Page 1

TRP-C68

8-Channel Analog Input to Digital Output Isolated Module

Support ASCII and Modbus RTU protocol

User’s Manual

Printed Sep. 2013 Rev 1.4

Trycom Technology Co.,Ltd

No.35, Zhongxing Rd., Guishan Township, Taoyuan County 333, Taiwan.

Tel : 886-3-350-3351 Fax: 886-3-350-3352

Web: www.trycom.com.tw

Copyright

Copyright Notice: The information in this manual is subject to change without notice to improve reliability, design and

function and does not represent a commitment on the part manufacturer. No part of this manual may be

reproduced, copied, or transmitted in any form, without prior written permission by the manufacturer. Products

mentioned in this manual are mentioned for identification purposes only. In this manual, product names appearing

may or may not be registered trademarks of their respective companies or copyright.

Page 2

2

1. Introduction

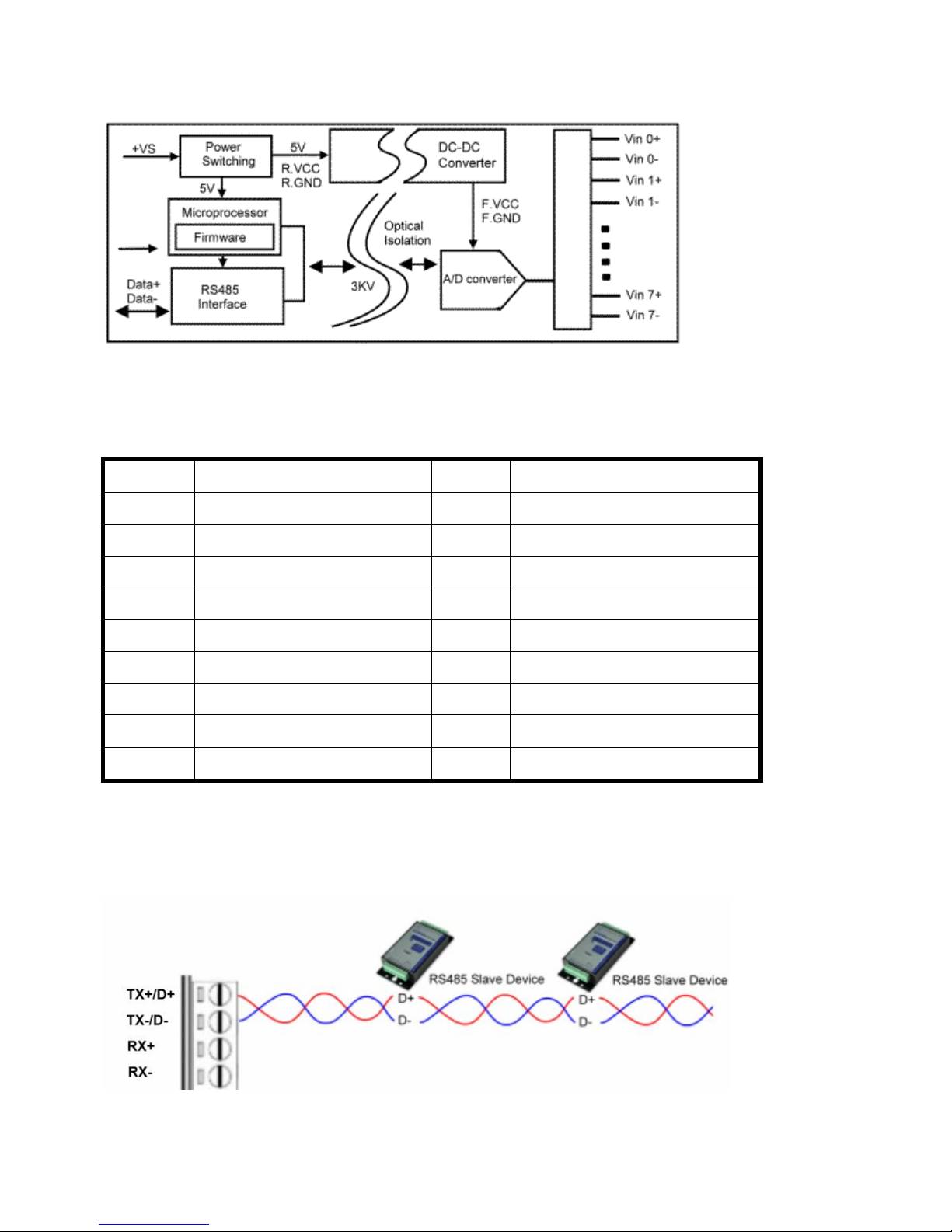

TRP-C68, an 8-channel Analog to Digital Converter (ADC), takes an analog input signal and

converts the input into a digital output signal. It accepts analog input-a voltage or a current-and

supports the sample rate in “Normal” or “Fast” mode. All channels feature screw terminals for

convenient connection, All analog inputs are provided with isolation and surge protection to

protect the module against high voltage spikes, as well as ground potential differences. TRP-C68

support both ASCII and Modbus protocol, with a full set of command, dual watch-dog, and auto

reset function the module can be remote controlled by PC in ASCII or Modbus RTU protocol.

1-1. Features

Support ASCII and Modbus RTU protocol.

Photo Isolation 3750V between digital and analog.

All channels can input analog signal by voltage or current.

Baud rate from 1.2Kbps to 115.2Kbps.

Surge protection on RS-485 interface.

LED display to indicate power and communication.

Dual Watchdog for hardware reset circuit and host operating status.

External switch for hardware and module’s configuration.

Support screw terminal, or external DC power supply.

Wide input range DC power supply.

1-2. Specifications

Resolution: 16 Bit

Sample rate:

Normal mode: 10 sample / sec (24 bit).

Fast Mode: 60 sample / sec (16 bit).

Bandwidth:

Normal Mode: 15.72Hz.

Fast Mode:/78.72Hz…fast.

Zero drift: 0.03uV/C.

Span drift: 25 ppm/C.

Accuracy:

Normal 0.1 or better.

Fast: 0.5 or better.

Analog Input range:

Voltage: ± 10V, ± 5V,± 2.5V,± 1.25V,± 650mV.

Current: +/-20 mA

CMRR:92db min/50/60Hz.

Analog input over voltage protection:± 35V.

RS485 connector: Industrial plug-in screw terminal.

Communication Interface: RS485,2 wires.

Page 3

3

LED indicator: Power and communication.

Transmission distance : 4000ft(1200M).

Speed: From 1.2K to 115.2Kbps.

Power consumption:1.2 Watt.

Power requirement: DC input from +10 to 30 V.

Operating Temperature: 0 to 60℃.

Storage Temperature: -20 to 60℃.

Humidity: 10-90%, Non-condensing.

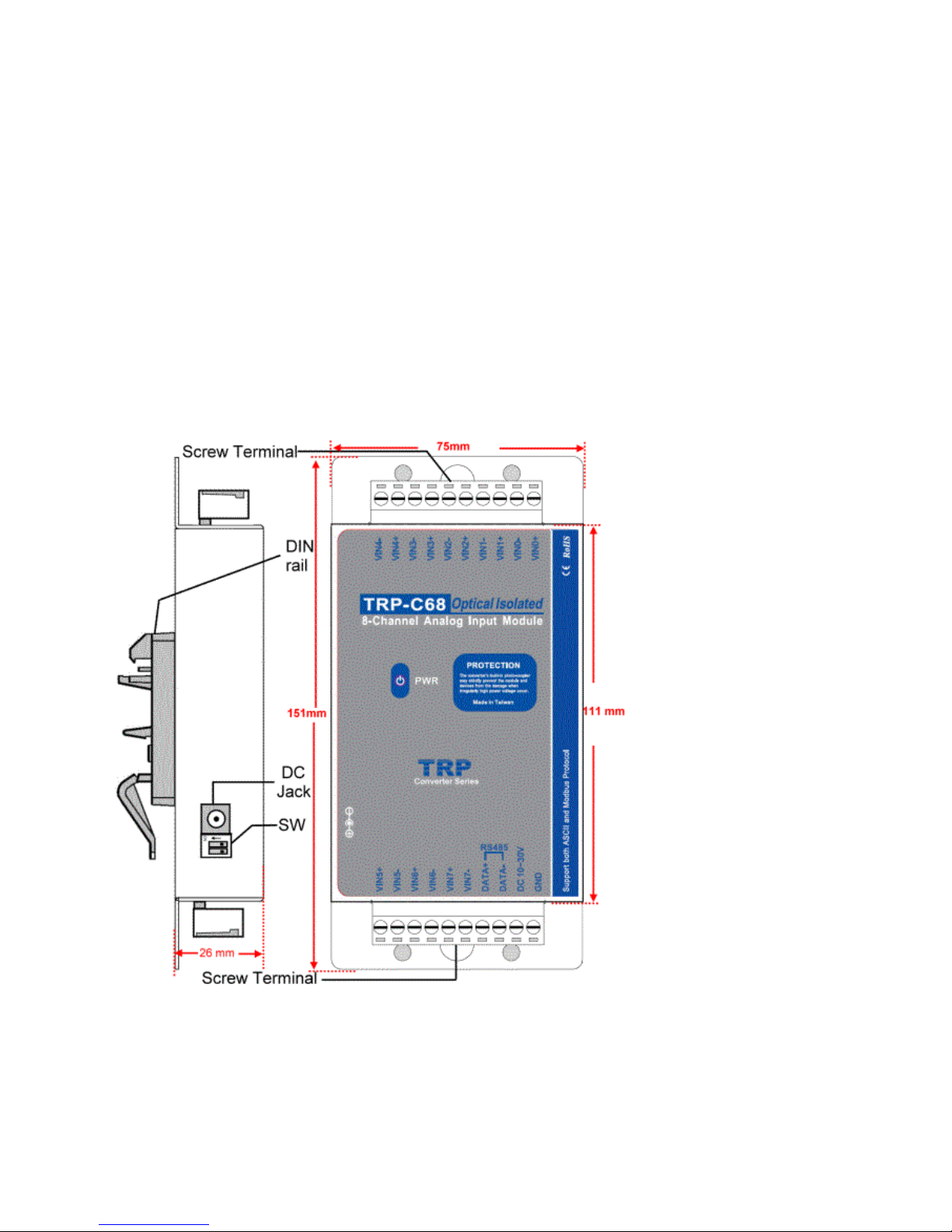

Dimension: 151mm X 75mm X 26mm.

Weight: 398g.

1-3. Panel layout

Page 4

4

1-4. Block Diagram

1-5. Pin Definitions

VIN5+ Analog Input Channel 5+ VIN4- Analog Input Channel 4-

VIN5- Analog Input Channel 5- VIN4+ Analog Input Channel 4+

VIN6+ Analog Input Channel 6+ VIN3- Analog Input Channel 3-

VIN6- Analog Input Channel 6- VIN3+ Analog Input Channel 3+

VIN7+ Analog Input Channel 7+ VIN2- Analog Input Channel 2-

VIN7- Analog Input Channel 7- VIN2+ Analog Input Channel 2+

DATA+ RS485 DATA+ VIN1- Analog Input Channel 1-

DATA- RS485 DATA- VIN1+ Analog Input Channel 1+

DC 10~30V Input Voltage DC 10~30V VIN0- Analog Input Channel 0-

GND Input Voltage Ground VIN0+ Analog Input Channel 0+

1-6. Communication Wiring

Page 5

5

2. Wire Connection for Digital Input

2-1. Wire Connection For Current Input

2-2. Wire Connection For Voltage Input

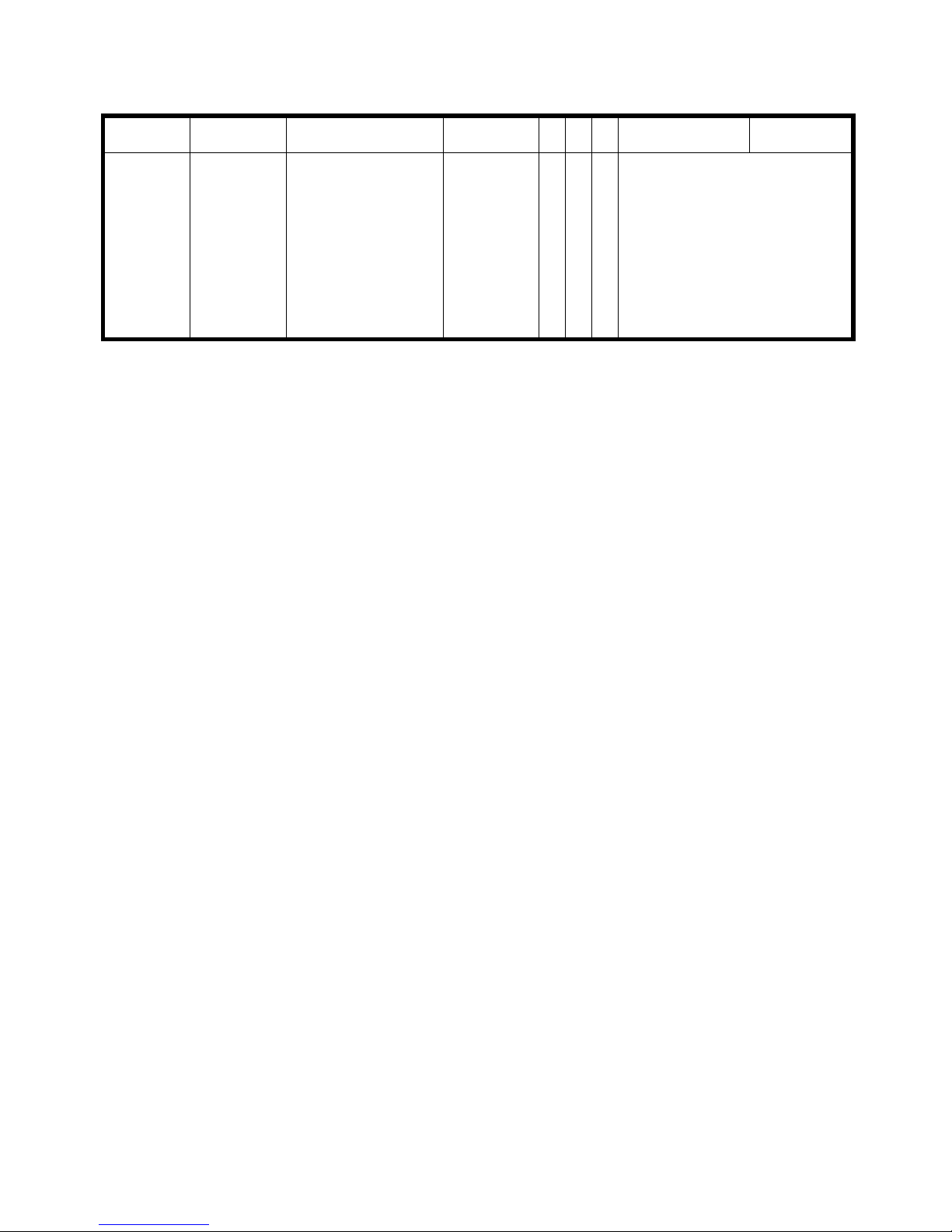

3. System Configuration Switch

The TRP-C68 DIO and AIO support the Modbus RTU and ASCII communication protocol, It has

a two pins external dip-switch that allow user to select protocol between Modbus RTU and ASCII.

The dip-switch also provides “back to INIT” function when user forget the configuring information

stored in EEPROM such as ID (RS-485 Module address), baud rate and data format.

*TRP-C68 Default setting:

ID Address: 01,

Baud Rate: 9600,

Analog Mode Type: 08,

Checksum: Disable,

Data Format: 00,

All analog input channels: Enable,

RS485 communication data format: N, 8, 1.

Page 6

6

Modbus

Protocol

(Factory

)

Modbus Communication Protocol.

Back to

INIT

for

Modbus

Step1. Adjust to “on off” position

Step2. Reboot the system.

ASCII

Protocol

ACSII communication protocol.

Back to

INIT

for

ASCII

Step1. Adjust to “on on” position

Step2. Reboot the system.

*INIT: ID=00, Baud-Rate: 9600, Data format: 00, TT=08. RS485 communication protocol:N,8,1

* The INIT* mode: if you forgot the C68 ID or baud-rate before you adjusted, you can adjust the

switch to INIT* mode then easy to get ID=00.

3-1. How to manually more positive voltage calibration

Send command "$ID7"…....make sure the TRP-C68 8 CH. enable.

Send command "~IDE0"….calibration enable.

Send command "~IDE1"….set up the calibration enable.

Send command "$ID8"........perform the Zero calibration.

Send command "~IDE1".....set up calibration enable again.

Send command "$ID9"... ….perform the full calibration.

Send command "~IDE0"......calibration disable.

Page 7

7

4. Function description

Auto voltage calibration: The TRP-C68 will auto calibrate the voltage when power up. However

user may also use voltage calibrating command to correct the voltage while the environment

temperature is obvious difference, or the module was long period in idle. When the voltage must

be calibrated by software command, it is necessary to reboot the module before calibration.

Dual Watchdog: Module self watchdog: The module’s watchdog is a hardware reset circuit while

working in harsh or noisy environment, the module may be down. The circuit may enable the

module to continue working and never halt.

Host watchdog: The host watchdog is a software function to monitor the module's output states.

The purpose is to prevent the RS-485 network from communication problem or host halt due to

unexpected situation. When the timeout interval expired, the module will turn all outputs to

predefined safe value. This can prevent the controlled target from unexpected situation.

5. ASCII Command Description

The TRP-C68 DIO and AIO support the ASCII communication protocol, the serial communication

data format is Parity check: None, data Bit: 8, Stop bit: 1, baud rate can setting from

1200bps~115200bps.

5-1.Factory Setting

ID Address: 01,

RS485 communication protocol: 9600, 8, N, 1

AI Mode Type: ±10V

Checksum: Disable.

5-2.Protocol Syntax

Command Format:” Leading Code”+”ID Address”+”Command”+”CHK”+(cr) .

Response Format:”Leading Code”+”ID Address”+”Data”+”CHK”+ (cr) .

5-3. How to Calculate the Check Sum

1. Calculate the ASCII sum of all characters of the command string except the character return.

2. Mask the sum of string with OFFH.

Example:

Send the command is “$06M”.

Sum of string is “$”+”0”+”6”+”M”=“24H”+”30H”+” 4D“=“A1H”……The checksum and [CHK]=“A1”.

Response string with checksum is :”A1“.

Page 8

8

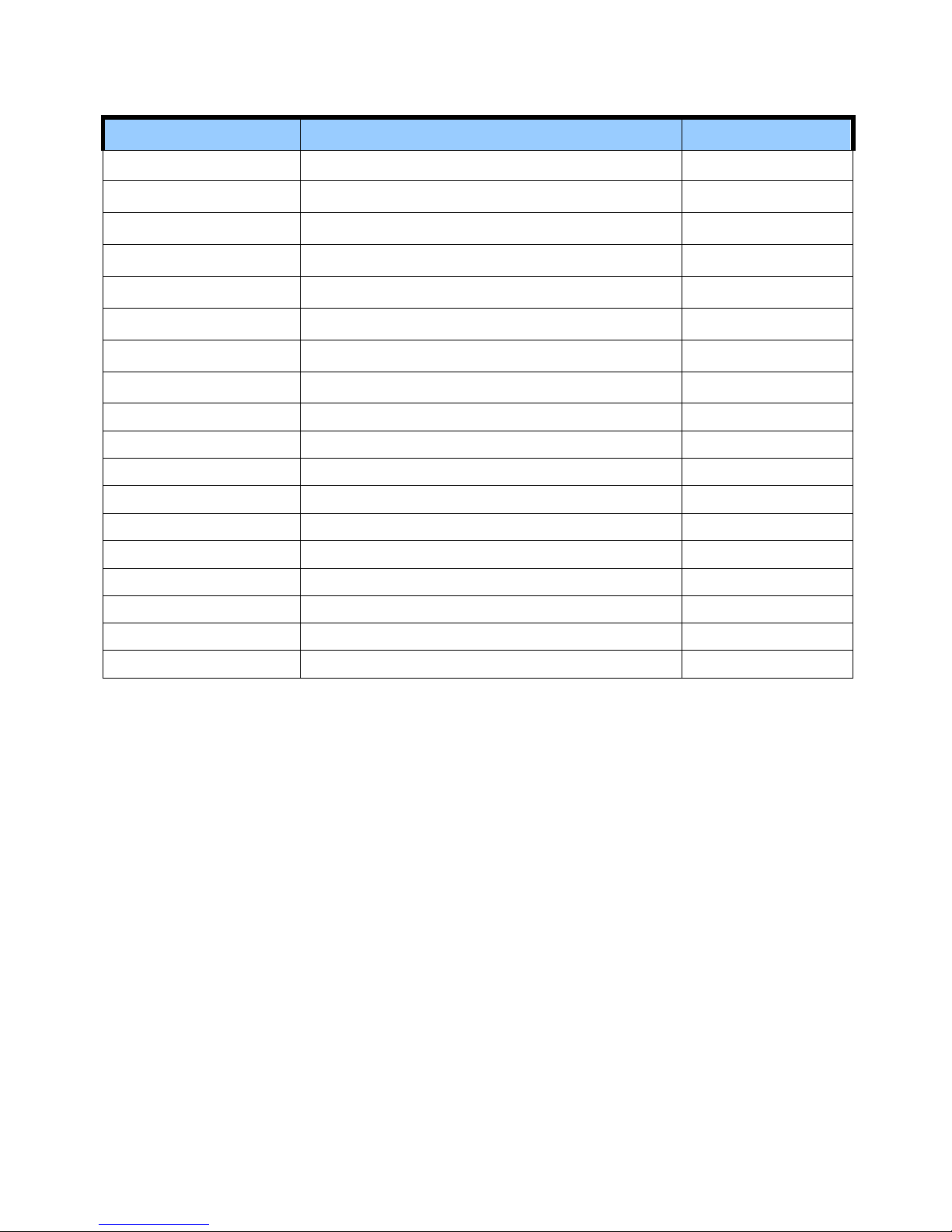

5-4. ASCII Command List

Command List Function Description Page Index

%IDNNTTBBDD(CHK)(cr) Set the module configuration

5-5

#ID(CHK)(cr) Read all analog input

5-9

#IDN(CHK)(cr) Read analog input from N channel

5-10

$ID2(CHK)(cr) Read the module’s configuration

5-11

$ID5(CHK)(cr) Read reset status

5-12

$ID6HL(CHK)(cr) Select analog input channel enable/disable

5-13

$ID7(CHK)(cr) Read analog channel enable/disable status

5-14

~01EV(CHK)(cr) Set up the calibration enable/disable

5-15

$ID8(CHK)(cr) Perform zero calibration

5-16

$ID9(CHK)(cr) Perform full calibration

5-17

$IDRS(CHK)(cr) Perform software reset

5-18

$IDM(CHK)(cr) Read the module’s name

5-19

$IDF(CHK)(cr) Read the module’s firmware version and date

5-20

~IDONN(CHK)(cr)

Chang the module’s name

5-21

~IDWENN(CHK)(cr) Enable watch dog and set up timeout value

5-22

~IDWD(CHK)(cr) Disable watchdog

5-23

~IDWR(CHK)(cr) Read watchdog timeout value

5-24

~**(CHK)(cr) System stand by (Host ok!)

5-25

Page 9

9

5-5.Set the module’s configuration

*The module must be reboot, When you set up module’s configuration after.

Command %IDNNTTBBDD(CHK)(cr)

Syntax

Description

% First leading code

ID Address of setting module from 00~FF(HEX)

NN New address of setting from 00~FF(HEX)

TT Analog input type setting

BB New baud rate setting

DD Data Format

CHK Checksum

(cr) Carriage return

Response !ID(CHK)(cr) Command valid

?ID(CHK)(cr) Command Invalid

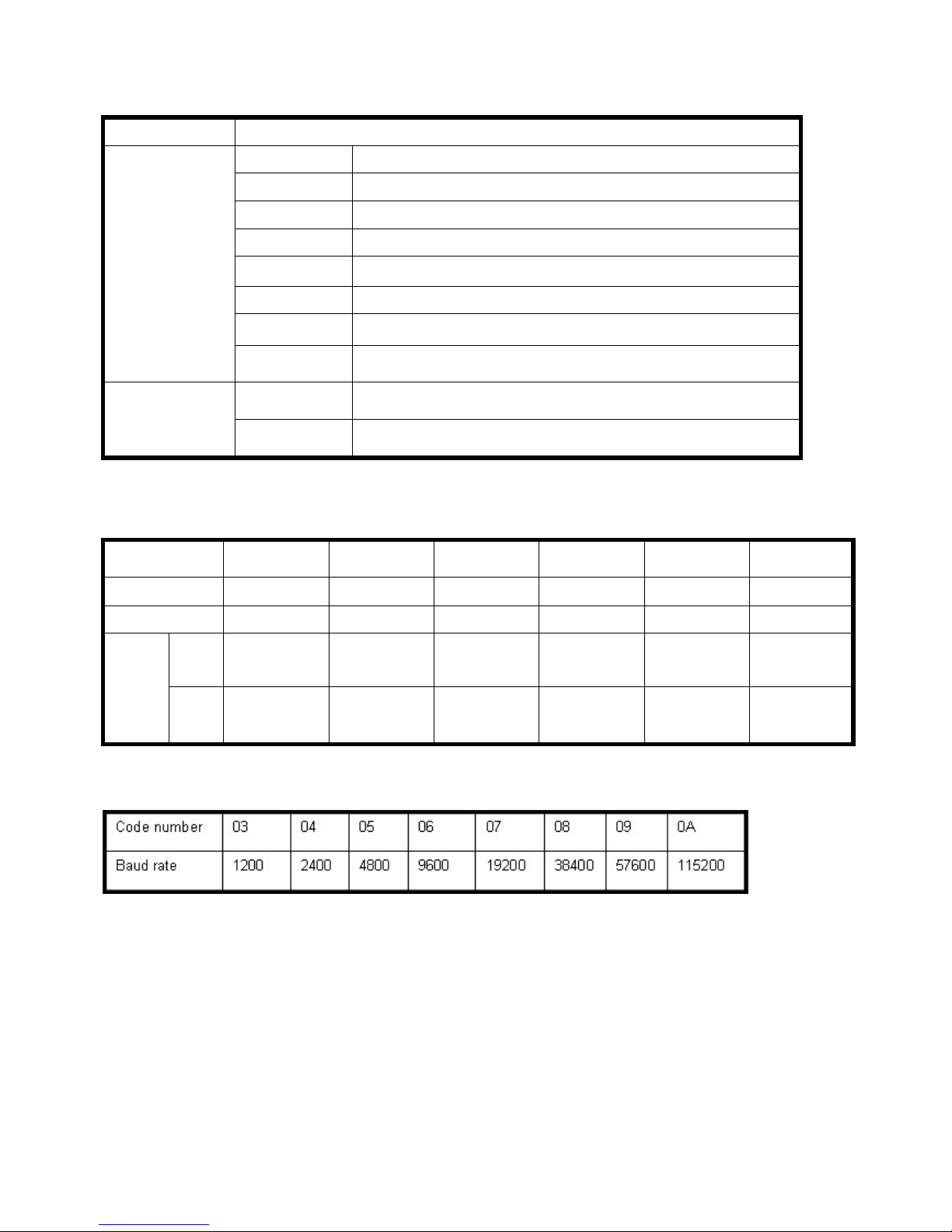

5-6. (TT) Analog input type

5-7. (BB) Baud Rate Setting

Type Code 08 09 0A 0B 0C 0D

Voltage: ±10V ±5V ±2.5V ±1.25V ±650mV ±20mA

% of FSR

±100 % ±100 % ±100 % ±100 % ±100 % ±100 %

2’S

complem

ent

Fast

Mode

0000~8000~FFFF 0000~8000~FFFF 0000~8000~FFFF 0000~8000~FFFF 0000~8000~FFFF 0000~8000~FFFF

Normal

Mode

000000~800000~

FFFFFF

000000~800000~F

FFFFF

000000~800000~F

FFFFF

000000~800000~F

FFFFF

000000~800000~F

FFFFF

000000~800000~F

FFFFF

Page 10

10

5-8. (DD) Data format setting

Example:

Send command:”%0003080600”,

New ID=03, Analog input= ±10V, Baud Rate=9600, Checksum=Disable DD=00

, Response:”!03”.

*If you turn on the system setting switch, the ID will become to “00”,

Then send command read analog input CH-0 voltage “#030”,

Response:” >03+07.63178”=+7.63178V / Unit: Voltage.

Example: Send command:%00030B0501 Response:”!03,

New ID=03, Analog input= ±1.25V, Baud Rate=4800, Checksum=Disable DD=01.

Then send command read analog input CH-0 FSR of percent “#030”,

Response:” >03+063.3626” =63.3626 % / Unit: %.

Example: Send command:%0101080602 Response:”!01,

New ID=01, Analog input= ±10V, Baud Rate=9600, Checksum=Disable,

Normal mode, DD=02.

Then send command read analog input CH-0 FSR of percent “#010”,

Response:” >017FF99F / Unit: 2’s complement 3 Byte

000000~800000~FFFFFF.

*TRPCOM utility is the utility for user to configure the module, the utility also with on-line RS485

modules scanning and searching function. You can find the utility in the TRP-C68 support CD

which is bundled in TRP-C68 standard package.

Bit 7 6 5 4 3 2

1 0

Function

Rejection

*0=60Hz

1=50Hz

Checksum

*0:Disable

1:Enable

Mode

*0=Normal

1=Fast

0 0 0

Engineer Unit Format

*00=Voltage

01=Percent

10=2’s Complement HEX Format

Page 11

11

5-9. Read all analog input

Command #ID(CHK)(cr)

Syntax

Description

# First leading code

ID Address of setting module from 00~FF(HEX)

CHK Checksum

(cr) Carriage return

Response !IDData0~7(CHK)(cr) Channel 0,1,2,3,4,5,6,7 Data

?ID(CHK)(cr) Command Invalid

Example

Send command:”#01” Read the all analog input channels data.

IF TT=08 the data will be show

Response: “>01+02.667+00.006+00.002+00.000+00.000+00.000+00.000+00.000”…..Show the

channel 0~7 voltage between -10V~+10V. / Unit: Voltage

Page 12

12

5-10. Read analog input from N channel

Command #IDN(CHK)(cr)

Syntax

Description

# First leading code

ID Address of setting module from 00~FF(HEX)

N Analog channel 0~7

CHK Checksum

(cr) Carriage return

Response !IDData(CHK)(cr) Data: Channel N data

?ID(CHK)(cr) Command Invalid

Example:

Send command:”#010” Read the analog input channel 0 value.

Response: >01+03.82062 Channel 0=+3.82062. /Unit: Voltage

5-11. Read Module’s Configuration

Command $ID2(CHK)(cr)

Syntax

Description

$ First leading code

ID Address of setting module from 00~FF(HEX)

2 Read module’s configuration

CHK Checksum

(cr) Carriage return

Response !IDTTBD00(CHK)(cr) TT: Analog input type BD: Baud rate type

?ID(CHK)(cr) Command Invalid

Example:

Send command:”$012” …..Read module’s configuration.

Response:!01080600 TT=08=-10V~+10V……. Refer 5-6

, Baud rate=06=9600…..Refer 5-7.

Page 13

13

5-12. Read reset status

Command $ID5(CHK)(cr)

Syntax

Description

$ First leading code

ID Address of setting module from 00~FF(HEX)

5 Read reset status

CHK Checksum

(cr) Carriage return

Response !IDS(CHK)(cr) S=1 Reset S=0 No Reset

?ID(CHK)(cr) Command Invalid

Example:

Send command: ”$015”.

Response: !011 1:Module have been reset.

*If the module is system halt or detect abnormal voltage, the module will auto restart and flag of

reset set up to “1” until use “$ID5”.

5-13. Select analog input channel enable/disable

Command $ID6HL(CHK)(cr)

Syntax

Description

$ First leading code

ID Address of setting module from 00~FF(HEX)

6 Set up channel enable/disable

HL H: Channel 4~7, L: Channel 0~3 , 0:disable 1:enable

CHK Checksum

(cr) Carriage return

Response !ID(CHK)(cr) Command valid

?ID(CHK)(cr) Command Invalid

Example:

Send command:”$0160F”….Channel0~3 enable, Channel4~7 disable,

Response: !01.

Page 14

14

Then send command:”#01”……Read channel 0~7,

Response:” +02.130+07.512-01.765-02.986+00.000+00.000+00.000+00.000,

From channel 4~7 is disable.

5-14. Read analog input channel enable/disable status

Command $ID7(CHK)(cr)

Syntax

Description

$ First leading code

ID Address of setting module from 00~FF(HEX)

7 Read analog input channel enable/disable status

CHK Checksum

(cr) Carriage return

Response !IDHL(CHK)(cr) H: Channel 4~7 L: Channel 0~3

0:Channel disable 1:Channel Enable

?ID(CHK)(cr) Command Invalid

Example:

Send command:”$017”,

Response: “!010F” Channel 4~7 disable, Channel 0~3 enable.

5-15. Set up the calibration Enable/Disable

Command ~IDEV(CHK)(cr)

Syntax

Description

$ First leading code

ID Address of setting module from 00~FF(HEX)

EV V=0 Disable V=1 Enable

CHK Checksum

(cr) Carriage return

Response !ID(CHK)(cr) Command valid

?ID(CHK)(cr) Return not enable calibration before calibration command

Example:

Send command:”~01E1”,

Response: “!01”…… Enable calibration.

*Refer to paragraph 4 Function description before calibration.

5-16. Perform Zero Calibration

Page 15

15

Command $ID8(CHK)(cr)

Syntax

Description

$ First leading code

ID Address of setting module from 00~FF(HEX)

8 Perform zero calibration

CHK Checksum

(cr) Carriage return

Response !ID(CHK)(cr) Command valid

?ID(CHK)(cr) Return not enable calibration before calibration command

Example:

Send command:”$018”,

Response: “!01”.

*Refer to paragraph 4 Function description before calibration.

5-17. Perform Full Calibration

Command $ID9(CHK)(cr)

Syntax

Description

$ First leading code

ID Address of setting module from 00~FF(HEX)

9 Perform full calibration

CHK Checksum

(cr) Carriage return

Response !ID(CHK)(cr) Command valid

?ID(CHK)(cr) Return not enable calibration before calibration command

Example:

Send command:”$019”,

Response: “!01”.

*Refer to paragraph 4 Function description before calibration.

5-18. Perform software Reset

Page 16

16

Example:

Send command:”$01RS”…….Reset ,

Response:”!01”……… ………Have been reset.

5-19. Read the module’s name

Example:

Send command:$01M…Read the TRP-C68’s name ,

Response:”!01TRPC68”……. The module’s name is “TRPC68.

5-20. Read the module’s firmware version

Page 17

17

Command $IDF(CHK)(cr)

Syntax

Description

$ First leading code

ID Address of setting module from 00~FF(HEX)

F Read firmware

CHK Checksum

(cr) Carriage return

Response !IDNNYYMMDD(CHK)(cr) NN: Module’s name YYMMDD: Release Date

?ID(CHK)(cr) Command Invalid

Example:

Send command:$01F…Read the module’s firmware version,

Response:” !01C68M070407”……. The module’s version date is “07/04/2007”.

5-21. Change the module’s name

Example:

Send command:”~01Oabcdef”….. Change the module name become to “abcdef”,

Response:”!01”……. . Command valid.

Then send the command “$01M”…read the module name,

Response:”!01abcdef”……. .The TRP-C68’s name is “abcdef”.

5-22. Enable watchdog and set the timeout value

Page 18

18

Example:

Send Command:”~01WEFF”….. Set the watchdog time for 25.5 Sec,

Response:”!01”……. . Command valid, When module count to 25.5 Sec the watchdog will into

safe mode, then PWR LED will flash, if the host send “~**” before timeout, the watchdog will

recount.

5-23. Disable watchdog

Example:

Send Command:”~01WD”….. Watchdog disable.

Response:”!01”……. . Command valid, System LED will stop flashing.

5-24. Read watchdog timeout value

Page 19

19

Example:

Send Command:”~01WR”…. Read watchdog timeout value,

Response:” !01WD0F”……. . Command valid, set the watchdog timeout is “0F”..1.6 Sec.

5-25. System stand by (Host OK!)

*If watchdog is in enable, send the “Host Ok!” before watchdog timeout (B) the watchdog will

re-count, PWR LED will flashing after watchdog timeout.

6. Modbus/RTU Command Description

Page 20

20

The TRP-C68 AIO support Modbus/RTU protocol, The serial communication data format is

Start bit: 1,

Data bit: 8,

Parity check: None,

Stop bit: 1,

Baud-rate: 1200bps~115200bps.

6-1. Modbus Syntax

Command Format :ID(HEX)+FC(HEX)+SU(HEX)+DA(HEX) or RC(HEX)+CRC16(HEX),

Response Format : ID(HEX)+FC(HEX)+SU(HEX)+DA(HEX) or RC(HEX)+CRC16(HEX),

Error Format: ID(HEX)+ FC(HEX)+ CRC16(HEX).

ID: RS485 Device Address (HEX)…..1~247 1Byte,

FC: Function Code (HEX)…1 Byte,

SU: Sub Function (HEX)…..1 Byte,

DA: Data Format….No Limit,

RC: Reserved code…No Limit,

CRC: Cyclic Redundancy Check…2 Byte.

*Error Response: If CRC IS mismatches error the response is empty!

7. Modbus/RTU Command List

Page 21

21

Command List Function Description Index

ID 46 00 00 (CRC) Read the module’s name 7-1

ID 46 04 IP 00 00 00 (CRC) Set up the module’s address 7-2

ID 46 05 00 (CRC) Read the module’s configuration 7-3

ID 46 06 00 BD 00 TT 00 DF 00 00 (CRC) Set up the module’s configuration 7-4

ID 46 07 00 (CRC) Read the module’s Firmware 7-5

ID 46 08 00 (CRC) Read the reset status 7-6

ID 46 09 00 (CRC) Set up the module reset 7-7

ID 46 21 HL 00(CRC) Select analog channel Disable/Enable 7-8

ID 46 22 00 (CRC) Read all channel Disable/Enable status 7-9

ID 46 25 XX 00 (CRC) Perform Spam Calibration 7-10

ID 46 26 00 (CRC) Perform Zero Calibration 7-11

ID 46 27 00 (CRC) Perform full Calibration 7-12

ID 03 00 NN 00 CN (CRC) Read one or multi channel analog input data 7-13

ID 04 00 NN 00 CN (CRC) Read one or multi channel analog input data 7-13

Page 22

22

7-1.Read the module’s name

Command ID 46 00 00 (CRC)

Syntax

Description

ID Address of setting module 01~247

46 Function code

00 Read module’s name

00 Reserved code

Response

ID 46 00 00 0C 68 00 (CRC)

ID 46 00 00

…

.Module command Line

0C 68 :Module’s Name is C68

ID C6 00 (CRC) ID C6 (CRC) C6:Error function code 00 : Reserved code

Example:

Send Command:”01 46 00 00”…….Read the TRP-C68’s name,

Response:”01 46 00 00 0C 68 00 “……Module’s name is C68,

Error Response: “01 C6 00 ”……Error code.

7-2. Set up the module’s address

Command ID 46 04 IP 00 00 00 (CRC)

Syntax

Description

ID Address of setting module 1~247

46 Function Code

04 Set up module’s ID

IP New module’s ID

00 00 00 Reserved code

Response

ID 46 04 00 00 00 00 (CRC) ID 46 04 00 00 00 00 ….Command valid.

ID C6 00 (CRC) ID C6 (CRC) C6:Error function code 00 : Reserved code

Example:

Send Command:”01 46 04 02 0 0 0”…….Set up the new ID is “02”,

Response:” 01 46 04 00 00 00 00 “……New ID changes to 02 ,

Error Response: “01 C6 00”……Error code.

Page 23

23

7-3. Read the module’s configuration

Command ID 46 05 00 (CRC)

Syntax

Description

ID Address of setting module 1~247

46 Function Code

05 Read module’s configuration

00 Reserved code

Response

ID 46 05 00 BD 00 TT 00 DF 00 00 (CRC)

ID 46 05 00 ……Module command Line

BD: Baud-Rate….See 7-3-2

TT: Analog Input type….See 7-3-1

DF: Data format….See 7-3-3

ID C6 00 (CRC) ID C6 (CRC) C6:Error function code 00 : Reserved code

7-3-1. (TT) Analog input type

7-3-2. (BB) Baud Rate Setting

7-3-3. (DD) Data format setting

Example:

Type Code 08 09 0A 0B 0C 0D

Voltage: ±10V ±5V ±2.5V ±1.25V ±650mV ±20mA

% of FSR

±100 % ±100 % ±100 % ±100 % ±100 % ±100 %

2’S complement

HEX

0000~8000~FFFF

(HEX)

0000~8000~FFFF

(HEX)

0000~8000~FFFF

(HEX)

0000~8000~FFFF

(HEX)

0000~8000~FFFF

(HEX)

0000~8000~FFFF

(HEX)

Bit 7 6 5 4 3 2

1 0

Function

Rejection

*0=60Hz

1=50Hz

Checksum

*0:Disable

1:Enable

Mode

*0=Normal

1=Fast

0 0 0

Engineer Unit Format

*00=Voltage

01=Percent

10=2’s Complement HEX Format

Page 24

24

Send Command:”01 46 05 00”…Read TRP-C68’s configuration,

Response:” 01 46 05 00 06 00 08 00 08 00 00 “

Error Response: “01 C6 00 ”……Error code .

7-4. Set up the module’s configuration

Command ID 46 06 00 BD 00 TT 00 DF 00 00 (CRC)

Syntax

Description

ID Address of setting module 1~247

46 Function Code

06 Set up module’s configuration

00 BD 00 TT 00 DF 00 00

BD: Baud-Rate….See 7-3-2

TT: Analog Input type….See 7-3-1

DF: Data format….See 7-3-3

Response

ID 46 06 00 00 00 00 00 00 00 00 (CRC)

ID 46 06 00

……

Module command Line

00 00 00 00 00 00 00 00 : Reserved code

ID C6 00 (CRC) ID C6 (CRC) C6:Error function code 00 : Reserved code

Example:

Send Command:” 1 46 06 00 05 00 08 00 00 00 00”…….Set up TRP-C68’s configuration,

Response:” 01 46 06 00 00 00 00 00 00 00 00 “…Command valid!,

Error Response: “01 C6 ”……Error code,

*Baud-Rate set to 4800

Analog input typ:+/-10V

Data format:00.

Page 25

25

7-5. Read the module’s Firmware

Command ID 46 07 00 (CRC)

Syntax

Description

ID Address of setting module 1~247

46 Function Code

07 Read module’s Firmware

00 Reserved code

Response

ID 46 07 YY MM DD 00(CRC)

ID 46 20 ……Module command Line

YY:Year, MM :Month ,DD:Date ,

00 : Reserved code

ID C6 00 (CRC) ID C6 (CRC) C6:Error function code 00 : Reserved code

Example:

Send Command:”01 46 07 00”…….Set up TRP-C68’s configuration,

Response:” 01 46 07 07 04 07 00“…2007 /04/07 12.2006 TRP-C68 Firmware Version,

Error Response: “01 C6 00 ”……Error code.

7-6.Read the reset status

Command ID 46 08 00 (CRC)

Syntax

Description

ID Address of setting module 01~247

46 Function code

08 Read reset status

00 Reserved code

Response

ID 46 08 XX 00 (CRC)

ID 46 0

8 00 ….Module command Line

XX=01 Have been reset , 00:Have been read

ID C6 00 (CRC) ID C6 (CRC) C6:Error function code 00 : Reserved code

Example:

Send Command:”01 46 08 00”…….Read the TRP-C68’s reset status,

Response:”01 46 08 01 00 “……Have been reset,

Error Response: “01 C6 00 ”……Error code.

Page 26

26

7-7.Set up the module reset

Command ID 46 09 00 (CRC)

Syntax

Description

ID Address of setting module 1~247

46 Function Code

09 Module Reset

00 Reserved code

Response

ID 46 09 00 (CRC) Module reset

ID C6 00 (CRC) ID C6 (CRC) C6:Function Code 00: Reserved code

Example:

Send Command:”01 46 09 00”,

Response:”01 46 09 00...Command valid,

Error Response: “01 C6 00”…Error code.

7-8. Select analog channel Disable/Enable

Command ID 46 21 HL 00 (CRC)

Syntax

Description

ID Address of setting module 1~247

46 Function Code

21 Read module’s Firmware

HL

H: Channel 4~7 L: Channel 0~3

0:Channel disable 1:Channel Enable

00 Reserved code

Response

ID 46 21 NN 00(CRC) Command valid

ID C6 00 (CRC) ID C6 (CRC) C6:Error function code 00 : Reserved code

Example:

Send Command:”01 46 21 0F 00”……Enable Channel 0~3, Disable Channel 4~7,

Response:” 01 46 21 0F 00 “…Command Valid,

Error Response: “01 C6 00 ”……Error code.

Page 27

27

7-9. Read all channel Disable/Enable status

Command ID 46 22 00 (CRC)

Syntax

Description

ID Address of setting module 1~247

46 Function Code

22 Read all channel disable/enable status

00 Reserved code

Response

ID 46 22 HL 00 (CRC)

ID 46 2

2 ……

Module command Line

HL=Channel 0~F enable/disable status

00 : Reserved code

ID C6 00 (CRC) ID C6 (CRC) C6:Error function code 00 : Reserved code

Example:

Send command :”01 46 22 00”…..Data Channel,

Response:” 01 46 22 0F 00”…Channel 0~3 is enable, Channel 4~7 is disable,

Error Response: “01 C6 00 ”……Error code.

7-10. Perform Spam Calibration

Command ID 46 25 XX 00 (CRC)

Syntax

Description

ID Address of setting module 1~247

46 Function Code

25 Spam calibration enable

XX XX=00 Disable XX=01 Enable

00 Reserved code

Response

ID 46 25 00 00 (CRC)

ID 46 2

5 00 ……

Module command Line

00 : Reserved code

ID C6 00 (CRC) ID C6 (CRC) C6:Error function code00 : Reserved code

Example:

Send command ”01 46 25 01 00”,

Response:” 01 46 25 00”…Set up enable,

Error Response: “01 C6 00”……Error code.

*Refer to paragraph 4 Function description before calibration.

Page 28

28

7-11. Perform Zero Calibration

Command ID 46 26 00 (CRC)

Syntax

Description

ID Address of setting module 1~247

46 Function Code

26 Spam zero calibration

00 Reserved code

Response

ID 46 26 00 (CRC)

ID 46 26

……

Module command Line

00 : Reserved code

ID C6 00 (CRC) ID C6 (CRC) C6:Error function code 00 : Reserved code

Example:

Send command :”01 46 26 00”,

Response:” 01 46 26 00”….Command valid,

Error Response: “01 C6 00 ”……Error code.

*Refer to paragraph 4 Function description before calibration.

7-12. Perform full Calibration

Command ID 46 27 00 (CRC)

Syntax

Description

ID Address of setting module 1~247

46 Function Code

27 Spam full calibration

00 Reserved code

Response

ID 46 27 00 (CRC)

ID 46 27

……

Module command Line

00 : Reserved code

ID C6 00 (CRC) ID C6 (CRC) C6:Error function code 00 : Reserved code

Example:

Send command :”01 46 27 00”,

Response:” 01 46 27 00”….Command valid,

Error Response: “01 C6”……Error code.

*Refer to paragraph 4 Function description before calibration.

Page 29

29

7-13. Read one or multi channel analog input data

Command

ID 03 00 NN 00 CN (CRC)

ID 04 00 NN 00 CN (CRC)

Syntax

Description

ID Address of setting module 1~247

03 or 04 Function Code

00 NN Start channel from NN=00~07

00 CN How many channel want to read CN=1~8

Response

ID 03/04 BC ST DATA (CRC)

ID 03

or 04

……Module command Line

BC: Byte Counter

ST:01…when Voltage or % of FSR is Positive

ST:00…. when Voltage or % of FSR is Negative

ST:02…..when fast mode and engineer mode is 2byte

ST:03…..when normal mode and engineer mode is 3byte

DATA: Analog Input value

ID 83 ER (CRC)

ID 83 :Function Code

ER=00 Syntax error

ER=01 Data Format error

ER=02 Start channel error

ER=03 I/O out of range

Example:

TT=08, DF:00

Send command “1 3 0 0 0 1”…Read channel 0 voltage

Response:” 01 03 05 10 00 87 89 65 “.......+8.78965V.

*When voltage or % of FSR mode the data length is 5 byte, 1st byte is 10: Positive,00: Negative

Example:

When DF is 02 (Engineer and normal mode) ,Byte Counter is 3 bytes .

TT=08, DF:02 DF: fast mode display 3 byte,

Send command “01 03 00 00 01 “…Read channel 0 engineer mode :0000~8000~FFF /HEX=

-10V~0V~+10V

Response:” 01 03 03 B7 BD DB “....10: Engineer mode AC 1A =about +4.3V

When DF is 22 (Engineer And fast Mode)..Byte Counter Is 2 Bytes

TT=08, DF:22 DF: fast mode display 2 byte,

Send command “01 03 00 00 01 “…Read channel 0 engineer mode :0000~8000~FFF /HEX=

-10V~0V~+10V

Response:” 01 03 02 AC 1A “....10: Engineer mode AC 1A =about +3.3V

Example:

TT=08, DF:02 DF: normal mode display 3 byte, Engineer Mode

Send command “01 03 00 00 01 “…Read channel 0 engineer mode :000000~800000~FFFFF

Page 30

30

/HEX=

-10V~0V~+10V

Response:” 01 03 03 EE 1C BD “....10: Engineer mode EE 1C BD =about +8.58V

Example:

TT=09, DF:01

Send command “01 46 06 00 06 00 09 00 01 00 00”….BD=9600,TT=09=+/-5V,DF=01

=% of FSR……set up configuration …see 7.4

Response:” 01 46 06 00 00 00 00 00 00 00 00”

Send command “01 03 00 00 01 “…Read channel 0 % of FSR

Response:” 01 03 05 10 00 51 43 59 “....51 43 59= + 51.4359 %......about +2.55V

Example:

Send command :”01 03 00 00 00 08”…..Read all channel,

Response:” 01 03 28 00 00 02 27 97 00 00 00 00 61 10 00 00 01 22 00 00 00 00 61 10 00 00 00

00 10 00 00 00 00 10 00 00 00 00 10 00 00 00 00 ” Voltage/ Unit . Data format=00

Note: Some Modbus utility support 2 byte data each channel like Modbus Poll , but the

TRP-C68 standard mode is support 5 byte for display , If user use the that utility ,the

TRP-C68 must be adjust the data format .

Example :

Send command: “02 46 06 00 06 00 08 00 02 00 00”….Set the BD=06=9600, TT=08=+/-10V,

DF=02=Engineer display.

Response: “02 46 06 00 00 00 00 00 00 00 00”……Command valid.

Then send the command : “1 3 0 0 0 1”……Read channel 0 voltage

Response:” 02 03 02 E1 C1” ….Channel 0 data is =”E1 C1”

Note: The engineer’s display is 0000(hex)~8000(hex)~FFFF(hex)=-10V~0V~+10V

Example:

TT=09, DF:01

Send command “01 46 06 00 06 00 09 00 01 00 00”….BD=9600,TT=09=+/-5V,DF=01

=% of FSR……set up configuration …see 7.4

Response:” 01 46 06 00 00 00 00 00 00 00 00”

Send command “01 03 00 00 01 “…Read channel 0 % of FSR

Response:” 01 03 05 10 00 51 43 59 “....51 43 59= + 51.4359 %......about +2.55V

Example:

TT=08, DF=00

Send command “01 03 00 05 0 3 “…Read channel 5~7

Page 31

31

Response:” 01 03 0F 10 00 79 88 53 10 00 00 14 35 10 00 19 37 00 “….Channel 5=+7.98853V,

Channel 6=+0V, Channel 7=+1.937V

7. How to use the utility for windows

The TRPCOM utility can help you to test and configuration the module’s data transmit and

receive analog input data and output communication status. User may download TRPCOM

software from TRYCOM web www.trycom.com.tw.

1.The “Setting”function is for user to initiate the software to set the Com Port from 1 to 20 and

setting the Baud-Rate from 1200 to 115200,Checksum Enable or Disable. …See Figure 1

*The Module Factory Setting is “9600” and “ID” is 01, Checksum is Disable.

*Turn module’s switch to “OFF,ON” position into ASCII communication mode.

2.The “Terminal” function is for user to input command, user can control all of module’s digital

input/output status or wait to get module response status …See Figure 2.

Figure 1

Page 32

32

If you don’t know the module’s ID may select “Scan” to find the module’s setting.

Figure 2

Page 33

33

Select the module which one you want setting then click “Configuration”.

Example: TRP-C68 Configuration

A: Get analog input voltage Value please click “D0~D7” button.

B: Set up new RS485 ID, Baud-Rate and data format then click “Write to EEPROM” button.

Page 34

34

8.Application

9. Using the Modbus poll for test the TRP-DIO and AIO

The Modbus poll is the very popular utility that supports the Modbus RTU/ASCII and Modbus

TCP/IP, you can download that for test the any TRP-DIO and AIO basic Modbus function.

The download website is http://www.modbustools.com/modbus_poll.asp

Loading...

Loading...