Page 1

Limited One Year Warranty

T&S warrants to the original purchaser (other than

for purposes of resale) that such product is free from

defects in material and workmanship for a period of

one (1) year from the date of purchase. During this

one-year warranty period, if the product is found to

be defective, T&S shall, at its options, repair and/

or replace it. To obtain warranty service, products

must be returned to...

T&S Brass and Bronze Works, Inc.

Attn: Warranty Repair Department

2 Saddleback Cove

Travelers Rest, SC 29690

Shipping, freight, insurance, and other transportation charges of the product to T&S and the return

of repaired or replaced product to the purchaser are

the responsibility of the purchaser. Repair and/or

replacement shall be made within a reasonable time

after receipt by T&S of the returned product. This

warranty does not cover Items which have received

secondary finishing or have been altered or modified after purchase, or for defects caused by physical abuse to or misuse of the product, or shipment

of the products.

Any express warranty not provided herein, and

any remedy for Breach of Contract which might arise,

is hereby excluded and disclaimed. Any implied

warranties of merchantability or fitness for a particular purpose are limited to one year in duration. Under

no circumstances shall T&S be liable for loss of

use or any special consequential costs, expenses

or damages.

Some states do not allow limitations on how long

and implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so

the above limitations or exclusions may not apply

to you. Specific rights under this warranty and other

rights vary from state to state.

P/N: 098-005910-45 Rev.2

Date: 980504

Drawn: CW

Checked: MAB 7-23-98

Approved: MVW 7-23-98

Installation and

Maintenance

Instructions

B-0695 Service Sink

Fittings with Concealed

By-Pass Mixing Valves

Deutsch: Installations- und

Wartungsanleitungen

Español: la Instalación y las

Instrucciones de

Mantenimiento

Français: les Instructions

d’Installation et

d’Entretien

Page 2

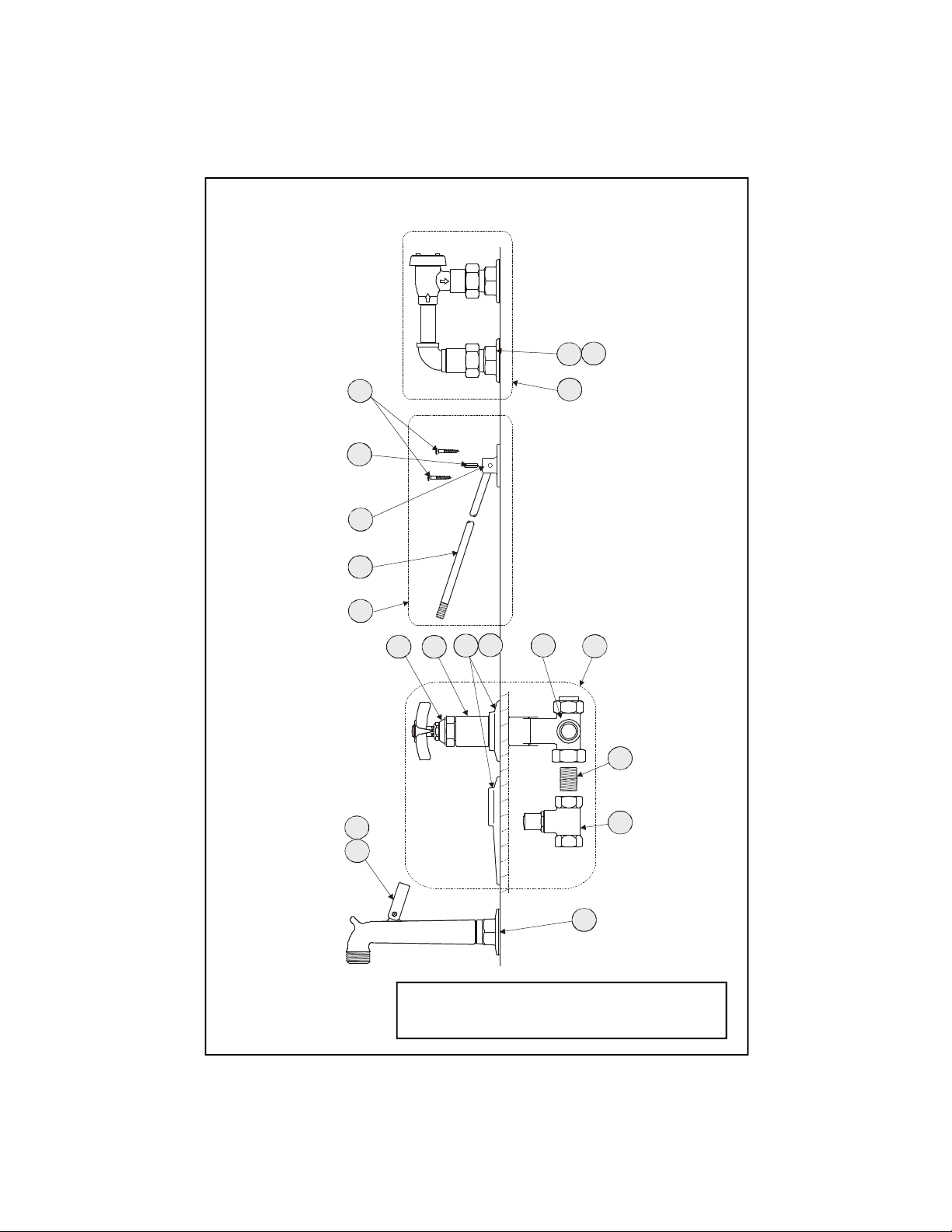

Exploded View

7112

15

1319181716

14

10

11

3

2

8

6

9

5

4

* Some items are listed for instructional purposes

and may not be sold as separate parts.

Page 3

Part Number Guide

Vacuum Breaker

1 Asm, Vacuum Breaker B-0929-A

2 Asm, Coupling Flange 002893-40

3 Washer, Coupling Nut 001019-45

Mixing Valve Assembly

4 Asm, By-Pass Mixing Valve B-1035

5 Body, Valve *

6 Asm, Spindle (Eterna) Hot 005960-40

7 Escutcheon Tube *

8 Escutcheon *

9 Set Screw, Escutcheon Flange *

10 Loose Key Stop 009745-45

11 Nipple, Close 1/2" *

Nozzle Assembly w/ Brace

19 Asm, Nozzle w/ Brace B-0671-POL

12 Flange 000013-40

13 Asm, Nozzle *

14 Asm, Upper Nozzle Support 009546-40

15 Support Rod *

16 Flange, Support *

17 Roll Pin *

18 Screw, Wall Mount 000915-45

Page 4

General Instructions

Installation: (Vacuum Breaker)

1. Drill holes 3-3/4” center-to-center in

wall where you will be installing no.1.

Note: Please consult applicable

plumbing codes for proper installed

height of no.1 over outlet of no.13.

2. Remove no.3 from no.1, install no.3

onto piping.

1

3

wall

outlet

5. (For B-0695 ST and B-0696 ST

models, add no.10 by using no.11 to

join the couplings together.)

Make connections to no.4:

B-0695: 1/2” IPS (Iron Pipe Size) female

union inlets; 1/2” close nipples.

B-0696: 5/8” union inlets; must solder

copper piping to inlets.

B-0695 ST: use B-0416 stops; 1/2” NPT

(National Pipe Thread) piping.

B-0696 ST: installer must supply 5/8”

solder joint to 1/2” NPT (National Pipe

Thread) adapter in order to attach supply

lines to no.10.

Installation: Nozzle

inlet

2

3. Reattach no.1 to no.3, making sure

no.2 is in place and tighten with a

wrench.

Installation: (Faucet Body)

4. After unpacking no.4, remove no.6,

no.7, no.8 and no.9 from no.5.

(Loosen no.8 at base of no.9, slide

both off no.5.)

wall

11

5

inlet

10

9

6

Use no.10 and no.11 for B-0695 ST

8

7

9

8

and B-0696 ST models

6. Attach no.12, onto supply pipe;

screw no.15 into no.13 attachment.

15

13

12

supply

line

7. Mark holes on wall for attachment

of no.16; use provided no. 18 to

secure no.16 to wall.

8. Insert no.17 into hole of no.16.

18

16

17

15

9. Turn on water and check for leaks.

See flow diagram on page 8.

Page 5

Instrucciones

Generales

Instalación: (Anti-sifón)

1. Perfore huecos de 9.5cm de centro a

centro en la pared donde la parte No.1

será instalada.

Nota: Por favor consulte codigos

aplicables de plomería para la apropiada

altura de instalación de la parte No.1

sobre el surtido de la parte No.13.

2. Remueva la parte No.3 de la parte

No.1, instale la parte No.3 en la

tubería.

1

3

2

pared

Salida

Entrada

3. Reemplaze la parte No.1 a la parte

No.3, asegurandose que la parte No.2

esté en su sitido y aprete con una

llave.

Instalación: (Canilla)

4. Después de desempacar la parte

No.4, remueva las partes No.6, No.7 y

No.8 da la parte No.5. (Afloje la parte

No.8 a la base de la parte No.9, deslize

ambos de la parte No.5.)

pared

11

5

Entrada

10

9

6

Use las partes No.

10 y 11 para los

modelos B-0695

ST y B-0696 ST.

8

7

9

8

5. (Para modelos B-0695 ST y B-0696

ST, agrege la parte No.10 usando la

parte No.11 para unir los enganches.)

Para Hacer Conecciones a la parte No.4:

B-0695: 1/2” IPS (Tamaño de tubería de

hierro) entradas de uniones femeninas

tubo enrroscado corto de 1/2”.

B-0696: Uniones de entrada de 5/8” tiene

que soldar tubería de cobre a las entradas.

B-0695 ST: Use pares modelo B-0416;

tubería NPT (Rosca Nacional De Tubo).

B-0696 ST: El instalador debe de surtir la

coyuntura soldada de 5/8” al adaptador de

1/2” NPT (Rosca Nacional De Tubo) en

orden de unir las lineas de surtido a la

parte No.10.

Instalación: Boquilla

6. Junte la parte No.12 a la linea de

surtido; atornille la parte No.15

dentro del encaje de la parte No.13.

15

13

7. Para colocar la parte No.16 marque

los huecos en la pared; para mantener

la parte No.16 use la parte No.18 que

esta surtida.

8. Insarte la

parte No.17

dentro del

hueco de la

parte No.16.

9. Abra la fuente de agua e

inspeccione por filtraciones.

Vea el diagrama de

desagüe en la pagina 8.

12

Linea

de

Surtido

18

16

17

15

Page 6

Instructions

Générales

L’Installation: La VanneCaisse-Vide

1. Percer les trous 9.5cm de centre-àcentre où vous aller installer Nº.1.

Noter: Prier consulter les codes

plomberies applicables pour la

haulteur correcte de l’installation de

Nº.1 au-dessous-de la sortie de Nº.13.

2. Enlever Nº.3 de Nº.1, installer Nº.3

sur la tuyauterie.

3

le

mur

la

sortie

5. (Pour les modeles B-0695 et B-0696

ST, ajouter Nº.10 en utilisant Nº.11

pour joindre les raccords ensemble)

Faire les branchements à Nº.4:

B-0695: les arrivèes unions IPS (Iron Pipe

Size) de 1/2”; les raccords proches de 1/2”.

B-0696: les arrivèes unions de 5/8”; on

devoir souder les tuyaux cuivres aux

arrivèes.

B-0695 ST: utiliser les arrêts B-0416; le

tuyau NPT (National Pipe Thread) de 1/2”.

B-0696 ST: L’installeur devoir fournir le

joint de sordure de 5/8” à l’adapteur NPT

(National Pipe Thread) de 1/2” pour

attacher les tuyaux qui fournir l’eau à

Nº.10.1

L’Installation: De L’Ajutage

l’arrivèe

2

3. Réattacher Nº.1 à Nº.3, soyez

certain que Nº.2 être à sa place et

resserrer avec une clef.

L’Installation: Du Robinet

4. Après on vider la bôite, enlever

Nº.6, N.7, N.8 et Nº.9 de Nº.5.

(Desserrer Nº.8 à base de Nº.9, faire

glisser tous les deux de Nº.5.)

le mur

11

10

5

l’arrivèe

9

6

Utiliser Nº.10 et Nº.11 pour les modèles

8

7

9

8

B-0695 et B-0696 ST

6. Attacher Nº.12 sur le tuyau qui

fournir l’eau; visser Nº.15 dans

l’accessoire de Nº.13.

13

15

12

fournir

tuyau

7. Marquer les trous sur le mur pour

attacher Nº.16; utiliser le Nº.18 fourni

pour attacher Nº.16 au mur.

8. Insérer

Nº.17 dans

le trou de

Nº.16.

18

16

17

15

9. Recommencer l’eau et vérifier s’il

y a des fuites.

Voir le diagramme de la

circulation au page 8.

Page 7

Allgemeine

Anleitungen

Installation: Vakuumunterbrecher

1. Löcher, die von Mitte zu Mitte 9,5

cm entfernt sind, in die Wand bohren,

wo Nr. 1 installiert werden soll.

Anmerkung: Für die richtige Höhe von

Nr. 1 über dem Auslauf von Nr. 13 bitte

die zutreffenden Installateurvorschriften

nachsehen.

2. Nr. 3 von Nr. 1 entfernen, Nr. 3 auf

dem Rohrsystem installieren.

Wand

1

3

2

Ablauf

Einlauf

3. Nr. 1 wieder mit Nr. 3 verbinden.

Sicherstellen, daß Nr. 2 richtig

eingesetzt ist, und mit einem

Schraubenschlüssel festziehen.

Installation: (Armaturrumpf)

5. (Für die Modelle B-0695 ST und

B-0696 ST Nr. 10 hinzufügen und Nr.

11 verwenden, um die Kupplungen

miteinander zu verbinden.

Herstellung der Verbindung mit Nr. 4:

B-0695: Einlaufrohr mit 1/2” IPS FE

Innenverschraubung;1/2” Verschlußnippel.

B-0696: 5/8” Einlaufrohre; Kupferrohre

müssen mit Einlaufrohren verschweißt

werden.

B-0695 ST: B-0416 Stopfen benutzen;

Rohre Größe 1/2” NPT. (National Pipe

Thread)

B-0696 ST: Der Installateur muß das 5/8”

Verbindungstück mit dem 1/2”NPT.

(National Pipe Thread) Zwischenstück

verschweißen, um die Zulaufrohre mit Nr.

10 zu verbinden.

Schwenkhahninstallation

6. Nr. 12 mit dem Zulaufrohr verbinden;

Nr. 15 in Nr. 13 einschrauben.

15

13

12

4. Nach dem Auspacken von Nr. 4, Nr.

6, 7, 8 und 9 von Nr. 5 entfernen.

(Nr. 8 unten auf Nr. 9 lösen, beide von

Nr. 5 abziehen.

Wand

11

10

5

Einlauf

9

8

7

6

Nr.10 und Nr.11 für Modelle B-0695

ST und B-0696 ST benutzen.

9

8

7. Löcher an der

Wand für Teil 16

markieren;

mitgelieferte Nr. 18

benutzen, um Nr. 16

an der Wand zu

Zulaufrohr

18

16

17

befestigen.

8. Nr. 17 in das Loch

15

von Nr. 16 einfügen.

9. Wasserzufuhr andrehen und auf

Lecks prüfen.

Siehe Durchflußdiagram auf Seite 8.

Page 8

Flow diagram

B-0929A

Vacuum

Breaker

Upper Nozzle

Support

Spindle

Assembly

Escutcheon

Support Rod

Spout

Plumbing supplied

by others

Wall

Concealed

By-Pass

Mixing Valve

B-0416

Stop

Water

Supply

Inlet

T&S BRASS AND BRONZE WORKS, INC.

A firm commitment to application-engineered plumbing products

2 Saddleback Cove, P.O. Box 1088, T & S Brass-Europe

Travelers Rest, SC 29690 ‘De Veenhoeve’

Phone: (864) 834-4102 Oude Nieuwveenseweg 84

Fax: (864) 834-3518 2441 CW Nieuwveen

E-mail: tsbrass@tsbrass.com The Netherlands

Loading...

Loading...