T&S Brass Manuals B-7000-LR-99 Installation Manual

Installation and

Maintenance

Limited Two Year Warranty

T&S warrants to the original purchaser (other

than for purposes of resale) that such product is

free from defects in material and workmanship

for a period of two (2) years from the date of

purchase, except hose. Hose supplied by T&S

carries a 90-day warranty only. During this twoyear warranty period, if the product is found to be

defective, T&S shall, at its option, repair and/or

replace it. To obtain warranty service, products

must be returned to...

T&S Brass and Bronze Works, Inc.

Attn: Warranty Repair Department

2 Saddleback Cove

Travelers Rest, SC 29690

Shipping, freight, insurance, and other

transportation charges of the product to T&S and

the return of repaired or replaced product to the

purchaser are the responsibility of the purchaser.

Repair and/or replacement shall be made within

a reasonable time after receipt by T&S of the

returned product. This warranty does not cover

Items which have received secondary fi nishing

or have been altered or modifi ed after purchase,

or for defects caused by abuse to or misuse of

the product, or shipment of the products.

Any express warranty not provided herein, and

any remedy for Breach of Contract which might

arise, is hereby excluded and disclaimed. Any

implied warranties of merchantability or fi tness

for a particular purpose are limited to two years in

duration. Under no circumstances shall T&S be

liable for loss of use or any special consequential

costs, expenses or damages.

Some states do not allow limitations on how

long and implied warranty lasts or the exclusion

or limitation of incidental or consequential

damages, so the above limitations or exclusions

may not apply to you. Specifi c rights under this

warranty and other rights vary from state to state.

Instructions

B-7000-SERIES

EPOXY POWDER

COATED & STAINLESS

STEEL REELS

U.S. Patent #D551,945

Attention California Residents:

“WARNING: This product contains chemicals

known to the State of California to cause cancer,

and birth defects or other reproductive harm.”

P/N: 098-014921-45 Rev.7

Date: 08-06-15

Drawn: TEH

Checked: JRM 08-07-15

Approved: JHB 08-07-15

Español:

Instrucciones de instalación y

mantenimiento

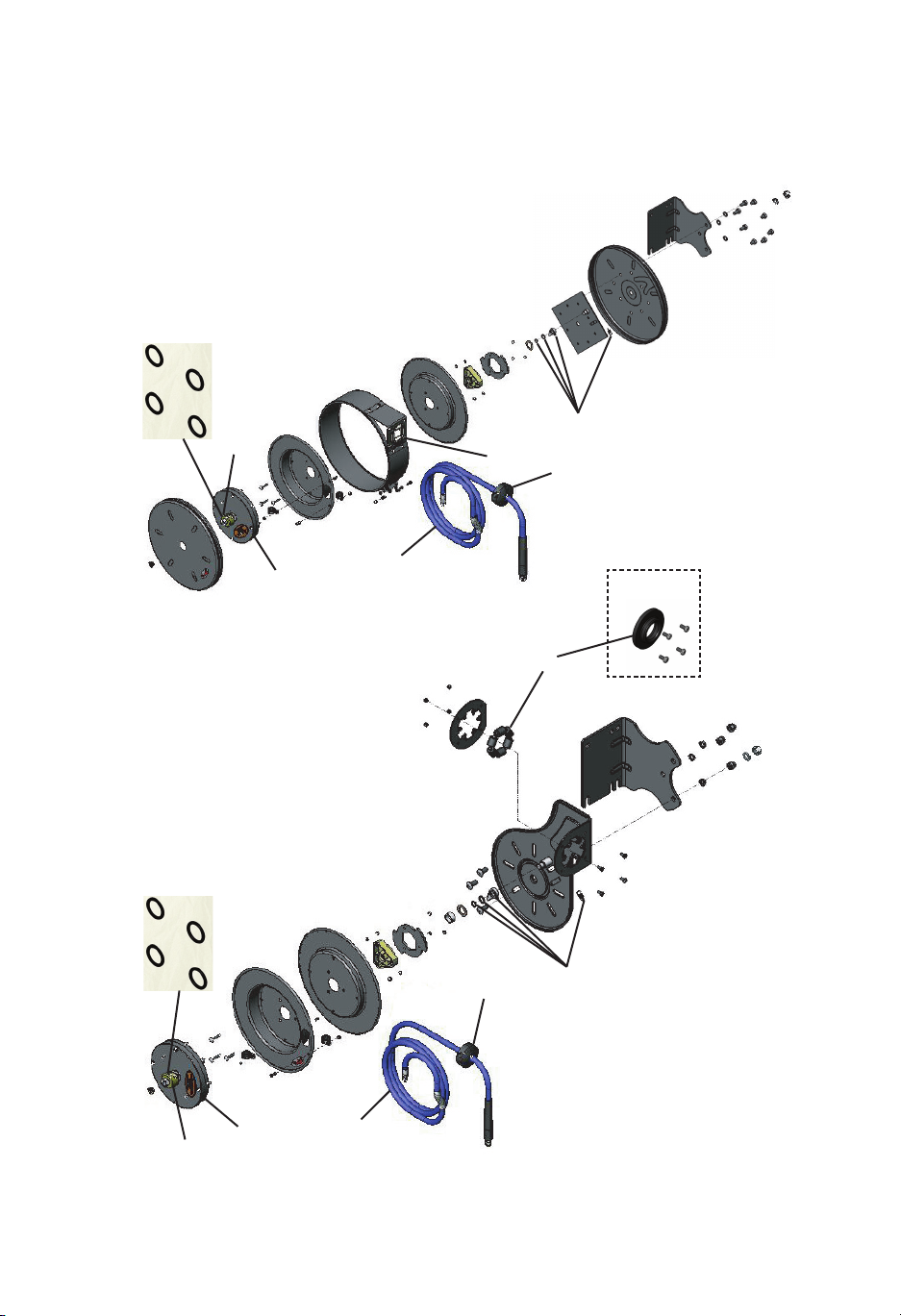

Enclosed Hose Reel

scale 5:1

7

Exploded View

1

Open Hose Reel

scale 5:1

7

4

5

6

2

3

3

B-7102

5

4

2

1

6

2

Part Number Guide

SWIVEL KITS - 1

PART NUMBER HOSE I.D. HOSE LENGTH MAX. PRESSURE

014946-45

017355-45

* 014947-45

SPRING ASSEMBLIES - 2

PART NUMBER HOSE I.D. HOSE LENGTH MAX. PRESSURE

017362-45

014932-45

014934-45

014933-45 (S/S)

014935-45 (S/S)

HOSE STOP KITS - 3

PART NUMBER HOSE I.D. HOSE LENGTH MAX. PRESSURE

G016590-45

014949-45

* 014950-45

RATCHET KITS - 4

PART NUMBER HOSE I.D. HOSE LENGTH MAX. PRESSURE

017359-45

014940-45

3/8”

3/8”

1/2”

3/8”

3/8”

3/8”; 1/2”

3/8”

3/8”

3/8”

3/8”

1/2”

3/8”

3/8”; 1/2”

15’/30’/35’/50’

12’

35’/50’

12’

15’/30’/35’

35’ (1/2” Only)/50’

15’/30’/35’

50’

12’

15’/30’/35’/50’

35’/50’

12’

15’/30’/35’/50’

300 psi

300 psi

300 psi

300 psi

300 psi

300 psi

300 psi

300 psi

300 psi

300 psi

300 psi

300 psi

300 psi

ROLLER/HOSE GUIDE KITS - 5

PART NUMBER HOSE I.D. HOSE LENGTH MAX. PRESSURE

017352-45

** 015996-45

014936-45 (ES)

014938-45

014937-45 (EL)

S/S = Stainless Steel ES = Enclosed Small EL = Enclosed Large

* Limited Quantities Available

3/8”

3/8”

3/8”

3/8”; 1/2”

3/8”; 1/2”

12’

15’

30’

15’/35’/50’

50’

** For use with Hose Reel 089-015401-45

3

300 psi

300 psi

300 psi

300 psi

300 psi

Part Number Guide

HOSE KITS - 6

PART NUMBER HOSE I.D. HOSE LENGTH MAX. PRESSURE

017938-45

014944-45

014943-45

014941-45

014942-45

* 015089-45

* 014945-45

O-RING KIT - 7

PART NUMBER HOSE I.D. HOSE LENGTH MAX. PRESSURE

014948-45 ALL ALL 300 psi

S/S = Stainless Steel ES = Enclosed Small EL = Enclosed Large

3/8”

3/8”

3/8”

3/8”

3/8”

1/2”

1/2”

12’

15’

30’

35’

50’

35’

50’

300 psi

300 psi

300 psi

300 psi

300 psi

300 psi

300 psi

* Limited Quantities Available

** For use with Hose Reel 089-015401-45

4

Important Safety Instructions

DANGER: Immediate hazards which will result in severe personal injury or death.

WARNING: Hazards or unsafe practices which could result in severe personal

injury or death.

CAUTION: Hazards or unsafe practices which may result in minor personal injury

or product or property damage.

WARNING: Failure to read, understand or follow these instructions could lead

to hazards or unsafe practices which could result in severe personal injury or

death.

CAUTION: Operators need to be instructed on the safe, proper use and mainte-

nance of this product. Keep this manual for future reference. Hazards or unsafe

practices

may result in minor personal injury or product or property damage.

TOOLS: (a) wrench: 10mm, 13mm, 16mm & 19mm; (b) nut driver: 8mm and

10mm; (c) needle-nose pliers (d) cross-recess screw driver #2, and (e) external retaining ring pliers. B-7102 models include a fl at wrench.

Installation

MOUNTING

MOUNTING B-7102

General Instructions

Important Safety Instructions

DANGER: Immediate hazards which will result in severe personal injury or death.

WARNING: Hazards or unsafe practices which could result in severe personal

injury or death.

CAUTION: Hazards or unsafe practices which may result in minor personal injury

or product or property damage.

WARNING: Failure to read, understand or follow these instructions could lead

to hazards or unsafe practices which could result in severe personal injury or

death.

CAUTION: Operators need to be instructed on the safe, proper use and mainte-

nance of this product. Keep this manual for future reference. Hazards or unsafe

practices

TOOLS: (a) wrench: 10mm, 13mm, 16mm & 19mm; (b) nut driver: 8mm and

10mm; (c) needle-nose pliers (d) cross-recess screw driver #2, and (e) external retaining ring pliers. B-7102 models include a fl at wrench.

may result in minor personal injury or product or property damage.

Installation

MOUNTING

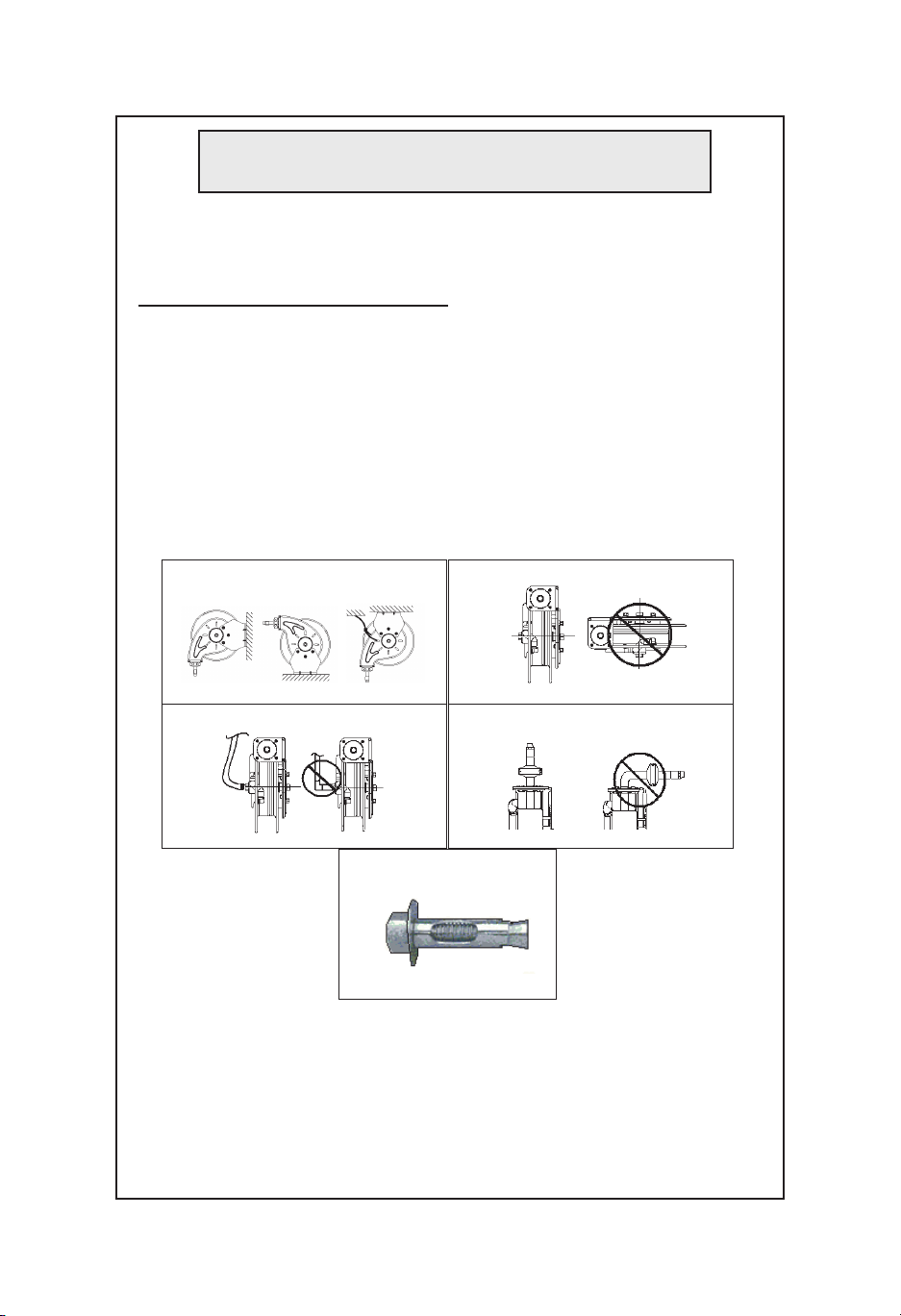

Reels complete with hose come set at proper tension and are ready to install. (Fig. 1)

Fixed base of reel allows mounting in several different positions including wall mount,

base down, or base up. If moving guide arm, three nuts (17mm SS or 19mm painted)

on side of reel must be removed. If reel is enclosed version, remove and mount

base to surface, then attach reel to base.

MOUNTING B-7102

The B-7102 mounting fl ange is part of the support frame. This hose reel can be

positioned as wall mounted (as shipped) or base up. To convert from one position to

another:

• Temporarily clamp unit to a work surface. Remove all tension from reel; see “Tension Adjustment.”

• Slide fl at wrench provided between spool assembly and support frame onto shaft to

hold it from turning during the next step.

• Loosen but do not remove the shaft nut (22mm hex) until the shaft is free to turn in

the support frame hole.

• Remove the (2) screws securing the hose guide bracket, move the bracket to the

desired location and reinstall the screws.

• Turn the spool and shaft relative to the support frame until the hose fi tting at the

formed metal tube assembly is parallel with the hose guide bushing centerline.

• Retighten the shaft nut. Re-tension reel (see “Tension Adjustment”)

5

Installation

Installation

General Mounting Requirements

• (Fig. 2) Main-shaft must be horizontal.

• (Fig. 3a) Swivel inlet must be connected with fl exible hose. Rigid pipe may cause

• (Fig. 3b) Centerline of spool assembly must be in-line with hose pull out. To adjust

• Qualifi ed personnel must evaluate wall or ceiling fastening. Mounting through the

General Instructions

premature wear and affect performance.

guide arm, remove screws holding it to base and rotate to desired group of mounting holes.

(4) 1/2” dia. holes on the base may vary due to surface materials. A possible

method for concrete, brick and cement block is a sleeve anchor type stud fastener

(fi g. 4) instead of, sometimes diffi cult to install, long lag bolts.

Fig. 1

Fig. 3a

Fig. 2

Fig. 3b

Fig. 4

6

Loading...

Loading...