1

User instructions

Orbis – OB38200, OB38400, OB45200,

OB45400, OB50200, OB50400,

OBLP452/400

Rotary floor cleaning machines

03-6120-0000 Iss.2 03/10

CAUTION

–

READ THESE INSTRU

CTIONS BEFORE USING THE MACHINE

ORIGINAL INSTRUCTIONS

2

3

Contents

Diagrams...........................................................................................................................................4

1 Product Information....................................................................................................................5

1.1 Important Safety Advice...................................................................................................5

1.2 Guidelines for the operator...............................................................................................5

1.3 Transporting the machine................................................................................................6

1.4 Symbols & Markings........................................................................................................6

2 Preparing for use.......................................................................................................................6

2.1 Electrical connection........................................................................................................6

3 Preparing for use.......................................................................................................................7

3.1 Fitting the handle.............................................................................................................7

4 Controls.....................................................................................................................................7

5 Fitting a brush or drive disc and pads.........................................................................................7

6 Adjusting the handle height........................................................................................................7

7 Operation...................................................................................................................................7

7.1 Starting the machine........................................................................................................7

7.2 Polishing..........................................................................................................................8

7.3 Scrubbing and Shampooing.............................................................................................8

7.4 Fitting the solution tank....................................................................................................8

7.5 Removing the solution tank..............................................................................................8

7.6 The vacuum unit..............................................................................................................8

7.7 Fitting the vacuum skirt....................................................................................................8

7.8 Fitting the vacuum unit.....................................................................................................9

7.9 Using the vacuum unit.....................................................................................................9

8 Storage......................................................................................................................................9

9 Maintenance..............................................................................................................................9

10 After Sales Service....................................................................................................................9

11 Guarantee...............................................................................................................................10

12 Waste Electrical & Electronic Equipment (WEEE)....................................................................10

13 Technical specification.............................................................................................................11

14 Accessories.............................................................................................................................12

15 Fault diagnosis.........................................................................................................................12

16 Declaration of Conformity.........................................................................................................14

4

Diagrams

5

IMPORTANT

BEFORE USE READ THESE INSTRUCTIONS AND RETAIN FOR FUTURE REFERENCE

1 Product Information

These commercial floor treatment machines are

designed for the scrubbing and polishing or hard

floors and/or shampooing of carpets in indoor

areas.

This machine must only be used for the

manufacturer’s approved application. Do not

use the machine where it is suspected that the

carpet, floor or upholstery contains health

endangering dust or debris such as asbestos or

chemical waste. If this is suspected do not

proceed, contact your supervisor, supplier or

Truvox International for advice.

The following instructions contain important

information about the machine and safety advice

for the operator.

Equipment must be operated, serviced and

maintained in accordance with the

manufacturer’s instructions. If in doubt contact

the supplier of your machine.

NOTE - To protect the machine from possible

damage during transit, the machine base and

handle are packed seperately. Ensure that both

items are present and follow the simple assembly

instructions to bring the machine into service.

These instructions are valid for the following

models:

OB38200, OB38400, OB45200, OB45400,

OB50200, OB50400, OBLP452/400

1.1 Important Safety Advice

When using electrical equipment basic safety

precautions should be followed including the

following.

• Read all instructions carefully before use.

• This appliance is suitable for commercial use,

for example in hotels, schools, hospitals,

factories, shops, offices, rental businesses and

other than normal housekeeping purposes.

• This machine is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they

have been given supervision or instruction

concerning use of the machine by a person

responsible for their safety.

• Keep children and unauthorised persons away

from the machine when in use.

• Before using the appliance, check that the

mains power voltage corresponds with the

voltage shown on the rating plate.

• All parts are to be positioned as indicated in the

instructions before using the machine.

• Do not operate the machine if it malfunctions or

is damaged in any way. Contact an authorised

service agent for repair or adjustment.

• Do not operate switches or touch the mains

plug with wet hands as this may cause electric

shock.

• When unplugging pull the plug, not the supply

cord.

• Do not pull or carry by cord, use cord as a

handle, close a door on cord, or pull around

sharp edges or corners.

• Keep hair, loose clothing, fingers and all parts

of body away from openings and moving parts.

• Keep cord away from heated surfaces.

• Do not use where hazardous dust is present.

• Do not use in an explosive atmosphere.

• Do not pick up oil or other flammable material.

• Do not use to pick up moisture or any liquids.

• Do not leave the machine connected to the

electricity supply when not in use, always

remove the plug from the socket-outlet.

• Switch off the machine before removing the

plug.

• The power supply cord must be regularly

inspected for signs of damage. If the power

supply cord is damaged, it shall only be

replaced by the manufacturer, its service agent

or a similar qualified person in order to avoid a

hazard.

• Only replace the supply cord with the type

specified in the instruction manual.

• Do not operate the machine with a damaged

supply cord or plug, or after the machine

malfunctions or is damaged in any way.

Contact an authorised Service Agent for repair

or adjustment.

• The plug of the power supply cord must be

removed from the socket-outlet before

commencing cleaning of the machine or

undertaking maintenance operations.

• Do not kink or twist the power cord.

• Take care when using a machine near the top

of stairs to avoid overbalancing.

WARNING

Keep the power supply cord clear of

moving parts and/or rotating brushes.

During operation hazard may occur when

running the machine over the power supply

cord.

1.2 Guidelines for the operator

WARNING

Operators must be fully trained in the use

of the machine in accordance with these

instructions, able to perform user

maintenance and the correct selection of

accessories.

6

• Operators should be physically capable to

manoeuvre, transport and operate the

machine.

• Operators should be able to recognise unusual

operation of the machine and report any

problems.

• Only use the machine on firm level surfaces.

• Wear suitable footwear to avoid slipping.

• Wear suitable clothing to keep dry and warm.

• Where possible implement job rotation and

adequate rest periods to avoid continuous use

of the same muscles.

• Let the machine do the work. Grip the handle

as lightly as possible.

• Stand with feet slightly apart to maintain good

balance. Avoid twisting the body more than 45

degrees.

• Do not leave machine running unattended

• Do not smoke when using the machine.

• Do not put any objects into openings. Do not

use with any opening blocked: keep free of

dust, debris, hair, or anything that may reduce

air flow.

WARNING This machine is for dry use

only.

CAUTION - This machine is for indoor

use only and should not be used or

stored outdoors or in wet conditions.

CAUTION - If it is suspected that there is

hazardous dust or flammable materials

stop cleaning the area immediately and

consult your superior.

WARNING Only use accessories and

spare parts provided with the machine or

those approved by the manufacturer.

The use of other accessories may impair

the safety of the machine.

• Ensure the machine is switched off before

adding or changing accessories.

1.3 Transporting the machine

CAUTION – Incorrect lifting techniques

may result in personal injury, where

applicable do not lift large and heavy

machines without assistance. We advise that the

manual handling regulations are followed.

Please refer to the technical table for details on

weight of machine.

When transporting the machine ensure that all

components, tanks and removable parts are

securely fastened, and that the supply cord and

plug are not trailing. Detach hose and wand from

machine where applicable.

When transporting the machine the handle

should be locked in the upright position.

Take extreme care when moving the machine up

or down steps or stairs.

1.4 Symbols & Markings

WARNING

WARNING – READ THESE

INSTRUCTIONS BEFORE

USING MACHINE

Earth symbol

2 Preparing for use

2.1 Electrical connection

Before connecting the machine to the power

supply, check that your supply voltage

corresponds with that marked on the rating label.

The power supply cord plus any extension leads

should not exceed 30m in total, otherwise you

may experience problems starting up the

machine. The cross-section of any extension

cable wiring must be at least 2,5 mm².

Should an extension cord be used, ensure cord

rating is adequate for the equipment. Do not use

extension cord in coiled condition as this could

result in overheating of the cord.

UK only

The supply cord for 230v models is fitted with a

plug containing a 13 amp fuse. Should the fuse

require replacement it must only be replaced by a

13 amp fuse conforming to BS1362, and the fuse

cover must be refitted. If the fuse cover is lost the

plug must not be used until the correct

replacement cover is fitted.

IMPORTANT - If the supply cord is damaged, it

must only be replaced by a special cord available

from the manufacturer or an authorised service

agent.

WARNING – THIS APPLIANCE MUST

BE EARTHED

7

3 Preparing for use

3.1 Fitting the handle

1 Carefully remove the machine base and

handle from their respective packaging.

2 Check that the following items are present

with the base:-

- M8 x 70 Bolt (3)

- Nyloc Hex. nut (3)

- Plain washer (6)

- 13mm A/F Spanner (2)

3 Take handle and check that ‘O’ rings on

either side of the knuckle pivot are seated in

their grooves, and that the datum mark on

the pivot gear is aligned with the handle tube.

If this is not the case, raise the handle

adjustment lever and rotate the pivot gear

until the datum mark is in line with the handle

tube, and release the adjustment lever.

4 With the handle held vertically and cable

winder to the rear, lower pivot between the

raised flanges on the machine base.

5 Align holes in pivot with those on base and fit

the three M8 bolts, washers and nuts, and

tighten using the spanners supplied (Fig.1).

6 Connect supply lead from handle to socket

on motor housing.

4 Controls

The operating controls for all models are located

on the handle (Fig 2 ).

1 - Switch trigger, left hand

Used to switch motor ON and OFF. Can only

be operated with handle in working position,

and if left hand interlock button (2) has

previously been depressed

2 - Interlock button, left hand

This must be depressed initially to enable left

hand switch trigger to switch motor on.

3 - Switch trigger, right hand

Used to switch motor ON and OFF. Can only

be operated with handle in working position,

and if right hand interlock button (4) has

previously been depressed.

4 - Interlock button, right hand

This must be depressed initially to enable

right hand switch trigger to switch motor on.

5 - Handle adjustment lever

Used to adjust handle to comfortable working

height. Note: For safety reasons the machine

cannot be operated unless the handle is

moved to a working height.

6 - Solution feed lever

Operates flow valve in solution tank (if fitted).

- Pull lever to release solution.

- Release lever to stop flow.

7 - Socket connector

Connection point for vacuum unit lead.

Drive plate

Attachment point for brush or drive disc and

pad.

Cable winder

Used to hold supply cord in place on handle

when machine is not in use. Can be turned to

enable quick release of cord.

Motor overload cut-out

Protects motor from overload and possible

damage. The cut-out will reset automatically

when cooled sufficiently, enabling the motor to

restart.

Neon indicator (on handle)

Lights when the machine is connected to the

power supply.

5 Fitting a brush or drive disc and pads

WARNING - This appliance has been

designed for use with the pads

specified by the manufacturer. The

fitting of other pads may affect its

performance and safety.

Always ensure machine is unplugged before

fitting or removing parts.

• Adjust handle to the fully upright position.

• Pull handle down until it rests on the floor and

the brush guard is raised.

• Fit the brush/drive disc onto the drive plate and

rotate it anti-clockwise until secure.

• Return machine to upright position.

• IMPORTANT - Never allow the cleaning

head to rest on the brush or drive disc and

pad when not in use.

6 Adjusting the handle height

Select the most comfortable handle height using

the adjustment lever as previously described (see

Controls) and lock in position.

7 Operation

The normal movement of a machine in use is

from side to side across the floor. This is

achieved automatically by raising or lowering the

handle whilst it is engaged in the normal working

position.

Lowering the handle thereby increasing the

pressure at the rear of the brush/drive disc,

moves the machine to the left. Raising the handle

increasing the pressure on the front of the

brush/drive disc moves the machine to the right.

Effective cleaning and polishing is achieved by

moving the machine in a backwards direction.

Do not leave the machine standing on a brush or

drive disc and pad when not in use.

7.1 Starting the machine

• Fully unwind the supply cord from the handle

and plug into a convenient socket outlet. The

neon indicator on the handle should light

showing that power is available.

• With the handle set at a convenient working

height and with both left and right hands on the

handle, depress both interlock buttons with the

8

thumbs and squeeze both switch triggers to

start the machine (Fig.3).

WARNING - Never start the machine

without pads fitted.

• Once the machine has started the interlock

buttons should be released.

• To stop the machine release both switch

triggers.

Orbis 452/400 dual speed

The speed selector switch on the dual speed

model is located on the motor housing. Ensure

machine is switched off before changing the

speed setting.

7.2 Polishing

• Fit polishing brush or drive disc and pad

suitable for the speed of the machine and the

surface to be polished. (see Accessories).

• Apply polish to the floor in accordance with the

manufacturers instructions.

• Do not keep the machine rotating on one spot

for more than 3 seconds, as this could cause

overheating and damage the floor surface.

7.3 Scrubbing and Shampooing

• For scrubbing or shampooing the solution tank

must be fitted as described (see Fitting the

solution tank).

• Fit a brush or drive disc and pad suitable for

the surface to be cleaned. (see Accessories).

• WARNING - This appliance has been

designed for use with the brushes specified

by the manufacturer. The fitting of other

brushes may affect its safety.

• Fill the solution tank with water and an

appropriate measure of detergent.

• IMPORTANT - Use only cleaning agents

suitable for automatic machines i.e. low

foaming, and follow the chemical manufactuers’

directions regarding use, handling, disposal

and health and safety provisions.

• Before starting the machine release a liberal

amount of cleaning solution from the tank to the

floor. The flow of solution from the tank is

controlled by moving the left hand lever.

Releasing the lever stops the flow.

• Proceed to operate the machine in the normal

manner, releasing more cleaning solution from

time to time as required.

• Do not keep the machine rotating on one spot

for more than 3 seconds, as this could cause

overheating and damage the floor surface.

• Dirty water should not be allowed to

accumulate on the floor, it should be removed

to prevent dirt from settling. We suggest using

a suction dryer for this purpose.

• When scrubbing/shampooing is complete,

unplug the machine from the power supply,

empty the solution tank and clean and dry the

machine.

• IMPORTANT - Dispose of unused cleaning

solution in accordance with the manufacturer’s

directions.

7.4 Fitting the solution tank

NOTE - The solution tank is supplied as an

accessory item, complete with attachments and

fitting instructions.

• Move the handle to the upright position and

clamp the tank support bracket to the handle

tube in the specified position (Fig.4). (Refer to

the instructions supplied with the tank).

• Take the solution tank and pass the ring on the

tank chain over the left hand operating lever

and locate the ring in the inside slot on the top

of the lever. Rest the solution tank on the

support bracket with the handle tube in the

groove on the back of the tank.

• To secure the tank in position, engage the

locking bar on the back of the tank.

• Adjust the length of the chain by means of the

screw and nut adjuster to ensure there is no

tension on the chain when the flow control lever

is not being used.

• Take the plastic tube supplied and push rigid

end of tube into the connector on the underside

of the solution tank, and the other end onto the

tube at the rear of the motor housing. The tank

connector is of the sealed lock-in type once the

tube is connected. To release, press down on

the orange collar of the connector with the

finger tips and pull out tube.

7.5 Removing the solution tank

• Pull off plastic tube from machine base.

• Raise locking bar on back of tank.

• Lift off tank and detach chain ring from lever.

7.6 The vacuum unit

NOTE - The vacuum unit and vacuum skirt are

supplied as accessory items, complete with

attachments and fitting instructions.The vacuum

unit combined with the vacuum skirt provides full

dust control, eliminating the need to pre-dust or

post dust the floor. The unit is designed to fit

readily to all Orbis models.

IMPORTANT - The vacuum unit is NOT

suitable for any form of wet cleaning.

7.7 Fitting the vacuum skirt

• Unplug and lay the machine down with the

handlebar resting on the floor. Remove the

brush or drive disc.

• Stretch and fit the rubber buffer around the

brush guard.

• The flexible section of the skirt has a special

spring sewn into the fabric. Fit this spring

section into the groove in the rubber buffer.

9

• The spring is a reasonably tight fit to prevent

accidental movement in use and therefore must

be pulled onto the buffer by stretching.

• With the skirt on the buffer it can be moved in

its groove to bring the hose connector to the

rear, ensuring the base moulding lies in the cutout provided in the outer ring of the skirt,

enabling free movement when in use (Fig.5).

7.8 Fitting the vacuum unit

• Stand machine upright, and clamp the vacuum

unit support bracket to the handle tube in the

specified position. (Refer to the instructions

supplied with the unit).

• Rest the vacuum unit on the support bracket

with the control switch to the rear, and engage

the locking bar on the back of the unit to secure

it in position.

• Push the flexible hose on to the vacuum unit

and skirt.

• Plug the electrical lead from the vacuum unit

into the socket situated on the left side of the

handle moulding.

• The machine is now ready for use. The switch

controlling the vacuum unit is located on the

back of the unit. The OFF position is marked O.

7.9 Using the vacuum unit

IMPORTANT - For maximum suction the

sliding shutter on the top of the unit must be

closed.

• Dust collected by the unit is contained within

the filter bag located behind the front cover.

• To replace the filter bag, switch off vacuum

unit, release front cover catch and lift off

cover.

• Remove and dispose of used bag. Fit new

bag and replace front cover.

8 Storage

• Always unplug the machine after use.

• Wrap the supply cord around the handlebar

and cable winder ensuring that the plug is not

trailing on the floor.

• The machine should normally be stored with

the handle in the fully upright position.

• Never store the machine with a brush or drive

disc and pad fitted as this causes distortion,

and results in instability during operation.

• Store the machine in a dry indoor area only.

9 Maintenance

WARNING - Before undertaking

maintenance operations or

adjustments switch off machine and

unplug from the electricity supply.

The machine requires minimum maintenance

apart from the following checks by a trained

operator.

• Supply cord - Regularly inspect sheath, plug

and cord anchorage for damage or loose

connection. Only replace the supply cord with

the type specified in these instructions.

• Solution tank - Check water flow, if restricted

inspect hoses and tubes for blockage or kinks.

Dismantle control valve to clean if necessary.

Check switch interlock for correct operation.

• Vacuum unit - All dust bags must be changed

regularly and hoses and connectors checked

for blockage to avoid unsatisfactory results.

• Motor overload cut-out - All machines are

fitted with an automatic reset motor overload

cut-out. The cut-out will operate to protect the

motor from overheating by switching the

machine off when there is excessive

friction/resistance to the cleaning head on the

floor. This is usually caused by the stickiness of

the pad or floor. Turn the cleaning pad over or

if both sides are dirty replace with a clean pad.

It is not possible to obtain a good finish on the

floor using a dirty pad. Should the cut-out

operate it will reset automatically when the

motor has cooled sufficiently, usually after 15 30 mins.

10 After Sales Service

Truvox machines are high quality machines that

have been tested for safety by authorised

technicians. It is always apparent that after longer

working periods, electrical and mechanical

components will show signs of wear and tear or

ageing.

Under extreme or specialised conditions and/or

insufficient maintenance, shorter maintenance

intervals are necessary. Use only original Truvox

spare parts. Use of other spare parts will

invalidate all warranty and liability claims.

Should you require after sales service please

contact the supplier from whom you purchased

the machine, who will arrange service. Repairs

and servicing of Truvox products should only be

performed by trained staff. Improper repairs can

cause considerable dangers to the user.

10

11 Guarantee

Your product is guaranteed for two year from the

date of original purchase, or hire purchase,

against defects in materials or workmanship

during manufacture. Within the guarantee period

we undertake at our discretion, to repair or

replace free of charge to the purchaser, any part

found to be defective, subject to the following

conditions.

CONDITIONS

1. Claims made under the terms of the

guarantee must be supported by the original

invoice/bill of sale issued at the time of sale,

or the machine Serial Number.

2. For claims under this guarantee contact the

supplier from whom you purchased the

product who will arrange the appropriate

action. Do not initially return the product as

this could result in transit damage.

3. Neither Truvox nor its distributors shall be

liable for any incidental or consequential loss.

4. This guarantee is governed by the laws of

England. This guarantee does not cover any

of the following: Periodic maintenance, and

repair or replacement of parts due to normal

wear and tear.

5. This guarantee is governed by the laws of

England. This guarantee does not cover any

of the following: Periodic maintenance, and

repair or replacement of parts due to normal

wear and tear.

• Damage caused by accident, misuse or

neglect, or the fitting of other than genuine

Truvox parts.

• Defects in other than genuine Truvox

parts, or repairs, modifications or

adjustments performed by other than a

Truvox service engineer or authorised

service agent.

• Costs and risks of transport relating directly or

indirectly to the guarantee of this product.

• Consumable items and wear parts such as

drive belts.

This guarantee does not affect your statutory

rights, nor your rights against the supplier arising

from their sales or purchase contract.

12 Waste Electrical & Electronic Equipment

(WEEE)

Do not dispose of this device with

unsorted waste. Improper disposal

may be harmful to the environment

and human health.

Please refer to your local waste

authority for information on return

and collection systems in your area.

11

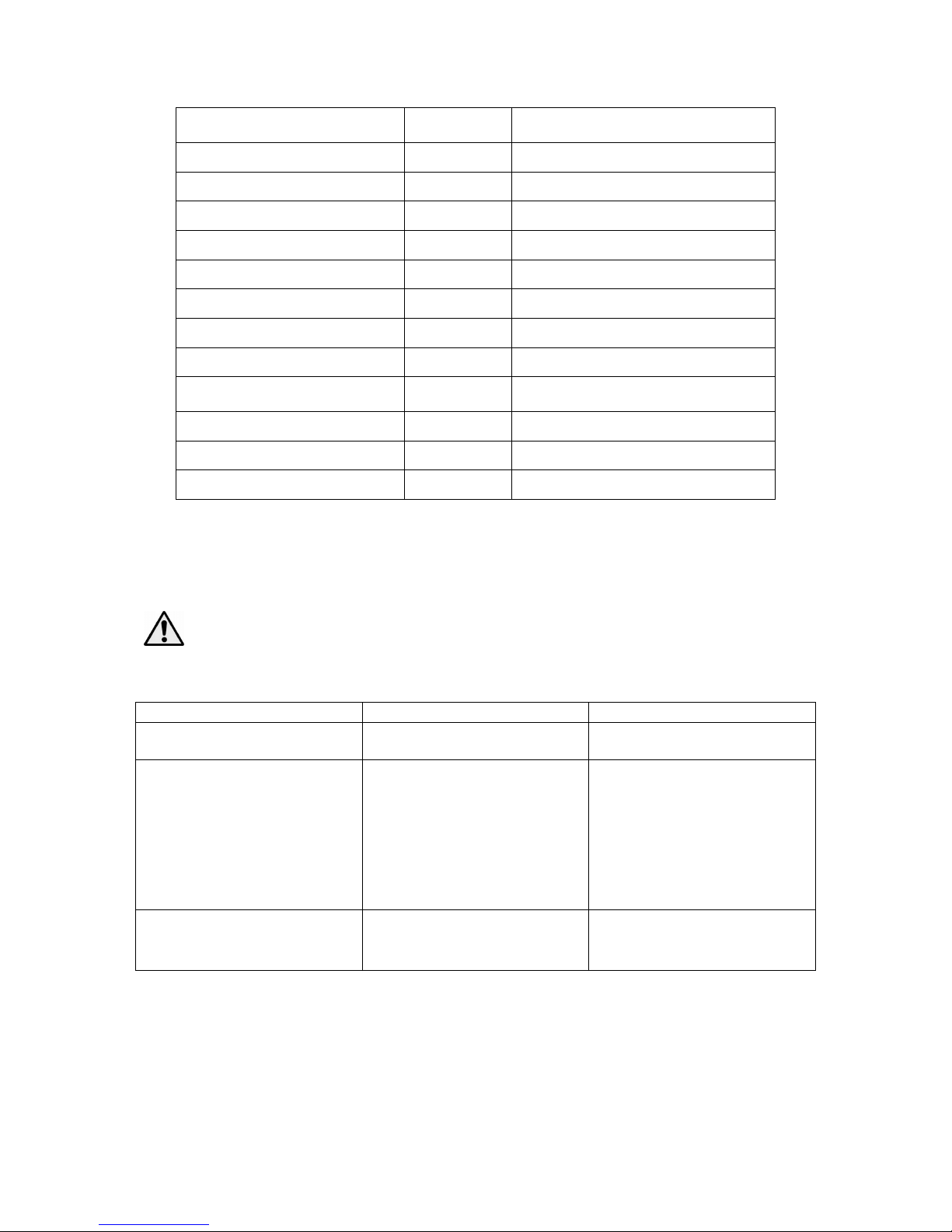

13 Technical specification

All models : 230-240 V ∼ 50 Hz, Class I construction. Enclosure to IPX4. Fitted with 15m supply cord and 13A fused plug.

Model

Orbis 200

38cm

OB38200

Orbis 200

43cm

OB45200

Orbis 200

50cm

OB50200

Orbis 200hd

43cm

OB45200/HD

Orbis 400

38cm

OB38400

Orbis 400

43cm

OB45400

Orbis 400

50cm

OB45400

Orbis Duo

43cm

OB38200

Voltage AC (~) /

Frequency

V / Hz 230 / 50

230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50 230 / 50

Pad Diameter cm 38 43 50 43 38 43 50 43

Height mm 1150 1210 1210 1210 1210 1210 1210 1210

Pad Pressure g/cm² 28 22 18 27 28 22 18 27

Speed rpm 190 190 190 190 380 380 380 Lo/hi speed

Motor ac induction

Motor Rating W 1100

1100 1100 1100 1100 1100 1100 1100

Cable Length m 15

15 15 15 15 15 15 15

Weight kgs 32 32 32 32 40 32 32 40

Noise Level dB(A) 53 53 53

53 53 53 53 53

Noise level with

vacuum

dB(A) 69

69 69 69 69 69 69 69

Handle

vibration

m/s² < 2,5

< 2,5 < 2,5 < 2,5 < 2,5 < 2,5 < 2,5 < 2,5

Warranty 2 years

1 Noise levels measured at a distance of 0.25 metre from machine and 1.5 metres above floor, when scrubbing a hard floor. Measurements recorded using

a hand held meter.

2 Handle vibration does not exceed 2,5 m/s², when operating on any surface with brush or pads.

Measurements recorded by an independent test laboratory

12

14 Accessories

Item Part No. Usage

Polypropylene scrubbing brush 03-3431-0000

wet scrubbing

Tynex scrubbing brush 03-3432-0000

heavy duty wet scrubbing

Shampoo brush 03-3433-0000

carpet cleaning

Bassine polishing brush 03-3434-0000

polishing and spray cleaning

Gumati polishing brush 05-3435-0000

polishing and spray cleaning

Standard drive disc (see note 1) 05-3436-0000

retains cleaning pads

Flexi-drive disc 05-3437-0000

retains cleaning pads

Solution tank 05-3438-0000

scrubbing/shampooing

Anti-splash water skirt 05-3439-0000 prevents splashing when wet scrubbing

Vacuum unit and hose 05-3440-0000

dust extraction

Vacuum skirt 05-3441-0000

dust extraction

Paper filter bags (10 pack) 02-3526-0000

dust collection

1 - Suitable for 45cm 200 machine only.

IMPORTANT : Genuine accessories are only available from authorised Service Agents or Truvox

Customer Services Department

15 Fault diagnosis

WARNING - Before undertaking maintenance operations or adjustments switch off

machine and unplug from the electricity supply.

The following simple checks may be performed by the operator.

Trouble Reason Remedy

Machine not working, neon

indicator not lit.

Lack of voltage/electrical

supply.

Check fuse *, supply cord, plug

and socket outlet.

Machine not working, neon

indicator lit.

Switch interlock incorrectly

operated.

Loose overload cut-out

operated.

Check operating procedure in

instructions.

Check brush/pad for good

condition

Check correct liquid type and

quantity.

Check liquid dilution.

Allow motor to cool.

Machine wobbles or vibrates

excessively.

Pad worn or damaged

Pad dirty

Pad loose

Renew pad

Clean the pad

Tighten pad lock

* If the fuse blows several times, the machine should be checked by an authorised Service Agent.

13

14

16 Declaration of Conformity

EC Declaration of Conformity

We, Truvox International Ltd.

of Third Avenue, Millbrook,

Southampton, Hampshire

England

SO15 0LE

declare that the machinery

Make : Rotary floor cleaning machines

Type : Orbis Rotaries

Model : OB38200…, OB38400…, OB45200…, OB45400…,

OB50200…, OB50400…, OBLP452/400…

Serial Number : from 000001

Year of Construction : 2010

has been manufactured using the following transposed harmonised European Standards and

technical specifications.

Ref No Title

2006/42/EC Machinery Directive and subsequent amendments

2006/95/EC The Low Voltage Directive and subsequent amendments

BS EN 60335-1

BS EN 60335-2-67

2004/108/EC The EMC Directive and subsequent amendments

EN61000-3-2

EN61000-3-3

EN55014-1

EN55014-2

Signed in : SOUTHAMPTON, England

on the 29th day of December 2009

Signature :

Name : David Overell Technical file: Orbis 200, 400, Duo Iss. 1

Position : Managing Director Mark Campbell

Product Support Manager

15

16

Truvox International Limited

Third Avenue, Millbrook, Southampton, Hampshire SO15 0LE, England

Tel: +44 (0) 23 8070 2200 Fax: +44 (0) 23 8070 5001

e-mail: truvox@truvox.com Web: www.truvox.com

Authorised dealer:

Loading...

Loading...