Page 1

GAS FLOW MULTI-METER

MODELS 5300 / 5310 /

5320 / 5330 / 5303

OPERATION AND SERVICE MANUAL

P/N 6011689, REVISION F

MARCH 2021

Page 2

Page 3

iii

Warranty

Copyright

TSI Incorporated / 2019-2021 / All rights reserved.

Address

TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 USA

WARNING

TSI® flow meters employ a heated platinum sensor. They should not be used with flammable or

explosive gases or mixtures.

CAUTION

TSI® flow meters are not medical devices under FDA 510k and in no situation should they be

utilized for human respiration measurements.

LIMITATION OF WARRANTY AND LIABILITY (effective February 2015)

(For country-specific terms and conditions outside of the USA, please visit www.tsi.com.)

Seller warrants the goods, excluding software, sold hereunder, under normal use and service as described in the operator's

manual, to be free from defects in workmanship and material for 12 months, or if less, the length of time specified in the

operator's manual, from the date of shipment to the customer. This warranty period is inclusive of any statutory warranty. This

limited warranty is subject to the following exclusions and exceptions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other components when indicated in specifications,

are warranted for 90 days from the date of shipment;

b. Pumps are warranted for hours of operation as set forth in product or operator’s manuals;

c. Parts repaired or replaced as a result of repair services are warranted to be free from defects in workmanship and material,

under normal use, for 90 days from the date of shipment;

d. Seller does not provide any warranty on finished goods manufactured by others or on any fuses, batteries or other consumable

materials. Only the original manufacturer's warranty applies;

e. This warranty does not cover calibration requirements, and seller warrants only that the instrument or product is properly

calibrated at the time of its manufacture. Instruments returned for calibration are not covered by this warranty;

f. This warranty is VOID if the instrument is opened by anyone other than a factory authorized service center with the one

exception where requirements set forth in the manual allow an operator to replace consumables or perform recommended

cleaning;

g. This warranty is VOID if the product has been misused, neglected, subjected to accidental or intentional damage, or is not

properly installed, maintained, or cleaned according to the requirements of the manual. Unless specifically authorized in a

separate writing by Seller, Seller makes no warranty with respect to, and shall have no liability in connection with, goods which

are incorporated into other products or equipment, or which are modified by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated herein. NO OTHER EXPRESS OR

IMPLIED WARRANTY OF FITNESS FOR PARTICULAR PURPOSE OR MERCHANTABILITY IS MADE. WITH RESPECT TO

SELLER’S BREACH OF THE IMPLIED WARRANTY AGAINST INFRINGEMENT, SAID WARRANTY IS LIMITED TO CLAIMS

OF DIRECT INFRINGEMENT AND EXCLUDES CLAIMS OF CONTRIBUTORY OR INDUCED INFRINGEMENTS. BUYER’S

EXCLUSIVE REMEDY SHALL BE THE RETURN OF THE PURCHASE PRICE DISCOUNTED FOR REASONABLE WEAR AND

TEAR OR AT SELLER’S OPTION REPLACEMENT OF THE GOODS WITH NON-INFRINGING GOODS.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR BUYER, AND THE LIMIT OF

SELLER'S LIABILITY FOR ANY AND ALL LOSSES, INJURIES, OR DAMAGES CONCERNING THE GOODS (INCLUDING

CLAIMS BASED ON CONTRACT, NEGLIGENCE, TORT, STRICT LIABILITY OR OTHERWISE) SHALL BE THE RETURN OF

GOODS TO SELLER AND THE REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR

REPLACEMENT OF THE GOODS. IN THE CASE OF SOFTWARE, SELLER WILL REPAIR OR REPLACE DEFECTIVE

SOFTWARE OR IF UNABLE TO DO SO, WILL REFUND THE PURCHASE PRICE OF THE SOFTWARE. IN NO EVENT

SHALL SELLER BE LIABLE FOR LOST PROFITS, BUSINESS INTERRUPTION, OR ANY SPECIAL, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL DAMAGES. SELLER SHALL NOT BE RESPONSIBLE FOR INSTALLATION,

DISMANTLING OR REINSTALLATION COSTS OR CHARGES. No Action, regardless of form, may be brought against Seller

more than 12 months after a cause of action has accrued. The goods returned under warranty to Seller's factory shall be at

Buyer's risk of loss, and will be returned, if at all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND LIABILITY, which contains the complete

and exclusive limited warranty of Seller. This LIMITATION OF WARRANTY AND LIABILITY may not be amended, modified or its

terms waived, except by writing signed by an Officer of Seller.

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI attention to any problems. If any malfunction is

discovered, please contact your nearest sales office or representative, or call TSI's Customer Service department at (800) 6801220 (USA) or (001 651) 490-2860 (International) or visit www.tsi.com.

Page 4

iv Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Trademarks

TSI and the TSI logo are registered trademarks of TSI Incorporated in the United States and may be protected under other

country’s trademark registrations. FLO-Sight is a trademark of TSI Incorporated.

Page 5

v

Contents

Warranty ............................................................................................................................................................ iii

Contents ............................................................................................................................................................. v

CHAPTER 1 Unpacking and Parts Identification ......................................................................................... 1

List of Standard Components ............................................................................................................ 1

5300 Series High Flow Gas Flow Multi-Meter ............................................................................ 1

Standard Accessory Kit ..................................................................................................................... 2

5300 Series Standard Accessory Kit (53000) ............................................................................. 2

Low Pressure Measurement Kit ........................................................................................................ 3

5300 Series Low Pressure Measurement Kit (5300-LPMK) ....................................................... 3

Optional Accessories ......................................................................................................................... 3

5300 Series Accessories ............................................................................................................ 3

5000 Series Universal Accessories ............................................................................................ 4

CHAPTER 2 Meter Setup ................................................................................................................................. 7

Instrument Overview ......................................................................................................................... 7

5300 Series High Flow Gas Flow Multi-Meter ............................................................................ 7

Supplying Power ............................................................................................................................... 8

USB Hub Cable ........................................................................................................................... 8

Communications ................................................................................................................................ 9

USB-C to USB-A Cable .............................................................................................................. 9

USB-A to RS-232 Cable ........................................................................................................... 10

Connecting Inlet Filter ..................................................................................................................... 11

Changing Tube Ends ....................................................................................................................... 12

Using 0.5 inch or 15 mm Tube Ends ............................................................................................... 13

Low Pressure Measurement Kit ...................................................................................................... 14

5300 Series Low Pressure Measurement Kit (5300-LPMK) ..................................................... 14

CHAPTER 3 Meter Operation ........................................................................................................................ 17

Getting Started ................................................................................................................................ 17

Power Button ............................................................................................................................ 17

Initialization and Warm-Up ........................................................................................................ 17

Touchscreen Display ................................................................................................................ 17

Measurement Parameters ............................................................................................................... 17

Flow Measurement ................................................................................................................... 17

Temperature Measurement ...................................................................................................... 18

Absolute Pressure Measurement ............................................................................................. 18

Low Differential Pressure Measurement ................................................................................... 18

Relative Humidity Measurement ............................................................................................... 18

Volume Measurement ............................................................................................................... 18

Totalizer Measurement ............................................................................................................. 18

Units of Measurement ..................................................................................................................... 19

Type of Gas ..................................................................................................................................... 19

Model Numbers based on Gas Calibration ............................................................................... 19

Meter Configuration ......................................................................................................................... 20

Data Logging ................................................................................................................................... 20

Preset Logging Configurations and Sample Points .................................................................. 20

CHAPTER 4 Touchscreen Navigation ......................................................................................................... 21

Display Overview ............................................................................................................................. 21

Meter Home Screen .................................................................................................................. 21

Menu Screen ............................................................................................................................. 22

Measurements .......................................................................................................................... 22

Page 6

vi Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Type of Gas ............................................................................................................................... 22

Flow Directional Indicators ........................................................................................................ 23

Pause/Play Display ................................................................................................................... 23

Configuring the Meter ...................................................................................................................... 24

Measurement Parameters ........................................................................................................ 24

Units of Measurement ............................................................................................................... 24

Flow Conditions ......................................................................................................................... 25

Type of Gas ............................................................................................................................... 25

Locking the Meter ...................................................................................................................... 26

Volume and Triggers ....................................................................................................................... 27

Setting Triggers ......................................................................................................................... 28

Making Volume Measurements ................................................................................................ 29

Data Logging ................................................................................................................................... 30

Logging Parameters .................................................................................................................. 30

Log Data .................................................................................................................................... 31

Export Data Files ....................................................................................................................... 31

Delete Data Files ....................................................................................................................... 32

Rotate Screen .................................................................................................................................. 33

Alerts ................................................................................................................................................ 33

Meter Information............................................................................................................................. 34

Updating Firmware .................................................................................................................... 35

Device Settings ................................................................................................................................ 36

Reset Device Settings ..................................................................................................................... 38

Zero Low Pressure .................................................................................................................... 39

Reset Totalizer .......................................................................................................................... 39

Reset Device to Factory Defaults ............................................................................................. 39

CHAPTER 5 Maintenance .............................................................................................................................. 41

Flow Sensor ..................................................................................................................................... 41

Re-Certification ................................................................................................................................ 41

Damaged Tube End Connections ................................................................................................... 41

Cases ............................................................................................................................................... 41

Storage ............................................................................................................................................ 42

CHAPTER 6 Troubleshooting ....................................................................................................................... 43

Technical Contacts .......................................................................................................................... 44

Returning the Gas Flow Multi-Meter for Service ............................................................................. 44

CHAPTER 7 FLO-Sight™ PC Software ........................................................................................................ 45

CHAPTER 8 Serial Command Set ................................................................................................................ 47

Commands for Flow Rate, Temperature, Pressure, and Volume ................................................... 47

Measurement Setup Commands ..................................................................................................... 47

Miscellaneous Commands .............................................................................................................. 48

APPENDIX A 5300 Series Flow Multi-Meter Specifications ...................................................................... 49

5300 Series Pressure Drop ............................................................................................................. 51

5300 Series Dimensions .................................................................................................................. 52

APPENDIX B Standard Flow Rate vs. Volumetric Flow Rate ................................................................... 53

APPENDIX C Humidity Compensation ........................................................................................................ 55

Disable / Enable Humidity Compensation ................................................................................. 55

APPENDIX D Remote Flow ........................................................................................................................... 57

Theory of Operation ......................................................................................................................... 57

Remote Flow Setup ......................................................................................................................... 57

Page 7

1

C H A P TE R 1

Unpacking and

Parts Identification

List of Standard Components

Carefully unpack the instrument and accessories from the shipping container. Check the individual

parts against the list of components in tables below. If any parts are missing or damaged, notify

TSI® immediately.

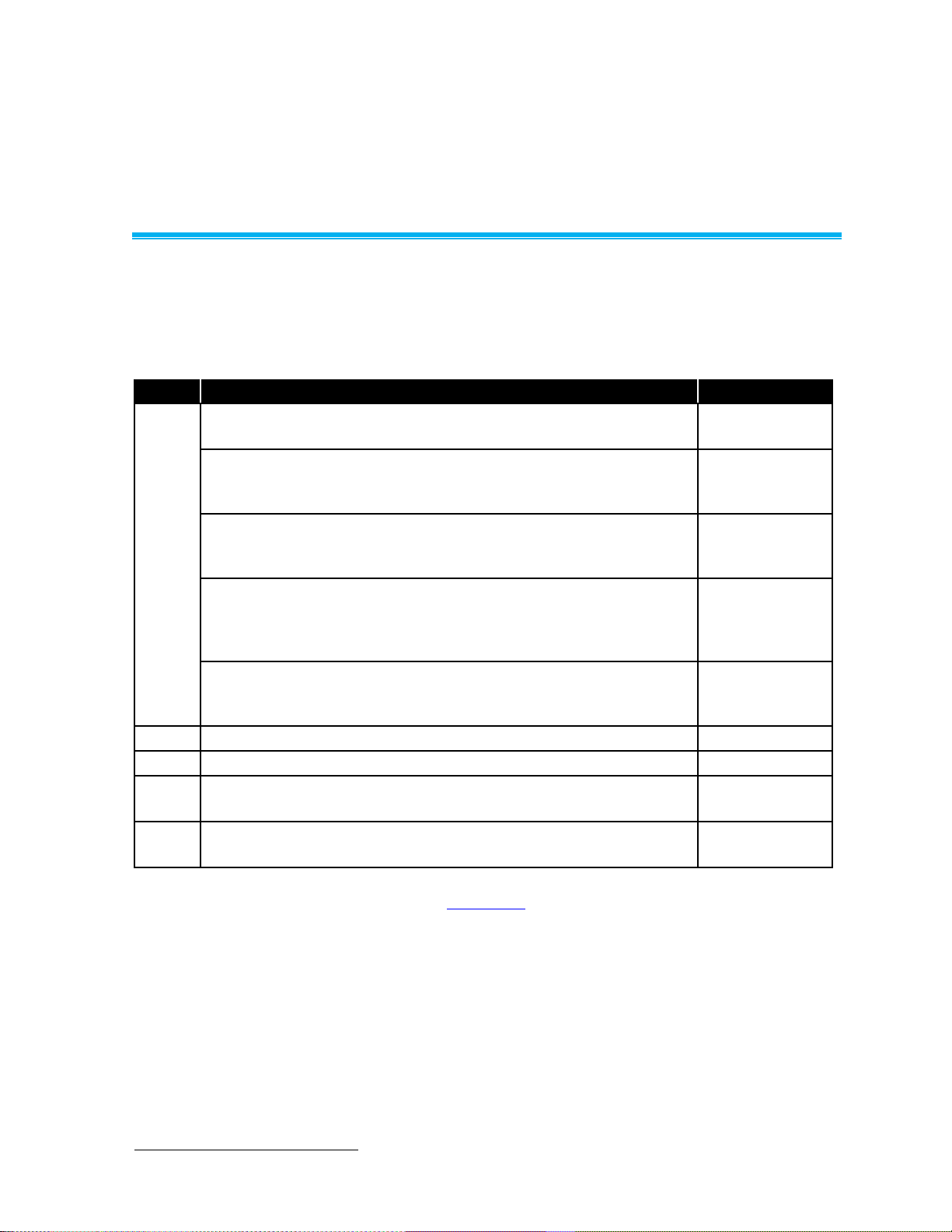

5300 Series High Flow Gas Flow Multi-Meter

Qty.

Item Description

Part/Model

1

High Flow Gas Flow Multi-Meter, 22-mm ISO tube ends

Measures Flow, Temperature, Absolute Pressure

5300

High Flow Gas Flow Multi-Meter, 22-mm ISO tube ends

Measures Flow, Volume, Temperature, Absolute Pressure, Differential

Pressure

5310

High Flow Gas Flow Multi-Meter, 22-mm ISO tube ends

Measures Flow, Volume, Temperature, Absolute Pressure, Differential

Pressure, Relative Humidity

5320

High Flow Gas Flow Multi-Meter (High Accuracy), 22-mm ISO tube ends,

includes Tabletop Stand

Measures Flow, Volume, Temperature, Absolute Pressure, Differential

Pressure, Relative Humidity

5330

High Flow Gas Flow Multi-Meter (Wide Accuracy Spec), 22-mm ISO

tube ends

Measures Flow, Temperature, Absolute Pressure

5303

1

Calibration Certificate

N/A

1

5300 Series Standard Accessory Kit

53000

1

Low Pressure Measurement Kit

(5310/5320/5330 models only)

5300-LPMK

1

License key for FLO-Sight™ PC Software

(Includes a free trial of the advanced version)

5000-PC

*FLO-Sight PC Software can be downloaded from www.tsi.com.

™

FLO-Sight is a trademark of TSI Incorporated.

Page 8

2 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

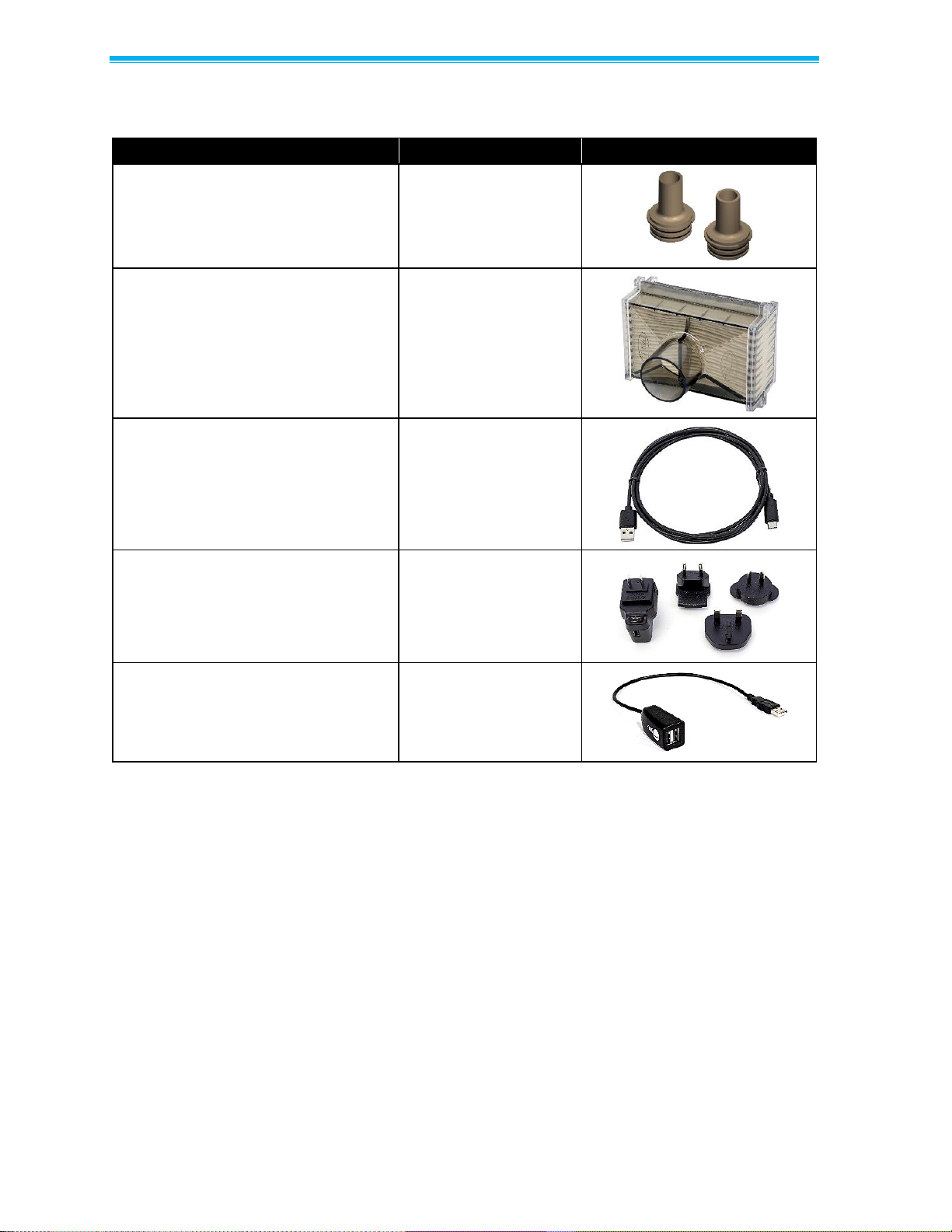

Standard Accessory Kit

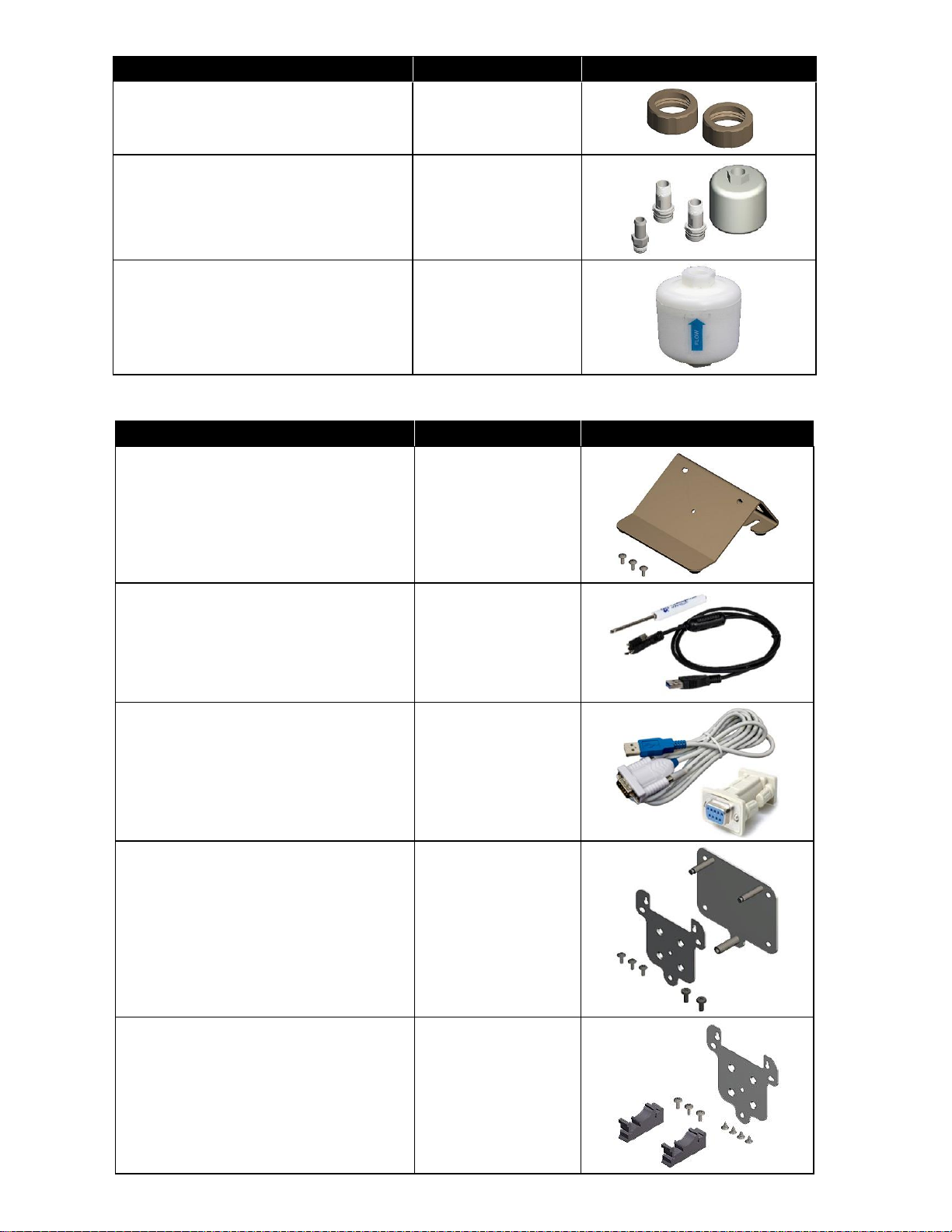

5300 Series Standard Accessory Kit (53000)

Item Description

TSI® Part Number

Picture

5300 Series 1/2 inch Tube Ends (2)

5300-05IN

5300 Series Inlet Filter Low Pressure

5300-IF-LP

5000 Series USB-C to USB-A Power

and Communications Cable (6 ft.)

5000-USBC-A

5000 Series Universal Power Supply

5.0 VDC ±5%, 500 mA maximum

5000-UPS

5000 Series USB Hub Cable

5000-HUB

Page 9

Operation and Service Manual 3

Low Pressure Measurement Kit

5300 Series Low Pressure Measurement Kit (5300-LPMK)

Item Description

Quantity

Picture

22 mm (M/F) Airway Pressure

Fitting with Screen

2

1/8 inch ID x 1/4 inch OD Tubing

96 inches

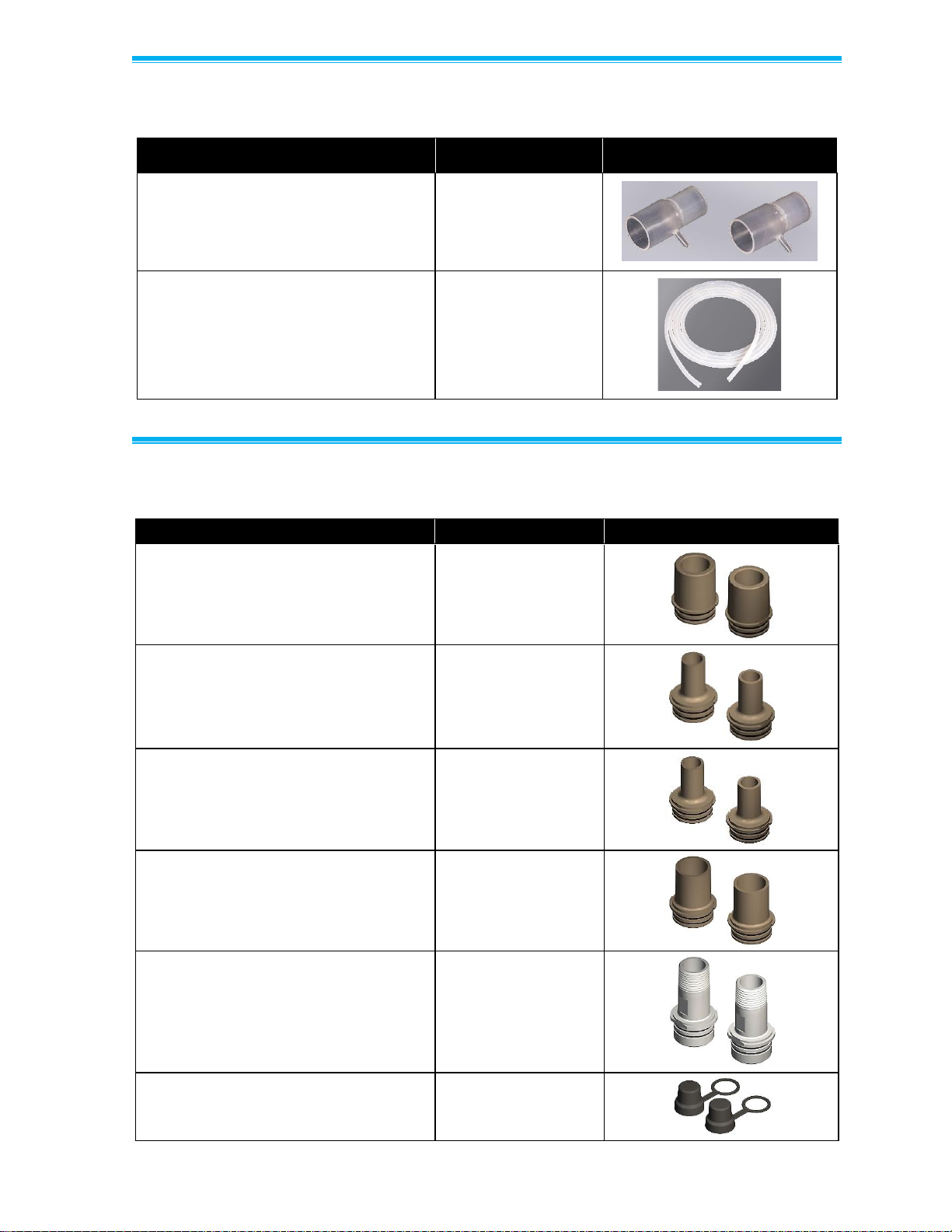

Optional Accessories

5300 Series Accessories

Item Description

TSI® Part Number

Picture

5300 Series 22 mm M/15 mm F ISO

Tube Ends (2)

5300-22MM

5300 Series 1/2 inch Tube Ends (2)

5300-05IN

5300 Series 15 mm ISO Tube Ends (2)

5300-15MM

5300 Series 3/4 inch Tube Ends (2)

5300-075IN

5300 Series High Pressure 3/8 inch

NPT Tube Ends (2)

5300-375NPT

5300 Series End Caps (2)

5300-EC

Page 10

4 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Item Description

TSI® Part Number

Picture

5300 Series Collars (2)

5300-C

5300 Series High Pressure Kit

5300-HPK

5300 Series Inlet Filter – High Pressure

5300-IF-HP

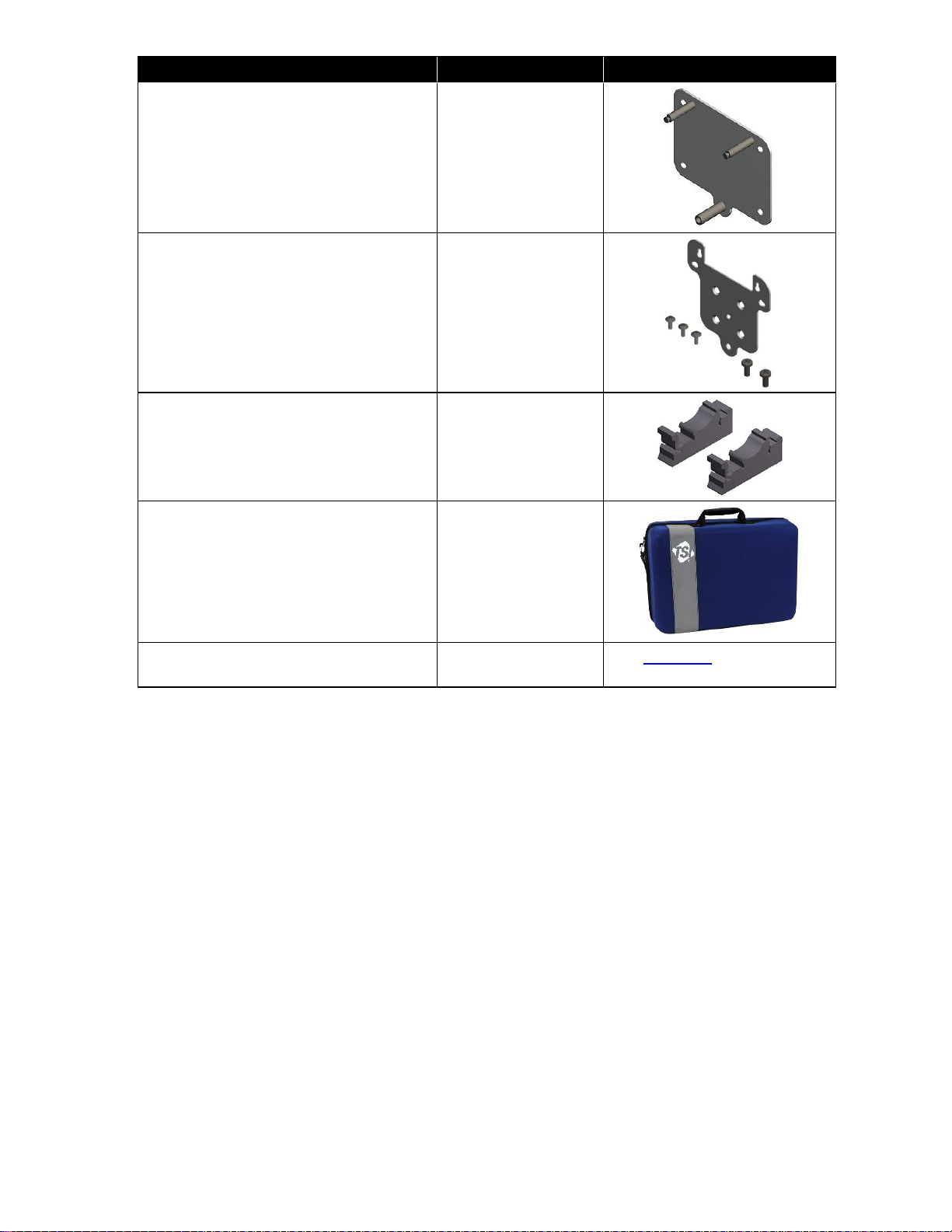

5000 Series Universal Accessories

Item Description

TSI® Part Number

Picture

5000 Series Tabletop Stand

5000-TTS

5000 Series USB-C to USB-A Power

and Communications Cable with Screw

Lock (6 ft.)

5000-USB-LOCK

5000 Series USB-RS-232 Cable with

Null Modem Converter

5000-RS232

5000 Series Wall Mounting Kit

5000-WMK

5000 Series Wall Mounting –

DIN Rail Kit

5000-WMDRK

Page 11

Operation and Service Manual 5

Item Description

TSI® Part Number

Picture

5000 Series Wall Mounting –

Back Plate Only

5000-WMBP

5000 Series Wall Mounting –

Meter Plate Only

5000-WMMP

5000 Series Wall Mounting DIN Rail –

Clips Only (2)

5000-WMDRC

5000 Series Deluxe Carrying Case

5000-DCC

FLO-Sight™ PC Software

(Advanced Version)

5000-PC-ADV

See Chapter 7 for more

information.

Page 12

6 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

(This page intentionally left blank)

Page 13

7

C H A P TE R 2

Meter Setup

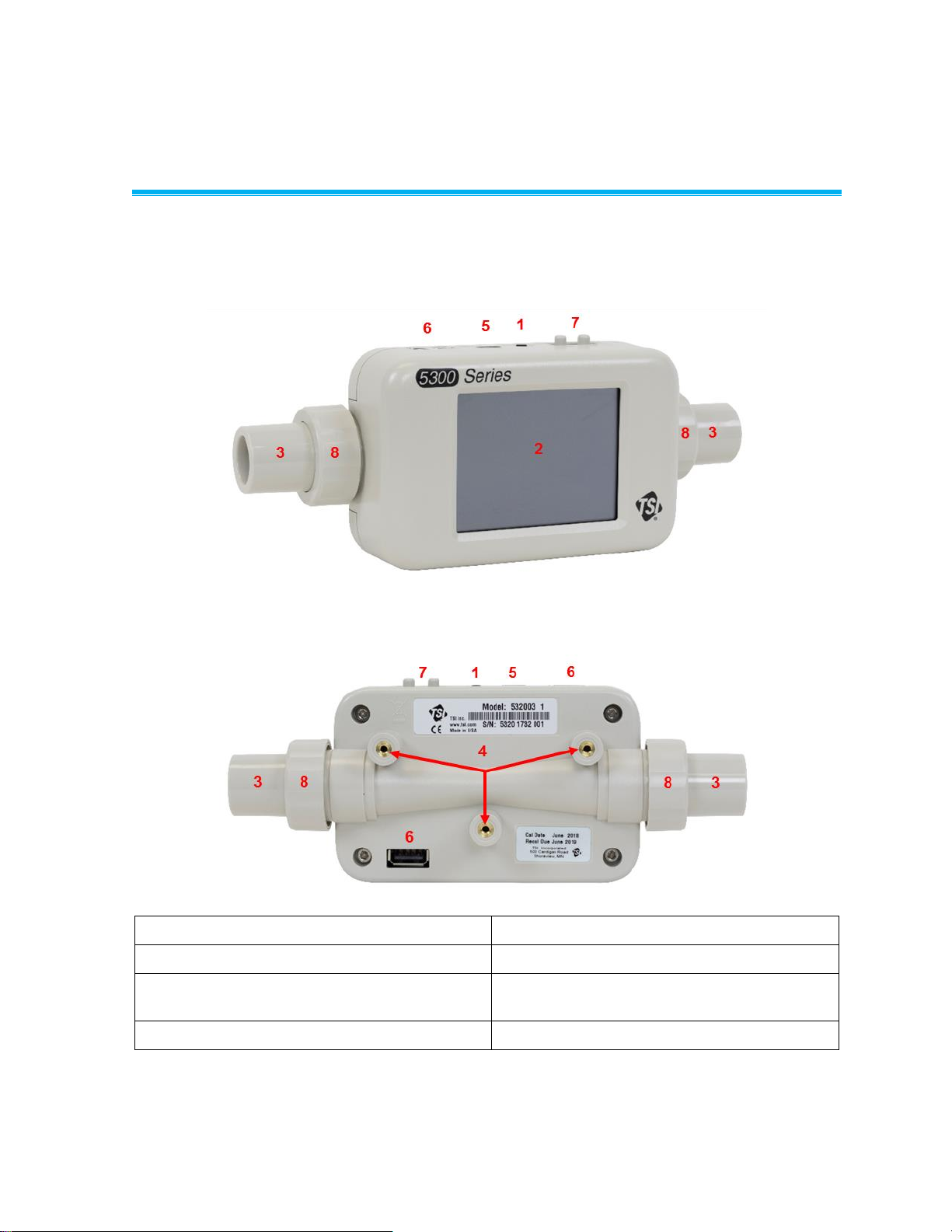

Instrument Overview

5300 Series High Flow Gas Flow Multi-Meter

Meter Front

Meter Back

1. Power Button (On/Off)

5. USB-C Power / Communications Port

2. Color Touchscreen Display *

6. USB-A Communications Ports (2)

3. Interchangeable Tube Ends

7. Differential Pressure Ports

(5310 / 5320 / 5330 models only)

4. Mounting Inserts (M3 thread size)

8. Collars

* The touchscreen display is resistive and responds to applied pressure

Page 14

8 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Supplying Power

The 5300 Series Multi-Meter can be powered by connecting the USB-C to USB-A Power and

Communications Cable from the USB-C port on the meter to: 1) the 5000 Series Universal Power

Supply, 2) a computer, or 3) an alternative USB-compatible source that can provide 5 VDC.

(1) (2)

(3)

Power Supply: 5.0 VDC ±5%, 500 mA maximum

USB Hub Cable

Some computer USB ports are not capable of sufficiently powering the meter. The meter may fail to

power on, or the meter may power on but be unable to complete the startup process.

If you are unable to power your meter from the computer, connect using the provided USB hub cable.

To do this, connect the USBC-A power cable to the USB hub cable, plug the hub cable into the USB-A

port of the computer, and plug the other end of the USBC-A cable into the USB-C port located on top

of the meter.

Page 15

Operation and Service Manual 9

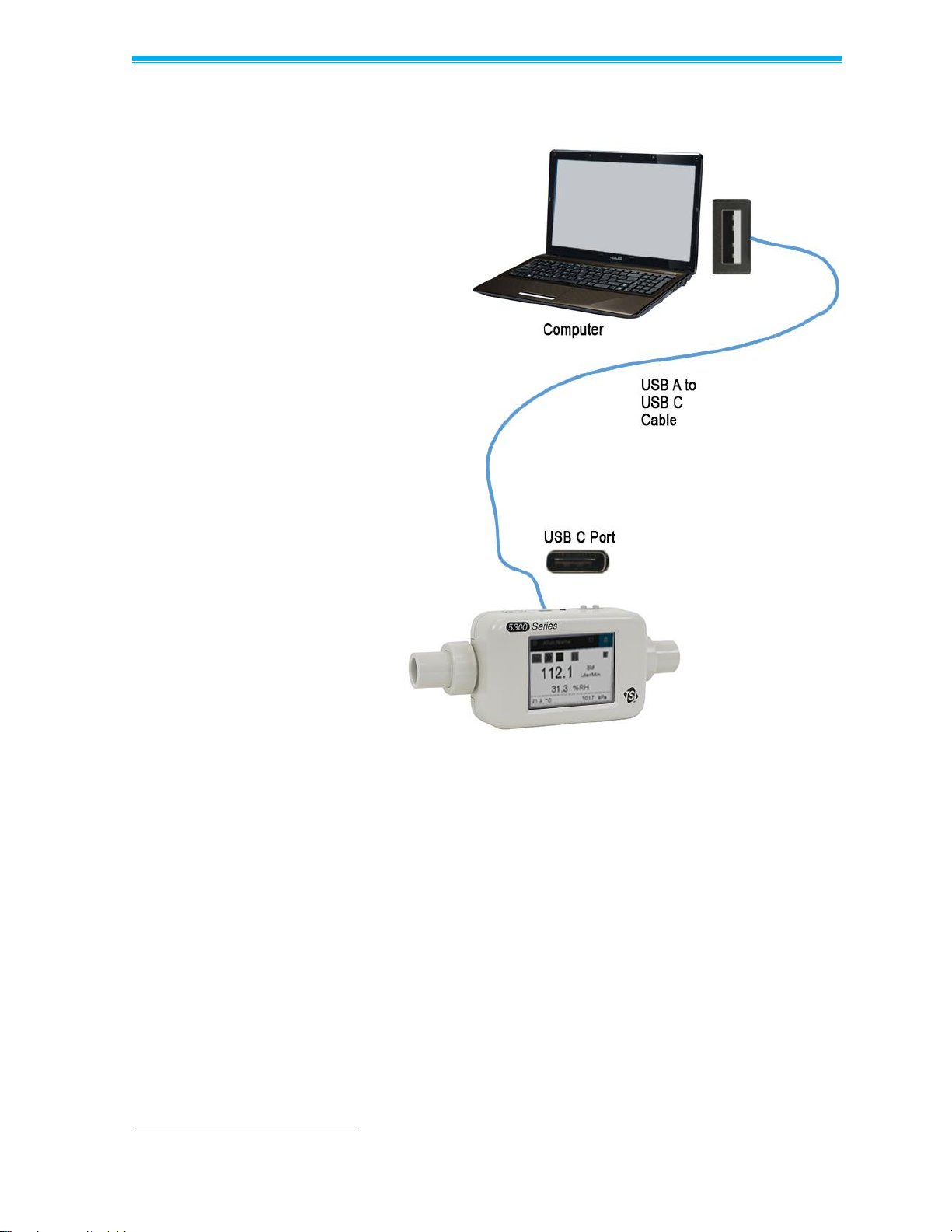

Communications

USB-C to USB-A Cable

In addition to supplying power, the

5000 Series USB-C to USB-A cable

(5000-USBC-A) provides direct

communication between the MultiMeter and a computer. The graphic

to the right shows the connection

scheme.

You can view real-time

measurements and control your

meter through FLO-Sight™ PC

Software or through an alternative

program such as HyperTerminal® or

PuTTY using ASCII commands.

For more details, please refer to the

FLO-Sight™ PC Software Manual

or the Series 5200/5300 ASCII

Command Set Manual.

®

HyperTerminal is a registered trademark of Hilgraeve, Incorporated

Page 16

10 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

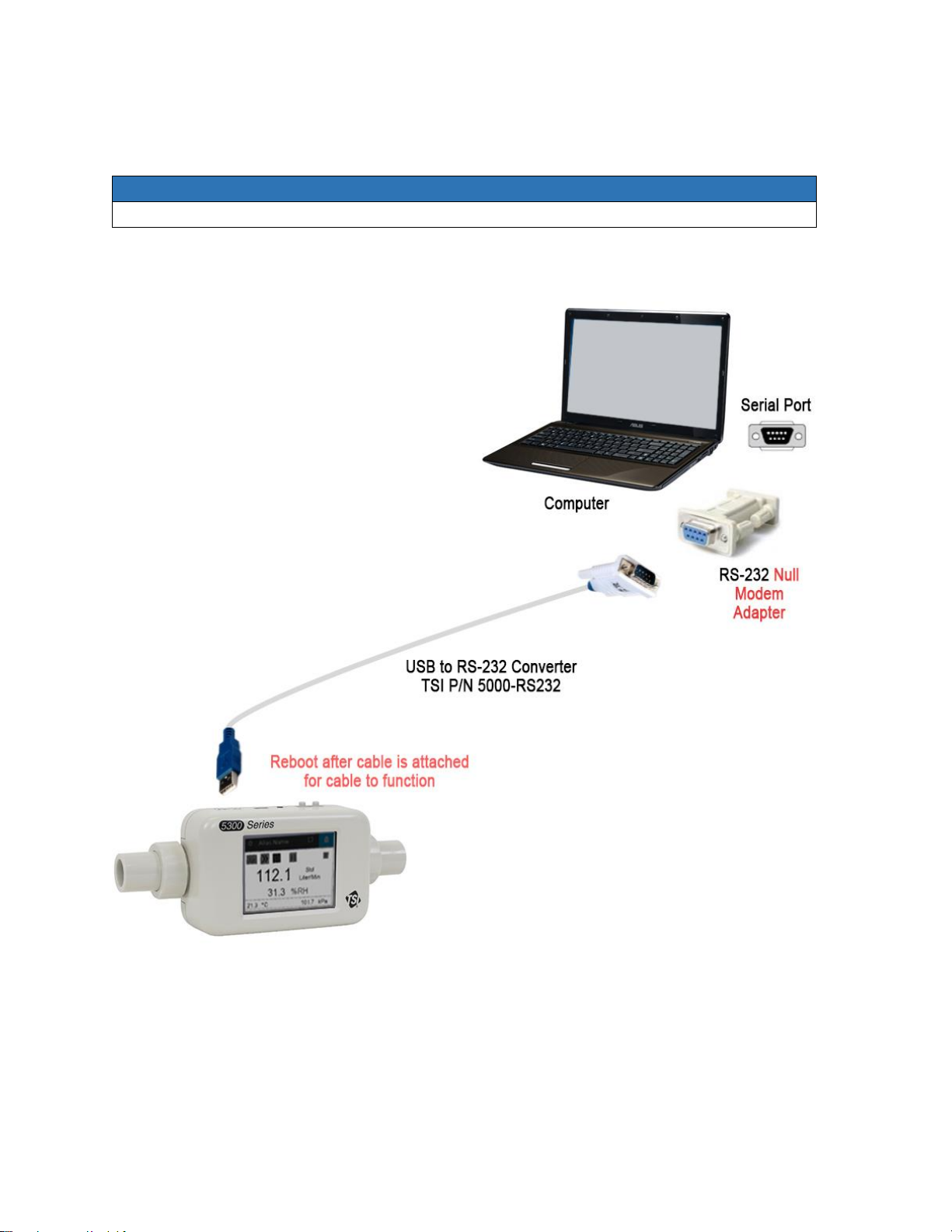

USB-A to RS-232 Cable

To communicate via serial, you can purchase the optional USB-A to RS-232 Serial Cable Kit

(5000-RS232) which is comprised of a USB-A to RS-232 serial cable and null modem converter. The

cable can be connected from either USB-A port on the meter. See the image below for connecting the

Multi-Meter via RS-232.

NOTE

The Multi-Meter must be rebooted after connecting the adapter and cable in order to load the driver.

Once the cable is connected and the meter has been rebooted, you can communicate via serial with

the ASCII commands found in the Series 5200/5300 ASCII Command Set Manual.

RS-232 Settings

• Baud Rate 115,200 k (by default,

unit can be switched to 38.4 k)

• Data Bits 8

• Parity None

• Stop Bits 1

• Flow Control None

Page 17

Operation and Service Manual 11

Connecting Inlet Filter

The 5300 Series Gas Flow Multi-Meters have an exposed thermal flow sensor that is highly sensitive

to foreign matter and particles within the gas flow. TSI® supplies inlet filters for both low pressure and

high pressure applications and recommends that these filters be used at all times while testing with the

instrument. After attaching the inlet filter, connect the flow tube to the inlet side of the filter.

If you are measuring a bidirectional gas flow and are concerned about foreign matter or particles

entering the flow stream from either side of your test setup, TSI® recommends an inlet filter be placed

on both sides of the meter.

CAUTION

Always use a filter on the inlet of the flow meter. Failure to filter the gas flow may

change the calibration and/or permanently damage the sensor.

NOTE

Connecting a second inlet filter or tube to the outlet side of the 5300 Series Gas Flow Multi-Meter

will create back pressure. In general, minimize back pressure on the meter to maintain the highest

possible accuracy.

See Appendix A for the pressure drop created by connecting the supplied inlet filters to the 5300

Series Multi-Meter along with additional specifications.

Page 18

12 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

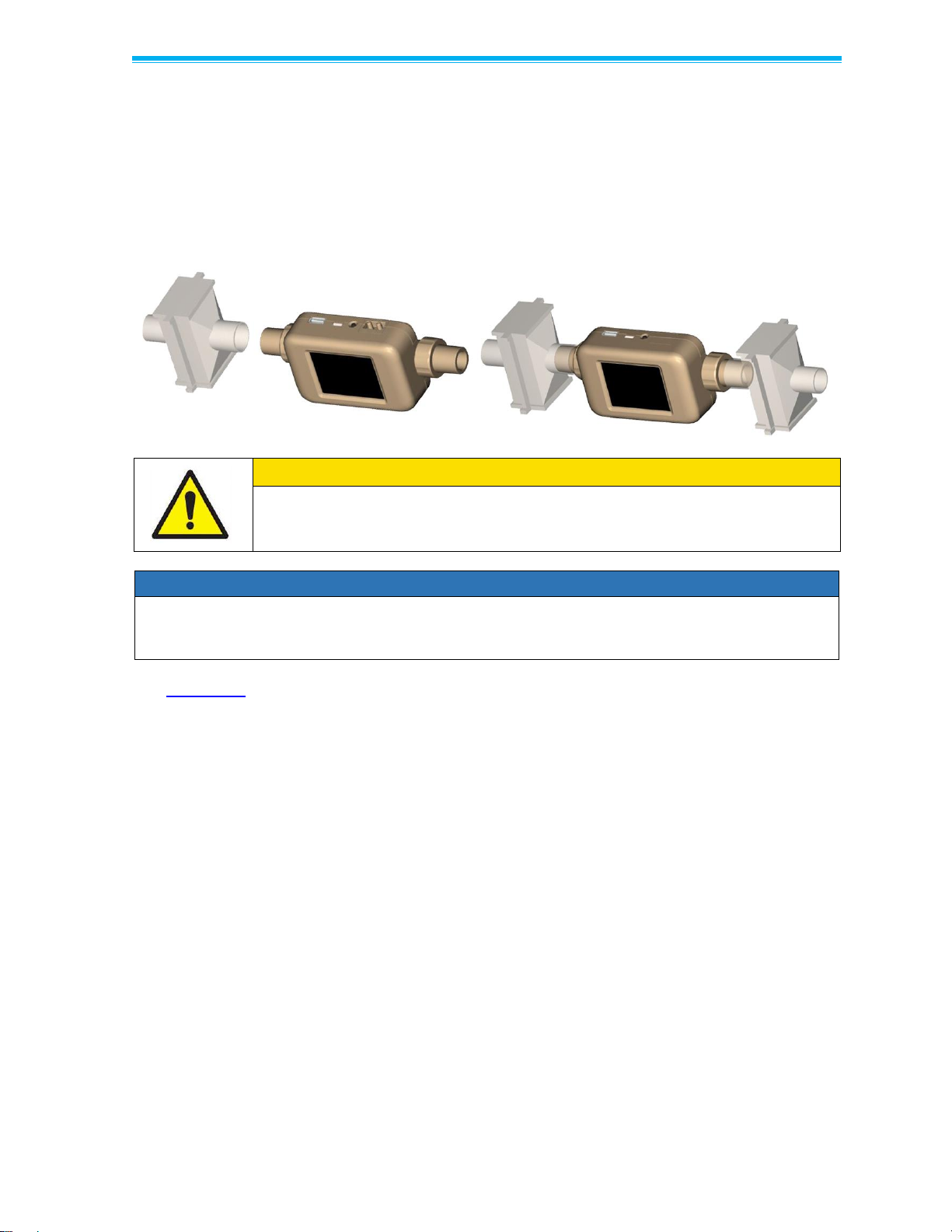

Changing Tube Ends

The 5300 Series Gas Flow Multi-Meter incorporates interchangeable tube ends that can be easily

configured by you without the need for special tools or additional accessories. Follow the step-by-step

instructions below to remove and replace the 5300 Series Gas Flow Multi-Meter tube ends.

NOTE

5200 Series Low Flow Multi-Meter and 5300 Series High Flow Multi-Meter tube ends are not

interchangeable.

Step 1: Unscrew and remove the collars then remove the tube ends by pulling them straight out of

the meter.

Step 2: Select your desired size of tube ends and insert them into the meter while aligning the anti-

rotation notch on the tube end with the tab on the meter.

Step 3: After aligning the tube ends into the meter, slide the collars back on and tighten them by

rotating clockwise.

NOTE

Contact TSI® if you would like specifications for designing your own custom tube ends.

Page 19

Operation and Service Manual 13

Using 0.5 inch or 15 mm Tube Ends

When using a 5300 Series meter with 0.5 inch or

15-mm tube end adapters, if the filter is connected

as shown right then no further action is needed.

If the 0.5 inch or 15-mm tube ends are connected

directly to the instrument, you should select the

“Using 0.5 inch or 15 mm ends” Toggle Switch in

the meter’s Settings screen.

NOTE

The 5300 Series Flow Multi-Meter will still measure within its published accuracy specification even

if this recommendation is not followed, but selecting the toggle switch with this setup ensures the

most accurate flow measurement readings.

This toggle switch can be found by clicking

on the Settings button in the Menu header.

1. Select the Config tab.

2. Click the Edit button.

3. Click the toggle switch.

4. Select Save.

Page 20

14 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

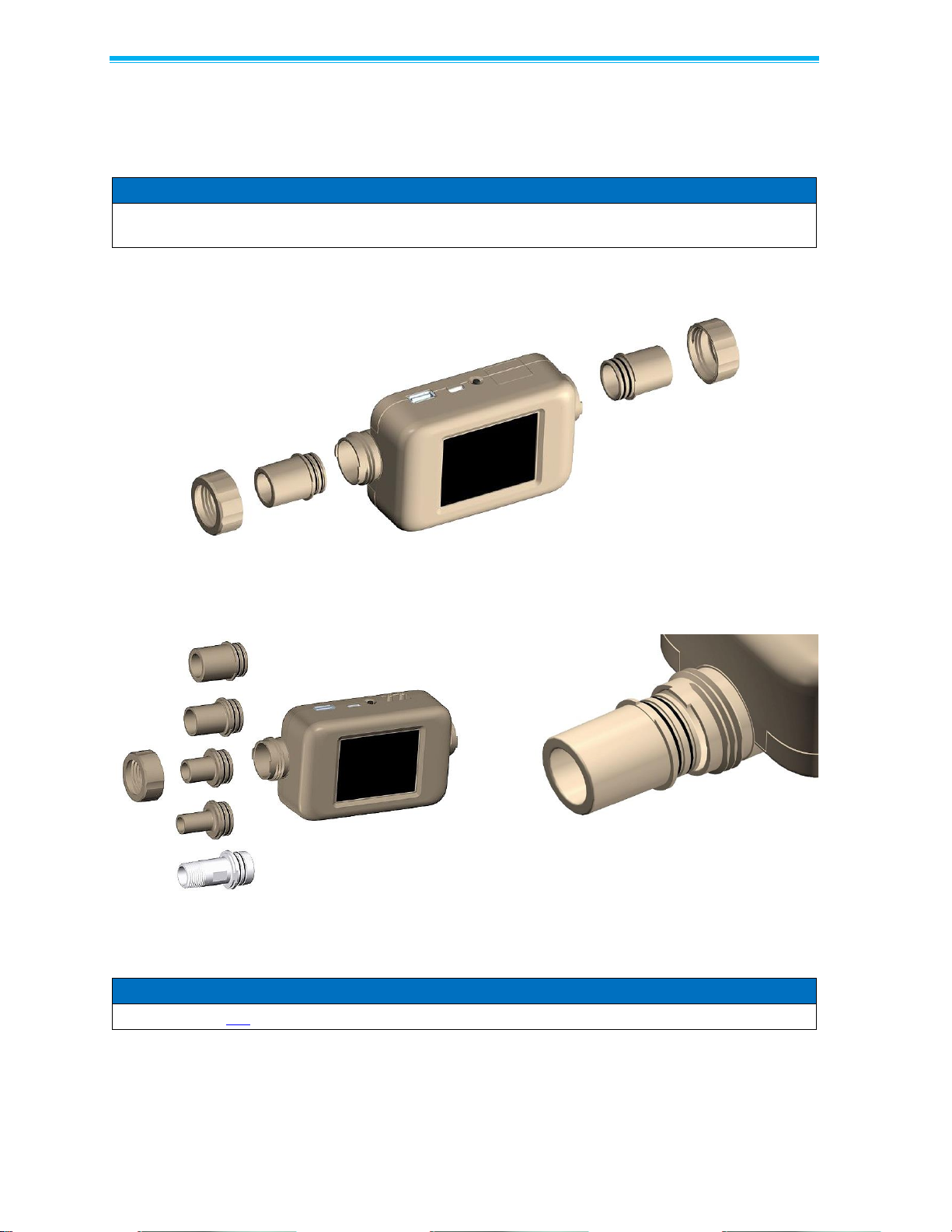

Low Pressure Measurement Kit

TSI® includes a Low Pressure Measurement Kit (5300-LPMK) to utilize the low differential pressure

measurement available on models 5310, 5320, and 5330. The kit comes complete with the airway

pressure fittings and tubing needed to connect the breathing or test circuit to the Flow Multi-Meter. See

below for instructions on connecting the Low Pressure Measurement Kits to the 5300 Series.

NOTE

TSI® does not require that these kits be utilized to make differential pressure measurements but

provides them simply as a convenience.

5300 Series Low Pressure Measurement Kit (5300-LPMK)

Standard Setup: 22-mm ISO Tube Ends

Step 1: Locate and attach a 22-mm Airway Pressure Fitting to the outlet side tube end of the 5300

Series Multi-Meter with the barb facing up.

Step 2: Measure and cut a length of tubing and connect it from the Airway Pressure Fitting barb to

the (+) port on the Multi-Meter.

Step 3: Attach a filter (5300-IF-LP) to the inlet side tube end of the Multi-Meter.

Page 21

Operation and Service Manual 15

Alternative Setup: 15-mm, 3/4 inch, or 1/2 inch Tube Ends

Step 1: Remove the collars and tube ends from the Multi-Meter and then screw the collars back on.

Step 2: Insert the Airway Pressure Fitting into the outlet side of the Multi-Meter in the inverted

direction with the barb facing up.

Step 3: Measure and cut a length of tubing and connect it from the Airway Pressure Fitting barb to

the (+) port of the Multi-Meter.

Step 4: Insert the Inlet Filter (5300-IF-LP) supplied in the Standard Accessory Kit into the inlet side of

the Multi-Meter in the inverted direction.

Step 5: Insert alternative tube ends into the inlet of the Filter and into the outlet side of the Airway

Pressure Fitting.

Page 22

16 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

(This page intentionally left blank)

Page 23

17

C H A P TE R 3

Meter Operation

CAUTION

TSI® flow meters are not medical devices under FDA 510k and in no situation should

they be utilized for human respiration measurements.

Getting Started

Power Button

The Multi-Meter may turn itself on once it is supplied with power. If the meter does not turn on

automatically, press the Power button on top of the meter and the unit will power ON. To turn the

instrument OFF, press and hold the Power button for 5 seconds.

Initialization and Warm-Up

It takes approximately 40 seconds for the 5300 Series Gas Flow Multi-Meter to initialize and warm-up.

A TSI® splash screen will be displayed during this initialization period. Once this process has

completed, the Flow Multi-Meter will begin displaying measurements and users will be able to fully

operate meter. No additional meter warm-up time is needed.

Touchscreen Display

The 5300 Series meters utilize a 2.8-inch color LCD touchscreen display for easy viewing and

operation. The touchscreen display is resistive and responds to pressure applied from a finger, stylus,

or other instrument. The Flow Multi-Meter touchscreen can be operated while wearing gloves.

Measurement Parameters

The 5300 Series Gas Flow Multi-Meter measures flow rate, flow volume, temperature, absolute

pressure, low differential pressure (Models 5310, 5320, 5330 only), and relative humidity (Models

5320 and 5330 only). All measurements made by the 5300 Series Multi-Meter are NIST traceable.

Flow Measurement

The 5300 Series Gas Flow Multi-Meters incorporate TSI® Incorporated’s proprietary platinum film

sensor designed for measuring gas flows with high accuracy and fast response time while minimizing

the pressure drop. Flow measurements are bi-directional and depending on the model can be selected

to measure air, oxygen, air/oxygen mixtures, nitrogen, and carbon dioxide. Flow measurement data is

available on the meter, through FLO-Sight™ PC Software, or via ASCII commands.

Meter Orientation

Although the 5300 Series can measure flow in both directions, TSI® recommends that flow be run

through the meter from left to right as this is the orientation in which the meter was calibrated. There is

an arrow printed on the bottom of the meter for reference.

Flow measured in this direction will be displayed as positive while flow measured in

the reverse direction will be shown as negative.

For maximum flow accuracy at low flows, TSI® also recommends that the meter be run in a

horizontal orientation.

Page 24

18 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Temperature Measurement

The 5300 Series Multi-Meters have an independent temperature transducer in the flow tube to

measure and display the gas temperature. The temperature sensor is also used for temperature

compensation of flow rate and for converting flow from standard to volumetric units. Temperature

measurement data is available on the meter, through FLO-Sight™ PC Software, or via

ASCII commands.

NOTE

At low flow rates, the temperature inside of the flow tube will increase because of the heat

generated by the thermal flow sensor. This effect is normal and the temperature of the incoming gas

will be measured once flow resumes.

Absolute Pressure Measurement

The 5300 Series Multi-Meters measure absolute or barometric pressure near the outlet of the flow

path. This pressure measurement is required for converting standard flow to volumetric flow. Absolute

pressure measurement data is available on the meter, through FLO-Sight™ PC Software, or via

ASCII commands.

Low Differential Pressure Measurement

Models 5310, 5320, and 5330 Gas Flow Multi-Meters have the ability to measure differential pressure,

also known as breathing circuit pressure. The pressure differential of flows can be measured at the

meter or at any point along the circuit. Low pressure measurement data is available on the meter,

through FLO-Sight™ PC Software, or via ASCII commands. When combined with absolute pressure,

low pressure readings can be used to calculate a volume flow rate at a remote point in the system.

See Appendix D for more information on Remote Flow Measurements.

Relative Humidity Measurement

Models 5320 and 5330 Gas Flow Multi-Meter includes a relative humidity sensor near the inlet of the

flow path. In addition to providing a humidity measurement, sensor readings are used to compensate

the air flow for humidity effects to provide an equivalent dry-gas flow measurement. Relative humidity

measurement data is available through the meter, FLO-Sight™ PC Software, or via ASCII commands.

NOTE

Humidity compensation does not apply to oxygen or carbon dioxide gas flows.

Volume Measurement

5300 Series Gas Flow Multi-Meters measure total volume by integrating flow over time. This is a

calculated measurement performed by the Multi-Meter and is controlled through triggers. You can set

begin and end triggers for volume measurements using flow rate, absolute pressure, or low differential

pressure values.

See the topic “Volume and Triggers” in Chapter 4 of this manual for more information on triggering and

volume measurements. For models 5310, 5320, and 5330 you can set triggers and take volume

measurements through the meter or with FLO-Sight™ PC Software. Volume measurements are

available via ASCII commands for all 5300 Series models.

Totalizer Measurement

All 5300 Series Gas Flow Multi-Meters include a totalizer feature that measures total volume by

integrating flow over time. This is a calculated measurement performed by the meter and operates as

a running total. The totalizer count begins automatically when the meter is powered on regardless if

the totalizer parameter is displayed or not. You can reset the totalizer count back to zero within the

meter. Totalizer measurements can be viewed on the meter and in FLO-Sight™ PC Software.

Page 25

Operation and Service Manual 19

Units of Measurement

The 5300 Series Gas Flow Multi-Meter allows for user-selectable units of measurement options for all

available measurement parameters. Units of measurement can be configured directly through the

meter or with FLO-Sight™ PC Software. Please see "Configuring the Meter" in Chapter 4 for

instructions on changing units.

The table below outlines the default units and optional user-selectable units for each measurement

parameter.

Measurement

Factory Default Units

Optional User-Selectable Units

Flow

Liters per Minute (L/min)

Cubic Feet per Minute (ft3/min)

Flow Gas Standard

Standard (Std)

Volumetric (Vol)

Actual (Act)

Remote (Rem)

Temperature

Degrees Celsius (°C)

Degrees Fahrenheit (°F)

Kelvin (K)

Absolute Pressure

Kilopascals (kPa)

Pascals (Pa)

Hectopascals (hPa)

Millibars (mbar)

Pounds per Square inch (PSI)

inches of Water (inH2O)

Centimeters of Water (cmH2O)

Millimeters of Mercury (mmHg)

Low Pressure

(5310, 5320, 5330

models only)

Centimeters of Water (cmH2O)

Pascals (Pa)

Hectopascals (hPa)

Kilopascals (kPa)

Millibars (mbar)

Pounds per Square inch (PSI)

inches of Water (inH2O)

Millimeters of Mercury (mmHg)

Relative Humidity

(models 5320, 5330 only)

Percent Relative Humidity

(%RH)

Temperature Dew Point in Degrees C (TdpC)

Temperature Dew Point in Degrees F (TdpF)

Volume

Liters (L)

Milliliters (mL)

Cubic Feet (ft3)

Totalizer

Liters (L)

Milliliters (mL)

Cubic Feet (ft3)

Type of Gas

The 5300 Series is capable of measuring Air, Nitrogen, Oxygen, Air/Oxygen Mix, or Carbon Dioxide

depending on the model. Flow meter models with an air calibration also include nitrogen correction as

a gas type option. You can select the type of gas to be measured from the available gas calibrations

on your meter. The type of gas can be set on the meter directly, through FLO-Sight™ PC Software, or

via ASCII commands.

Model Numbers based on Gas Calibration

Air, N2

Air, O2, Air/

O2 Mix, N2

Air, CO

2

, N

2

O2 Only

CO2 Only

5300 Series

5300-1

5300-2

5300-3

5300-4

5300-5

Page 26

20 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Meter Configuration

The 5300 Series Multi-Meter enables you to select measurement parameters to display, units of

measurement, and the type of gas to be measured directly from the meter’s touchscreen display.

There is an option to lock the meter which restricts you from changing measurement settings directly

from the Meter Home Screen. The lock function is set to disabled as its default so that measurement

settings can be changed freely.

If the lock function is enabled, you must unlock the meter before you can make changes to

measurement settings on the Meter Home Screen. You can lock and unlock the screen through the

meter itself, but the lock function can only be enabled and disabled through FLO-Sight™ PC Software.

See "Configuring the Meter" in Chapter 4 for step-by-step instructions on configuring the meter

through the touchscreen display. Additional settings can be configured using FLO-Sight™ software or

with ASCII commands.

Data Logging

Series 5300 Multi-Meters can save measurement data on their internal memory which can be exported

for viewing and analysis. Data can be logged for the flow rate, low pressure, temperature, absolute

pressure, and humidity (if available) measurement parameters.

Models 5310, 5320, and 5330 enable you to configure logging parameters and initiate data log

sessions directly from the meter. See “Data Logging” in Chapter 4 for instructions on logging data

through the meter. Data logging can also be done with the advanced version of FLO-Sight™ PC

Software for all 5000 Series models. Please refer to the FLO-Sight™ PC Software Manual for more

information.

The table below shows the preset data logging configurations available on the meter and specifies the

number of sample points collected for each configuration. The maximum number of sample points per

log file when logging through the meter is 15,000. A blank field indicates the configuration is

unavailable from the touchscreen display. For example, the box for a 1 second Test Length @ 100 ms

Sample Time Intervals is blank and is therefore unavailable on the meter.

Preset Logging Configurations and Sample Points

Sample

Time

Interval

Test Lengths

1 sec

5 secs

15 secs

1 min

10 mins

1 hour

5 hours

24 hours

1 ms

1000

5000

15000

5 ms

200

1000

3000

100 ms 50

150

600

1 second 60

600

3600

5 seconds

120

720

3600

1 minute 60

300

1440

5 minutes

12

60

288

NOTE

Sample time intervals and test lengths can be customized with FLO-Sight™ PC Software. The

maximum number of sample points per log file is 100,000 when logging through FLO-Sight™

PC Software.

Page 27

21

C H A P TE R 4

Touchscreen Navigation

Display Overview

Meter Home Screen

Upon startup, the home screen of the meter will be loaded. The home screen is where you will see

real-time data for multiple measurements, interact with the display, and make changes to the meter

through the settings menu.

1. Meter Home Tab

6. Volume and Triggers Tab *

2. Measurement Readings

7. Log Data Button *

3. Type of Gas

8. Menu Drop-down Screen

4. Flow Directional Indicator

9. Device Name and Information

5. Pause Display Button

10. Alerts Indicator

*Available on 5310, 5320, and 5330 models only

Page 28

22 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Menu Screen

1. Go to Meter Home Screen

5. Rotate Display 180º

2. Set Logging Parameters *

6. Settings Menu

3. Data Management *

7. Press anywhere outside menu to close menu

screen

4. Reset Device Settings

*Available on 5310, 5320, and 5330 models only

Measurements

Up to four measurement parameters

can be displayed simultaneously on the

home screen. You can configure the

fields to display any available

measurement parameters as well as

change units of measurement.

Type of Gas

The Meter Home Screen displays the

active gas calibration for the Flow

Multi-Meter. Certain models may be

calibrated for a single gas while others

may be calibrated to measure multiple

gases. The type of gas can be

changed after unlocking the meter for

configuration. See "Configuring the

Meter" in Chapter 4 for instructions on

changing the gas type.

Page 29

23

Flow Directional Indicators

On either side of the “Type of Gas” field, arrows point in the direction of gas flow through the meter and

correspond with changes in the direction of flow. In the default bidirectional mode, flow moving from left

to right → through the meter is shown as positive. Flow moving from right to left through the meter is

shown as negative. If the flow is zero, no indicator arrows will be displayed.

Pause/Play Display

The Pause button is used to pause the display from updating. When the Pause button is pressed, the

current measurement values will remain fixed on the screen. The meter will continue to make

measurements while paused, and pausing the display does not affect any active datalog sessions.

When paused, the button’s icon will change to a green play icon and the display function will become

disabled (grayed out). Press anywhere on the screen to re-enable display functionality. To un-pause

the display and resume screen updates, press the Play button.

Page 30

24 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Configuring the Meter

On the Meter Home Screen you can change the measurement parameters, units of measure, and the

type of gas to be measured. Changes can be made on the Meter tab and the Volume tab

(if available).

Measurement Parameters

Press a value field, use the scroll arrows to select a parameter, and click Save.

Units of Measurement

Press a units field, use the scroll arrows to select the desired units, and click Save.

Page 31

Operation and Service Manual 25

Flow Conditions

When Flow is selected as a measurement parameter, you have the option to select how the flow

measurement is calculated and displayed. These options are available in the Select Unit dialog box

that appears when the Units of Measurement field is pressed for a flow measurement.

Standard

This is flow rate the air would be moving if the temperature and pressure were at

standard conditions. For TSI® instruments, standard conditions are defined at 21.1°C

(70°F) and 101.3 kPa (14.7 psia).

Actual

This uses the actual temperature and pressure

of the gas to deliver the volumetric flow rate.

This is the true volume flow of the gas exiting

the flow meter.

User

This factor allows you to apply your own

temperature and pressure conditions to the

gas flow. You can specify these conditions

with FLO-Sight™ PC Software.

Remote

This option allows you to calculate volume flow rate at a remote point in the system

using the absolute pressure and differential pressure measurements. See Appendix D

for more information on Remote Flow Measurements.

Type of Gas

Press the type of gas field, use the scroll arrows to select the type of gas, and click Save.

NOTE

If an Air/Oxygen mix is selected, the meter assigns a 21% oxygen mix. The oxygen concentration

can be customized using FLO-Sight™ PC Software.

Page 32

26 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Locking the Meter

There is an option to lock the meter which restricts you from changing measurement settings directly

from the Meter Home Screen. With the lock function enabled, you must unlock the meter before you

can make changes to measurement settings on the Meter Home Screen.

You can lock and unlock the screen through the meter itself, but the lock function can only be enabled

and disabled through FLO-Sight™ PC Software. The lock function is set to disabled as its default so

that measurement settings can be changed freely.

Enable Meter Locking

To enable the locking function, connect the

meter to FLO-Sight™ PC Software, click on

the menu icon in the software and select

Settings. Make sure the device you want to

configure is selected, press the Edit button,

click the Device Lock toggle switch, and

press Save. The meter is now locked and

you will not be able to change measurement

parameters, units of measurement, or the

gas type without first unlocking the meter.

Unlock / Lock the Meter

Once the lock function is enabled through FLO-Sight™ PC Software, a lock icon will become visible in

the Menu header of the Flow Multi-Meter. You now must first unlock the meter before you can

configure measurement settings on the Meter Home Screen.

To unlock the meter, select the Menu drop-down on the home screen then select the Lock icon in the

Menu header. Once unlocked, the lock icon will change to an open lock and you can freely change

measurement settings on the Meter Home Screen.

Page 33

Operation and Service Manual 27

With the meter unlocked, navigate back to

the Meter Home Screen by selecting

Meter/Volume from the menu. The fields

unlocked for configuration on the Meter

Home Screen will have a gray box

displayed around them.

The meter will remain unlocked and open

for changes until you lock the meter. To lock

the meter and restrict changes to the Meter

Home Screen, navigate to the Menu dropdown and press the Lock icon. Once

locked, the lock icon will change to back

closed and you will no longer be able to

change measurement settings on the Meter

Home Screen.

Volume and Triggers

Volume is a calculated measurement that integrates flow over time and is controlled through triggers.

This feature is available through the meter for models 5310, 5320, and 5330 only and is located on the

Volume tab of the meter. You can control your volume measurements by selecting the trigger

parameter, trigger mode, and begin/end trigger values.

The graphic below shows conceptually how volume is measured between two trigger levels.

Page 34

28 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Setting Triggers

The meter must be stopped to edit trigger settings. On the Volume tab, confirm that the meter is

stopped (shown below left) and press on the field you would like to edit.

If a volume measurement is active (shown below right), then press the Stop button to cancel the

measurement and allow edits to be made to trigger settings.

Select Mode

With the volume screen stopped, press the middle fields to bring up the Select Mode dialog box. In this

screen you can choose your Trigger Parameter (Flow, Absolute Pressure, or Low Differential

Pressure) and Test Mode (Single or Continuous testing). Use the arrows to scroll through the selection

options and click Save to complete.

Trigger Parameter

Flow, Absolute Pressure, or Low Pressure

Test Mode

Single or Continuous

Single Test Mode: You must press the Play button before each volume measurement is taken.

Continuous Test Mode: The meter will continually make volume measurements each time the begin

trigger condition is met.

Page 35

Operation and Service Manual 29

Begin/End Triggers and Slope

With the volume screen stopped, press the fields that you would like to edit. In the Select Trigger and

Slope screens, you can select your Begin Trigger or End Trigger values and the Slopes of the triggers.

Use the arrows to scroll and select your Trigger Values and the Slopes of the values (Positive or

Negative). Once you have made your selections, click the Save button.

Begin / End Trigger Values

Select from available values

Begin / End Trigger Slopes

Positive or Negative

The slope of the trigger is the direction of the trigger parameter measurement reading as it passes the

trigger value as defined by you. A positive slope is ascending measurement readings (ex. 1, 2, 3, 4)

and a negative slope is descending readings (ex. 4, 3, 2, 1).

Please note the trigger options for the volume begin and end triggers. These are set as the default

options and cannot be changed by you.

Trigger

Units

Trigger Values

Flow

Std L/min

+/– 0.1, 0.5, 1, 2, 3, 5, 7.5, 10, 20

Absolute Pressure

kPa

90, 95, 98, 100, 102, 104, 107, 110

Low Differential Pressure

cmH2O

+/– 0.5, 1, 2, 3, 4, 5, 10

Making Volume Measurements

Once all settings have been saved, press the Play button to lock trigger settings and begin making

volume measurements.

Page 36

30 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Once the Play button is pressed to take measurements, the Flow Multi-Meter will notify you on screen

when the Begin Trigger, and then End Trigger, is reached. After the end trigger is reached, the meter

will display the calculated volume measurement.

Data Logging

Models 5310, 5320, and 5330 enable you to configure logging parameters and initiate data logging

sessions directly from their Flow Multi-Meter. On the Meter Home Screen of these models, a Log

button will be visible. In the Menu drop-down screen, these models will display options for “Logging

Parameters” and “Data Management.”

Logging Parameters

From the Meter Home Screen, press the Menu button and select Logging Parameters from the drop-

down menu. In the Logging Parameters screen, use the scroll arrows to select the Sample Time (aka

sample rate) and Test Length for data logs. The Log Name is automatically generated for each data

file (ex. Log 1, Log 2, Log 3…). Once selections have been made, click on SAVE.

Sample Time

The sample time determines the rate at which the Flow Multi-Meter will store measurement data points.

All data points are the average of 1 ms readings. For example, a 50 ms sample rate would log 20 data

points per second with each data point being comprised of the average of 50 one-millisecond readings.

Page 37

Operation and Service Manual 31

Test Length

The test length determines the duration of the data logging session.

NOTE

The Sample Time and Test Length fields are interrelated, and changing the option for one may

result in the option changing for the other. The maximum number of sample points per log file when

logging through the meter is 15,000. See the table “Preset Logging Configurations and Sample

Points” in Chapter 3 of this manual for more information. Custom sample times and test lengths can

be specified when logging data through FLO-Sight™ PC Software. The maximum number of sample

points per log file is 100,000 when logging through the software.

Log Data

To log data, press the LOG button from the Meter Home Screen. Once pressed, the Log button will

turn green and a clock will count down the test length time. After the logging session is complete, a log

file will be created and the log button will return to its normal state.

To stop an active data logging session, press the green data logging countdown button and select

Stop. No data file is created when a logging session is stopped.

NOTE

The meter will log data for all available measurement parameters (not including volume or totalizer

measurements) regardless of what is displayed on the screen.

Export Data Files

Logged data is saved in the meter’s internal memory with each logging session creating a new file. To

export data files, insert a USB flash drive into either of the meter’s USB-A ports, press the Menu

button from the Meter Home Screen, and select Data Management from the drop-down menu. The

Data Management screen displays the number of logged data files stored on the meter. A maximum of

20 datalog files can be stored on the Flow Multi-Meter.

Select EXPORT to copy all stored datalog files onto the inserted USB flash drive.

Page 38

32 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Exported data log files are saved in .csv format. Once on the flash drive, you can edit file names,

transfer the files to other devices, or delete the files at your discretion. In addition to measurement

readings, the .csv file (shown below) contains information about the meter, data logging parameters,

and gas conditions.

Delete Data Files

To delete logged data files, select Data Management from the Menu drop-down and press the

DELETE button. This will delete all files from the device; individual files cannot be deleted through

the meter.

NOTE

Additional data management functionality is available through FLO-Sight™ PC Software.

Page 39

Operation and Service Manual 33

Rotate Screen

You can rotate the screen of the 5300 Series Flow Multi-Meter to make it easier to view readings

during challenging test setups. The Rotate Screen icon is located in the Menu Header, and when

pressed, will rotate the meter’s screen 180 degrees.

NOTE

Directional flow indicators will remain unchanged.

Alerts

The Series 5300 Flow Multi-Meter can

display alert conditions when user-set

thresholds for a specified parameter are

met. Alerts can only be set through the

advanced version of FLO-Sight™

PC Software.

When an alert threshold is met, the Bell icon

on the meter will turn orange. The value of

the parameter that caused the alert will also

turn orange. When the threshold is no

longer met, the alert will cease and the

colors will change back to normal.

Page 40

34 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Meter Information

Pressing the Information icon or Device Name on the Home Screen will display information about

the meter.

Device Name

The name of the device is displayed in the Header Bar on the Home Screen with the text

“TSI 5000 Series” as the default text. The device name can be edited through FLO-Sight™ PC

Software only. Select the DONE button to return to the Home Screen.

Model Number

This field displays the model number of the instrument (ex. 5310). The dash number is the gas

calibration of the meter (ex. -2 above indicates Air/O2 calibration). There will be a letter or number after

the model-dash number that represents the hardware revision (ex. “A” in the above screenshot).

Serial Number

This is the serial number of the meter. The naming convention is as follows: 5XXX YYWW XXX

5XXX =

Model Configuration (ex. 5320)

YY =

Year of Manufacture

WW =

Week of Manufacture

XXX =

Manufactured Unit Number

Calibration Date

This is the date that the instrument was last calibrated by TSI®. TSI® recommends an annual

calibration for all flow meters.

IP Address

Each 5300 Series Flow Multi-Meter will have its own unique IP address. The IP address can be used

in establishing communication with a computer and communicating via ASCII commands. Please see

the Series 5200/5300 ASCII Command Set Manual for more information on communicating with

ASCII commands.

Firmware Version

This field displays the current firmware version being used by the Flow Multi-Meter. Firmware updates

can be uploaded through the USB-A port of the meter. The Check for Update button on the Meter

Information screen is used to load firmware updates from an inserted USB drive.

Page 41

Operation and Service Manual 35

Updating Firmware

TSI® may periodically release firmware updates for the 5000 Series. These update utilities can be

downloaded from www.tsi.com and then installed on the Flow Multi-Meter. Any additional instructions

for downloading files will be available at the time updates are released.

When an update is available, save the file to a USB flash drive and insert the drive into either USB-A

port on the meter. Wait a second after inserting for the meter to recognize the flash drive then select

the CHECK FOR UPDATE button from the Meter Information screen. If an update is located, an

“Update found…” message will appear. Click on the Update button to load the firmware update.

Please allow up to several minutes for the meter to update its firmware. Once complete, an

“Update Successful!” message will display briefly and the meter will automatically reboot. After

reboot the meter will be ready for operation. If the meter does not initialize after the firmware update,

an additional instrument reboot may be necessary.

Page 42

36 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Device Settings

In the Device Settings screen, you can view and edit device settings such as flow control, humidity

compensation, display update rate, and gas standard conditions. Open the Device Settings screen by

navigating to the Menu Screen and pressing the Gear icon in the header bar. The Device Settings

screen is comprised of three tabs: 4040 Mode, Config, and User Gas Std.

4040 Mode

On the “4040 Mode” tab in the Device Settings, you can disable the Bidirectional Flow and Humidity

Compensation features, returning the Flow Multi-Meter to a state similar to the 4000 Series flow

meter. To disable either of these features, select EDIT button and then click on the feature you would

like to disable. The button will slide to the left and become disabled. Press the SAVE button to save

your changes.

Disabling the Bidirectional Flow will result in the Flow Multi-Meter displaying and recording all flows,

regardless of their direction, as positive with a left to right → directional indicator.

Models 5320 and 5330 have the option to disable their Humidity Compensation feature. With humidity

compensation disabled, the 5300 Series will deliver flow readings irrespective of the water vapor

present in the gas flow.

Page 43

Operation and Service Manual 37

Display Update Rate

The update rate is the rate at which readings are updated on the meter display for all parameters. The

default update rate for the 5300 Series Multi-Meter is 0.5 seconds. To change this setting, select from

a list of options (0.5, 1, 2, 5, or 10 seconds). Note that you can specify a custom display update rate

through FLO-Sight™ PC Software.

To change the update rate, navigate to the Config tab in the Device Settings screen, press the EDIT

button, use the scroll arrows to select a new rate then click SAVE.

Using 0.5 inch or 15-mm Tube Ends

If the 0.5 inch or 15-mm tube ends are connected directly to the instrument, then TSI® recommends

selecting the Tube Ends Toggle Switch in the meter’s Settings screen. The 5300 Series will still

measure within its published accuracy spec even if this recommendation is not followed, but selecting

the toggle switch ensures the most accurate flow measurement readings.

See the section on this topic in Chapter 2 of this manual for more information on when to use the

0.5 inch or 15-mm Tube End toggle switch.

Page 44

38 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

User Gas Standard

The standard temperature and pressure

used for gas flow measurements is

displayed in the User Gas Std tab of the

Device Settings. The default standard

temperature and pressure is 21.11°C and

101.3 kPa, respectively.

The gas standard conditions can be

changed through FLO-Sight™ PC Software

only. Any changes made through the

software will be reflected on the meter.

Reset Device Settings

The Reset Device Settings screen is where you can:

• Zero the low differential pressure sensor

• Reset the totalizer counter

• Reset the meter back to factory defaults

Navigate to this screen by opening the Menu and selecting Reset Device Settings from the

drop-down.

Page 45

Operation and Service Manual 39

Zero Low Pressure

Models 5310, 5320, and 5330 Gas Flow Multi-Meters have an integrated differential pressure sensor.

To zero the differential pressure sensor, click the Zero button, then click the Zero button again in the

Zero Low Pressure dialog box.

Reset Totalizer

All 5300 Series Gas Flow Multi-Meters include a totalizer feature that measures total volume by

integrating flow over time. This is a calculated measurement performed by the meter and operates as

a running total. To reset the Totalizer counter to zero, select the middle RESET button, then click the

Reset button in the Rest Totalizer dialog box.

Reset Device to Factory Defaults

The 5300 Series Gas Flow Multi-Meter can be reset to its factory default settings. See the table below

for details on the settings which will be affected. Resetting the device to factory defaults will not affect

any logged data files stored on the meter. To reset to factory defaults, select the lower RESET button,

then click Reset in the Reset Settings dialog box.

Page 46

40 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Factory Default Settings

Description

Setting

Default Condition

Measurement Parameters

Flow

Std L/min

Temperature

o

C

Absolute Pressure

kPa

Gas Calibration

Type of Gas

Air (if available)

Gas Standard Conditions

Temperature

21.11oC

Absolute Pressure

101.3 kPa

Volume

Sampling Stopped

Std L

Begin Trigger

1 L, Positive slope

End Trigger

1 L, Negative slope

Flow Mode

Flow, Continuous

Logging Parameters

Sample Time

1 millisecond

Test Length

15 seconds

Log Name

Log 1

Meter Information

Device Name

“TSI 5000 Series”

Device Settings

Bidirectional Flow

Enabled

Humidity Compensation

Enabled (if available)

Update Rate (Display)

0.5 seconds

Page 47

41

C H A P TE R 5

Maintenance

Flow Sensor

Periodically inspect the flow sensor by looking into the outlet of the flow meter. Remove dust, particles

and fibers from the sensor, with clean, dry compressed air. The flow sensor will break if touched.

NOTE

NEVER RUN LIQUIDS THROUGH THE FLOW METER AND

NEVER TOUCH THE SENSOR WITH A BRUSH.

Dust or other deposits on the flow sensor will degrade the 5300 Series Multi-Meter’s flow accuracy.

CAUTION

The flow meter must be switched off for cleaning. Only use clean, dry, compressed air

when attempting to remove contamination from the sensor.

Re-Certification

To maintain a high degree of confidence in the measurements made by the 5300 Series Gas Flow

Multi-Meter, TSI® recommends that the instrument be returned to TSI® every 12 months for

re-certification. For a nominal fee, TSI® will recalibrate the unit and return it to you with an As-Found

and As-Left Certificate of Calibration with US National Institute of Standards Technology (NIST)

traceability. This annual re-certification assures you consistently accurate measurements and is

especially important for applications in which strict calibration records must be maintained.

To send your 5300 Series Gas Flow Multi-Meter back to TSI® for re-certification, please visit TSI

®

’s

website at www.tsi.com, select Register a repair / calibration under the Support tab, and follow the

instructions. If you are having difficulty completing this process, please contact TSI

®

’s Customer

Support Group for assistance by calling 800-680-1220 or 651-490-2860.

Damaged Tube End Connections

If the tube end connections become damaged, note that the 5300 Series Multi-Meter does not need to

come back to TSI® for repair. The damaged tube end connections can be replaced by ordering the

appropriate connection size. Reference the list of optional accessories in Chapter 1 of this manual for

part number.

Cases

If the instrument case or storage case needs cleaning, wipe it off with a soft cloth dipped in isopropyl

alcohol or mild detergent. Never submerge the Multi-Meter or allow liquids to enter the flow tube.

Page 48

42 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Storage

When storing the MultiMeter, always cover the

ends of flow tubes with the

provided end caps to

prevent dust or other

foreign matter from

entering the tube.

Page 49

Operation and Service Manual 43

C H A P TE R 6

Troubleshooting

The table below lists the symptoms, possible causes, and recommended corrective actions for

common problems encountered with the Multi-Meter. If the symptom is not listed, or if none of the

solutions solve the problem, please contact TSI® Customer Support at 1-800-680-1220 or

651-490-2860.

Symptom

Possible Causes

Corrective Action

No display.

Unit not switched on.

Switch on the unit.

No power to instrument.

Connect the USB-C to USB-A cable

from the USB-C port on the meter to a

USB compatible power source that

can provide 5 VDC.

When powered through a PC, the

meter recycles through boot up

process or is unable to complete

the initialization.

Computer USB port unable to

sufficiently power the meter.

Connect the USBC-A power cable to

the provided USB hub cable, then plug

the hub cable into the USB-A port of

the computer, and plug the USBC-A

cable into the USB-C port located on

top of the meter.

Temperature reads high at low or

zero flows.

Temperature sensor is being

heated from the flow sensor.

This is normal. Once flow exceeds

1 Std L/min, the temperature will track

the flowing gas temperature.

Flow readings fluctuate badly.

The flow is fluctuating.

Improve inlet conditions or increase

display averaging time. See the

Device Settings section in Chapter 4

of this manual for information on the

display update rate.

Display shows flows over-range

with no flow passing through flow

tube.

The sensor may be damaged

or broken.

Return flow meter to TSI® for service.

Page 50

44 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

Technical Contacts

• If you have technical or application questions about this instrument, contact an applications

engineer at one of the locations listed below.

• If the Gas Flow Multi-Meter fails, or if you are returning it for service, visit our website at

tsi.com/service or contact TSI® at:

TSI Incorporated

500 Cardigan Road

Shoreview, MN 55126 USA

Phone: +1-800-680-1220 (USA) or

+1 (651) 490-2860

E-mail: technical.services@tsi.com

TSI GmbH

Neuköllner Strasse 4

52068 Aachen

GERMANY

Telephone: +49 241-52303-0

Fax: +49 241-52303-49

E-mail: tsigmbh@tsi.com

TSI Instruments Ltd.

Stirling Road

Cressex Business Park

High Wycombe, Bucks

HP12 3ST

UNITED KINGDOM

Telephone: +44 (0) 149 4 459200

E-mail: tsiuk@tsi.com

TSI Instrument (Beijing) Co., Ltd.

Unit 1201, Pan-Pacific Plaza

No. 12 A, Zhongguancun South Avenue

Haidian District, Beijing, 100181

CHINA

Telephone: +86-10-8219 7688

Fax: +86-10-8219 7699

E-mail: tsibeijing@tsi.com

TSI Instruments Singapore Pte Ltd

150 Kampong Ampat

#05-05 KA Centre

Singapore 368324

Telephone: +65 6595-6388

Fax: +65 6595-6399

E-mail: tsi-singapore@tsi.com

TSI France Inc.

Hotel technologique

BP 100

Technopôle de Château-Gombert

13382 Marseille cedex 13

FRANCE

Telephone: +33 (0)1 41 19 21 99

Fax: +33 (0)1 47 86 00 07

E-mail: tsifrance@tsi.com

Returning the Gas Flow Multi-Meter for Service

Before returning the Gas Flow Multi-Meter to TSI® for service, visit our website at tsi.com/service or

call TSI® at 1-800-680-1220 (USA) or +1 (651) 490-2860 for specific return instructions. Customer

Service will need this information when you call:

• The instrument model number

• The instrument serial number

• A purchase order number (unless under warranty)

• A billing address

• A shipping address.

TSI® recommends that you keep the original packaging (carton and foam inserts) of the Gas Flow

Multi-Meter for use whenever the Gas Flow Multi-Meter is shipped, including when it is returned to

TSI® for service.

Page 51

Operation and Service Manual 45

C H A P TE R 7

FLO-Sight™ PC Software

All 5300 Series Gas Flow Multi-Meters come with FLO-Sight™ PC Software, FLO-Sight™ PC Software

allows you to fully control and operate their 5300 Series meters directly from your computer. Using the

meter through FLO-Sight™ PC Software also enables additional functionality and configuration options

not available from the meter itself.

FLO-Sight™ software has these basic features:

• Real-time display of all measurement parameters

• Min, max, and average readings

• Advanced meter configuration

FLO-Sight™ software advanced features include:

• Real-time graphing

• Data logging, download, and file management

• Alerts set for any parameter

• Multiple meter operation

There are two versions of FLO-Sight™ PC Software: Basic and Advanced. The Basic version is

available to all 5300 Series users and can be downloaded from TSI.com. The Advanced version has

additional features and can be purchased through the software itself or from TSI.com. A free trial of

the advanced version is included with the purchase of a 5300 Series Flow Multi-Meter.

Please refer to the FLO-Sight™ PC Software Manual for more information on downloading, installing,

and operating FLO-Sight™ PC Software.

Page 52

46 Gas Flow Multi-Meter Models 5300/5310/5320/5330/5303

(This page intentionally left blank)

Page 53

Operation and Service Manual 47

C H A P TE R 8

Serial Command Set

The 5000 Series can establish communication with a computer over either a direct USB link utilizing a

NDIS driver or over RS-232 utilizing a USB to RS-232 converter. Once the meter has been connected,

you can communicate via serial using ASCII commands.

The ASCII commands are case sensitive. Upper case letters are used throughout the command set

except as designated. Each command sent to the flow meter must be terminated by a carriage return

(CR = 0x0d). Line feeds (LF = 0x0a) are ignored.

Listed below is a summary of the commands. For more details, please refer to the 5000 Series ASCII

Command Set Manual.

Commands for Flow Rate, Temperature, Pressure, and Volume

Command

Description

Backward Compatible

with 4000/4100 Series

DmFTPnnnn

Returns flow rate, temperature, and absolute

pressure data at an interval equal to the

sample rate.

Yes

DmFTPHLInnnn

Returns flow rate, temperature, absolute

pressure, humidity, low pressure and

totalizer data at an interval equal to the

sample rate.

No

Vmnnnn

Returns a volume measurement by

integrating flow rate over time.

Yes

Measurement Setup Commands

Command

Description

Backward Compatible

with 4000/4100 Series

SBTxnnn.nn

Sets the begin-trigger level for starting data

acquisition.

Yes

SETxnnn.nn

Sets the end-trigger level for stopping data

acquisition.

Yes

CBT

Clears the begin-trigger level.

Yes

CET