TSC Auto ID Technology 2008001 User Manual

THERMAL TRANSFER / DIRECT THERMAL

BAR CODE PRINTER

MANUAL

USER’S

Contents

1. Introduction ............................................1

1.1 Product Introduction ...............................................................................1

1.2 Compliances ............................................................................................1

2. Operations Overview .....................................3

2.1 Unpacking and Inspection ......................................................................3

2.2 Printer Overview ......................................................................................4

2.2.1 Front View ......................................................................................4

2.2.2 Interior view....................................................................................5

2.2.3 Rear View........................................................................................6

2.3 Operator Controls....................................................................................7

2.3.1 Front Panel Display .......................................................................7

2.3.2 LED Indicators ...............................................................................7

2.3.3 Front Panel Keys ...........................................................................8

2.4 Setting Up the Printer..............................................................................8

2.5 Installation of Ribbon..............................................................................9

2.5.1 Loading Ribbon .............................................................................9

2.6 Installation of Media ..............................................................................12

2.6.1 Loading Roll Labels.....................................................................12

3. Menu Function .........................................14

3.1 Setup Menu Overview............................................................................15

3.1.1 Printer Setup ................................................................................16

3.1.2 Sensor...........................................................................................23

3.1.3 Serial Comm.................................................................................31

3.1.4 Ethernet........................................................................................34

3.2 File Manager...........................................................................................37

3.2.1 File List.........................................................................................37

3.2.2 Avail. Memory...............................................................................37

3.2.3 Del. All Files..................................................................................38

3.3 Diagnostics ............................................................................................39

3.3.1 Print Config. .................................................................................39

3.3.2 Dump Mode..................................................................................40

3.3.3 Rotate Cutter................................................................................41

3.4 Language................................................................................................41

3.5 Service....................................................................................................42

3.5.1 Initialization..................................................................................42

i

3.5.2 Mileage Info..................................................................................43

4. Diagnostic Tool.........................................44

4.1 Start the Diagnostic Tool.......................................................................44

4.2 Printer Function (Calibrate sensor, Ethernet setup, RTC setup………)

.......................................................................................................................45

5. Troubleshooting ........................................46

5.1 Common Problems................................................................................46

6. Maintenance ...........................................50

Revise History ...........................................52

ii

1. Introduction

1.1 Product Introduction

Thank you very much for purchasing TSC bar code printer.

This printer is designed with die-casting aluminum chassis and print mechanism, metal

cover with large clear media view window, which ensuring to work for the extreme and

heavy duty industrial environment and applications.

With back-lit graphic LCD display, printer status can be managed easier and operated

more user friendly. The moveable sensor design can accept wide range of label media.

All of the most frequently used bar code formats are included. Fonts and bar codes can

be printed in any one of the four directions. This printer is built-in the high quality, high

performance MONOTYPE IMAGING® True Type font engine and one CG Triumvirate

Bold Condensed smooth font. With flexible firmware design, user can also download the

True Type Font from PC into printer memory for printing labels. Besides the scalable

font, it also provides a choice of five different sizes of alphanumeric bitmap font, OCR-A

and OCR-B fonts. By integrating rich features, it is the most cost-effective and high

performance printer in its class!

1.2 Compliances

CE Class A:

EN55022:1998+A1:2000+A2:2003:

EN55024:1998+A1:2001+A2:2003:

EN 61000-4 SERIES REQULATIONS

ETSI EN 301 489-17:V1.2.1(2002-08)

FCC:

CFR 47, Part 15/CISPR 22 3RD EDITION:1997, Class A

UL, CUL

UL 60950 3rd

TÜV-GS:

EN60950: 2000

Federal Communication Commission Interference Statement

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the

interference by one of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that

may cause undesired operation.

INFORMATION TO USER

To assure continued compliance, (example - use only shielded interface cables

when connecting to computer or peripheral devices) any changes or

modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate this equipment.

Wichtige Sicherheits-Hinweise

1.Bitte lesen Sie Diese Hinweis sorgfältig durch

2.Heben Sie diese Anleitung fűr den späteren Gebrauch auf.

3.Vor jedem Reinigen ist das Gerät vom Stromentz zu trennen. Verwenden Sie Keine

Flűssig-oder Aerosolreiniger. Am besten eignet sich ein angefeuchtetes Tuch zur

Reinigung.

4.Die Netzanschlußsteckdose soll nahe dem Gerät angebraucht und leicht zugänglich

sein.

5.Das Gerät ist vor Feuchtigkeit zu schűtzen.

6.Bei der Aufstellung des Gerätes ist auf sicheren Stand zu achten. Ein Kippen oder

Fallen könnte Beschädigungen hervorrufen.

7.Beáchten Sie beim Anschluß an das stromnetz die Anschlußwerte.

8. Dieses das Gerät kann bis zu einer Außentemperatur von maximal 40℃ betieben

werden.

2

2. Operations Overview

2.1 Unpacking and Inspection

This printer has been specially packaged to withstand damage during shipping.

Please carefully inspect the packaging and printer upon receiving the bar code printer.

Please retain the packaging materials in case you need to reship the printer.

Unpacking the printer, the following items are included in the carton.

One printer unit

One Windows labeling software/Windows driver CD disk

One quick installation guide

One power cord

One USB interface cable

If any parts are missing, please contact the Customer Service Department of your

purchased reseller or distributor.

3

2.2 Printer Overview

2.2.1 Front View

1

2

3

4

1. LED indicators

2. LCD display

3. Front panel buttons

4. Paper exit chute

5. Printer right side cover

6. Cutter module (Option)

5

6

4

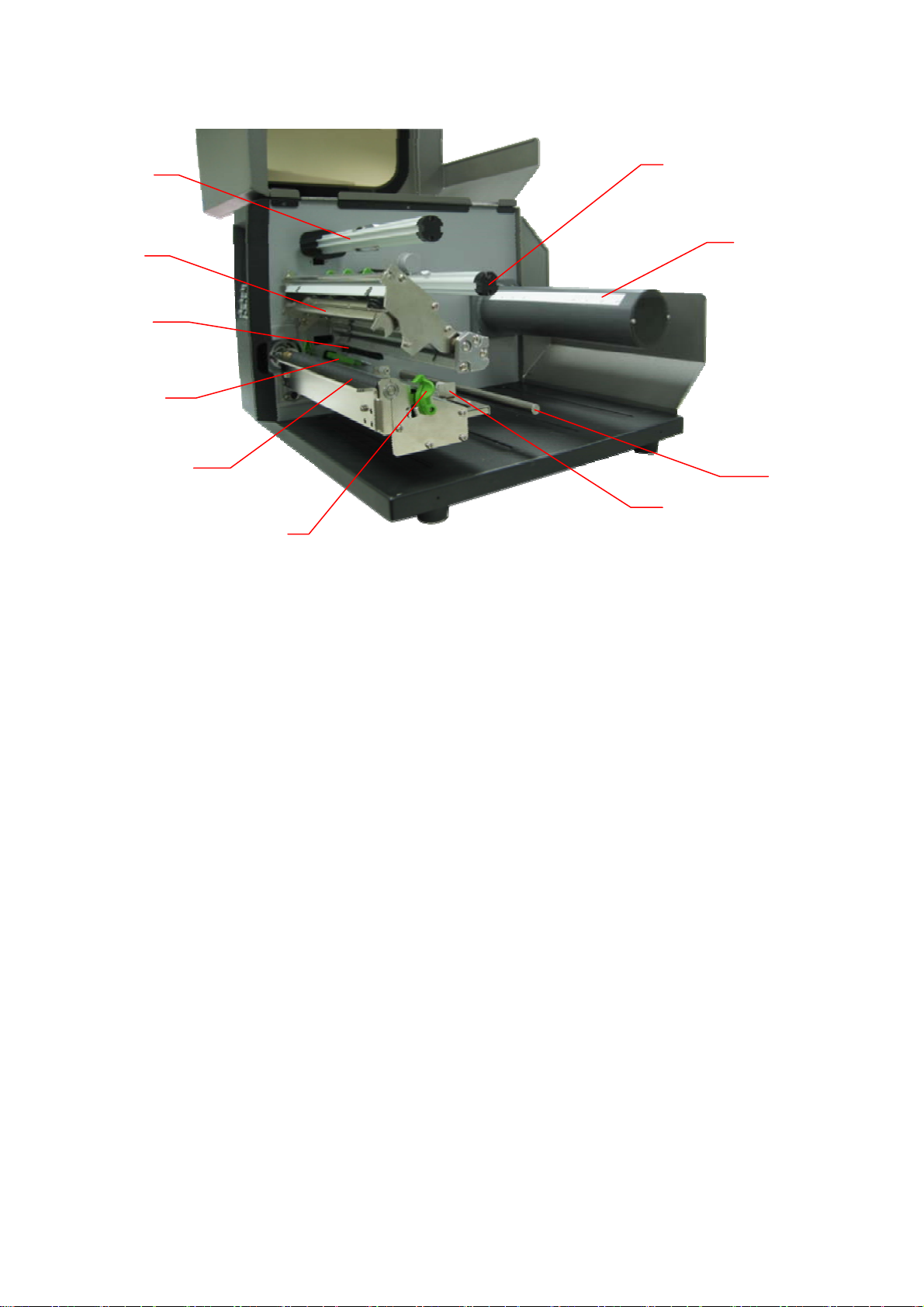

2.2.2 Interior view

1

2

3

4

5

1. Ribbon rewind spindle

6

7

8

9

10

2. Print head

3. Ribbon sensor

4. Media sensor

5. Platen roller

6. Print head release lever

7. Ribbon supply spindle

8. Label supply spindle

9. Media guide bar

10. Label guide

5

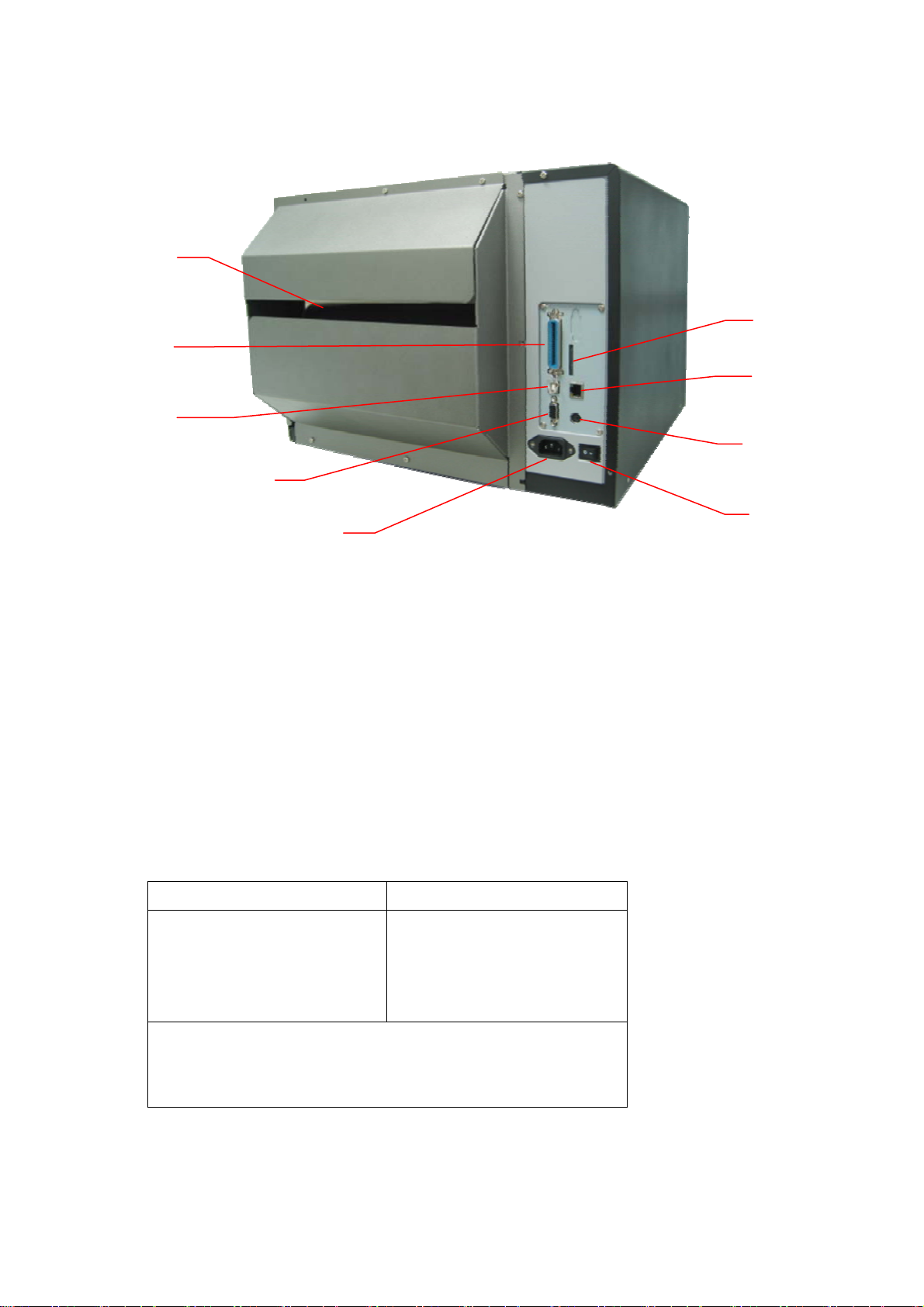

2.2.3 Rear View

1

2

3

4

5

6

7

8

9

1. Fan-fold paper entrance chute

2. Centronics interface

3. USB interface

4. RS-232C interface

5. Power jack socket

*6. SD card slot

7. Ethernet interface

8. PS/2 interface

9. Power switch

* Recommended SD card specification.

SD V 1.0, V 1.1 SD V 2.0 (SDHC)

128MB

256MB

512MB

1GB

-Supported DOS FAT file system.

4GB class 6

-Folders stored on the SD card should be in the 8.3 filename format.

-Approved SD card manufacturer: SanDisk, Transcend.

6

2.3 Operator Controls

2.3.1 Front Panel Display

LCD display

Front panel buttons

LED indicators

2.3.2 LED Indicators

LED Status Indication

Off The printer power is turned off

On The printer power is turned on

On Printer is ready

Pause

Blinking

Downloading data into printer.

Off Printer is ready

On "CARRIAGE OPEN" or “CUTTER ERROR”

Blinking "NO PAPER", "PAPER JAM" or "NO RIBBON"

7

2.3.3 Front Panel Keys

Keys Function

1. Enter the menu

2. Exit from a menu or cancel a setting and return to the previous menu

Pause/Resume the printing process

Advance one label

Scroll up the menu list

Scroll down the menu list

Enter/Select cursor located option

2.4 Setting Up the Printer

1. Place the printer on a flat, secure surface.

2. Make sure the power switch is off.

3. Connect the printer to the computer with the provided USB cable.

4. Plug the power cord into the AC power cord socket at the rear of the printer, and

then plug the power cord into a properly grounded power outlet.

8

2.5 Installation of Ribbon

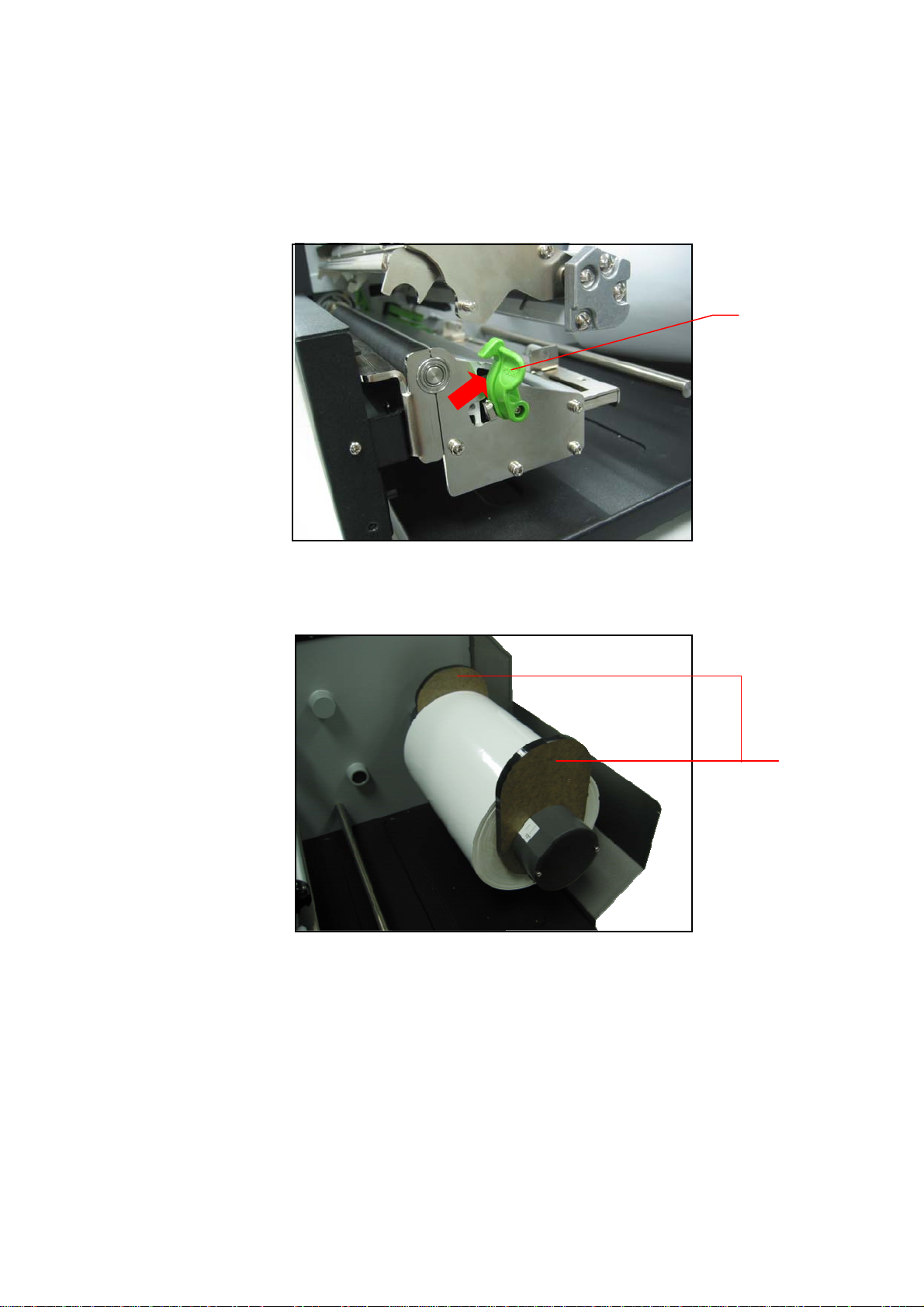

2.5.1 Loading Ribbon

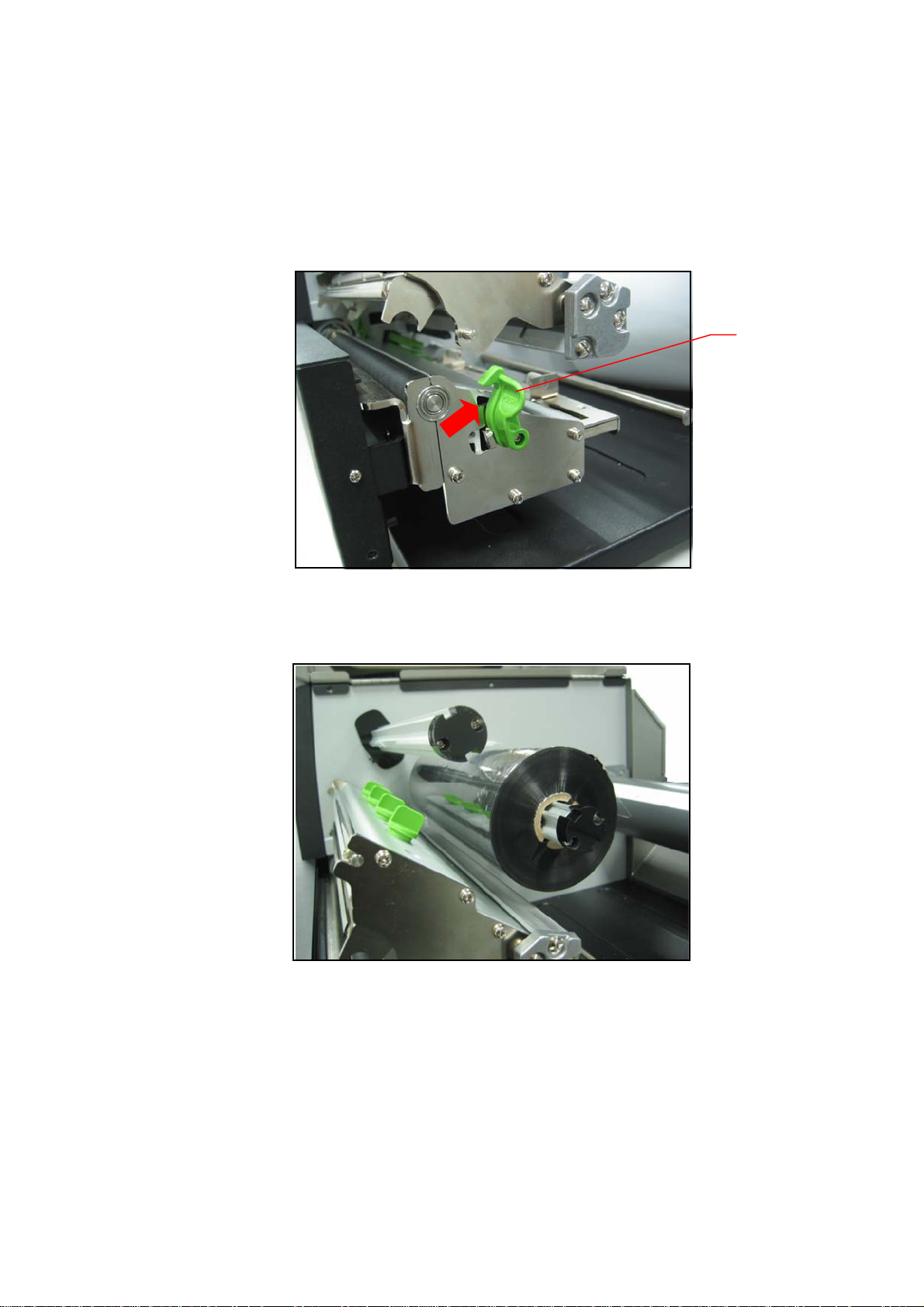

1. Lift open printer right side cover.

2. Push the print head release lever to open the print head mechanism.

Print head

release lever

3. Install the ribbon onto the ribbon supply spindle.

4. Place a paper core onto the ribbon rewind spindle.

9

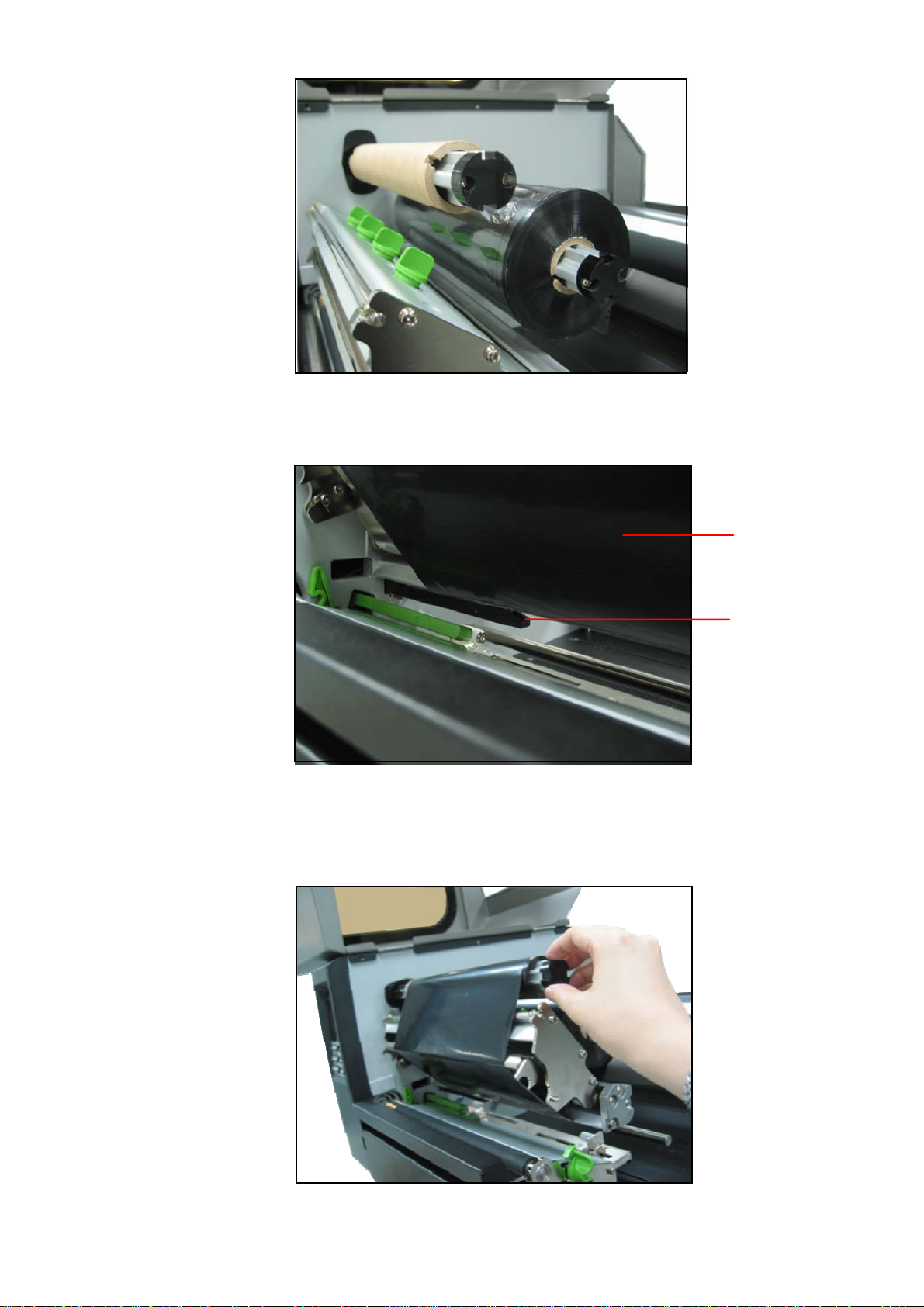

5. Thread the ribbon through the ribbon sensor slot and then through the open space in

between print head and platen.

Ribbon

Ribbon

sensor

5. Stick the ribbon onto the ribbon rewind paper core. Keeping the ribbon flat and

without wrinkles.

6. Wind the ribbon clockwise about 5~10 circles onto the ribbon rewind spindle until it

is smooth and properly stretched.

10

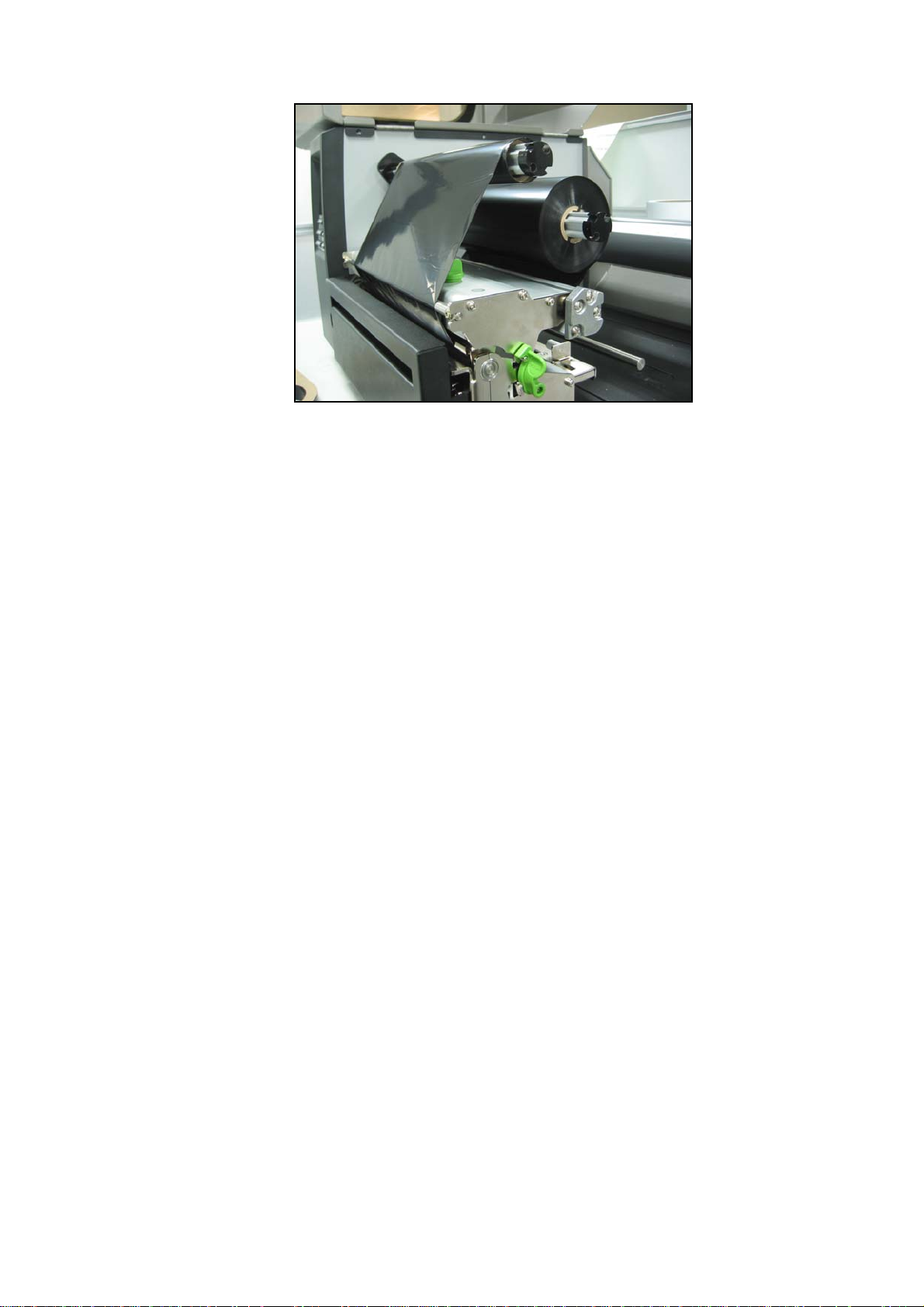

7. Close the print head mechanism making sure the latches are engaged properly.

11

2.6 Installation of Media

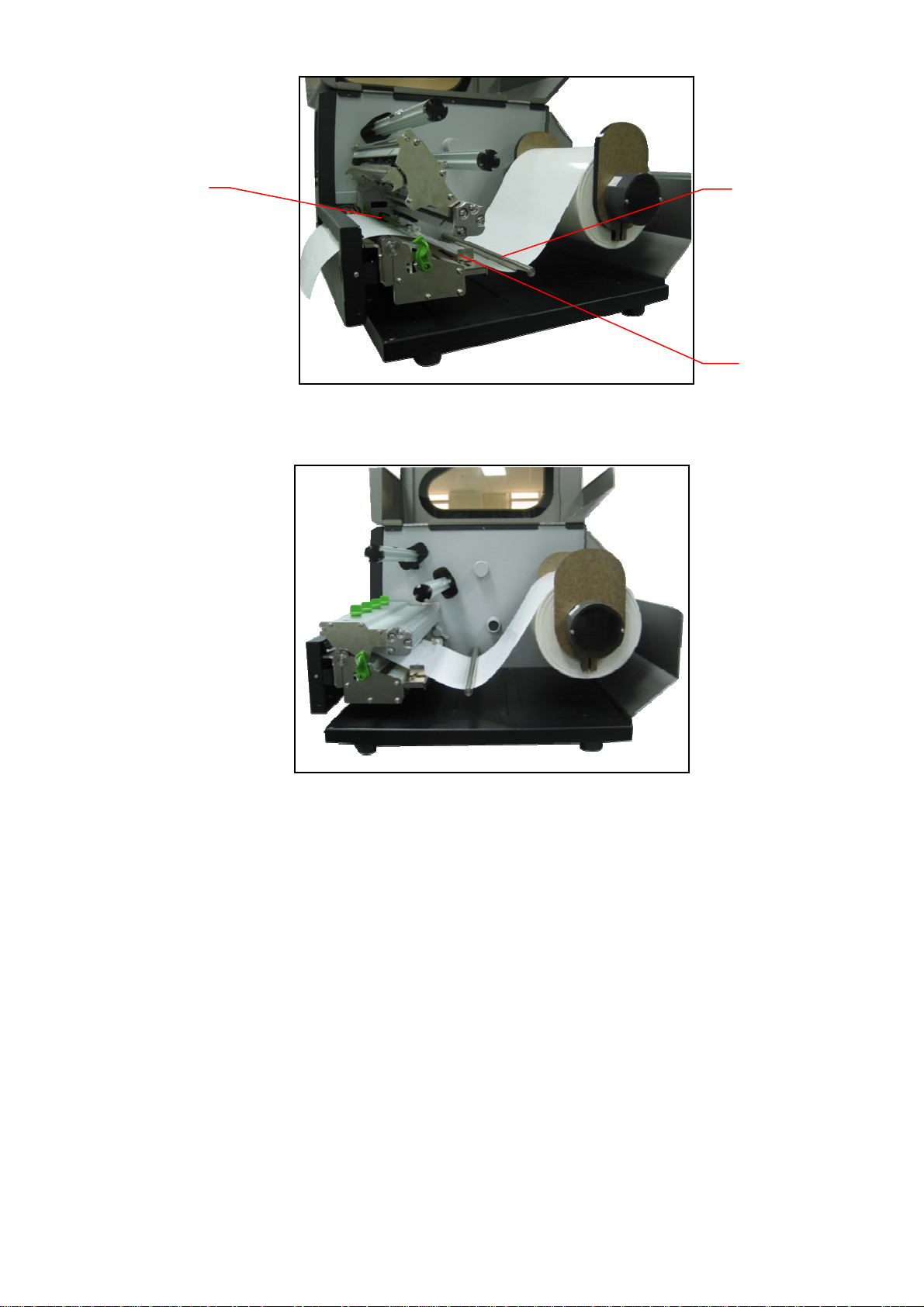

2.6.1 Loading Roll Labels

1. Lift open printer right side cover.

2. Push the print head release lever to open the print head mechanism.

2. Insert a media holder guide and a roll of media into the label supply spindle.

Print head

release lever

3. Place another media holder guide into the label supply spindle and make sure the

media is set on the center of spindle.

Media holder

guide

4. Pull label roll leading edge forward through the media guide bar, label guide, media

sensor and place the label leading edge onto the platen roller.

12

Media sensor

Media guide bar

Label guide

5. Adjust the label guide to fit the width of the label.

6. Close the print head mechanism making sure the latches are engaged properly.

7. Using the front display panel, set the media sensor type and calibrate the selected

sensor.

Note: Please calibrate the gap/black mark sensor when changing media.

13

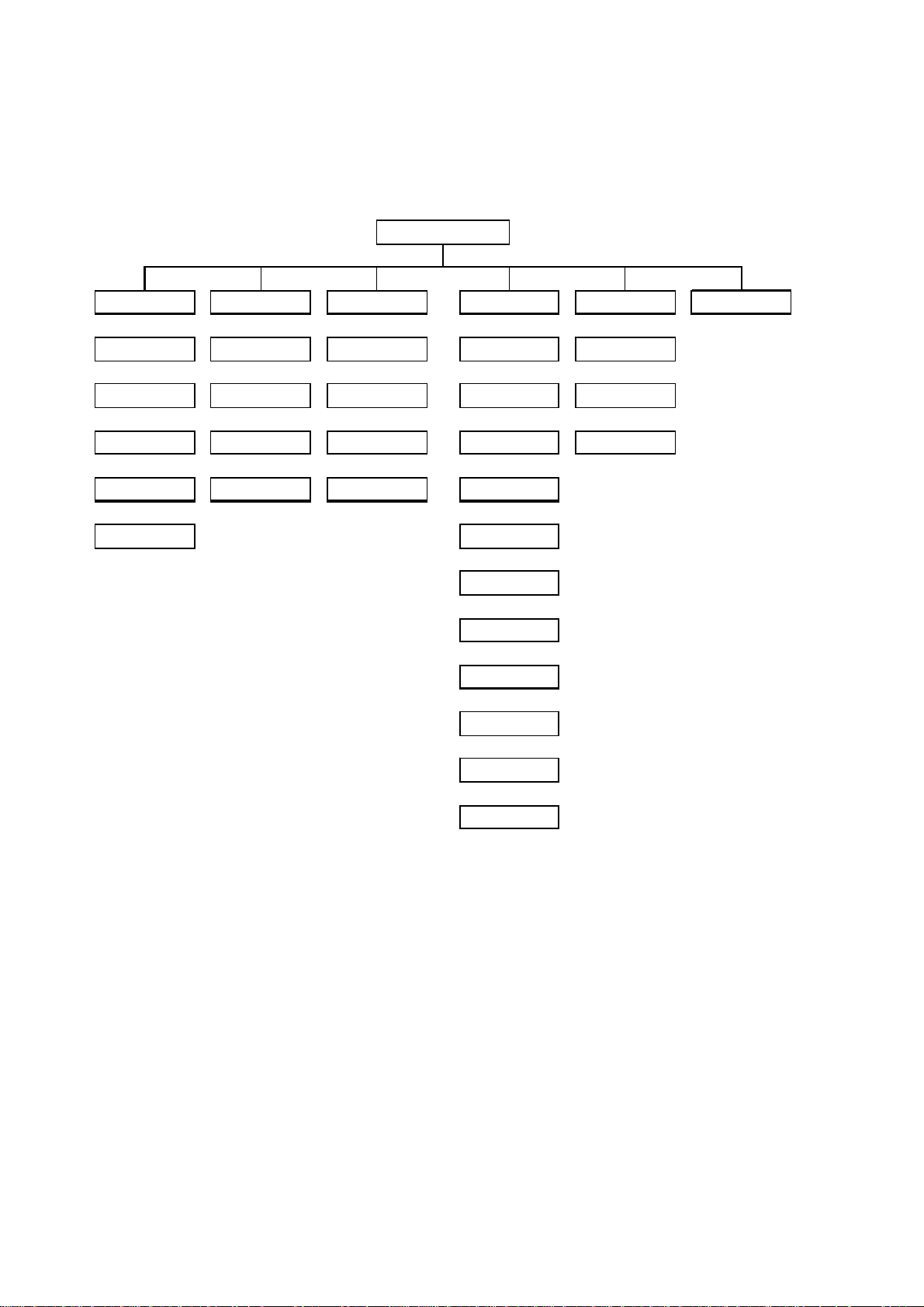

3. Menu Function

Avail

Main Menu Overview

Main Menu

Setup File Manager Diagnostics Language Serv ice Exit

↓↓↓ ↓↓

Printer Setup File List Print Config. English

↓↓↓ ↓

Sen sor

↓↓↓ ↓

Serial Comm. Del. All Files Ro tate Cutter Chinese(SC) Exit

↓↓↓ ↓

*Ethernet Exit

↓↓

Exit

.

Dump Mode Chinese(TC)

Exit

Japanese

German

↓

Italian

↓

French

↓

Russian

↓

Polish

↓

Spanish

↓

Exit

Initialization

↓

Mileage Info.

↓

Notice:

* The Ethernet function is available for TTP-2410M series only and option for TTP-246M

Plus series.

* Ethernet function is available on the LCD display when Ethernet card is installed.

14

Loading...

Loading...