Page 1

TRP-C37

Ethernet to RS232/422/485 Converter

User’s Manual

Printed May. 2011 Rev 1.1

Trycom Technology Co., Ltd

1F, No.2-11, Sihu street, Yingge Township, Taipei, Taiwan ROC

T el: 886-2-86781191, Fax: 886-2-86781172

Web: www.trycom.com.tw

Copyright

Copyright Notice: The information in this manual is subject to change without prior notice in order to improve

reliability , design and function and dosed not represent a commitment on the part of the manufacturer. No part of this

manual may be reproduced, copied, or transmitted in any form without the prior written permission of manufacturer.

Acknowledgment Products mentioned in this manual are mentioned for identification purpose only. Products manes

appearing in this manual may or may not be registered trademarks or copyright of their respective companies.

Page 2

2

1. Introduction

TRP-C37 is suitable industrial environment Ethernet serial server, wide range power input and

serial communicate protection, Built-in surge, over current ,over voltage ensure RS422/485

serial communication quality ; Increase watchdog function will auto reset when Ethernet serial

server or power fail, if careless lost password or wrong setting value that can fast back to factory

by external switch.

TRP-C37 support 3 operates mode, “Direct IP Mode”, “Virtual COM Mode”, and “Paired Mode”,

RS232 interface has one D-SUB 9pin connector and screw terminal block for RS422/485. The

Ethernet port support Auto-MDIX and Auto-select 10/100MB.

TRP-C37 offers maximum connection 16 host clients to link the one serial server, it is easy to

operate in Modscan32 and Modbus Poll many application uses Virtual-COM mode and Pair

Mode.

TRP-C37 provides a watchdog timer function, The Watchdog timer allows the system to

automatically recover from a system crash. When the TRP-C37 MCU stop working correctly, the

watchdog timer waits for a preset period of time, and performs a hardware reset.

When TRP-C37 working at unstable voltage industrial environment, the power detection circuit

can prevent the power fail cause of the boot fail then auto re-boot.

1-1 Features

z Wide range DC input power supply.

z Support watchdog function prevents system fail.

z Support Auto-MDIX twisted pair crossover detection and Auto-Correction.

z Maximum Connection 16 Client PC at Server Mode.

z Auto fast Bi-direction RS485 hardware.

z Surge protection and over current and over voltage on RS-422/485 data lines.

z Support baud rate from1200~921600Kbps.

z Auto switching RS-232/422/485 signal.

z Virtual COM drivers for Windows 98/WIN2000/WIN XP/Vista/WIN2003/WIN 7.

z Virtual Com Support Server, Client, UDP mode.

z Fully compatible with Ethernet and TCP/IP protocol.

z Supports 10/100 Mbps Ethernet.

z Power/Link/RX/TX mode LED indicator.

z Heart Beat function ensures a reliable communicating connection.

z Auto Pair-mode when power or Ethernet fail.

z Back to factory by external switch.

z Support configuration by serial console.

z Update the firmware from Ethernet.

z Dual power input select from screw terminal or DC-jack.

Page 3

3

1-2 Specification.

z Power Input Voltage: DC +10V to +30V.

z LAN: Auto-MDIX, 10/100 Mbps Auto-detecting.

z RS-232: TX, RX, RTS, CTS, DTR, DSR, DCD, GND.

z RS485 signal: differential 2 half-duplex wires (DATA+, DATA-).

z RS422 signal: differential 4 full-duplex wires.(TX+,RX+,TX-,RX-)

z Data Rate: 1200,2400,4800,9600,19200,38400,57600,115200,921600 K bps .

z Parity: none, even, odd.

z Data Bits: 5, 6, 7 or 8.

z Stop Bits: 1, 1.5 or 2.

z Protocol: TCP, IP, ARP, DHCP, Telnet, HTTP, UDP, ICMP

z External switch: OFF OFF :TCP and VSP mode.

ON OFF : Option .

OFF ON :Option.

ON ON :Back to Factory.

z Virtual-Com mode support RS232 TXD,RXD,GND.

RS422 TX+,TX-,RX+,RX-.

RS485 DATA+,DATA-.

z Power supply: Screw terminal or DC jack.

z Serial interface: +/-15 KV ESD.

z RS422/485 interface: Surge, over current, over voltage protection.

z Power consumption: 12V/140mA.

z Operating Temperature:-10 to 65 °C.

z Humidity: 0~90% Non-Condensing.

z Dimensions: 151(L)*75(W)*26(H) mm.

z Weight: 395g with packing.

2. Hardware Description

2-1. Panel layout

Page 4

4

Notice: User can only choose either external DC-Jack or Screw terminal DC input. Do not use

external DC-Jack and screw terminal DC input simultaneously.

2-2. LED indicator

PWR LED: System is ready.(Blinking)

LINK LED: Ethernet cable connection and data active.

TX/RX LED: UART Transiting/Receiving Indicator.

DC Jack: Power Input DC +10V to +30V. (Pleas use the 5.5*2.1mm DC JACK).

2-3. Reset Button

Push the reset button will Re-Boot.

2-4. DIP Switches

A double DIP switch allows the TRP-C37 to be placed into TCP/Option/Factory Mode.

Page 5

5

OFF OFF: Normal mode.

ON OFF: Option.

OFF ON: Option.

ON ON: Back to factory.

2-5.Factory Setting

Factory Setting: *Adjust the external switch to ON ON will back to factory.

Page 6

6

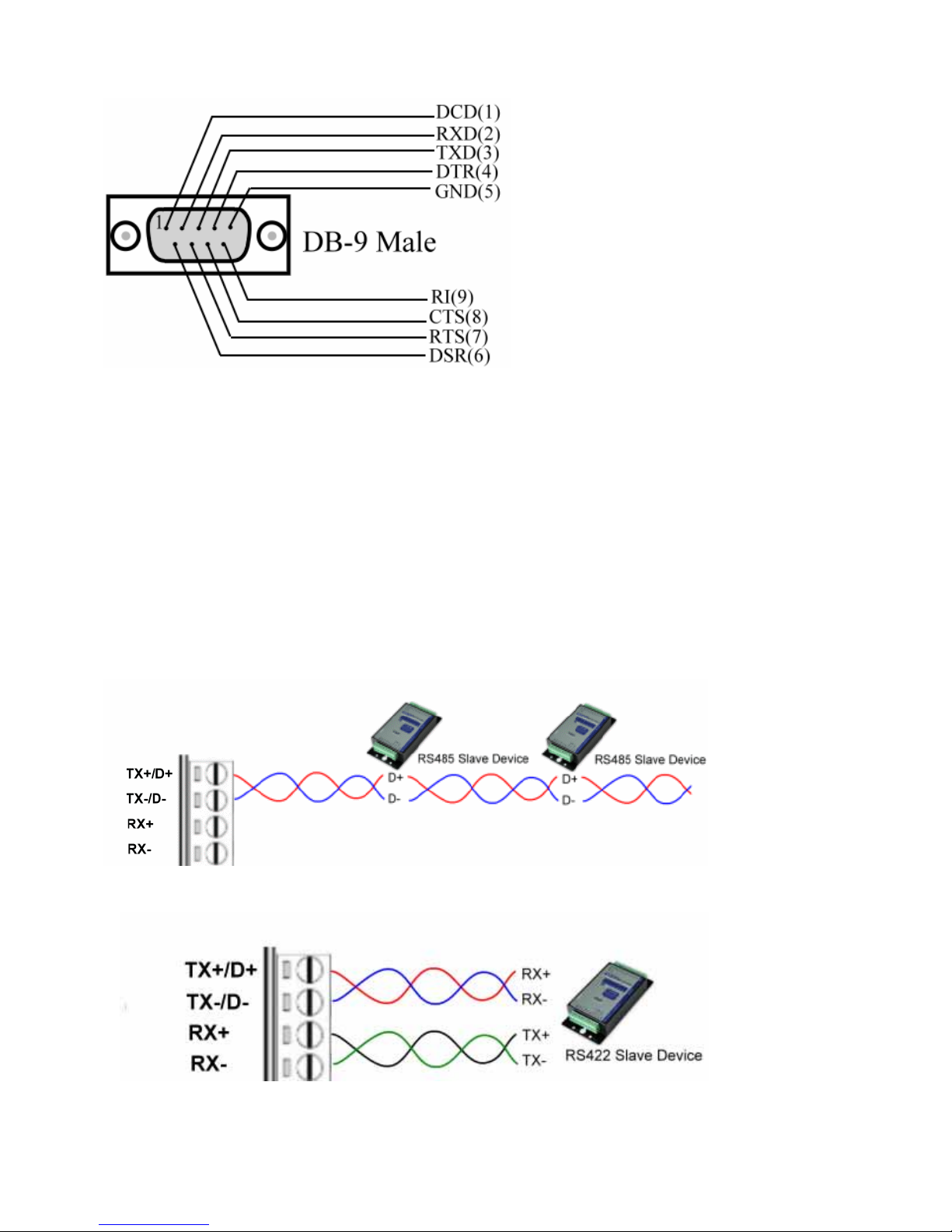

2-6. D-sub 9 Pin male Configuration

3. Install TRP-C37 Hardware

STEP1: Connect power source with TRP-C37, the PWR LED will blinking.

STEP2: Connect TRP-C37 with LAN port by RJ45 cable.

If the cable is properly connected the “LINK” LED will light up.

*The TRP-C37 Support Auto-MDIX, A straight-through or crossover RJ45 cable can

be used to make a connection directly to the HUB/Router/PC LAN port.

STEP3: Connect TRP-C37 to RS232 device by Null-Modem cable (Maximum 15M).

Connect TRP-C37 to RS422/485 by AWG #12~30 wires (Maximum 1.2KM).

3-1. RS485 Wiring

3-2. RS422 Wiring

3-3. RS232 Wiring

Refer to the Pin out table for connections.

Page 7

7

4. How to configure TRP-C37

There are 3 ways to access the TRP-C37.

a. TRP-C37X DSM Software.

b. WEB Server

Page 8

8

c. Serial Console.

Page 9

9

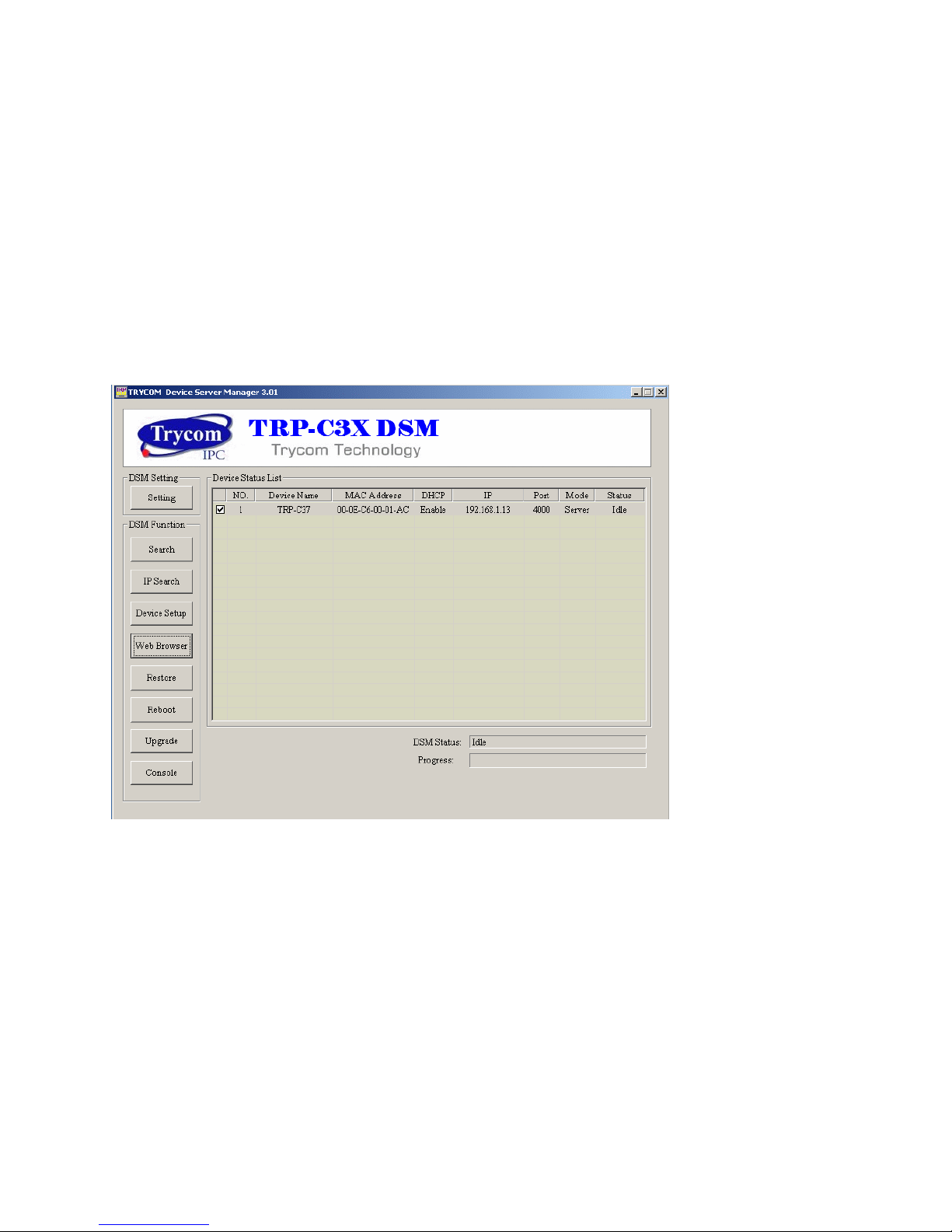

4-1. Using TRP-C37X DSM Utility.

The “TRP-C37X DSM utility” software performs several functions:

A: Searching for TRP-C37 connected to the network.

B: Displaying and changing the configuration of TRP-C37.

C: Upgrading the TRP-C37 firmware.

*Refer the Firmware upgrade help file.

D: Saving and Loading Configuration from external log File or EEPROM.

4-2. Searching LAN for TRP-C37

Once TRP-C37 is connected to the LAN the TRP-C37X DSM software will search it and display it

in a window by name, IP address, Mac….Information.

4-3.Configuring Server Properties

Select the “NO.” item and Double click to open the Server configuration, after setting then

click “Submit” will save the configuration to EEPROM.

Page 10

10

Device Name

Device server name, Maximum 10 chars.

Model Name:

TRP-C37.

MAC Address

The Device server MAC address.

DHCP

If DHCP is disabled, it allows user setting the IP address, Subnet mask, Gateway.

If DHCP is enabled ,the IP address, Subnet mask, Gateway address will be dynamically

configuration by DHCP server such router.

When “DHCP” is enabled ,but the DHCP server is not available on the network, the TRP-C37 will

timeout then back to factory setting IP=192.168.1.1.

Server Listening IP

The TRP-C37 IP address.

Server Data listening port

RS232/422/485 port address.

Client Destination IP

When user using the paired mode, the client setting need to input Server IP and PORT which

one need to connect.

Client Destination port

RS232/422/485 port address.

Port: 16 bit number. (1 ~ 65535)

Netmask

Page 11

11

The default LAN Netmask is configured for a Class C address. This maybe reconfigured by the

user.

Gateway

Input the gateway IP address that can be allows users to access the serial server from internet.

DNS

Short for Domain Name System, an Internet service that translates domain names into IP

addresses. Because domain names are alphabetic, they're easier to remember. The Internet

however, is really based on IP addresses. Every time you use a domain name, therefore, a DNS

service must translate the name into the corresponding IP address.

Transmit timer:1~500 ms/Unit

Time interval to send out serial data char packet.

*The function main support serial data input to TRP-C37 RS232/422/485 port, if serial data

is a mass of serial data over 1K Byte ,Trying to adjust the Timer to 200ms.

Hear Beat: Disable /Enable

When Hear Beat enable, the TRP-C37 allows user open a TCP 5300 port, 10 sec interval to

send out data char packet that provides a easy way to ensure the communications between Host

PC Client and server devices.

Maximum Connection: 1~16

The function allows the user to configure the TRP-C37 in Server mode adjust 1~16 TCP client

host connections.

TCP Keep Alive: 1~7 /Minute

When TRP-C37 in Server mode, the TRP-C37 without data over the 1~7 Min setting value,

The TRP-C37 will be disconnect TCP.

When TRP-C37 in Client mode, the TRP-C37 without data over the 1~7 Min setting value,

The TRP-C37 will be reconnecting TCP.

New Password: 1234

It only accepts value from1000~9999 integer, if input the wrong password over 5 times, the

WEB-Page will lock until the TRP-C37 re-boot.

Firmware Version: ABC

AB: Suitable DSM utility version

C: Release Version

Example: If the firmware version is 351.

Please run the DSM utility is Version:3.5

Serial Port setting

Baud Rate: UART Speed from 1200,2400,4800,9600,19200,38400,57600,115200,921600 K bps

Data Bit: 5,6,7,8

Parity: Odd, Even, None

Stop Bits: 1, 1.5,2.

Flow Control: Xon/Xoff, Hardware, None

Submit

Save the setting value to EEPROM.

Page 12

12

Save

Save the setting value to external log file.

Load

Load the setting value to external log file.

Upgrade

Upgrade the TRP-C37 firmware

*Wrong way the upgrade firmware will cause the TRP-C37 system fail.

4-4 using the WEB Server mode

The Web Server can be used to configure the TRP-C37 Serial Server from any web browser

software (such as I.E).

In Internet Explorer type the IP Address of the Serial Server into the address field and press the

Enter key. The following window will appear:

Example:

If TRP-C37 IP is 192.168.1.1 Please Input the 192.168.1. 1 then enter at web address,

the web-page will appear….. See diagram below.

4-5 Using the serial console mode

The serial console can be used to configure the TRP-C37 Serial Server from DB-9 connector link

Page 13

13

the HOST PC by null modem cable.

Insert the TRP-Serial CD then find the CONSOLE.exe, The CONSOLE file support all windows

O.S include MS-DOS, Run the CONSOLE file and Re-boot the TRP-C37 then select correct

host COM port number and data format.

5. Install the Virtual-COM

The Virtual-COM utility support TCP/IP、UDP data mapping to the HOST PC virtual-com, it can

creative Maximum 512~1024 virtual-com port, Support Server、Client、UDP mode, Support all

Windows O.S include Win98/Win2000/WinXP/Vista/Win2003/WIN7,Support Multi-virtual com at

different PC to one serial server; Support Ethernet and Internet , If TRP-C37 off line or power fail,

The Virtual-Com utility will try to Reconnection.

Step 1. Adjust the switch to “OFF, OFF”… The switch position at Normal-mode.

Step 2. Insert the TRP-Serial CD and find the TRP-C37 folder.

Step 3.Click “Vcomm.exe” icon then install Virtual-COM utility.

*The Virtual COM utility support multi-language, please select which language do you need.

Page 14

14

Step4. Click “OK” button and select “VSP run as Client support Server Device”.

Step5. Select “Create virtual serial by device scanner”, then press “OK”

Step6. Run VCOMM.exe then click right button select “New Virtual COM”

Step7. Select “Select Serial Port” and input TRP-C37 IP and port then press “OK”.

Page 15

15

Step8. If Virtual-Com setting success, the display will appear bellow.

Step9. Run TRPCOM utility then select virtual-com port make a TRP-C37 loop test.

*If in VCOMM‘s configuration select “Boot with windows”, the virtual-com will Auto-connection

when windows start.

Page 16

16

6. Application

6-1 Direct IP Mode

*Keep DIP switch to the OFF, OFF Position.

Example:

Step1: Connect PC-----Ethernet-----TRP-C37-----RS485---TRP-C28 (RS485 ID=01)

Step2.Run TRPCOM utility and input IP/Port, click “Link” button, then Send Command , The

Response will appear TRP-C28 I/O Status.

Page 17

17

Step3.Send Command “#010003”, The Response will enable TRP-C28 Relay1 and Relay2

enable.

6-2 Virtual COM Mode

*Keep DIP switch to the OFF, OFF Position.

Example:

Step1. Connect PC-----Ethernet------TRP-C37-----RS485---TRP-C28 (RS485 ID=01).

Page 18

18

Step2. Run Virtual-COM utility and make a virtual-COM port, Run TRPCOM utility and input com

port number, press “OK”.

Step3.Select “Terminal” and send command, the response will appear TRP-C28 channel 2

counter value.

6-3 Paired Mode

*Keep DIP switch to the OFF, OFF Position.

Page 19

19

Example:

Step1. Connect PC---RS232---TRP-C37-----Ethernet------TRP-C37----RS422 (loop back

TX+ÆRX+,TX-ÆRX-).

Step2.Run DSM set up TRP-C37 Client, Input destination IP and Port.

Step3.Run DSM set up TRP-C37 Server and be sure the IP and port as same as client setting.

*Adjust Maximum Connection to 16.

Page 20

20

Step4. Run the windows utility “hyper Terminal” and select com port number, and press “OK”.

Step5. Key-in some chars the hyper terminal will show loop back.

*Try to disconnect power or RJ45 cable, the TRP-C37 will Auto Re-connection.

6-4 Multi-Client PC to 1 TRP-C37 Server

*Keep DIP switch to the OFF, OFF Position.

*The function main support serial data input to TRP-C37 RS232/422/485 port, if serial data

is a mass of serial data over 1K Byte ,Trying to adjust the” Transmit Timer” to 200ms.

Page 21

21

Example:

*Running at Multi-Direct IP Mode

Step1.Connect Multi-PC ---Ethernet----TRP-C37 Server----TRP-C28 (RS485 ID=1)

Step2.Run DSM Set up TRP-C37 Maximum connection=8.

Step3.All host PC run TRPCOM and input IP, Port, click “Link” button, then Send Command, The

Response will appear TRP-C28 I/O Status.

.

*Running at Multi-Virtual COM Mode

Step1. All PC run Virtual com utility and make a self virtual-COM port, Run TRPCOM utility and

select com port number, and press “OK”.

Page 22

22

Step3.Select “Terminal” and send command, the response will appear TRP-C28 channel 2

counter value.

6-5 Broadcast Mode

*The function main support serial data input to TRP-C37 RS232/422/485 port, if serial data is a

mass of serial data over 1K Byte ,Trying to adjust the” Transmit Timer” to 200ms.

Page 23

23

6-6 Heart Beat

The heart Beat function help customer detection the TRP-C37 LAN on–line or off-line, User can

open one 5300 port, if TRP-C37 on line, the 5300 port will send a char package period of 5 sec.

Page 24

24

Step1: Run TRP-C37X DSM.exe to set up the heart beat enable.

Step2: RUN TRPCOM then click “Link” button

Wait until the Response screen appear the message

Page 25

25

7. Using TRPCOM Utility test TRP-C37.

TRP-Serial Test Utility is demo utility which may help to test direct IP Mode .User may find the

utility in the TRP-C37 support CD. Double click “TRPCOM Utility”, the installShield Wizard will

guide you complete installation.

User can directly link TRP-C37 to TRP-Serial Remote IO Modules by RS485, The basic wiring

connect.

RS485 Test

Run TRPCOM and send command “$01M” and get response.

Page 26

26

RS422 Loop Test

Hardware wiring connection for RS422 loop test.

TX+ to RX+, TX- to RX-

RS232 Loop Back Test

Hardware wiring connection for RS232 Loop Test.

TXD to RXD, RTS to CTS.

Page 27

27

RUN TRPCOM test utility then connect correct IP and Port then click the “Loop Test” button”

8. Application

Page 28

28

Loading...

Loading...