Page 1

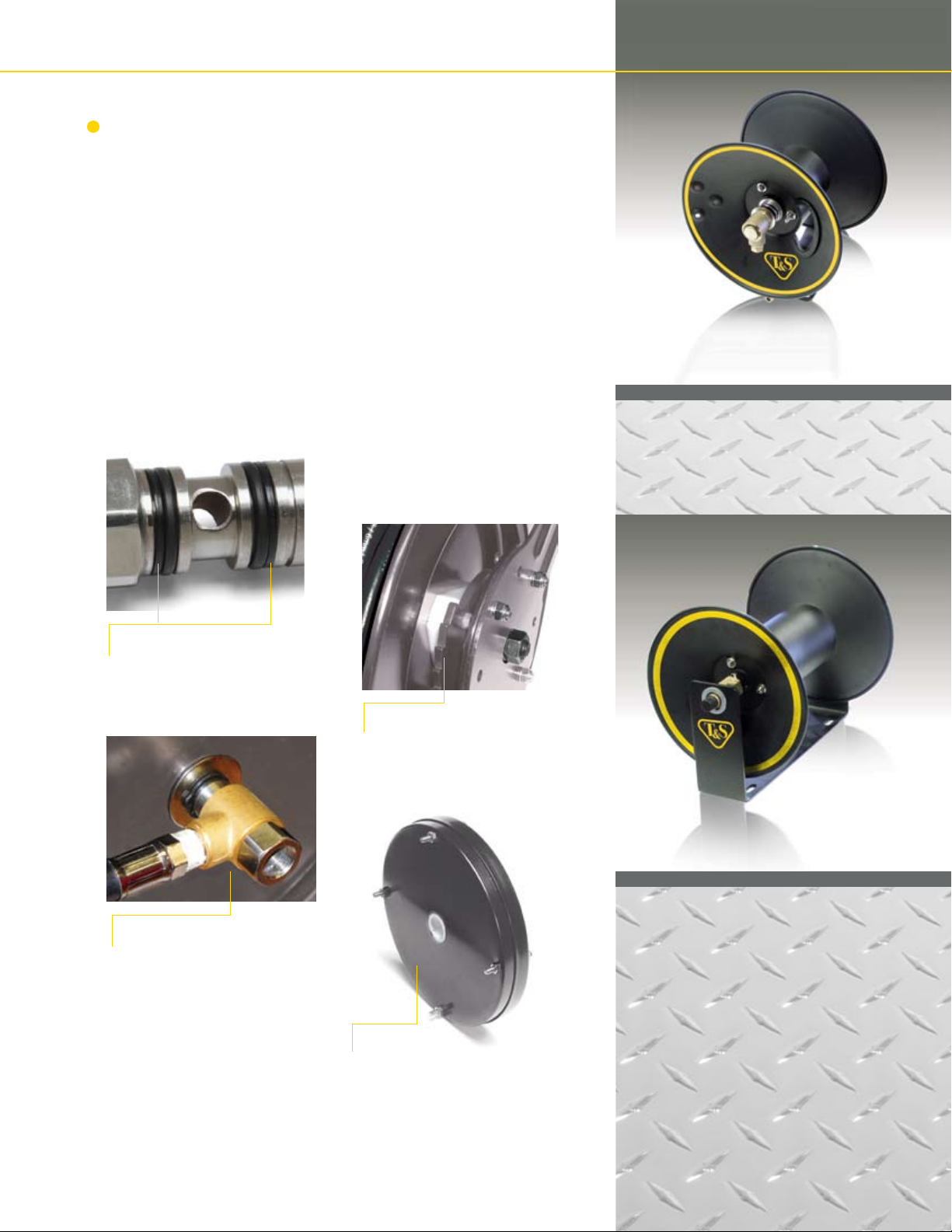

INDUSTRIAL

HOSE REELS

Setting a new standard with

high-quality, best-in-class features

at a better value

Page 2

INDUSTRIAL

HOSE REELS

T&S Industrial Hose Reels:

Setting a new standard

T&S Industrial-Reels provide the high-quality, best-in-class features you

would expect from a superior industrial hose reel, while offering a better

value than the competition. I-Reels are heavier-duty, more rust-resistant and

longer-lasting than their counterparts because we have custom-engineered

them to meet your most grueling demands.

T&S targeted the common weaknesses of the typical hose reel so we could

offer you a product with reliability built in.

• Heavy-grade metal components last longer than typical plastic parts.

• Epoxy powder coating is more durable than liquid paint finishes that

wear easily.

• Stainless steel fasteners reduce corrosion.

• Adjustable guide arm and a four-roller hose outlet allow smoother

operation.

More than just Hose Reels

Beyond the reel itself, we offer what no one else can: rapid shipping and

exceptional service. Since we have locations on the East and West Coasts,

any order placed by noon can be delivered the next day to anywhere in the

country using our Quick-Ship program. And the dedicated customer service

team at T&S is ready to support any need you have, with representatives

available 8 am EST – 5 pm PST. T&S has become well-known for our

excellence in customer service, and we are delighted to bring that service to

our industrial hose reel customers. It’s just another way we’re setting a new

standard in the industrial hose reel industry.

Open Spring-Driven

Hose Reel –

Powder Coated Steel

For more information

or to order, visit

i-reels.tsbrass.com or

call Customer Service

at 1-800-476-4103.

2

T&S Industrial Hose Reels offer

superior quality and better value

T&S I-Reels are available in both spring-driven and hand-crank models.

Each model has been designed for increased efficiency and extended

product life, with numerous features that enhance operation.

Page 3

T&S Hose Reels reduce downtime and

increase productivity

Hose reels bring efficiency and productivity to your workplace. Since reels

wind and store hoses, they solve common problems like tangling, bringing

an advanced level of performance. And since a stored, wound hose prevents

excessive weathering, a reel also extends the life of your hose. A hose reel

offers compact design for space efficiency, and a customizable length of

hose means easy adaptability to a variety of tasks or locations. The effort of

winding and unwinding becomes easy with either our spring-driven or hand-

crank models. Because they offer enhanced productivity and efficiency, hose

reels pay for themselves many times over.

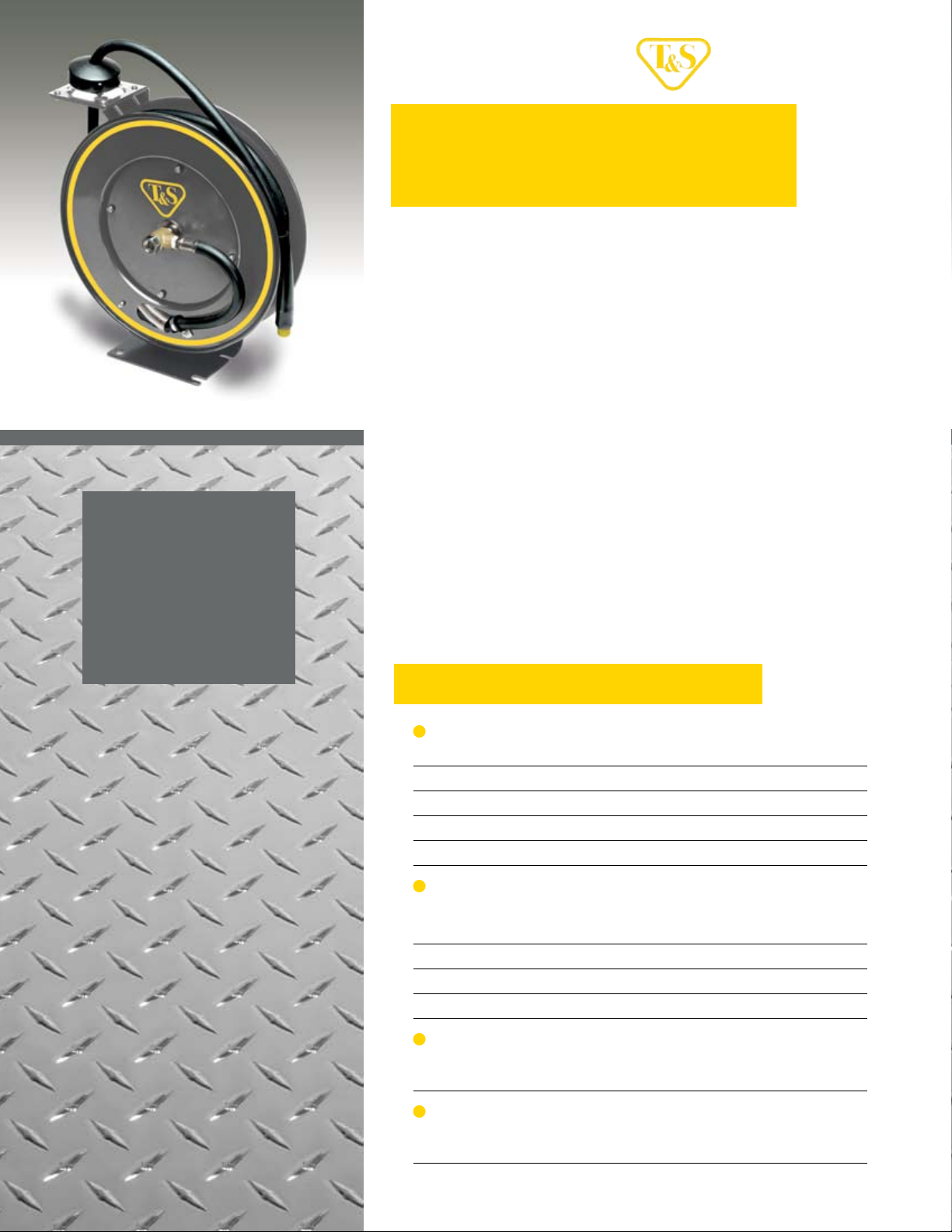

Open Hand-Crank

Hose Reels –

Powder Coated Steel

(ab ove and b elow )

• Auxiliary backup O-rings extend

life span and increase productivity.

• Easily accessible full-flow brass

swivel on a stainless steel shaft

that prevents galling and leakage,

eliminating rust.

• Impact-resistant, ¼” thick steel

ratchet assembly has eight catch

points.

• Mainsprings are enclosed in a steel

cartridge providing safer handling.

3

Page 4

For dimensions,

see pages 8-10.

For accessories,

see page 13.

For mounting

brackets, see

pages 11-12.

Open Spring–Driven Hose Reels

Open Spring-Driven Reels

Epoxy Coated Steel

35’ – 65’ Hose

Key Features:

• Select models with low and medium-pressure hose capability

(hose not included)

• Other low-pressure models include hose

• Easily accessibile full-flow brass swivel on a stainless steel shaft that

prevents galling and leakage, eliminating rust

• Auxiliary backup O-rings that extend life span and increase

productivity

• Mainspring is fully enclosed in a lubricated, steel cartridge, instead

of a dangerous exposed spring found on some competitor’s models

• Impact-resistant, 1/4” thick steel ratchet assembly with eight catch

points for improved productivity

• Drum support, base and arm all more than 3/16” thick, for

increased product life and reduced downtime

• 6-1/2” wide L-shaped base with groove reinforcement to ensure

stable support

• 4-direction non-snag rollers to reduce hose wear abrasion

Epoxy Coated Steel Reels

Low-Pressure (300 psi/20 Bar) With Hose

GSA-2L35-P 1/4” I.D. with 35’ hose

GSA-3L35-P 3/8” I.D. with 35’ hose

GSA-3L50-P 3/8” I.D. with 50’ hose

GSA-4L50-P 1/2” I.D. with 50’ hose

GSA-6L65-P 3/4” I.D. with 65’ hose

Low-Pressure (300 psi/20 Bar) Without

Hose

GSA-3L35-PN 3/8” I.D. x 35’ capability

GSA-3L50-PN 3/8” I.D. x 50’ capability

GSA-4L50-PN 1/2” I.D. x 50’ capability

GSA-6L65-PN 3/4” I.D. x 65’ capability

Medium-Pressure (2250 psi/155 Bar)

Without Hose

GSA-3M50-PN 3/8” I.D. x 50’ capability

Medium-Pressure (2000 psi /138 Bar)

Without Hose

GSA-4M50-PN 1/2” I.D. x 50’ capability

4

Page 5

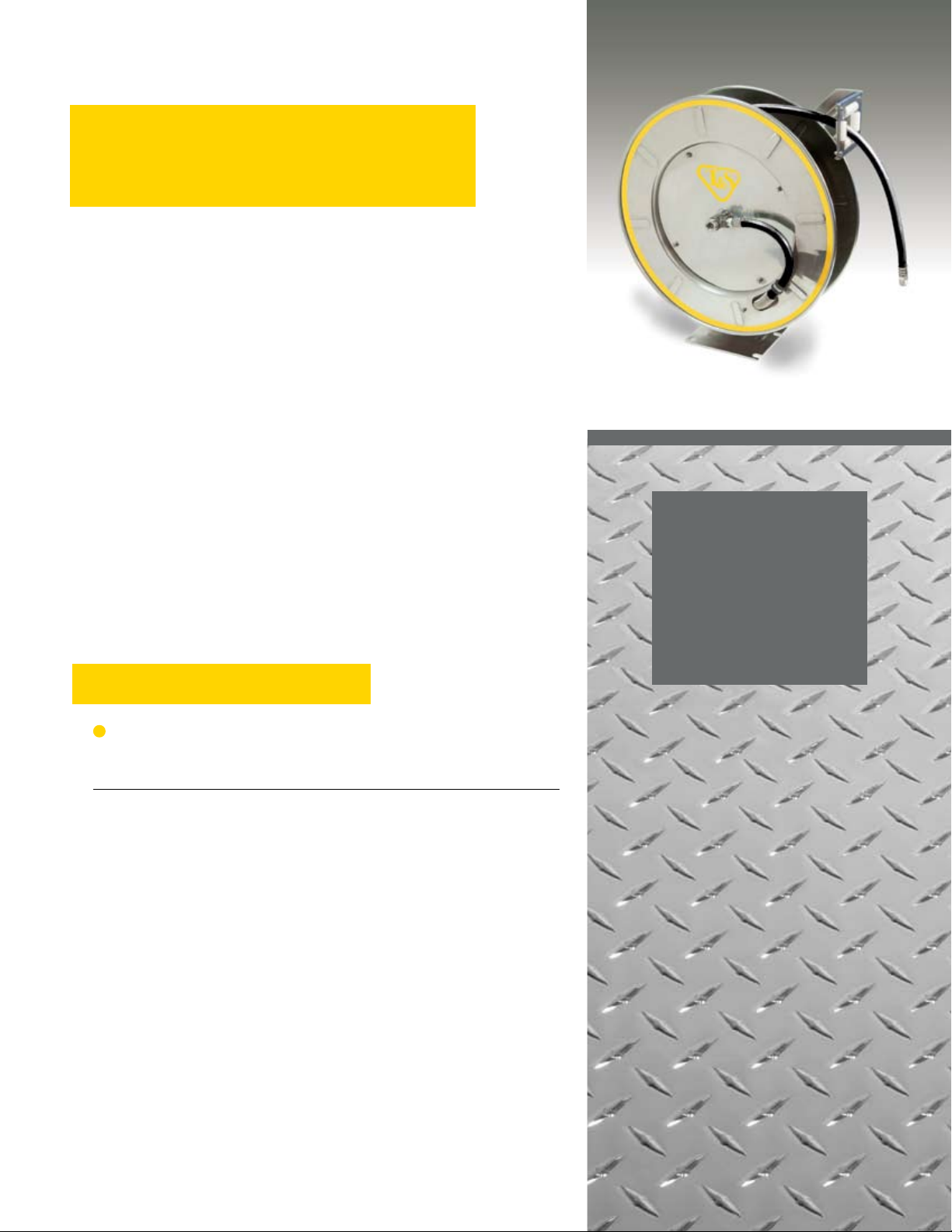

Open Spring-Driven Reels

Stainless Steel

50’ Hose Capable

Key Features:

• Low-pressure hose capability (hose not included)

• Easily accessibile full-flow brass swivel on a stainless steel shaft that

prevents galling and leakage, eliminating rust

• Auxiliary backup O-rings that extend life span and increase

productivity

• Mainspring is fully enclosed in a lubricated, stainless steel cartridge,

instead of dangerous exposed spring found on some competitor’s

models

• Impact-resistant, 1/4” thick steel ratchet assembly with eight catch

points for improved productivity

• Drum support, base and arm all more than 3/16” thick, for

increased product life and reduced downtime

• 6-1/2” wide L-shaped base with groove reinforcement to ensure

stable support

• 4-direction non-snag rollers to reduce hose wear abrasion

For dimensions,

see page 8-9.

For accessories,

see page 13.

For mounting

brackets, see

pages 11-12.

Stainless Steel Reel

Low-Pressure (300 psi/20 Bar) Without

Hose

GSA-4L50-SN 1/2” I.D. x 50’ capability

5

Page 6

For dimensions

and accessories,

see page 13.

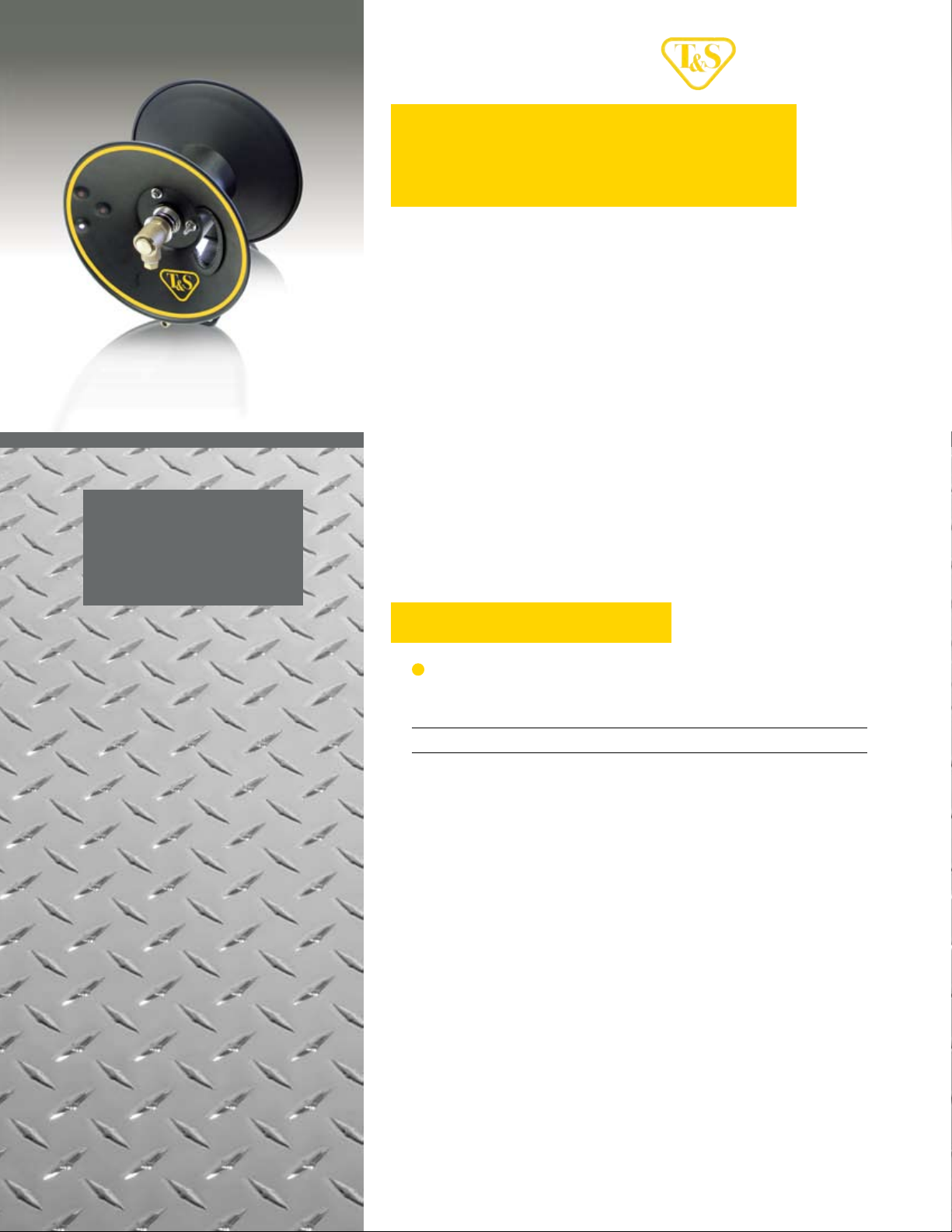

Open Hand–Crank Reels

Open Hand-Crank Reels

Small Frame

50’ – 100’ Hose Capacity

Key Features:

• High-pressure hose capability (hose not included)

• Epoxy coated steel

• High-pressure hose capability

• Brass NPT swivel inlet allows hose to enter from outside the hose

drum, preventing restriction caused by typical inside drum design

• Automatic brake system prevents automatic unwinding and

increases productivity

• Heavy-duty steel frame with rolled edges and corrosion-resistant

powder coating to provide strength and extended life

• Removable handle

• Lightweight, compact design for easy storage

Small Frame Reels

High-Pressure (3,000 psi/200 Bar)

Without Hose

GHA-2H100-PN 1/4” I.D. x 100’ capable

GHA-3H50-PN 3/8” I.D. x 50’ capable

6

Page 7

Open Hand-Crank Reels

Medium Frame

100’ – 200’ Hose Capacity

Key Features:

• Low and high-pressure hose capability (hose not included)

• Epoxy coated steel

• Brass NPT swivel inlet allows hose to enter from outside the hose

drum, preventing restriction caused by typical inside drum design

• Automatic brake system prevents automatic unwinding, increases

productivity

• Heavy-duty steel frame with rolled edges and corrosion-resistant

powder coating provides strength and extended life

• Removable handle

• Lightweight, compact design for easy storage

For dimensions,

see page 14.

For accessories,

see page 13.

Medium Frame Reels

Low-Pressure (300 psi/20 Bar) Without

Hose

GHA-3L100-PN 3/8” I.D. x 100’ capable

Without Hose

GHA-3H100-PN 3/8” I.D. x 100’ capable

GHA-2H200-PN 1/4” I.D. x 200’ capable

High-Pressure (3,000 psi/200 Bar)

7

Page 8

Technical Data Open Spring-Driven Reels

Epoxy Coated Steel

35’ – 65’ Hose Capacity

(hose included with -P models)

Models:

Hose I.D. Pressure Hose Length Lbs. (approx.)

GSA-2L35-P Yes 1/4” Low 35’ 32

GSA-3L35-P Yes 3/8” Low 35’ 32

GSA-3L50-P Yes 3/8” Low 50’ 53

GSA-4L50-P Yes 1/2” Low 50’ 64

GSA-6L65-P Yes 3/4” Low 65’ 99

GSA-3L35-PN No 3/8” Low 35’ capable 30

GSA-3L50-PN No 3/8” Low 50’ capable 51

GSA-4L50-PN No 1/2” Low 50’ capable 62

GSA-6L65-PN No 3/4” Low 65’ capable 92

GSA-3M50-PN No 3/8” Medium 50’ capable 55

GSA-4M50-PN No 1/2” Medium 50’ capable 60

(see photo and

spec’s. on p.10)

(see photo and

spec’s. on p.10)

8

Stainless Steel

50’ Hose Capacity

(hose not included; reel shown with hose)

Models:

Hose I.D. Pressure Hose Length Lbs. (approx.)

GSA-4L50-SN No 1/2” Low 50’ capable 46

Page 9

Technical Data Open Spring-Driven Reels

Models:

GSA-2L35-P

GSA-3L35-P

GSA-3L35-PN

15-1/2”

3-1/8”

5-3/16”

1/2” O.D.

Models:

GSA-3L50-P

GSA-4L50-P

GSA-3L50-PN

GSA-4L50-PN

GSA-4L50-SN

GSA-3M50-PN

GSA-4M50-PN

15-5/16”

20-5/8”

21-1/2”

6-7/16”

14-7/16“ O.D.

7-1/16”

5-1/4”

6-1/8”

6-1/8”

4”

1/2” O.D.

6”

Inlet and outlet dimensions

(NPT) based on Hose I.D.

Mounting plate holes

are 1/2” O.D.

19-5/8” O.D.

8-7/16”

9

Page 10

Technical Data Open Spring-Driven Reels

Models:

GSA-6L65-P

GSA-6L65-PN

Models:

Hose I.D. Pressure Hose Length Lbs. (approx.)

GSA-6L65-P Yes 3/4” Low 65’ 99

GSA-6L65-PN No 3/4” Low 65’ capable 92

GSA-6L65-P

27-1/16”

14-3/8”

45°

9-5/16”

7-1/8”

1/2” O.D.

24-1/2” O.D.

11”

GSA-6L65-PN

27-1/16“

14-3/8”

Hose Stop

Included with

Hose Reel

24-1/2” O.D.

45°

7-1/8”

1/2” O.D.

11”

9-5/16”

10

Page 11

Technical Data Mounting Brackets for

Open Spring-Driven Reels

Epoxy Coated Black Steel

G016636-45

3.13”

OR

Stainless Steel

Small Bracket

• Epoxy coated black steel

• Fits 3/8” x 15’, 30’ and

35’ hose reels

For Use On Models:

GSA-2L35-P

GSA-3L35-P

GSA-3L35-PN

5.25”

Mounting Hardware

not included

G016652-45

Universal Pivot

Bracket

• Epoxy coated black steel

• Fits all T&S and I-Reel

hose reels

For Use On Models:

All Open Spring-Driven

Hose Reels

4.47”

Epoxy Coated Black Steel

330° of rotation

7.32”

Mounting Hardware

not included

5-5/16”

mount to

wall

5-5/16”

mount to wall

11

Page 12

Technical Data Mounting Brackets for

Open Spring-Driven Reels

Epoxy Coated Black Steel

G016637-45

Medium Bracket

• Epoxy coated black steel

• Fits 3/8” x 50’ and

all 1/2” hose reels

For Use On Models:

GSA-3L50-P

GSA-4L50-P

GSA-3L50-PN

GSA-4L50-PN

GSA-4M50-PN

GSA-3M50-PN

4.00”

6.00”

5.42”

G016737-45

Universal Swivel

Bracket

• Stainless steel

• Fits all stainless steel

hose reels

For Use On Model:

GSA-4L50-SN

6.63”

5.42”

6.00”

5.25”

8.00”

5.63”

4.00”

3.13”

Stainless

Steel

Mounting hardware

not included

8.00”

12

Page 13

Technical Data Open Hand-Crank Reels

Small Frame

50’ – 100’ Hose Capacity

(hose not included)

Models:

Hose I.D. Pressure Hose Length Lbs. (approx.)

GHA-2H100-PN No 1/4” High 100’ capable 8.4

GHA-3H50-PN No 3/8” High 50’ capable 8.4

13-3/4”

11-1/4”

13”

Hose Reel

Accessories

7-7/8”

4-3/8”

3-5/16”

4-1/4”

3-15/16“ O.D.

3-5/16”

4-1/4”

10-5/8”

O.D.

Black Epoxy Coated

Inlet and outlet dimensions

(NPT) based on Hose I.D.

Hose Stops

Part Number Hose I.D.

G016590-45 1/4”

G014949-45 3/8”

G014950-45 1/2”

Mounting plate holes

are 13/32” O.D.

13

Page 14

Technical Data Open Hand-Crank Reels

Medium Frame

100’ – 200’ Hose Capacity

(hose not included)

Models:

Hose I.D. Pressure Hose Length Lbs. (approx.)

GHA-2H200-PN No 1/4” High 200’ capable 16.5

GHA-3H100-PN No 3/8” High 100’ capable 16.5

GHA-3L100-PN No 3/8” Low 100’ capable 16.5

22”

16-15/16”

N/A

12”

8-5/8”

10-15/16”

13-3/4”

3-15/16“ O.D.

2”

3-3/8”

10-5/8”

O.D.

Black Epoxy Coated

Inlet and outlet dimensions (NPT)

based on Hose I.D.

14

Mounting plate

holes are 13/32” O.D.

Page 15

I-Reel Industrial Hose

Reel Accessories

5WG-1000-01

Water Gun

Includes Quick-Disconnect

and 1/2” and 3/8” Adapters

MV-3516- Series:

-21 ½” NPT x ½” Hose Barb Connector

-22 ½” NPT x ¾” Hose Barb Connector

-23 ½” NPT x 1” Hose Barb Connector

-24 (no connector or adapter)

-25 ½” NPT x ³/8” NPT Female Adapter

MV-3516

Aluminum Rear

Trigger Water Gun

5/16” I.D. Flow Orifice

Other Hose Reels

Water Guns

B-7245-06

Heav y-duty Industrial

Dual-Arm Open Hose Reel

with MV-2516 Rear Trigger Water Gun

and 3/4” diameter 50’ Hose

Option:

B-7245-03 with MV-2522 Front Trigger

Water Gun

MV-2516-32

Rear Trigger Water Gun

1/2” NPT Female Inlet, 7/16” Orifice

and 3/4” Coupling

EB-2322

Spray Valve Extension Unit

3/8” NPT Female Inlet

MV-2522-32

Front Trigger Water Gun

1/2” NPT Female Inlet, 7/16” Orifice

and 3/4” Coupling

15

Page 16

Service Sink Faucets

Vacuum Breakers

B-0655-BSTP

Polished Chrome

Service Sink Faucet

Option:

B-0655-BSTR rough chrome

finish

I-Reel Industrial Hose Reel Accessories

B-0665-BSTR

Rough Chrome

Service Sink Faucet

Option:

B-0665-BSTP polished chrome

finish

B-0962

Continuous Pressure

Vacuum Breaker Assembly

B-0512

Shut-off Control Valve

B-0963

Continuous Pressure

Vacuum Breaker Assembly

16

Page 17

Vacuum Breakers

Concealed Valves

B-0929-A

Atmospheric Vacuum Breaker

Assembly

B-0969

Atmospheric Vacuum

Breaker Assembly

B-0965

Atmospheric Vacuum

Breaker Assembly

B-1025-ST

Concealed Straight Valve

B-1035-ST

Concealed Bypass Mixing

Valve

17

Page 18

Single Temperature

Washdown Stations

I-Reel Industrial Hose

Reel Accessories

MV-1907-12CW

Washdown Station

MV-0771-12CW

Washdown Station

MV-0771-12C

3/4” Mixing Valve

18

MV-0771-12R

Water Mixing Station

MV-1907-12C

Cast Bronze Valve/ Wall

Brackets (2)

Page 19

Model Page

I-Reel Spring-Driven

•

Hose Reels

GSA-2L35-P .............. 4, 8, 9

GSA-3L35-P .............. 4, 8, 9

GSA-3L50-P .............. 4, 8, 9

GSA-4L50-P .............. 4, 8, 9

GSA-6L65-P .............. 4, 8, 10

GSA-3L35-PN ........... 4, 8, 9

GSA-3L50-PN ........... 4, 8, 9

GSA-4L50-PN ........... 4, 8, 9

GSA-3M50-PN .......... 4, 8, 9

GSA-4M50-PN .......... 4, 8, 9

GSA-6L65-PN ........... 4, 8, 10

GSA-4L50-SN ........... 5, 8, 9

I-Reel Hand-Crank Hose Reels

•

GHA-2H100-PN ....... 6, 13

GHA-2H200-PN ....... 7, 14

GHA-3H50-PN ......... 6, 13

GHA-3H100-PN ....... 7, 14

GHA-3L100-PN ........ 7, 14

Accessories – Hose Stops

•

G016590-45 ............. 13

G014949-45 ............. 13

G014950-45 ............. 13

Accessories – Vacuum Breakers,

•

Water Guns, Concealed Valves,

Washdown Stations, Service Sink

Faucets, Other Hose Reels

5WG-1000-01 .......... 15

B-0512 ...................... 16

B-0655-BSTP ............ 16

B-0655-BSTR ............ 16

Model Page

Accessories – Vacuum

•

Breakers, cont.

B-0665-BSTP ............ 16

B-0665-BSTR ............ 16

B-0929-A .................. 17

B-0962 ...................... 16

B-0963 ...................... 16

B-0965 ...................... 17

B-0969 ...................... 17

B-1025-ST ................. 17

B-1035-ST ................. 17

B-7245-03 ................ 15

B-7245-06 ................ 15

EB-2322 .................... 15

MV-0771-12C ........... 18

MV-0771-12CW ........ 18

MV-0771-12R ............ 18

MV-1907-12C ............ 18

MV-1907-12CW ......... 18

MV-2516 .................... 15

MV-2522 ................... 15

MV-3516 series .......... 15

Mounting Brackets For

•

Spring-Driven Hose Reels

G016636-45 ............. 11

G016637-45 ............. 12

G016652-45 ............. 11

G016737-45 .............. 12

Index

Company History

Ahead of the Competition

In rigorous head-to-head testing, T&S hose reels consistently ranked well

above the competition. With a life cycle greater than most competitor

reels, T&S is the clear choice for your industrial hose reel needs.

T&S Brass: A Heritage of Excellence

With our steadfast commitment to quality, T&S Brass and Bronze Works,

Inc. has set the standard of excellence for the plumbing industry for

more than half a century. Founded in 1947, T&S originally developed

foodservice plumbing equipment, including the market’s first pre-rinse

unit, which quickly became the industry standard.

Today, T&S produces faucets, fittings and specialty products for a

number of markets across the United States and throughout the world.

We have over 30 years of experience serving specialty applications in

the hose reel market, and we’re pleased to bring our knowledge and

high performance to the industrial sector. Leading the way in innovation,

quality manufacturing and customer service, T&S remains dedicated to

the same commitment of excellence that first established our reputation

as the single source solution for plumbing. It’s a reputation our

customers have learned to trust.

19

Page 20

INDUSTRIAL

HOSE REELS

Warranty Information

All T&S Industrial Hose Reels (except hose) have a two-year limited

warranty, to be free from defects in material and workmanship for a

period of two (2) years from the date of purchase. Hose supplied by

T&S carries a 90-day warranty only. Liability is limited thereunder to

factory repair and/or replacement of material found to be defective,

after examination by T&S, during the warranty period. No claims for

labor, shipping costs or consequential damages will be accepted or

honored.

Replacement and/or repair under this warranty will be made within a

reasonable time after receipt by T&S of the allegedly defective item.

Items which have received secondary finishing or have been altered

in any way after purchase are not covered by this warranty. Claim

resulting from damaged cartons must be filed with the carrier.

Some states do not allow limitations on how long an implied warranty

lasts or on the exclusion of incidental or consequential damages,

so all the limitations or exclusions appearing herein may not be

permitted by your state and, therefore, your local statutes should

be consulted with respect thereto or with respect to any other rights

which your state statutes may specifically confer on you.

After receiving proper authorization, all returns of merchandise

which are claimed defective under this warranty must be sent to T&S

Brass and Bronze Works, Inc., P.O. Box 1088, 2 Saddleback Cove,

Travelers Rest, South Carolina 29690, clearly marked to the attention

of Warranty Repair Department. Shipping charges, both ways, shall

be paid by the customer.

TM

T&S Brass & Bronze Works, Inc.

East Coast West Coast

P.O. Box 1088 709 E. Cochran Street

2 Saddleback Cove Unit D&E

Travelers Rest, SC 29690 Simi Valley, CA 93065

Telephone: 1-800-476-4103 Telephone: 1-800-423-0150

Fax: 1-80 0-868-0084 Fax: 1-80 0-273-7718

i-reels.tsbrass.com

800-016722-45 Rev. 2

Loading...

Loading...