.

c. Flow Device as Nozzle or

Flow Grid.

LEAKAGE TEST

Surface Area

Static Pressure

Flow Device

Tightness Class

Test Length

Run Test

d. Leakage class as A, B, C, or D. Note that tests with negative

pressures must be selected as negative tests, as indicated by -.

e. Test Length, or duration of leakage test, usually 5 minutes.

2. Increase the blower speed until

the desired static pressure is

achieved.

3. When the static pressure has

stabilized, select Run Test and

press .

4. The display will show the

readings on the right. Leakage

Factor and Leak Rate will

update in real time, while other

parameters will remain constant.

If the Leakage Factor and Leak

Rate are sufficiently stable,

LEAKAGE TEST

Leakage Factor x.xx

Leak Limit x.xx

Leak Rate x.xx

Status OK

Flow Device Flow Grid

Baro Pressure 20.20

Temperature 20C

Time 9:55

Standard TestXXX

Sample

0

(Sample Saved 1)

press the START soft key or the key to begin the leak test.

Pressing the ESC key will exit back to the previous screen.

5. After the leak test is complete, the Model TA465-P will prompt you

to press the SAVE or PRINT soft key. You can also press the ESC

key here to back out to the previous screen without saving

the data.

After completing leakage testing for a section of duct, you can move

on to the next section.

Page 21

Performing a Duct Leakage Test

15

Instrument Operation if SMACNA Test Protocol is Selected

1. Enter key parameters:

a. Surface Area of ductwork

section to be tested.

b. Static Pressure of test, as

measured by Model

PVM620 micromanometer.

c. Flow Device as Nozzle or

Flow Grid.

d. Leakage class as a number

from 1 to 48. Typical values

are 3, 6, 12, 24, or 48.

e. Test Length, or duration of

leakage test.

2. Increase the blower speed

until the desired static pressure

is achieved.

3. When the static pressure has

stabilized, select Run Test and

press .

4. The display will show the

readings on the right. Leakage

LEAKAGE TEST

Surface Area

Static Pressure

Flow Device

Leakage Class

Test Length

Run Test

LEAKAGE TEST

Leakage Factor x.xx

Leak Limit x.xx

Leak Rate x.xx

Status OK

Flow Device Flow Grid

Baro Pressure 20.20

Temperature 20C

Time 9:55

Standard TestXXX

Sample

0

(Sample Saved 1)

Stop(Save) Print

Factor and Leak Rate will update in real time, while other

parameters will remain constant.

If the Leak Factor and Leak Rate are sufficiently stable, press the

START soft key or the key to begin the leak test. Pressing the

ESC key will exit back to the previous screen.

5. After the leak test is complete, the Model TA465-P will prompt

you to press the SAVE or PRINT soft key. You can also press the

ESC key here to back out to the previous screen without saving

the data.

After completing leakage testing for a section of duct, you can move

on to the next section.

Page 22

16 Chapter 3

DANGER

Turn the isolation switch to the OFF position and wait 10 minutes

prior to disconnecting power.

Troubleshooting Guide

Symptom

Recommended Action

Fan motor will not run.

• Check the power connection.

• Circuit Breaker may have

tripped.

Static pressure reading (on

PVM620) is zero.

• Check the connections.

Static pressure reading (on

PVM620) is too low.

Required static pressure cannot

be achieved with motor speed

control settings at the maximum.

• Leakage rate is too high.

Check for leaks using soap

bubbles or smoke pallets.

Alternatively, test a smaller

section of the ductwork.

Leak Flow (on TA465-P) shows

flashing XXX.XX.

• Check the pressure tube

connections to the TA465-P

meter.

• Leak flow is too low. Use low

flow nozzle adapter.

CAUTION

If recommended actions are used and the problem persists

DO NOT service further. Return to TSI® Incorporated for servicing.

Page 23

17

Appendix A

Specifications

Pressure Measurement (PVM620)

Range ..................................

± 3,735 Pa (± 15 in. W.G.)

Resolution ...........................

0.1 Pa (0.001 in. W.G.)

Accuracy .............................

1% of reading ± 1 Pa

(± 0.005 in. W.G.)

Actual duct static range .......

± 2,500 Pa (± 10 in. W.G.) at Zero Flow

Volume Flow Measurement (TA465-P)

Wilson radial flow grid .........

High leakage range: 10 to 200 l/s

(36 to 720 m3/hr, 21 to 424 cfm)

15 mm conical inlet

nozzle adapter ....................

Low leakage range: 1 to 13 l/s

(3.6 to 46.9 m3/hr, 2 to 27.5 cfm)

Resolution ...........................

0.01 l/s (0.01 m3/hr, 0.01 cfm)

Accuracy .............................

± 2.5% of reading ± 0.01 l/s

(± 0.04 m3/hr, ± 0.02 cfm)

Temperature Measurement (TA465-P)

K Type thermocouple probe

To EN60584 (IEC 584)

Barometric Pressure Measurement (TA465-P)

Range ..................................

690 to 1,241 hPa

(517.5 to 930.87 mm Hg,

20.36 to 36.648 in. Hg)

Accuracy .............................

± 2% of reading

Power Requirements

Model PAN331* ..................

220 to 240 V, 1 Phase, 50/60 Hz, 10A

Model PAN331-110* ...........

110 to 120 V, 1 Phase, 50/60 Hz, 16A

Model PAN311** .................

220 to 240 V, 1 Phase, 50/60 Hz, 10A

Model PAN311-110** ..........

110 to 120 V, 1 Phase, 50/60 Hz, 16A

Weight ................................

71 kg (157 lbs.)

Dimensions (L x W x H) ....

1,130 mm x 660 mm x 510 mm

(44.5 in. x 26 in. x 20 in.)

TA465-P and PVM620 .......

See specification sheets for details on

individual instruments

* Model: instruments included

** Model: instruments NOT included

(Specifications subject to change without notice.)

Page 24

18 Appendix A

0

500

1000

1500

2000

2500

3000

0 50 100 150 200 250

Static Pressure Pa.

Volume Flow l/s

Panda Fan Performance Graph (metric units)

Page 25

Specifications

19

0

1

2

3

4

5

6

7

8

9

10

11

0 50 100 150 200 250 300 350 400 450 500

Static Pressure ins.w g.

Volume Flow CFM

Panda Fan Performance Graph (imperial units)

Page 26

20 Appendix A

Environmental Requirements

Ambient Air Temperature ....

-10 to +40°C

Relative Humidity ................

0~95%, non-condensing

Altitude ................................

2000m or less

Transportation and Storage

Storage Temperature ..........

-10 to +40°C

IMPORTANT—

Read Before Using the PANDA for the First Time

It is IMPORTANT that the PANDA be connected to the power supply

using a 30 mA residual-current device (RCD) or Ground Fault Circuit

Interrupter (GFCI).

It is IMPORTANT that the 110V PANDA (yellow power socket) be

connected only to 110V to 120V supplies. Connecting it to a higher

voltage supply will permanently damage the inverter.

The 220V/240V PANDA (blue power socket) should only be

connected to 200V to 240V power supplies.

Page 27

21

Appendix B

Leakage Testing Standards Highlights

Different standards are used throughout the world to specify duct air

tightness and leakage requirements. The PAN300 duct leakage test

system has a duct leakage application to automatically compare the

actual leakage flow with the maximum allowed leakage flow for EN

and SMACNA standards. Field technicians can also use the duct

leakage application to determine actual leakage flow and manually

compare it to maximum leakage from another standard. The PAN300

duct leakage test system cannot determine the appropriate leakage

classification for a given duct.

Standards Supported

Standard

US- or EU-

Based

Description

BS EN 12237:2003

EU

Ventilation for buildings—Ductwork—

Strength and leakage of circular sheet

metal ducts.

BS EN 1507:2006

EU

Ventilation for buildings—Sheet metal

air ducts with rectangular section—

Requirements for strength and

leakage.

DW/143

EU

HVAC—A practical guide to Ductwork

leakage testing.

Eurovent 2/2

EU

Air leakage rate in sheet metal air

distribution systems.

SMACNA HVAC Air

Duct Leakage Test

manual, First

edition, 1985

US

Duct construction leakage

classification, expected leakage rates

for sealed and unsealed ductwork,

duct leakage test procedures,

recommendations on use of leakage

testing, types of test apparatus and

test setup and sample leakage

analysis.

TSI® has made every effort to accurately reflect the standards

referenced. Please refer to the actual standards for more detailed

information and to make the best interpretation of each statement.

Page 28

22 Appendix B

The scope of the standards listed above includes many items other

than duct leakage. This summary, however, is limited to duct

leakage testing.

EU Standards

Ductwork classification and maximum air leakage. Note that EN1507,

EN12237 Eurovent 2/2 and DW/143 all have the same formula to

determine f

max

, the Air Leakage Limit, although DW/143 uses units of

l/s/m2 whereas others use m3/s/m2.

• EN 1507 (rectangular ductwork)

Air

Tightness

Class

Air Leakage

Limit (f

max

)

m3/s/m2

Static Pressure Limit (ps) Pa

Negative

Positive at

pressure class

1 2 3

A 200

400

B 500

400

1000

2000

C 750

400

1000

2000

D* 750

400

1000

2000

* Class D ductwork is only for special apparatus

• EN12237 (circular ductwork)

Air

Tightness

Class

Air leakage

limit (f

max

)

m3*/s/m2

Static Pressure Limit (ps)

Pa

Negative

Positive

A 500

500

B 750

1000

C 750

2000

D* 750

2000

* Class D ductwork is only for special apparatus

Page 29

Leakage Testing Standards Highlights 23

• Eurovent 2/2 Air Tightness For Installed Duct Testing:

Air Tightness

Class

Air leakage limit (f

max

)

m3/s/m2

A B C

• DW/143: A Practical Guide to Ductwork Leakage Testing

Duct

Pressure

Class

Static Pressure

Limit

Maximum

Air Velocity

m/s

Air leakage

limits

l/s/m2

Positive

Pa

Negative

Pa

Low-pressure

– Class A

500

500

10

0.027*p

t

0.65

Medium-

pressure –

Class B

1000

750

20

0.009*p

t

0.65

High pressure

– Class C

2000

750

40

0.003*p

t

0.65

Figure 12. Allowable Air Leakage Rates from DW/143

Page 30

24 Appendix B

• The measured leakage flow rates shall be corrected if the

temperature and/or barometric pressure are different from

standard conditions (+20ºC and 101 325 Pa) as follows:

where:

qv=corrected flow leakage rate

q

measured

= measured flow leakage rate

t = measured temperature (ºC)

p = measured barometric pressure (Pa)

• The test report shall give the following general information of the

test performed:

o Date and place

o Test personnel and witness

o Test equipment, including pressuring means and measuring

instruments

o Air temperature and barometric pressure during the test

o Building and project reference

o Design of installed ductwork including dimensions, thickness

of materials, types of stiffening, length, type of duct/tubes and

fittings, assembly method and distance of hangers/supports

o Required air tightness class and design operating pressure of

the installed ductwork

o Installer of ductwork

o Manufacturer of the ductwork

o Measured values of:

1. Ductwork surface area (A)

2. Total joint length (L)

3. Test pressure (p

test

)

4. Leakage flow rate (qv) corrected for temperature and

barometric pressure

5. Pressurizing time

o Calculated values of

1. Leakage factor (f)

2. Air leakage limit (f

max

) according to the formulas given in

table above at the measured test pressure (p

test

)

o Air tightness class achieved

Page 31

Leakage Testing Standards Highlights 25

• For tests including several test pressures it is recommended to

plot the leakage factors as a function of test pressure in a

diagram together with the air leakage limit curve.

US Standards

Ductwork classification and maximum air leakage

Duct Class

½-, 1-,

2-inwg

3-inwg

4-, 6-, 10-inwg

Seal Class

C B A

Sealing

Applicable

Transverse

Joints Only

Transverse

Joints and

Seams

Joints, Seams and

All Wall

Penetrations

Leakage Class

Rectangular

Metal

24

12

6

Round

Metal

12 6 3

Maximum air leakage is then defined as

F=CLP

0.65

where: F = Maximum air leakage (cfm/100 ft2)

CL = Leakage class

P = Pressure (inwg)

Page 32

26 Appendix B

Figure 13. Allowable Air Duct Leakage from Round Ducts,

per SMACNA Standard

Figure 14. Allowable Air Duct Leakage from Rectangular Ducts,

per SMACNA Standard

• The SMACNA standard does not generally require correcting

leakage flow rates to standard conditions, unless:

1. Air temperature <40ºF or >100 ºF

2. Elevation <1500 ft above sea level

3. Duct static pressure <-20 inwg or >+20 inwg

Page 33

Leakage Testing Standards Highlights 27

Should one of these conditions not be satisfied, then correcting

the leakage to standard conditions may be done using one of

these formulas:

1. ACFM=SCFM * (460+T)/530

where T = actual dry bulb air temperature (ºF)

moisture is negligible

pressure between -20 and +20 inwg

2. ACFM = SCFM * 0.075/d

where d = air density from psychrometric chart

3. ACFM=lb dry air/minute * humid volume (ft3/lb dry air)

• The SMACNA standard does not specify the information to be

reported, but instead defers to project documents. However, the

SMACNA standard does include a sample test report that

includes:

o Test date and place

o Test personnel and witness

o Building and project reference

o Duct section tested

o Specified leakage class, test pressure and duct construction

pressure class

o Measurements of:

▪ Ductwork surface area

▪ Leakage flow and calculations required to determine

leakage flow

Page 34

28 Appendix B

(This page intentionally left blank)

Page 35

29

Appendix C

Typical Setup

Page 36

30 Appendix C

(This page intentionally left blank)

Page 37

31

Appendix D

Procedure for Using Smoke Pellets in

Leakage Testers

As shown in the sketch below, a rubber bung is fitted into the hole in

the duct adapter which holds the wire coil.

When a smoke pellet is required to be used, remove the bung and fit

a pellet into the wire coil as shown in the sketch.

Light the pellet and immediately plug into the hole in the duct adapter

and proceed with the test.

The pellet should emit dense white smoke for up to a minute.

Duct

Pellet Holder

Smoke Pellet

Flexible Ducting

Duct Adapter

Page 38

32 Appendix D

(This page intentionally left blank)

Page 39

Page 40

TSI Instruments Ltd.

Visit our website at www.tsi.com for more information.

UK Tel: +44 149 4 459200

France Tel: +33 1 41 19 21 99

Germany Tel: +49 241 523030

P/N 6005447 Rev B ©2021 TSI Incorporated Printed in U.S.A.

Loading...

Loading...