Page 1

SIDEPAK™ PERSONAL

AEROSOL MONITOR

MODEL AM520/AM520i

USER GUIDE

P/N 6009829 REV. L

MARCH 2021

Page 2

Page 3

iii

Copyright ©

TSI Incorporated / 6009829 / Revision L / 2016-2021 / All rights reserved.

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA

Fax No.

(651) 490-3824

Limitation of Warranty and Liability (effective February 2015)

Seller warrants the goods, excluding software, sold hereunder, under normal use and

service as described in the operator's manual, to be free from defects in workmanship

and material for 24 months, or if less, the length of time specified in the operator's

manual, from the date of shipment to the customer. This warranty period is inclusive of

any statutory warranty. This limited warranty is subject to the following exclusions

and exceptions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other

components when indicated in specifications, are warranted for 90 days from the

date of shipment;

b. SidePak AM520/AM520i internal pump and battery are warranted for one (1) year

from the date of manufacture.

c. Parts repaired or replaced as a result of repair services are warranted to be free

from defects in workmanship and material, under normal use, for 90 days from the

date of shipment;

d. Seller does not provide any warranty on finished goods manufactured by others or

on any fuses, batteries or other consumable materials. Only the original

manufacturer's warranty applies;

e. This warranty does not cover calibration requirements, and seller warrants only that

the instrument or product is properly calibrated at the time of its manufacture.

Instruments returned for calibration are not covered by this warranty;

f. This warranty is VOID if the instrument is opened by anyone other than a factory

authorized service center with the one exception where requirements set forth in the

manual allow an operator to replace consumables or perform recommended

cleaning;

g. This warranty is VOID if the product has been misused, neglected, subjected to

accidental or intentional damage, or is not properly installed, maintained, or cleaned

according to the requirements of the manual. Unless specifically authorized in a

separate writing by Seller, Seller makes no warranty with respect to, and shall have

no liability in connection with, goods which are incorporated into other products or

equipment, or which are modified by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS

stated herein. NO OTHER EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR

PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE. WITH RESPECT TO

SELLER’S BREACH OF THE IMPLIED WARRANTY AGAINST INFRINGEMENT,

SAID WARRANTY IS LIMITED TO CLAIMS OF DIRECT INFRINGEMENT AND

EXCLUDES CLAIMS OF CONTRIBUTORY OR INDUCED INFRINGEMENTS.

BUYER’S EXCLUSIVE REMEDY SHALL BE THE RETURN OF THE PURCHASE

PRICE DISCOUNTED FOR REASONABLE WEAR AND TEAR OR AT SELLER’S

OPTION REPLACEMENT OF THE GOODS WITH NON-INFRINGING GOODS.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER

OR BUYER, AND THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES,

INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING CLAIMS

BASED ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR

OTHERWISE) SHALL BE THE RETURN OF GOODS TO SELLER AND THE

REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION OF SELLER, THE

Page 4

iv

REPAIR OR REPLACEMENT OF THE GOODS. IN THE CASE OF SOFTWARE,

SELLER WILL REPAIR OR REPLACE DEFECTIVE SOFTWARE OR IF UNABLE TO

DO SO, WILL REFUND THE PURCHASE PRICE OF THE SOFTWARE. IN NO

EVENT SHALL SELLER BE LIABLE FOR LOST PROFITS, BUSINESS

INTERRUPTION, OR ANY SPECIAL, INDIRECT, CONSEQUENTIAL OR

INCIDENTAL DAMAGES. SELLER SHALL NOT BE RESPONSIBLE FOR

INSTALLATION, DISMANTLING OR REINSTALLATION COSTS OR CHARGES. No

Action, regardless of form, may be brought against Seller more than 12 months after a

cause of action has accrued. The goods returned under warranty to Seller's factory

shall be at Buyer's risk of loss, and will be returned, if at all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY

AND LIABILITY, which contains the complete and exclusive limited warranty of Seller.

This LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or

its terms waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are

to our customers, our service policy is designed to give prompt attention to any

problems. If any malfunction is discovered, please contact your nearest sales office or

representative, or call TSI's Customer Service department at (800) 680-1220 (USA) or

(001 651) 490-2860 (International).

Trademarks

TSI and TSI logo are registered trademarks of TSI Incorporated in the United States

and may be protected under other country’s trademark registrations.

SidePak and TrakPro are trademarks of TSI Incorporated.

Windows is a registered trademark of Microsoft Corporation.

Tygon is a registered trademark of Saint-Gobain Performance Plastics Corporation

Zefon is a registered trademark of Zefon International, Inc.

Page 5

v

CONTENTS

SAFETY INFORMATION ................................................................... IX

Intrinsic Safety Rating Information (AM520i only) ........................... xi

Instructions Specific to Hazardous Area Installations ..................... xiii

Additional information ..................................................................... xv

Intended Use—AM520i ................................................................... xv

Intended Use—AM520 ................................................................... xv

IECEx (Sira, Issued 2018), IECEx (SIMTARS, Issued 2019) ..... xv

ATEX (Sira 18ATEX2150X, Issued 2018) ................................... xv

North America (CAN/US, Issued 2018) .......................................xvi

CHAPTER 1 UNPACKING AND PARTS IDENTIFICATION ............ 1

CHAPTER 2 SETTING UP ................................................................ 7

Supplying Power to the SidePak™ Aerosol Monitor ........................ 7

Installing and Charging the Lithium Ion Rechargeable

Battery Pack .................................................................................. 7

Installing the Lithium Ion Battery Pack .......................................... 8

Removing the Lithium Ion Battery Pack ........................................ 9

Smart Battery Management System™

technology ........................... 9

Storing the Battery Pack between Uses ......................................... 10

Using the AC Adapter (power supply) ............................................ 11

Battery LED ..................................................................................... 11

Battery Icon on Display ................................................................... 12

Displayed Battery Life ..................................................................... 12

Installing TrakPro™ Data Analysis Software .................................. 12

CHAPTER 3 OPERATION .............................................................. 13

Overview ......................................................................................... 13

Identifying SidePak™ AM520/AM520i Features ............................ 13

USB Port ...................................................................................... 13

Power Port ................................................................................... 14

Exhaust Port ................................................................................ 14

Inlet .............................................................................................. 14

Battery Screws ............................................................................ 15

Keypad Functions ........................................................................... 16

Main Menu ...................................................................................... 17

Power Up ........................................................................................ 18

Power Down .................................................................................... 18

Survey Mode ................................................................................... 18

Data Logging ................................................................................... 19

Run Mode ....................................................................................... 21

Survey Mode ............................................................................... 21

Manual Mode ............................................................................... 21

Program Mode ............................................................................. 21

Page 6

vi

Settings ........................................................................................... 22

Setting the Log Interval ................................................................ 23

Setting the Time Constant ........................................................... 24

Setting the Time and Date and Date Format ............................... 26

Battery Units ................................................................................ 27

Screen Save Delay ...................................................................... 27

Language ..................................................................................... 28

Information ................................................................................... 28

Calibration ....................................................................................... 28

Zeroing the Instrument (Zero Cal) ............................................... 30

Flow Cal ....................................................................................... 31

User Cal ....................................................................................... 32

Data ................................................................................................. 33

Statistics ...................................................................................... 33

Clear Memory .............................................................................. 33

Alarms ............................................................................................. 34

Post-Sampling Data Reporting and Graphing ................................ 36

CHAPTER 4 MAINTENANCE ......................................................... 37

Returning the Instrument to TSI for Service ................................... 37

General Cleaning ............................................................................ 37

Using and Maintaining Built-in Impactors ....................................... 38

Using and Maintaining the Respirable Cyclone .............................. 42

Cleaning the Cyclone................................................................... 43

Using and Maintaining the Diesel Particulate Matter

DPM Cyclone ............................................................................... 44

Cleaning the Diesel Particulate Matter DPM Cyclone ................. 46

Calibrating of Measuring DPM ........................................................ 47

AM520/AM520i Field Service Kit – sold separately ........................ 48

CHAPTER 5 TROUBLESHOOTING ............................................... 49

Troubleshooting Table .................................................................... 50

Technical Contacts.......................................................................... 54

International Contacts .................................................................. 55

Service ......................................................................................... 55

Technical Support ........................................................................ 56

Returning for Service ...................................................................... 57

APPENDIX A SPECIFICATIONS .................................................... 59

APPENDIX B CUSTOM CALIBRATIONS ...................................... 63

Developing a Photometric Calibration Factor for a

Specific Aerosol ........................................................................... 64

Photometric Calibration Factor Procedure .................................. 64

Page 7

vii

APPENDIX C CONVERTING STORED DATA TO

CALIBRATED DATA .................................................................. 67

APPENDIX D

CSA CERTIFICATE OF COMPLIANCE ..................................... 69

AM520 DECLARATION OF CONFORMITY .............................. 70

AM520i DECLARATION OF CONFORMITY ............................. 72

Page 8

viii

(This page intentionally left blank)

Page 9

ix

Safety Information

When operated according to the manufacturer’s instructions, this

device is a Class I laser product as defined by U.S. Department of

Health and Human Services standards under the Radiation Control

for Health and Safety Act of 1968.

A certification and identification label similar to the one shown below

is affixed to each instrument.

There are no user-serviceable parts inside this instrument. Performing

services other than those described in this manual may result in

exposure to harmful (visible) laser radiation. A warning label like the

one shown below is affixed to the internal laser device.

DANGER: VISIBLE LASER

RADIATION WHEN OPEN. AVOID

DIRECT EXPOSURE TO BEAM

WARNING: NO USER SERVICEABLE

PARTS INSIDE. REFER SERVICING

TO QUALIFIED PERSONNEL.

Consult manual in all cases where the symbol is marked to find

out the nature of the potential HAZARD(S) and any actions which

must be taken to avoid them.

W A R N I N G S

• EXPLOSION HAZARD/ DANGER – DO NOT

OPERATE THIS EQUIPMENT UNTIL YOU

READ AND UNDERSTAND THE MANUAL FOR

ALL WARNINGS AND INSTALLATION

INSTRUCTIONS

Page 10

x

W A R N I N G S

• INTRINSICALLY SAFE (AM520i only)

• THE EFFECT OF THE INTERNAL LASER ON

GAS MIXTURES HAS NOT BEEN EVALUATED

BY CSA

• EXPLOSION HAZARD – SUBSTITUTION OF

COMPONENTS MAY IMPAIR INTRINSIC

SAFETY

W A R N I N G S

• FOR USE WITH BATTERY PACK PART

NUMBER 803322 (AM520i) ONLY

• FOR USE WITH BATTERY PACK PART

NUMBERS 803300 or 803322 (AM520) ONLY

• CHANGE AND/OR RECHARGE BATTERIES IN

A NON-HAZARDOUS LOCATION ONLY

• BATTERIES TO BE CHARGED WITH POWER

SUPPLY 803302 ONLY

• TO PREVENT IGNITION OF A HAZARDOUS

ATMOSPHERE, BATTERIES MUST ONLY BE

CHANGED IN AN AREA KNOWN TO BE

NON-HAZARDOUS

W A R N I N G S

• PRIOR TO ENTERING A HAZARDOUS

LOCATION, SEAL THE USB PORT WITH THE

ATTACHED USB DUST PLUG

• TO PREVENT IGNITION OF FLAMMABLE OR

COMBUSTIBLE ATMOSPHERES, READ,

UNDERSTAND AND ADHERE TO THE

MAINTENANCE PROCEDURES CONTAINED

IN THIS MANUAL

• SUBSTITUTION OF COMPONENTS MAY

IMPAIR INTRINSIC SAFETY

Page 11

Safety Information xi

The label on the intrinsic safety rating label directs you to read all

the warnings in the manual.

Intrinsic Safety Rating Information (AM520i only)

CSA

CLASS 2258-03 PROCESS CONTROL EQUIPMENT –

Intrinsically Safe and Non-Incendive Systems - For

Hazardous Locations – Certified to Canadian Standards

Class I, Division I, Groups A, B, C, D,

Class II, Division I, Groups E, F, G,

Class III; T4; Ex ia IIC T4 Ga

Rated: 12Vdc SELV, 3.0A

Ta = 0 °C to +50 °C

CLASS 2258-83 PROCESS CONTROL EQUIPMENT –

Intrinsically Safe and Non-Incendive Systems - For

Hazardous Locations – Certified to US Standards

Class I, Division 1, Groups A, B, C, D; T4

Class I Zone 0 AEx ia IIC T4 Ga

Rated: 12Vdc SELV, 3.0A

Ta = 0 °C to +50 °C

IECEx & ATEX

IECEx SIR 18.0043X

Sira 18ATEX2150X

Ex ia IIC T4 Ga

Ex ia I Ma

Rated: 12Vdc SELV

Ta = 0°C to +50°C

IECEx (SIMTARS)

IECEx SIM 19.0009X

Ex ia IIC T4 Ga

Ex ia I Ma

Rated: 12Vdc SELV

Ta = 0°C to +50°C

Page 12

xii

WARNING

Any damage to the base unit that results in a cracked or broken

case should be immediately returned to TSI® for repair as it may

affect safety rating compliance of the equipment. A damaged case

could allow for the ingress of dust, dirt or other material and

moisture into the unit and diminish the safety of the device.

W A R N I N G

• DO NOT attempt to disassemble or service the

battery pack.

• DO NOT short-circuit the battery pack.

• DO NOT incinerate or destroy the battery pack.

• DO NOT attempt to charge the battery packs

using anything except a TSI® approved power

supply. Doing so may cause permanent damage

to the pack.

Failure to comply with any of these warnings can

cause burns, blindness, severe injury or death. TSI®

will not service any pack which has been damaged

due to user neglect.

Keep away from children. DO NOT dispose of battery

pack in fire. Always dispose of your pack in

compliance with regional requirements.

Used in a manner not specified by TSI®, the protection

provided by the AM520/AM520i may be impaired.

The safety of any system incorporating an

AM520i/AM520 is the responsibility of the assembler

of the system.

Page 13

Safety Information xiii

W A R N I N G

• DO NOT ATTEMPT TO CONNECT THE USB

INTERFACE IN A HAZARDOUS AREA

• DO NOT OPEN WHEN AN EXPLOSIVE

ATMOSPHERE IS PRESENT

• EXPLOSION HAZARD – SUBSTITUTION OF

COMPONENTS MAY IMPAIR INTRINSIC SAFETY

• POTENTIAL ELECTROSTATIC CHARGING

HAZARD – SEE INSTRUCTIONS IN THE

MANUAL

• THE EFFECT OF THE INTERNAL LASER ON

GAS/PARTICLE MIXTURES HAS NOT BEEN

EVALUATED

WARNING

The safety of any system incorporating an AM520i/AM520 is the

responsibility of the assembler of the system.

Instructions Specific to Hazardous Area Installations

[in accordance with IEC 60079-0:2011 clause 30 (AM520i only)]

The following instructions relevant to safe use in a hazardous area

apply to equipment covered by certificate numbers IECEx SIR

18.0043X, IECEx SIM 19.0009X, and Sira 18ATEX2150X.

1. The certification marking is as follows:

Ex ia IIC T4 Ga (Protection method markings)

0°C to +50°C (Ambient Temperature Range)

AM520i (Model Number)

TSI Incorporated (Manufacturer’s Name)

500 Cardigan Rd, (Manufacturer’s Address)

Shoreview, MN

55126-3996, USA

520iYYWWNNN (S/N with Year/Week of Manufacture)

2. The equipment may be used in Zones 0, 1 & 2 with flammable

gases and vapors with apparatus groups IIA, IIB & IIC and with

temperature classes T1, T2, T3, T4.

3. The equipment may be used in mines susceptible to firedamp

with apparatus group I.

Page 14

xiv

4. The maximum surface temperature of the AM520i is 143.8°C

5. The equipment is only certified for use in ambient temperatures in

the range 0°C to +50°C and should not be used outside this

range.

6. Installation shall be carried out in accordance with the applicable

code of practice by suitably-trained personnel.

7. With regard to explosion safety, there are no special checking or

maintenance conditions other than a periodic check.

8. With regard to explosion safety, it is not necessary to check for

correct operation.

9. The equipment contains no user-replaceable parts and is not

intended to be repaired by the user. Repair of the equipment shall

only be carried out by the manufacturer, or approved and

qualified agents, in accordance with the applicable code of

practice unless otherwise prohibited.

10. If the equipment is likely to come into contact with aggressive

substances, e.g. acidic liquids or gases that may attack metals or

solvents that may affect polymeric materials, then it is the

responsibility of the user to take suitable precautions that prevent

it from being adversely affected, thus ensuring that the type of

protection is not compromised.

11. The certificate number has an “X” suffix which indicates that

special conditions of installation and/or use apply. Those

installing or inspecting this equipment must have access to the

contents of the certificate or these instructions. The conditions

listed in the certificate are reproduced below:

i. For application in the hazardous area, connection to the

Micro USB 2.0 Type B port terminal shall not be made. When

used outside of the hazardous area, the USB terminal may be

connected to non-intrinsically safe mating Micro USB 2.0

Type B port of a computer that shall be powered only by a

certified safety extra low-voltage (SELV) supply (per IEC

60950) having a Um output voltage limit of [25 VDC at

90 Watts].

Page 15

Safety Information xv

ii. The AM520i shall only be charged in the non-hazardous area

using the charger specifically supplied for use with the unit

approved as SELV (or Class 2, for North America) equipment

against IEC 60950. The maximum output voltage from the

charger shall not exceed 12 VDC. The battery pack assembly

model number 803322 shall only be removed or replaced in

the non-hazardous area.

Additional information

For reference, TSI® Incorporated main repair address is specified in

the beginning of Chapter 5 of this manual. In addition, International

repair/service addresses can be found in the Technical Contacts

section of Chapter 5.

Intended Use—AM520i

The AM520i is intended to measure the mass concentration of

particles suspended in air in hazardous locations as described by the

User Warnings, and Safety Marketing. Consult your company’s safety

professional for local standards.

Intended Use—AM520

The AM520 is intended to measure the mass concentration of

particles suspended in air in nonhazardous locations as described by

the User Warnings, and Safety Marketing. Consult your company’s

safety professional for local standards.

The specific standards against which the AM520i has been evaluated

are as follows:

IECEx (Sira, Issued 2018), IECEx (SIMTARS, Issued 2019)

• IEC 60079-0 Ed. 6: Explosive atmospheres – Part 0: Equipment –

General requirements

• IEC 60079-11 Ed. 6: Explosive atmospheres – Part 11:

Equipment protection by intrinsic safety “i”

ATEX (Sira 18ATEX2150X, Issued 2018)

• EN 60079-0: 2012/A11:2013 Explosive atmospheres – Part 0:

Equipment – General requirements

• IEC 60079-11:2012 Explosive atmospheres – Part 11:

Equipment protection by intrinsic safety “i”

Page 16

xvi

North America (CAN/US, Issued 2018)

• CAN/CSA-C22.2 No. 61010-1-12 (reaffirmed 2017): Safety

requirements for electrical equipment for measurement, control,

and laboratory use - Part 1: General requirements – Third Edition;

Update No. 1: July 2015; Update No. 2: April 2016

• CAN/CSA C22.2 No. 60079-0:15 Explosive Atmospheres – Part

0: Equipment – General Requirements – Third Edition

• CAN/CSA C22.2 No. 60079-11:14 Explosive Atmospheres – Part

11: Equipment Protection by Intrinsic Safety “i” – Second Edition

• CAN/CSA C22.2 No. 60529:16 Degrees of protection provided by

enclosures (IP Code) – Second Edition

• ANSI/UL 60079-0-2013 Explosive Atmospheres – Part 0:

Equipment – General Requirements Sixth Edition

• ANSI/UL 60079-11-2014 Explosive Atmospheres – Part 11:

Equipment Protection by Intrinsic Safety ″i" Sixth Edition

• ANSI/UL 61010-1-2016 Safety Requirements for Electrical

Equipment for Measurement, Control, and Laboratory Use – Part

1: General Requirements Third Edition

• ANSI/IEC 60529 - 2004 (reaffirmed 2011) Degrees of Protection

Provided By Enclosures (IP Code)

• ANSI/UL 913-2015 Standard for Intrinsically Safe Apparatus and

Associated Apparatus for Use in Class I, II, III, Division 1,

Hazardous (Classified) Locations Seventh Edition

Page 17

1

Chapter 1

Unpacking and Parts Identification

Carefully unpack the AM520/AM520i SidePak™ Personal Aerosol

Monitor from the shipping container. Use the table below to

identify the components that are included with the unit. A photo

and description of each item follows the table. If any parts are

missing, contact TSI® immediately. This list also includes items

that are not packaged with the product, yet available as

accessories sold separately.

AM520 with all accessories

(AM520i not shown)

Page 18

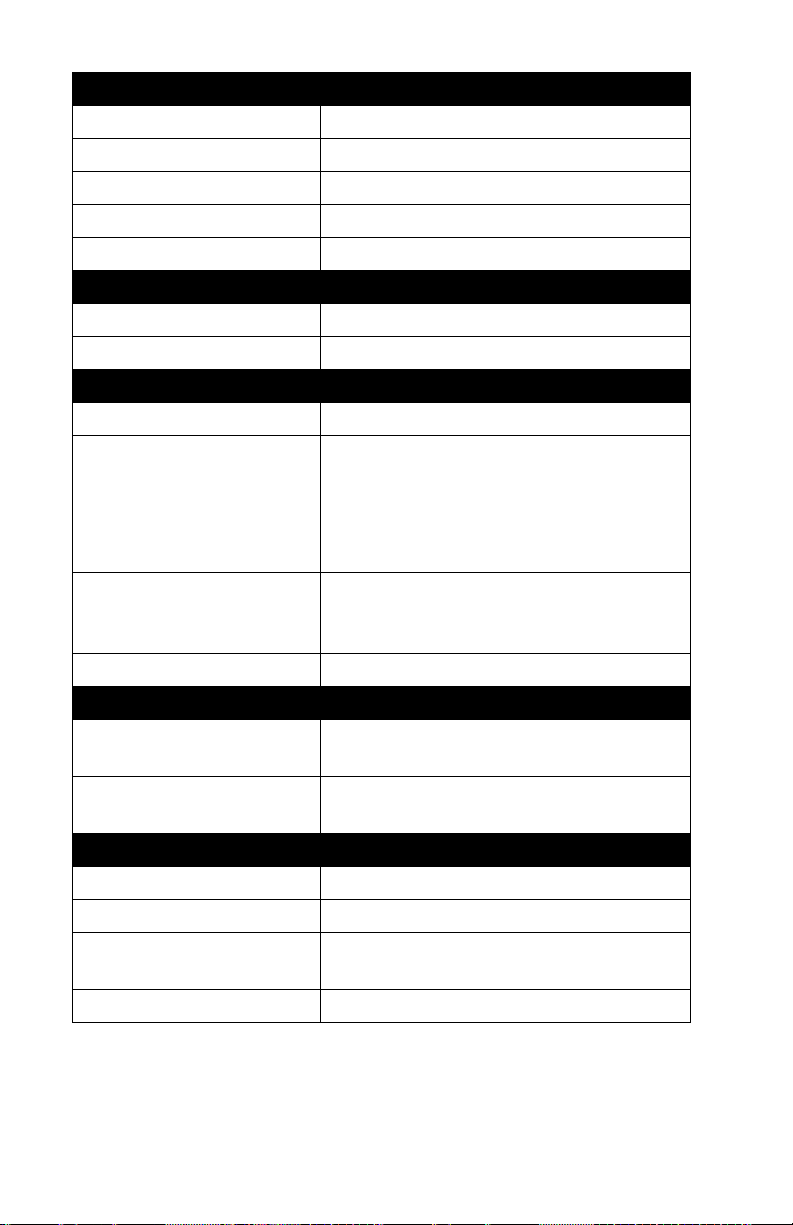

2 Chapter 1

Item Description

Part/Order

Number

Reference Picture

AM520 Personal Aerosol

Monitor

(shown with battery pack)

AM520

AM520i Personal

Aerosol Monitor

(shown with battery pack)

AM520i

AM520 Battery Pack,

5100 mAH

803300 or

803322

AM520 / AM520i Battery

Pack, 5100 mAH for use

in either product

803322

Single Carry Case

803313

Impactor Kit

(impactor oil, impactor

disc (3x), Blank inlet,

PM1 inlet, PM

2.5

inlet,

PM5 inlet, PM10 inlet.

6 ea. inlet gaskets)

803301

Page 19

Unpacking and Parts Identification 3

Item Description

Part/Order

Number

Reference Picture

PM2.5 Impactor Kit

803312

Dorr-Oliver 10-mm Nylon

Cyclone Kit

801701

DPM Cyclone Kit

803303

Calibration Jar, 1 liter

(accessory sold

separately)

803310

(photo courtesy of Zefon®)

TrakPro™ Data Analysis

Software CD

(The software can be

downloaded for free at

www.tsi.com.)

803309

(CD not

included, but

can be

ordered

separately)

AM520/AM520i Field

Service Kit

(includes: 3 ea. USB

Dust Plugs / 3 ea.

Impactor Disks / 6 ea.

Impactor Gaskets

803306

Zero Filter

800663

Page 20

4 Chapter 1

Item Description

Part/Order

Number

Reference Picture

AM520/AM520i Power

Supply with Universal

Plug Set

803302

USB Cable

803305

Sample Tube, Tygon®

conductive tubing

3 feet ( ~1 m)

801703

Phillips Screwdriver

803307

Calibration Certificate

N/A

AM520/AM520i

User Guide

6009829

Page 21

Unpacking and Parts Identification 5

Item Description

Part/Order

Number

Reference Picture

Quick Start Guide and

Keypad Functions

6009830

SidePak™

AM520/AM520i Personal

Aerosol Monitor Li-Ion

Battery Maintenance

Card

6009831

Page 22

6 Chapter 1

(This page intentionally left blank)

Page 23

7

Chapter 2

Setting Up

Supplying Power to the SidePak™ Aerosol Monitor

Attach the rechargeable battery pack to the SidePak™ Personal

Aerosol Monitor before use. This will “wake up” the battery from

storage mode. The battery can power the AM520/AM520i by itself or

in conjunction with the TSI® AC adapter.

The SidePak™ monitor also contains a miniature coin cell for

powering a Real-Time Clock. Changing the battery pack or

disconnecting the power supply/charger will not cause data to be lost.

Flash memory retains the data. The coin cell will last for many years.

TSI® will install a new coin cell, if necessary, when the unit is returned

for service. The coin cell is not user-serviceable.

NOTE

Only the AM520i is rated intrinsically safe for use in hazardous

locations when operated in accordance to this manual.

Installing and Charging the Lithium Ion Rechargeable Battery Pack

Battery packs slide on and off the AM520/AM520i in the direction

shown below:

NOTE

Plug in power cord and charge fully before turning on instrument

the first time. See Smart Battery Management™ System

technology below.

Page 24

8 Chapter 2

Installing the Lithium Ion Battery Pack

1. Place the battery pack under

the AM520/AM520i.

2. Push firmly to slide into place.

3. Fasten it in place using the

two battery screws provided.

Page 25

Setting Up 9

Removing the Lithium Ion Battery Pack

1. To remove battery, remove

battery screws.

2. Firmly grip sides of

instrument and sides

of battery.

3. Pull apart.

Smart Battery Management System™ technology

The rechargeable Lithium Ion battery pack is designed with Smart

Battery Management System™ (SBMS) technology. It contains a gas

gauge/supervisor chip to monitor pack capacity and control

charging/discharging.

The SBMS supervisor prevents the battery from overcharging when

the AC adapter has been left plugged into the battery. At end of the

charge cycle the SBMS supervisor disconnects (stops charging) the

cells while continuing to pass power on to the instrument. The

SBMS supervisor also prevents excessive discharge when the

battery is depleted.

Page 26

10 Chapter 2

TSI® recommends fully charging the battery before first use of a new

instrument. The battery can be charged when not installed in the

instrument. Accordingly, a second battery can be charged on its own,

while the equipment is in use with another battery. TSI® also

recommends recharging the battery after each use.

The SBMS system requires a few charge/discharge cycles to learn

the capacity of a new pack. (It should be close to capacity when you

first receive the battery.)

The SBMS system will learn the battery pack capacity more quickly if

the pack is fully charged and then fully discharged multiple times.

To maintain the greatest accuracy of the SBMS gas gauge, you

should periodically fully discharge then fully charge the battery (once

every few months).

Storing the Battery Pack between Uses

The rechargeable battery must not be allowed to sit in a fully

discharged state for long periods of time to prevent damage to the

instrument. The battery pack should be charged before storage and

recharged every six (6) months when not being used.

The rechargeable battery will last longer if it is stored in a cool place.

Hot temperatures over long periods of time (several months) will

increase cell internal self-discharge and eventually degrade the

battery capacity.

Page 27

Setting Up 11

W A R N I N G

Remove Li-ion battery during storage and transportation

of instrument.

Using the AC Adapter (power supply)

The AC adapter powers

the AM520/AM520i

from an AC wall outlet,

and charges the

rechargeable battery

pack. The AC adapter

can run the instrument

and charge the battery

at the same time. The

battery will charge more

slowly when the

instrument is running.

Connect the AC adapter to an AC wall outlet and plug the other end

into the barrel jack on the side of the rechargeable battery.

Normal charge time is about four (4) hours with the instrument off or

when the battery is removed from the instrument.

Battery LED

When charging the battery, the

green LED in the battery pack will

repeatedly flash from dim to bright.

When the battery is fully charged,

the LED will stay on until the AC

adapter is unplugged.

If the temperature is too hot or too

cold to charge the battery, the LED

will flash 3 seconds on, then

1 second off. If the battery has an

internal fault that prevents charging,

the LED flashes rapidly.

Page 28

12 Chapter 2

Battery Icon on Display

When the battery is charging, the battery icon on the instrument

display repeatedly flashes a pattern with increasing numbers of

segments. When charging is complete, the icon indicates a full

charge. A full battery icon means at least 10 hours of battery life is

available. When battery life is less than 10 hours, the battery icon will

show proportionally less full.

When the battery life remaining is less than 15 minutes, the battery

icon will flash red. When the battery is depleted, the AM520/AM520i

will display a “LOW BATTERY” message for 5 seconds and then turn

itself off.

Displayed Battery Life

The AM520/AM520i shows battery life remaining in Hours:Minutes or

Minutes (user selectable) when displaying the Survey mode menu or

while actively data logging and showing the Logging menu. Those

screens may first show battery life as asterisks (*) for a few seconds

while the instrument gathers power consumption data. If the AC

adapter is plugged in, "A/C Power" is displayed.

Installing TrakPro™ Data Analysis Software

TrakPro™ Data Analysis Software can preprogram the SidePak™

AM520/AM520i monitor, download data, view data, create graphs and

statistical reports, and combine graphs with data from other TSI®

instruments that use TrakPro™ software. Refer to the TrakPro™ Data

Analysis Software manual for installation and operating instructions.

Page 29

13

Chapter 3

Operation

Overview

The SidePak™ Personal Aerosol Monitor is a miniature batteryoperated laser photometer that measures airborne particle massconcentration in units of milligrams per cubic meter (mg/m3).

The built-in sampling pump flow rate is user-adjustable; giving the

user the flexibility to attach a wide variety of inlet conditioners to

sample from the worker’s breathing zone or other locations. The

rugged belt-mountable unit is small, quiet, and lightweight, minimizing

interference and discomfort for the wearer. The high resolution OLED

display shows aerosol concentration and 8-hour TWA (time-weighted

average) in real time. Information can be stored and later downloaded

via a Windows®-based PC using the enclosed TrakPro™ software

and USB (Universal Serial Bus) communications cable.

Identifying SidePak™ AM520/AM520i Features

USB Port

Use the Universal Serial Bus

(USB) port and USB cable to

connect the instrument to an

available USB port on your

computer. The connector on the

instrument is a USB Micro-B

receptacle.

Page 30

Chapter 3

14

Power Port

Connect the power supply to

this port to charge the TSI®

battery pack or to power the

instrument at any time.

NOTE

Many power supplies look

alike. Use the proper power

supply to prevent damage.

NOTE

After charging the battery, close/seal the AC power port with the

attached AC dust plug.

Exhaust Port

Air drawn though the

instrument exits here.

Inlet

Interchangeable inlet.

Install the standard

inlet or one of four

impactors provided

with SidePak™

AM520/AM520i Kits.

Page 31

Operation

15

Battery

Screws

Remove these

two screws to

remove the

battery.

Page 32

Chapter 3

16

Keypad Functions

To turn the instrument ON, press the ESC key.

To turn the instrument OFF, press and hold the ESC key for three (3)

seconds (release key when the countdown reaches "0 SECONDS."

The model number, serial number, and firmware revision are

displayed for a few seconds before entering Survey Mode.

Press the ESC key twice to enter the Main Menu.

ESC key. Used to turn power on and off, and to go

back to the previous menu.

Use the ▲▼ arrow keys to scroll through vertical

menus and to change numeric values.

Use the (ENTER) key to execute selected menu

options and confirm changes.

Locked keypad. To lock the keypad, press the ▲

key and simultaneously press (ENTER). A red

lock icon is briefly shown to indicate that the keys

are locked. To unlock the keypad, use the same

method.

This function is only available from Survey Mode or

Logging Mode while the screen saver is active, or

while Program Logging is active and the “PROG

DELAY” screen is shown while waiting for Program

Logging to start.

Page 33

Operation

17

Main Menu

The menu structure of the SidePak™ monitor is very easy to use. The

graphic below shows the menu structure from the Main Menu. After

power up, the instrument will be in Survey Mode as indicated by the

.

From the Main Menu, use the ▲ ▼ keys to select one of the following

category menus and then press the Enter key:

• Run Mode

• Settings

• Calibration

• Data

• Alarms

Refer to the sections below for details on each of the sub-menu items

under each category.

Page 34

Chapter 3

18

Power Up

Turn the instrument on

by pressing the ESC

key. The instrument

displays the TSI® logo

followed by the model

number, serial number,

and firmware version.

The instrument will begin Survey

Mode. "Survey" will display briefly,

then just the survey mass

concentration reading.

Power Down

To power the instrument off, press and hold the ESC key and release

it after the 3-second countdown reaches zero.

Survey Mode

After Powering Up the unit, it will be in

“SURVEY” mode, data logging is not yet

enabled. Use the Enter key to toggle back

and forth between the Survey mode screen

and the Survey mode menu. The Survey

mode menu displays:

• Real-time aerosol concentration in units of milligrams per cubic

meter (mg/m³)

• Percentage of logging memory available

• Battery life remaining

• Time of day

• Current Date

• Currently selected calibration factor

Page 35

Operation

19

When the monitor is in Survey screen saver mode, the title “Survey”

and the battery icon are briefly displayed and will disappear after a

few seconds. Real-time aerosol concentration is shown at a random

screen location, which changes every 15 minutes to prevent display

burn-in.

In this mode, the pushbuttons can be locked by first pressing

key, then simultaneously pressing ENTER key. A red lock icon is

briefly shown to indicate that the keys are locked. The keys can be

unlocked in the same fashion: by first pressing the key, then

simultaneously pressing ENTER key.

When in the Survey mode, you can access the Main Menu by

pressing the ESC key twice.

Data Logging

The AM520/AM520i can log data in either:

• Manual logging mode, or

• Program logging mode.

To run the instrument in Manual logging

mode, select Manual Mode from the RUN

MODE menu and press the ENTER key.

The instrument will immediately start logging and it will use the Log

Interval (set in the Log Interval option of the SETTINGS menu).

Manual logging stops automatically when logging memory is full or

the ESC key is pressed.

To run the AM520/AM520i in Program logging mode, select the

desired program logging mode from the RUN MODE menu, and press

ENTER. There are five program logging modes available. The default

names are “Prog 1” through “Prog 5”. These can be renamed and the

values set using TrakPro™ Data Analysis Software. If a specific start

time or date was selected using TrakPro™ software, the instrument

will wait until the start time and then automatically begin logging. If the

start time/date is in the past, the instrument will show the error

message "Invalid start time."

If the instrument is programmed to wait before logging, it will show a

“PROG DELAY” screen with the current time/date and the

programmed start time/date. If the starting time/date is more than one

minute in the future, the instrument will turn off the pump and laser in

order to save power.

Page 36

Chapter 3

20

The “PROG DELAY” screen will disappear

after a few seconds and “PROG DELAY”

will flash briefly once every two seconds to

show that the instrument is waiting to start.

If a key is pressed while the instrument is

waiting, it will show the full “PROG DELAY”

screen again.

Programmed logging mode uses start and stop time/date, logging

interval, Test length, number of Tests, and wait time between Tests

programmed in TrakPro™ software.

While data logging is active, the screen can be toggled back and forth

between the LOGGING DATA menu and the screen saver. The

LOGGING DATA menu displays:

• Real-time aerosol

concentration in units of

milligrams per cubic meter

(mg/m³)

• Which logging mode is being

used

• Battery life remaining

• 8-hour Time Weighted

Average (TWA), if available

• Time spent logging

• Time of day

• Current date

• Log interval

Six menu items are displayed at a time. Scroll down to view additional

menu items that are off screen.

The AM520/AM520i displays the “Logging

Data” screen saver after a user-selectable

delay, or if ENTER is pressed. It can be

toggled back and forth between the

LOGGING DATA menu and the screen

saver using the ENTER key.

The screen saver briefly displays the title “Logging Data” and shows

the battery icon. These disappear after a few seconds to save power.

Real-time aerosol concentration is shown at a random screen

location. When the screen saver is active, the keys can be locked by

first pressing the ▲ key, and simultaneously pressing ENTER key. A

red lock icon is briefly shown to indicate that the keys are locked.

The keys can be unlocked in the same fashion: by first pressing the

▲ key, and simultaneously pressing ENTER key. The keys can also

be locked/unlocked while the “PROG DELAY” screen is active waiting

for programmed logging to start.

Page 37

Operation

21

To stop logging or cancel a logging program, press the ESC key. If

logging is already in process, you will have to confirm by pressing

ENTER. When data logging stops, the instrument displays a message

showing whether any data was saved.

Run Mode

The Run Mode menu contains the

following options:

• Survey

• Manual Mode

• Prog 1 though Prog 5

Use the ▲ ▼ keys to make a selection,

and press ENTER to accept.

Survey Mode

See description of Survey Mode above.

Manual Mode

Data logging begins when Manual Mode is selected by pressing

ENTER. The data logging session is called a “Test”. See Data

Logging, above. The test is stopped by pressing ESC then ENTER.

While running a manual test, the display shows LOGGING DATA as

well as the time constant concentration. Manual tests use the logging

interval defined in Log Interval under the SETTINGS menu.

Each test is assigned a sequential number (for example, TEST#1,

TEST#2, … TEST#100) until memory is used up or cleared.

Press or ESC to stop a test in progress. The instrument will ask to

confirm to stop the test or not, while data logging continues. If ESC is

pressed to continue, there will be no break in the logged data.

Program Mode

Prog 1 …Prog 5 activates a data logging test that has been

preprogrammed using TrakPro™ Data Analysis Software.

Preprogramming allows a great deal of flexibility that is not available

with manual logging, such as predefined start and stop times, logging

intervals, calibration factors, and more. See the TrakPro™ software

manual for more information.

Page 38

Chapter 3

22

During data logging, use the ESC key to view:

• Battery life remaining

displayed in minutes

• 8-hour TWA

• Elapsed time

• Current time and date

• Log interval

If the user-selectable screen save delay elapses without a key being

pressed, the display reverts back to the LOGGING DATA screen

saver.

To stop a test, press the ESC key. The instrument will confirm to stop

the test or not, while data logging continues. If the ESC key is

pressed, data logging will continue with no break in the logged data.

If a test in progress is stopped, the instrument will display the

message “Logging Stopped” and show whether any data was saved.

If the test is stopped before any data points have been recorded, the

display will show “no data saved”. This may happen if the logging

interval is set to one minute and the test is stopped before the first

data point is recorded.

Settings

Access the SETTINGS menu from the

MAIN MENU, then use the ▼ key to select

SETTINGS and press .

The SETTINGS menu provides access to

the following items. Use the ▲ ▼ keys to

select the item you want to access and

press . Each selection is described in

detail below.

• Log Interval

• Time Constant

• Time/Date

• Battery Units

• Screen Save Delay

• Language

• Information

Page 39

Operation

23

Setting the Log Interval

The Log Interval is the time interval used

between recorded data points during

Manual Mode logging operations (log

intervals for Prog-1 through Prog-5 are set

using TrakPro™ Software). For example, if

the Log Interval is set to 30 seconds, a data

point is stored to memory once every 30

seconds. Longer Log Intervals can be used

to conserve memory for long duration tests.

The SidePak™ AM520/AM520i always makes a measurement once

every second regardless of the log interval selected. Using a log

interval greater than one second results in stored data points that are

averages of the 1-second readings. For example, a 10-second log

interval will result in one stored data point every 10 seconds. Each of

those data points will represent the computed average of ten,

1-second readings.

DO NOT mistake log intervals with Time Constant. Log intervals only

affect recorded readings. Time Constant only affects the

AM520/AM520i OLED display.

Five log intervals choices are preprogrammed. This list of available

log intervals can be modified using TrakPro™ Software.

After selecting Log Interval from the Setup Menu, the display will

show LOG INTVLx where "x" is a number from 1 to 5. This is the

currently selected log interval. The value of that log interval is shown

on the second line.

Use the ▲ ▼ keys to scroll through the available log intervals. Press

when the interval you want to use is displayed. The factory-preset

choices are:

• Log Interval 1: 1 Sec.

• Log Interval 2: 1 Min.

• Log Interval 3: 5 Mins.

• Log Interval 4: 15 Mins.

• Log Interval 5: 30 Mins.

Page 40

Chapter 3

24

Setting the Time Constant

The Time Constant is used to dampen

fluctuations in the displayed readings and

make them easier to read. The Time

Constant setting affects values shown on

the instruments display only. DO NOT

mistake Time Constant with logging

intervals. Time Constant only affects the

display. Log intervals only affect recorded

readings.

The SidePak™ AM520/AM520i always makes a measurement once

every second and updates the display every second regardless of the

Time Constant selected. Using a Time Constant greater than one

second results in displayed readings that are averages of the

1-second readings. For example, a 10-second Time Constant will

cause the display to show an average of the most recent ten

1-second readings. In other words it is a 10-second "moving

average," updated every second.

There are five preprogrammed choices for Time Constant. If

necessary, the list of available Time Constant may be permanently

altered using TrakPro™ Software.

After selecting TIME CONSTANT from the SETTINGS menu, the

display will show Time Constant x where "x" is a number from 1 to 5.

This is the currently active Time Constant. The value of that Time

Constant is shown on the second line.

Use the ▲ ▼ keys to scroll through the available Time Constants.

Press when the Time Constant you want to use is displayed. The

factory-preset choices are:

• Time Constant 1: 1 sec

• Time Constant 2: 5 sec

• Time Constant 3: 10 sec

• Time Constant 4: 15 sec

• Time Constant 5: 30 sec

Page 41

Operation

25

Log Interval vs. Time Constant

• The Log Interval is the time interval used between recorded data

points. It can be set using the SETTINGS menu and in Program

logging mode using TrakPro™ software.

• The AM520/AM520i always takes a measurement once every

second regardless of the Log Interval. Using a Log Interval

greater than one second results in stored data points that are

averages of the 1-second readings. For example, a 10-second

log interval will result in one stored data point every 10 seconds,

with each data point being the average of ten 1-second

readings. Using a longer logging interval conserves memory in

the instrument during long sample runs.

• The Time Constant is an averaging period used to dampen

fluctuations in displayed readings so they are easier to read.

• The AM520/AM520i always takes a measurement once every

second regardless of the Time Constant selected. Using a Time

Constant greater than one second results in displayed readings

that are averages of the 1-second readings. For example, a

10-second Time Constant will cause the display to show an

average of the most recent ten 1-second readings. This results

in a 10-second moving average, updated on the display every

second.

• DO NOT mistake “Time Constants” with “Log Intervals.”

Time Constants affect only the display. Log Intervals affect

only the recorded readings. Therefore, the recorded logged data

will generally not match the displayed log data.

• When using general Alarms or STEL Alarms, the alarm is

triggered based on the displayed Time Constant reading, not the

value of the logged data over the Log Interval. Therefore, the

recorded logged data will generally not match the alarm values

exactly. For instance, if a Time Constant of 30 seconds and a

Log Interval of one second are chosen, the displayed reading

will be smoothed out over 30 seconds. Since the Alarms trigger

from the displayed value and not the logged value, there could

be one or more data points saved in the logged Test with values

above the Alarm setting, but if the average over 30 seconds is

less than the Alarm setting, the Alarm will not trigger.

Page 42

Chapter 3

26

Setting the Time and Date and Date

Format

Set the Date Format

The date format is user-selectable. The

formats available are:

• yyyy/mm/dd (default)

• mm/dd/yyyy

• dd/mm/yyyy

where yyyy is the 4-digit year, mm is the

2-digit month, and dd is the 2-digit day of

month.

1. Select SETTINGS from the MAIN MENU with the ▲ ▼ keys and

press .

2. Under SETTINGS MENU, select TIME/DATE with the ▲ ▼ keys

and press .

3. Under TIME/DATE, select Format with the ▲ ▼ keys and

press .

4. Use the ▲ ▼ keys, select the desired format, then press .

5. Press the ESC key to return to TIME/DATE menu.

Set the Current Time

1. Select SETTINGS from the MAIN

MENU with the ▲ ▼ keys and

press .

2. Under SETTINGS MENU, select

TIME/DATE with the ▲ ▼ keys and

press .

3. Under the TIME/DATE menu, use the ▲ ▼ keys to select the

time.

4. Set the correct hour in 24-hour format (e.g., 3 pm = 15 hours)

then press .

5. Set the correct minutes using the ▲ ▼ keys then press .

6. Press the ESC key to return to TIME/DATE menu.

Page 43

Operation

27

Set the Current Date

1. Select SETTINGS from the MAIN

MENU with the ▲ ▼ keys and

press .

2. Under SETTINGS menu, select

TIME/DATE with the ▲ ▼ keys and

press .

3. Under TIME/DATE menu, select the date and press RETURN.

4. Use the ▲ ▼ keys to set the month, day and year and press

after each value is entered.

5. Press the ESC key to return to TIME/DATE menu.

Battery Units

Battery life remaining can be displayed in

minutes or in hours and minutes.

1. Select SETTINGS from the MAIN

MENU with the ▲ ▼ keys and

press .

2. Under SETTINGS menu, select Battery Units with the ▲ ▼ keys

and press .

3. Use the ▲ ▼ keys to select Minutes or Hour+Min and press .

The format selected will be displayed on all screens, then return

to the SETTINGS menu.

Screen Save Delay

The OLED screen display can be set to

go blank after a period of time to

conserve battery life. To set the delay:

1. Select SETTINGS from the MAIN

MENU with the ▲ ▼ keys and

press .

2. Under SETTINGS menu, select Screen Save Delay with the ▲

▼ keys and press .

3. Use the ▲ ▼ keys to select the delay. Options are 10, 15, 20, 30

or 60 seconds.

4. Press . The delay selected takes effect immediately, and returns

to the SETTINGS menu.

Page 44

Chapter 3

28

Language

The display language can be changed to

English (default) or Chinese. To set the

language:

1. Select SETTINGS from the MAIN

MENU with the ▲ ▼ keys and

press .

2. Under SETTINGS menu, select Language with the ▲ ▼ keys

and press .

3. Use the ▲ ▼ keys to select the desired language.

4. Press . The language you selected takes effect immediately,

and returns to the SETTINGS menu.

Information

Information about the SidePak™ model

number, serial number, firmware version

and last date of calibration is displayed

under the INFORMATION selection. To

view the information:

1. Select SETTINGS from the MAIN

MENU with the ▲ ▼ keys and

press .

2. Under SETTINGS menu, select Information with the ▲ ▼ keys

and press .

3. View the information.

4. Press RETURN to return to the SETTINGS menu.

Calibration

The calibration (CAL) factor is a multiplier that is applied to the raw

data prior to being displayed or recorded. The purpose of the

calibration factor is to compensate the readings for aerosols that have

different photometric properties than the aerosol used during factory

calibration.

Page 45

Operation

29

Effect of Calibration Factors on Full Scale and Alarms

• Note that the instrument maximum full scale reading is not fixed

at 100 mg/m³; it changes when the Calibration Factor is

changed.

• For instance, if a Calibration factor of 2.00 is chosen, all

readings are multiplied by 2.00, and the effective maximum full

scale reading of the instrument is then 200 mg/m³.

• Since the range of selectable Calibration factors is 0.10 to

10.00, the effective maximum full scale reading can be

anywhere between 10.0 and 1000 mg/m³.

• Since the Alarm value must be allowed to approach full scale,

the maximum Alarm value is 999 mg/m³. This creates a

situation where the Alarm value can be set higher than the

maximum full scale reading. In this case, the instrument will

never be able to read high enough to trigger the Alarm.

• To prevent this situation, the instrument displays the message

“Warning: Alarm value is out of range” if you try to enter a

value that is out of range.

There are three items on the Calibration menu.

Zero Cal

This activates a function which

re-zeroes the measurement

using a filter.

Flow Cal

This activates a function which

allows you to set the pump

voltage to achieve the desired

sample flow.

User Cal

This allows you to select a

photometric calibration factor

to adjust the instrument

response to more closely

match the properties of the

aerosol being measured.

Page 46

Chapter 3

30

Zeroing the Instrument (Zero Cal)

For best results, it is important to zero the

instrument before each test. This ensures

accurate data, especially for low aerosol

concentrations. The process only takes a

few minutes.

1. Locate the zero filter provided with the

AM520/AM520i kit and attach it to the

inlet of the SidePak™ monitor.

2. Start the instrument by pressing the

ESC key. After the monitor goes into

SURVEY mode, press the ESC key to

reach the MAIN MENU.

3. Under MAIN MENU, use the ▲ ▼

keys to scroll to CALIBRATION and

press .

4. Under the CALIBRATION menu, use

the ▲ ▼ keys to scroll to Zero Cal and

press .

5. The instrument will prompt you to attach the zero filter to the inlet.

When the zero filter is connected, press .

6. The instrument will count-down from 60 to 0 and display Zero Cal

Complete.

7. Press the RETURN key to return to the CALIBRATION menu.

8. The instrument is now ready to make accurate measurements.

Page 47

Operation

31

Flow Cal

Aerosol concentration measurements with

the SidePak™ AM520/AM520i monitor are

accurate regardless of the flow rate through

the instrument. However, size-selective

aerosol sampling inlets such as impactors

and cyclones require specific flow rates to

function within their design specifications. If

using a size-selective inlet, adjust the flow

rate precisely. It is always a good practice to

adjust the flow rate before the start of a

sampling session.

AM520 connected to TSI 4146 Flow Meter (sold separately)

To adjust the flow rate, you will need a flow calibrator. This can be a

simple rotameter or a precision flow calibrator often used for setting

the flow on personal sampling pumps. A flow calibrator is an optional

item and is not included with standard AM520/AM520i kits.

1. Connect a flow calibrator to the inlet.

2. Start the instrument by pressing the ESC key. After the

SidePak™ monitor goes into SURVEY mode, press the key to

reach the MAIN MENU.

3. Under MAIN MENU, use the ▲ ▼ keys to scroll to

CALIBRATION and press .

4. Under the CALIBRATION menu, use the ▲ ▼ keys to select

FLOW CAL and press .

5. Press .

6. Each single click of an ▲ ▼ key changes the flow by 1 percent of

the available range. The flow rate can be changed more quickly

by holding the arrow key down. The range is 0 to 200.

Page 48

Chapter 3

32

User Cal

Selecting a Photometric Calibration Factor

will cause the SidePak™ monitor's response

for all subsequent measurements to be

multiplied by the new calibration factor. User

cal 1 to 7 can be selected through the user

interface or TrakPro™ software.

To select the calibration factor through the user interface:

1. Under MAIN MENU, use the ▲ ▼ keys to scroll to

CALIBRATIONS and press .

2. Under CALIBRATION menu, use the ▲ ▼ keys to select USER

CAL and press .

3. Under USER CAL, use the ▲ ▼ keys to select the calibration you

want and then press to confirm the setting.

User Cal 1 (Factory) is set to 1.00 by TSI® and cannot be

adjusted.

User Cal 2 (Ambient) is set to 0.38 by TSI® and cannot be

adjusted.

User Cal 3 to 7 default to 1.00 and can be adjusted from 0.10 to

10.00 through TrakPro™ software.

User Cal 3 to 7 can be changed in the field through the

AM520/AM520i menu, after pressing to select the desired

factor, adjust the value of the cal factor using the ▲ ▼ keys.

Press the key again to accept the changes and return to the

CALIBRATION Menu.

After selecting Cal Factor, the display will show the currently active

cal factor (“CF= x.xx”) when the Survey menu is displayed.

Page 49

Operation

33

Data

The DATA menu lets you view statistics

of the SidePak™ monitor and clear

the memory.

Statistics

To view Statistics:

1. Select Data from the MAIN MENU with

the ▲ ▼ keys and press .

2. Under DATA menu, select Statistics

with the ▲ ▼ keys and press .

3. Select the Test (for example Test 3)

with the ▲ ▼ keys and press .

4. The Statistics menu displays computed statistics for each test (up

to 100 tests) that have been made using Run Manual, and Prog 1

through Prog 7 data logging methods. The statistics computed by

the SidePak™ AM520/AM520i include:

• Max: Maximum concentration value recorded (mg/m3)

• Min: Minimum concentration value recorded (mg/m3)

• Avg: Average of recorded concentration values (mg/m3)

• TWA: 8-hour time-weighted average (mg/m3)

• Time: Elapsed time of test

5. If the display shows N/A for the TWA, it means that there is not

enough data in that test to compute the TWA. The instrument

must be operated for a minimum of 15 minutes before a valid

TWA may be calculated.

6. Press the MENU key to return to STATISTICS menu.

Clear Memory

Clear Memory permanently erases all

logged data and associated statistics stored

in memory. It will not affect the Prog-1

through Prog-7 stored programs, stored Cal

Factors, or any other settings.

Page 50

Chapter 3

34

To Clear Memory

1. Select Data from the MAIN MENU with the ▲ ▼ keys and

press .

2. Under DATA menu, select Clear Memory with the ▲ ▼ keys and

press .

3. You will be prompted to confirm your intention.

4. Press Enter. You will be returned to the Data menu.

Alarms

The unit is equipped with two alarm types:

• General Alarm

• STEL Alarm

Both the General Alarm and the STEL Alarm have five default alarm

settings: 0.5 mg/m3, 1 mg/m3, 3 mg/m3, 5 mg/m3, and 15 mg/m3 and

OFF.

TrakPro™ v5 software can be used to set alarm values from 0.001 to

999 mg/m3.

A General Alarm is active during Survey mode and while data

logging. If the displayed Time Constant reading exceeds the Alarm

value, the alarm triggers. Depending on settings in the ALARMS

menu, the display will flash red or the LEDs on the membrane switch

may flash or an audible beeper may sound. All three of those alarm

indications can be turned ON/OFF through the ALARMS menu.

Once triggered, the Alarm stays active until the displayed reading

drops below 95% of the Alarm value. The alarm can be “delayed” or

“muted” with the Ringback delay function. If the displayed reading is

more than 90% of the Alarm value, the display flashes yellow.

A STEL Alarm is active during data logging only and is not active in

Survey mode. If the displayed Time Constant reading exceeds the

STEL Alarm value, the STEL Alarm triggers. When the STEL Alarm

triggers, a STEL Record is started in the logged data. A STEL Record

contains the average concentration taken every minute during the

length of the STEL Record.

Page 51

Operation

35

STEL Record length is selectable from 5 to 30 minutes through

TrakPro™ software. Since the start of a STEL Record is not usually

aligned with the Log Interval, the values of averages saved in the

STEL Record will generally not match the values saved each Log

Interval.

Ringback delay: The Ringback delay is a

user function that will “mute” an activated

alarm for the selected period of time.

General Alarms and STEL Alarms can be

muted for the duration of the Ringback delay

setting: 30 sec, 1 min, 3 min, 5 min, 10 min,

off. After the Ringback delay expires, the

Alarm will sound again.

When an alarm sounds, the Ringback delay can be activated by

pressing the button. The Ringback delay button is functional even

when the front panel is locked.

To select an alarm and an alarm action:

1. Select ALARMS from the MAIN MENU with the ▲ ▼ keys and

press .

The ALARMS menu has the following options:

• Select Alarm

• Select STEL

• LEDs

• Audible

• Screen

• Ringback

2. Select Alarm or STEL with the ▲ ▼ keys and press .

3. Select the setting you want to use from the list of available values

with the ▲ ▼ keys and press

4. Use the ▲ ▼ keys to select an alarm indicator: LEDs, Audible,

Screen or Ringback and press .

5. Turn the indicator ON or OFF for LEDs, Audible, and Screen.

6. Select a Ringback delay time from the RINGBACK menu.

Page 52

Chapter 3

36

Post-Sampling Data Reporting and Graphing

After collecting and logging data, all tests and data can be

downloaded to a personal computer via the supplied USB cable. For

data report generation and graphing, use the TSI® TrakPro™ v5.x.x

Data Analysis Software (TSI® P/N 7003173).

With the TrakPro™ software, you can also program the internal

settings of the AM520/AM520i units for performing future dust

monitoring studies. See the product information of the TSI® TrakPro™

software for all the features and capabilities that enhance the use of

your SidePak™ AM520/AM520i Personal Aerosol Monitor.

TrakPro™ software is available for download from the TSI® website

at: https://www.tsi.com/support/tsi-software-and-firmware/.

Page 53

37

Chapter 4

Maintenance

The SidePak™ AM520/AM520i Personal Aerosol Monitor requires

periodic maintenance. The most common procedures are:

• General cleaning

• Impactor maintenance

• Cyclone maintenance

• Charging batteries

• Zeroing the Instrument

In addition to the procedures in this chapter, TSI® recommends that

you return your SidePak™ AM520/AM520i Personal Aerosol Monitor

to the factory for annual calibration. Regular factory-authorized

cleaning and recalibration helps ensure that your instrument is

working properly, has the latest updates, and will provide accurate

and reliable measurements.

Returning the Instrument to TSI® for Service

When sending the instrument to TSI® for repair or service, include all

parts and accessories. To troubleshoot a problem, a TSI® Technician

will attempt to recreate the problem by running the instrument. All

equipment used with the instrument is needed to do this.

W A R N I N G

Remove Li-ion batteries from instrument before shipping. DO NOT

ship AM520/AM520i with batteries installed.

General Cleaning

General cleaning of the SidePak™ AM520/AM520i case should be

done with soap and water applied with a damp cloth.

NOTE

DO NOT use chemical cleaners, alcohol or petroleum derived

cleaners on the case or front panel of the instrument.

Page 54

Chapter 4

38

Use a foam or lint-free swab to clean the alarm vents on the front of

the unit.

NOTE

DO NOT use high pressure compressed air as this may harm the

internal membrane of the alarm horn and re-aerosolize particulate

matter.

Using and Maintaining Built-in Impactors

Included with the instrument is a set of

four impactor inlets and gaskets that can

be used in place of the standard inlet to

conveniently separate specific particle

size fractions. The 50% cut-off size is

marked in micrometers (μm) on each

inlet. The four impactor inlets provide

cuts at 1.0 μm, 2.5 μm, 5 μm, and

10 μm, corresponding to PM

1.0

, PM

2.5

,

PM5, and PM10 specifications respectively. All inlets are made of

conductive plastic to eliminate particle losses due to static charges.

The “standard inlet” does not have a size marking on the top edge

and does not cause any specific particle size separations. It is

intended for use with external size-selective aerosol samplers such as

a cyclone or external impactor at any flow rate within the allowable

range. When using a cyclone or external impactor, the impactor disk

should not be used.

NOTE

SidePak™ monitor built-in impactors must be operated with the

flow rate set to 1.7 L/min for proper performance. Using other flow

rates will result in unknown particle size fractions. The standard

inlet can be used at any flow rate.

Always use the standard (unmarked) inlet when sampling through

an external size-selective sampler such as a cyclone or external

impactor.

Page 55

Maintenance

39

SidePak™ size-selective inlets are used

with an internal impactor disk (provided).

The impactor disk functions as a

collection plate where particles larger

than the cut-size are trapped. The same

impactor disk is used for all impactors,

but it is not used for the standard inlet.

To make sure unwanted (large) particles

remain trapped on the impactor disk, it is

necessary to apply 1 to 4 drops of

impactor oil on the impactor disk for

particles to stick to. Wipe off any excess oil if necessary.

NOTE

Size-selective impactors will not function unless an impactor disk is

installed. To ensure proper performance, the impactor disk should

be removed, cleaned and re-oiled prior to each use.

1. Remove the impactor by loosening the two captive screws that

hold the impactor in place.

2. Flip the instrument upside down

to remove the impactor disk.

Page 56

Chapter 4

40

3. Clean the impactor inlet and

impactor disk with a clean lintfree swab or microfiber cloth and

light solvent. Gently blow

impactor body dry with

canned/pressurized clean air or

allow to air dry. Use a lint-free

swab or microfiber cloth to clean

impactor well inside the

instrument case to remove

accumulated particles.

WAR NI NG

To prevent driving

contamination into the optics,

never blow air directly into the

sample inlet opening of the

AM520/AM520i.

4. Apply 1 to 4 drops of oil to the

top of the impactor disk

(collection plate). Wipe off

excess oil if necessary.

5. Slide the impactor disk into the

impactor well until it is seated.

Page 57

Maintenance

41

6. Place inlet gasket on the inlet so that the tabs on the gasket fit

inside the inlet around inner tabs of the inlet as shown.

7. Place impactor inlet on

instrument.

8. Secure the impactor assembly

back onto the instrument body by

tightening the two captive

screws. To avoid damage,

DO NOT over-tighten.

Page 58

Chapter 4

42

Using and Maintaining the Respirable Cyclone

The 10-mm Nylon

Dorr-Oliver Cyclone

included with the

AM520/AM520i can

be used to

differentiate between

the respirable fraction

and other portions of the ambient aerosol. It is ideal for making

breathing zone measurements because it can be attached to a

worker's clothing near his or her head. TSI® supplies a U-tube and

clip with the cyclone specifically for this purpose.

4 µm is internationally accepted as the 50% cut-off size for respirable

aerosols. Particles larger than 4 µm impact onto the surfaces of the

upper respiratory tract and cannot reach the lungs. The cyclone

accessory provided with SidePak™ AM520/AM520i is designed to

provide a cut-off at 4 µm. This is specified as a 50% cut-off at 4 µm.

The cyclone works by forcing the particle-laden air sample to swirl

inside the cyclone body. Larger (higher mass) particles cannot follow

the air stream and become trapped while smaller particles stay in the

air stream and pass through. When using the cyclone, assume that all

particles smaller than the cut-off size pass through and all larger

particles become trapped in the grit potentiometer.

The cut-off size for any cyclone is dependent on flow rate.

NOTE

It is very important that the sample flow rate through the SidePak™

AM520/AM520i monitor be set at 1.7 liters per minute (L/min). If

some other flow rate is set, the cut-off size will be unknown.

1. Install the standard inlet (unmarked) on the SidePak™

AM520/AM520i body without an impactor disk inside.

2. Attach the cyclone and sample tube onto the inlet.

3. Adjust the flow rate to 1.7 L/min. See the Operation chapter for

instructions on setting the flow rate.

The SidePak™ monitor and cyclone are now ready to use. Attach the

cyclone to the individual test subject's clothing using the U-tube and

clip provided with the cyclone.

Page 59

Maintenance

43

Cleaning the Cyclone

The 10-mm Nylon Dorr-Oliver Cyclone should be cleaned prior to

each use. In most cases, simply cleaning the grit potentiometer is all

that is necessary. Inspect the inside of the cyclone body regularly and

clean it if necessary.

1. Unscrew the grit potentiometer from the bottom of the cyclone.

Remove the stainless steel cyclone clip and pull the cap off.

2. Hold the open end of the grit potentiometer down and tap it on a

hard surface to dislodge particles. Repeat with the cyclone body.

NOTE

If dirt is visible inside either the grit potentiometer or the cyclone

body, it may be necessary to blow canned/pressurized air into the

cyclone parts and/or to clean them with soap and water. A mild

solvent like isopropanol may also be used inside the cyclone. Make

certain that the cyclone is perfectly dry before re-assembly

and use.

3. Re-assemble the cyclone. Note that the stainless steel cyclone

clip that holds the cap onto the body will only fit one way. The

cyclone cleaning procedure is now completed.

Exploded View of 10 mm Nylon Dorr-Oliver Cyclone

Page 60

Chapter 4

44

Using and Maintaining the Diesel Particulate Matter DPM Cyclone

The DPM Cyclone included with the AM520/AM520i can be used to

differentiate between the diesel particulate matter and other portions

of the ambient aerosol. It is ideal for making breathing zone

measurements because it can be attached to clothing near the

wearers face/breathing zone. TSI® supplies a U-tube, clip, and a DorrOliver cyclone with the DPM cyclone specifically for this purpose.

The DPM cyclone is designed with a 50 percent cut-off size of

0.8 µm. The Dorr-Oliver cyclone is positioned upstream of the DPM

cyclone to filter out particles larger than 4 µm preventing large

particles from clogging the inlet of the DPM cyclone.

The cyclone works by forcing the particle-laden air sample to swirl

inside the cyclone body. Larger (higher mass) particles cannot follow

the air stream and become trapped while smaller particles stay in the

air stream and pass through. When using the cyclone, you can

assume that all particles smaller than the cut-off size pass through

and all larger particles become trapped in the grit potentiometer.

The cut-off size for any cyclone is dependent on flow rate.

NOTE

It is very important that the sample flow rate through the SidePak™

monitor be set at 1.7 liters per minute (L/min). If some other flow