TTP/TDP 243/342

THERMAL TRANSFER / DIRECT THERMAL

BAR CODE PRINTER

SERVICE

MANUAL

TTP-243 Bar Code Printer

Service Manua

l

Table Of Contents

1. FUNDAMENTALS ABOUT THE SYSTEM ........................................................................ 1

1.1 Features of the TTP/TDP-243 Series........................................................................... 1

1.2 Model Naming Syntax..................................................................................................1

1.3 Overview ......................................................................................................................2

1.3.1 Front View............................................................................................................. 2

1.3.2 Rear View............................................................................................................. 3

1.4 Basic Specifications ..................................................................................................... 4

1.5 Effective Print Area....................................................................................................... 6

1.6 Available Bar Codes..................................................................................................... 6

1.7 Various Sensors........................................................................................................... 7

2. SUPPLY SPECIFICATIONS............................................................................................... 9

2.1 Types of Paper............................................................................................................. 9

2.2 Specifications...............................................................................................................9

2.3 Ribbon Sizes and Shapes.......................................................................................... 11

3. ELECTRONICS ................................................................................................................ 12

3.1 Circuit Description...................................................................................................... 12

3.2 MCU Pin Description.................................................................................................. 15

3.3 Reset Circuit...............................................................................................................17

3.4 Memory System ......................................................................................................... 17

3.5 Connector Circuit Diagram......................................................................................... 18

3.6 Real-Time Clock Circuit.............................................................................................. 20

3.7 Decode Circuit............................................................................................................ 21

3.8 Thermal Head Drive/ Protection and History Control Circuit......................................23

3.9 24V/5V Converter Circuit............................................................................................ 24

3.10 Stepping Motor And DC Motor Driver/ Protection Circuit......................................... 25

3.11 Communication (Serial & Parallel Port) Circuit......................................................... 27

3.12 Cutter Drive Circuit................................................................................................... 28

3.13 Mainboard Replacement.......................................................................................... 29

i

TTP-243 Bar Code Printer

Service Manua

l

3.14 Flash memory Replacement .................................................................................... 33

3.15 Cutter, DC Motor, Stepping Motor Driver IC Replacement ...................................... 34

4. MECHANISM.................................................................................................................... 35

4.1 Cutter Installation ....................................................................................................... 35

4.2 Print Head Replacement............................................................................................ 36

4.3 DC Motor Replacement.............................................................................................. 38

4.4 Ribbon Rewind Spindle Encoder Replacement ......................................................... 39

4.5 Felt Fabric Replacement............................................................................................ 40

4.6 Stepping Motor Replacement..................................................................................... 42

4.7 Black Mark Sensor / Gap Sensor (Receiver) Replacement....................................... 43

4.8 Ribbon Sensor (Receiver) Replacement.................................................................... 44

4.9 Ribbon Sensor (Transmitter) / Gap Sensor (Transmitter) Replacement....................46

4.10 Platen Replacement................................................................................................. 47

4.11 Parts List .................................................................................................................. 50

5. TROUBLE SHOOTING..................................................................................................... 60

5.1 Error Messages.......................................................................................................... 60

5.2 Trouble Shooting........................................................................................................ 61

5.3 Calibrate the Gap Register......................................................................................... 62

5.4 Self-test......................................................................................................................62

5.5 Ram Clear.................................................................................................................. 62

5.6 Diagnosis Operation Procedure................................................................................. 62

5.7 Testing Sensors ......................................................................................................... 63

5.8 Cleaning the Print Head............................................................................................. 65

ii

TTP-243 Bar Code Printer

Service Manua

l

1. FUNDAMENTALS ABOUT THE SYSTEM

1.1 Features of the TTP/TDP-243 Series

1. TTP-243 bar code printer prints bar codes, characters, logos, on various types of labels and

tickets by direct thermal or thermal transfer printing.

2 TTP-243 adopts a “BASIC-like” high level programming language to help users programme

the desired label forms with ease.

3. TTP-243 bar code printer can be connected to a personal computer or an optional LCD

keyboard to execute the programs downloaded in the printer’s memory. The printer is

equipped with the following standard devices: black mark sensor, peel off module and real

time clock

4. TTP-243 bar code printer provides a selection of optional features, including cutter module,

memory module, portable LCD keyboard, etc.

5. The user friendly “Label Today!” package is bundled with TTP-243.

1.2 Model Naming Syntax

T T P – 2 4 3

(1) (2) (3) (4)

(1) Print method:

TTP – Thermal Transfer Printing

TDP – Thermal Direct Printing

(2) Resolution of print head (DPI)

(3) Maximum print width (Inch)

(4) Maximum print speed (Inch/Sec)

1

TTP-243 Bar Code Printer

Service Manua

1.3 Overview

1.3.1 Front View

Operation Panel

l

Top Cover

Cover Release Button

Fig. 1.1 Front View of TTP-243

Note: The one difference between TTP model and TDP model is the ribbon

mechanism.

Front Panel

2

TTP-243 Bar Code Printer

Service Manua

1.3.2 Rear View

Power

Switch

l

-

DC Power Jack

Label

Entrance

(External

Mount Use)

Centronics Interface

Fig. 1.2 Rear view of TTP-243

3

TTP-243 Bar Code Printer

Service Manua

l

1.4 Basic Specifications

Thermal transfer and direct thermal printing

High dot density printing (203 dots/inch)

Selectable print speeds at 1.5”, 2.0” or 3.0” per second

Supports parallel and serial interface

Maximum media width up to 4.4” (114 mm)

Adjustable label edge guide

International character sets

Print area is 4.09”W x 90”L (without any file downloaded in the printer memory)

User selectable bar code ratios and heights

Prints on labels or tickets

Equipped with black mark sensor

Equipped with Real Time Clock

Comes with self-peeling function

Buzzer provided to warn of possible errors

Label stock and thermal transfer ribbon are easy to install

Internal label print counter

Self test and hex dump mode

Downloadable fonts from label design software

Electronics/Communication Specifications

Electrical

CPU: MITSUBISHI M37720S1BFP

TPH: ROHM 4” KF-2004-GC17B

Stepping Motor: Mitsumi

DC Motor: DC24V

Memory:

─DRAM: MOSEL 2 Mb.

─Flash: ATMEL 1 Mb

Adapter 100~240VAC±10%, 50~60Hz

Regulations: CE, FCC, UL, CUL, TÜV-GS, CNS

Communications Interface:

Serial port: RS-232C (DB-9) at 2400, 4800, 9600 or 19200 baud rate

─Word Length: 7 or 8 data bits, 1 or 2 stop bits, selectable parity

─Handshaking: XON/XOFF and DSR/DTR

Parallel port: Standard parallel interface

Input Buffer: 60KB

4

TTP-243 Bar Code Printer

Service Manua

l

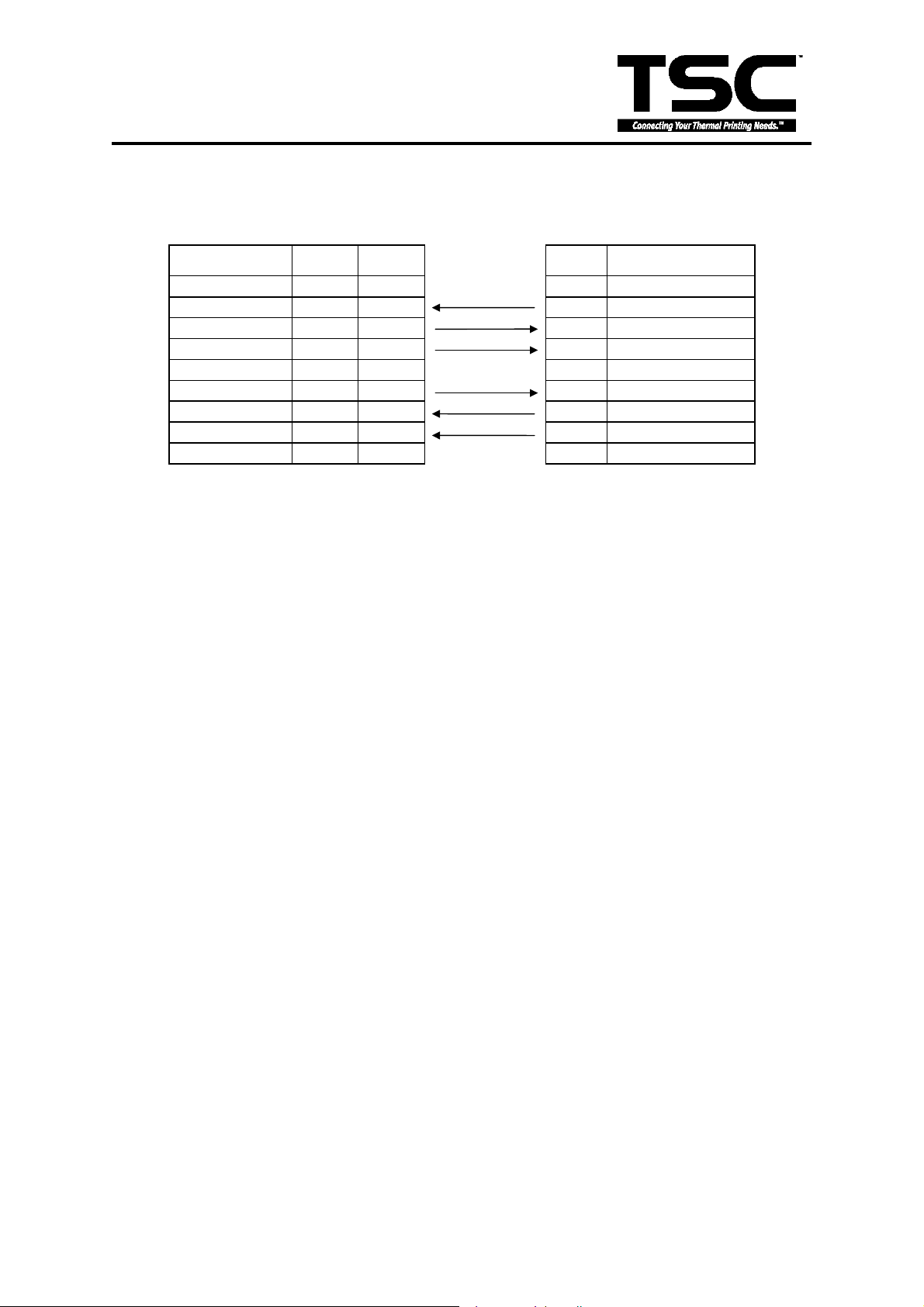

RS-232 Interface Pin Configuration:

Host Function 9 Pin 25 Pin 9 Pin Printer Function

RxD

TxD

DTR 4 20 4 DSR

GND 5 7 5 GND

DSR 6 6 6 RDY

RTS 7 4 7 N/C

CTS 8 5 8 RDY

9 +5V

2

3 2

3

2 TxD

1

3

+5V

RxD

5

TTP-243 Bar Code Printer

Service Manua

l

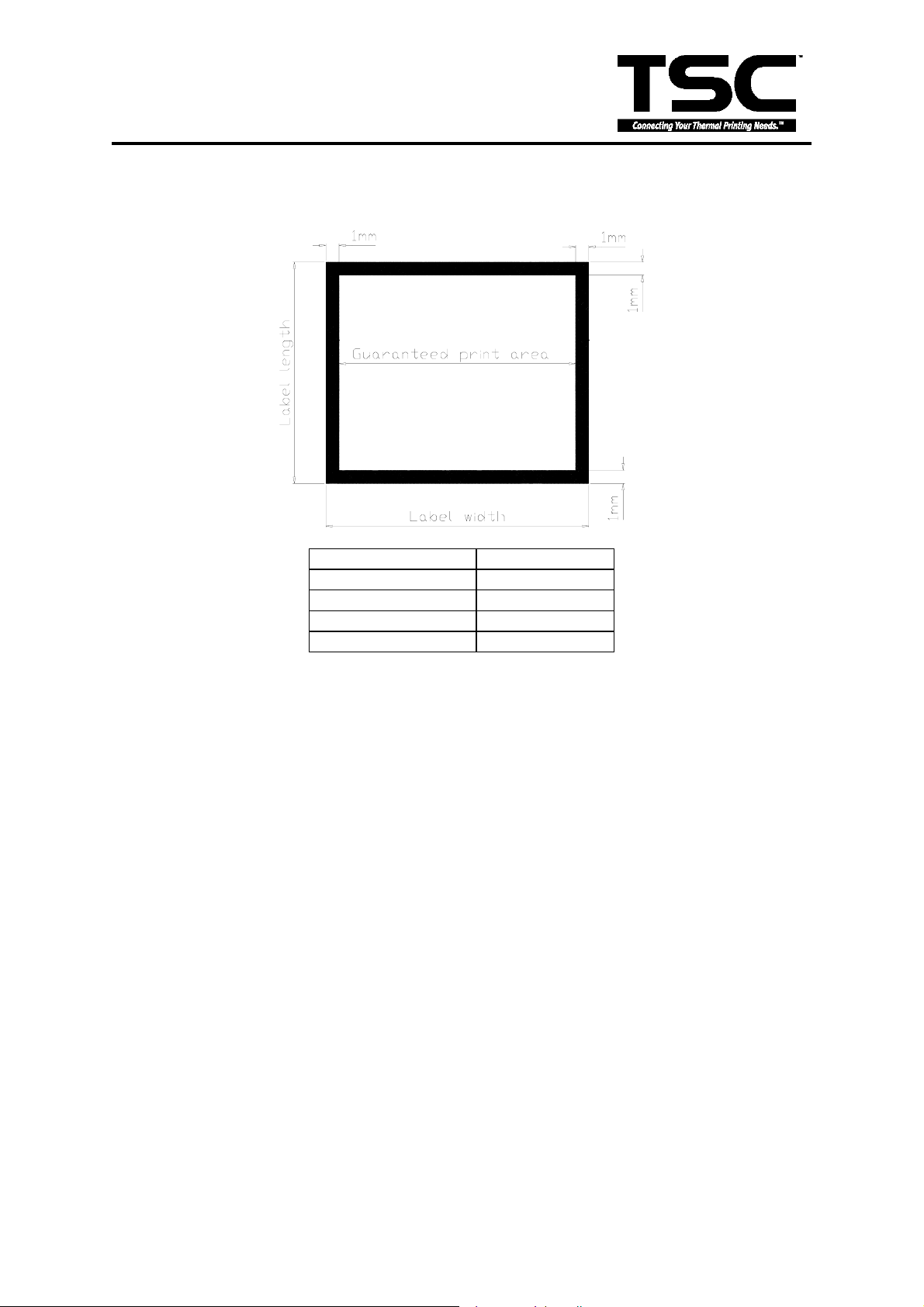

1.5 Effective Print Area

Label/Ticket Length

Effective Print Length 10mm~2284mm

Label/Ticket Width 25mm~103mm

Effective Print Width 23mm~101mm

No Print Area 1mm

12mm~2286mm

1.6 Available Bar Codes

Code 39

Code 93

Code 128 UCC

Code 128, Subsets A, B, and C

Codabar

Interleaved 2 of 5

EAN-8, EAN-13, EAN-128

UPC-A, UPC-E

EAN and UPC with 2 or 5 digits add-on

UPC Shipping container code

Postnet

Maxicode

PDF-417

DataMatrix

6

TTP-243 Bar Code Printer

Service Manua

l

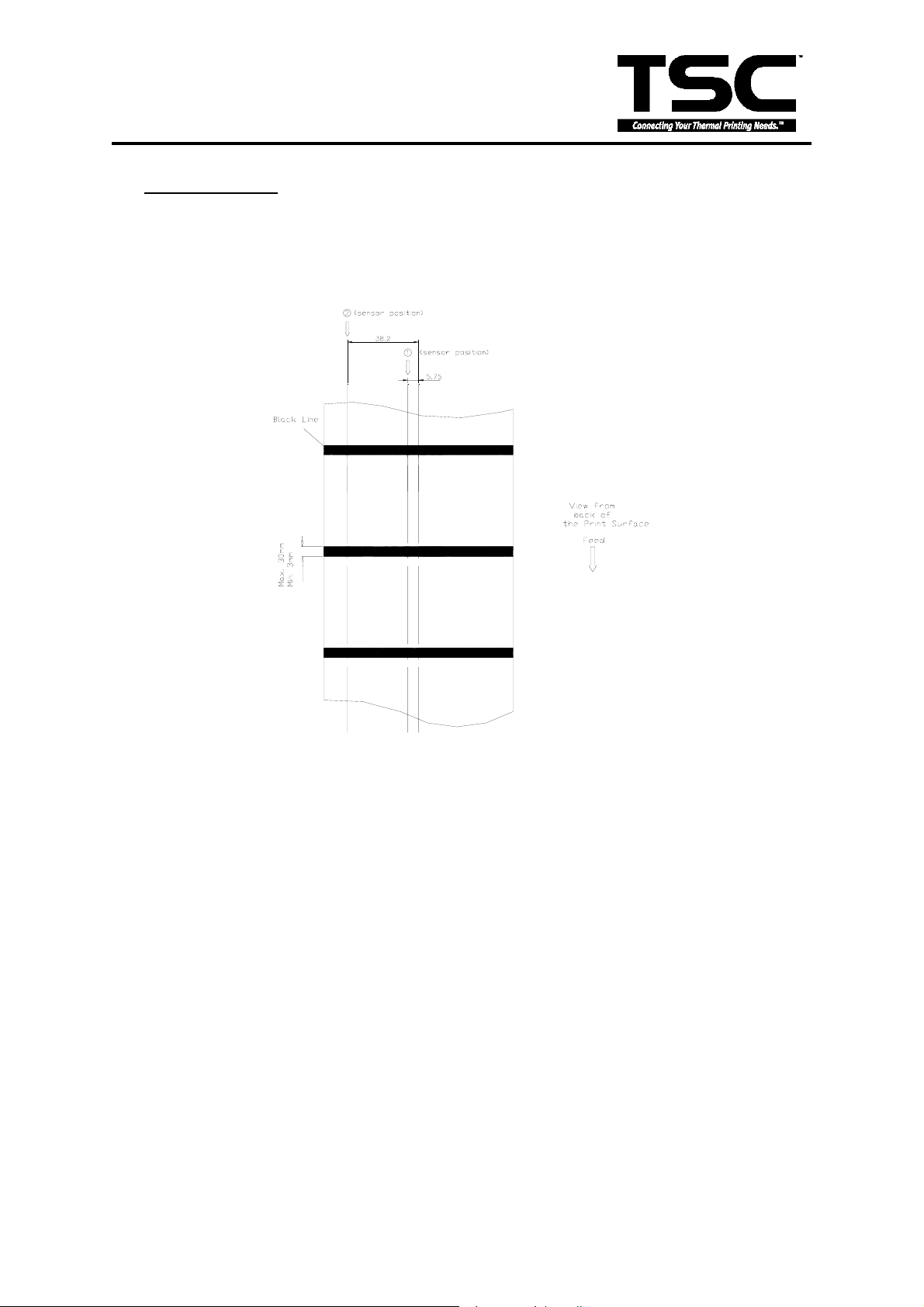

1.7 Various Sensors

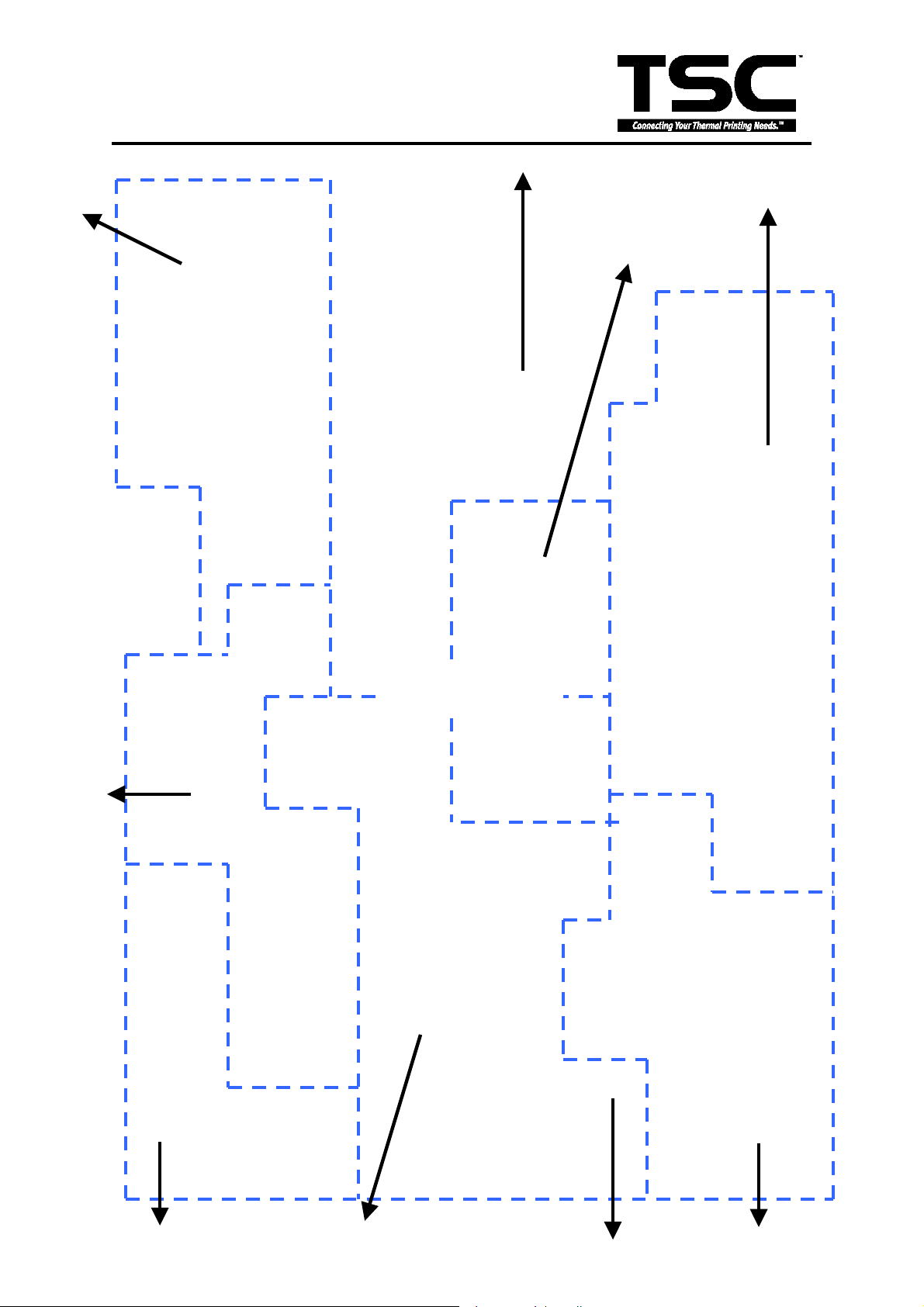

(1) Feed Gap Sensor

The feed gap sensor detects a label gap to locate the starting print position of the next

label. The sensor is mounted 4 mm off the center line of the main mechanism.

.

In case of Label

(2) Black Mark Sensor

The black mark sensor locates the position of label by emitting infrared rays onto the

black mark at the back of the ticket. The sensor is mounted 5.75 mm off the center line of

the ticket roll width on the mechanism.

7

TTP-243 Bar Code Printer

Service Manua

In case of Ticket

The default sensor position is (1) as shown on the figure below. To change to the (2)

position, the customer should notify the manufacturer in advance. There can be only

one position for the sensor. Once the sensor position is agreed upon, it can not be

changed afterwards.

l

(3) Ribbon End Sensor

The sensor detects the end portion of the ribbon. The ribbon end must be transparent.

(4) Label End Sensor

The sensor detects the end portion of the label.

(5) Peel off Sensor

The sensor detects the backing paper of a label.

(6) Ribbon encoder

The encoder is used to detect if the ribbon is broken.

8

TTP-243 Bar Code Printer

Service Manua

l

2. SUPPLY SPECIFICATIONS

2.1 Types of Paper

Two types of media are available for TTP-243: label and ticket.

In TTP-243, there are two types of sensors for paper: gap sensor and black mark

sensor.

Label and ticket can be further classified into direct thermal type or thermal transfer

type.

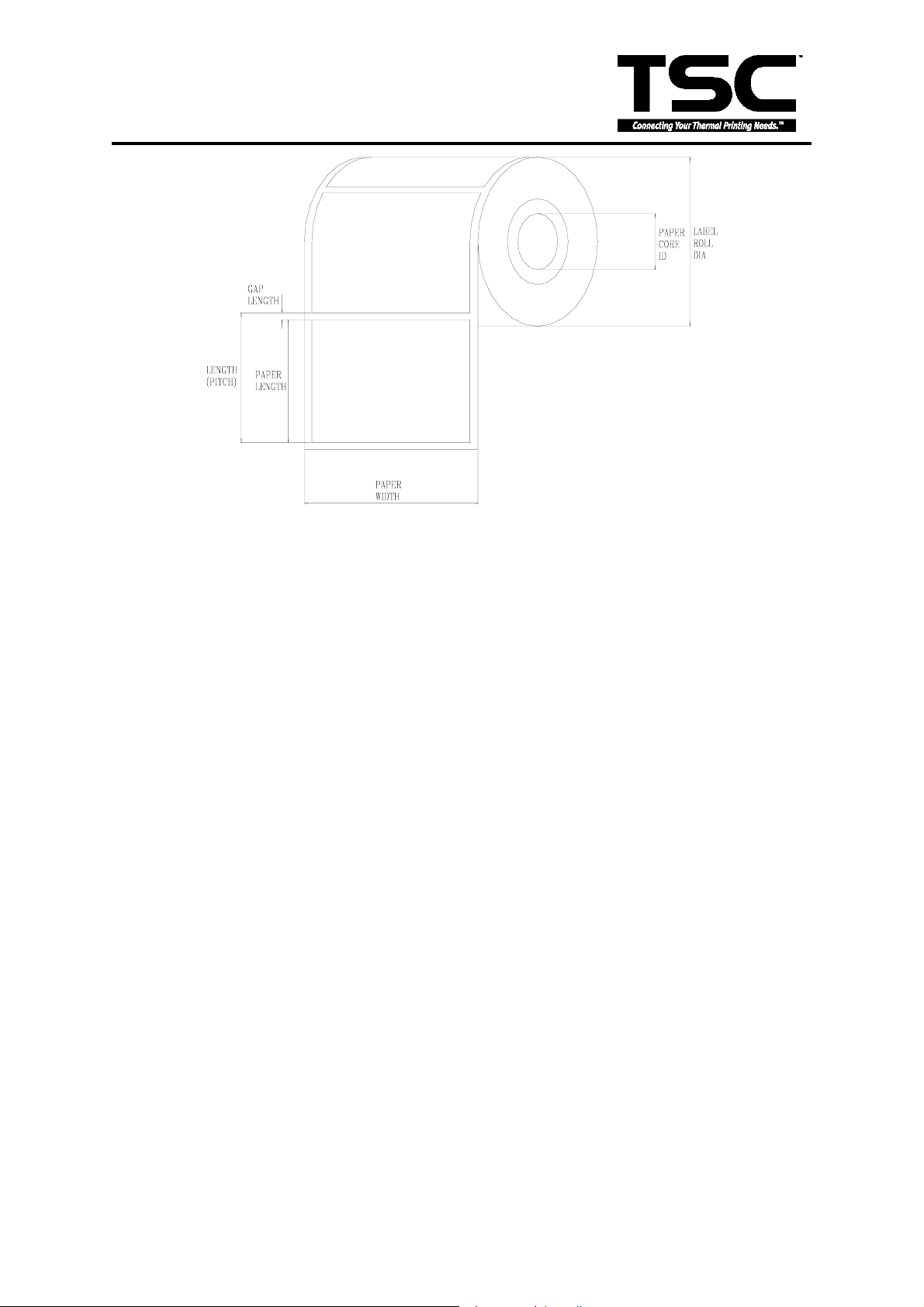

2.2 Specifications

Items Label

Paper Width

Length (Pitch)

Paper

Thickness

Paper Weight Max 240 g/m2

Max. Roll

Diameter

(1” core)

Roll Up Method Print surface wound outside as standard

Paper Core ID.

Note: (1). The width and thickness quoted above are said of the label plus its backing

paper.

(2). Likewise, the approval of label entails that of its backing paper.

(3). In the peel off mode, the minimum pitch is 35mm.

(4). In the cutter mode, it is required the paper be wound outside. Otherwise,

paper jam tends to result.

(5). In the cutter mode, the paper thickness is 0.2 mm at maximum, and the paper

weight is 100 g/m

(6). Paper shape is as shown on next page.

(7) Tag is 0.2mm in thickness, and is less than 100g/m

Max.114mm

Min. 25mm

12∼2286mm

0.20 mm

Inner roll diameter. Max 4.3” (110mm)

External roll diameter. Max 8.4”

(214mm)

φ25.7±0.3mm

2

at maximum.

2

in weight.

9

TTP-243 Bar Code Printer

Service Manua

l

10

TTP-243 Bar Code Printer

Service Manua

l

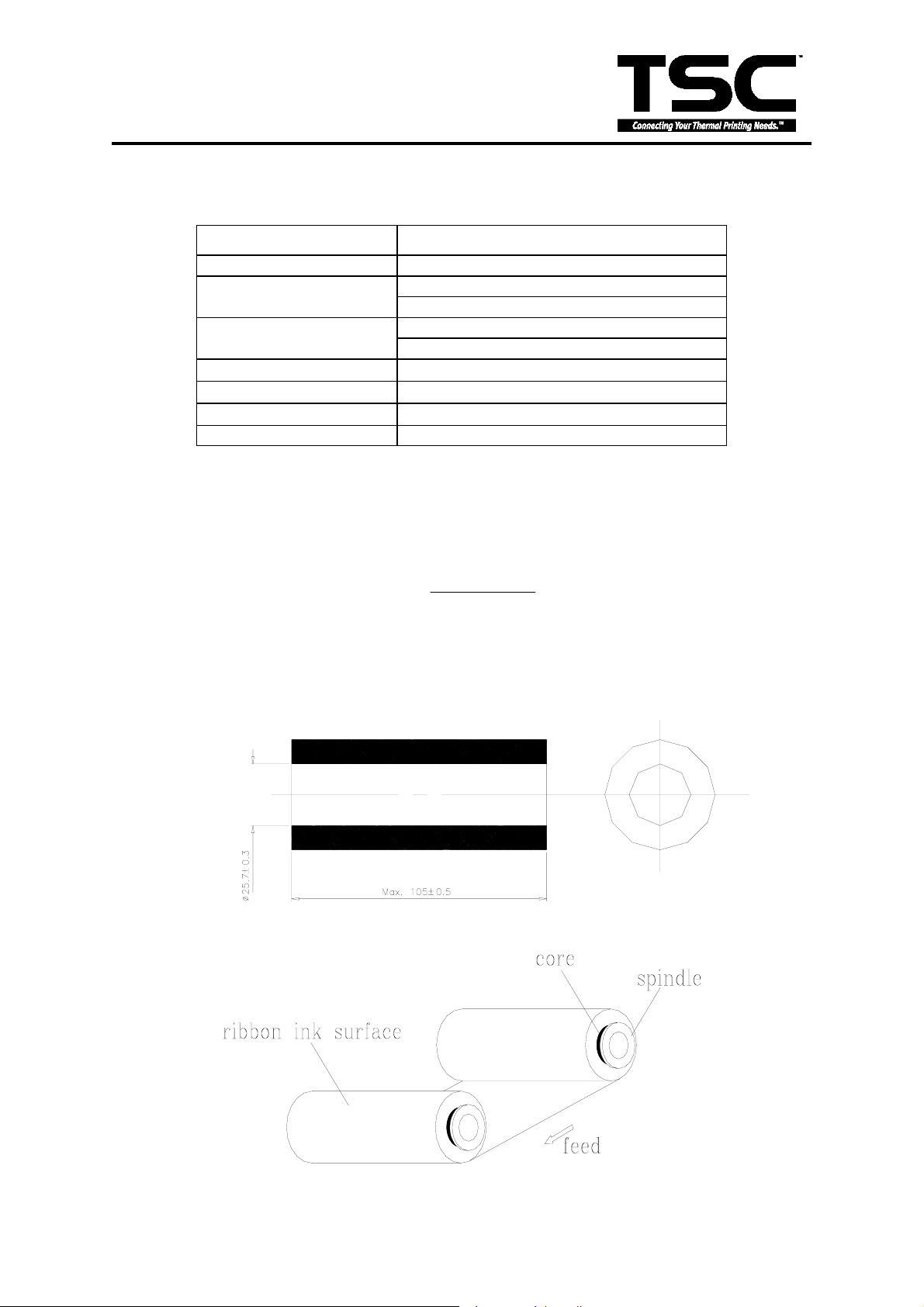

2.3 Ribbon Sizes and Shapes

Item Specifications

Ribbon shape Spool type

Ribbon width

Ribbon winding width

Leading tape

End tape

Max. ribbon OD.

Winding method Ink surface to be wound outside

Max. 110mm

Min. 40mm

Max. 110mm

Min. 40mm

Polyester film, 335±5mm long

Polyester film (transparent), 250±5mm long

φ67mm

Note: The maximum length of ribbon depends on its thickness and core outside diameter.

The formula below defines the correlation between ribbon roll length and ribbon core

diameter.

22

π

)d(D

= L

L = Ribbon length

D = Max. roll diameter

d = Ribbon core outside diameter

t = Ribbon thickness

×−

t4

where

,

11

TTP-243 Bar Code Printer

M

Service Manua

l

3. ELECTRONICS

3.1 Circuit Description

R8

3.3KR91.8K

GAP_EMITTER

74LS05

R10

910

PH_DETECT SENSOR

POWER LED

ONLINE LED

ERROR LED

PAUSE BUTTON

FEED BUTTON

RIBBON SENSOR

PEEL SENSOR

B.L. SENSOR

GAP SENSOR

DECODER SENSOR

CUTTER SENSOR

BUZZER

56

U7C

8 9

74LS05

R11

430

COMMUNICATION SYSTEM

U7A

74LS05

34

U7B

74LS05

U7D

/ERROR

/ERROR

SELECT

SELECT

12

DO0

DO1

DO2

DO3

DO4

DO5

DO6

55

VCC

VCC88AVCC89VREF

P106/MA8

P107/MA9

P105/RAS

P104/CAS

P56/TB0IN

P55/TA4IN

P52/TA3OUT

P50/TA2OUT

P51/TA2IN

P54/TA4OUT

P61/RTP01

P91/DMAREQ0

P87/TXD1

P85/CLK1

90

A0/MA0

A1/MA1

A2/MA2

A3/MA3

A4/MA4

A5/MA5

A6/MA6

A7/MA7

A8/D8

A9/D9

A10/D10

A11/D11

A12/D12

A13/D13

A14/D14

A15/D15

P44/QCL

P43/MX

P70/AN0

P71/AN1

P76/AN6

P77/AN7

P75/AN5

C70

0.1u

C49

0.1u

DO7

P92

R/W

ST0

ST1

76

83

RESET

36

RESETOUT

VSS

35

40

24

P84/CTS1/RTS1

M37721S1AFP

CNVSS

AVSS91VSS

34

92

P101/INT123P100/INT0

P93/DMAREQ1

U1

RDY31HOLD32BYTE

33

41

97

P73/AN3

85

蜂鳴器

2

C2

0.1u

16MHz

P82/RXD0

87

P80/CTS0/RTS0

84

P83/TXD0

86

P81/CLK0

2

P66/RTP12

1

P67/RTP13

79

P90/DMAACK0

22

P102/INT2

96

P74/AN4

27

P45/VDA

26

P46/VPA

25

P47/DBC

98

P72/AN2

8

P60/RTP00

6

P62/RTP02

3

P65/RTP11

5

P63/RTP03

4

P64/RTP10

9

P57/TB1IN

13

P53/TA3IN

81

P86/RXD1

21

P103/TC

30

46

BHE

72

P97/DMAREQ3

73

P96/DMAACK3

74

P95/DMAREQ2

75

P94/DMAACK2

45

BLE

37

XIN

X1

R13

1M

38

XOUT

U2

OUT1VCC

GND

S-807

3

RX2

RX2

RX1

RX1

TX1

TX1

TX2

TX2

PE

PE

INT

INT

C3

20P

C4

20P

+5V

DO[0..7]

ALE

44

ALE

A23/D748A22/D649A21/D550A20/D451A19/D352A18/D253A17/D154A16/D0

77

MA0

71

MA1

70

69

MA2

68

MA3

67

MA4

66

MA5

65

MA6

64

MA7

18

MA8

17

MA9

63

A8

62

A9

61

A10

60

A11

59

A12

58

A13

57

A14

56

A15

19

/RAS

20

/CAS

39

/E

E

R/W

47

43

ST0

42

ST1

10

11

14

16

15

12

7

78

80

28

29

100

82

99

94

93

RDY

95

+5V

L5

L21

L1

MA[0..9]

ST0

ST1

U5E

74HC04

1011

MA[0..9]

A[8..15]

4

5

1

2

74HC32

U24B

U24A

74HC32

MOTOR SYSTEM

PHASE1

PHASE1

PHASE2

PHASE2

I1

I1

I0

I0

PHASE3

PHASE3

DCM

DCM

CUTTER

CUTTER

MOTOR

MOTOR

R/W

R/W

PRINT SYSTEM

DI

DI

/LAT

/LAT

HISTORY

HISTORY

Vdet

Vdet

CLK

CLK

TM

TM

PH_HEAT

PH_HEAT

PH

PH

6

U24C

9

10

3

74HC32

8

MEMORY SYSTE

/RAS

/RAS

DRAMWR

DRAMWR

DRAMOE

DRAMOE

/OE

/OE

R/W

R/W

C1

C7

10u

0.1u

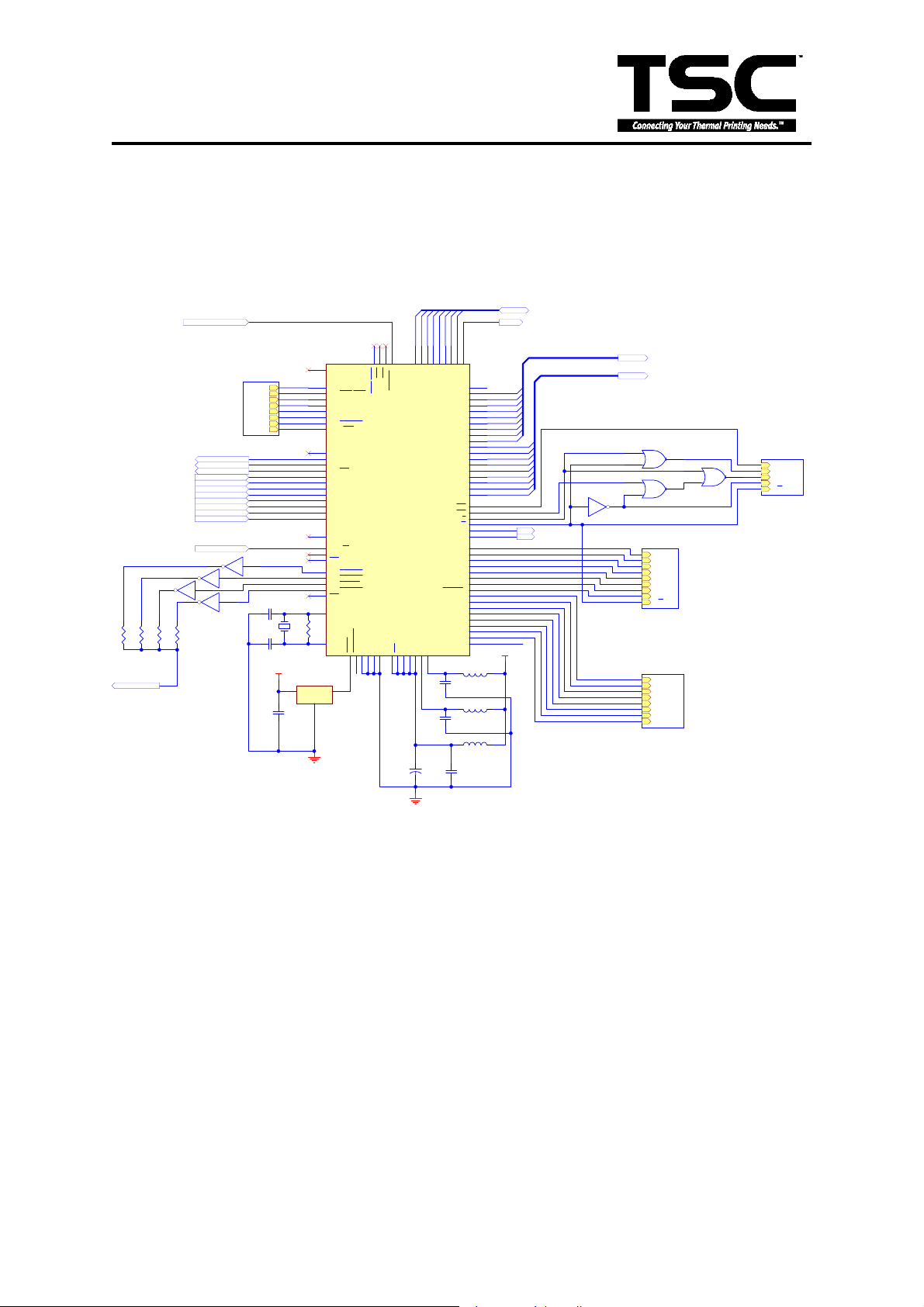

Fig. 3.1 MCU Circuit Diagram

The above is the MCU circuit diagram.

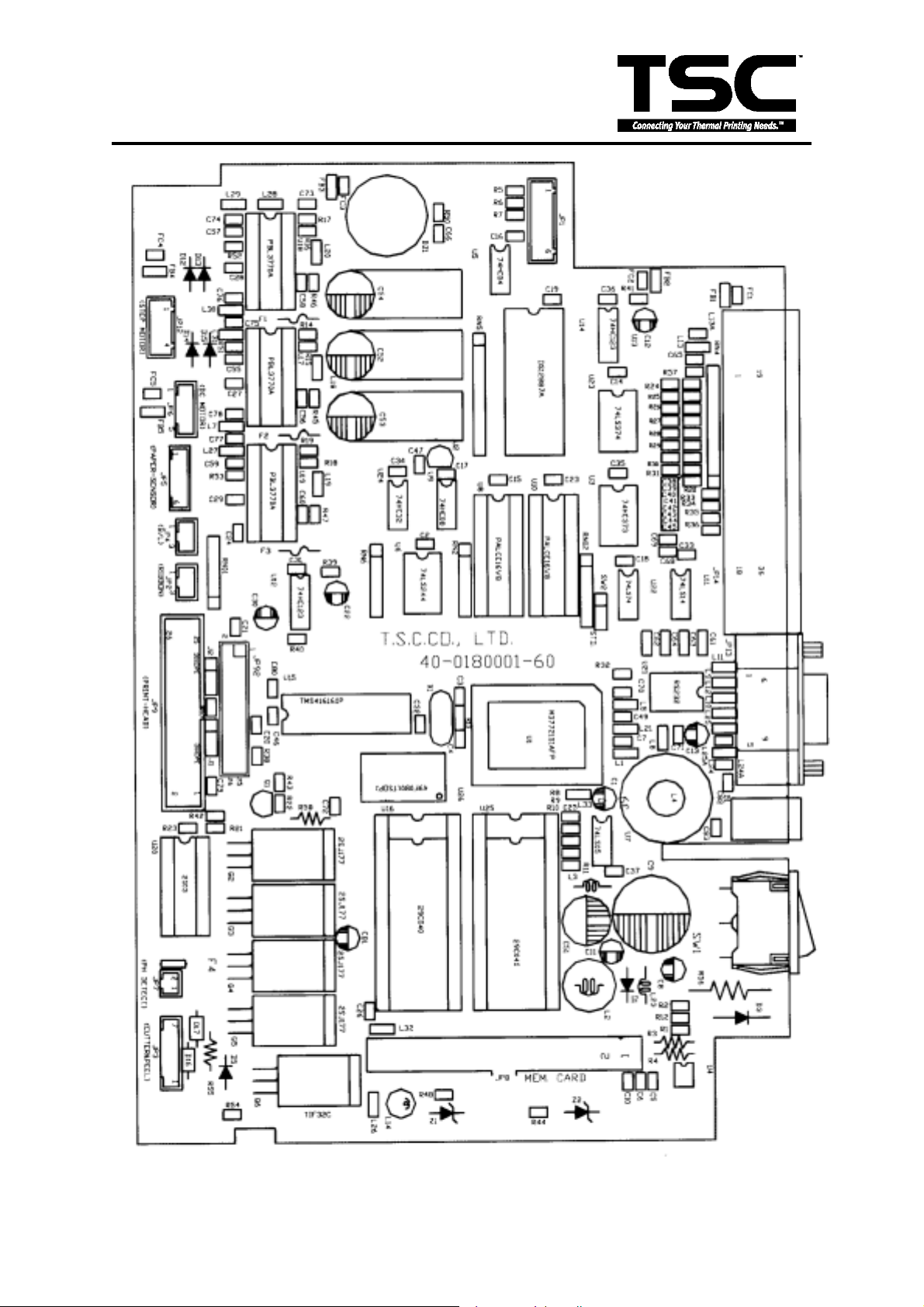

The main board of TTP-243 includes five system blocks:

A. Memory System (decoder & memory block)

B. Motor System (stepping motor, DC motor and cutter block)

C. Print head System

D. Communication System (serial & parallel port block)

E. Power System

The figure below shows the PCB system area.

12

TTP-243 Bar Code Printer

Motor System

Service Manua

l

Real Time Clock

Communication Port

Memory

Decoder System

Print Head

Cutter System

Memory System

13

External Memory

Connector

Power System

TTP-243 Bar Code Printer

g

Service Manua

l

. 3.2 System Block of PCB

Fi

14

TTP-243 Bar Code Printer

Service Manua

l

3.2 MCU Pin Description

Pin Name Input/Output Function

Vcc, Vss Power supply

CNVss CNVss input Input This pin controls the processor mode.

/RESET Reset input Input To enter the reset state, this pin must be

XIN Clock input Input

X

Clock output Output

OUT

/E Enable output Output Data/instruction read and data write are

BYTE Bus width

Input In memory expansion mode or

selection input

/HOLD /HOLD input

Input This is an input pin for the /HOLD

pin

/RDY /RDY input pin

ψ1 Clock ψ1

Input

Output

output

ST0, ST1 Status signal

Output The bus use status output is generated

output pin

Supply 5V±10% to Vcc and 0V to Vss.

Connect to Vss for single-chip mode,

and to Vcc for external ROM types.

kept at “L” condition, and maintained for

the required time.

These are I/O pins of internal clock

generating circuit. Connect a ceramic or

quartz crystal resonator between X

X

. When an external clock is used,

OUT

IN

and

the clock source should be connected to

the X

pin, and the X

IN

pin and should

OUT

be left open.

performed when output from this pin is

“L”.

microprocessor mode, this pin

determines whether the external data

bus is 8-bit width or 16-bit width. The

width is 16 bits for “L” signal input and 8

bits for “H” signal input.

request signal.

This is an input pin for the /RDY signal.

This is theψ1 output pin which is

divided the clock X

pin by 2.

IN

in 2-bit code

AVcc, AVss Analog supply

input

V

Reference

REF

voltage input

A0/MA0~

A7/MA7

Address

low-order/DRA

M address

Power supply for the A-D converter.

Connect AV

and AVSS to VSS

CC

externally.

Input This is reference voltage input pin for

the A-D converter.

Output This is an output pin for the 8 low-order

bits of addresses. When the DRAM is to

be accessed, the row and column

addresses are generated by means of

time division multiplexing.

15

TTP-243 Bar Code Printer

Service Manua

l

A8/D8~

A15/D15

Address

medium-order/

data high-order

A16/D0~

A23/D7

Address high-

order/data

low-order

R/W, /BHE

ALE, /BHE

P40~P4

P50~P5

P60~P6

P70~P7

P80~P8

P90~P9

Memory Control

signal output

I/O port P4 I/O

7

I/O port P5 I/O

7

I/O port P6 I/O

7

I/O port P7 I/O

7

I/O port P8 I/O

7

I/O port P9 I/O

7

P100~P107 I/O port P10 I/O

I/O When the BYTE pin is set to “L” in memory

expansion mode or microprocessor mode and

external data bus is 16-bit width, high-order

data (D15~D8) is input or output when /E

output is “L” and an address (A15~A8) is

output when /E output is “H”.

If the BYTE pin is “H” that is an external data

bus is 8-bit width, only address (A15~A8) is

output.

I/O

In memory expansion mode or microprocessor

mode low-order data (D7~D0) is input or output

when /E output is “L” and an address (A23~A16) is

output when /E output is “H”.

Output These are R/W, /BHE, ALE, and /BLE output

pins.

This port is provided 5-bit I/O. As it has an I/O

register, it is possible to perform programming to

determine whether each bit serves as an input pin

or an output pin.

This port is used for 8-bit I/O. It has basically the

same function as port P4. In addition, it provides

the timer A2, timer A3, timer A4 I/O pins and

TimeB0 and TimeB1 input pins.

This port is used for 8-bit I/O. It has basically the

same function as port P4. In addition, pins P60

through P63 and pins P64 through P67 are

capable of functioning as a 4-bit real-time output,

respectively.

This port is used for 8-bit I/O. It has basically the

same function as port P4. In addition, it provides

the input pins for analog inputs AN0 through AN7.

Pin P77 is also used for A-D conversion start

trigger input.

This port is used for 8-bit I/O. It has basically the

same function as port P4. In addition, it provides

RxD, TxD, CLK, /CTS//RTS terminals for UART 0

and UART 1.

This is an 8-bit I/O port. It has basically the same

function as port P4. In addition, it provides the

DMA request input pin and DMA acknowledge

signal output pin.

This is an 8-bit I/O port. It has basically the same

function as port P4. In addition, it provides the

/INT0, /INT1, /INT2 input pins, /TC I/O pins, and

/RAS, /CAS, MA8, MA9 output pin.

16

TTP-243 Bar Code Printer

Service Manua

l

3.3 Reset Circuit

VCC

U2

2

C2

0.1u

VCC

OUT

GND

3

1

/RESET

CONNECT WITH MCU RESET PIN

S-807

Fig. 3.3 Reset Circuit

This is the reset circuit .The 80746ALO IC outputs the system reset signal of “LOW”

when the driving voltage is lower than 4.6V (Typical).

3.4 Memory System

A[0..18]

MA[0..9]

DO[0..7]

A[8..18]

MA[0..9]

/LCAS

/UCAS

DRAMWR

DRAMOE

R/W

ROM1

ROM2

DO[0..7]

VCC

1

6

21

MA0

17

A0

MA1

18

A1

19

MA2

A2

20

MA3

A3

23

MA4

A4

24

MA5

A5

25

MA6

A6

26

MA7

A7

27

MA8

A8

28

MA9

A9

16

NC/A10

15

NC/A11

TMS416160P

14

/RAS

/OE

RAS

31

LCAS

30

UCAS

13

W

29

OE

2

DO0

DQ0

VCC

VCC

VCC

3

DO1

DQ1

4

DO2

DQ2

5

DO3

DQ3

7

DO4

DQ4

8

DO5

DQ5

9

DO6

DQ6

10

DO7 A8

DQ7

DO0

33

DQ8

34

DO1

DQ9

U15

35

DO2

DQ10

36

DO3

DQ11

38

DO4

DQ12

39

DO5

DQ13

40

DO6

DQ14

41

DO7

DQ15

11

NC

12

NC

32

NC

GND

GND

GND

22

37

42

U16

MA0

11

MA1

10

MA2

9

MA3

8

MA4

7

MA5

6

MA6

5

MA7

27

26

A9

23

A10

25

A11

4

A12

28

A13

29

A14

3

A15

2

A16

30

A17

1

A18

29C040

A012AD0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

13

DO0

14

DO1

AD1

15

DO2

AD2

17

DO3

AD3

18

DO4

AD4

19

DO5

AD5

20

DO6

AD6

21

DO7

AD7

16

GND

32

VCC

VCC

31

WE

24

OE

22

CE

U25

MA0

A012AD0

11

MA1

A1

10

MA2

A2

9

MA3

A3

8

MA4

A4

7

MA5

A5

6

MA6

A6

5

MA7

A7

A8

27

A8

A9

26

A9

A10

23

A10

25

A11

A11

4

A12

A12

28

A13

A13

29

A14

A14

3

A15

A15

2

A16

A16

30

A17

A17

1

A18

A18

29C040

Fig. 3.4 FLASH ROMS and DRAM Diagram

This is the memory circuit. The U16&U17 type 512K Byte FLASH ROM and U15 type

2M Byte DRAM are used. The MCU R/W pin becomes “H” when reading Flash ROM or

DRAM, and “L” when writing.

DO0

13

14

DO1

AD1

15

DO2

AD2

17

DO3

AD3

18

DO4

AD4

19

DO5

AD5

20

DO6

AD6

21

DO7

AD7

16

GND

32

VCC

VCC

31

WE

24

OE

22

CE

17

TTP-243 Bar Code Printer

C

Service Manua

l

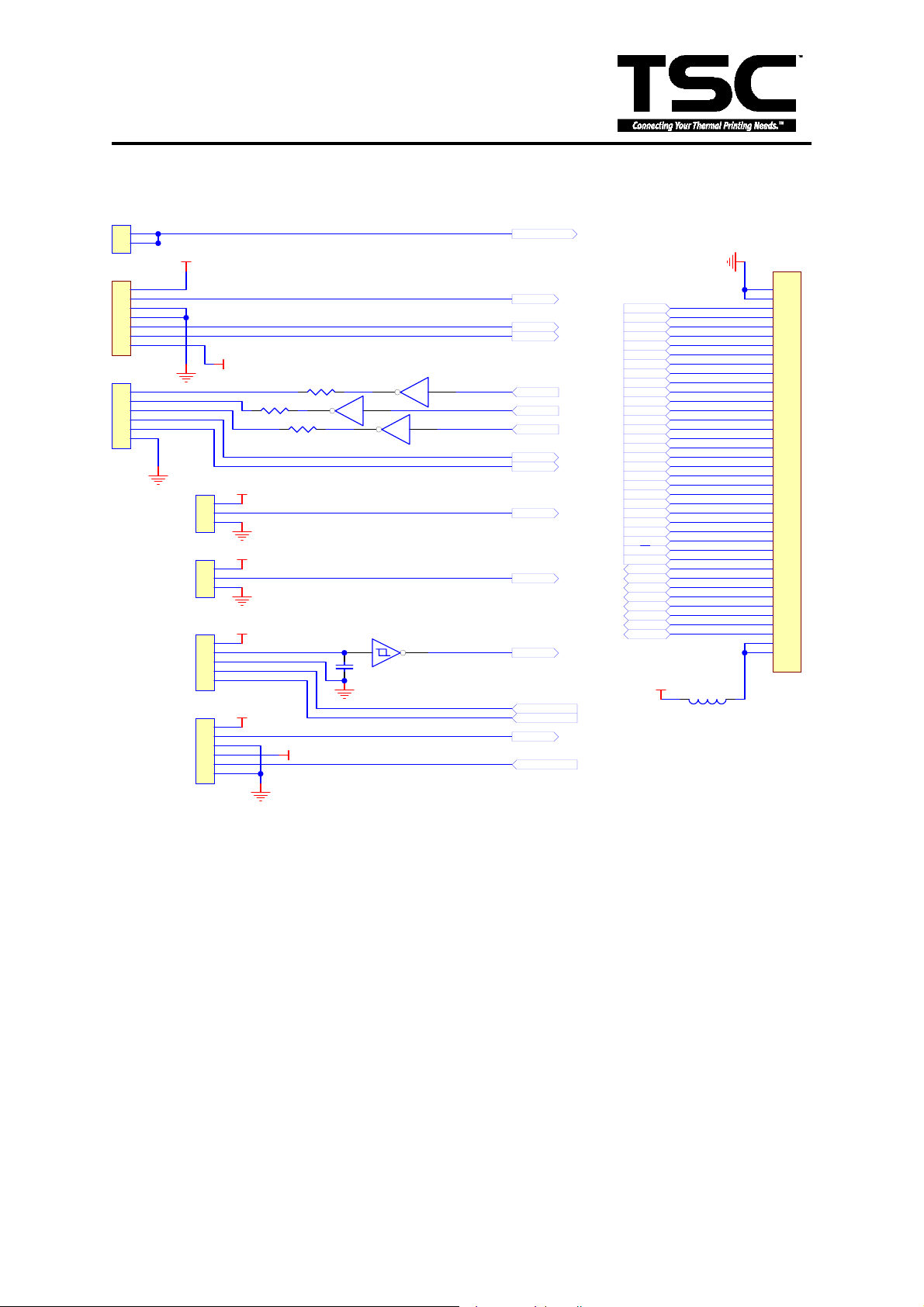

3.5 Connector Circuit Diagram

1

1

2

2

PH_DERECT

PH_DERECT

JP3

7

6

5

4

3

2

1

ER&PEEL

JP1

1

2

3

4

5

6

6 PIN

JP8

+5V

+24V

U5A

74HC04

12

56

JP2

RIBBON

JP4

B.L.

JP6

DC MOTOR

JP5

6 PIN

R5

100

R6

100

74HC04

R7

100

+5V

1

2

3

+5V

1

2

3

+5V

1

2

3

DCMA

4

5

DCMB

+5V

1

2

3

4

5

6

+5V

34

U5B

74HC04

U11A

1 2

C68

74LS14

0.1u

U5C

Fig. 3.5 Connector Circuit Diagram

PH_DETECT

P65

CUTTER

P53

P45

P46

P47

P72

P60

P62

P63

P57

DC_MOTOR_A

DC_MOTOR_B

P64

GAP_EMITTER

1

2

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

/RESET

/E

R/W

OE

DO0

DO1

DO2

DO3

DO4

DO5

DO6

DO7

+5V

L32

BEAD

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Memory card connector

JP8

MEM.

P45~P47 are output pins from MCU, which control the Power-on, Feed and Error LEDs

respectively. The LED lights on when the signal is “low”, goes out when the signal is

“on”.

P72: the detect pin of push button.(normally at ‘high’ level)

P60: the detect pin of feed button. (normally at ‘high’ level)

P65: the detect pin of the peel-off sensor. (normally at ‘high’ level)

P62: the detect pin of the ribbon sensor. (normally at ‘high’ level)

P63: the detect pin of the black mark sensor. (normally at ‘high’ level)

P64: the detect pin of the gap sensor and print head micro sensor. (normally at ‘high’

level)

18

Loading...

Loading...