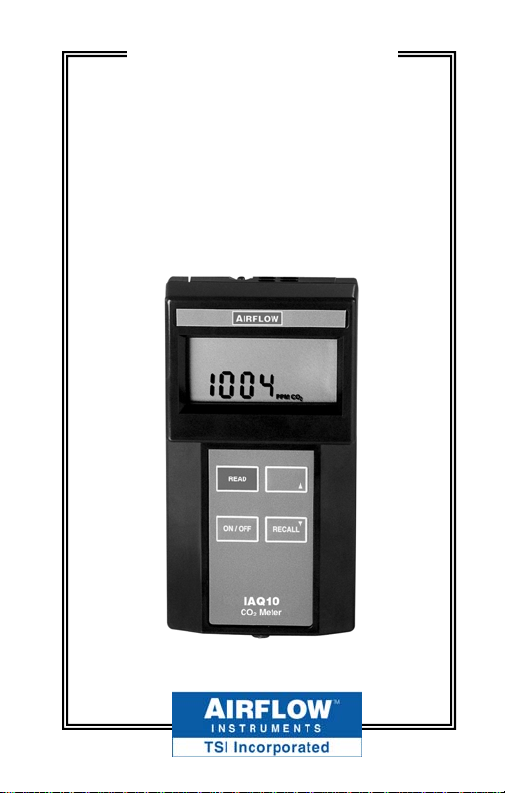

Page 1

OWNER’S MANUAL

CO2 Meter

Model IAQ10

Page 2

LIMITATION OF WARRANTY AND LIABILITY

Seller warrants the goods sold hereunder, under normal use and service as described in

the operator's manual, shall be free from defects in workmanship and material for

twenty-four (24) months, or the length of time specified in the operator's manual, from

the date of shipment to the customer. This warranty period is inclusive of any statutory

warranty. This limited warranty is subject to the following exclusions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other

components when indicated in specifications, are warranted for 90 days from the

date of shipment.

b. Parts repaired or replaced as a result of repair services are warranted to be free

from defects in workmanship and material, under normal use, for 90 days from the

date of shipment.

c. Seller does not provide any warranty on finished goods manufactured by others or

on any fuses, batteries or other consumable materials. Only the original manufacturer's warranty applies.

d. Unless specifically authorized in a separate writing by Seller, Seller makes no

warranty with respect to, and shall have no liability in connection with, goods which

are incorporated into other products or equipment, or which are modified by any

person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS

stated herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER

OR BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES,

INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS

BASED ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE)

SHALL BE THE RETURN OF GOODS TO SELLER AND THE REFUND OF THE

PURCHASE PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR

REPLACEMENT OF THE GOODS. IN NO EVENT SHALL SELLER BE LIABLE FOR

ANY SPECIAL, CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL

NOT BE RESPONSIBLE FOR INSTALLATION, DISMANTLING OR REINSTALLATION

COSTS OR CHARGES. No Action, regardless of form, may be brought against Seller

more than 12 months after a cause of action has accrued. The goods returned under

warranty to Seller's factory shall be at Buyer's risk of loss, and will be returned, if at all,

at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY

AND LIABILITY, which contains the complete and exclusive limited warranty of Seller.

This LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or

its terms waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are

to our customers, our service policy is designed to give prompt attention to any

problems. If any malfunction is discovered, please contact your nearest sales office or

representative, or call Customer Service department at +44 (0) 149 4 459200 (UK),

(800) 874-2811 (USA), or (1) 651-490-2811 (International).

ii

Page 3

Table of Contents

LIMITATION OF WARRANTY AND LIABILITY ...... ii

SECTION 1 General Description .....................................2

SECTION 2 Theory of Operation: NDIR Sensor ...........2

SECTION 3 Safety ..............................................................3

SECTION 4 Setting-Up the Model IAQ10 ......................4

Supplying Power ...........................................................4

Installing the Batteries...................................................4

Using the Optional AC Adapter..................................4

SECTION 5 Operation of the Model IAQ10................... 5

ON/OFF Key..................................................................5

READ Key ....................................................................... 6

(5) Key............................................................................ 7

RECALL (6) Key........................................................... 7

SECTION 6 Maintenance of the Model IAQ10..............8

Case .................................................................................. 8

Storage .............................................................................8

SECTION 7 Service Information ......................................8

Factory Calibration ........................................................ 9

Field Verification..........................................................10

SECTION 8 Troubleshooting of the

Model IAQ10 ................................................................ 13

SECTION 9 Internal DIP Switch Settings .....................14

Specifications.....................................................................17

1

Page 4

SECTION 1

General Description

The Model IAQ10 is a hand-held meter to

measure Carbon Dioxide (CO

), displayed

2

in units of parts per million (ppm). An

NDIR sensor in the top end of the meter

measures gas content by diffusion through

sensing holes.

The IAQ10 ships in a pouch that provides a

small amount of protection to the display

and the sensing holes in the top of the

instrument case. The instrument ships with

batteries (which are not installed), a

calibration sheet, and this Owner’s Manual.

SECTION 2

Theory of Operation: NDIR Sensor

The IAQ10 measures carbon dioxide

concentration by relying on one of the

natural properties of CO

molecules: CO2

2

molecules absorb light at a specific wavelength of 4.26 µm. This wavelength is in the

infrared (IR) range. High concentrations of

CO

molecules absorb more light than low

2

2

Page 5

concentrations. This technique is called

non-dispersive infrared (NDIR) detection.

SECTION 3

Safety

When using the IAQ10 to check for CO

2

values, make certain that you can safely

raise and hold the instrument while

making measurements. Be especially

careful when working on a ladder.

Observe all necessary precautions so that

the unit does not become caught in moving

machinery or touch any exposed electrical

wiring.

DANGER!

Use with corrosive or other dangerous or

explosive gas mixtures is not recommended.

3

Page 6

SECTION 4

Setting-Up the Model IAQ10

Supplying Power

The IAQ10 can be powered in one of two

ways: four AA-size batteries or the optional

AC adapter.

Installing the Batteries

Insert four AA batteries as indicated by the

diagram located on the inside of the battery

compartment. The Model IAQ10 is designed to operate only with alkaline

batteries. When 15% battery life is remaining, the battery indicator will blink,

indicating the batteries need to be changed.

At 0%, “LO” will display and the meter will

shut off within 10 seconds.

Using the Optional AC Adapter

The optional AC adapter allows you to

power the Model IAQ10 from a wall outlet.

When using the AC adapter, the batteries

(if installed) will be bypassed. The AC

adapter is NOT a battery charger.

4

Page 7

SECTION 5

Operation of the Model IAQ10

Note: Do not hold the instrument close to your

face. Humans exhale CO

and this will affect

2

the accuracy of the readings.

When pressing the keys on the keypad, the

Model IAQ10 will beep to confirm the

function. If you press a key and the Model

IAQ10 does not beep, the Model IAQ10

does not allow that function during the

selected mode. (See Section 9 for information on disabling this feature through an

internal DIP switch.)

ON/OFF Key

Press the ON/OFF key to turn the Model

IAQ10 on and off. When the instrument is

first turned on, it goes through a preprogrammed power-up sequence that includes

an internal self-check.

First, all displayable LCD segments will

appear. If a problem is detected, the display

will show “CAL” to indicate that it should

be returned for servicing and/or

5

Page 8

calibration. When the Model IAQ10

completes the internal self-check, it will

display the approximate percentage of

battery life remaining.

Note: The sensor needs up to 10 minutes to

stabilize in still air before displayed readings

can be considered accurate. Moving the

instrument may decrease this stabilization time.

READ Key

Carbon dioxide concentrations will be

displayed in parts per million (ppm). The

IAQ10 can be left in a room to monitor

general conditions, but it is important to

ensure that the sensing holes at the top of

the meter are not covered or in a

downward position.

Press the READ key once to start taking a

CO

sample; press it again to end the

2

sample. The minimum sample time is five

seconds, even if the second press occurs

after two, three, or four seconds. SAMPLE

will flash on the display while the instrument takes a measurement.

6

Page 9

The display updates every second and each

reading is the average of five samples.

(5) Key

The instrument only displays CO

.

2

RECALL (6) Key

Press the RECALL key repeatedly to

display: minimum value (MIN), maximum

value (MAX), average value (AVG), and

number of seconds sampled (COUNT).

Press the READ key to return to normal

measuring mode.

The instrument does not store readings.

The information viewed in the recall mode

is for the sample reading just taken. Once a

new sample starts or the instrument is

turned off, all previous data is lost.

The (5) and (6) references on keys are

used during the field calibration process.

7

Page 10

SECTION 6

Maintenance of the Model IAQ10

The Model IAQ10 requires very little

maintenance to keep it performing well.

Case

If the instrument case or storage case needs

cleaning, wipe it off with a soft, damp

cloth. Never submerge the IAQ10 in any

liquid or allow any liquid to enter the

sensing holes.

Storage

When storing the Model IAQ10 for more

than a month, TSI

recommends removing

the batteries. This prevents possible

damage due to battery leakage.

SECTION 7

Service Information

Please return your Product Registration

Card immediately. This allows us to send

service reminders, special offers, and

important information about your product.

8

Page 11

Before sending your instrument for

calibration or repair, you should call

Customer Service. The service department

will provide you with the cost of service or

calibration, Return Material Authorization

(RMA) number, and shipping instructions.

Please have the following information

available when you call:

• Owner’s name, address, and phone

number

• Billing address, if different and

applicable

• Instrument name and model

• Serial number

• Date of purchase

• Where purchased

TSI

recommends that you keep a “calibra-

tion log” and keep all records of service on

your instrument.

Factory Calibration

To maintain a high degree of accuracy in

your measurements, TSI recommends that

you return your instrument to the factory

for annual calibration. For a nominal fee,

we will calibrate the unit and return it to

9

Page 12

you with a NIST (US National Institute of

Standards and Technology) traceable

certificate. This “annual checkup” assures

you of consistently accurate readings; it is

especially important in applications where

strict calibration records must be maintained.

Send the instrument to TSI Instruments

Ltd. prepaid. Securely package your

instrument in a strong container surrounded by at least 5 cm of suitable shockabsorbing material. Include a purchase

order that clearly shows the instrument

model number and serial number, a contact

name, phone, fax number, and RMA

number. Mark the outside of your shipping

container with the RMA number. This will

expedite processing of your instrument

when we receive it.

Field Verification

Field verification of your CO

instrument is

2

recommended monthly. You need a gas

tank and regulator. Calibration grade gases

are available through local industrial gas

supply.

10

Page 13

1. Turn the instrument off. Under the

batteries, move DIP switch # 7 to ON.

Turn the instrument back on.

2. Press and hold the READ key to begin

the calibration procedure. The display

will begin a countdown from 5 to 0.

Release the key when the display reads

0. If the key is released too soon or too

late, the instrument will go back to sam-

pling in real-time. “ZerO” will appear

on the display if the instrument is in

calibration mode.

3. Install the regulator on the zero calibra-

tion gas tank and connect tubing from

the regulator to the inlet fitting on the

top of the Model IAQ10. The regulator

has a fixed flow rate of 0.3 L/min. Do

not use a flow rate lower than

0.25 L/min or higher than 1.0 L/min.

4. Turn on gas flow.

5. Press and release the READ key to begin

a zero reading. The Model IAQ10 begins

a 60-second countdown during the zero

reading. The actual zero reading is

taken in the last 10 seconds. When the

countdown is completed, the display

11

Page 14

indicates “SPAN” and the span concen-

tration.

6. Install the regulator on the span calibra-

tion cylinder and connect tubing from

the regulator to the inlet fitting on the

top of the Model IAQ10.

7. Use 5 and 6 to adjust the concentra-

tion displayed on the Model IAQ10 to

match the concentration on the span gas

cylinder.

8. Press and release the READ key to take

a span gas reading. The Model IAQ10

starts a 60-second countdown. When the

countdown reaches zero, the instrument

returns to the normal measurement

mode.

9. With the gas still connected, observe the

reading on the display. It should indicate the span gas concentration. If not,

repeat this procedure.

10. If the displayed reading is accurate,

remove the regulator and tubing. The

calibration is now complete.

11. Before taking measurements, turn the

instrument off and move DIP switch #7

back to OFF.

12

Page 15

SECTION 8

Troubleshooting of the Model IAQ10

This table lists the symptoms, possible

causes, and recommended solutions for the

Model IAQ10.

Symptom

No display Unit not

Low or dead

Dirty battery

Batteries

BAT is

blinking

Cal err Error in field

Possible

Causes

switched on

batteries

contacts

installed

incorrectly

Dirty battery

contacts

Batteries are

low

calibration

Corrective

Action(s)

Switch on the

unit

Replace the

batteries

Clean the

battery

contacts

Refer to

battery

illustration

inside battery

cover

Clean the

battery

contacts

Replace the

batteries

Perform

calibration

again

13

Page 16

Symptom

Display

reads “LO”

Possible

Causes

Batteries are

low

Corrective

Action(s)

Replace the

batteries

Note: If your symptoms are not remedied

by the suggested corrective action, call TSI

Instruments Ltd.

SECTION 9

Internal DIP Switch Settings

To access the DIP switches, remove the

batteries from the battery compartment. On

the inside of the battery compartment,

there is a window with eight DIP switches.

The table below shows the functions for

each switch.

CAUTION:

Make certain that power is turned off before

changing DIP switch settings.

14

Page 17

DIP

Switch OFF

1-3 Must be OFF ----4 not assigned not assigned

5 not assigned not assigned

6 Beep is turned

OFF

7 Normal mode Field Verifica-

8 not assigned not assigned

- The ON position is away from the batteries

and OFF is towards the batteries.

ON

Beep is turned

ON

tion mode

- Switch 1 is towards the top of the case and

Switch 8 is nearest the bottom.

15

Page 18

Page 19

Specifications

(subject to change without notice)

CO2 Sensor type:

Dual wavelength detector with non-

Range: 0 to 5000 ppm

Accuracy ±3% of reading or ±50 ppm, whichever

Resolution 1 ppm

Response time <10 minutes in still air

dispersive infrared (NDIR) sensor

is greater

1, 2

Operating Temperature Range:

5 to 70°C

External Meter Dimensions:

89 mm × 168 mm × 41 mm

Display: LCD, 4 digits, 10-mm high

Power requirements:

Four (4) AA-size alkaline batteries

Battery Life: Minimum 10 hours using alkaline

1

Add ±0.36% of reading per °C away from calibration temperature

2

Under standard barometric pressure of 29.92 in Hg (406.8 inches H2O)

[101.4 kPa].

batteries

Page 20

TSI Instruments Ltd. October 2005

Lancaster Road Printed in USA

Cressex Business Park Part No. 1980532, Rev. A

High Wycombe

Buckinghamshire Tel: +44 (0) 149 4 459200

HP12 3QP England Fax: +44 (0) 149 4 459700

info@airflowinstruments.co.uk Copyright © 2005

E-mail:

www.airflowinstruments.co.uk TSI Incorporated

Web:

Loading...

Loading...