Page 1

Limited One Year Warranty

T&S warrants to the original purchaser (other

than for purposes of resale) that such product is

free from defects in material and workmanship

for a period of one (1) year from the date of

purchase. During this one-year warranty period,

if the product is found to be defective, T&S shall,

at its options, repair and/or replace it. To obtain

warranty service, products must be returned

to...

T&S Brass and Bronze Works, Inc.

Attn: Warranty Repair Department

2 Saddleback Cove

Travelers Rest, SC 29690

Shipping, freight, insurance, and other

transportation charges of the product to T&S

and the return of repaired or replaced product

to the purchaser are the responsibility of the

purchaser. Repair and/or replacement shall be

made within a reasonable time after receipt by

T&S of the returned product. This warranty does

not cover Items which have received secondary

fi nishing or have been altered or modifi ed after

purchase, or for defects caused by physical

abuse to or misuse of the product, or shipment

of the products.

Any express warranty not provided herein, and

any remedy for Breach of Contract which might

arise, is hereby excluded and disclaimed. Any

implied warranties of merchantability or fi tness

for a particular purpose are limited to one year in

duration. Under no circumstances shall T&S be

liable for loss of use or any special consequential

costs, expenses or damages.

Some states do not allow limitations on how

long and implied warranty lasts or the exclusion

or limitation of incidental or consequential damages, so the above limitations or exclusions may

not apply to you. Specifi c rights under this war-

ranty and other rights vary from state to state.

Installation and

Maintenance

Instructions

B-7245-SERIES

EPOXY POWDER

COATED

STEEL REEL

P/N: 098-014920-45 Rev 0

Date: 03-25-04

Drawn: TEH

Checked: KG 08-22-04

Approved: MVW 08-25-04

Page 2

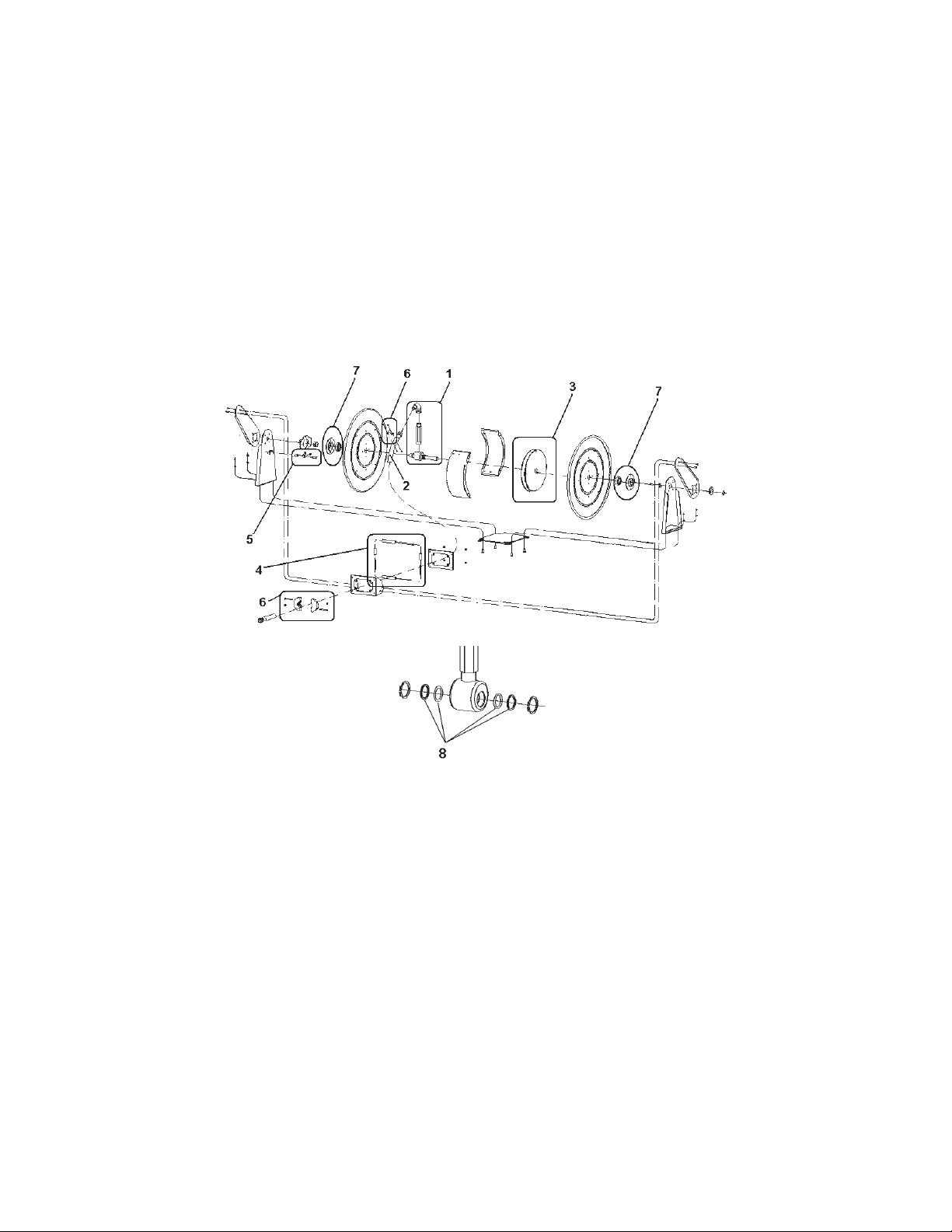

Exploded View

2

Page 3

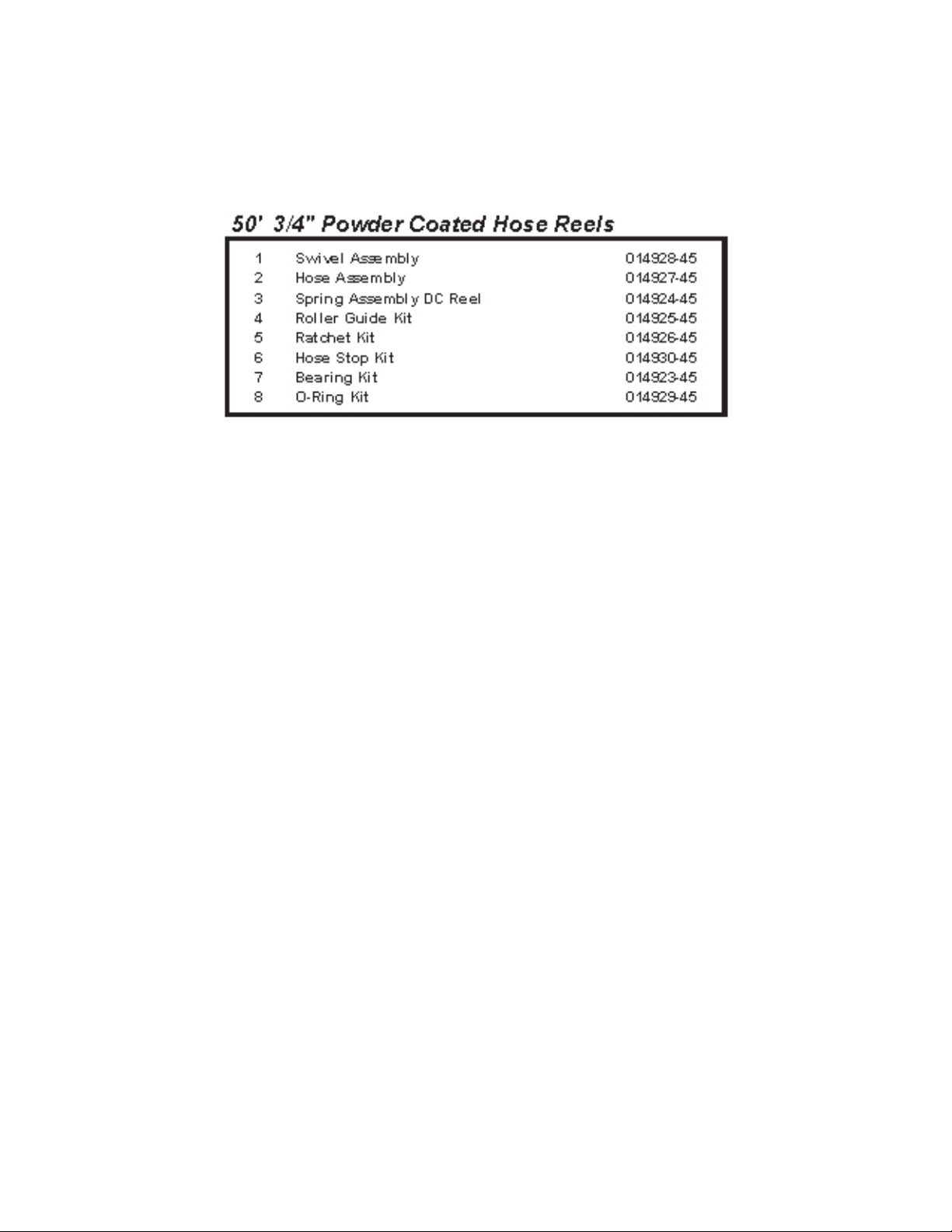

Part Number Guide

3

Page 4

General Instructions

General Instructions

Important Safety Instructions

DANGER: Immediate hazards which will result in severe personal in-

jury or death.

WARNING: Hazards or unsafe practices which could result in severe

personal injury or death.

CAUTION: Hazards or unsafe practices which may result in minor per-

sonal injury or product or property damage.

WARNING: Failure to read, understand or follow these instructions

could lead to hazards or unsafe practices which could result in severe personal injury or death.

CAUTION: Operators need to be instructed on the safe, proper use and

maintenance of this product. Keep this manual for future reference.

Hazards or unsafe practices may result in minor personal injury or

product or property damage.

TOOLS: (a) wrench: 10mm, 13mm, 16mm & 19mm; (b) nut driver: 8mm and

10mm; (c) needle-nose pliers

(d) cross-recess screw driver #2, and

(e) external retaining ring pliers.

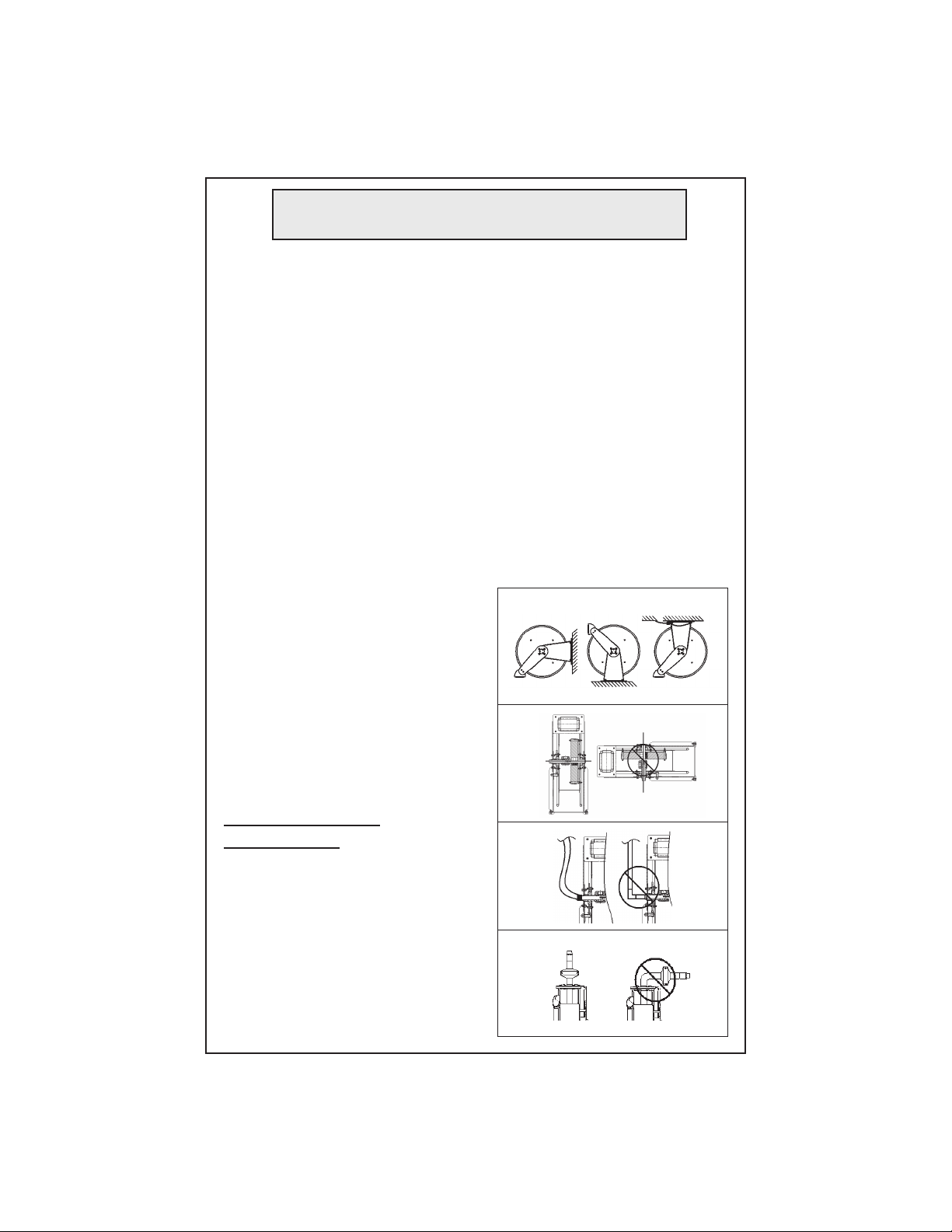

Fig. 1

Installation

MOUNTING

Reels complete with hose come set

at proper tension and are ready to

install. (Fig. 1) Fixed base of reel allows

mounting in several different positions

including wall mount, base down, or

base up. Remove four screws on side

of reel to move guide arm.

Fig. 2

General Mounting

Requirements

• (Fig. 2) Main-shaft must be horizontal.

• (Fig. 3a) Swivel inlet must be

connected with fl exible hose. Rigid pipe

may cause premature wear and affect

performance.

• (Fig. 3b) Centerline of spool assembly

must be in-line with hose pull out.

To adjust guide arm, remove screws

holding it to base and rotate to desired

group of mouting holes.

Fig. 3a

Fig. 3b

4

Page 5

General Instructions

• Qualifi ed personnel must evaluate wall or

ceiling fastening. Mounting through the

(4) 1/2” dia. holes on the base may vary

due to surface materials. A possible method

for concrete, brick and cement block is a

sleeve anchor type stud fastener (fi g. 4)

instead of, sometimes diffi cult to install,

long lag bolts.

Fig. 4

SECONDARY SUPPORT

WARNING: A secondary support chain is required for all objects

mounted over head to protect personnel in case of failure in mounting hardware or structure.

• (Fig. 5) Attach support cable/chain

to one of the slots in guide arm. Other

end of support cable to be attached to

a support other than the main one

supporting the hose reel.

• The safety chain/cable should allow

reel to drop no more than 6 to 12 in.

if primary connection is released.

Fig. 5

Adjustment

RATCHET LOCK

CAUTION: To avoid damage to the reel or personnel, always hold on

to hose while it is rewinding. Hazards or unsafe practices which may

result in minor personal injury or product or property damage.

• Ratchet “clicks” four

times every half-spool

revolution.

• (Fig. 6) To latch reel,

slowly pull out hose and

allow it to retract after

clicks 1-4.

• (Fig. 7) To unlatch,

slowly pull out hose until

“clicking” stops, then let

hose rewind until hose

stop rests against guide.

• To disable ratchet, see

section in servicing on

“Ratchet Lock

Replacement/Removal”.

Fig. 6

Fig. 7

5

Page 6

General Instructions

TENSION ADJUSTMENT

CAUTION: Always leave at least 1-2 turns between full extension and

when the spring is wound tight. If entire hose cannot be pulled out,

decrease tension until full extension is possible. Failure to test for

adequate spring revolutions can cause damage to reel. Hazards or

unsafe practices may result in minor personal injury or product or

property damage.

• Reels shipped with hose are

pre-tensioned at factory. Reels

shipped without hose are pre tensioned after installing hose,

but before making fi nal hose

or inlet connections.

• (Fig. 8) To pre-tension hose

reel, remove hose stop (cross recess screwdriver #2) and pull

hose out to allow one full wrap. Lockout drum from turning by engaging

ratchet (fi g.6) and loop hose back on drum. Repeat until desired tension

is achieved. After tension is set, pull out hose. If full hose extension is not

possible, remove pre-tension turns as needed by reversing process. Reinstall

hose stop.

Service

CAUTION: Remove all tension before servicing. Hazards or unsafe

practices may result in minor personal injury, product or property

damage.

WARNING: Before performing any service, always disconnect and lock

out compressed air or fluid, and remove all spring tension. Hazards

or unsafe practices could result in severe personal injury or death.

Fig. 8

HOSE INSTALLATION AND REPLACEMENT

• Remove all tension from reel (see Tension Adjustment). Remove ball stop (cross-recess #2), unwind hose on reel, remove strain-relief to

drum (8mm nut) and disconnect hose from swivel riser. Feed new hose

through roller guide and to swivel riser. Connect hose to swivel (use

Tefl on tape or thread sealant), install drum mounted strain relief clamp,

wind onto drum assembly, re-tension reel and install ball stop.

6

6

Page 7

General Instructions

RATCHET LOCK REPLACEMENT/REMOVAL

NOTE: Ratchet spring alone may be replaced without dissembling reel. Use

needle-nose pliers to remove old

spring and to assist in installing new one.

To replace or remove ratchet:

• Turn off air/fl uid supply and disconnect

supply hose

• Remove all tension, see “Tension

Adjustment”

• (Fig. 9) Remove stand from shaft on ratchet

side (13mm nut), external retaining ring pliers

• (Fig. 10) Replace or remove ratchet lock

and spring (19mm & 16mm nuts)

• Reinstall stand and tighten screws.

• Retension, see “Tension Adjustment”

MAINSPRING ASSEMBLY REPLACEMENT

WARNING: Never remove spring from its sealed container. Replace-

ment springs are in a sealed assembly for safety. There is no need

to remove them. Serious injury or death could result from removal of

spring from its container.

NOTE: If spring is to be replaced when not broken make sure to remove all

tension before proceeding.

If reel will not develop tension or retract hose, the main-spring spool assembly

will need to be replaced. To replace main-spring spool assembly:

To replace or remove main-spring:

• Turn off or lockout air/fl uid supply to

reel and disconnect supply hose.

• Remove reel from mounting and

relocate to bench top

• Pull hose out completely to expose

interior of drum

• Remove roller guide arms on each side

of reel (10mm & 13mm nuts, external

retaining ring pliers)

• Dissemble shaft support plate from base

• Remove stand, bearing cup and bearing on side opposite of fl uid path

• Remove drum fl ange stand and hub assembly on spring side of reel (10mm

nuts)

• Remove main spring assembly (10mm nuts)

• Reverse procedure to add new spring assembly

• Re-tension reel as in “Tension Adjustment”

Fig. 9

Fig. 10

Fig. 11

7

Page 8

General Instructions

SWIVEL REPLACEMENT

To replace swivel:

• Turn off or lockout air/fl uid supply

to reel and disconnect supply hose

from inlet on shaft

• Remove reel from mounting and

relocate to bench-top

• Remove tension from reel (see

Tension Adjustment)

• Remove hose from drum and dis-

connect from swivel (8mm nuts on strain relief)

• Remove external retaining rings from both sides of mainshaft

• Remove roller guide arms and stand from fl uid inlet side (10mm and 13mm

nuts)

• Remove swivel assembly from spool and spring components (10mm nuts)

• Reverse above procedure and install new swivel assembly (use Tefl on

tape or thread sealant on hose connections)

O-RING REPLACEMENT

CAUTION: Carefully replace o-rings making sure not to damage ma-

chined sealing surfaces. O-ring life and sealing ability may otherwise be affected. Hazards or unsafe practices may result in minor

personal injury, product or property damage.

To replace o-ring:

• Remove swivel from reels as per

“Replace Swivel” procedure.

• Remove retaining ring and slowly

remove outer swivel from inner

shaft

• Remove old o-rings and back-up

rings and replace using supplied

lubricant

• Reverse above procedure and

install new swivel (use Tefl on tape

or sealant on hose connections)

• Reverse “Replace Swivel”

procedure to re-install swivel assembly and install new swivel (use Tefl on

tape or thread sealant on hose connections)

Fig. 12

Fig. 13

8

Page 9

General Instructions

Preventative Maintenance

HOSE

• Check wear near hose-stop and end fi tting. If barb fi tting or hose is damaged cut off hose end and reattach new barb fi tting and clamp.

• Check wear along entire hose length. Replace if needed.

SWIVEL

• Check leaks by spraying with soapy water from hand spray bottle. If bubbles

form, replace swivel.

ROLLER GUIDE

• Check rollers for wear. If rollers on one side have more wear than the other

side, then guide position might need readjustment.

MOUNTING

• Check tightness of mounting bolts and condition of safety cable/chain and

attachment points.

9

Page 10

7”

MOUNTING DIAGRAM

SCALE 1:2

9 3/4”

1/2” DIA. HOLES

TYP. 4 PLACES

10

Page 11

RELATED T&S BRASS PRODUCT LINE

T&S BRASS AND BRONZE WORKS, INC.

A fi rm commitment to application-engineered plumbing products

2 Saddleback Cove, P.O. Box 1088, T & S Brass-Europe

Travelers Rest, SC 29690 ‘De Veenhoeve’

Phone: (864) 834-4102 Oude Nieuwveenseweg 84

Fax: (864) 834-3518 2441 CW Nieuwveen

E-mail: tsbrass@tsbrass.com The Netherlands

Loading...

Loading...