Tryax TY30-VS Operation Manual

Tryax Limited Jubilee Trade Centre,Jubilee Road,Letchworth Garden City,Herts,SG6 1SP,UK

Phone +44(0) 1462-481295 Fax +44 (0) 1462-685275 www.tryax.com

TRYAX

Vertical Diamond Cut Alloy Wheel Lathe

Operation Manual USA

Model:

TY30-VS

Tryax Limited Jubilee Trade Centre,Jubilee Road,Letchworth Garden City,Herts,SG6 1SP,UK

Phone +44(0) 1462-481295 Fax +44 (0) 1462-685275 www.tryax.com

Table of Contents

1. Safety Notes ........................................................................................................... 3

1.1 Safety Specification ........................................................................................................ 3

1.2 General Safety Notes ...................................................................................................... 3

1.3 Notes after Operation Stops .......................................................................................... 4

1.4 Notes on Handling Abnormal Status ............................................................................ 4

1.5 Maintenance Safety Notes ............................................................................................. 4

1.5.1 Routine Maintenance ....................................................................................... 4

1.6 Noise ................................................................................................................................ 5

2. Machine Brief Introduction ................................................................................. 6

2.1 Mechanical Specification ............................................................................................... 6

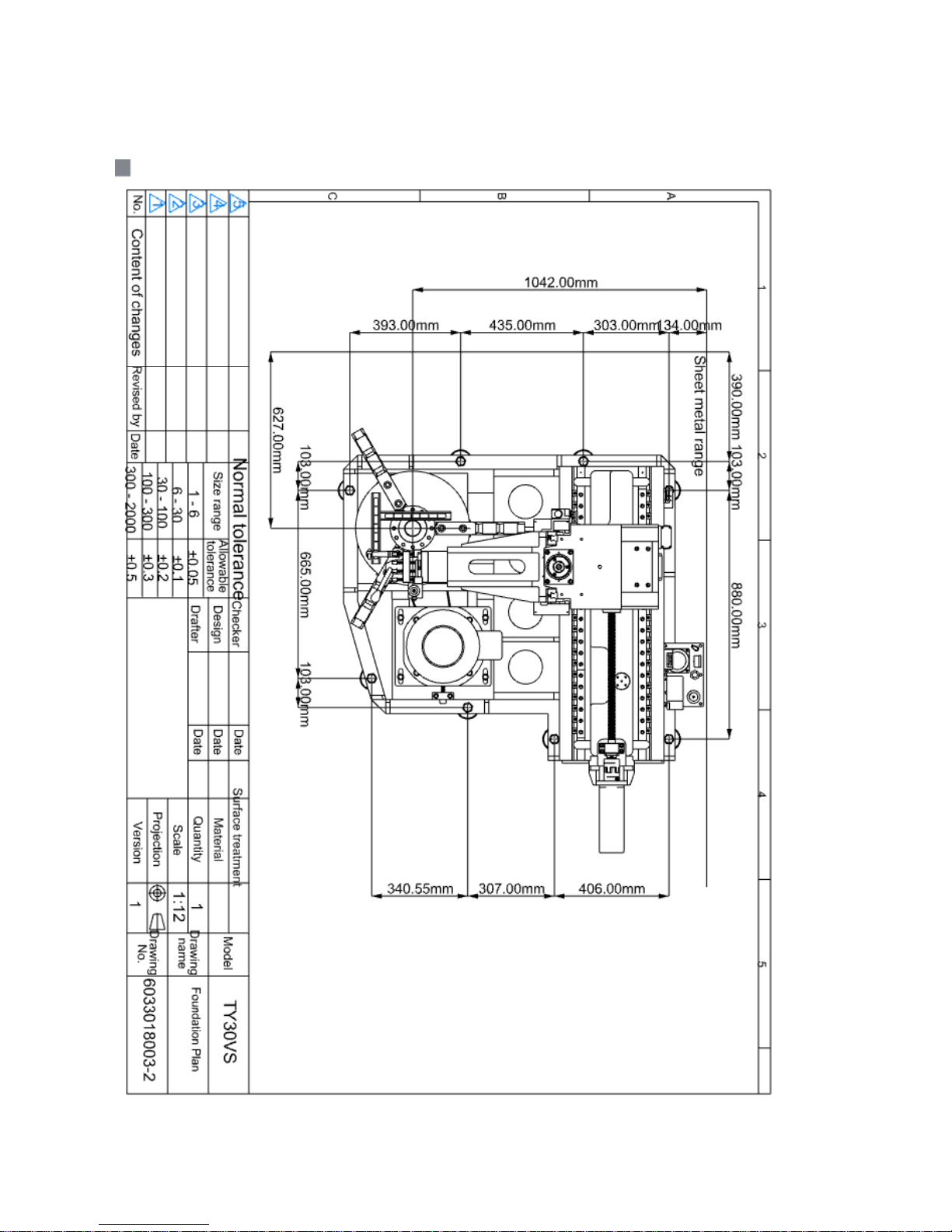

Machinery Outline Scheme Diagram .............................................................................

2.3 Assembly Drawing & Machine list ............................................................................... 8

2.4 Foundation Plan ............................................................................................................. 9

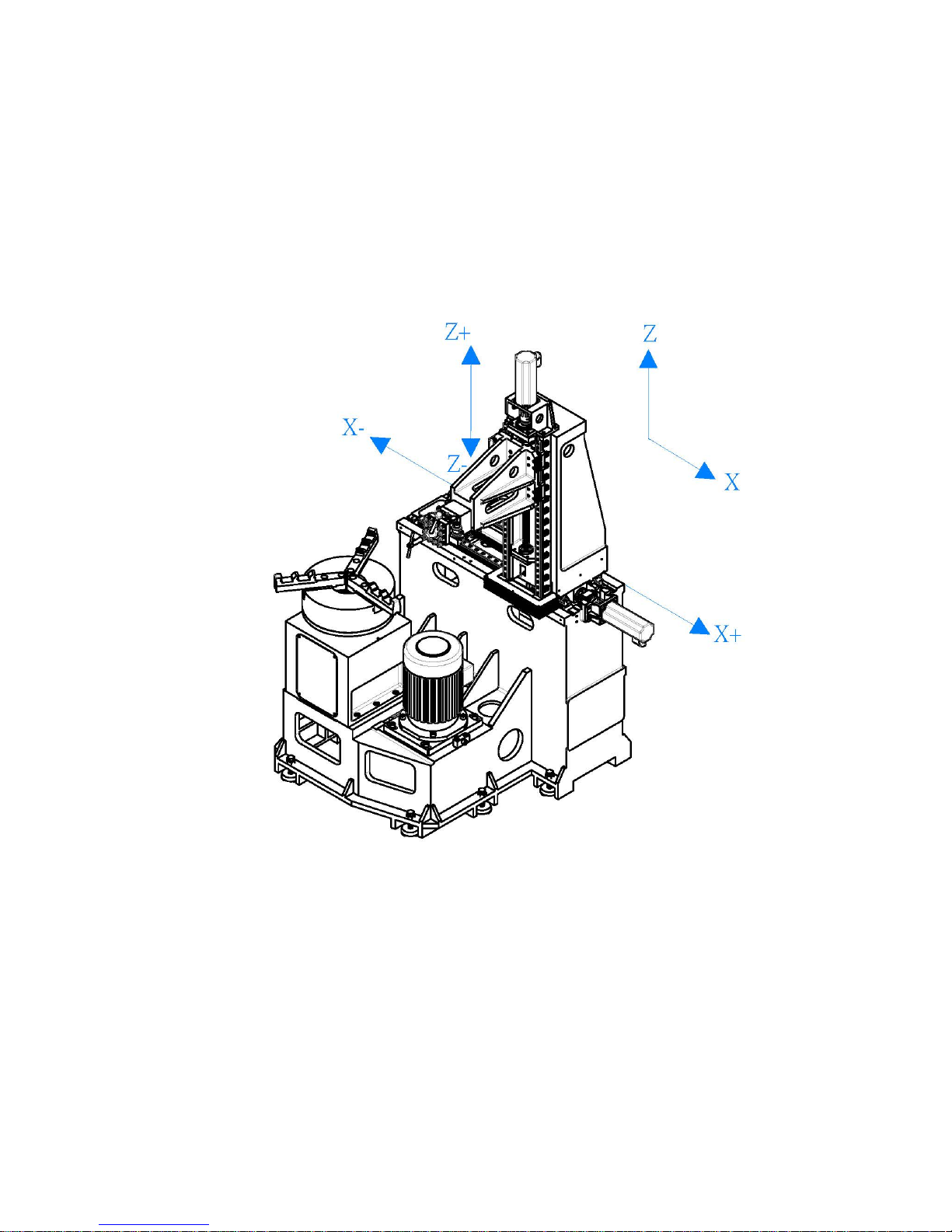

2.5 Mechanical Coordinate System .................................................................................. 10

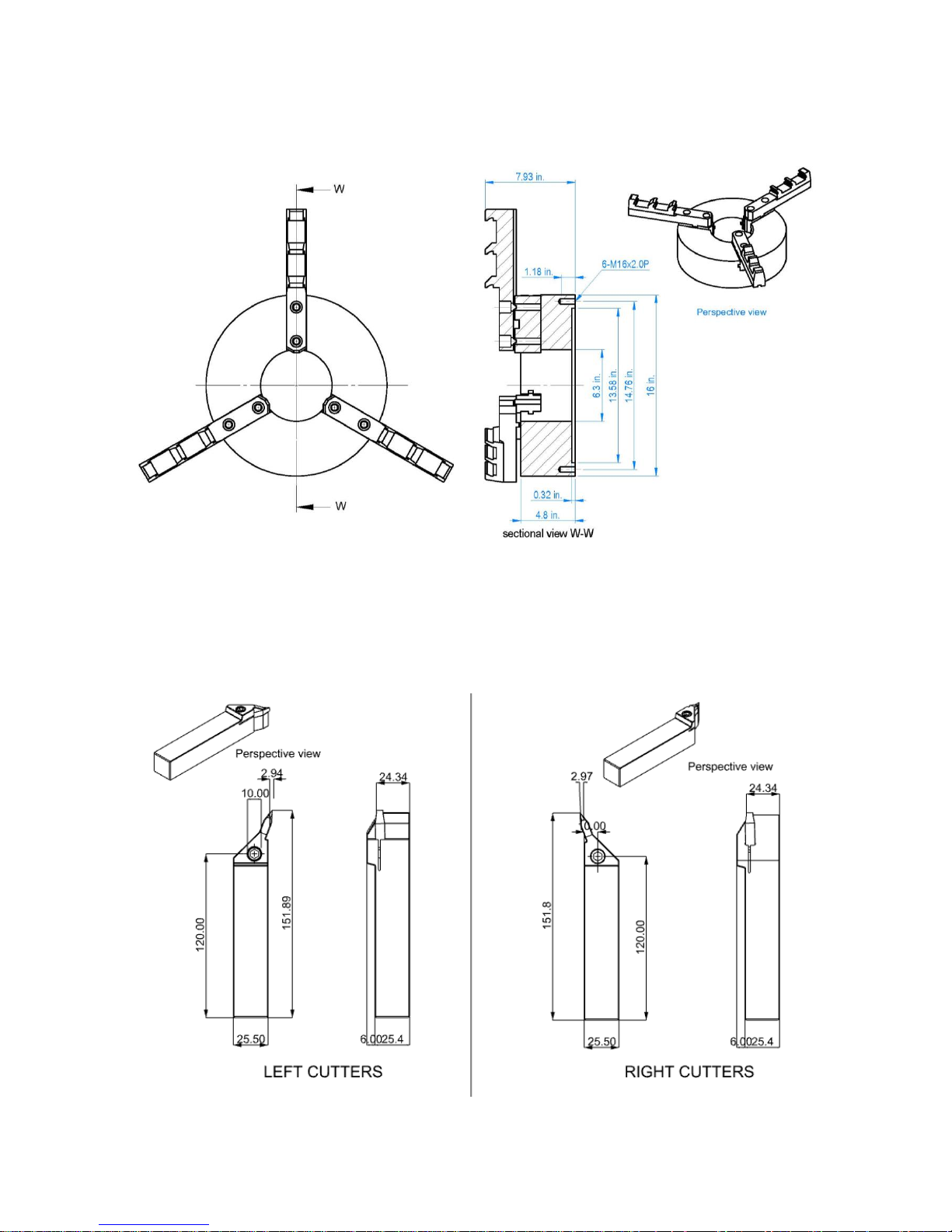

2.6 Jaw Chuck size ............................................................................................................. 10

2.7 Tool Holder Dimension Drawing ................................................................................ 11

3. Move, Store and Install the Machine ................................................................ 11

3.1 Pre-installation Work

3.2 Unload and Moving the Machine ............................................................................... 13

3.3 Installation & Levelling

3.3.1 Machine Installation and Leveling ...................................................................

3.3.2 Install the Peripherals ................................................................................... 16

3.4 Power Requirement ..................................................................................................... 17

3.5 Compressed Air Source ............................................................................................... 18

3.6 Other Objects ............................................................................................................... 18

4. Pre-boot Preparation Works ............................................................................. 19

4.1 Pre-boot Check ............................................................................................................. 19

4.2 Oil-feed and Oil Types ................................................................................................. 20

4.2.1 Machine’s Oil-feed Points ............................................................................. 20

4.2.2 Referenced Machine Oils .............................................................................. 20

4.3 Chips Conveyor System ............................................................................................... 21

5. Machine Maintenance and Tuning ................................................................... 22

5.1 Maintenance Period ..................................................................................................... 22

5.1.1 Maintenance Interpretation .......................................................................... 22

5.1.2 Machine Regular Maintenance Frequency List .......................................... 22

5.1.3 Maintenance Check Sheet ............................................................................. 24

5.2 Soft jaw chuck Mechanism.......................................................................................... 26

5.3 Forced Auto Lubricator ............................................................................................... 26

6. Troubleshooting .................................................................................................. 29

6.1 Machine Troubleshooting ............................................................................................ 29

6.2 Quick-Wear Part List .................................................................................................. 30

7. Machine Parts List ............................................................................................. 31

3

1. Safety Notes

1.1 Safety Specification

This machine is equipped with safety devices designed to protect operators from being hurt

or the machine being damaged. Operators should thoroughly read this Manual as well as

undergo the compulsory training programme before operating this Machine.

Ensure there is sufficient space around the Machine to open the electrical-box door for

maintenance/repair and space to allow normal access to and from the machine. Assign

qualified electrical personnel to wire this Machine from the plant power supply.

Do not operate the machine if any safety devices have been damaged or removed.

.

1.2 General Safety Notes

1. If you have any safety queries – do not operate the machine.

2. All maintenance and repairs must be undertaken by skilled and trained personnel..

3. Operator should wear appropriate clothing during operation. Do not wear loose fitting

clothing and remove or cover rings and watches.

4. Operators must use approved personal safety equipment.

5. Do not allow other personnel to stand around the machine while it is operating.

6. Ensure the work area around the machine is free from obstruction.

7. When cleaning the machine or removing machined parts do not climb into the

machine.

8. Keep the work area clean and dry.

9. Do not store or keep flammable or hazardous substances near the machine.

10. Do not try to modify this Machine or method of operation.

11. Keep the observation window clean.

12. This Machine is equipped with three-colour alarm light to indicate the alarm status

(red-danger (push the emergency-stop button), amber-warning (abnormal occurs), and

green-normal in operation).

13. Do not attempt to machine oversize work pieces.

14. Do not leave any article or tool within the work chamber.

4

1.3 Notes after Machining Operation Stops

1. Before opening the Access Doors, be sure that the chuck has stopped turning.

2. After the dry-cutting process is complete and before removing the workpiece, be sure

to put on safety gloves (to avoid skin-burn).

1.4 Notes on Handling Abnormal Status

1. Once an abnormal status occurs, press the emergency stop button immediately.

2. Before accessing Machine’s inner space, be sure that the main power supply is off and

the machine is stationary.

3. If in doubt, press the Emergency Stop Button and seek advice.

1.5 Maintenance Safety Notes

1. Before performing maintenance works, shut down main power supply and lock off.

2. Do not leave the machine in an exposed condition and un- attended..

3. After work is completed, do not leave any tool or part in the Machine or on the

operation panel.

4. Clean up the chip tank regularly and wear the correct hand-protection to prevent

allergy or cuts.

5. Keep the observation window clean. If the transparency is blurred, replace it

immediately.

1.5.1 Routine Maintenance

(1) Keep the Machine bed clean.

(2) Tune the indicating gauges (pneumatic and lube oil) to correct positions.

(3) Ensure that lube oil reaches the guide-way.

5

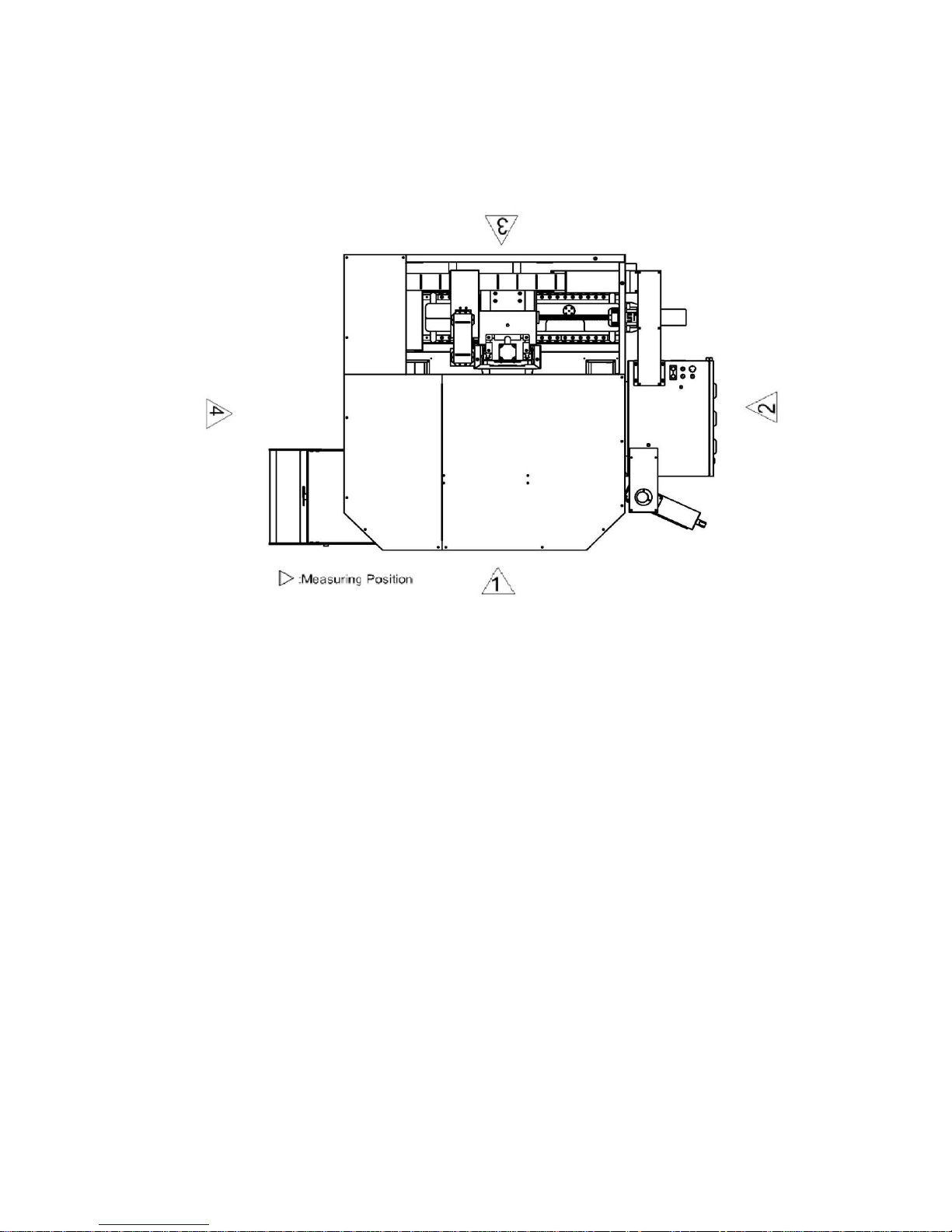

1.6 Noise

Per ISO/DIS 230-5 Standard, noise of Machine either at stationary or running status should

be lower than 80 dBA. If over this level, inform us immediately to correct the Machine. The

inspection positions are shown in the figure below.

Measurement standard: according to Machinery Directive 98/38/CE Annex I article 1.7.4(f)

specification.

Spindle speed: 80% of the maximum speed value.

Measuring distance: 1m from the machine housing.

Measurement height: 1.6m from the ground

6

2. Machine Brief Introduction

2.1 Mechanical Specification

Standard accessories:

1. Digitising Probe

2. Diamond Cutter

3. USB & Etherent Ports

4. Halogen Work Light

5. Auto Lube

6. Way Covers

7. Chip Tray

8. Tools & Tool Box

9. Four Way Tool Post

TY30-VS SPECIFICATION

Model

Unit

VTL30

Control

Control System

BECKHOFF

Travel

X-axis Travel

mm(inch)

508(20")

Z-axis Travel

mm(inch)

457(18")

Max.Turning Diameter

mm(inch)

762(30")

Table

Jaw Chuck(Manual)with Soft Jaw

inch

16" - 3

Distance

Distance from Spindle end to Table

mm(inch)

0-457(0~18")

Spindle Nose Taper / Tool

A2-6

Spindle

Spindle Speed

rpm

60~1000

Spindle Type

Belt Drive

Spindle Motor

KW(HP)

7.6(10HP)/4P

2 axes Servo Motors (X/Z)

KW

1.3

Feed

X-axis Rapid Traverse

M/min

10 / Direct

Drive

Z-axis Rapid Traverse

M/min

10 / Direct

Drive

Cutting Feedrate

M/min

10

Min. Input Unit

mm/min

0.001

Installation

Requirements

Weight (about)

t

2

7

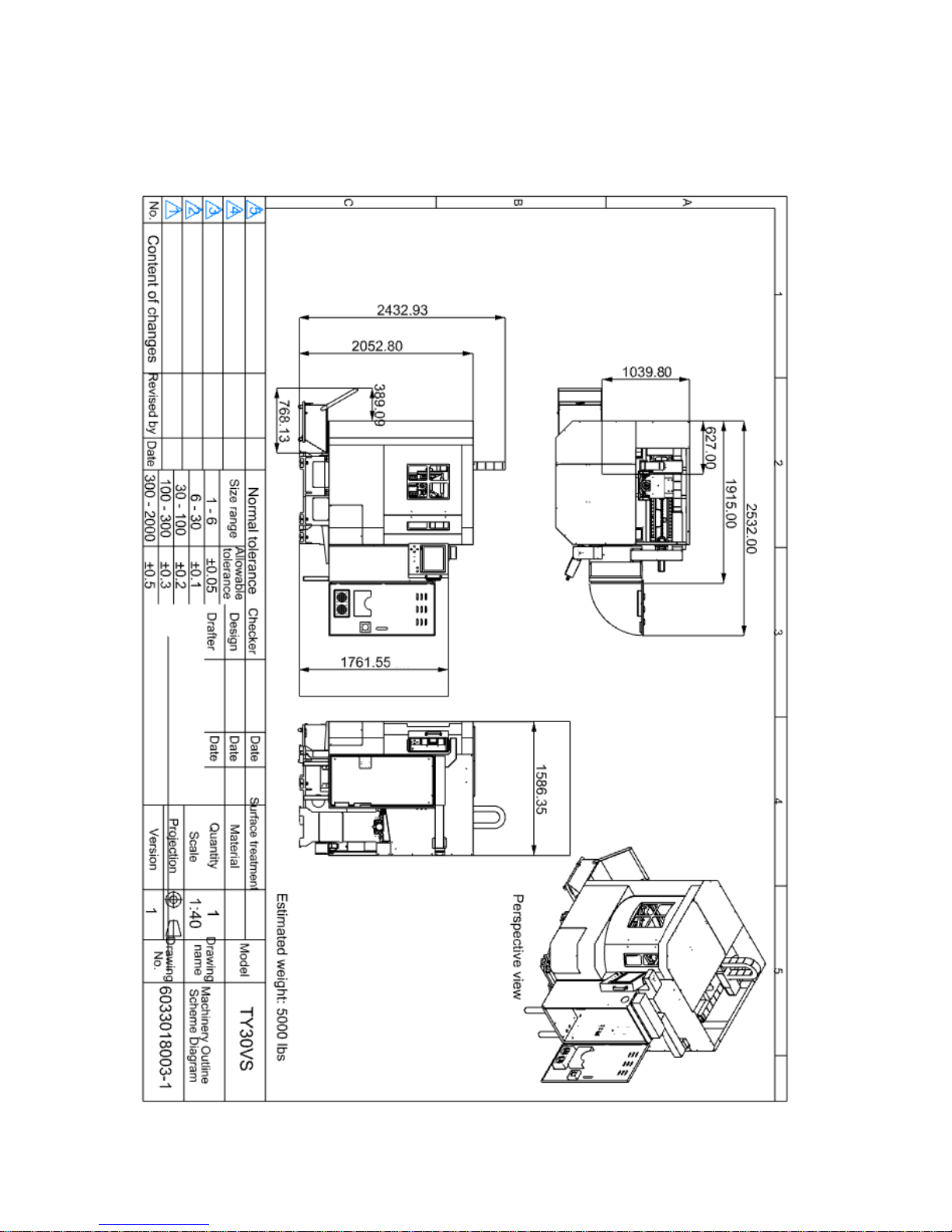

2.2 Machinery Outline Scheme Diagram

8

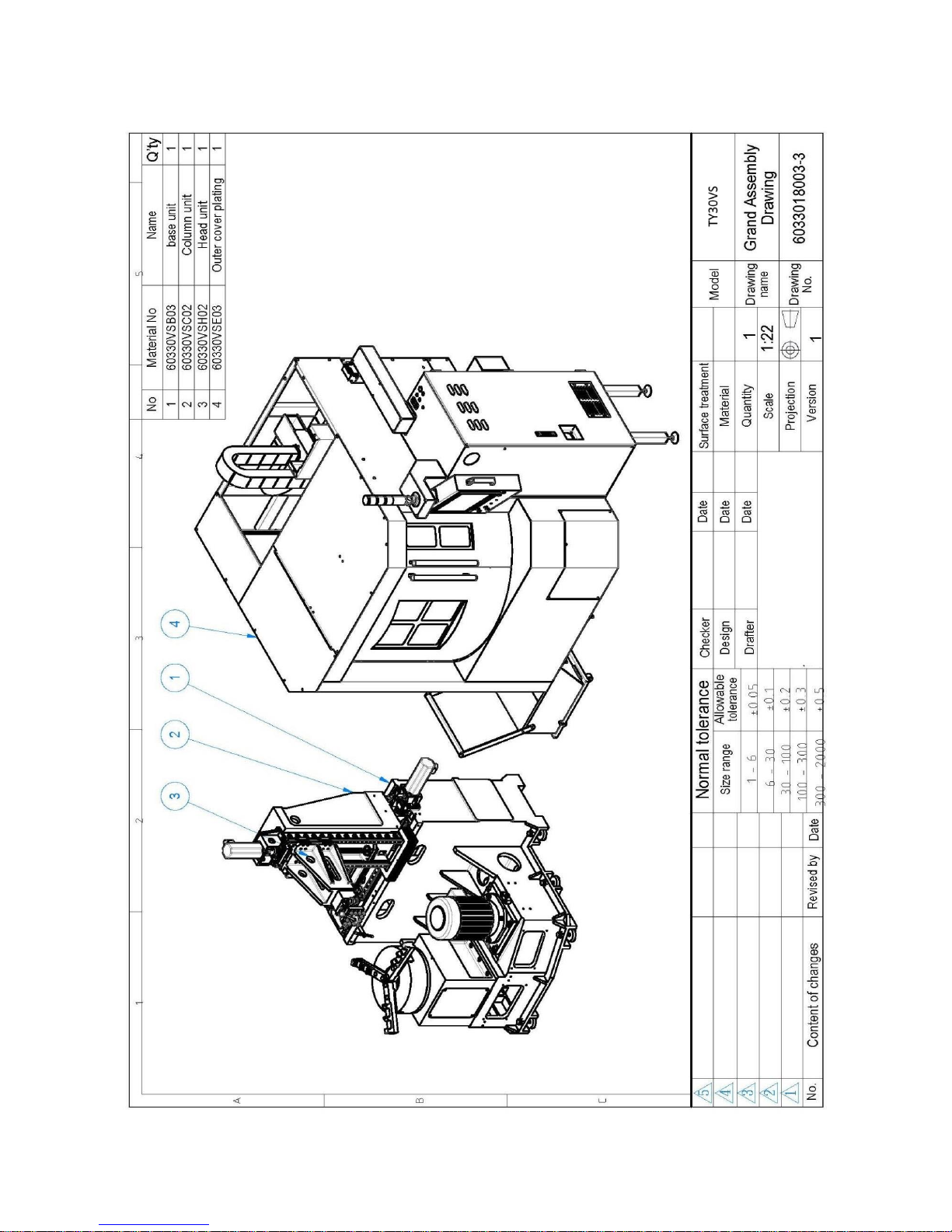

2.3 Assembly Drawing & Machine list

9

2.4 Foundation Plan

10

2.5 Mechanical Coordinate System

Axis-definitions are expressed in below:

X-axis: X-axis is the direction that tool post moves right/left; (+) for right movement and (-)

for left one.

Z-axis: Z-axis is the direction that tool post moves up/down; (+) for up movement and (-)

for down one. tool post

11

2.6 Jaw Chuck size

2.7 Tool Holder Dimension Drawing

12

3. Move, Store and Install the Machine

3.1 Pre-installation Preparation Works

1. Power source: required power supply specification:

Power

Voltage

Frequency

Phase

Specification

220V

60 HZ

3+Neutral+Earth

2. Pneumatic - air pressure used to clean up spindle, cool down cutting is 5 ~ 7 KG/CM

2

,

at least 90 NL/min of supply.

3. Oils: feed in required oils before starting this Machine:

Purpose

Product name

Viscosity (40°C)

Capacity

Remark

Lube oil

Guide-way oil

61.2 ~ 74.8

2L

ISO VG68,R-68, K68

4. Precision measuring equipment:

1. 0.02mm/M level meter, at least two pieces.

2. Gauge-carried magnetic seat 1/100, 2/1000mm, one or more set each.

3. One granite right-angle ruler.

5. Space requirement:

To plan for Machine layout space, reserve sufficient space for the

operation/maintenance and access to and from the machine.

Loading...

Loading...